Physical Stability of Lotus Seed and Lily Bulb Beverage: The Effects of Homogenisation on Particle Size Distribution, Microstructure, Rheological Behaviour, and Sensory Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Product Development

2.3. Homogenisation Treatment of LLB

2.4. Particle Size Distribution

2.5. Microstructure Observation

2.6. Rheological Properties

2.7. The Sedimentation Test and Sedimentation Index

2.8. Turbidity Measurement

2.9. Colour Parameters

2.10. pH and Total Soluble Solids (TSS)

2.11. Ascorbic Acid Content (AAC)

2.12. Sensory Evaluation

2.13. Statistical Analysis

3. Results

3.1. Particle Size Distribution (PSD)

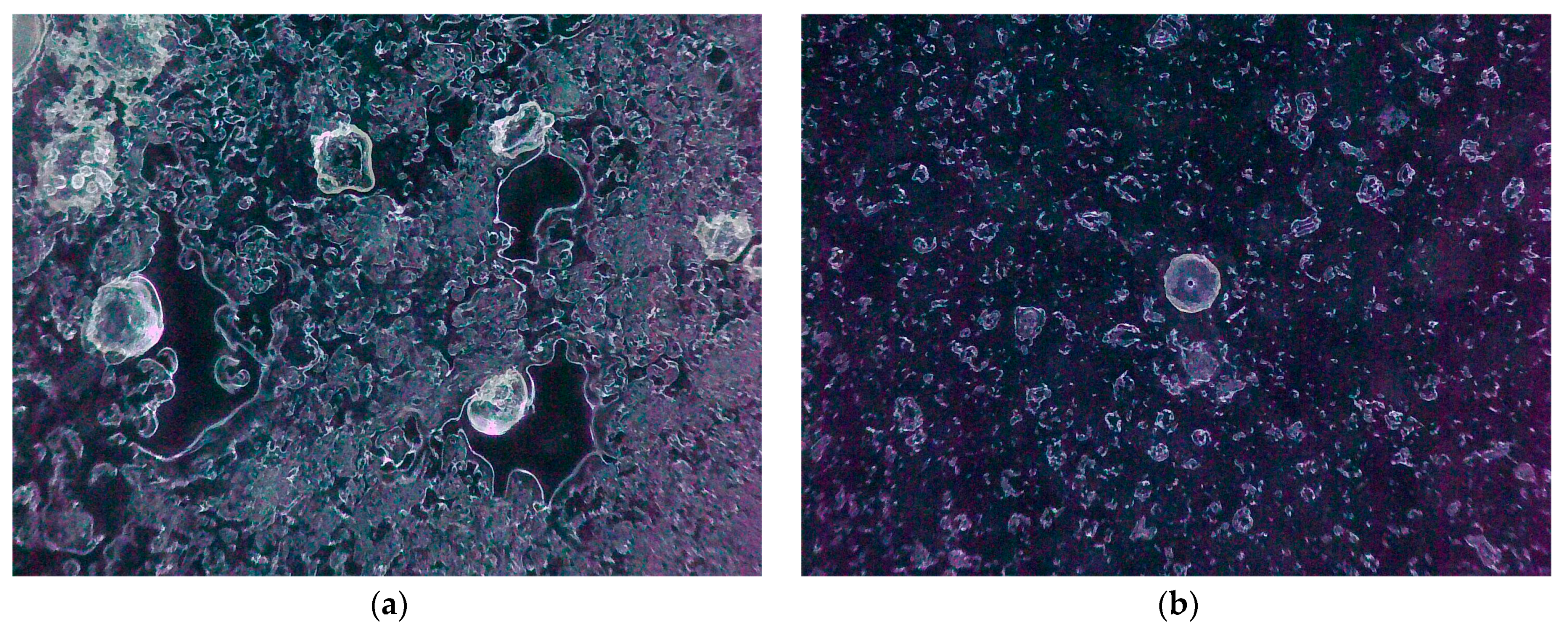

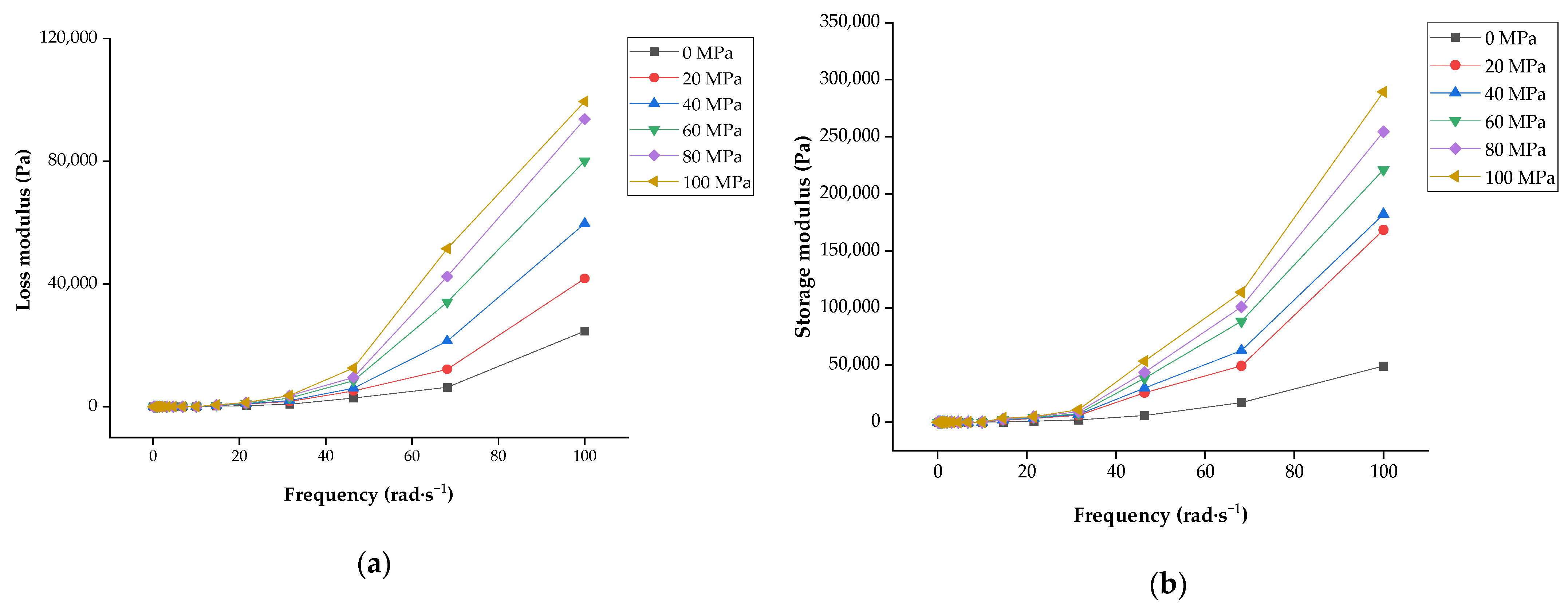

3.2. Microstructure

3.3. Rheological Characterisation

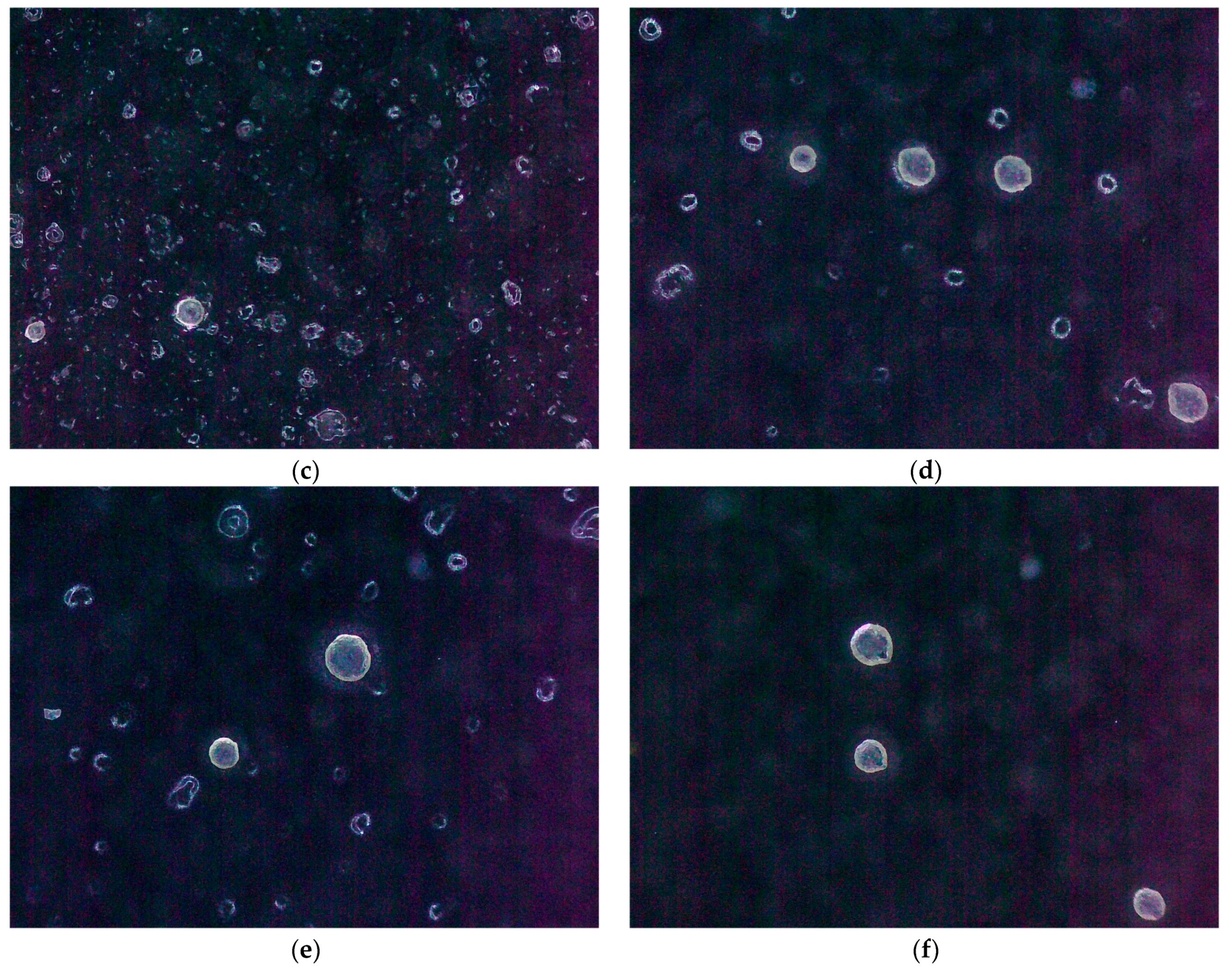

3.3.1. Steady-State Shear Properties

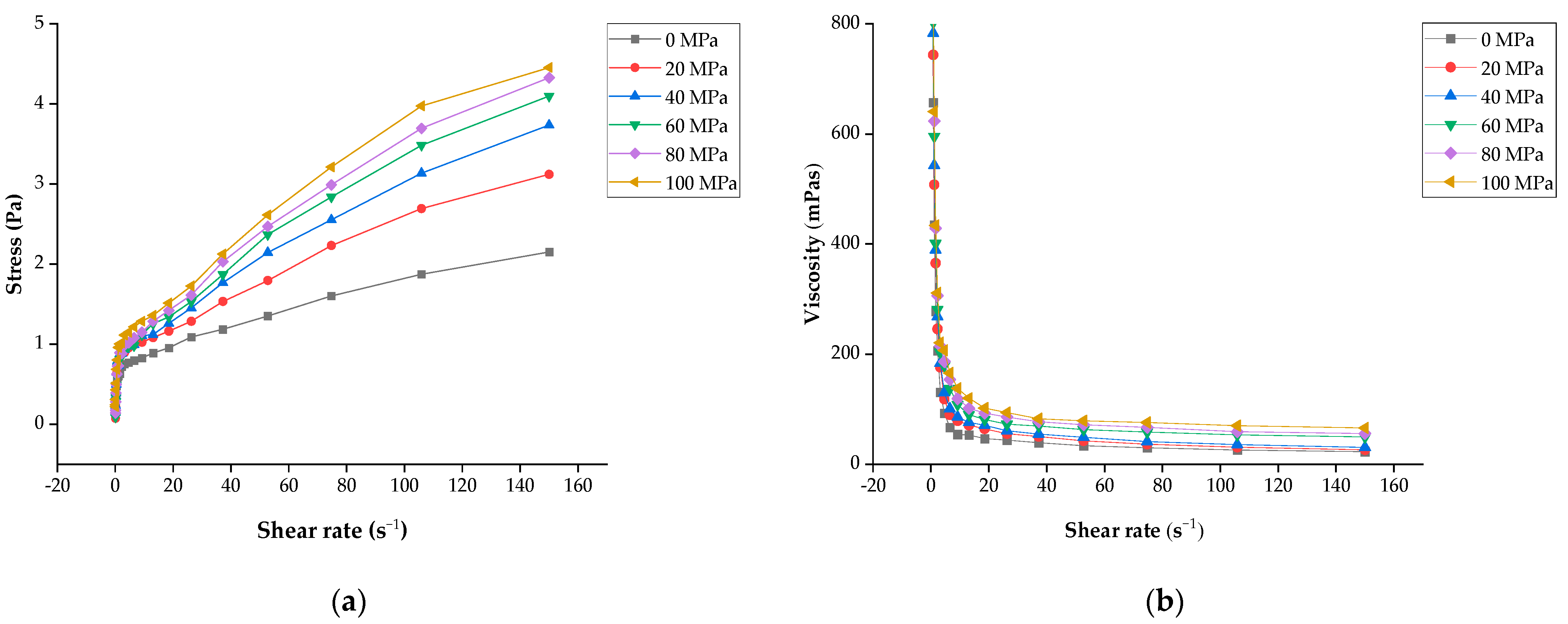

3.3.2. Dynamic Shear Properties

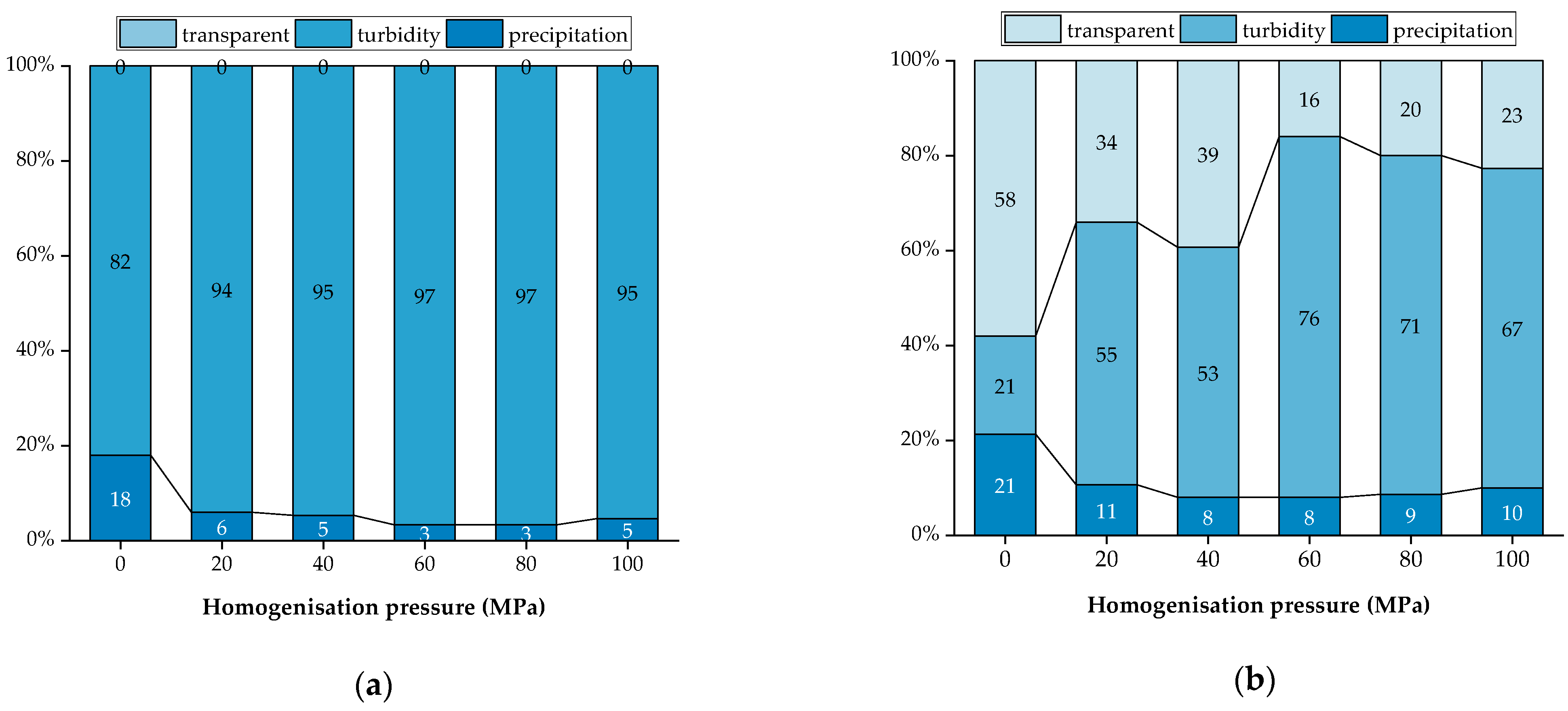

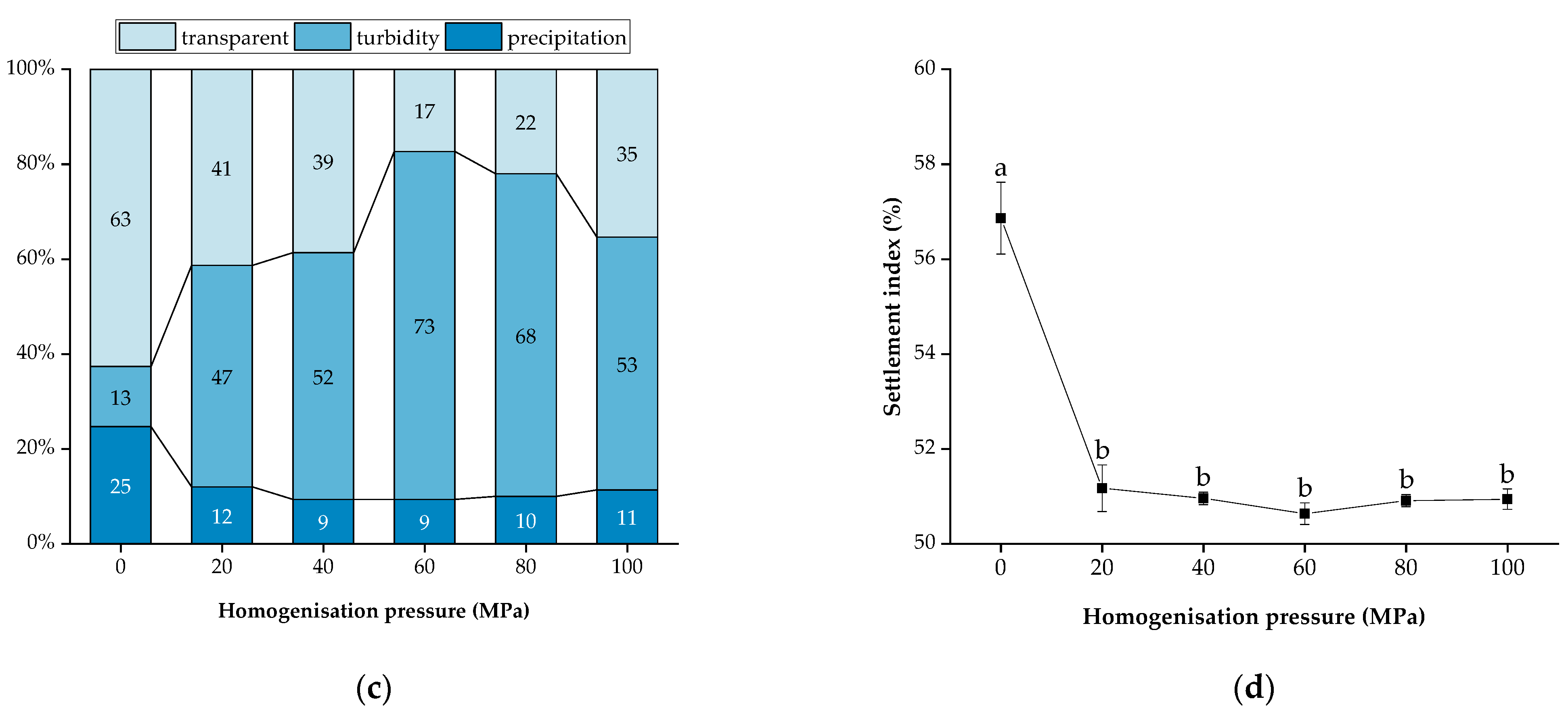

3.4. Pulp Sedimentation

3.5. Turbidity

3.6. Colour Value

3.7. pH and TSS

3.8. Ascorbic Acid Content

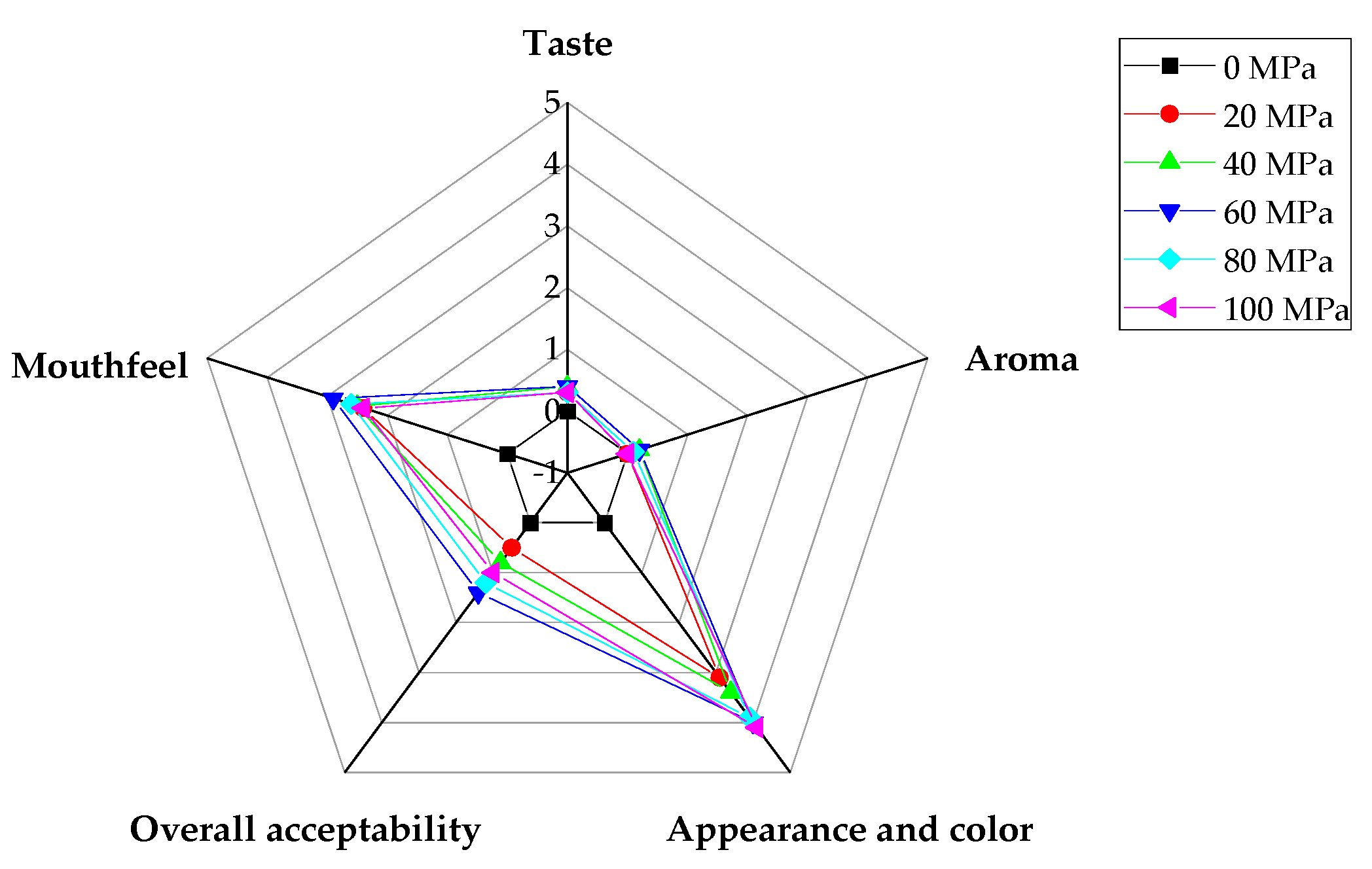

3.9. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ni, Y.; Zhang, Z.; Fan, L.; Li, J. Evaluation of physical stability of high pressure homogenization treatment cloudy ginkgo beverages. LWT 2019, 111, 31–38. [Google Scholar] [CrossRef]

- Cichońska, P.; Domian, E.; Ziarno, M. The Effect of High-Pressure Homogenization on the Texture of Fermented Bean-Based Beverages®. J. Postępy Tech. Przetwórstwa Spożywczego 2022, 1, 37–45. [Google Scholar]

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, H.; Zhang, W.; Wu, H.; Wang, Z. Evaluation of nutrition components in Lanzhou lily bulb by confocal Raman microscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 244, 118837. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Zhang, Y.; Yan, L.; Guo, Y.; Niu, L. Phenolic Compounds and Antioxidant Activity of Bulb Extracts of Six Lilium Species Native to China. Molecules 2012, 17, 9361–9378. [Google Scholar] [CrossRef] [PubMed]

- Bangar, S.P.; Dunno, K.; Kumar, M.; Mostafa, H.; Maqsood, S. A comprehensive review on lotus seeds (Nelumbo nucifera Gaertn.): Nutritional composition, health-related bioactive properties, and industrial applications. J. Funct. Foods 2022, 89, 104937. [Google Scholar]

- Zhao, X.; Cheng, M.; Wang, C.; Jiang, H.; Zhang, X. Effects of dairy bioactive peptides and lotus seeds/lily bulb powder on flavor and quality characteristics of goat milk yogurt. J. Food Biosci. 2022, 47, 101510. [Google Scholar] [CrossRef]

- Yang, W.; Wang, P.; Zhang, W.; Xu, M.; Yan, L.; Yan, Z.; Du, W.; Ouyang, L.; Liu, B.; Wu, Z.; et al. Review on preservation techniques of edible lily bulbs in China. CyTA—J. Food 2022, 20, 172–182. [Google Scholar] [CrossRef]

- Silva, V.M.; Sato, A.C.K.; Barbosa, G.; Dacanal, G.; Ciro-Velásquez, H.J.; Cunha, R.L. The effect of homogenisation on the stability of pineapple pulp. Int. J. Food Sci. Technol. 2010, 45, 2127–2133. [Google Scholar] [CrossRef]

- Patrignani, F.; Rossi, S.; Vannini, L.; Lanciotti, R. High-Pressure Homogenization Effects on Spoilage and Pathogenic Microorganisms in Foods. In Innovative Food Processing Technologies: A Comprehensive Review; Academic Press: Cambridge, MA, USA, 2021; pp. 274–292. [Google Scholar]

- Malik, T.; Sharma, R.; Ameer, K.; Bashir, O.; Amin, T.; Manzoor, S.; Ahmed, I.A.M. Potential of high-pressure homogenization (HPH) in the development of functional foods. Int. J. Food Prop. 2023, 26, 2509–2531. [Google Scholar] [CrossRef]

- Suárez-Jacobo, Á.; Gervilla, R.; Guamis, B.; Roig-Sagués, A.; Saldo, J. Effect of UHPH on indigenous microbiota of apple juice. Int. J. Food Microbiol. 2009, 136, 261–267. [Google Scholar] [CrossRef]

- Salehi, F. Physico-chemical and rheological properties of fruit and vegetable juices as affected by high pressure homogenization: A review. J. Int. J. Food Prop. 2020, 23, 1136–1149. [Google Scholar] [CrossRef]

- Renoldi, N.; Melchior, S.; Calligaris, S.; Peressini, D. Application of high-pressure homogenization to steer the technological functionalities of chia fibre-protein concentrate. Food Hydrocoll. 2023, 139, 108505. [Google Scholar] [CrossRef]

- Wellala, C.K.D.; Bi, J.; Liu, X.; Liu, J.; Lyu, J.; Zhou, M. Effect of high pressure homogenization on mixed juice stability, rheology, physicochemical properties and microorganism reduction. J. Food Sci. Technol. 2020, 57, 1944–1953. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; Cheng, L.; Zhang, R.; Yang, Z. Impact of high-pressure homogenization on physico-chemical, structural, and rheological properties of quinoa protein isolates. Food Struct. 2022, 32, 100265. [Google Scholar] [CrossRef]

- Suárez-Jacobo, Á.; Rüfer, C.E.; Gervilla, R.; Guamis, B.; Roig-Sagués, A.X.; Saldo, J. Influence of ultra-high pressure homogenisation on antioxidant capacity, polyphenol and vitamin content of clear apple juice. Food Chem. 2011, 127, 447–454. [Google Scholar] [CrossRef]

- Szczepańska, J.; Skąpska, S.; Połaska, M.; Marszałek, K. High pressure homogenization with a cooling circulating system: The effect on physiochemical and rheological properties, enzymes, and carotenoid profile of carrot juice. Food Chem. 2022, 370, 131023. [Google Scholar] [CrossRef] [PubMed]

- Donsì, F.; Ferrari, G.; Maresca, P. High-Pressure Homogenization for Food Sanitization. Global Issues in Food Science and Technology; Academic Press: Cambridge, MA, USA, 2009; pp. 309–352. [Google Scholar]

- Floury, J.; Desrumaux, A.; Legrand, J. Effect of ultra-high-pressure homogenization on structure and on rheological properties of soy protein-stabilized emulsions. Food Sci. 2002, 67, 3388–3395. [Google Scholar] [CrossRef]

- Mesa, J.; Hinestroza-Córdoba, L.I.; Barrera, C.; Seguí, L.; Betoret, E.; Betoret, N. High homogenization pressures to improve food quality, functionality and sustainability. Molecules 2020, 25, 3305. [Google Scholar] [CrossRef]

- He, A.; Xu, B. High-pressure homogenization (HPH) improves food quality of plant-based milk alternatives. Int. J. Food Sci. Technol. 2024, 59, 399–407. [Google Scholar] [CrossRef]

- Kubo, M.T.K.; Augusto, P.E.; Cristianini, M. Effect of high pressure homogenization (HPH) on the physical stability of tomato juice. Food Res. Int. 2013, 51, 170–179. [Google Scholar] [CrossRef]

- Saricaoglu, F.T.; Atalar, I.; Yilmaz, V.A.; Odabas, H.I.; Gul, O. Application of multi pass high pressure homogenization to improve stability, physical and bioactive properties of rosehip (Rosa canina L.) nectar. Food Chem. 2019, 282, 67–75. [Google Scholar] [CrossRef] [PubMed]

- Staubmann, L.; Mistlberger-Reiner, A.; Raoui, E.M.; Brunner, G.; Sinawehl, L.; Winter, M.; Liska, R.; Pignitter, M. Combinations of hydrocolloids show enhanced stabilizing effects on cloudy orange juice ready-to-drink beverages. Food Hydrocoll. 2023, 138, 108436. [Google Scholar] [CrossRef]

- Zhong, Z.; Xiong, Y.L. Thermosonication-induced structural changes and solution properties of mung bean protein. Ultrason. Sonochem. 2020, 62, 104908. [Google Scholar] [CrossRef] [PubMed]

- Santana, M.C.D.; Ferreira, M.M.C.; Pallone, J.A.L. Control of ascorbic acid in fortified powdered soft drinks using near-infrared spectroscopy (NIRS) and multivariate analysis. J. Food Sci. Technol. 2020, 57, 1233–1241. [Google Scholar] [CrossRef] [PubMed]

- Pali, O.; Verma, A.; Gond, G.; Paikra, S. Formulation of recipe and organoleptic evaluation of carrot and sweet lime blended nectar beverage. J. Pharm. Innov. 2023, 12, 819–821. [Google Scholar]

- Codina-Torrella, I.; Guamis, B.; Zamora, A.; Quevedo, J.M.; Trujillo, A.J. Microbiological stabilization of tiger nuts’ milk beverage using ultra-high pressure homogenization. A preliminary study on microbial shelf-life extension. Food Microbiol. 2018, 69, 143–150. [Google Scholar] [CrossRef]

- Liu, J.; Wang, R.; Wang, X.; Yang, L.; Shan, Y.; Zhang, Q.; Ding, S. Effects of high-pressure homogenization on the structural, physical, and rheological properties of lily pulp. Foods 2019, 8, 472. [Google Scholar] [CrossRef]

- Augusto, P.E.; Ibarz, A.; Cristianini, M. Effect of high pressure homogenization (HPH) on the rheological properties of tomato juice: Time-dependent and steady-state shear. J. Food Eng. 2012, 111, 570–579. [Google Scholar] [CrossRef]

- Kruszewski, B.; Zawada, K.; Karpiński, P. Impact of high-pressure homogenization parameters on physicochemical characteristics, bioactive compounds content, and antioxidant capacity of blackcurrant juice. Molecules 2021, 26, 1802. [Google Scholar] [CrossRef] [PubMed]

- Gul, O.; Saricaoglu, F.T.; Atalar, I. Effect of high pressure homogenization on microstructure and rheological properties of hazelnut beverage cold-set gels induced glucono-δ-lactone. LWT 2021, 143, 111154. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Jiang, S.W.; Cao, X.M.; Jiang, S.T.; Pan, L.J. Effect of high pressure homogenization (HPH) on the physical properties of taro (Colocasia esculenta (L). Schott) pulp. J. Food Eng. 2016, 177, 1–8. [Google Scholar] [CrossRef]

- Ong, K.S.; Chiang, J.H.; Sim, S.Y.J.; Liebl, D.; Madathummal, M.; Henry, C.J. Functionalising insoluble pea protein aggregates using high-pressure homogenisation: Effects on physicochemical, microstructural and functional properties. Food Struct. 2022, 34, 100298. [Google Scholar] [CrossRef]

- Huang, X.; Yang, Y.; Liu, Q.; He, W.-Q. Effect of high pressure homogenization on sugar beet pulp: Physicochemical, thermal and structural properties. LWT 2020, 134, 110177. [Google Scholar] [CrossRef]

- Atencio, S.; Verkempinck, S.H.; Bernaerts, T.; Reineke, K.; Hendrickx, M.; Van Loey, A. Impact of processing on the production of a carotenoid-rich Cucurbita maxima cv. Hokkaido pumpkin juice. Food Chem. 2022, 380, 132191. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Guan, Y.; Bi, J.; Liu, X.; Yi, J.; Chen, Q.; Wu, X.; Zhou, M. Change of the rheological properties of mango juice by high pressure homogenization. LWT-Food Sci. Technol. 2017, 82, 121–130. [Google Scholar] [CrossRef]

- Zaaboul, F.; Raza, H.; Cao, C.; Yuanfa, L. The impact of roasting, high pressure homogenization and sterilization on peanut milk and its oil bodies. Food Chem. 2019, 280, 270–277. [Google Scholar] [CrossRef] [PubMed]

- Mercan, E.; Sert, D.; Akın, N. Determination of powder flow properties of skim milk powder produced from high-pressure homogenization treated milk concentrates during storage. LWT 2018, 97, 279–288. [Google Scholar] [CrossRef]

- Masson, L.M.; Rosenthal, A.; Calado, V.M.; Deliza, R.; Tashima, L. Effect of ultra-high pressure homogenization on viscosity and shear stress of fermented dairy beverage. LWT-Food Sci. Technol. 2011, 44, 495–501. [Google Scholar] [CrossRef]

- Nayak, M.; Pandey, V.; Shaw, S.; Makinde, O.; Ramadan, K.; Ben Henda, M.; Tlili, I. Thermo-fluidic significance of non Newtonian fluid with hybrid nanostructures. Case Stud. Therm. Eng. 2021, 26, 101092. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Jiang, S.W.; Cai, J.; Cao, X.M.; Zheng, Z.; Jiang, S.T.; Wang, H.L.; Pan, L.J. Effect of high pressure homogenization (HPH) on the rheological properties of taro (Colocasia esculenta (L). Schott) pulp. Innov. Food Sci. Emerg. Technol. 2018, 50, 160–168. [Google Scholar] [CrossRef]

- Jiao, B.; Wu, B.; Fu, W.; Guo, X.; Zhang, Y.; Yang, J.; Luo, X.; Dai, L.; Wang, Q. Effect of roasting and high-pressure homogenization on texture, rheology, and microstructure of walnut yogurt. Food Chem. X 2023, 20, 101017. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Xiao, D.; Lu, J.; Jiao, C.; Lei, Y.; Liu, D.; Wang, J.; Zhang, Z.; Liu, Y.; Shen, G.; et al. Effect of high-pressure homogenization on microstructure and properties of pomelo peel flour film-forming dispersions and their resultant films. Food Hydrocoll. 2020, 102, 105628. [Google Scholar] [CrossRef]

- Gul, O.; Saricaoglu, F.T.; Mortas, M.; Atalar, I.; Yazici, F. Effect of high pressure homogenization (HPH) on microstructure and rheological properties of hazelnut milk. Innov. Food Sci. Emerg. Technol. 2017, 41, 411–420. [Google Scholar] [CrossRef]

- Mei, J.; Feng, F.; Li, Y. Effective of different homogeneous methods on physicochemical, textural and sensory characteristics of soybean (Glycine max L.) yogurt. CyTA J. Food. 2017, 15, 21–26. [Google Scholar]

- Saricaoglu, F.T. Application of high-pressure homogenization (HPH) to modify functional, structural and rheological properties of lentil (Lens culinaris) proteins. Int. J. Biol. Macromol. 2020, 144, 760–769. [Google Scholar] [CrossRef]

- Tan, J.; Kerr, W.L. Rheological properties and microstructure of tomato puree subject to continuous high pressure homogenization. J. Food Eng. 2015, 166, 45–54. [Google Scholar] [CrossRef]

- Hu, K.; Chen, D.; Chen, M.; Xiang, A.; Xie, B.; Sun, Z. Effect of high pressure processing on gastrointestinal fate of carotenoids in mango juice: Insights obtained from macroscopic to microscopic scales. Innov. Food Sci. Emerg. 2023, 85, 103325. [Google Scholar] [CrossRef]

- Bi, C.-H.; Wang, P.-L.; Sun, D.-Y.; Yan, Z.-M.; Liu, Y.; Huang, Z.-G.; Gao, F. Effect of high-pressure homogenization on gelling and rheological properties of soybean protein isolate emulsion gel. J. Food Eng. 2020, 277, 109923. [Google Scholar] [CrossRef]

- da Silva, L.F.R.; Gomes, A.D.S.; Castro, D.R.G.; Souza, F.D.C.D.A.; Mar, J.M.; da Silva, L.S.; Sanches, E.A.; Bezerra, J.D.A.; Bakry, A.M.; Campelo, P.H. Ultrasound-assisted homogenization and gum Arabic combined to physicochemical quality of cupuaçu juice. J. Food Process. Preserv. 2019, 43, e14072. [Google Scholar] [CrossRef]

- Leite, T.S.; Augusto, P.E.D.; Cristianini, M. Using high pressure homogenization (HPH) to change the physical properties of cashew apple juice. Food Biophys. 2015, 10, 169–180. [Google Scholar] [CrossRef]

- Moon, J.H.; Yoon, W.B. Analysis of the Effect of High-Pressure Homogenization (HPH) on the Settling Velocity of Particles in an Alcoholic Rice Beverage Using Video Recording, Turbidity and Computational Fluid Dynamic Simulation. J. Texture Stud. 2015, 46, 74–86. [Google Scholar] [CrossRef]

- Kruszewski, B.; Domian, E.; Nowacka, M. Influence of High-Pressure Homogenization on the Physicochemical Properties and Betalain Pigments of Red Beetroot (Beta vulgaris L.) Juice. Molecules 2023, 28, 2018. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, L.; Yang, Y.; Gou, X.; Niu, P.; Guo, Y. Changes in the physicochemical properties, aromas and polyphenols of not from concentrate (NFC) apple juice during production. CyTA J. Food 2018, 16, 755–764. [Google Scholar] [CrossRef]

- Shao, Y.; Yuan, Y.; Xi, Y.; Zhao, T.; Ai, N. Effects of Homogenization on Organoleptic Quality and Stability of Pasteurized Milk Samples. Agriculture 2023, 13, 205. [Google Scholar] [CrossRef]

- Vasquez-Rojas, W.V.; Parralejo-Sanz, S.; Martin, D.; Fornari, T.; Cano, M.P. Validation of High-Pressure Homogenization Process to Pasteurize Brazil Nut (Bertholletia excelsa) Beverages: Sensorial and Quality Characteristics during Cold Storage. Beverages 2023, 9, 22. [Google Scholar] [CrossRef]

- Xia, X.; Dai, Y.; Wu, H.; Liu, X.; Wang, Y.; Cao, J.; Zhou, J. Effects of pressure and multiple passes on the physicochemical and microbial characteristics of lupin-based beverage treated with high-pressure homogenization. J. Food Process. Preserv. 2019, 43, e13912. [Google Scholar] [CrossRef]

- Sidhu, J.S.; Singh, R.K. Ultra high pressure homogenization of soy milk: Effect on quality attributes during storage. Beverages 2016, 2, 15. [Google Scholar] [CrossRef]

- Pérez-Conesa, D.; García-Alonso, J.; García-Valverde, V.; Iniesta, M.-D.; Jacob, K.; Sánchez-Siles, L.M.; Ros, G.; Periago, M.J. Changes in bioactive compounds and antioxidant activity during homogenization and thermal processing of tomato puree. Innov. Food Sci. Emerg. Technol. 2009, 10, 179–188. [Google Scholar] [CrossRef]

- Velázquez-Estrada, R.M.; Hernández-Herrero, M.M.; Rüfer, C.E.; Guamis-López, B.; Roig-Sagués, A.X. Influence of ultra high pressure homogenization processing on bioactive compounds and antioxidant activity of orange juice. Innov. Food Sci. Emerg. Technol. 2013, 18, 89–94. [Google Scholar] [CrossRef]

- Pisoschi, A.M.; Danet, A.F.; Kalinowski, S. Ascorbic acid determination in commercial fruit juice samples by cyclic voltammetry. J. Anal. Methods Chem. 2008, 2008, 937651. [Google Scholar] [CrossRef] [PubMed]

| Homogenisation Pressure | D10 (μm) | D50 (μm) | D90 (μm) | Particle Distribution Span |

|---|---|---|---|---|

| 0 MPa | 25.41 ± 0.02 a | 71.06 ± 0.29 a | 218.43 ± 9.99 a | 2.72 ± 0.13 e |

| 20 MPa | 6.44 ± 0.02 b | 32.92 ± 0.15 b | 84.69 ± 0.32 b | 2.38 ± 0.01 d |

| 40 MPa | 5.83 ± 0.02 c | 31.22 ± 0.13 c | 73.84 ± 0.15 c | 2.18 ± 0.05 c |

| 60 MPa | 2.68 ± 0.02 d | 15.82 ± 0.13 d | 51.27 ± 0.16 d | 3.07 ± 0.02 b |

| 80 MPa | 2.43 ± 0.02 e | 12.67 ± 0.07 e | 44.55 ± 0.34 de | 3.32 ± 0.01 a |

| 100 MPa | 2.33 ± 0.02 f | 10.94 ± 0.04 f | 39.49 ± 0.50 e | 3.40 ± 0.03 a |

| Homogenisation Pressure | Relative Turbidity (%) | PH | TSS (◦Brix) | Ascorbic Acid (mg·100 mL−1) |

|---|---|---|---|---|

| 0 MPa | 1.06 ± 0.16 c | 4.61 ± 0.03 a | 4.98 ± 0.31 c | 13.88 ± 1.78 a |

| 20 MPa | 5.15 ± 0.11 b | 4.55 ± 0.05 b | 5.63 ± 0.31 b | 13.60 ± 1.76 a |

| 40 MPa | 5.29 ± 0.20 b | 4.54 ± 0.04 b | 5.73 ± 0.25 b | 13.32 ± 1.28 a |

| 60 MPa | 9.08 ± 1.09 a | 4.51 ± 0.04 b | 6.27 ± 0.15 a | 13.03 ± 1.08 a |

| 80 MPa | 8.88 ± 0.76 a | 4.49 ± 0.05 b | 6.30 ± 0.26 a | 12.47 ± 0.88 ab |

| 100 MPa | 8.73 ± 0.29 a | 4.48 ± 0.03 b | 6.33 ± 0.25 a | 11.05 ± 0.69 b |

| Homogenisation Pressure | L* | a* | b* | ΔE |

|---|---|---|---|---|

| 0 MPa | 32.73 ± 0.54 d | −0.58 ± 0.35 a | −3.79 ± 0.02 a | 0.00 ± 0.00 d |

| 20 MPa | 35.88 ± 0.02 b | −0.77 ± 0.02 bc | −4.34 ± 0.08 b | 3.20 ± 0.03 b |

| 40 MPa | 36.31 ± 0.45 b | −0.73 ± 0.02 b | −4.30 ± 0.02 b | 3.62 ± 0.45 b |

| 60 MPa | 37.23 ± 0.51 a | −0.83 ± 0.02 e | −4.59 ± 0.05 c | 4.47 ± 0.50 a |

| 80 MPa | 36.44 ± 0.04 ab | −0.79 ± 0.02 de | −4.51 ± 0.04 c | 3.79 ± 0.05 b |

| 100 MPa | 35.09 ± 0.41 c | −0.73 ± 0.02 bc | −4.34 ± 0.10 b | 2.42 ± 0.41 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.; Qiu, X.; Pei, Y.; Zhang, Z.; Liu, G.; Luan, J.; Nie, J.; Li, X. Physical Stability of Lotus Seed and Lily Bulb Beverage: The Effects of Homogenisation on Particle Size Distribution, Microstructure, Rheological Behaviour, and Sensory Properties. Foods 2024, 13, 769. https://doi.org/10.3390/foods13050769

Su J, Qiu X, Pei Y, Zhang Z, Liu G, Luan J, Nie J, Li X. Physical Stability of Lotus Seed and Lily Bulb Beverage: The Effects of Homogenisation on Particle Size Distribution, Microstructure, Rheological Behaviour, and Sensory Properties. Foods. 2024; 13(5):769. https://doi.org/10.3390/foods13050769

Chicago/Turabian StyleSu, Jiajia, Xiaokun Qiu, Yi Pei, Zhuo Zhang, Guanghui Liu, Jiaojiao Luan, Jiangli Nie, and Xihong Li. 2024. "Physical Stability of Lotus Seed and Lily Bulb Beverage: The Effects of Homogenisation on Particle Size Distribution, Microstructure, Rheological Behaviour, and Sensory Properties" Foods 13, no. 5: 769. https://doi.org/10.3390/foods13050769

APA StyleSu, J., Qiu, X., Pei, Y., Zhang, Z., Liu, G., Luan, J., Nie, J., & Li, X. (2024). Physical Stability of Lotus Seed and Lily Bulb Beverage: The Effects of Homogenisation on Particle Size Distribution, Microstructure, Rheological Behaviour, and Sensory Properties. Foods, 13(5), 769. https://doi.org/10.3390/foods13050769