AI-Powered Innovations in Food Safety from Farm to Fork

Abstract

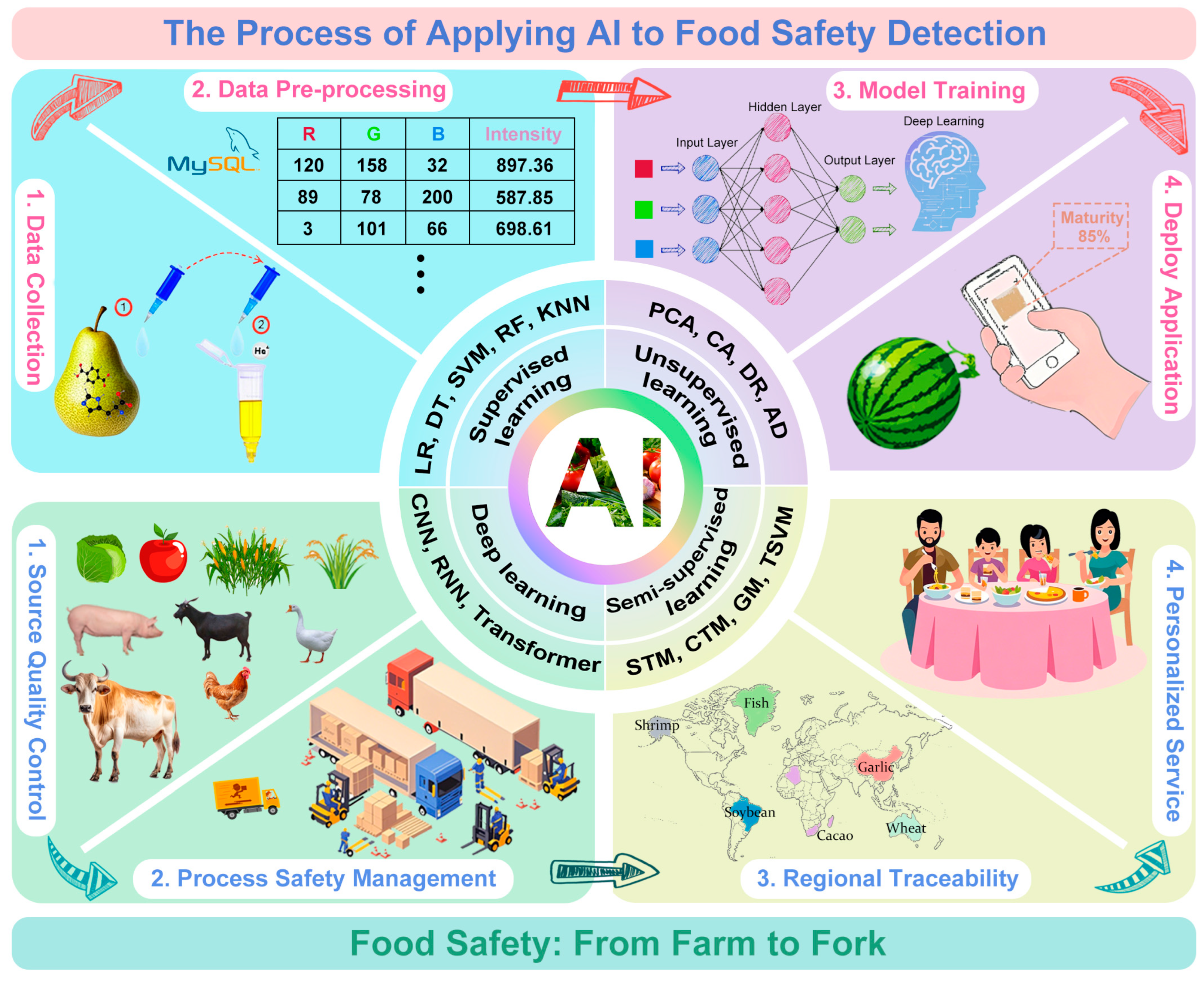

1. Introduction

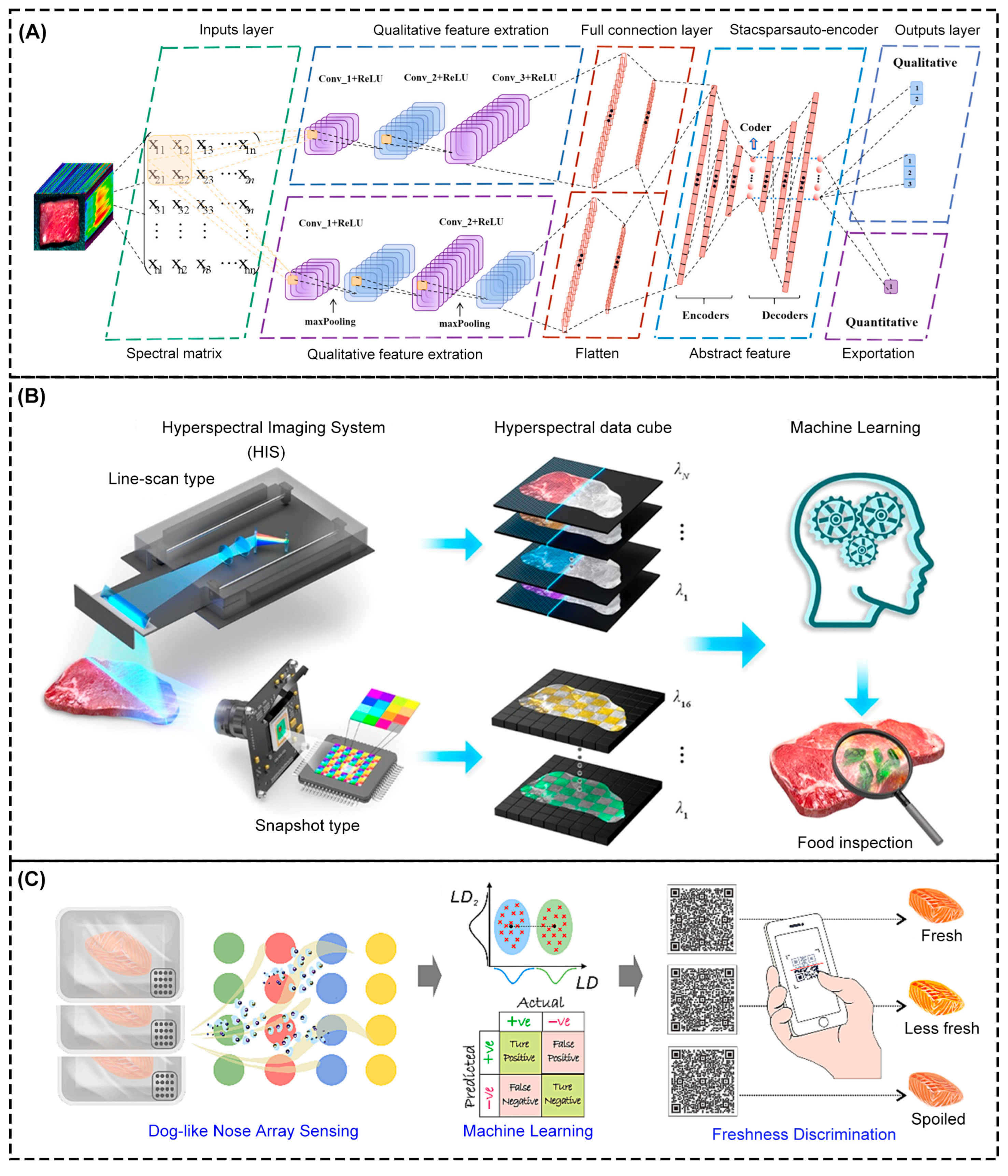

2. AI-Based Food Detection Technology

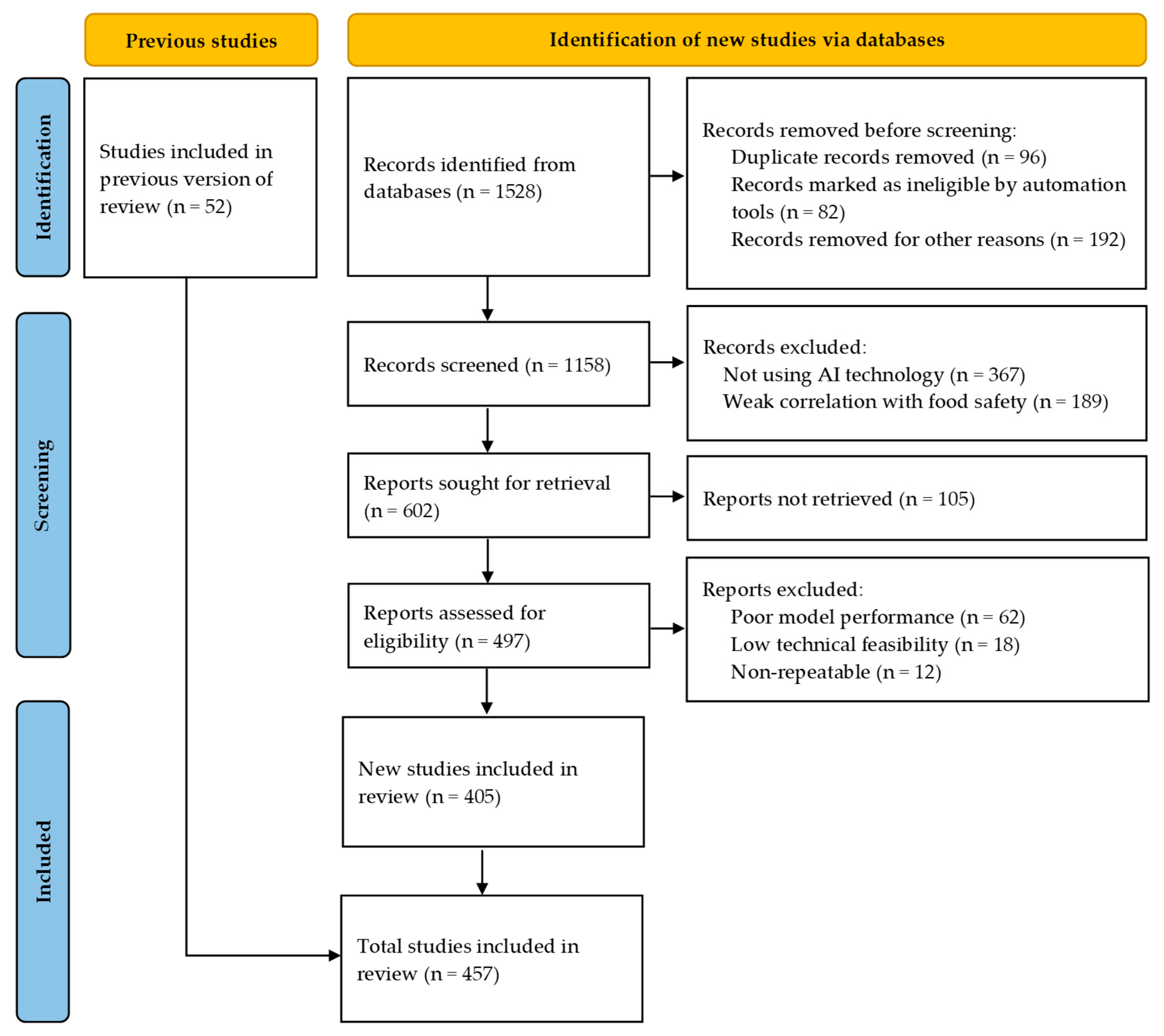

2.1. Literature Search and Screening Methods

2.2. Background of AI Applications in Food Safety

2.3. Classification of AI Algorithms in Food Monitoring

2.3.1. Supervised Learning

2.3.2. Unsupervised Learning

2.3.3. Semi-Supervised Learning

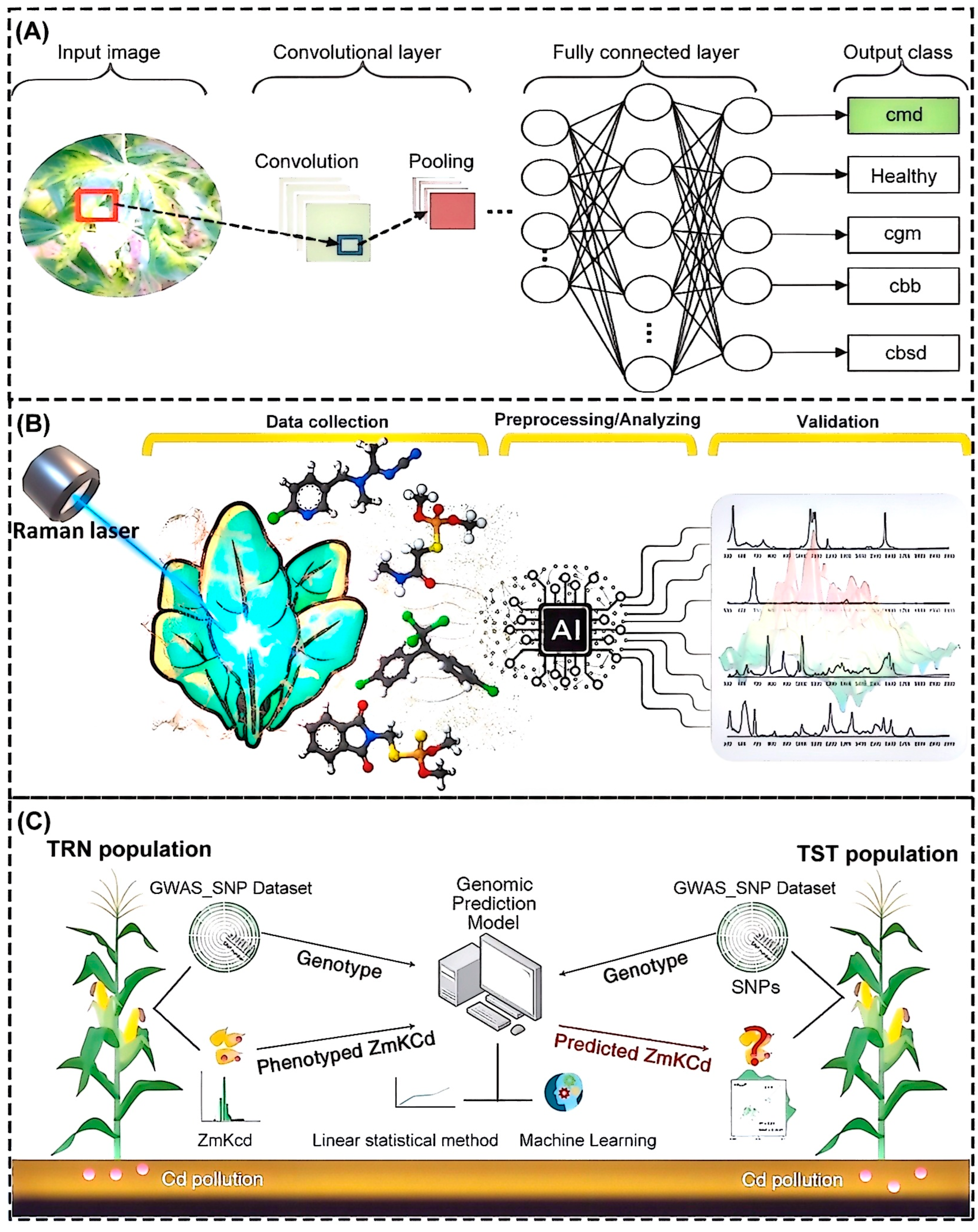

2.3.4. Deep Learning

2.4. Critical Analysis of AI Technologies in Food Safety

3. Intelligent Application of AI from Farm to Fork

3.1. AI-Based Food Source Management in Farming

3.2. AI-Based Sorting in Food Ingredients

3.3. AI-Based Food Storage Monitoring in Warehouses

3.4. AI-Based Quality Control in Food Processing

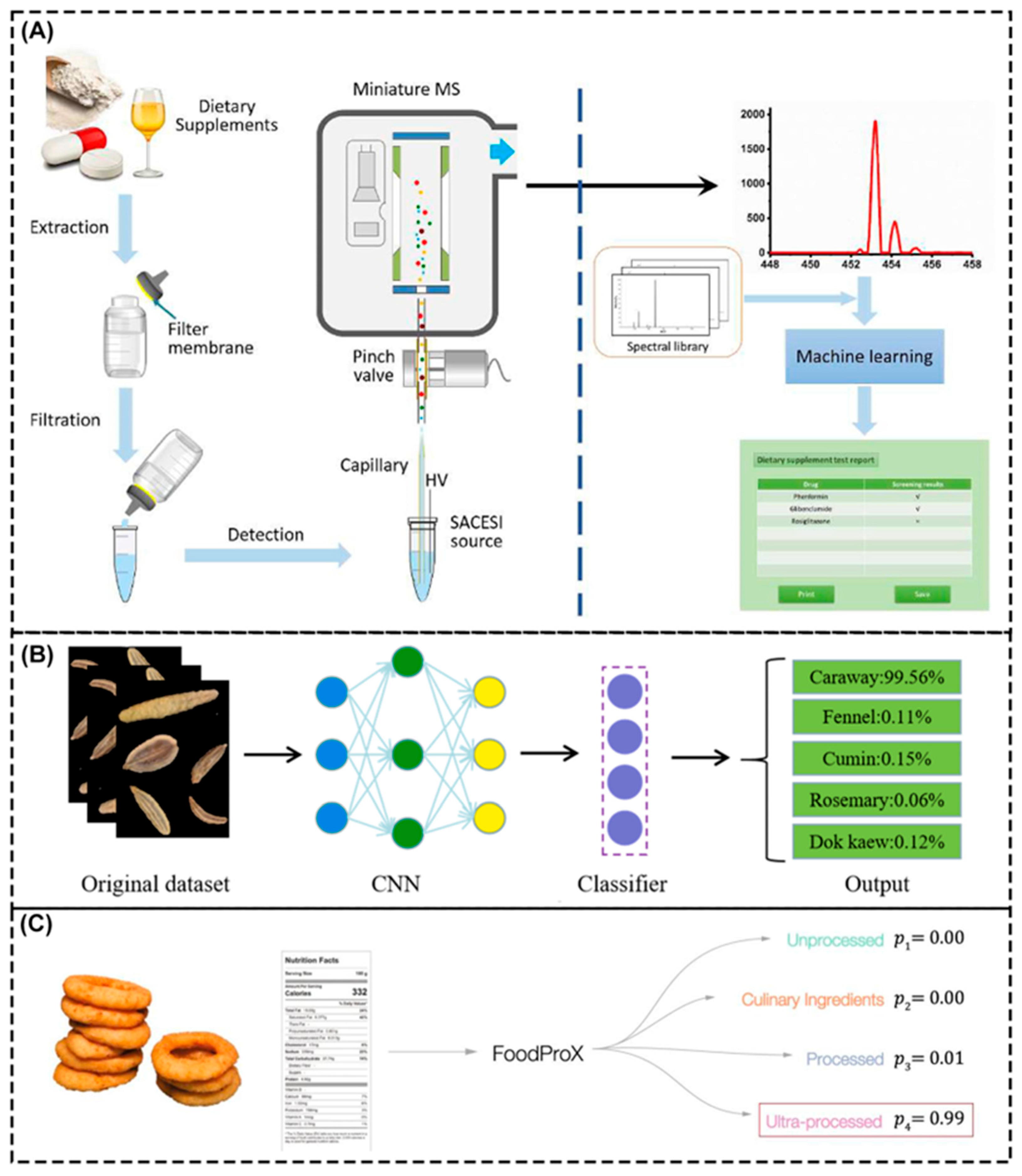

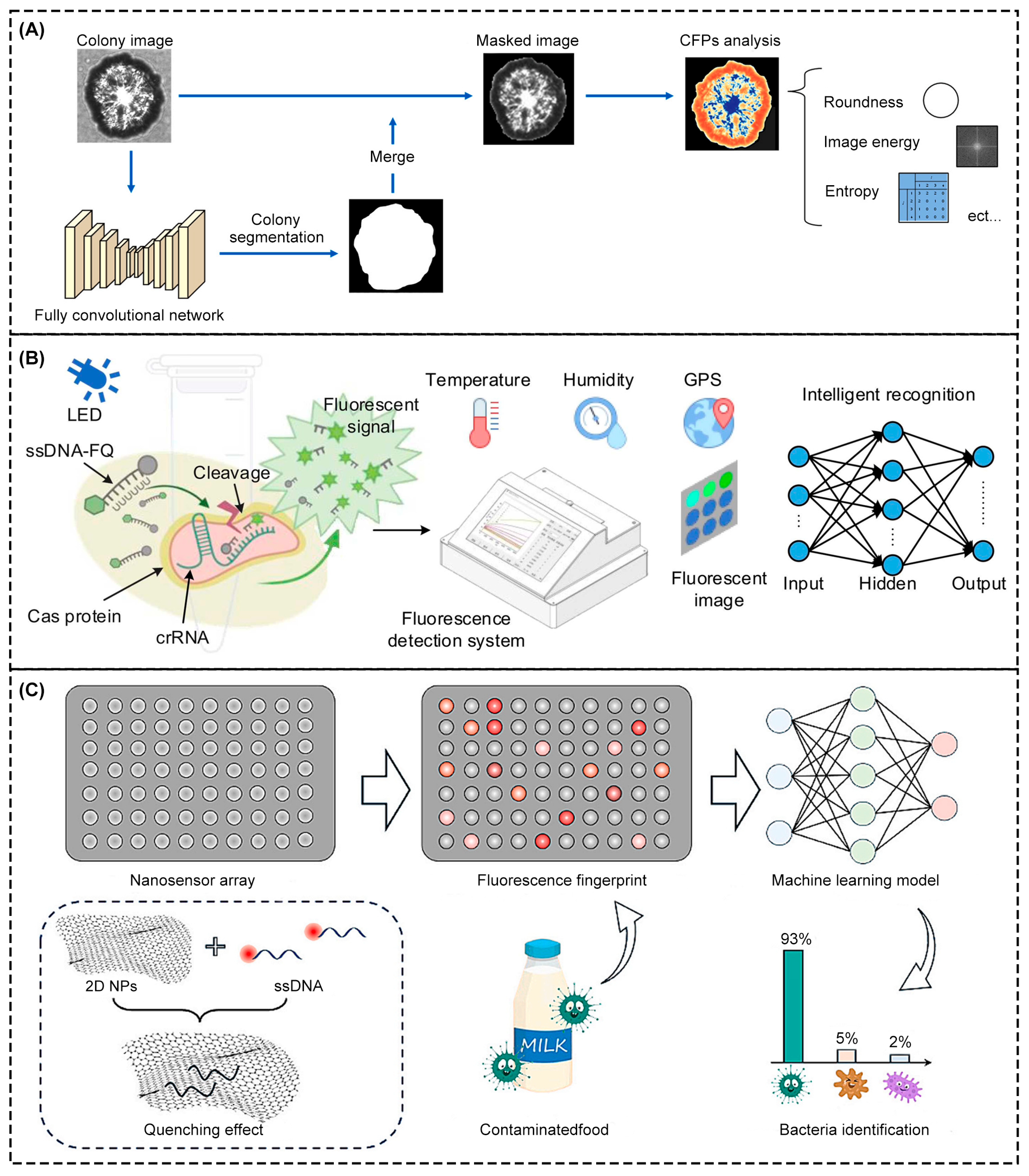

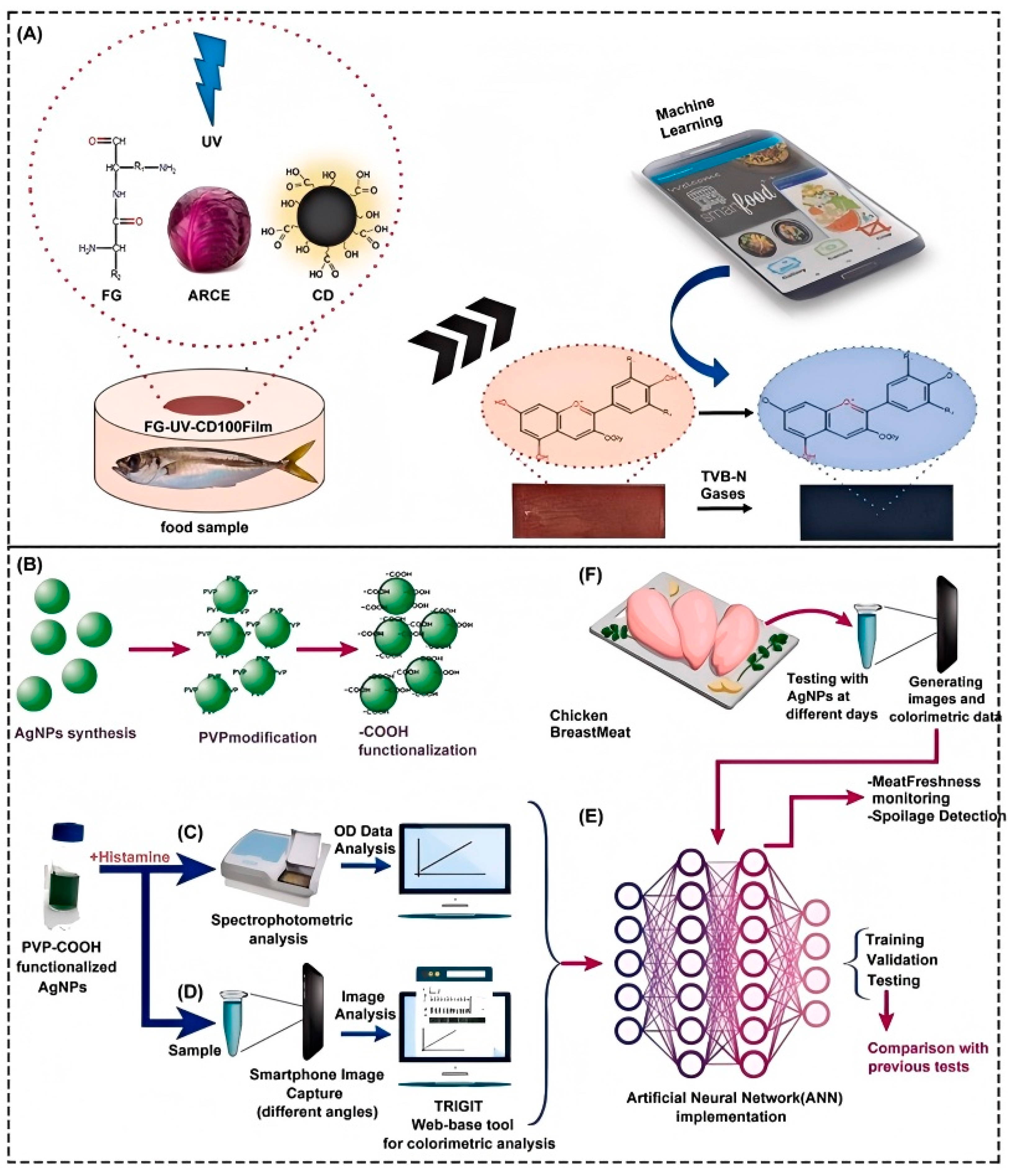

3.5. AI-Based Detection in Food Products

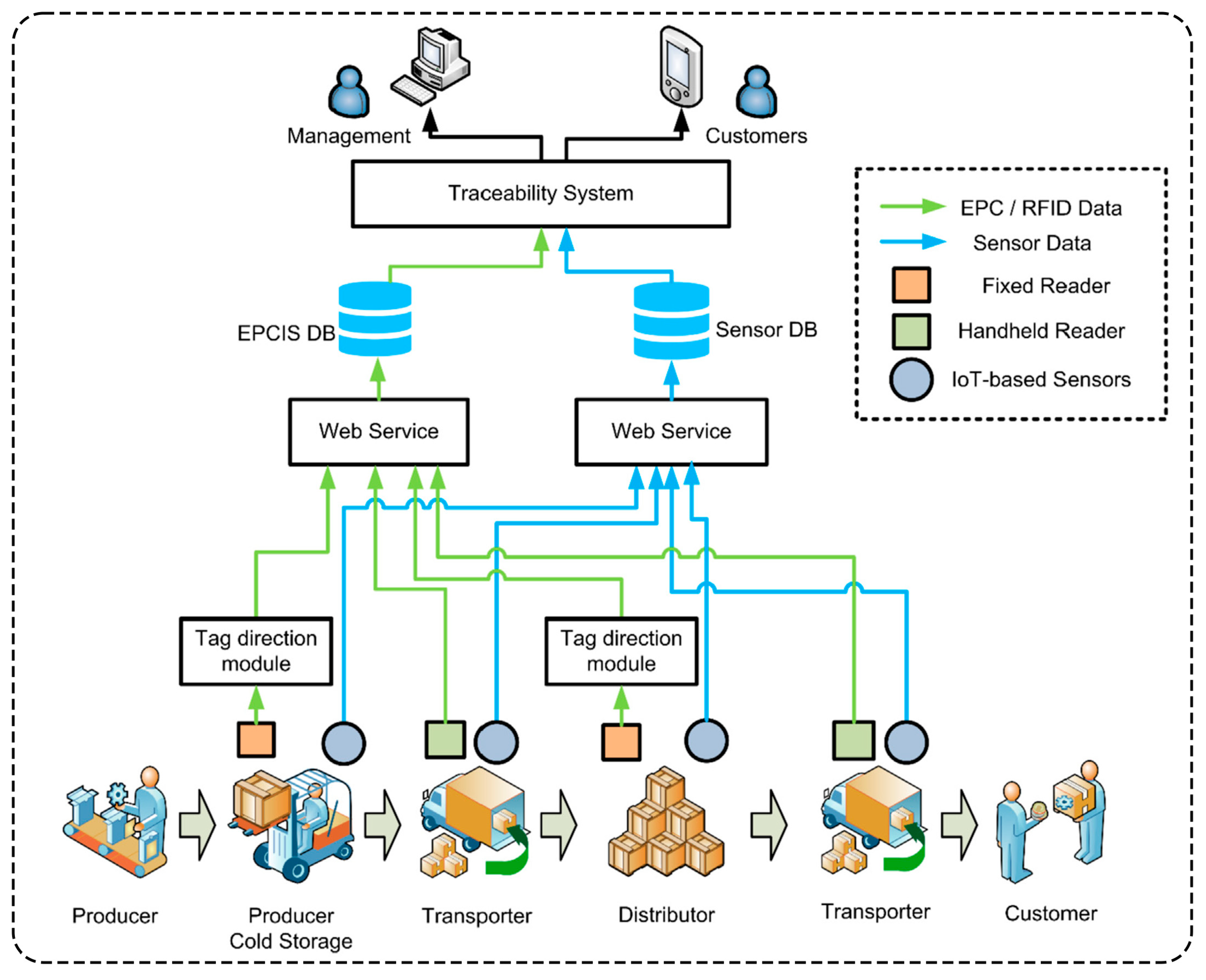

3.6. AI-Based Blockchain for Food Traceability

3.7. AI-Based Personalized Meal Services for the Table

4. Challenges and Future Directions of AI in Food Safety

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | anomaly detection |

| Acc. | accuracy |

| AE | automatic encoder |

| ACC | average correlation coefficient |

| AI | artificial intelligence |

| ANN | artificial neural network |

| AUC | area under curve |

| Aug-MLP | enhanced multilayer perceptron |

| BP | backpropagation |

| CA | cluster analysis |

| CNN | convolutional neural network |

| CNN-SSAE | convolutional neural network-stacked sparse auto-encoder |

| CTM | co-training model |

| DL | deep learning |

| DNN | deep neural network |

| DR | dimension reduction |

| DT | decision tree |

| ELM | extreme learning machine |

| E-nose | electronic nose |

| ERC | entropy rate clustering |

| FT-NIS | Fourier transform near-infrared spectroscopy |

| GA | genetic algorithm |

| GA-BP | genetic algorithm–backpropagation |

| CR | classification rate |

| GBM | gradient boosting machine |

| GC × GC/TOF-MS | full two-dimensional gas chromatography–time-of-flight mass spectrometry |

| GC-MS | gas chromatography–mass spectrometry |

| GelMA | gelatin–methylacrylyl |

| GM | generative model |

| GNB | gaussian naive Bayes |

| ID | impurity detection |

| IR | infrared radiation |

| K-means | K-means clustering algorithm |

| KNN | K-nearest neighbor |

| KPCA | kernel principal component analysis |

| L1-RLR | L1-regularized logistic regression |

| LR | loss rate |

| LDA | linear discriminant analysis |

| LR | linear regression |

| LSTM | long short-term memory |

| MAE | mean absolute error |

| ML | machine learning |

| MRFCN | multi-scale residuals full convolutional networks |

| MSE | mean square error |

| MSRD | multi-scale ridge detection |

| NonNN | non-neural network |

| OFX | ofloxacin |

| PCA | principal component analysis |

| PFALs | plant factories with artificial lighting |

| PHI | post-harvest interval |

| PLS-DA | partial least squares discriminant analysis |

| QDA | quadratic discriminant analysis |

| R2 | determination coefficient |

| RBF | radial basis function |

| RBF ANN | radial basis function artificial neural network |

| RBFNN | radial basis function neural network |

| ResNet18 | residual network 18 |

| RFW | reduced food waste |

| RUN | reduced unmet needs |

| RF | random forest |

| RNN | recurrent neural network |

| rrBLUP | ridge regression best linear unbiased prediction |

| RS | region segmentation |

| RSDE | random subspaces discriminative ensemble |

| SAC | soft actor–critic |

| SEM | scanning electron microscope |

| SERS | surface-enhanced raman spectroscopy |

| SFMA | seven F1 macro average |

| STM | self-training model |

| SVM | support vector machine |

| TD-NMR | time domain NMR |

| TSVM | transduction SVM |

| TFMA | three F1 macro average |

| VGG16 | visual geometry group 16-layer network |

| VOCs | volatile organic compounds |

| XAI | explainable AI |

| YOLOv8 | You Only Look Once Version 8 |

References

- Khan, R.; Anwar, F.; Ghazali, F.M. A comprehensive review of mycotoxins: Toxicology, detection, and effective mitigation approaches. Heliyon 2024, 10, e28361. [Google Scholar] [CrossRef] [PubMed]

- Hirt, H. Healthy soils for healthy plants for healthy humans How beneficial microbes in the soil, food and gut are interconnected and how agriculture can contribute to human health. Embo Rep. 2020, 21, e51069. [Google Scholar] [CrossRef]

- Gao, H.Y.; Dai, X.T.; Wu, L.H.; Zhang, J.X.; Hu, W.Y. Food safety risk behavior and social Co-governance in the food supply chain. Food Control 2023, 152, 109832. [Google Scholar] [CrossRef]

- Qin, K.; Zhang, J.X.; Qian, H.; Wu, L.H. Risk evaluation, spatiotemporal evolution, and driving factors of provincial food safety in China. Ecol. Indic. 2024, 166, 112505. [Google Scholar] [CrossRef]

- Sridhar, A.; Ponnuchamy, M.; Kapoor, A.; Prabhakar, S. Valorization of food waste as adsorbents for toxic dye removal from contaminated waters: A review. J. Hazard. Mater. 2022, 424, 127432. [Google Scholar] [CrossRef]

- Fahey, J.W.W.; Burak, J.S.; Evans, D. Sprout microbial safety: A reappraisal after a quarter-century. Food Front. 2023, 4, 318–324. [Google Scholar] [CrossRef]

- Abia, W.A.; Montgomery, H.; Nugent, A.P.; Elliott, C.T. Tropane alkaloid contamination of agricultural commodities and food products in relation to consumer health: Learnings from the 2019 Uganda food aid outbreak. Compr. Rev. Food Sci. Food Saf. 2021, 20, 501–525. [Google Scholar] [CrossRef]

- Zeng, S.Y.; Sun, X.C.; Wan, X.H.; Qian, C.C.; Yue, W.K.; Sohan, A.; Lin, X.D.; Yin, B.F. A cascade Fermat spiral microfluidic mixer chip for accurate detection and logic discrimination of cancer cells. Analyst 2022, 147, 3424–3433. [Google Scholar] [CrossRef]

- Roy, V.; Srivastava, S.K. The safety-quality dominant view of food chain integrity: Implications for consumer-centric food chain governance. Int. J. Manag. Rev. 2022, 24, 3–24. [Google Scholar] [CrossRef]

- Matsuhisa, N. Spoiler alert of foods by your phone. Nat. Food 2023, 4, 362–363. [Google Scholar] [CrossRef]

- Sealy, C. Biodegradable paper sensor detects spoiled food Carbon. Mater. Today 2023, 62, 10–11. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, C.; Long, Y.; Chen, Q.; Zhang, W.; Liu, G. Food additives: From functions to analytical methods. Crit. Rev. Food Sci. Nutr. 2022, 62, 8497–8517. [Google Scholar] [CrossRef] [PubMed]

- Raita, J.; Ahmed, H.; Chen, K.; Houttu, V.; Haikonen, R.; Karlund, A.; Kortesniemi, M.; Yang, B.; Koistinen, V.; Hanhineva, K. Existing food processing classifications overlook the phytochemical composition of processed plant-based protein-rich foods. Nat. Food 2025, 6, 503–512. [Google Scholar] [CrossRef] [PubMed]

- Novais, C.; Molina, A.K.; Abreu, R.M.V.; Santo-Buelga, C.; Ferreira, I.C.F.R.; Pereira, C.; Barros, L. Natural Food Colorants and Preservatives: A Review, a Demand, and a Challenge. J. Agric. Food Chem. 2022, 70, 2789–2805. [Google Scholar] [CrossRef]

- Verma, D.K.; Thakur, M.; Singh, S.; Tripathy, S.; Gupta, A.K.; Baranwal, D.; Patel, A.R.; Shah, N.; Utama, G.L.; Niamah, A.K.; et al. Bacteriocins as antimicrobial and preservative agents in food: Biosynthesis, separation and application. Food Biosci. 2022, 46, 101594. [Google Scholar] [CrossRef]

- da Silva, B.D.; Bernardes, P.C.; Pinheiro, P.F.; Fantuzzi, E.; Roberto, C.D. Chemical composition, extraction sources and action mechanisms of essential oils: Natural preservative and limitations of use in meat products. Meat Sci. 2021, 176, 108463. [Google Scholar] [CrossRef]

- Ong, K.J.; Johnston, J.; Datar, I.; Sewalt, V.; Holmes, D.; Shatkin, J.A. Food safety considerations and research priorities for the cultured meat and seafood industry. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5421–5448. [Google Scholar] [CrossRef]

- Wang, S.H.; Wang, S.Z.; Chen, T.N.; Yu, J.X.; Shi, Y.R.; Chen, G.S.; Xu, J.Q.; Qiu, J.L.; Zhu, F.; Ouyang, G.F. Detection and health implications of phthalates in tea beverages in market: Application of novel solid-phase microextraction fibers. Sci. Total Environ. 2024, 953, 176031. [Google Scholar] [CrossRef]

- Mamun, A.A.; Prasetya, T.A.E.; Dewi, I.R.; Ahmad, M. Microplastics in human food chains: Food becoming a threat to health safety. Sci. Total Environ. 2023, 858, 159834. [Google Scholar] [CrossRef]

- Sani, M.A.; Zhang, W.; Abedini, A.; Khezerlou, A.; Shariatifar, N.; Assadpour, E.; Zhang, F.; Jafari, S.M. Intelligent packaging systems for the quality and safety monitoring of meat products: From lab scale to industrialization. Food Control 2024, 160, 110359. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Wang, N.; Xiao, B.; Sun, X.; Li, J.; Zhong, K.; Yang, L.; Pang, X.; Huang, F.; et al. Critical review and recent advances of emerging real-time and non-destructive strategies for meat spoilage monitoring. Food Chem. 2024, 445, 138755. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.F.; Fu, C.; Lee, Y.Y. The Modulatory Role of Bioactive Compounds in Functional Foods on Inflammation and Metabolic Pathways in Chronic Diseases. Foods 2025, 14, 821. [Google Scholar] [CrossRef] [PubMed]

- Villamil, R.-A.; Romero, L.-N.; Ruiz, J.-P.; Patino, D.-C.; Gutierrez, L.-F.; Cortes, L.-Y. The Effects of Daily Consumption of Functionalized Yogurts with Sacha Inchi Oil and Interspecific Hybrid Palm Oil on the Lipid Profile and ApoB/ApoA1 Ratio of Healthy Adult Subjects. Foods 2024, 13, 3973. [Google Scholar] [CrossRef]

- Miller, V.; Micha, R.; Choi, E.; Karageorgou, D.; Webb, P.; Mozaffarian, D. Quality of Evidence for the Association of Foods and Nutrients With CVD and Diabetes. JAMA Netw. Open 2022, 5, e2146705. [Google Scholar] [CrossRef]

- Zavadlav, S.; Blazic, M.; van de Velde, F.; Vignatti, C.; Fenoglio, C.; Piagentini, A.M.; Pirovani, M.E.; Perotti, C.M.; Bursac Kovacevic, D.; Putnik, P. Sous-Vide as a Technique for Preparing Healthy and High-Quality Vegetable and Seafood Products. Foods 2020, 9, 1537. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Qin, Y.; Zhou, X.; Jin, W.; He, Z.; Li, X.; Wang, Q. Microalgae as future food: Rich nutrients, safety, production costs and environmental effects. Sci. Total Environ. 2024, 927, 172167. [Google Scholar] [CrossRef]

- Aghababaei, A.; Aghababaei, F.; Pignitter, M.; Hadidi, M. Artificial Intelligence in Agro-Food Systems: From Farm to Fork. Foods 2025, 14, 411. [Google Scholar] [CrossRef]

- Brauge, T.; Mougin, J.; Ells, T.; Midelet, G. Sources and contamination routes of seafood with human pathogenic Vibrio spp.: A Farm-to-Fork approach. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13283. [Google Scholar] [CrossRef]

- Boix-Fayos, C.; de Vente, J. Challenges and potential pathways towards sustainable agriculture within the European Green Deal. Agric. Syst. 2023, 207, 103634. [Google Scholar] [CrossRef]

- Raki, H.; Aalaila, Y.; Taktour, A.; Peluffo-Ordóñez, D.H. Combining AI Tools with Non-Destructive Technologies for Crop-Based Food Safety: A Comprehensive Review. Foods 2024, 13, 11. [Google Scholar] [CrossRef]

- Li, Y.; Man, S.; Ye, S.; Liu, G.; Ma, L. CRISPR-Cas-based detection for food safety problems: Current status, challenges, and opportunities. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3770–3798. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Ma, J.; Wang, Q.; Sun, D.-W. Applications of machine learning techniques for enhancing nondestructive food quality and safety detection. Crit. Rev. Food Sci. Nutr. 2023, 63, 1649–1669. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, S.; He, X.; He, X.; Yue, T. Construction of a Food Safety Evaluation System Based on the Factor Analysis of Mixed Data Method. Foods 2024, 13, 2680. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, F.; Chen, Y.; Xie, Y.; Wang, R.; He, Y.; Song, P. Xanthan gum/ZrMOF biodegradable gel fertilizer: Sustainable water retention and crop growth. Int. J. Biol. Macromol. 2025, 291, 138969. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wang, D.; Rietjens, I.M.C.M.; Zheng, L. Current and emerging issues in chemical food safety. Curr. Opin. Food Sci. 2025, 62, 101284. [Google Scholar] [CrossRef]

- Leskovac, A.; Petrovic, S. Pesticide Use and Degradation Strategies: Food Safety, Challenges and Perspectives. Foods 2023, 12, 2709. [Google Scholar] [CrossRef]

- Li, Y.; Yang, F.; Yuan, R.; Zhong, X.; Zhuo, Y. Electrochemiluminescence covalent organic framework coupling with CRISPR/Cas12a-mediated biosensor for pesticide residue detection. Food Chem. 2022, 389, 133049. [Google Scholar] [CrossRef]

- Gavahian, M.; Pallares, N.; Al Khawli, F.; Ferrer, E.; Barba, F.J. Recent advances in the application of innovative food processing technologies for mycotoxins and pesticide reduction in foods. Trends Food Sci. Technol. 2020, 106, 209–218. [Google Scholar] [CrossRef]

- Jia, M.; Zhongbo, E.; Zhai, F.; Bing, X. Rapid Multi-Residue Detection Methods for Pesticides and Veterinary Drugs. Molecules 2020, 25, 3590. [Google Scholar] [CrossRef]

- Wang, B.; Xie, K.; Lee, K. Veterinary Drug Residues in Animal-Derived Foods: Sample Preparation and Analytical Methods. Foods 2021, 10, 555. [Google Scholar] [CrossRef]

- Xu, C.; Zheng, S.; Xia, X.; Li, J.; Yu, Q.; Wang, Y.; Jin, Q.; Wang, C.; Gu, B. Core-satellite-structured magnetic nanozyme enables the ultrasensitive colorimetric detection of multiple drug residues on lateral flow immunoassay. Anal. Chim. Acta 2024, 1325, 343115. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Jin, Y.; Fan, C.; Xu, Y.; Li, J.; Pan, W.; Lou, Z.; Chen, H.; Jin, B. Exploring the trophic transfer and effects of microplastics in freshwater ecosystems: A focus on Bellamya aeruginosa to Mylopharyngodon piceus. Environ. Pollut. 2024, 357, 124426. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, J.; Huang, H.; Ma, Y.; Zhao, X. Research and application of MOFs-derived porous carbon materials in food safety detection: A review. Trends Food Sci. Technol. 2024, 147, 104449. [Google Scholar] [CrossRef]

- Truong, A.M.; Luong, H.Q. A non-destructive, autoencoder-based approach to detecting defects and contamination in reusable food packaging. Curr. Res. Food Sci. 2024, 8, 100758. [Google Scholar] [CrossRef]

- Yu, W.; Hu, M.; Qi, W.; Dou, L.; Pan, Y.; Bai, Y.; Shao, S.; Liu, M.; Lin, J.; Ke, Y.; et al. From pretreatment to assay: A chemiluminescence- and optical fiber-based fully automated immunosensing (COFFAI) system. Sens. Actuator B-Chem. 2022, 362, 131820. [Google Scholar] [CrossRef]

- Liang, M.; Zhang, G.; Song, J.; Tan, M.; Su, W. Paper-Based Microfluidic Chips for Food Hazard Factor Detection: Fabrication, Modification, and Application. Foods 2023, 12, 4107. [Google Scholar] [CrossRef]

- Jiang, W.; Tang, Q.; Zhu, Y.; Gu, X.; Wu, L.; Qin, Y. Research progress of microfluidics-based food safety detection. Food Chem. 2024, 441, 138319. [Google Scholar] [CrossRef]

- Zolti, O.; Suganthan, B.; Ramasamy, R.P. Lab-on-a-Chip Electrochemical Biosensors for Foodborne Pathogen Detection: A Review of Common Standards and Recent Progress. Biosensors 2023, 13, 215. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Zhang, P.; Wang, D.; Jiang, J.; Chen, X.; Liu, Y.; Zhang, Z.; Tang, B.Z.; Li, P. AIEgens enabled ultrasensitive point-of-care test for multiple targets of food safety: Aflatoxin B1 and cyclopiazonic acid as an example. Biosens. Bioelectron. 2021, 182, 113188. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Yildiz, Z.; Yildiz, P.; Strachowski, P.; Forough, M.; Esmaeili, Y.; Naebe, M.; Abdollahi, M. Advanced technologies in biodegradable packaging using intelligent sensing to fight food waste. Int. J. Biol. Macromol. 2024, 261, 129647. [Google Scholar] [CrossRef]

- Zhou, Z.; Tian, D.; Yang, Y.; Cui, H.; Li, Y.; Ren, S.; Han, T.; Gao, Z. Machine learning assisted biosensing technology: An emerging powerful tool for improving the intelligence of food safety detection. Curr. Res. Food Sci. 2024, 8, 100679. [Google Scholar] [CrossRef] [PubMed]

- Yin, B.F.; Wan, X.H.; Yue, W.K.; Zhou, T.; Shi, L.Y.; Wang, S.B.; Lin, X.D. A portable automated chip for simultaneous rapid point-of-care testing of multiple β-agonists. Biosens. Bioelectron. 2023, 239, 115586. [Google Scholar] [CrossRef]

- Adade, S.Y.-S.S.; Lin, H.; Johnson, N.A.N.; Nunekpeku, X.; Aheto, J.H.; Ekumah, J.-N.; Kwadzokpui, B.A.; Teye, E.; Ahmad, W.; Chen, Q. Advanced food contaminant detection through multi-source data fusion: Strategies, applications, and future perspectives. Trends Food Sci. Technol. 2025, 156, 104851. [Google Scholar] [CrossRef]

- Moulahoum, H.; Ghorbanizamani, F. Navigating the development of silver nanoparticles based food analysis through the power of artificial intelligence. Food Chem. 2024, 445, 138800. [Google Scholar] [CrossRef]

- Yin, B.F.; Wan, X.H.; Yang, M.Z.; Qian, C.C.; Sohan, A. Wave-shaped microfluidic chip assisted point-of-care testing for accurate and rapid diagnosis of infections. Mil. Med. Res. 2022, 9, 8. [Google Scholar] [CrossRef] [PubMed]

- Mu, W.; Kleter, G.A.; Bouzembrak, Y.; Dupouy, E.; Frewer, L.J.; Al Natour, F.N.R.; Marvin, H.J.P. Making food systems more resilient to food safety risks by including artificial intelligence, big data, and internet of things into food safety early warning and emerging risk identification tools. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13296. [Google Scholar] [CrossRef]

- Wang, P.-L.; Xie, L.-H.; Joseph, E.A.; Li, J.-R.; Su, X.-O.; Zhou, H.-C. Metal-Organic Frameworks for Food Safety. Chem. Rev. 2019, 119, 10638–10690. [Google Scholar] [CrossRef]

- Wang, Q.; Chang, K.; Yang, Q.; Wu, W. Semiconductor-based surface-enhanced Raman scattering sensing platforms: State of the art, applications and prospects in food safety. Trends Food Sci. Technol. 2024, 147, 104460. [Google Scholar] [CrossRef]

- Yin, B.; Zeng, S.; Liu, J.; Muhammad, R.; Jiang, Z.; Tan, G.; Yang, Q. Dual-Mode Microfluidic Workstation for Rapid Detection of Multiple Mycotoxins on Chip. Foods 2025, 14, 1928. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, S.; Zhang, Y.; Feng, Y.; Liu, J.; Zhu, H. Artificial Intelligence in Food Safety: A Decade Review and Bibliometric Analysis. Foods 2023, 12, 1242. [Google Scholar] [CrossRef]

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, Big Data, and Artificial Intelligence in Agriculture and Food Industry. IEEE IoT J. 2022, 9, 6305–6324. [Google Scholar] [CrossRef]

- Yi, L.Z.; Wang, W.F.; Diao, Y.H.; Yi, S.L.; Shang, Y.; Ren, D.B.; Ge, K.; Gu, Y. Recent advances of artificial intelligence in quantitative analysis of food quality and safety indicators: A review. Trac-Trends Anal. Chem. 2024, 180, 117944. [Google Scholar] [CrossRef]

- Bec, K.B.; Grabska, J.; Huck, C.W. Miniaturized NIR Spectroscopy in Food Analysis and Quality Control: Promises, Challenges, and Perspectives. Foods 2022, 11, 1465. [Google Scholar] [CrossRef]

- Guo, M.; Wang, K.; Lin, H.; Wang, L.; Cao, L.; Sui, J. Spectral data fusion in nondestructive detection of food products: Strategies, recent applications, and future perspectives. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13301. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Han, M.; Ma, A.; Jiang, F.; Chen, R.; Dong, Y.; Wang, X.; Ruan, S.; Chen, Y. A machine vision-assisted Argonaute-mediated fluorescence biosensor for the detection of viable Salmonella in food without convoluted DNA extraction and amplification procedures. J. Hazard. Mater. 2024, 466, 133648. [Google Scholar] [CrossRef]

- Meng, W.; Yang, Y.; Zhang, R.; Wu, Z.; Xiao, X. Triboelectric-electromagnetic hybrid generator based self-powered flexible wireless sensing for food monitoring. Chem. Eng. J. 2023, 473, 145465. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, M.; Zhu, T.; Wan, Z.; Chen, X.; Xiao, X. Wireless charging flexible in-situ optical sensing for food monitoring. Chem. Eng. J. 2024, 488, 150808. [Google Scholar] [CrossRef]

- Yin, B.F.; Qian, C.C.; Wang, S.B.; Wan, X.H.; Zhou, T. A Microfluidic Chip-Based MRS Immunosensor for Biomarker Detection via Enzyme-Mediated Nanoparticle Assembly. Front. Chem. 2021, 9, 688442. [Google Scholar] [CrossRef]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Garaus, M. Using blockchain to signal quality in the food supply chain: The impact on consumer purchase intentions and the moderating effect of brand familiarity. Int. J. Inf. Manag. 2023, 68, 102514. [Google Scholar] [CrossRef]

- Nath, P.C.; Mishra, A.K.; Sharma, R.; Bhunia, B.; Mishra, B.; Tiwari, A.; Nayak, P.K.; Sharma, M.; Bhuyan, T.; Kaushal, S.; et al. Recent advances in artificial intelligence towards the sustainable future of agri-food industry. Food Chem. 2024, 447, 138945. [Google Scholar] [CrossRef] [PubMed]

- Röhrs, S.; Rohn, S.; Pfeifer, Y. Risk Classification of Food Incidents Using a Risk Evaluation Matrix for Use in Artificial Intelligence-Supported Risk Identification. Foods 2024, 13, 3675. [Google Scholar] [CrossRef]

- Li, P.R.; Shi, L.Y.; Zhao, J.C.; Liu, B.; Yan, H.; Deng, Y.B.; Yin, B.F.; Zhou, T.; Zhu, Y.G. Topology optimization design of a passive two-dimensional micromixer. Chem. Phys. Lett. 2023, 821, 140445. [Google Scholar] [CrossRef]

- Yin, B.F.; Yue, W.K.; Sohan, A.; Wan, X.H.; Zhou, T.; Shi, L.Y.; Qian, C.C.; Lin, X.D. Construction of a desirable hyperbolic microfluidic chip for ultrasensitive determination of PCT based on chemiluminescence. J. Mater. Chem. B 2023, 11, 1978–1986. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Guo, Y.; Zhang, X.; Liu, J.; Gong, P.; Su, Z.; Fan, L.; Li, G. Emerging Nanoparticles in Food: Sources, Application, and Safety. J. Agric. Food Chem. 2023, 71, 3564–3582. [Google Scholar] [CrossRef]

- Chowdhury, M.A.H.; Ashrafudoulla, M.; Mevo, S.I.U.; Mizan, M.F.R.; Park, S.H.; Ha, S.-D. Current and future interventions for improving poultry health and poultry food safety and security: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1555–1596. [Google Scholar] [CrossRef]

- Ghimpeteanu, O.M.; Pogurschi, E.N.; Popa, D.C.; Dragomir, N.; Dragotoiu, T.; Mihai, O.D.; Petcu, C.D. Antibiotic Use in Livestock and Residues in Food-A Public Health Threat: A Review. Foods 2022, 11, 1430. [Google Scholar] [CrossRef] [PubMed]

- Grujovic, M.Z.; Mladenovic, K.G.; Semedo-Lemsaddek, T.; Laranjo, M.; Stefanovic, O.D.; Kocic-Tanackov, S.D. Advantages and disadvantages of non-starter lactic acid bacteria from traditional fermented foods: Potential use as starters or probiotics. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1537–1567. [Google Scholar] [CrossRef]

- Hua, Z.; Yu, T.; Liu, D.; Xianyu, Y. Recent advances in gold nanoparticles-based biosensors for food safety detection. Biosens. Bioelectron. 2021, 179, 113076. [Google Scholar] [CrossRef]

- Yin, B.; Yue, W.; Sohan, A.S.M.M.F.; Zhou, T.; Qian, C.; Wan, X. Micromixer with Fine-Tuned Mathematical Spiral Structures. Acs Omega 2021, 6, 30779–30789. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Xue, Z.; Peng, B.; Kou, X.; Gao, Z. Research progress of dual-mode sensing technology strategy based on SERS and its application in the detection of harmful substances in foods. Trends Food Sci. Technol. 2024, 148, 104487. [Google Scholar] [CrossRef]

- Luo, X.; Han, Y.; Chen, X.; Tang, W.; Yue, T.; Li, Z. Carbon dots derived fluorescent nanosensors as versatile tools for food quality and safety assessment: A review. Trends Food Sci. Technol. 2020, 95, 149–161. [Google Scholar] [CrossRef]

- Yousefi, H.; Su, H.-M.; Imani, S.M.; Alkhaldi, K.; Filipe, C.D.M.; Didar, T.F. Intelligent Food Packaging: A Review of Smart Sensing Technologies for Monitoring Food Quality. ACS Sens. 2019, 4, 808–821. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Ouyang, Z.; Zhang, Y.; Lu, Y.; Wei, C.; Tu, Y.; He, B. Research progress on the artificial intelligence applications in food safety and quality management. Trends Food Sci. Technol. 2025, 156, 104855. [Google Scholar] [CrossRef]

- Barthwal, R.; Kathuria, D.; Joshi, S.; Kaler, R.S.S.; Singh, N. New trends in the development and application of artificial intelligence in food processing. Innov. Food Sci. Emerg. Technol. 2024, 92, 103600. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, X.; Liu, N.; Liu, C.; Jiang, A.; Chen, L. Integrating AI with detection methods, IoT, and blockchain to achieve food authenticity and traceability from farm-to-table. Trends Food Sci. Technol. 2025, 158, 104925. [Google Scholar] [CrossRef]

- Yin, B.; Jiang, Z.; Muhammad, R.; Liu, J.; Wang, J. Nanozyme-Powered Multimodal Sensing for Pesticide Detection. Foods 2025, 14, 1957. [Google Scholar] [CrossRef]

- Adak, A.; Pradhan, B.; Shukla, N. Sentiment Analysis of Customer Reviews of Food Delivery Services Using Deep Learning and Explainable Artificial Intelligence: Systematic Review. Foods 2022, 11, 1500. [Google Scholar] [CrossRef]

- Preethi, P.; Swathika, R.; Kaliraj, S.; Premkumar, R.; Yogapriya, J. Deep Learning-Based Enhanced Optimization for Automated Rice Plant Disease Detection and Classification. Food Energy Secur. 2024, 13, e70001. [Google Scholar] [CrossRef]

- Pfisterer, K.J.; Amelard, R.; Chung, A.G.; Wong, A. A new take on measuring relative nutritional density: The feasibility of using a deep neural network to assess commercially-prepared pureed food concentrations. J. Food Eng. 2018, 223, 220–235. [Google Scholar] [CrossRef]

- Maimaitijiang, M.; Sagan, V.; Sidike, P.; Hartling, S.; Esposito, F.; Fritschi, F.B. Soybean yield prediction from UAV using multimodal data fusion and deep learning. Remote Sens. Environ. 2020, 237, 111599. [Google Scholar] [CrossRef]

- Alsubai, S.; Alqahtani, A.; Alanazi, A.; Bhatia, M. Decision-Tree-Assisted Intelligent Framework for Food Quality Analysis. IEEE Internet Things J. 2024, 11, 30800–30807. [Google Scholar] [CrossRef]

- van Asselt, E.D.; Noordam, M.Y.; Pikkemaat, M.G.; Dorgelo, F.O. Risk-based monitoring of chemical substances in food: Prioritization by decision trees. Food Control 2018, 93, 112–120. [Google Scholar] [CrossRef]

- Mao, Y.; Cheng, S.; Qin, Y.; Qin, Z.; Tian, S. Grade identification of rice eating quality via a novel flow-injection voltammetric electronic tongue combined with SFFS-BO-SVM. Sens. Actuator B-Chem. 2024, 411, 135700. [Google Scholar] [CrossRef]

- Li, Q.; Lei, T.; Cheng, Y.; Wei, X.; Sun, D.-W. Predicting wheat gluten concentrations in potato starch using GPR and SVM models built by terahertz time-domain spectroscopy. Food Chem. 2024, 432, 137235. [Google Scholar] [CrossRef] [PubMed]

- de Santana, F.B.; Neto, W.B.; Poppi, R.J. Random forest as one-class classifier and infrared spectroscopy for food adulteration detection. Food Chem. 2019, 293, 323–332. [Google Scholar] [CrossRef]

- Geng, Z.; Duan, X.; Li, J.; Chu, C.; Han, Y. Risk prediction model for food safety based on improved random forest integrating virtual sample. Eng. Appl. Artif. Intell. 2022, 116, 105352. [Google Scholar] [CrossRef]

- Rashvand, M.; Ren, Y.; Sun, D.-W.; Senge, J.; Krupitzer, C.; Fadiji, T.; Miro, M.S.; Shenfield, A.; Watson, N.J.; Zhang, H. Artificial intelligence for prediction of shelf-life of various food products: Recent advances and ongoing challenges. Trends Food Sci. Technol. 2025, 159, 104989. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, S.Y.; Zhu, H.Y.; Wan, X.H.; Sohan, A.; Yin, B.F. A Portable Automated Microfluidic Platform for Point-of-Care Testing for Multiple Mycotoxins in Wine. Foods 2024, 13, 2066. [Google Scholar] [CrossRef]

- Rong, D.; Wang, H.Y.; Xie, L.J.; Ying, Y.B.; Zhang, Y.S. Impurity detection of juglans using deep learning and machine vision. Comput. Electron. Agric. 2020, 178, 105764. [Google Scholar] [CrossRef]

- Wyrzykowska, B.; Szymczyk, K.; Ichihashi, H.; Falandysz, J.; Skwarzec, B.; Yamasaki, S.-i. Application of ICP Sector Field MS and Principal Component Analysis for Studying Interdependences among 23 Trace Elements in Polish Beers. J. Agric. Food Chem. 2024, 72, 17121. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Zhao, M.; Zhou, L.; Zhang, M.; Liu, J.; Marchioni, E. Identification and Differentiation of Wild Edible Mushrooms Based on Lipidomics Profiling Combined with Principal Component Analysis. J. Agric. Food Chem. 2023, 71, 14390. [Google Scholar] [CrossRef]

- Farrugia, J.; Griffin, S.; Valdramidis, V.P.; Camilleri, K.; Falzon, O. Principal component analysis of hyperspectral data for early detection of mould in cheeselets. Curr. Res. Food Sci. 2021, 4, 18–27. [Google Scholar] [CrossRef]

- Goel, L.; Raman, S.; Dora, S.S.; Bhutani, A.; Aditya, A.S.; Mehta, A. Hybrid computational intelligence algorithms and their applications to detect food quality. Artif. Intell. Rev. 2020, 53, 1415–1440. [Google Scholar] [CrossRef]

- Ruedt, C.; Gibis, M.; Weiss, J. Quantification of surface iridescence in meat products by digital image analysis. Meat Sci. 2020, 163, 108064. [Google Scholar] [CrossRef] [PubMed]

- De Filippo, M.; Fasola, S.; Tanno, L.K.; Brambilla, I.; Votto, M.; La Grutta, S.; Marseglia, G.L.; Licari, A. Optimizing understanding of food-induced anaphylaxis phenotypes through clustering analysis. Clin. Exp. Allergy 2023, 53, 1050–1054. [Google Scholar] [CrossRef]

- Chen, T.J.; Wang, Y.N.; Xiao, C.Y.; Wu, Q.M.J. A Machine Vision Apparatus and Method for Can-End Inspection. IEEE Trans. Instrum. Meas. 2016, 65, 2055–2066. [Google Scholar] [CrossRef]

- Van De Looverbosch, T.; Bhuiyan, M.H.R.; Verboven, P.; Dierick, M.; Van Loo, D.; De Beenbouwer, J.; Sijbers, J.; Nicolaï, B. Nondestructive internal quality inspection of pear fruit by X-ray CT using machine learning. Food Control 2020, 113, 107170. [Google Scholar] [CrossRef]

- Liu, Y.; Pu, H.; Sun, D.-W. Efficient extraction of deep image features using convolutional neural network (CNN) for applications in detecting and analysing complex food matrices. Trends Food Sci Technol. 2021, 113, 193–204. [Google Scholar] [CrossRef]

- Gao, F.; Fu, L.; Zhang, X.; Majeed, Y.; Li, R.; Karkee, M.; Zhang, Q. Multi-class fruit-on-plant detection for apple in SNAP system using Faster R-CNN. Comput. Electron. Agric. 2020, 176, 105634. [Google Scholar] [CrossRef]

- Chakravartula, S.S.N.; Moscetti, R.; Bedini, G.; Nardella, M.; Massantini, R. Use of convolutional neural network (CNN) combined with FT-NIR spectroscopy to predict food adulteration: A case study on coffee. Food Control 2022, 135, 108816. [Google Scholar] [CrossRef]

- Phiphitphatphaisit, S.; Surinta, O. Multi-layer adaptive spatial-temporal feature fusion network for efficient food image recognition. Expert Syst. Appl. 2024, 255, 124834. [Google Scholar] [CrossRef]

- Seo, K.W.; Seo, J.; Kim, K.; Lim, S.J.; Chung, J. Prediction of biogas production rate from dry anaerobic digestion of food waste: Process-based approach vs. recurrent neural network black-box model. Bioresour. Technol. 2021, 341, 125829. [Google Scholar] [CrossRef] [PubMed]

- Castro, W.; Saavedra, M.; Castro, J.; Tech, A.R.B.; Chuquizuta, T.; Avila-George, H. Using recurrent neural networks to identify broken-cold-chain fish fillet from spectral profiles. Neural Comput. Appl. 2024, 36, 4377–4386. [Google Scholar] [CrossRef]

- Gong, W.; Yao, H.B.; Chen, T.; Xu, Y.; Fang, Y.; Zhang, H.Y.; Li, B.W.; Hu, J.N. Smartphone platform based on gelatin methacryloyl(GelMA)combined with deep learning models for real-time monitoring of food freshness. Talanta 2023, 253, 124057. [Google Scholar] [CrossRef]

- Kaur, R.; Choudhary, D.; Bali, S.; Bandral, S.S.; Singh, V.; Ahmad, M.A.; Rani, N.; Singh, T.G.; Chandrasekaran, B. Pesticides: An alarming detrimental to health and environment. Sci. Total Environ. 2024, 915, 170113. [Google Scholar] [CrossRef] [PubMed]

- Sindhu, S.; Manickavasagan, A. Nondestructive testing methods for pesticide residue in food commodities: A review. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1226–1256. [Google Scholar] [CrossRef]

- Umapathi, R.; Park, B.; Sonwal, S.; Rani, G.M.; Cho, Y.; Huh, Y.S. Advances in optical-sensing strategies for the on-site detection of pesticides in agricultural foods. Trends Food Sci. Technol. 2022, 119, 69–89. [Google Scholar] [CrossRef]

- He, H.; Sun, D.-W.; Wu, Z.; Pu, H.; Wei, Q. On-off-on fluorescent nanosensing: Materials, detection strategies and recent food applications. Trends Food Sci. Technol. 2022, 119, 243–256. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, J.; Han, L.; Wang, X.; Li, W.; Guo, H.; Wei, H. Nanozyme Sensor Arrays Based on Heteroatom-Doped Graphene for Detecting Pesticides. Anal. Chem. 2020, 92, 7444–7452. [Google Scholar] [CrossRef]

- Guo, Z.; Wu, X.; Jayan, H.; Yin, L.; Xue, S.; El-Seedi, H.R.; Zou, X. Recent developments and applications of surface enhanced Raman scattering spectroscopy in safety detection of fruits and vegetables. Food Chem. 2024, 434, 137469. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Zhang, M.; Zhu, Q.; Adhikari, B. Intelligent vegetable freshness monitoring system developed by integrating eco-friendly fluorescent sensor arrays with deep convolutional neural networks. Chem. Eng. J. 2024, 488, 150739. [Google Scholar] [CrossRef]

- Sambasivam, G.; Opiyo, G.D. A predictive machine learning application in agriculture: Cassava disease detection and classification with imbalanced dataset using convolutional neural networks. Egypt. Inform. J. 2021, 22, 27–34. [Google Scholar] [CrossRef]

- Christakakis, P.; Papadopoulou, G.; Mikos, G.; Kalogiannidis, N.; Ioannidis, D.; Tzovaras, D.; Pechlivani, E.M. Smartphone-Based Citizen Science Tool for Plant Disease and Insect Pest Detection Using Artificial Intelligence. Technologies 2024, 12, 101. [Google Scholar] [CrossRef]

- Tu, M.; Zhang, W.; Zhu, Y.; Ma, W.; Li, X.; Zhou, S.; Li, H.; Li, X. Accurate Quantification of Pure Thiacloprid with Mass Balance and Quantitative H-NMR. J. Anal. Test. 2024, 8, 1–8. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Xiang, Y.; Cao, H.; Li, Y. Simultaneous Determination of Trace Matrine and Oxymatrine Pesticide Residues in Tea by Magnetic Solid-Phase Extraction Coupled with Liquid Chromatography-Tandem Mass Spectrometry. J. Anal. Test. 2024, 8, 245–250. [Google Scholar] [CrossRef]

- Qu, G.; Chen, B.; Liu, S.; Zhang, Q.; Yang, Y.; Fu, Q. A Modified QuEChERS-DART-MS/MS Technique for High-Throughput Detection of Organophosphate Nerve Agent Hydrolysis Products in Environmental Samples. J. Anal. Test. 2023, 7, 163–171. [Google Scholar] [CrossRef]

- Jiang, Z.A.; Zhuang, Y.; Guo, S.T.; Sohan, A.; Yin, B.F. Advances in Microfluidics Techniques for Rapid Detection of Pesticide Residues in Food. Foods 2023, 12, 2868. [Google Scholar] [CrossRef]

- Shenashen, M.A.; Emran, M.Y.; El Sabagh, A.; Selim, M.M.; Elmarakbi, A.; El-Safty, S.A. Progress in sensory devices of pesticides, pathogens, coronavirus, and chemical additives and hazards in food assessment: Food safety concerns. Prog. Mater. Sci. 2022, 124, 100866. [Google Scholar] [CrossRef]

- Hajikhani, M.; Hegde, A.; Snyder, J.; Cheng, J.L.; Lin, M.S. Integrating transformer-based machine learning with SERS technology for the analysis of hazardous pesticides in spinach. J. Hazard. Mater. 2024, 470, 134208. [Google Scholar] [CrossRef]

- Wang, X.T.; Jiang, S.; Liu, Z.H.; Sun, X.M.; Zhang, Z.; Quan, X.B.; Zhang, T.; Kong, W.K.; Yang, X.T.; Li, Y. Integrated surface-enhanced Raman spectroscopy and convolutional neural network for quantitative and qualitative analysis of pesticide residues on pericarp. Food Chem. 2024, 440, 138214. [Google Scholar] [CrossRef] [PubMed]

- Zeng, S.Y.; Zhu, H.Y.; Sohan, A.; Liu, J.; Wan, X.H.; Lin, X.D.; Yin, B.F. A remote-controlled portable workstation for highly sensitive and real-time chemiluminescent detection of cadmium. Food Chem. 2024, 452, 139549. [Google Scholar] [CrossRef]

- Mao, C.; Song, Y.; Chen, L.; Ji, J.; Li, J.; Yuan, X.; Yang, Z.; Ayoko, G.A.; Frost, R.L.; Theiss, F. Human health risks of heavy metals in paddy rice based on transfer characteristics of heavy metals from soil to rice. Catena 2019, 175, 339–348. [Google Scholar] [CrossRef]

- Oladoye, P.O.; Olowe, O.M.; Asemoloye, M.D. Phytoremediation technology and food security impacts of heavy metal contaminated soils: A review of literature. Chemosphere 2022, 288, 132555. [Google Scholar] [CrossRef] [PubMed]

- Yin, B.F.; Wan, X.H.; Qian, C.C.; Sohan, A.; Zhou, T.; Yue, W.K. Enzyme Method-Based Microfluidic Chip for the Rapid Detection of Copper Ions. Micromachines 2021, 12, 1380. [Google Scholar] [CrossRef] [PubMed]

- Kovač, M.; Bulaić, M.; Jakovljević, J.; Nevistić, A.; Rot, T.; Kovač, T.; Dodlek Šarkanj, I.; Šarkanj, B. Mycotoxins, Pesticide Residues, and Heavy Metals Analysis of Croatian Cereals. Microorganisms 2021, 14, 1303. [Google Scholar] [CrossRef]

- Qin, G.; Niu, Z.; Yu, J.; Li, Z.; Ma, J.; Xiang, P. Soil heavy metal pollution and food safety in China: Effects, sources and removing technology. Chemosphere 2021, 267, 129205. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, H.-Q.; Chen, J.; Chang, J.-D.; Zhao, F.-J. Molecular mechanisms underlying the toxicity and detoxification of trace metals and metalloids in plants. J. Integr. Plant Biol. 2023, 65, 570–593. [Google Scholar] [CrossRef]

- Mandal, S.; Paul, D.; Saha, S.; Das, P. Deep learning assisted detection of toxic heavy metal ions based on visual fluorescence responses from a carbon nanoparticle array. Environ. Sci.-Nano 2022, 9, 2596–2606. [Google Scholar] [CrossRef]

- Yan, H.L.; Guo, H.Y.; Xu, W.X.; Dai, C.H.; Kimani, W.; Xie, J.Y.; Zhang, H.Z.F.; Li, T.; Wang, F.; Yu, Y.J.; et al. GWAS-assisted genomic prediction of cadmium accumulation in maize kernel with machine learning and linear statistical methods. J. Hazard. Mater. 2023, 441, 129929. [Google Scholar] [CrossRef]

- Mi, K.; Wu, X.; Lin, Z.M. Chemical risk assessment in food animals via physiologically based pharmacokinetic modeling- Part I: Veterinary drugs on human food safety assessment. Environ. Int. 2025, 197, 109339. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Xu, Y.J.; Jing, X.H.; Ma, W. SERS-active plasmonic metal NP-CsPbX3 films for multiple veterinary drug residues detection. Food Chem. 2023, 412, 135420. [Google Scholar] [CrossRef]

- Dong, F.J.; Ma, Z.Y.; Xu, Y.; Feng, Y.J.; Shi, Y.K.; Li, H.; Xing, F.K.; Wang, G.X.; Zhang, Z.X.; Yi, W.G.; et al. Monitoring of veterinary drug residues in mutton based on hyperspectral combined with explainable AI: A case study of OFX. Food Chem. 2025, 474, 143087. [Google Scholar] [CrossRef]

- Zhu, R.S.; Zhang, Z.X.; Cao, Y.Y.; Hu, Z.B.; Li, Y.; Cao, H.F.; Zhao, Z.Q.; Xin, D.W.; Chen, Q.S. CPDOS: A Web-Based AI Platform to Optimize Crop Planting Density. Agronomy 2023, 13, 2465. [Google Scholar] [CrossRef]

- Decardi-Nelson, B.; You, F.Q. Artificial intelligence can regulate light and climate systems to reduce energy use in plant factories and support sustainable food production. Nat. Food 2024, 5, 869–881. [Google Scholar] [CrossRef] [PubMed]

- Magnus, I.; Virte, M.; Thienpont, H.; Smeesters, L. Combining optical spectroscopy and machine learning to improve food classification. Food Control 2021, 130, 108342. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.; Kim, S.; Son, H.; Han, J.S.; Kim, U.J. Machine Vision with a CMOS-Based Hyperspectral Imaging Sensor Enables Sensing Meat Freshness. ACS Sens. 2024, 10, 236–245. [Google Scholar] [CrossRef]

- Qu, C.; Fang, H.; Yu, F.F.; Chen, J.N.; Su, M.K.; Liu, H.L. Artificial nose of scalable plasmonic array gas sensor for Multi-Dimensional SERS recognition of volatile organic compounds. Chem. Eng. J. 2024, 482, 148773. [Google Scholar] [CrossRef]

- Parastar, H.; van Kollenburg, G.; Weesepoel, Y.; van den Doel, A.; Buydens, L.; Jansen, J. Integration of handheld NIR and machine learning to “Measure & Monitor” chicken meat authenticity. Food Control 2020, 112, 107149. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, Y.; Li, L.; Yang, C.; Li, K.; Lan, X.; Zhang, Y.; Chen, J. How to Guarantee Food Safety via Grain Storage? An Approach to Improve Management Effectiveness by Machine Learning Algorithms. J. Biomed. Res. Environ. Sci. 2021, 2, 676–684. [Google Scholar] [CrossRef]

- Westerveld, J.J.L.; van den Homberg, M.J.C.; Nobre, G.G.; van den Berg, D.L.J.; Teklesadik, A.D.; Stuit, S.M. Forecasting transitions in the state of food security with machine learning using transferable features. Sci. Total Environ. 2021, 786, 147366. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.H.; Liu, Z.C.; Bera, T.; Ding, H.J.; Langley, D.A.; Jenkins-Barnes, A.; Furlanello, C.; Maggio, V.; Tong, W.D.; Xu, J. A deep learning model to recognize food contaminating beetle species based on elytra fragments. Comput. Electron. Agric. 2019, 166, 105002. [Google Scholar] [CrossRef]

- Cui, F.C.; Zheng, S.W.; Wang, D.F.; Ren, L.K.; Meng, Y.Q.; Ma, R.; Wang, S.L.; Li, T.T.; Li, X.P.; Li, J.R. Development of machine learning-based shelf-life prediction models for multiple marine fish species and construction of a real-time prediction platform. Food Chem. 2024, 450, 139230. [Google Scholar] [CrossRef]

- Mahata, B.; Acharyya, S.; Banerji, P.; Guha, P.K. Assessment of fish adulteration using SnO2 nanopetal-based gas sensor and machine learning. Food Chem. 2024, 438, 138039. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.Y.; Huo, X.M.; Ding, X.Y.; Zhu, P.Y.; Wan, Y.T.; Lu, X.Q.; Feng, R.; Yu, Q.; Wang, X.H. Rapid screening of illegally added drugs in functional food using a miniature ion trap mass spectrometer. Food Chem. 2022, 386, 132808. [Google Scholar] [CrossRef]

- Ni, J.G.; Zhao, Y.F.; Zhou, Z.G.; Zhao, L.G.; Han, Z.Z. Condiment recognition using convolutional neural networks with attention mechanism. J. Food Compos. Anal. 2023, 115, 104964. [Google Scholar] [CrossRef]

- Vandevijvere, S.; Jaacks, L.M.; Monteiro, C.A.; Moubarac, J.-C.; Girling-Butcher, M.; Lee, A.C.; Pan, A.; Bentham, J.; Swinburn, B. Global trends in ultraprocessed food and drink product sales and their association with adult body mass index trajectories. Obes. Rev. 2019, 20, 10–19. [Google Scholar] [CrossRef]

- Menichetti, G.; Ravandi, B.; Mozaffarian, D.; Barabási, A.-L. Machine learning prediction of the degree of food processing. Nat. Commun. 2023, 14, 2312. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.J.; Song, M.; Liu, S.T.; Wu, S.Z.; Thu, A.M. Analysis of phthalate plasticizer migration from PVDC packaging materials to food simulants using molecular dynamics simulations and artificial neural network. Food Chem. 2020, 317, 126465. [Google Scholar] [CrossRef]

- Yin, B.F.; Zhu, H.Y.; Zeng, S.Y.; Sohan, A.; Wan, X.H.; Liu, J.; Zhang, P.; Lin, X.D. Chip-based automated equipment for dual-mode point-of-care testing foodborne pathogens. Biosens. Bioelectron. 2024, 257, 116338. [Google Scholar] [CrossRef]

- Pang, Y.; Chen, Z.; Yang, D.; Fan, X.; Liang, Z.; Xu, Y.; Ye, S.; Liu, J.; Zhou, L. Immobilized CeO2@C-N Heterogenous Structures with Enhanced Dual Modal Photodynamic/Photothermal Bacterial Inactivation Under NIR Laser Irradiation. J. Anal. Test. 2023, 7, 189–203. [Google Scholar] [CrossRef]

- Lin, X.D.; Wu, H.T.; Zeng, S.Y.; Peng, T.; Zhang, P.; Wan, X.H.; Lang, Y.H.; Zhang, B.; Jia, Y.W.; Shen, R.; et al. A self-designed device integrated with a Fermat spiral microfluidic chip for ratiometric and automated point-of-care testing of anthrax biomarker in real samples. Biosens. Bioelectron. 2023, 230, 115283. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.Z.; You, Y.; Gunasekaran, S. LSPR-based colorimetric biosensing for food quality and safety. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5829–5855. [Google Scholar] [CrossRef]

- Magar, H.S.; Hemdan, B.A.; Rashdan, H.R.M.; Hassan, R.Y.A. Rapid and Selective Detection of Foodborne Pathogens Using a Disposable Bio-sensing System Designed by Stepwise Antibody Immobilization on AuNPs@Cu-MOF Nanocomposite. J. Anal. Test. 2024, 8, 478–492. [Google Scholar] [CrossRef]

- Tago, H.; Maeda, Y.; Tanaka, Y.; Kohketsu, H.; Lim, T.K.; Harada, M.; Yoshino, T.; Matsunaga, T.; Tanaka, T. Line image sensor-based colony fingerprinting system for rapid pathogenic bacteria identification. Biosens. Bioelectron. 2024, 249, 116006. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, K.X.; Bao, Q.; Sun, X.L. An intelligent and portable fiber optic real-time fluorescence detection system for pathogenic microorganisms detection. Sens. Actuator B-Chem. 2025, 423, 136733. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, Y.H.; Xiao, Z.L.; Luo, Y.C. Machine learning supported single-stranded DNA sensor array for multiple foodborne pathogenic and spoilage bacteria identification in milk. Food Chem. 2025, 463, 141115. [Google Scholar] [CrossRef] [PubMed]

- Bala, M.; Pandey, D.; Patel, N.; Yadav, S.; Sharma, A. Colorimetric Sensor for Detection of Tabun Mimic Diethyl Cyanophosphonate. J. Anal. Test. 2024, 8, 374–384. [Google Scholar] [CrossRef]

- Dogan, V.; Evliya, M.; Kahyaoglu, L.N.; Kiliç, V. On-site colorimetric food spoilage monitoring with smartphone embedded machine learning. Talanta 2024, 266, 125021. [Google Scholar] [CrossRef]

- Ghorbanizamani, F. A combinatorial approach to chicken meat spoilage detection using color-shifting silver nanoparticles, smartphone imaging, and artificial neural network (ANN). Food Chem. 2025, 468, 142390. [Google Scholar] [CrossRef]

- Behnke, K.; Janssen, M.F.W.H.A. Boundary conditions for traceability in food supply chains using blockchain technology. Int. J. Inf. Manag. 2020, 52, 101969. [Google Scholar] [CrossRef]

- Bumblauskas, D.; Mann, A.; Dugan, B.; Rittmer, J. A blockchain use case in food distribution: Do you know where your food has been? Int. J. Inf. Manag. 2020, 52, 102008. [Google Scholar] [CrossRef]

- Casino, F.; Kanakaris, V.; Dasaklis, T.K.; Moschuris, S.; Stachtiaris, S.; Pagoni, M.; Rachaniotis, N.P. Blockchain-based food supply chain traceability: A case study in the dairy sector. Int. J. Prod. Res. 2021, 59, 5758–5770. [Google Scholar] [CrossRef]

- Friedman, N.; Ormiston, J. Blockchain as a sustainability-oriented innovation?: Opportunities for and resistance to Blockchain technology as a driver of sustainability in global food supply chains. Technol. Forecast. Soc. Change 2022, 175, 121403. [Google Scholar] [CrossRef]

- Kamilaris, A.; Fonts, A.; Prenafeta-Boldu, F.X. The rise of blockchain technology in agriculture and food supply chains. Trends Food Sci. Technol. 2019, 91, 640–652. [Google Scholar] [CrossRef]

- Saurabh, S.; Dey, K. Blockchain technology adoption, architecture, and sustainable agri-food supply chains. J. Clean. Prod. 2021, 284, 124731. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Lopez, C.; Lu, H.; Elgueta, S.; Chen, H.; Boshkoska, B.M. Blockchain technology in agri-food value chain management: A synthesis of applications, challenges and future research directions. Comput. Ind. 2019, 109, 83–99. [Google Scholar] [CrossRef]

- Richter, B.; Rurik, M.; Gurk, S.; Kohlbacher, O.; Fischer, M. Food monitoring: Screening of the geographical origin of white asparagus using FT-NIR and machine learning. Food Control 2019, 104, 318–325. [Google Scholar] [CrossRef]

- Li, B.; Liu, M.; Lin, F.; Tai, C.; Xiong, Y.F.; Ao, L.; Liu, Y.M.; Lin, Z.X.; Tao, F.; Xu, P. Marker-Independent Food Identification Enabled by Combing Machine Learning Algorithms with Comprehensive GC × GC/TOF-MS. Molecules 2022, 27, 6237. [Google Scholar] [CrossRef]

- Alfian, G.; Syafrudin, M.; Farooq, U.; Ma’arif, M.R.; Syaekhoni, M.A.; Fitriyani, N.L.; Lee, J.; Rhee, J. Improving efficiency of RFID-based traceability system for perishable food by utilizing IoT sensors and machine learning model. Food Control 2020, 110, 107016. [Google Scholar] [CrossRef]

- Nogales, A.; Díaz-Morón, R.; García-Tejedor, A.J. A comparison of neural and non-neural machine learning models for food safety risk prediction with European Union RASFF data. Food Control 2022, 134, 108697. [Google Scholar] [CrossRef]

- Hall, K.D.; Ayuketah, A.; Brychta, R.; Cai, H.; Cassimatis, T.; Chen, K.Y.; Chung, S.T.; Costa, E.; Courville, A.; Darcey, V.; et al. Ultra-Processed Diets Cause Excess Calorie Intake and Weight Gain: An Inpatient Randomized Controlled Trial of Ad Libitum Food Intake. Cell Metab. 2019, 30, 67–77.e3. [Google Scholar] [CrossRef] [PubMed]

- Carlo, M.; Pasquale, F.; Annalisa, R.; Paolo, M.; Gianfranco, P.; Francesco, C. Food structure, function and artificial intelligence. Trends Food Sci. Technol. 2022, 123, 251–263. [Google Scholar] [CrossRef]

- Rodrigues, M.; Miguéis, V.; Freitas, S.; Machado, T. Machine learning models for short-term demand forecasting in food catering services: A solution to reduce food waste. J. Clean. Prod. 2024, 435, 140265. [Google Scholar] [CrossRef]

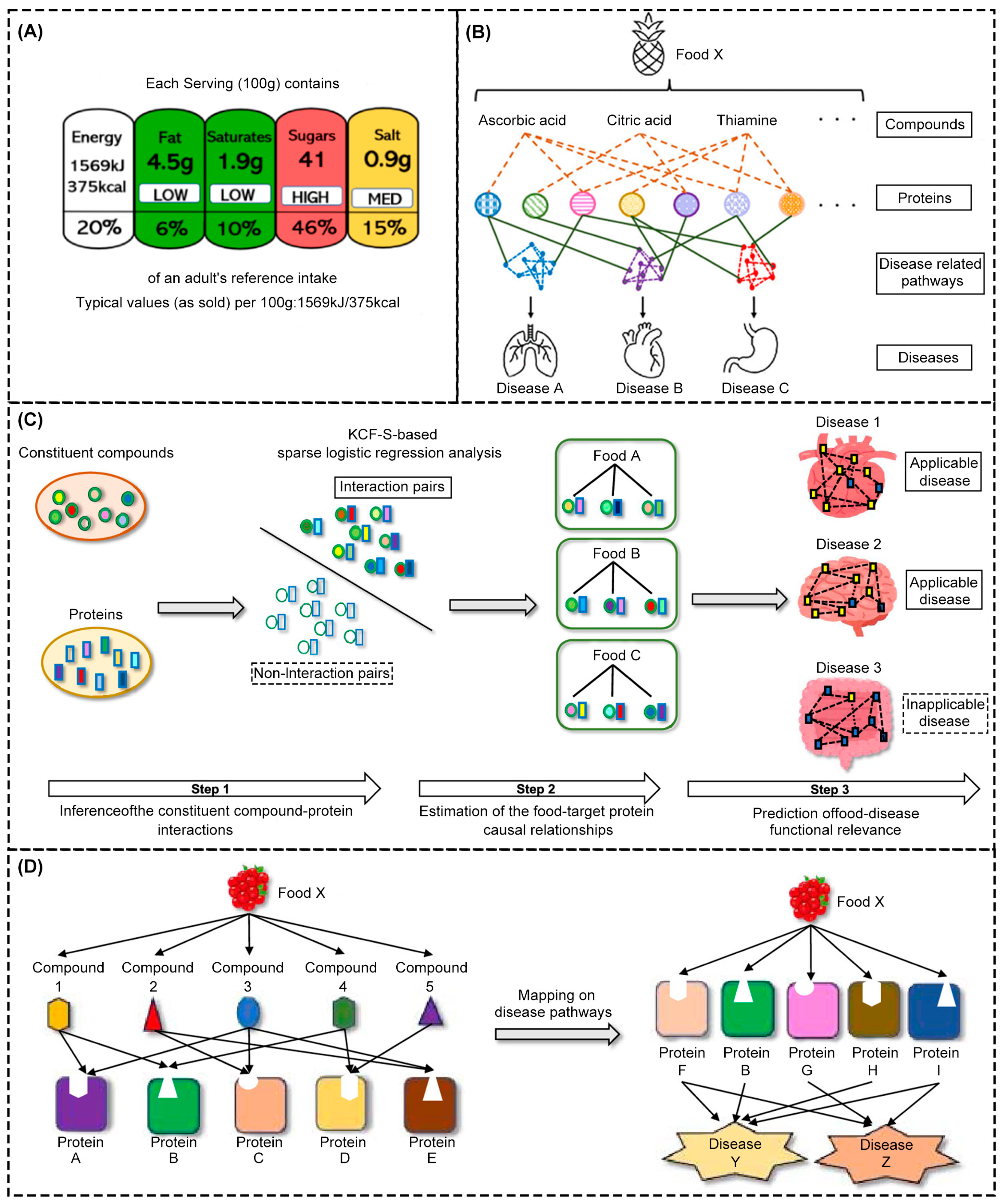

- Inoue, N.; Shibata, T.; Tanaka, Y.; Taguchi, H.; Sawada, R.; Goto, K.; Momokita, S.; Aoyagi, M.; Hirao, T.; Yamanishi, Y. Revealing Comprehensive Food Functionalities and Mechanisms of Action through Machine Learning. J. Chem. Inf. Model. 2024, 64, 5712–5724. [Google Scholar] [CrossRef]

- Razavi, R.; Xue, G. Predicting Unreported Micronutrients From Food Labels: Machine Learning Approach. J. Med. Internet Res. 2023, 25, e45332. [Google Scholar] [CrossRef] [PubMed]

- Armand, T.P.T.; Nfor, K.A.; Kim, J.-I.; Kim, H.-C. Applications of Artificial Intelligence, Machine Learning, and Deep Learning in Nutrition: A Systematic Review. Nutrients 2024, 16, 1073. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, T.; Zheng, Y.; Zhang, W.; Yun, Y.-H. Deep learning in food authenticity: Recent advances and future trends. Trends Food Sci. Technol. 2024, 144, 104344. [Google Scholar] [CrossRef]

- Huang, W.; Wang, X.; Zhang, J.; Xia, J.; Zhang, X. Improvement of blueberry freshness prediction based on machine learning and multi-source sensing in the cold chain logistics. Food Control 2023, 145, 109496. [Google Scholar] [CrossRef]

- Kachouei, M.A.; Kaushik, A.; Ali, M.A. Internet of Things-Enabled Food and Plant Sensors to Empower Sustainability. Adv. Intell. Syst. 2023, 5, 2300321. [Google Scholar] [CrossRef]

- El Jarroudi, M.; Kouadio, L.; Delfosse, P.; Bock, C.H.; Mahlein, A.-K.; Fettweis, X.; Mercatoris, B.; Adams, F.; Lenne, J.M.; Hamdioui, S. Leveraging edge artificial intelligence for sustainable agriculture. Nat. Sustain. 2024, 7, 846–854. [Google Scholar] [CrossRef]

- Deng, X.; Cao, S.; Horn, A.L. Emerging Applications of Machine Learning in Food Safety. Annu. Rev. Food Sci. Technol. 2021, 12, 513–538. [Google Scholar] [CrossRef]

- Yang, X.; Ho, C.-T.; Gao, X.; Chen, N.; Chen, F.; Zhu, Y.; Zhang, X. Machine learning: An effective tool for monitoring and ensuring food safety, quality, and nutrition. Food Chem. 2025, 477, 143391. [Google Scholar] [CrossRef]

- Zhang, Y.; Bao, X.; Zhu, Y.; Dai, Z.; Shen, Q.; Xue, Y. Advances in machine learning screening of food bioactive compounds. Trends Food Sci. Technol. 2024, 150, 104578. [Google Scholar] [CrossRef]

- Wang, X.; Bouzembrak, Y.; Lansink, A.G.J.M.O.; van der Fels-Klerx, H.J. Application of machine learning to the monitoring and prediction of food safety: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 416–434. [Google Scholar] [CrossRef]

- Barel, J.M.; Petchey, O.L.; Ghaffouli, A.; Jassey, V.E.J. Uncovering microbial food webs using machine learning. Soil Biol. Biochem. 2023, 186, 109174. [Google Scholar] [CrossRef]

- Jarray, N.; Ben Abbes, A.; Farah, I.R. Machine learning for food security: Current status, challenges, and future perspectives. Artif. Intell. Rev. 2023, 56, S3853–S3876. [Google Scholar] [CrossRef]

- Dahl, J.F.; Schlangen, M.; van der Goot, A.J.; Corredig, M. Predicting rheological parameters of food biopolymer mixtures using machine learning. Food Hydrocoll. 2025, 160, 110786. [Google Scholar] [CrossRef]

- Hossain, M.; Mullally, C.; Asadullah, M.N. Alternatives to calorie-based indicators of food security: An application of machine learning methods. Food Policy 2019, 84, 77–91. [Google Scholar] [CrossRef]

- Oliveira Chaves, L.; Gomes Domingos, A.L.; Louzada Fernandes, D.; Ribeiro Cerqueira, F.; Siqueira-Batista, R.; Bressan, J. Applicability of machine learning techniques in food intake assessment: A systematic review. Crit. Rev. Food Sci. Nutr. 2023, 63, 902–919. [Google Scholar] [CrossRef]

- Schroeder, V.; Evans, E.D.; Wu, Y.-C.M.; Voll, C.-C.A.; McDonald, B.R.; Savagatrup, S.; Swager, T.M. Chemiresistive Sensor Array and Machine Learning Classification of Food. ACS Sens. 2019, 4, 2101–2108. [Google Scholar] [CrossRef] [PubMed]

- Hema, V.S.V.; Manickavasagan, A. Blockchain implementation for food safety in supply chain: A review. Compr. Rev. Food Sci. Food Saf. 2024, 23, e70002. [Google Scholar] [CrossRef] [PubMed]

- Rogerson, M.; Parry, G.C. Blockchain: Case studies in food supply chain visibility. Supply Chain Manag.-Int. J. 2020, 25, 601–614. [Google Scholar] [CrossRef]

- Qiu, Z.; Chen, X.; Xie, D.; Ren, Y.; Wang, Y.; Yang, Z.; Guo, M.; Song, Y.; Guo, J.; Feng, Y.; et al. Identification and detection of frozen-thawed muscle foods based on spectroscopy and machine learning: A review. Trends Food Sci. Technol. 2025, 155, 104797. [Google Scholar] [CrossRef]

- Weston, M.; Geng, S.; Chandrawati, R. Food Sensors: Challenges and Opportunities. Adv. Mater. Technol. 2021, 6, 2001242. [Google Scholar] [CrossRef]

- Klerkx, L.; Jakku, E.; Labarthe, P. A review of social science on digital agriculture, smart farming and agriculture 4.0: New contributions and a future research agenda. Njas-Wagening. J. Life Sci. 2019, 90, 100315. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Cerchione, R. The digital and sustainable transition of the agri-food sector. Technol. Forecast. Soc. Change 2023, 187, 122222. [Google Scholar] [CrossRef]

- Klerkx, L.; Rose, D. Dealing with the game-changing technologies of Agriculture 4.0: How do we manage diversity and responsibility in food system transition pathways? Glob. Food Secur.-Agric. Policy Econ. Environ. 2020, 24, 100347. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, M.; Mujumdar, A.S.; Li, J. AI-based additive manufacturing for future food: Potential applications challenges and possible solutions. Innov. Food Sci. Emerg. Technol. 2024, 92, 103599. [Google Scholar] [CrossRef]

| AI Branch | Advantages | Disadvantages | Applicable Scenarios |

|---|---|---|---|

| Supervised learning | Easy to explain, suitable for small samples | Depends on labeled data, limited ability to extract complex features | Classification tasks, such as disease recognition, pesticide residue detection |

| Unsupervised learning | No need for labeled data, ability to discover hidden patterns | Poor result interpretability, relies on assumptions about data distribution | Anomaly detection, food sorting |

| Semi-supervised learning | Combine limited labeled data with abundant unlabeled data to cut labeling costs. | High model complexity, need to balance the impact of labeled and unlabeled data | Small sample scenarios |

| Deep learning | Automatic feature extraction, capable of handling high-dimensional data | High demand for computing resources, poor interpretability | Image recognition, such as meat freshness, pathogen detection |

| Internet of things | Real-time monitoring, fusion of multi-source data | Data heterogeneity, transmission delay | Warehouse environment monitoring |

| Blockchain | Data immutability, enhanced traceability transparency | High storage costs, difficulty in collaborative governance | Full-chain traceability, production–distribution–consumption |

| Foods | Detection Methods | ML Algorithms | Model Performance | Ref. |

|---|---|---|---|---|

| Nut | Machine vision | MRFCN, CNN | RS: 99.4% Acc., ID: 96.1% Acc. | [100] |

| Can | Machine vision | ERC, MSRD | MSRD: 99.48% Acc. | [107] |

| Pear | X-ray tomography | SVM | SVM: 92.2% Acc. | [108] |

| Fish | Colorimetry | CNN, VGG16 | CNN: 96.2% Acc. | [115] |

| Cassava | Machine vision | CNN | CNN: 93% Acc. | [123] |

| Tomato | Machine vision | YOLOv8 | Test confidence: 87% | [124] |

| Spinach | SERS | Transformer | Transformer: 98.4% Acc., MAE = 0.966 | [130] |

| Fruits | SERS | CNN, SVM, RF | CNN: 99.62% Acc. | [131] |

| Water | Fluorescence sensor | Aug-MLP, KNN, SVM, GNB, RF | Aug-MLP: 83.1% Acc. | [139] |

| Corn | Genomics technology | Bayes, rrBLUP, RF | rrBLUP: ACC = 0.89, MAE = 0.0037 | [140] |

| Mutton | Hyperspectral imaging | CNN-SSAE | CNN-SSAE: 93.65% Acc. | [143] |

| Crop | Data-driven | GA, BP | GA: 98.18% R2 | [144] |

| Lettuce | Sensor data | SAC | 32.34% energy saved | [145] |

| Nut | Spectrum | ELM, SVM, LDA, QDA, PLS-DA | SVM: 5.54% LR, 98% CR | [146] |

| Meat | Fluorescence spectrum | LDA, QDA | Linear, R2 = 0.99 | [147] |

| Chicken | SERS, gas array sensor | PCA, LDA | LDA: 96.9% Acc. | [148] |

| Chicken | IR | RSDE | RSDE: 95% Acc. | [149] |

| Crop | Data-driven | BP, SVM | Error: 15%~20% | [150] |

| Crop | Data-driven | XGBoost | SFMA = 0.61, TFMA = 0.51 | [151] |

| Crop | Machine vision | CNN | CNN: 83.8% Acc. | [152] |

| Fish | E-nose | BP, GA-BP, RBFNN, ELM | RBF: MAE = 0.118, R2 = 0.9994 | [153] |

| Fish | Gas sensor | RF, SVM, DNN | RF, SVM: 95.83% Acc. | [154] |

| Foods | Detection Methods | ML Algorithms | Model Performance | Ref. |

|---|---|---|---|---|

| Condiment | Machine vision | CNN | CNN: 95.71% Acc. | [156] |

| Functional food | Ion trap analysis | SVM | SVM: 99.78% sensitivity | [155] |

| Cereal | Data-driven | RF | RF: AUC = 0.96 | [158] |

| Fatty food | GC-MS | RBF ANN | R2 0.95, MSE = 0.046 | [159] |

| Milk | Line image sensor | XGBoost | XGBoost 96% Acc. | [165] |

| Pork | Fluorescence detection | RBFNN | RBFNN: 100% Acc. | [166] |

| Milk | Fluorescence sensor | ANN | ANN: 93.8% Acc. | [167] |

| Fish | Colorimetry | RF | RF: 98.8% Acc. | [169] |

| Chicken | Colorimetry | ANN | ANN: R2 = 0.9946 | [170] |

| Asparagus | FT-NIS | SVM | SVM: 89% Acc. | [178] |

| Liquor | GC × GC/TOF-MS | PCA, SVM, RF | SVM: 97.67% Acc., RF: 95.36% Acc. | [179] |

| Feed | Data-driven | NN, Non-NN | NN: 86.02% Acc. | [181] |

| Noodles | SEM, TD-NMR | KPCA | / | [183] |

| Meat | Data-driven | RF, LSTM, Transformer | RFW 4% to 52%, RUN 3% to 16% | [184] |

| Food composition | Data-driven | L1-RLR | L1-RLR: 84% Acc., AUC = 0.92 | [185] |

| Micronutrient | Data-driven | RF, GBM, SVM, KNN | Accuracy >80% | [186] |

| Dimensionality | Challenges | Future Direction |

|---|---|---|

| Technical level |

|

|

| Data level |

|

|

| Regulation and ethics |

|

|

| Application and industry |

|

|

| Environmental sustainability |

|

|

| Global perspective |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, B.; Tan, G.; Muhammad, R.; Liu, J.; Bi, J. AI-Powered Innovations in Food Safety from Farm to Fork. Foods 2025, 14, 1973. https://doi.org/10.3390/foods14111973

Yin B, Tan G, Muhammad R, Liu J, Bi J. AI-Powered Innovations in Food Safety from Farm to Fork. Foods. 2025; 14(11):1973. https://doi.org/10.3390/foods14111973

Chicago/Turabian StyleYin, Binfeng, Gang Tan, Rashid Muhammad, Jun Liu, and Junjie Bi. 2025. "AI-Powered Innovations in Food Safety from Farm to Fork" Foods 14, no. 11: 1973. https://doi.org/10.3390/foods14111973

APA StyleYin, B., Tan, G., Muhammad, R., Liu, J., & Bi, J. (2025). AI-Powered Innovations in Food Safety from Farm to Fork. Foods, 14(11), 1973. https://doi.org/10.3390/foods14111973