Machine-Learning-Assisted Aroma Profile Prediction in Five Different Quality Grades of Nongxiangxing Baijiu Fermented During Summer Using Sensory Evaluation Combined with GC×GC–TOF-MS

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples and Reagents

2.1.1. Collecting the Samples

2.1.2. Chemicals and Reagents

2.2. Analysis of Sensory Flavor Characteristics

2.3. The Total Acids, Total Esters, and GC-FID Detection of Samples

2.4. Analysis of VOCs Using GC×GC–TOF-MS

2.4.1. Preparing the Solution for the Internal Standard

2.4.2. The HS-SPME Method

2.4.3. The GC×GC–TOF-MS Method

2.5. ML Model Construction

2.6. Statistical Analysis and Mapping

2.6.1. The Processing of GC×GC–TOF-MS Data

2.6.2. The Chemometric Analysis of GC×GC–TOF-MS Data

2.6.3. Data Processing of ML Models

3. Results and Discussion

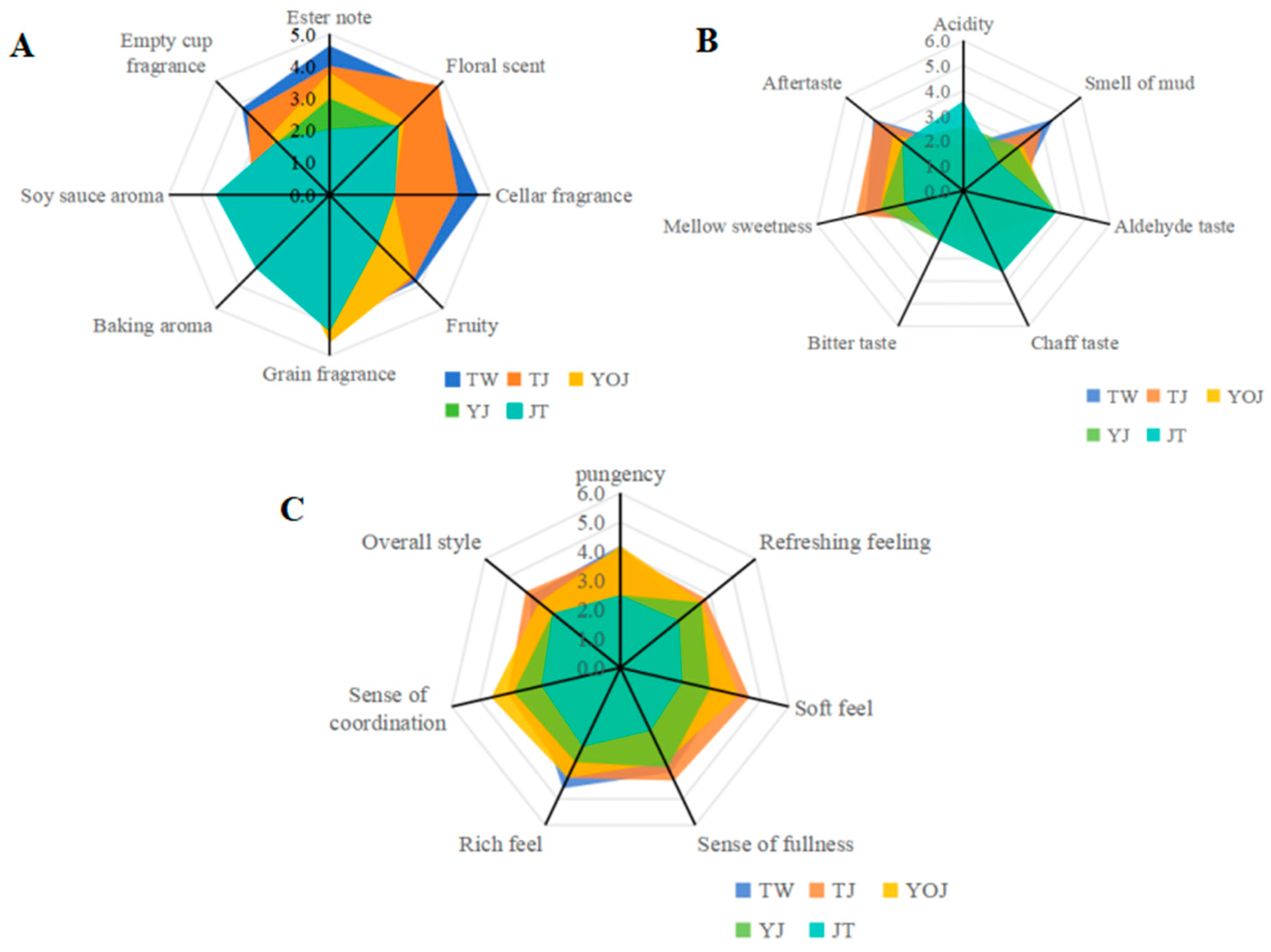

3.1. The Analysis of Sensory Flavor Differences and Characteristics Across Samples

3.2. Detection and Differences of Total Acids, Total Esters, and the Main VOCs in the Samples

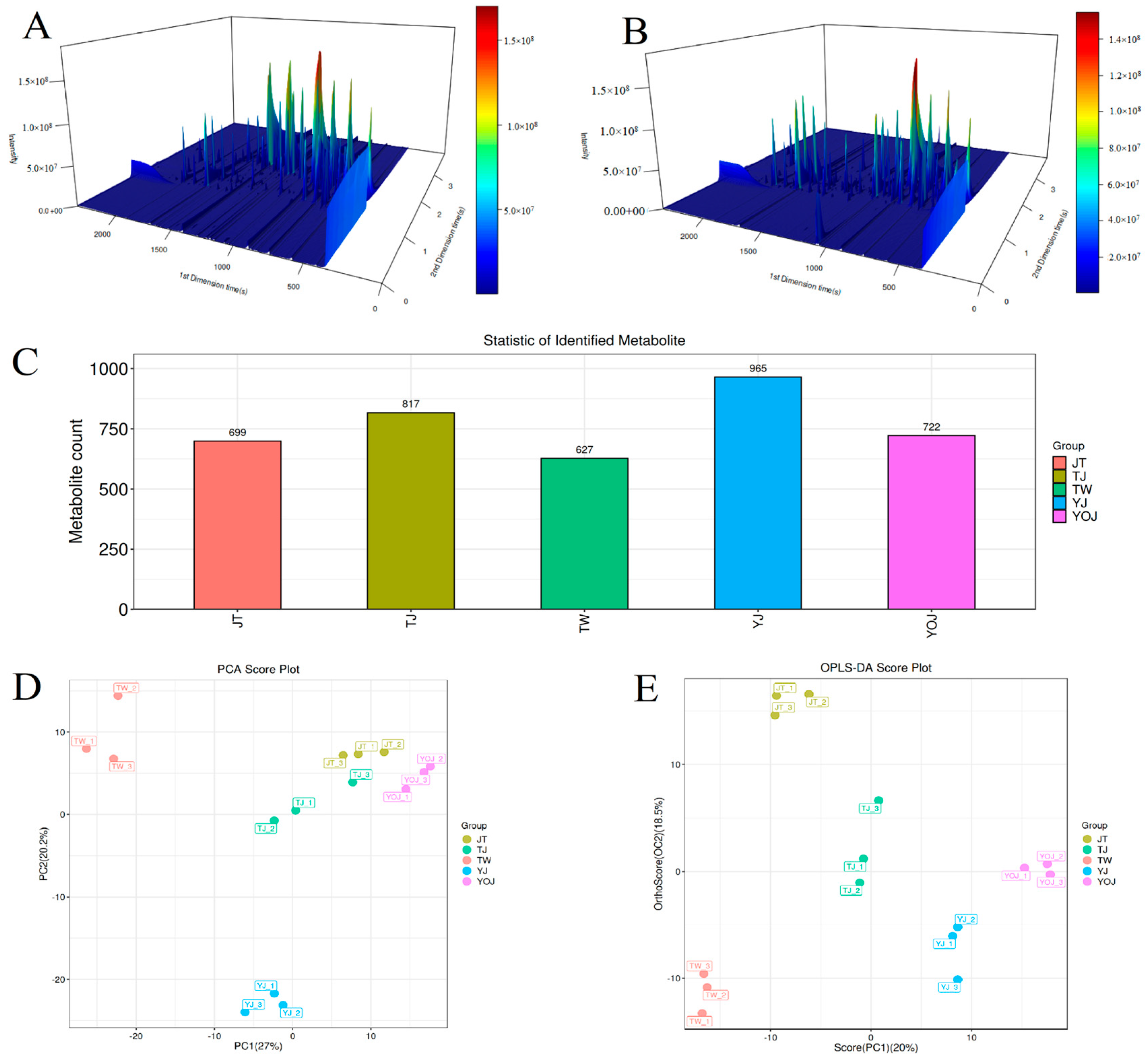

3.3. Identification and Statistical Analysis of VOCs Based on GC×GC-TOF-MS

3.3.1. Identifying the VOCs

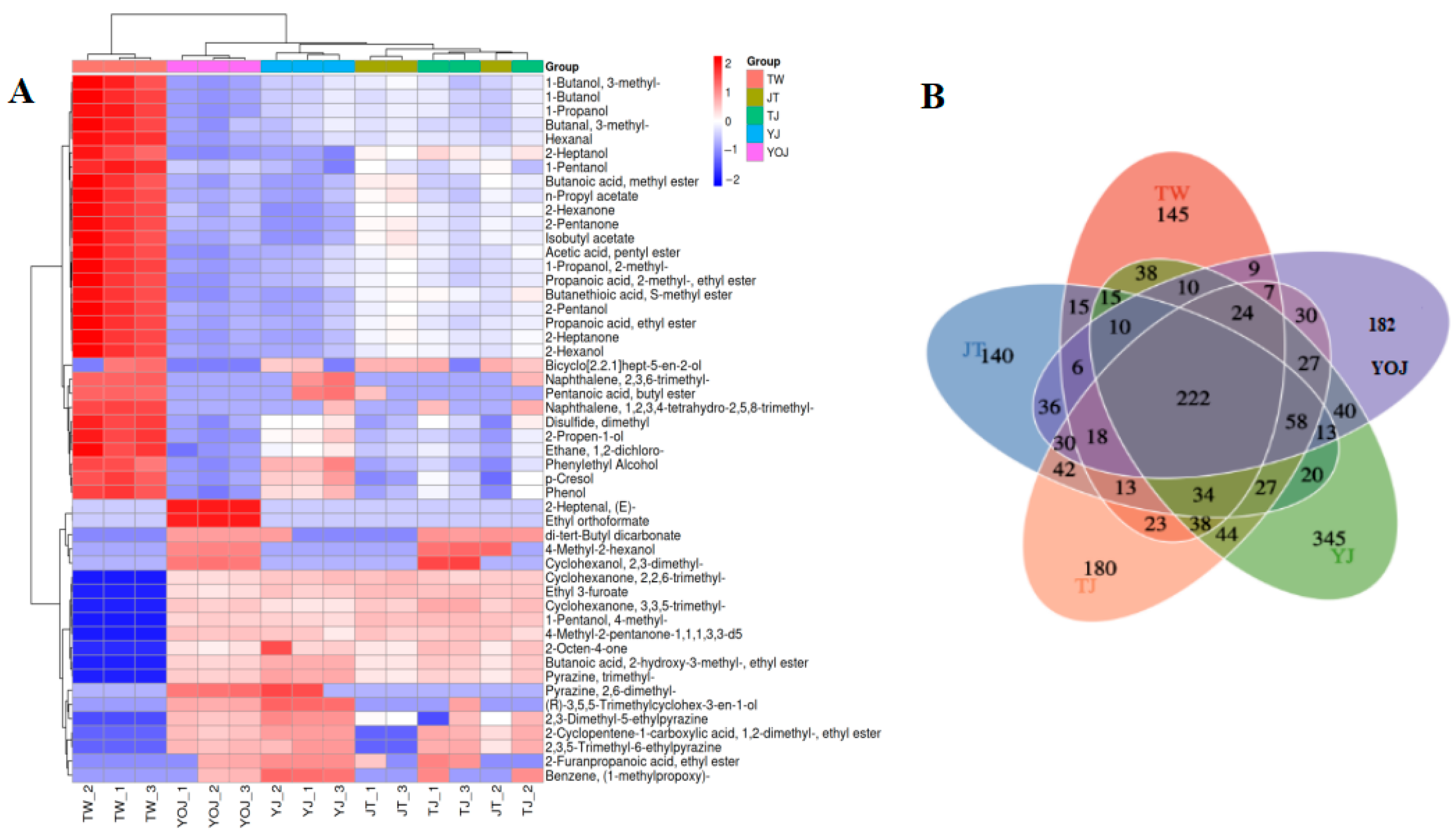

3.3.2. The Comparison of Relative Amounts of VOCs

3.3.3. The Principal Component Analysis (PCA) and Partial Least-Squares-Discriminant Analysis (OPLS-DA) of the VOCs

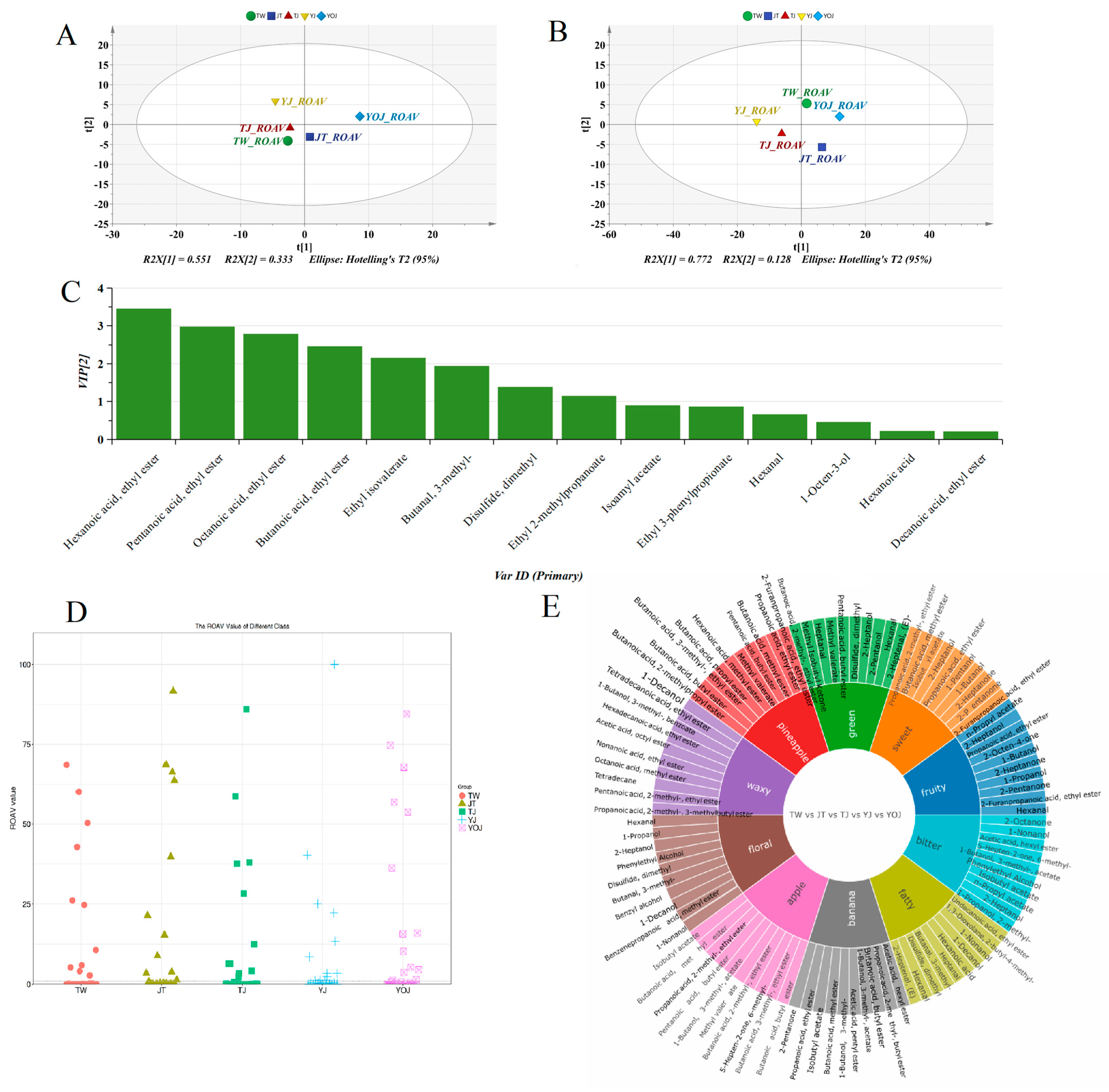

3.4. The Comparison of Key Differential VOCs and Their ROAVs in the Samples

3.4.1. The Comparison of Quantities and Relative Contents of Key Differential VOCs

3.4.2. The Comparison of ROAVs of Key Differential VOCs in the Samples

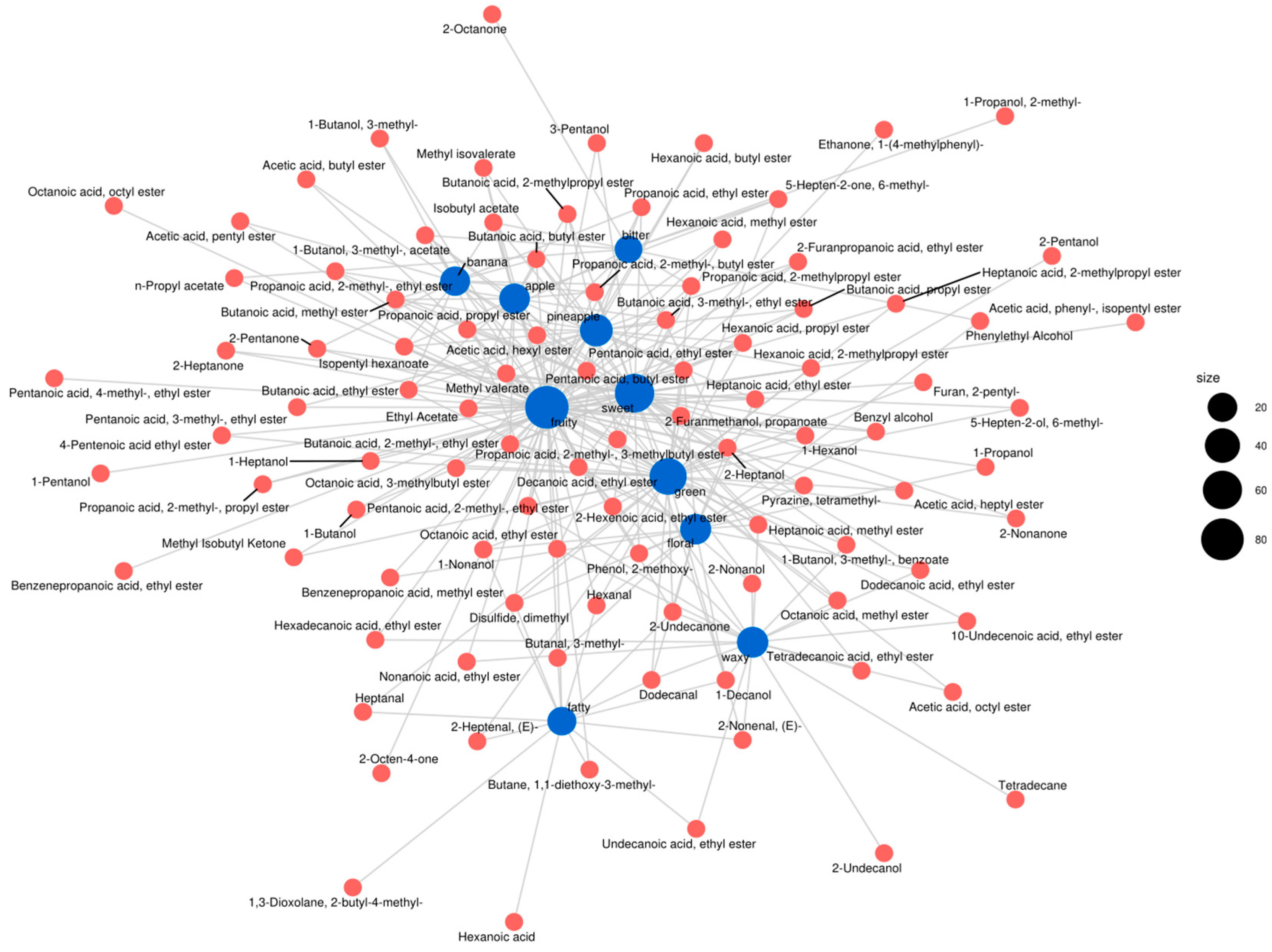

3.4.3. The Network Diagram of Relationships Between Various VOCs for Imparting the Unique Sensory of Aroma Characteristics Among Samples

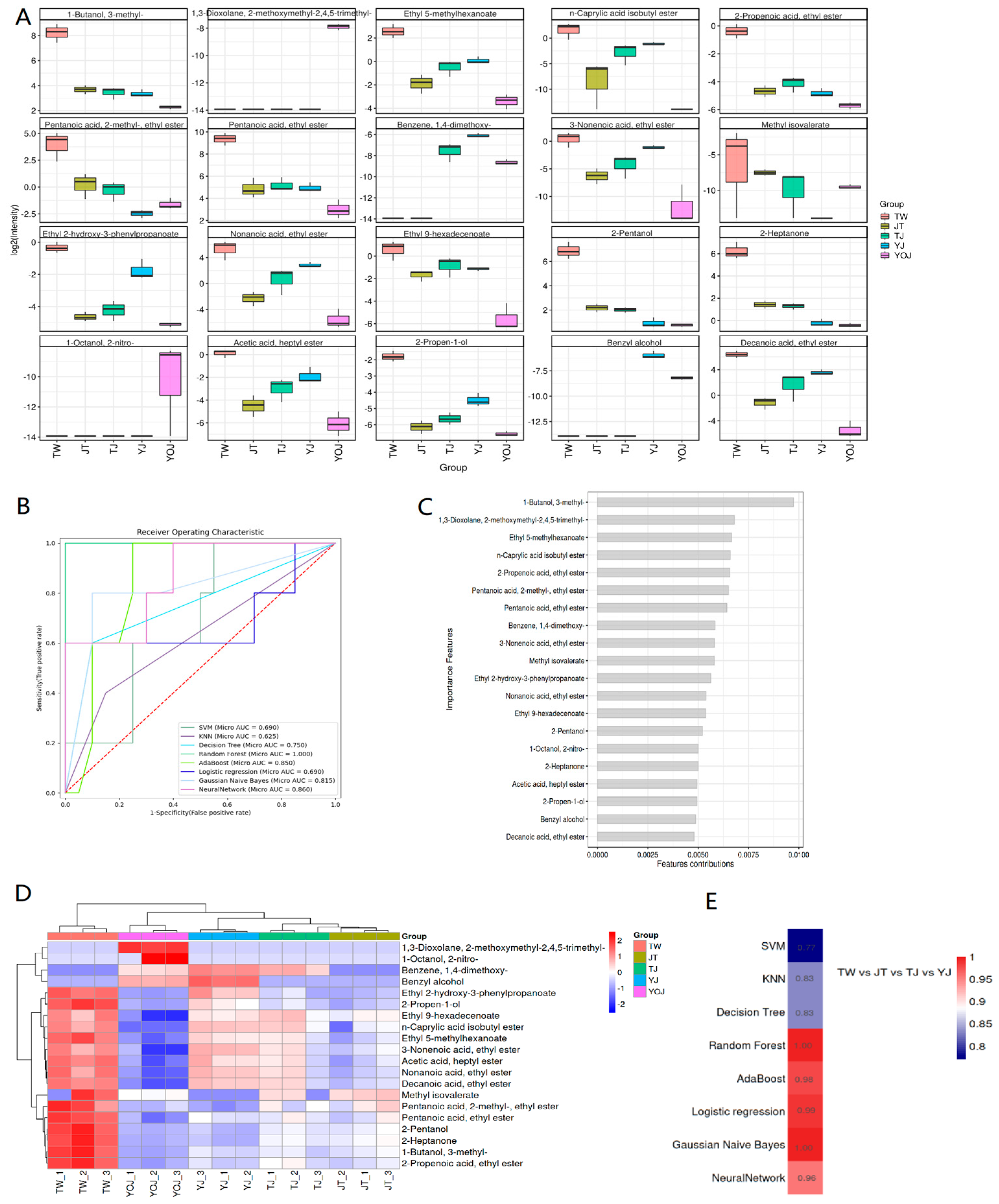

3.5. Development of the Classification and Prediction Models for Baijiu Flavor Based on ML Algorithms

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, L.Q.; Tang, P.; Zhang, P.J.; Lu, J.; Chen, Y.F.; Xiao, D.G.; Guo, X.W. Unraveling the aroma profiling of baijiu: Sensory characteristics of aroma compounds, analytical approaches, key odor-active compounds in different baijiu, and their synthesis mechanisms. Trends Food Sci. Technol. 2024, 146, 104376. [Google Scholar] [CrossRef]

- Yuan, H.W.; Zhang, Z.; Ding, L.P.; Jiang, Q.; Li, Q.; Huang, J.; Wang, S.T.; Li, L.; Nan, G.H.; Lou, K. Artificial vs. mechanical Daqu: Comparative Analysis of Physicochemical, Flavor, and Microbial Profiles in Chinese baijiu Starter Cultures. Fermentation 2025, 11, 135. [Google Scholar] [CrossRef]

- Xu, Y.Q.; Zhao, J.R.; Liu, X.; Zhang, C.S.; Zhao, Z.G.; Li, X.T.; Sun, B.G. Flavor mystery of Chinese traditional fermented baijiu: The great contribution of ester compounds. Food Chem. 2022, 369, 130920. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Y.L.; Hu, X.Y.; Li, H.H.; Zhao, D.R.; Wang, B.W.; Ye, X.Q.; Zhang, Y.Y.; Sun, B.G.; Sun, J.Y. Unraveling the role of peanut protein in baijiu-peanut pairing flavor complexity: A focus on ethanol-induced denaturation. Food Chem. 2025, 463, 141181. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.Y.; Liu, R.C.; Xie, Y.Q. Hydrogen bonding dominated self-assembly mechanism of amphiphilic molecules in Chinese baijiu. Food Chem. 2024, 452, 139420. [Google Scholar] [CrossRef]

- Cheng, W.; Chen, X.F.; Zhou, D.; Xiong, F.K. Applications and prospects of the automation of compound flavor baijiu production by solid-state fermentation. Int. J. Food Eng. 2022, 18, 737–749. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, M.; Zhang, J.; Ma, Z.; Cui, J.; Zhao, L.; Chen, L.; Shi, G.; Ding, Z. Refined regulation of polysaccharide biosynthesis in edible and medicinal fungi: From pathways to production. Carbohydr. Polym. 2025, 358, 123560. [Google Scholar] [CrossRef]

- Cheng, W.; Chen, X.F.; Lan, W.; Liu, G.D.; Xue, X.J.; Li, R.L.; Pan, T.Q.; Li, N.; Zhou, D.; Chen, X.J. Insights into the influence of physicochemical parameters on the microbial community and volatile compounds during the ultra-long fermentation of compound-flavor baijiu. Front. Microbiol. 2023, 14, 1272559. [Google Scholar] [CrossRef]

- Zou, W.; Zhao, C.Q.; Luo, H.B. Diversity and function of microbial community in Chinese strong-flavor baijiu ecosystem: A review. Front. Microbiol. 2018, 9, 671. [Google Scholar] [CrossRef]

- Yao, F.; Yi, B.; Shen, C.H.; Tao, F.; Liu, Y.M.; Lin, Z.X.; Xu, P. Chemical analysis of the Chinese liquor Luzhoulaojiao by comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry. Sci. Rep. 2015, 5, 9553. [Google Scholar] [CrossRef]

- Cheng, W.; Chen, X.; Guo, Y.; Zhou, D.; Zeng, H.; Fu, H. The microbial diversity and flavour metabolism of Chinese strong flavour baijiu: A review. J. Inst. Brew. 2023, 129, 15–38. [Google Scholar] [CrossRef]

- Jia, W.; Fan, Z.B.; Du, A.; Li, Y.L.; Zhang, R.; Shi, Q.Y.; Shi, L.; Chu, X.G. Recent advances in baijiu analysis by chromatography based technology—A review. Food Chem. 2020, 324, 126899. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.P.; Yang, K.Z.; He, Z.L.; Zhao, D.; Zheng, J.; Qian, M.C. Comparison of two data processing approaches for aroma marker identification in different distilled liquors using comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry dataset. J. Food Sci. 2023, 88, 2870–2881. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wang, C.C.; Wang, L.L.; Chen, S.; Xu, Y. Optimization and validation of a head space solid-phase microextraction-arrow gas chromatography-mass spectrometry method using central composite design for determination of aroma compounds in Chinese liquor (baijiu). J. Chromatogr. A 2020, 1610, 460584. [Google Scholar] [CrossRef] [PubMed]

- Li, H.H.; Qin, D.; Wu, Z.Y.; Sun, B.G.; Sun, X.T.; Huang, M.Q.; Sun, J.Y.; Zheng, F.P. Characterization of key aroma compounds in Chinese Guojing sesame-flavor baijiu by means of molecular sensory science. Food Chem. 2019, 284, 100–107. [Google Scholar] [CrossRef]

- Yu, M.G.; Yang, P.; Song, H.L.; Guan, X.S. Research progress in comprehensive two-dimensional gas chromatography-mass spectrometry and its combination with olfactometry systems in the flavor analysis field. J. Food Compos. Anal. 2022, 114, 104790. [Google Scholar] [CrossRef]

- Li, S.; Li, T.; Han, Y.R.; Yan, P.; Li, G.H.; Ren, T.T.; Yan, M.; Lu, J.; Qiu, S.Y. Machine learning discrimination and prediction of different quality grades of sauce-flavor baijiu based on biomarker and key flavor compounds screening. Food Chem. X 2024, 24, 101877. [Google Scholar] [CrossRef]

- Li, S.; Han, Y.R.; Wang, L.; Zhang, Y.; Wang, F.; Ou, Y.M.; Li, H.Y.; Yang, L.; Qiu, S.Y.; Lu, J. Machine learning-enhanced flavoromics: Identifying key aroma compounds and predicting sensory quality in sauce-flavor baijiu. Food Chem. 2025, 475, 143328. [Google Scholar] [CrossRef]

- He, X.; Yangming, H.; Górska-Horczyczak, E.; Wierzbicka, A.; Jeleń, H.H. Rapid analysis of baijiu volatile compounds fingerprint for their aroma and regional origin authenticity assessment. Food Chem. 2021, 337, 128002. [Google Scholar] [CrossRef]

- Wang, J.; Ming, Y.Z.; Li, Y.M.; Huang, M.Q.; Luo, S.Q.; Li, H.F.; Li, H.H.; Wu, J.H.; Sun, X.T.; Luo, X.L. Characterization and comparative study of the key odorants in Caoyuanwang mild-flavor style baijiu using gas chromatography-olfactometry and sensory approaches. Food Chem. 2021, 347, 129028. [Google Scholar] [CrossRef]

- Zhang, M.Z.; Wu, X.F.; Mu, D.D.; Xu, B.Y.; Xu, X.H.; Chang, Q.; Li, X.J. Profiling the influence of physicochemical parameters on the microbial community and flavor substances of zaopei. J. Sci. Food Agric. 2021, 101, 6300–6310. [Google Scholar] [CrossRef]

- GB/T 10781.1–2021; The Quality Requirements for Baijiu, Part 1, Nongxiangxing Baijiu. China Light Industry Federation: Beijing, China, 2021.

- Ren, J.M.; Li, Z.J.; Jia, W. Key Aroma Differences in Volatile Compounds of Aged Feng-Flavored Baijiu Determined Using Sensory Descriptive Analysis and GCxGC-TOFMS. Foods 2024, 13, 1504. [Google Scholar] [CrossRef]

- GB/T 10345-2022; Analytical Method for Baijiu. China Light Industry Federation: Beijing, China, 2022.

- Li, Q.Q.; Li, B.; Zhang, R.; Liu, S.Y.; Yang, S.P.; Li, Y.; Li, J.X. Flavoromics approach in critical aroma compounds exploration of peach: Correlation to origin based on OAV combined with chemometrics. Foods 2023, 12, 837. [Google Scholar] [CrossRef] [PubMed]

- Lan, W.; Cheng, W.; Li, R.L.; Zhang, M.; Li, M.M.; Zhang, Y.; Zhou, Y.B. Comparison of flavor differences between the juices and wines of four strawberry cultivars using two-dimensional gas chromatography-time-of-flight mass spectrometry and sensory evaluation. Molecules 2024, 29, 4691. [Google Scholar] [CrossRef]

- Robinson, A.L.; Boss, P.K.; Heymann, H.; Solomon, P.S.; Trengove, R.D. Development of a sensitive non-targeted method for characterizing the wine volatile profile using headspace solid-phase microextraction comprehensive two-dimensional gas chromatography time-of-flight mass spectrometry. J. Chromatogr. A 2011, 1218, 504–517. [Google Scholar] [CrossRef] [PubMed]

- Perestrelo, R.; Petronilho, S.; Câmara, J.S.; Rocha, S.M. Comprehensive two-dimensional gas chromatography with time-of-flight mass spectrometry combined with solid phase microextraction as a powerful tool for quantification of ethyl carbamate in fortified wines. The case study of Madeira wine. J. Chromatogr. A 2010, 1217, 3441–3445. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Chen, S.; Nie, Y.; Xu, Y. Characterization of volatile sulfur compounds in soy sauce aroma type Baijiu and changes during fermentation by GC × GC-TOFMS, organoleptic impact evaluation, and multivariate data analysis. Food Res. Int. 2020, 131, 109043. [Google Scholar] [CrossRef]

- Mu, X.Q.; Lu, J.; Gao, M.X.; Li, C.W.; Chen, S. Optimization and validation of a headspace solid-phase microextraction with comprehensive two-dimensional gas chromatography time-of-flight mass spectrometric detection for quantification of trace aroma compounds in Chinese liquor (baijiu). Molecules 2021, 26, 6910. [Google Scholar] [CrossRef]

- Yu, H.Y.; Zheng, D.W.; Xie, T.; Xie, J.R.; Tian, H.X.; Ai, L.Z.; Chen, C. Comprehensive two-dimensional gas chromatography mass spectrometry-based untargeted metabolomics to clarify the dynamic variations in the volatile composition of huangjiu of different ages. J. Food Sci. 2022, 87, 1563–1574. [Google Scholar] [CrossRef]

- Liang, H.M.; Gao, D.Y.; Wang, C.; Gao, H.H.; Guo, Y.Y.; Zhao, Z.Y.; Shi, H.M. Effect of fermentation strategy on the quality and aroma characteristics of yellow peach wines. Fermentation 2022, 8, 604. [Google Scholar] [CrossRef]

- Dong, W.; Dai, X.R.; Jia, Y.T.; Ye, S.T.; Shen, C.H.; Liu, M.; Lin, F.; Sun, X.T.; Xiong, Y.F.; Deng, B. Association between baijiu chemistry and taste change: Constituents, sensory properties, and analytical approaches. Food Chem. 2024, 437, 137826. [Google Scholar] [CrossRef]

- Gao, W.J.; Fan, W.L.; Xu, Y. Characterization of the key odorants in light aroma type Chinese liquor by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission studies. J. Agric. Food Chem. 2014, 62, 5796–5804. [Google Scholar] [CrossRef]

- Zhang, W.Z.; Han, X.L.; Wang, D.L.; Jiang, W.; Hao, L.G.; Chen, Y.Q.; Zhou, F.; Hu, J.X.; Meng, X.L. Characterization of the cellar mud odor compounds and their content variation in strong aroma base baijiu by GC/MS/O and means of molecular sensory science. Appl. Food Res. 2025, 5, 100671. [Google Scholar] [CrossRef]

- Wang, J.S.; Chen, H.; Wu, Y.S.; Zhao, D.R. Uncover the flavor code of strong-aroma baijiu: Research progress on the revelation of aroma compounds in strong-aroma baijiu by means of modern separation technology and molecular sensory evaluation. J. Food Compos. Anal. 2022, 109, 104499. [Google Scholar] [CrossRef]

- Sun, J.Y.; Wang, Z.; Sun, B.G. Low quantity but critical contribution to flavor: Review of the current understanding of volatile sulfur-containing compounds in baijiu. J. Food Compos. Anal. 2021, 103, 104079. [Google Scholar] [CrossRef]

- Cheng, W.; Lan, W.; Chen, X.F.; Xue, X.J.; Liang, H.P.; Zeng, H.W.; Li, R.L.; Pan, T.Q.; Li, N.; Yang, H.W. Source and succession of microbial communities and tetramethylpyrazine during the brewing process of compound-flavor baijiu. Front. Microbiol. 2024, 15, 1450997. [Google Scholar] [CrossRef]

- Wu, J.H.; Liu, Y.; Zhao, H.; Huang, M.Q.; Sun, Y.; Zhang, J.L.; Sun, B.G. Recent advances in the understanding of off-flavors in alcoholic beverages: Generation, regulation, and challenges. J. Food Compos. Anal. 2021, 103, 104117. [Google Scholar] [CrossRef]

- Li, S.; Han, Y.R.; Yan, M.; Qiu, S.Y.; Lu, J. Machine learning and multi-omics integration to reveal biomarkers and microbial community assembly differences in abnormal stacking fermentation of sauce-flavor baijiu. Foods 2025, 14, 245. [Google Scholar] [CrossRef]

| Category | CAS | Unit | Samples | ||||

|---|---|---|---|---|---|---|---|

| TW | TJ | YOJ | YJ | JT | |||

| Ethanol | / | v/v | 70.45 ± 0.08 | 67.75 ± 0.17 | 64.8 ± 0.26 | 53.46 ± 0.33 | 68.53 ± 0.06 |

| Total acid | / | g/L | 1.89 ± 0.33 a | 2.26 ± 0.65 a | 2.41 ± 0.05 b | 3.47 ± 0.05 a | 1.73 ± 0.14 c |

| Total ester | / | g/L | 21.87 ± 0.11 b | 12.78 ± 0.1 a | 8.78 ± 0.23 a | 8.35 ± 0.37 b | 19.51 ± 0.05 d |

| Acetaldehyde | 75-07-0 | mg/100 mL | 18.8 ± 0.75 | 11.00 ± 0.05 a | 11.06 ± 0 c | 9.42 ± 0.15 a | 18.53 ± 0.23 a |

| Methanol | 67-56-1 | 8.46 ± 0.23 a | 10.66 ± 0.15 a | 16.00 ± 0.1 a | 21.97 ± 0.65 a | 8.39 ± 0.04 a | |

| Ethyl acetate | 141-78-6 | 913.00 ± 0.1 a | 391.68 ± 0.05 b | 400.57 ± 0.05 b | 111.18 ± 0.17 a | 1031.19 ± 0.65 a | |

| n-propyl alcohol | 71-23-8 | 83.08 ± 0.13 a | 73.69 ± 0 c | 7141 ± 0 b | 55.54 ± 0.05 a | 87.27 ± 0.03 b | |

| Sec-butyl alcohol | 78-92-2 | 23.34 ± 0.23 a | 13.93 ± 0.05 d | 13.49 ± 0.17 a | 6.06 ± 0.53 a | 23.00 ± 0.1 a | |

| Acetaldehyde diethyl acetal | 105-57-7 | 29.36 ± 0.61 a | 14.82 ± 0.15 a | 12.96 ± 0.05 b | 6.24 ± 0.15 a | 26.73 ± 0.17 a | |

| Isobutanol | 78-83-1 | 15.59 ± 0.15 a | 11.44 ± 0.03 b | 10.65 ± 0.15 a | 6.17 ± 0.23 a | 17.35 ± 0.05 d | |

| n-butanol | 71-36-3 | 84.24 ± 0.23 a | 74.00 ± 0.1 a | 66.76 ± 0.05 b | 48.83 ± 0.25 a | 81.96 ± 0.23 a | |

| Ethyl butyrate | 105-54-4 | 160.53 ± 0 b | 78.07 ± 0.22 a | 76.79 ± 0.05 a | 28.65 ± 0.25 a | 177.00 ± 0.1 a | |

| Iso-amyl alcohol | 123-51-3 | 34.38 ± 0.18 a | 28.59 ± 0.23 a | 21.83 ± 0.05 b | 20.45 ± 0.15 a | 31.08 ± 0 b | |

| Ethyl lactate | 97-64-3 | 120.37 ± 0.05 b | 179.75 ± 0.13 d | 247.24 ± 0 c | 523.08 ± 0.25 d | 129.09 ± 0.05 b | |

| Ethyl caproate | 123-66-0 | 1480.92 ± 0.05 a | 987.32 ± 0.23 a | 510.91 ± 0.15 a | 312.05 ± 0.23 a | 89.14 ± 0 c | |

| Group | Esters | Hydrocarbons | Alcohols | Ketones | Ethers | Carboxylic Acids | Heterocyclic Compounds | Others | Total |

|---|---|---|---|---|---|---|---|---|---|

| TW | 149 | 37 | 50 | 32 | 25 | 28 | 25 | 281 | 627 |

| JT | 141 | 56 | 69 | 42 | 22 | 33 | 17 | 319 | 699 |

| TJ | 161 | 70 | 68 | 40 | 23 | 38 | 23 | 555 | 817 |

| YJ | 190 | 60 | 84 | 49 | 32 | 40 | 21 | 679 | 965 |

| YOJ | 144 | 33 | 78 | 42 | 27 | 33 | 20 | 345 | 722 |

| Group | Esters | Hydrocarbons | Alcohols | Ketones | Ethers | Carboxylic Acids | Heterocyclic Compounds | Others |

|---|---|---|---|---|---|---|---|---|

| TW | 60.73 ± 5.21 c | 1.21 ± 0.77 a | 23.06 ± 0.17 b | 1.96 ± 0.13 c | 1.7 ± 0.23 c | 2.61 ± 3.26 b | 2.91 ± 0.54 b | 5.82 ± 1.03 a |

| JT | 55.79 ± 5.67 ab | 0.76 ± 0.06 d | 19.10 ± 0.66 b | 1.32 ± 0.03 d | 2.02 ± 0.06 d | 3.71 ± 2.76 b | 4.17 ± 0.23 d | 13.13 ± 1.26 a |

| TJ | 60.04 ± 2.25 e | 2.43 ± 2.45 b | 18.96 ± 2.17 bc | 0.88 ± 0.22 d | 1.11 ± 0.03 a | 4.83 ± 0.14 b | 0.83 ± 0.07 d | 11.00 ± 0.1 a |

| YJ | 59.93 ± 2.19 b | 2.72 ± 0.77 a | 15.65 ± 1.98 bc | 1.54 ± 0.06 c | 1.48 ± 0.25 b | 2.71 ± 0.61 c | 0.70 ± 0.09 e | 15.27 ± 1.99 c |

| YOJ | 49.00 ± 0.1 a | 1.11 ± 0.18 d | 26.75 ± 1.77 b | 1.00 ± 0.1 a | 2.83 ± 0.22 d | 5.35 ± 0.95 d | 1.42 ± 1.06 b | 12.54 ± 2.76 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, D.; Cheng, W.; Jiang, C.; Pan, T.; Li, N.; Li, M.; Li, R.; Lan, W.; Du, X. Machine-Learning-Assisted Aroma Profile Prediction in Five Different Quality Grades of Nongxiangxing Baijiu Fermented During Summer Using Sensory Evaluation Combined with GC×GC–TOF-MS. Foods 2025, 14, 1714. https://doi.org/10.3390/foods14101714

Shao D, Cheng W, Jiang C, Pan T, Li N, Li M, Li R, Lan W, Du X. Machine-Learning-Assisted Aroma Profile Prediction in Five Different Quality Grades of Nongxiangxing Baijiu Fermented During Summer Using Sensory Evaluation Combined with GC×GC–TOF-MS. Foods. 2025; 14(10):1714. https://doi.org/10.3390/foods14101714

Chicago/Turabian StyleShao, Dongliang, Wei Cheng, Chao Jiang, Tianquan Pan, Na Li, Mengmeng Li, Ruilong Li, Wei Lan, and Xianfeng Du. 2025. "Machine-Learning-Assisted Aroma Profile Prediction in Five Different Quality Grades of Nongxiangxing Baijiu Fermented During Summer Using Sensory Evaluation Combined with GC×GC–TOF-MS" Foods 14, no. 10: 1714. https://doi.org/10.3390/foods14101714

APA StyleShao, D., Cheng, W., Jiang, C., Pan, T., Li, N., Li, M., Li, R., Lan, W., & Du, X. (2025). Machine-Learning-Assisted Aroma Profile Prediction in Five Different Quality Grades of Nongxiangxing Baijiu Fermented During Summer Using Sensory Evaluation Combined with GC×GC–TOF-MS. Foods, 14(10), 1714. https://doi.org/10.3390/foods14101714