Wild Hops in Breadmaking Among Bulgarians: From History to Modern Perspectives and Future Potentials

Abstract

1. Introduction

2. Materials and Methods

2.1. Literature Review

2.1.1. Historical and Linguistic Sources

2.1.2. Technical–Scientific Sources

2.2. Ethnobiological and Ethnographic Research

3. Results and Discussion

3.1. Historical and Literary Background

3.1.1. Bread Traditions in the Balkans and Among Bulgarians: Historical Perspectives

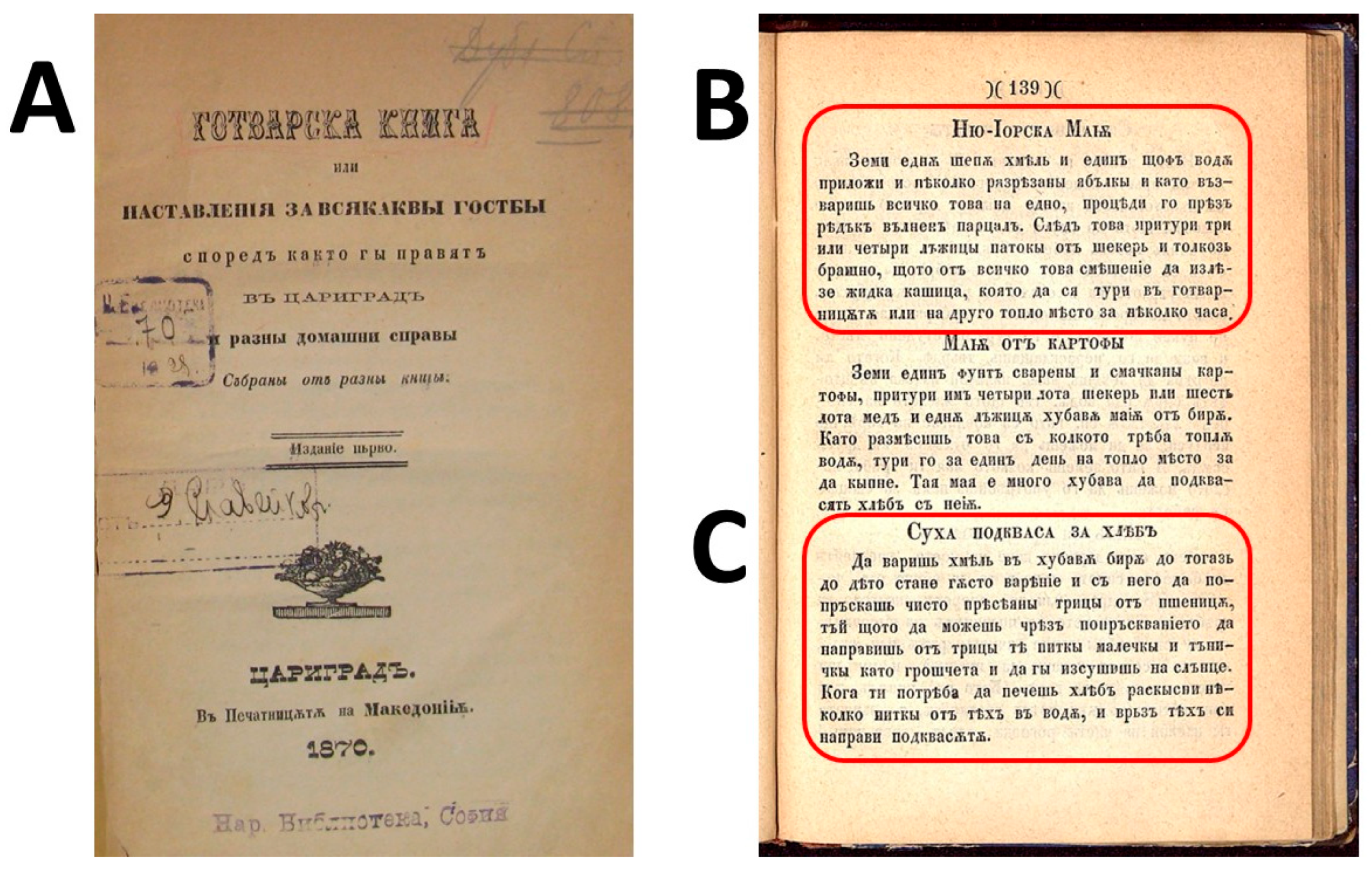

3.1.2. Occurrence of Hop Sourdough in Bulgarian Literary Sources

3.2. Fieldwork in Bulgaria and Moldovan Bessarabia

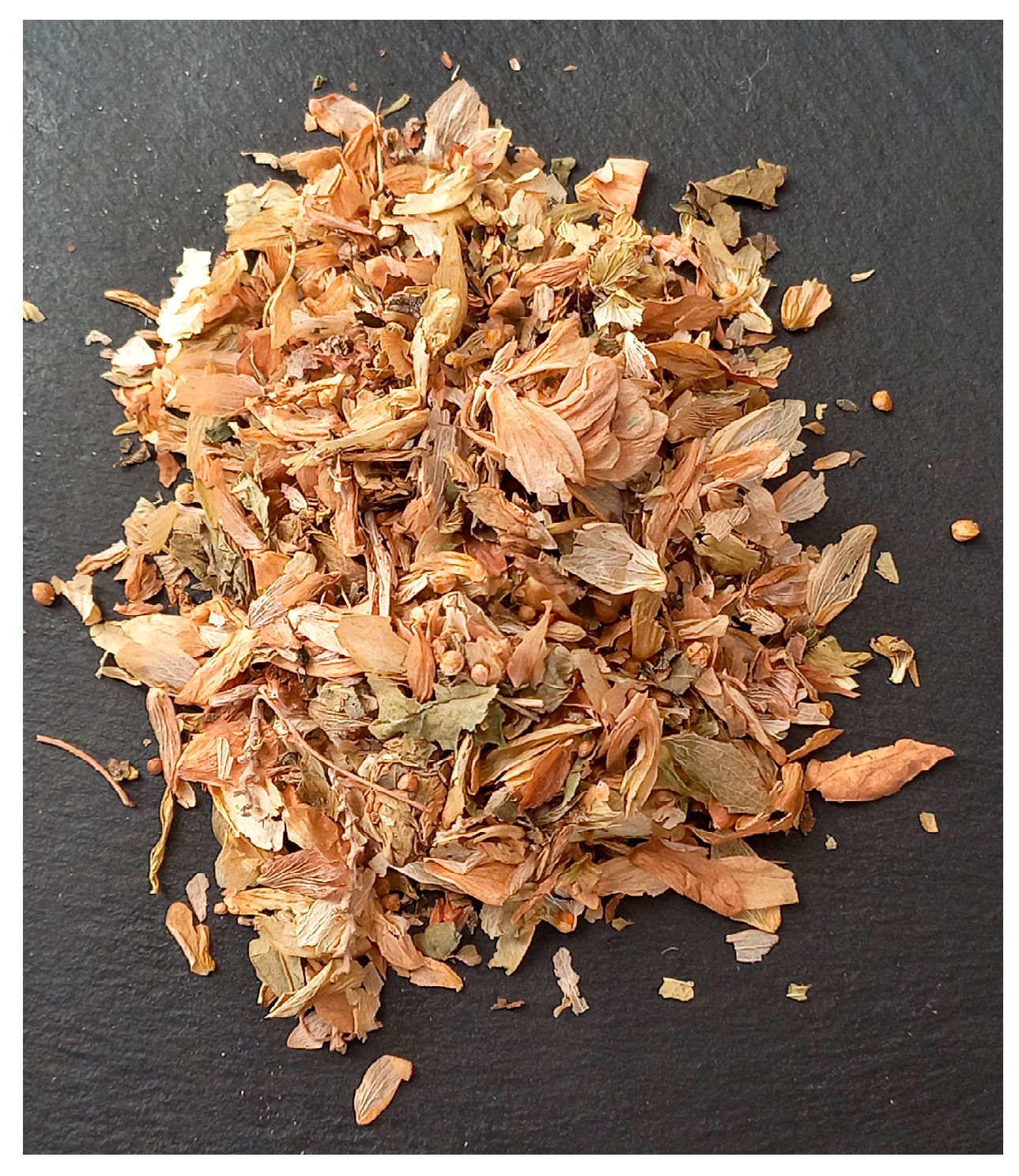

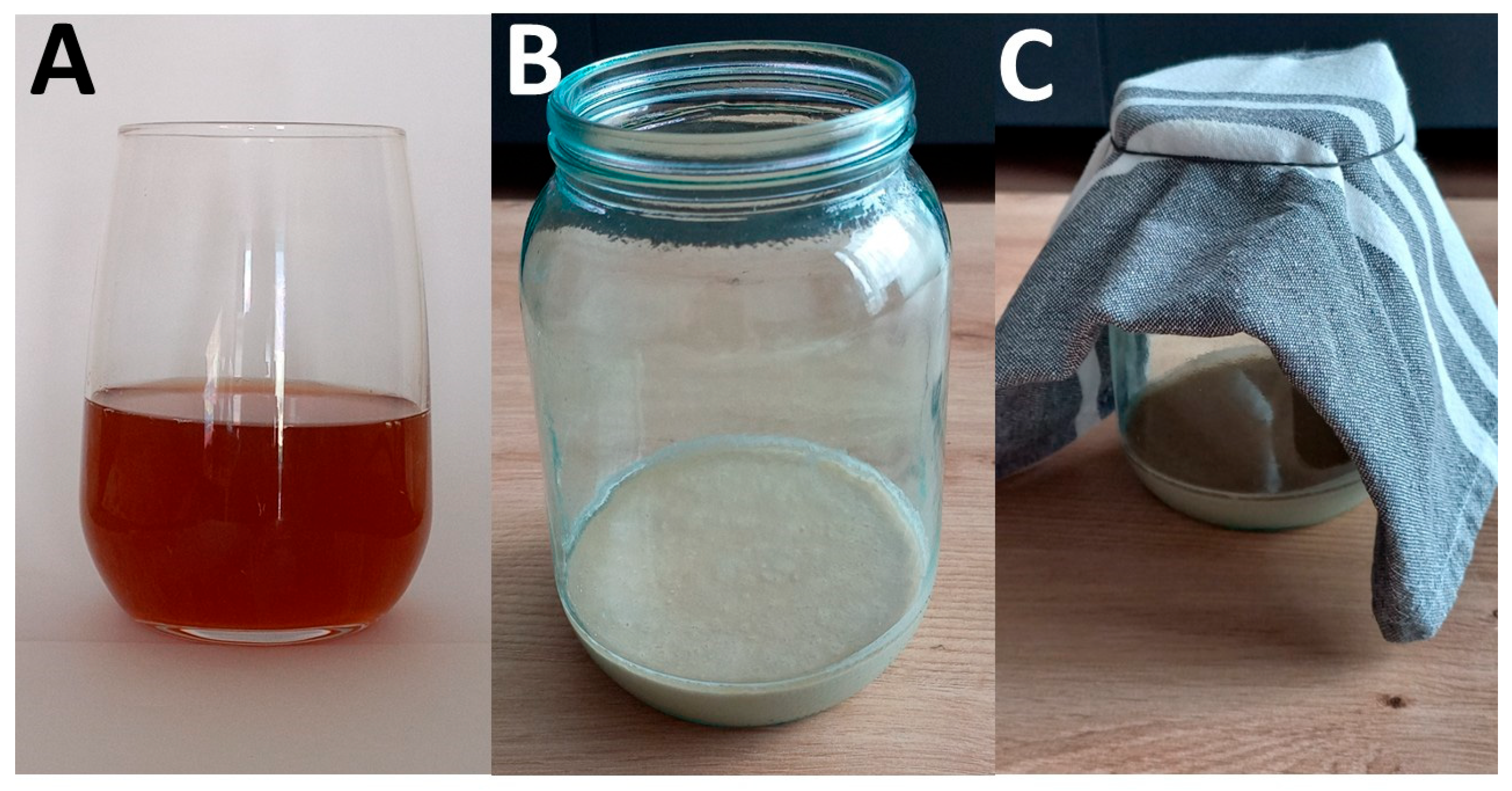

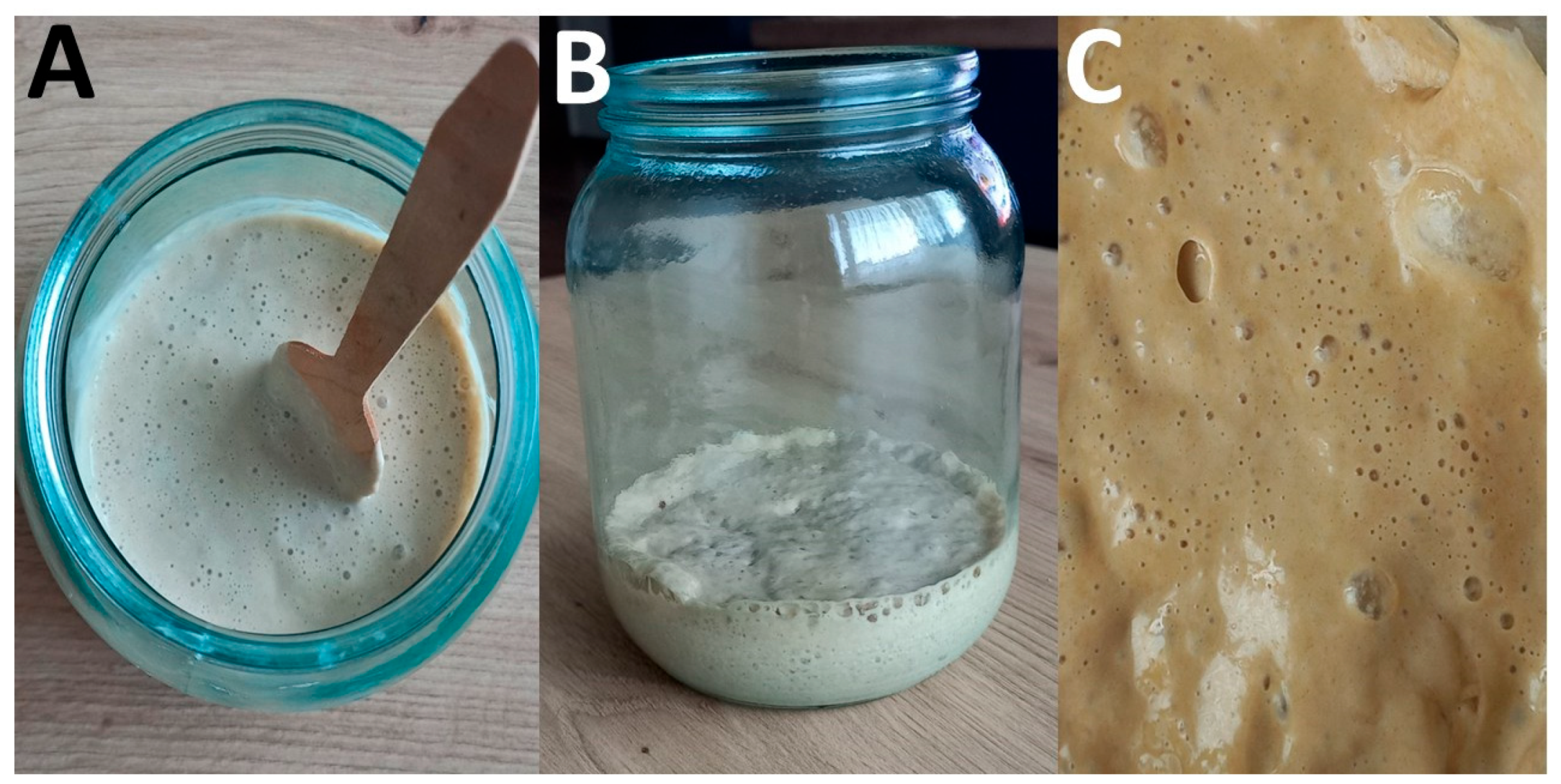

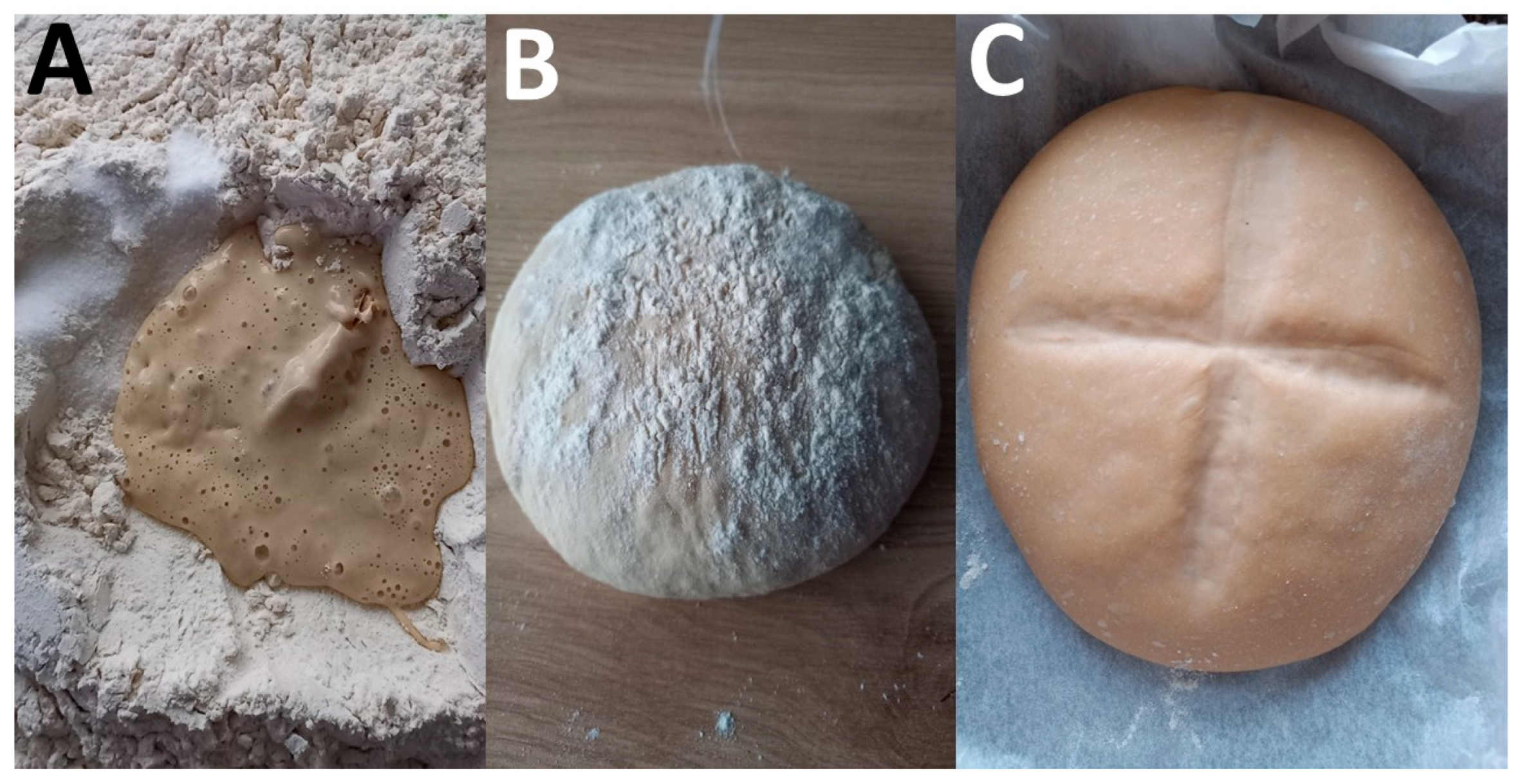

3.2.1. Preparation of the Hop Kvass—Fresh Form—And Breadmaking

3.2.2. Preparation of the Hop Kvass—Dry Form—And Breadmaking

3.2.3. Food Scouting, Cultural Sustainability, and the Role of Biocultural Refugia in Traditional Food Practices

3.3. Advancing from Tradition: Technical–Scientific State of the Art

3.3.1. Composition and Biological Properties of Hop Edible Parts

3.3.2. Effect of Hop Addition on the Quality Properties of Dough and Bread

3.4. Further Prospects for the Exploitation of Hops in Food Processing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Korpelainen, H.; Pietiläinen, M. Hop (Humulus lupulus L.): Traditional and present use, and future potential. Econ. Bot. 2021, 75, 302–322. [Google Scholar] [CrossRef]

- Karabín, M.; Hudcová, T.; Jelínek, L.; Dostálek, P. Biologically active compounds from hops and prospects for their use. Compr. Rev. Food Sci. Food Saf. 2016, 15, 542–567. [Google Scholar] [CrossRef]

- Wilson, D.G. Plant remains from the Graveney boat and the early history of Humulus lupulus L. in W. Europe. New Phytol. 1975, 75, 627–648. [Google Scholar] [CrossRef]

- Sõukand, R.; Pieroni, A.; Biró, M.; Dénes, A.; Dogan, Y.; Hajdari, A.; Kalle, R.; Reade, B.; Mustafa, B.; Nedelcheva, A.; et al. An ethnobotanical perspective on traditional fermented plant foods and beverages in Eastern Europe. J. Ethnopharmacol. 2015, 170, 284–296. [Google Scholar] [CrossRef] [PubMed]

- Maino, M.L.; Romina, A.; Mureșan, C.C. Functional Plant Substrates in Sourdough Fermentation: Hops, Kombucha, and Grape Pomace. Hop. Med. Plants 2024, 32, 35–55. [Google Scholar] [CrossRef]

- Nedelcheva, A.; Dogan, Y. Plants Used as Bread Yeast in the Balkans from an Ethnobotanical Point of View. In Fermented Food Products; Sankaranarayanan, A., Amaresan, N., Dhanasekaran, D., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 105–118. [Google Scholar]

- Zocchi, D.M.; Sulaiman, N.; Prakofjewa, J.; Sõukand, R.; Pieroni, A. Local Wild Food Plants and Food Products in a Multi-Cultural Region: An Exploratory Study among Diverse Ethnic Groups in Bessarabia, Southern Moldova. Sustainability 2024, 16, 1968. [Google Scholar] [CrossRef]

- Bernard, H.R. Research Methods in Anthropology: Qualitative and Quantitative Approaches, 4th ed.; Rowman & Littlefield: Lanham, MD, USA, 2017. [Google Scholar]

- Rotem, N. Historical Ethnography: Key Characteristics and the Journey Before, During, and After the Archival Field. Forum Qual. Sozialforschung/Forum: Qual. Soc. Res. 2024, 25. [Google Scholar] [CrossRef]

- Institute of Ethnology and Folklore Studies with Ethnographic Museum at the Bulgarian Academy of Sciences. Bulgarian Ethnography. 2019. Available online: https://balgarskaetnografia.com/ (accessed on 12 November 2023). (In Bulgarian).

- Institute for Bulgarian Language at the Bulgarian Academy of Sciences. Interactive Culinary Map of the Bulgarian Language Territory. 2019. Available online: https://kulinar.ibl.bas.bg/en/ (accessed on 16 February 2024).

- Institute for Bulgarian Language at the Bulgarian Academy of Sciences. Interactive Dialect Map of the Bulgarian Language. 2019. Available online: https://ibl.bas.bg/bulgarian_dialects/ (accessed on 12 June 2024).

- National Library St. Cyril and Methodius. Digital Library of Old Printed Books. 2021. Available online: https://digilib.nationallibrary.bg/sp/public/ua (accessed on 14 October 2024).

- Ferrari, R. Writing narrative style literature reviews. Med. Writ. 2015, 24, 230–235. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper, 5th ed.; Sage Publications: Los Angeles, CA, USA, 2020; 304p. [Google Scholar]

- Zocchi, D.M.; Mattalia, G.; Aziz, M.A.; Kalle, R.; Fontefrancesco, M.F.; Sõukand, R.; Pieroni, A. Searching for Germane Questions in the Ethnobiology of Food Scouting. J. Ethnobiol. 2023, 43, 19–30. [Google Scholar] [CrossRef]

- The ISE Code of Ethics. Available online: www.ethnobiology.net/what-we-do/core-programs/ise-ethics-program/code-of-Ethics (accessed on 30 October 2023).

- Pieroni, A.; Zocchi, D.M.; Alrhmoun, M.; Sulaiman, N.; Bavorova, M.; Sõukand, R. Not “Just Necessity”? Two-x-Eco-Cultural Dilemmas and the Ethnobiological Importance of the Informal Grannies’ Markets in Moldova. J. Ethnobiol. Ethnomed. 2025, 21, 17. [Google Scholar] [CrossRef]

- QSR International. NVivo Qualitative Data Analysis Software, Version 12.5.0; QSR International: Melbourne, Australia, 2019. [Google Scholar]

- Bencheva, J. The food of the nomads in the Balkan Middle Ages (XI-XV centuries). In A Thought. A Word. Text; University Press: Plovdiv, Bulgaria, 2018; pp. 20–26. (In Bulgarian) [Google Scholar]

- Ivanova, K. Old Bulgarian Literature. Vol. 4. Biographical Works; Bulgarian Academy of Science: Sofia, Bulgaria, 1986. (In Bulgarian) [Google Scholar]

- Arizanova, S. The food of medieval Bulgarian monks (according to hagiographic literature from the 13th–15th centuries). History 2009, 4, 9–18. (In Bulgarian) [Google Scholar]

- Georgieva, I. Bulgarian bread: Bread without yeast, bread with yeast. Bulg. Ethnol. 1993, 3, 5–23. (In Bulgarian) [Google Scholar]

- Bencheva, J. Let’s eat in the Balkans on the way to the Holy Land. Bulg. Ethnol. 2018, 4, 421–437. (In Bulgarian) [Google Scholar]

- Popova, J. Some Interesting Information of Western Travelers About the Balkan Population in the 15th Century; Bulgarian Academy of Sciences: Sofia, Bulgaria, 2018. (In Bulgarian) [Google Scholar]

- Georgieva, T. Bread-the key that separates and unites human worlds. Bulg. Folk. J. 1992, 2, 3–13. (In Bulgarian) [Google Scholar]

- Petrova, I. From handicraft goods to boutique product: The production of hand-made bread between Bulgarian traditions and global concept of healthy nutrition. J. Sociocult. Anthropol. 2020, 7, 16–30. (In Bulgarian) [Google Scholar]

- Pasqualone, A.; Vurro, F.; Summo, C.; Abd-El-Khalek, M.H.; Al-Dmoor, H.H.; Grgic, T.; Ruiz, M.; Magro, C.; Deligeorgakis, C.; Helou, C.; et al. The large and diverse family of Mediterranean flat breads: A database. Foods 2022, 11, 2326. [Google Scholar] [CrossRef] [PubMed]

- Taushanova, I. Cultural and domestic aspects of the use of bread in pre-modern Bulgarian society. Bulg. Sci. 2013, 54, 131–140. (In Bulgarian) [Google Scholar]

- Angelov, A.; Stoilova, E.; Dimitrov, T.; Gotcheva, V. Traditional Breads in Bulgaria. In Traditional European Breads; Garcia-Vaquero, M., Pastor, K., Orhun, G.E., McElhatton, A., Rocha, J.M.F., Eds.; Springer: Cham, Switzerland, 2023; pp. 61–79. [Google Scholar] [CrossRef]

- Mykolenko, S.; Lebedenko, T.; Ziubrovskyi, A. Traditional Ukrainian Bread Making. In Traditional European Breads: An Illustrative Compendium of Ancestral Knowledge and Cultural Heritage; Springer International Publishing: Cham, Switzerland, 2023; pp. 389–418. [Google Scholar] [CrossRef]

- Marinova, E.; Popova, T. Cicer arietinum (chickpea) in the Neolithic and Chalcolithic of Bulgaria: Implications for cultural contacts with the neighboring regions? Veg. His. Archaebotany 2008, 17, 73–80. [Google Scholar] [CrossRef]

- Gerov, N. Dictionary of the Bulgarian Language; Panchev, T.: Plovdiv, Bulgaria, 1895. (In Bulgarian) [Google Scholar]

- Achtarov, B.; Davidov, B.; Javashev, A. Materials for Bulgarian Botanical Glossary; Bulgarian Academy of Sciences: Sofia, Bulgaria, 1939. (In Bulgarian) [Google Scholar]

- Dictionary of the Bulgarian Language (online). Речник на Българския език (Онлайн). Available online: https://ibl.bas.bg/rbe/ (accessed on 20 February 2024).

- Koteva, M. Names Related to Food and Its Preparation in Bulgarian Dialects (Lexicosemantic Characteristics); DioMira: Sofia, Bulgaria, 2021; pp. 1–374. (In Bulgarian) [Google Scholar]

- Slaveykov, P.R. The Cookbook or Instructions for all Kinds of Guests According to How They Do in Constantinople and Various Household Chores. Collected from Various Books; Macedonia Press: Tsarigrad (Istanbul), Türkiye, 1870; pp. 1–207. (In Bulgarian) [Google Scholar]

- Doneva, B. The cookbook of P.R. Slaveykov. The oldest recipe book in Bulgarian language. In Food-Sacred and Profane; Goev, A., Ed.; Faber Press: Veliko Tarnovo, Bulgaria, 2012; pp. 225–238. (In Bulgarian) [Google Scholar]

- Radeva, L. Food and nutrition. In Pirin Region. Ethnographic, Folklore and Language Studies; Khadzhinikolov, V., Ed.; Bulgarian Academy of Sciences: Sofia, Bulgaria, 1980; pp. 347–367. [Google Scholar]

- Markova, М. Food and Nutrition: Between Nature and Culture; Academic Publishing House: Sofia, Bulgaria, 2011. (In Bulgarian) [Google Scholar]

- Ninova, Y. Place of bread in the culture of traditional society in Bulgaria. In Traditions, Modernization, Identities. The Traditional and the Modern in the Culture of Serbian and the Balkan Nations; University of Nish: Nish, Serbia, 2012; pp. 449–465. [Google Scholar]

- Jaskula, B.; Kafarski, P.; de Cooman, L. A kinetic study on the isomerization of hop α-acids. J. Agric. Food Chem. 2008, 56, 6408–6415. [Google Scholar] [CrossRef]

- Irakli, M.; Mygdalia, A.; Chatzopoulou, P.; Katsantonis, D. Impact of the combination of sourdough fermentation and hop extract addition on baking properties, antioxidant capacity and phenolics bioaccessibility of rice bran-enhanced bread. Food Chem. 2019, 285, 231–239. [Google Scholar] [CrossRef]

- Siepmann, F.B.; Ripari, V.; Waszczynskyj, N.; Spier, M.R. Overview of sourdough technology: From production to marketing. Food Bioprocess. Technol. 2018, 11, 242–270. [Google Scholar] [CrossRef]

- Chaplygina, I.A.; Batura, N.G.; Matyushev, V.V.; Tipsina, N.N.; Shmeleva, Z.N. The hop sourdough use to improve bread microbiological safety. IOP Conf. Ser. Earth Environ. Sci. 2020, 421, 032030. [Google Scholar] [CrossRef]

- Nelson, H.B. The Vanishing Hop-Driers of the Willamette Valley. Or. Hist. Q. 1963, 64, 267–271. [Google Scholar]

- Pieroni, A.; Quave, C.L.; Giusti, M.E.; Papp, N. “We are Italians!”: The hybrid ethnobotany of a Venetian diaspora in eastern Romania. Hum. Ecol. 2012, 40, 435–451. [Google Scholar] [CrossRef]

- Ghergariu, L. Observații lexicale pe marginea unor glosare. Limba Romana 1972, 21, 563–566. [Google Scholar]

- Güleç, H.; Durlu Özkaya, F. Gagauz Mutfak Kültürü. Karadeniz Araşt. 2022, 74, 463–491. (In Turkish) [Google Scholar] [CrossRef]

- Bogataj, J. Bread Treasures of Slovenia; Kmečli Glas: Ljubljana, Slovenia, 2003. [Google Scholar]

- Pieroni, A.; Sõukand, R. Ethnic and religious affiliations affect traditional wild plant foraging in Central Azerbaijan. Genet. Resour. Crop Evol. 2019, 66, 1495–1513. [Google Scholar] [CrossRef]

- Maurizio, A. Die Geschichte Unserer Pflanzennahrung von den Urzeiten bis zur Gegenwart; Paul Parey: Berlin, Germany, 1927. (In German) [Google Scholar]

- Nionelli, L.; Pontonio, E.; Gobbetti, M.; Rizzello, C.G. Use of hop extract as antifungal ingredient for bread making and selection of autochthonous resistant starters for sourdough fermentation. Int. J. Food Microbiol. 2018, 266, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Arruda, T.R.; Pinheiro, P.F.; Silva, P.I.; Bernardes, P.C. Exclusive raw material for beer production? Addressing greener extraction techniques, the relevance, and prospects of hops (Humulus lupulus L.) for the food industry. Food Bioprocess. Technol. 2022, 15, 275–305. [Google Scholar] [CrossRef]

- Ruggeri, R.; Loreti, P.; Rossini, F. Exploring the potential of hop as a dual purpose crop in the Mediterranean environment: Shoot and cone yield from nine commercial cultivars. Eur. J. Agron. 2018, 93, 11–17. [Google Scholar] [CrossRef]

- Sanchez-Mata, M.C.; Cabrera Loera, R.D.; Morales, P.; Fernandez-Ruiz, V.; Camara, M.; Diez Marqués, C.; Pardo-de-Santayana, M.; Tardio, J. Wild vegetables of the Mediterranean area as valuable sources of bioactive compounds. Genet. Resour. Crop. Evol. 2012, 59, 431–443. [Google Scholar] [CrossRef]

- Vidmar, M.; Abram, V.; Čeh, B.; Demšar, L.; Ulrih, N.P. White hop shoot production in Slovenia: Total phenolic, microelement and pesticide residue content in five commercial cultivars. Food Technol. Biotechnol. 2019, 57, 52–534. [Google Scholar] [CrossRef] [PubMed]

- Alonso-Esteban, J.I.; Pinela, J.; Barros, L.; Ćirić, A.; Soković, M.; Calhelha, R.C.; Torija-Isasa, E.; de Cortes Sánchez-Mata, M.; Ferreira, I.C.F.R. Phenolic composition and antioxidant, antimicrobial and cytotoxic properties of hop (Humulus lupulus L.) seeds. Ind. Crops Prod. 2019, 134, 154–159. [Google Scholar] [CrossRef]

- Astray, G.; Gullón, P.; Gullón, B.; Munekata, P.E.S.; Lorenzo, J.M. Humulus lupulus L. as a natural source of functional biomolecules. Appl. Sci. 2020, 10, 5074. [Google Scholar] [CrossRef]

- Koetter, U.; Biendl, M. Hops (Humulus lupulus): A review of its historic and medicinal uses. Herb. Gram. 2010, 87, 46–59. [Google Scholar]

- Kramer, B.; Thielmann, J.; Hickisch, A.; Muranyi, P.; Wunderlich, J.; Hauser, C. Antimicrobial activity of hop extracts against foodborne pathogens for meat applications. J. Appl. Microbiol. 2015, 118, 648–657. [Google Scholar] [CrossRef]

- Schurr, B.C.; Hahne, H.; Kuster, B.; Behr, J.; Vogel, R.F. Molecular mechanisms behind the antimicrobial activity of hop iso-α-acids in Lactobacillus brevis. Food Microbiol. 2015, 46, 553–563. [Google Scholar] [CrossRef]

- Van Cleemput, M.; Cattoor, K.; De Bosscher, K.; Haegeman, G.; De Keukeleire, D.; Heyerick, A. Hop (Humulus lupulus)-derived bitter acids as multipotent bioactive compounds. J. Nat. Prod. 2009, 72, 1220–1230. [Google Scholar] [CrossRef]

- Natarajan, P.; Katta, S.; Andrei, I.; Babu Roa Ambati, V.; Leonida, M.; Haas, G.J. Positive antibacterial co-action between hop (Humulus lupulus) constituents and selected antibiotics. Phytomedicine 2008, 15, 194–201. [Google Scholar] [CrossRef]

- Cermak, P.; Olsovska, J.; Mikyska, A.; Dusek, M.; Kadleckova, Z.; Vanicek, J.; Nyc, O.; Sigler, K.; Bostikova, V.; Bostik, P. Strong antimicrobial activity of xanthohumol and other derivatives from hops (Humulus lupulus L.) on gut anaerobic bacteria. APMIS 2017, 125, 1033–1038. [Google Scholar] [CrossRef]

- Miranda, C.L.; Elias, V.D.; Hay, J.J.; Choi, J.; Reed, R.L.; Stevens, J.F. Xanthohumol improves dysfunctional glucose and lipid metabolism in diet-induced obese C57BL/6J mice. Arch. Biochem. Biophys. 2016, 599, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Colgate, E.C.; Miranda, C.L.; Stevens, J.F.; Bray, T.M.; Ho, E. Xanthohumol, a prenylflavonoid derived from hops induces apoptosis and inhibits NF-kappaB activation in prostate epithelial cells. Cancer Lett. 2007, 246, 201–209. [Google Scholar] [CrossRef] [PubMed]

- Bohr, G.; Klimo, K.; Zapp, J.; Becker, H.; Gerhäuser, C. Cancer chemopreventive potential of humulones and isohumulones (hops α-and iso-α-acids): Induction of NAD (P) H: Quinone reductase as a novel mechanism. Nat. Prod. Comm. 2008, 3, 971–1976. [Google Scholar] [CrossRef]

- Zanoli, P.; Zavatti, M. Pharmacognostic and pharmacological profile of Humulus lupulus L. J. Ethnopharmacol. 2008, 116, 383–396. [Google Scholar] [CrossRef]

- Wang, S.; Dunlap, T.L.; Howell, C.E.; Mbachu, O.C.; Rue, E.A.; Phansalkar, R.; Chen, S.N.; Pauli, G.F.; Dietz, B.M.; Bolton, J.L. Hop (Humulus lupulus L.) extract and 6-prenylnaringenin induce P450 1A1 catalyzed estrogen 2-hydroxylation. Chem. Res. Toxicol. 2016, 29, 1142–1150. [Google Scholar] [CrossRef]

- Saito, K.; Matsuo, Y.; Imafuji, H.; Okubo, T.; Maeda, Y.; Sato, T.; Shamoto, T.; Tsuboi, K.; Morimoto, M.; Takahashi, H.; et al. Xanthohumol inhibits angiogenesis by suppressing nuclear factor-κB activation in pancreatic cancer. Cancer Sci. 2018, 109, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Kontek, B.; Jedrejek, D.; Oleszek, W.; Olas, B. Antiradical and antioxidant activity in vitro of hops-derived extracts rich in bitter acids and xanthohumol. Ind. Crops Prod. 2021, 161, 113208. [Google Scholar] [CrossRef]

- Leto, L.; Favari, C.; Agosti, A.; Del Vecchio, L.; Di Fazio, A.; Bresciani, L.; Mena, P.; Guarrasi, V.; Cirlini, M.; Chiancone, B. Evaluation of In Vitro-Derived Hop Plantlets, cv. Columbus and Magnum, as Potential Source of Bioactive Compounds. Antioxidants 2024, 13, 909. [Google Scholar] [CrossRef]

- Gianguzzi, V.; Leto, L.; Agosti, A.; Di Fazio, A.; Marra, F.P.; Cirlini, M.; Chiancone, B. Influence of Sucrose and Immersion Time on Humulus lupulus L., cv Columbus, Plantlet In Vitro Proliferation and Potentially Bioactive Compound Content. Plants 2025, 14, 537. [Google Scholar] [CrossRef]

- Rossini, F.; Virga, G.; Loreti, P.; Iacuzzi, N.; Ruggeri, R.; Provenzano, M.E. Hops (Humulus lupulus L.) as a novel multipurpose crop for the Mediterranean region of Europe: Challenges and opportunities of their cultivation. Agriculture 2021, 11, 484. [Google Scholar] [CrossRef]

- Ruggeri, R.; Rossini, F.; Roberto, S.R.; Sato, A.J.; Loussert, P.; Rutto, L.K.; Agehara, S. Development of hop cultivation in new growing areas: The state of the art and the way forward. Eur. J. Agron. 2024, 161, 127335. [Google Scholar] [CrossRef]

- Marceddu, R.; Carrubba, A.; Alfeo, V.; Alessi, A.; Sarno, M. Adapting American hop (Humulus lupulus L.) varieties to Mediterranean sustainable agriculture: A trellis height exploration. Horticulturae 2024, 10, 181. [Google Scholar] [CrossRef]

- Alfaro-Saiz, E.; Cámara-Leret, S.; González-González, M.; Fernández-Álvarez, Ó.; Rodríguez-Fernández, S.; López-López, D.; Paniagua-García, A.I.; Acedo, C.; Díez-Antolínez, R. The Memory of Hops: Rural Bioculture as a Collective Means of Reimagining the Future. Sustainability 2024, 16, 2470. [Google Scholar] [CrossRef]

- Lyu, J.I.; Ryu, J.; Seo, K.S.; Kang, K.Y.; Park, S.H.; Ha, T.H.; Ahn, J.W.; Kang, S.Y. Comparative study on phenolic compounds and antioxidant activities of hop (Humulus lupulus L.) strobile extracts. Plants 2022, 11, 135. [Google Scholar] [CrossRef] [PubMed]

- Kljakić, A.C.; Ocvirk, M.; Rutnik, K.; Košir, I.J.; Pavlić, B.; Mašković, P.; Mašković, J.; Teslić, N.; Stupar, A.; Uba, A.I.; et al. Exploring the composition and potential uses of four hops varieties through different extraction techniques. Food Chem. 2024, 447, 138910. [Google Scholar] [CrossRef]

- Rosa, R.S.; da Silva Lannes, S.C. Hop extracts and their utilizations: Perspectives based on the last 10 years of research. Braz. J. Pharm. Sci. 2024, 60, e23905. [Google Scholar] [CrossRef]

- Tyśkiewicz, K.; Tyśkiewicz, R.; Konkol, M.; Gruba, M.; Kowalski, R. Optimization of Antifungal Properties of Hop Cone Carbon Dioxide Extracts Based on Response Surface Methodology. Molecules 2024, 29, 2554. [Google Scholar] [CrossRef]

- Carbone, K.; Macchioni, V.; Petrella, G.; Cicero, D.O. Exploring the potential of microwaves and ultrasounds in the green extraction of bioactive compounds from Humulus lupulus for the food and pharmaceutical industry. Ind. Crops Prod. 2020, 156, 112888. [Google Scholar] [CrossRef]

- Pasquet, P.L.; Villain-Gambier, M.; Trébouet, D. By-Product Valorization as a Means for the Brewing Industry to move toward a Circular Bioeconomy. Sustainability 2024, 16, 3472. [Google Scholar] [CrossRef]

- Salanță, L.C.; Fărcaş, A.C.; Borșa, A.; Pop, C.R. Current strategies for the management of valuable compounds from hops waste for a circular economy. Food Chem. X 2023, 19, 100876. [Google Scholar] [CrossRef]

- Silva, K.F.C.; Strieder, M.M.; Pinto, M.B.C.; Rostagno, M.A.; Hubinger, M.D. Processing Strategies for Extraction and Concentration of Bitter Acids and Polyphenols from Brewing By-Products: A Comprehensive Review. Processes 2023, 11. [Google Scholar] [CrossRef]

- Sabbatini, G.; Mari, E.; Ortore, M.G.; Di Gregorio, A.; Fattorini, D.; Di Carlo, M.; Galeazzi, R.; Vignaroli, C.; Simoni, S.; Giorgini, G.; et al. Hop leaves: From waste to a valuable source of bioactive compounds–A multidisciplinary approach to investigating potential applications. Heliyon 2024, 10, e37593. [Google Scholar] [CrossRef] [PubMed]

- Do Nascimento, F.M.G.; Marques, S.P.D.; Trevisan, M.T.S.; Owen, R.W.; Pereira, L.R.; Lima, T.C.; de Sousa, A.F.; Maia, C.E.G. Inhibitory capacity of extracts and main constituents of hop flowers. Future J. Pharm. Sci. 2023, 9, 111. [Google Scholar] [CrossRef]

- Sluková, M.; Hinková, A.; Henke, S.; Smrž, F.; Lukačíková, M.; Pour, V.; Bubník, Z. Cheese whey treated by membrane separation as a valuable ingredient for barley sourdough preparation. J. Food Eng. 2016, 172, 38–47. [Google Scholar] [CrossRef]

- Sokolova, N. Effect of hop extracts on rheological properties of wheat dough. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1031, 012097. [Google Scholar] [CrossRef]

- Rak, V.; Yurchak, V.; Bilyk, O.; Bondar, V. Research into techniques for making wheat bread on hop leaven. East-Eur. J. Enterp. Technol. 2018, 1, 4–9. [Google Scholar] [CrossRef][Green Version]

- Ask, L.; Nair, B.; Asp, N.G. Effect of scalding procedures on the degradation of starch in rye products. J. Cereal Sci. 1991, 13, 15–26. [Google Scholar] [CrossRef]

- Wolgamuth, E.; Yusuf, S.; Hussein, A.; Pasqualone, A. A survey of laxoox/canjeero, a traditional Somali flatbread: Production styles. J. Ethn. Foods 2022, 9, 1–20. [Google Scholar] [CrossRef]

- Crowley, S.; Mahony, J.; van Sinderen, D. Current perspectives on antifungal lactic acid bacteria as natural bio-preservatives. Trends Food Sci. Technol. 2013, 33, 93–109. [Google Scholar] [CrossRef]

- Karadzhov, G.R.; Vasileva, M.N. Technology of Bread, Bakery and Confectionery Products; Matcom: Sofia, Bulgaria, 2007. (In Bulgarian) [Google Scholar]

- Protsenko, L.; Ryzhuk, S.; Litvynchuk, S.; Shevchenko, A.; Bober, A.; Shevchenko, O. Application of valuable hop compounds in bakery. In Bioenhancement and Fortification of Foods for a Healthy Diet; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Kyrykbaeva, S.; Kalibekkyzy, Z.; Kapshakbayeva, Z.; Baytukenova, S.; Assirzhanova, Z.; Baytukenova, S.; Mustafayeva, A.; Ospanova, B.; Utegenova, A. Evaluation of antimicrobial efficacy and shelf life of natural hop extract in cheese production. CyTA-J. Food 2025, 23, 2446821. [Google Scholar] [CrossRef]

- Samilyk, M.; Bolgova, N.; Samokhina, E.; Cherniavska, T.; Kharchenko, S. 2024 Use of hop extract in the biotechnology of kefir beverage. Sci. Horiz. 2024, 27, 97–106. [Google Scholar] [CrossRef]

- Kramer, B.; Mignard, C.; Warschat, D.; Gürbüz, S.; Aiglstorfer, P.; Muranyi, P. Inhibition of Listeria monocytogenes on Bologna by a beta acid rich hop extract. Food Control 2021, 126, 108040. [Google Scholar] [CrossRef]

- Comi, G.; Colautti, A.; Bernardi, C.E.M.; Stella, S.; Orecchia, E.; Coppola, F.; Iacumin, L. Leuconostoc gelidum is the major species responsible for the spoilage of cooked sausage packaged in a modified atmosphere, and hop extract is the best inhibitor tested. Microorganisms 2024, 12, 1175. [Google Scholar] [CrossRef]

- Sansawat, T.; Lee, H.C.; Singh, P.; Ha, S.D.; Kang, I. Inhibition of Listeria monocytogenes in deli-style Turkey using hop acids, organic acids, and their combinations. Poult. Sci. 2019, 98, 1539–1544. [Google Scholar] [CrossRef]

- Villalobos-Delgado, L.H.; Caro, I.; Blanco, C.; Bodas, R.; Andrés, S.; Giráldez, F.J.; Mateo, J. Effect of the addition of hop (infusion or powder) on the oxidative stability of lean lamb patties during storage. Small Rumin. Res. 2015, 125, 73–80. [Google Scholar] [CrossRef]

- Bilska, A.; Kobus-Cisowska, J.; Wojtczak, J.; Kowalski, R.; Kaczmarek, E. Antioxidant Activity of Humulus lupulus Phenolic Hop Extracts in Creating a New Pâté: An Element Affecting Fat Stability and Microbiological Quality during Storage. Molecules 2024, 29, 1561. [Google Scholar] [CrossRef] [PubMed]

- Mitton, F.M.; Turina, Y.; Kulisz, N.; Vittone, M.; Massa, A. Hop (Humulus lupulus) leaves as a functional ingredient to mitigate lipid oxidation and preserve PUFAs in rough scad patties. Food Chem. Adv. 2025, 6, 100865. [Google Scholar] [CrossRef]

- Hausser, C.; Parreidt, T.S. Antimicrobial hop extracts and their application to fresh produce. In Multidisciplinary Approaches for Studying and Combating Microbial Pathogens; Mendez-Vilas, A., Ed.; Brown Walker Press: Boca Raton, FL, USA, 2015; pp. 49–52. [Google Scholar]

- Semko, T.; Paska, M.; Ivanishcheva, O.; Kryzhak, L.; Pahomska, O.; Ternova, A.; Vasylyshyna, O.; Hyrych, S. Innovative approach to the production of craft bread: A combination of tradition and innovation. Potr. S. J. F. Sci. USA 2024, 18, 792–806. [Google Scholar] [CrossRef]

- Dymchenko, A.; Geršl, M.; Gregor, T. Trends in bread waste utilisation. Trends Food Sci. Technol. 2023, 132, 93–102. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nedelcheva, A.; Zocchi, D.M.; Sulaiman, N.; Sõukand, R.; Pieroni, A.; Pasqualone, A. Wild Hops in Breadmaking Among Bulgarians: From History to Modern Perspectives and Future Potentials. Foods 2025, 14, 1767. https://doi.org/10.3390/foods14101767

Nedelcheva A, Zocchi DM, Sulaiman N, Sõukand R, Pieroni A, Pasqualone A. Wild Hops in Breadmaking Among Bulgarians: From History to Modern Perspectives and Future Potentials. Foods. 2025; 14(10):1767. https://doi.org/10.3390/foods14101767

Chicago/Turabian StyleNedelcheva, Anely, Dauro Mattia Zocchi, Naji Sulaiman, Renata Sõukand, Andrea Pieroni, and Antonella Pasqualone. 2025. "Wild Hops in Breadmaking Among Bulgarians: From History to Modern Perspectives and Future Potentials" Foods 14, no. 10: 1767. https://doi.org/10.3390/foods14101767

APA StyleNedelcheva, A., Zocchi, D. M., Sulaiman, N., Sõukand, R., Pieroni, A., & Pasqualone, A. (2025). Wild Hops in Breadmaking Among Bulgarians: From History to Modern Perspectives and Future Potentials. Foods, 14(10), 1767. https://doi.org/10.3390/foods14101767