Real-Time Monitoring of Dough Quality in a Dough Mixer Based on Current Change

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Dough

2.3. Tensile Properties of the Dough

2.4. Measurement of the Change in Current in the Blending Process

2.5. Low Field Nuclear Magnetic Resonance (LF-NMR)

2.6. Dough Texture Analysis

2.7. Confocal Laser Scanning Microscopy (CLSM) Analysis

2.8. Scanning Electron Microscopy (SEM) Analysis

2.9. Final Noodle Quality

2.10. Statistical Analysis

3. Results and Discussion

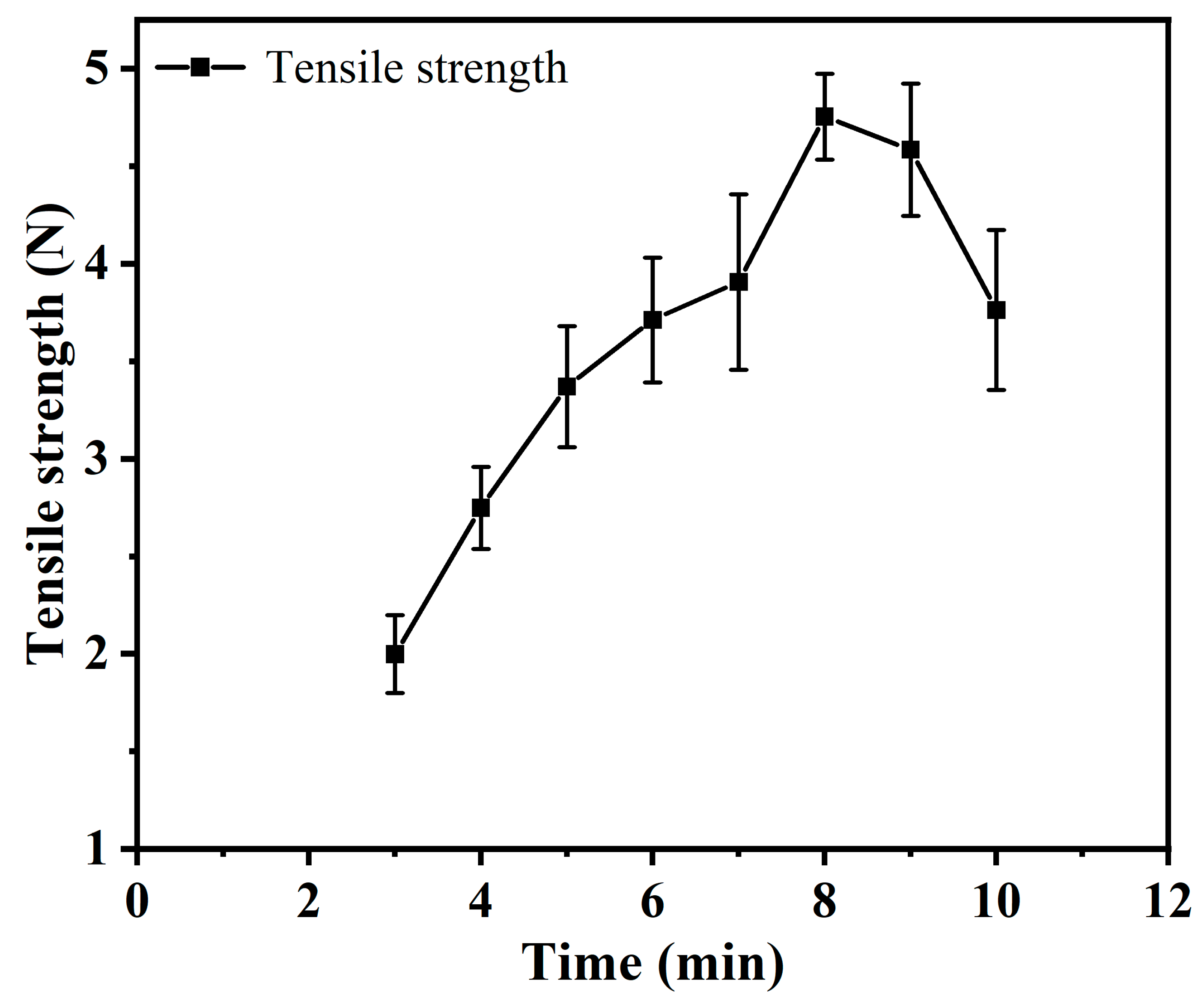

3.1. Analysis of the Tensile Capacity of the Dough

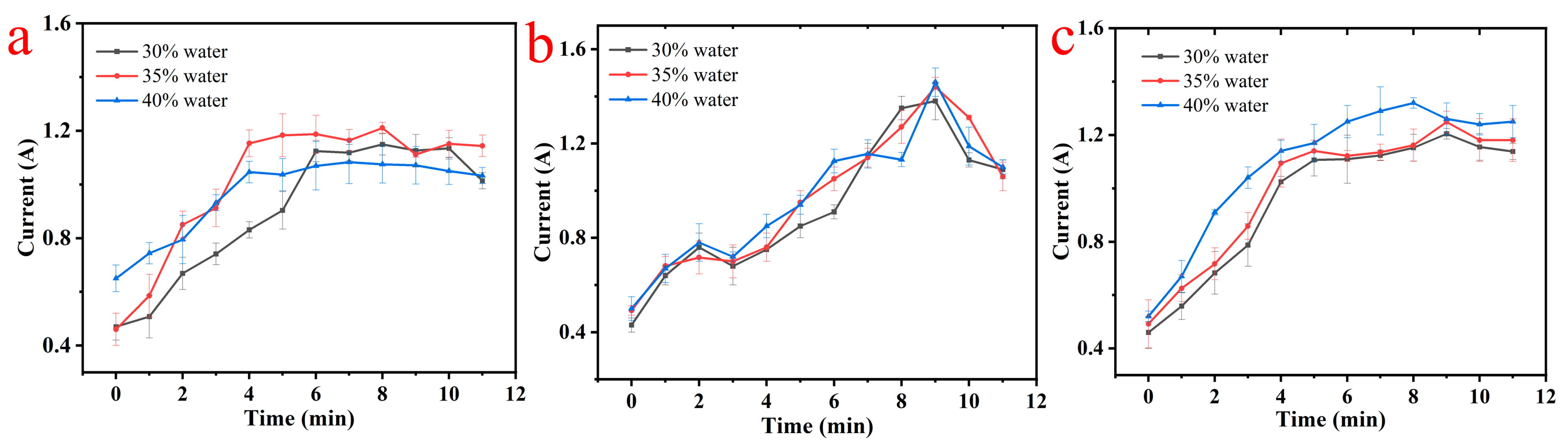

3.2. Measurement of Motor Current

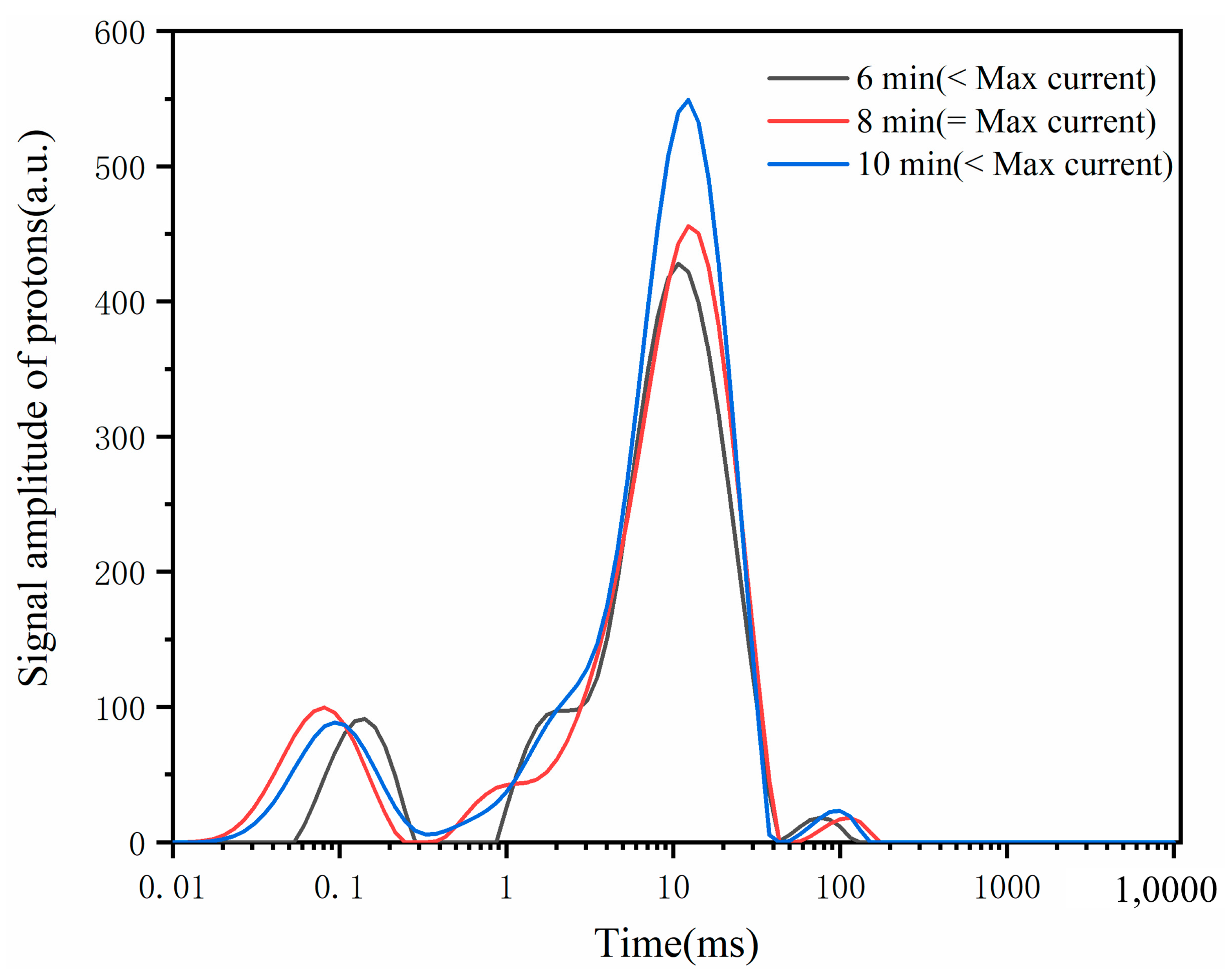

3.3. Dough Moisture Distribution

3.4. Dough Texture Analysis (TPA)

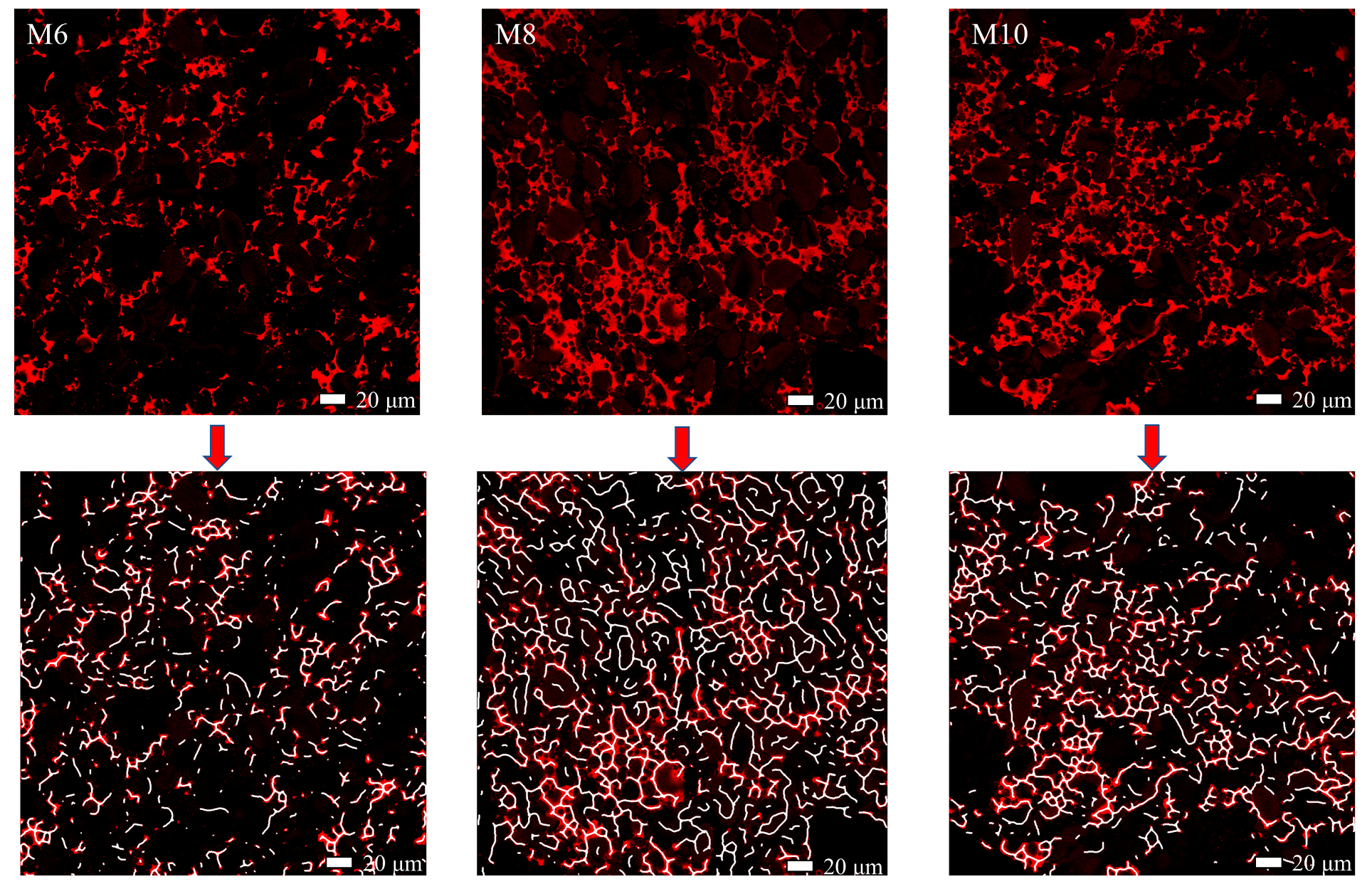

3.5. Confocal Laser Scanning Microscopy (CLSM) Analysis

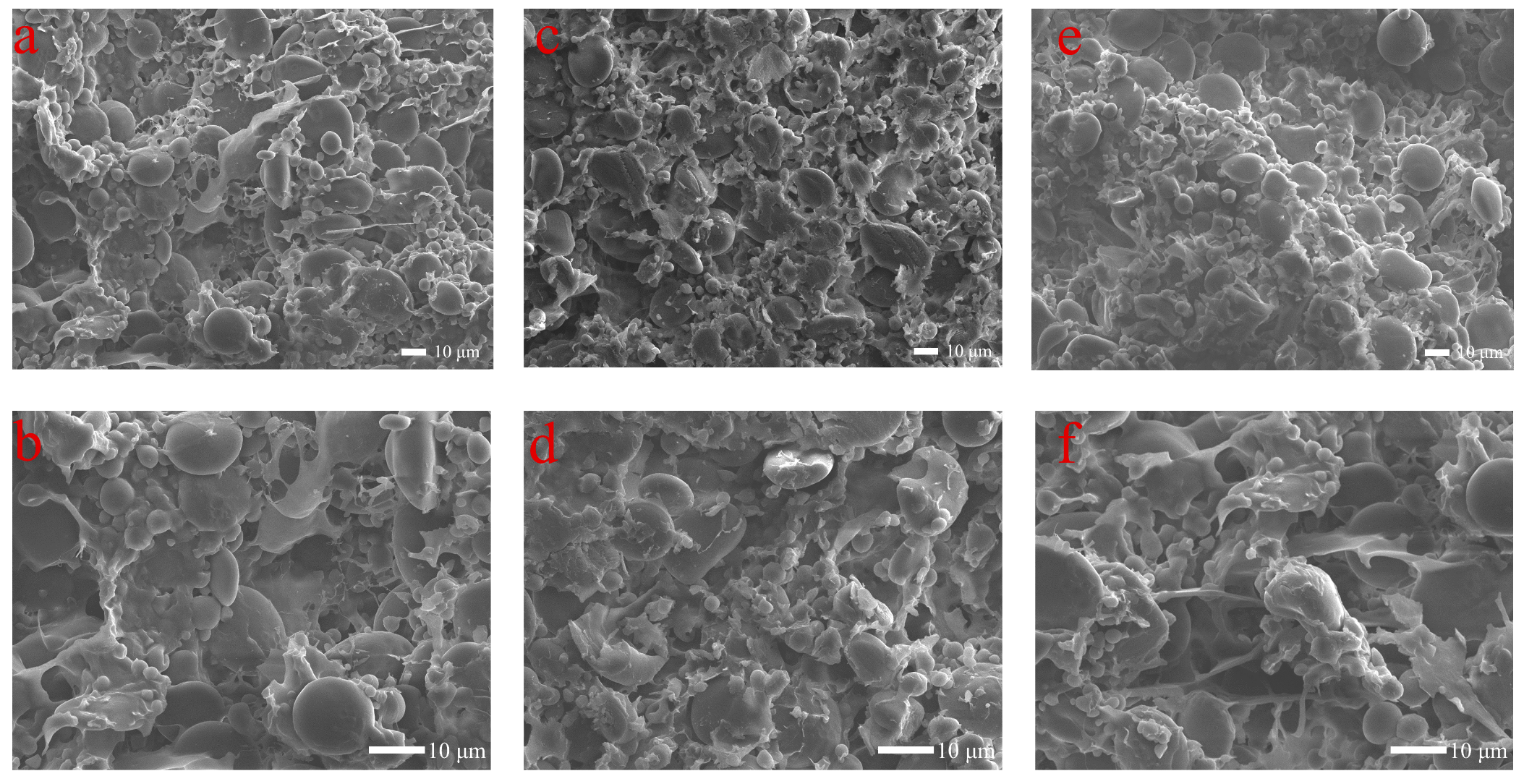

3.6. Scanning Electron Microscopy (SEM)

3.7. Comparison of Methods for Determining the Optimal Mixing Time

3.8. The Cooking Quality of Noodles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Obadi, M.; Zhang, J.; He, Z.; Zhu, S.; Wu, Q.; Qi, Y.; Xu, B. A review of recent advances and techniques in the noodle mixing process. LWT 2022, 154, 112680. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, M.; Jia, R.; Yang, T.; Sun, Q.; Li, M. Delineating the dynamic transformation of gluten morphological distribution, structure, and aggregation behavior in noodle dough induced by mixing and resting. Food Chem. 2022, 386, 132853. [Google Scholar] [CrossRef] [PubMed]

- Parenti, O.; Guerrini, L.; Mompin, S.B.; Toldrà, M.; Zanoni, B. The determination of bread dough readiness during kneading of wheat flour: A review of the available methods. J. Food Eng. 2021, 309, 110692. [Google Scholar] [CrossRef]

- He, Y.; Wang, A.; Chen, Z.; Nie, M.; Xi, H.; Gong, X.; Liu, L.; Wang, L.; Sun, J.; Bai, Y.; et al. Effects of egg powder on the structure of highland barley dough and the quality of highland barley bread. Int. J. Biol. Macromol. 2023, 240, 124376. [Google Scholar] [CrossRef] [PubMed]

- Della Valle, G.; Dufour, M.; Hugon, F.; Chiron, H.; Saulnier, L.; Kansou, K. Rheology of wheat flour dough at mixing. Curr. Opin. Food Sci. 2022, 47, 100873. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Li, L.; Xiang, L.; Zhao, L.; Liu, J.; Liu, S.; Yang, Q.; Wu, J.; Chen, X. Effect of gliadin from Psathrostachys huashanica on dough rheological properties and biscuit quality. Food Chem. 2023, 425, 136537. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Xing, Y.; Zhang, Y.; Zhang, B.; Jiang, X.; Wei, Y. Effect of mixing time on the structural characteristics of noodle dough under vacuum. Food Chem. 2015, 188, 328–336. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Al-Ansi, W.; Zhu, F.; Fan, M.; Li, Y.; Qian, H.; Wang, L. A novel kneading method for improving the quality of whole wheat dough and bread. J. Cereal Sci. 2023, 112, 103690. [Google Scholar] [CrossRef]

- Nirmala Prasadi, V.P.; Joye, I.J. Effect of soluble dietary fibre from barley on the rheology, water mobility and baking quality of wheat flour dough. J. Cereal Sci. 2023, 112, 103715. [Google Scholar] [CrossRef]

- Daniela, C.A.; Victoria, S.M.; Cecilia, P.M. Production of legume-wheat dough of optimum quality for breadmaking: Essential analyses required. Curr. Opin. Food Sci. 2023, 49, 100970. [Google Scholar] [CrossRef]

- Sun, X.; Wu, S.; Koksel, F.; Xie, M.; Fang, Y. Effects of ingredient and processing conditions on the rheological properties of whole wheat flour dough during breadmaking—A review. Food Hydrocoll. 2023, 135, 108123. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, Y.; Xu, B.; Jiang, S. Insight of the non-linear viscoelasticity of noodle dough using large amplitude oscillatory extension tests and the correlation with noodle quality. J. Food Eng. 2023, 341, 111320. [Google Scholar] [CrossRef]

- Shehzad, A.; Chiron, H.; Della Valle, G.; Lamrini, B.; Lourdin, D. Energetical and rheological approaches of wheat flour dough mixing with a spiral mixer. J. Food Eng. 2012, 110, 60–70. [Google Scholar] [CrossRef]

- Venturi, M.; Cappelli, A.; Pini, N.; Galli, V.; Lupori, L.; Granchi, L.; Cini, E. Effects of kneading machine type and total element revolutions on dough rheology and bread characteristics: A focus on straight dough and indirect (biga) methods. LWT 2022, 153, 112500. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, Y.; Xu, B.; Jiang, S. Analysis of the effect of rolling speed on the texture properties of noodle dough from water-solid interaction, development of gluten network, and bubble distribution. Food Chem. 2022, 404, 134359. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Yan, M.; Liu, X.; Ge, X.; Zeng, J.; Gao, H.; Zhang, G.; Li, W. Wheat starch particle size distribution regulates the dynamic transition behavior of gluten at different stages of dough mixing. Int. J. Biol. Macromol. 2023, 244, 125371. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Wang, L.; Ou, X.; Huang, J.; Luan, G. Structural support of zein network to rice flour gluten-free dough: Rheological, textural and thermal properties. Food Hydrocoll. 2023, 141, 108721. [Google Scholar] [CrossRef]

- Liu, L.; Hu, X.; Zou, L. Wheat polysaccharides and gluten effect on water migration and structure in noodle doughs: An 1H LF-NMR study. J. Cereal Sci. 2023, 110, 103628. [Google Scholar] [CrossRef]

- Xie, D.; Li, X.; Sun, Y.; Ren, S. Effect of different producing methods on physicochemical and fermentation properties of refrigerated dough. J. Food Compos. Anal. 2023, 119, 105268. [Google Scholar] [CrossRef]

- Liu, D.; Song, S.; Tao, L.; Yu, L.; Wang, J. Effects of common buckwheat bran on wheat dough properties and noodle quality compared with common buckwheat hull. LWT 2022, 155, 112971. [Google Scholar] [CrossRef]

- Lancelot, E.; Fontaine, J.; Grua-Priol, J.; Assaf, A.; Thouand, G.; Le-Bail, A. Study of structural changes of gluten proteins during bread dough mixing by Raman spectroscopy. Food Chem. 2021, 358, 129916. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Sun, Y.; Obadi, M.; Jiang, Y.; Chen, Z.; Jiang, S.; Xu, B. Effects of vacuum mixing and mixing time on the processing quality of noodle dough with high oat flour content. J. Cereal Sci. 2020, 91, 102885. [Google Scholar] [CrossRef]

- Yang, Y.-l.; Guan, E.-q.; Zhang, T.-j.; Xu, F.; Li, M.-m.; Bian, K. Behavior of wheat flour dough at different pretreated temperatures through rheological characteristics and molecular interactions of proteins. Food Chem. 2022, 404, 134188. [Google Scholar] [CrossRef] [PubMed]

- de la Peña, E.; Manthey, F.A.; Patel, B.K.; Campanella, O.H. Rheological properties of pasta dough during pasta extrusion: Effect of moisture and dough formulation. J. Cereal Sci. 2014, 60, 346–351. [Google Scholar] [CrossRef]

- Jia, R.; Zhang, M.; Yang, T.; Ma, M.; Sun, Q.; Li, M. Evolution of the morphological, structural, and molecular properties of gluten protein in dough with different hydration levels during mixing. Food Chem. X 2022, 15, 100448. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Zhang, Y.; Wu, L.; Xing, Y.; Kong, Y.; Sun, J.; Wei, Y. Impact of vacuum mixing on protein composition and secondary structure of noodle dough. LWT Food Sci. Technol. 2017, 85, 197–203. [Google Scholar] [CrossRef]

- Han, C.; Ma, M.; Yang, T.; Li, M.; Sun, Q. Heat mediated physicochemical and structural changes of wheat gluten in the presence of salt and alkali. Food Hydrocoll. 2021, 120, 106971. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, M.; Yang, T.; Li, M.; Sun, Q. Dynamic distribution and transition of gluten proteins during noodle processing. Food Hydrocoll. 2022, 123, 107114. [Google Scholar] [CrossRef]

| <Max. Current (=6 min) | =Max. Current (=8 min) | <Max. Current (=10 min) | |

|---|---|---|---|

| T21 (ms) | 0.22 ± 0.01 c | 0.26 ± 0.06 a | 0.23 ± 0.01 b |

| T22 (ms) | 42.15 ± 0.54 b | 45.03 ± 0.36 a | 42.96 ± 0.01 b |

| T23 (ms) | 88.59 ± 3.71 c | 117.40 ± 1.30 a | 108.70 ± 0.00 b |

| A21 (%) | 10.75 ± 0.70 c | 14.25 ± 0.51 a | 12.01 ± 1.01 b |

| A22 (%) | 88.07 ± 0.5 a | 84.67 ± 0.64 c | 86.70 ± 0.24 b |

| A23 (%) | 1.18 ± 0.20 b | 1.08 ± 0.18 c | 1.29 ± 0.17 a |

| <Max. Current (=6 min) | =Max. Current (=8 min) | <Max. Current (=10 min) | |

|---|---|---|---|

| hardness | 3579.12 ± 700 b | 4109.18 ± 975 a | 3025.98 ± 262 c |

| adhesiveness | 2550.59 ± 211 a | 5567.25 ± 210 a | 3261.14 ± 369 b |

| resilience | 8.50 ± 1.28 b | 10.08 ± 2.33 a | 8.88 ± 0.80 b |

| cohesion | 0.29 ± 0.03 b | 0.61 ± 0.07 a | 0.57 ± 0.04 a |

| springiness | 19.00 ± 3.48 c | 84.66 ± 9.78 a | 55.17 ± 4.63 b |

| gumminess | 1036.79 ± 297 c | 2103.12 ± 197 a | 1725.77 ± 226 b |

| chewiness | 204.77 ± 97 c | 1564.31 ± 513 a | 1006.58 ± 117 b |

| <Max. Current (=6 min) | =Max. Current (=8 min) | >Max. Current (=10 min) | |

|---|---|---|---|

| Gluten percentage area (%) | 18.22 ± 3.08 c | 25.26 ± 2.27 a | 23.07 ± 3.48 b |

| Gluten junctions | 180.25 ± 55.77 c | 299.25 ± 55.71 b | 327.75 ± 52.0 a |

| Total gluten length (×103 μm) | 15.88 ± 3.51 b | 21.06 ± 2.5 a | 21.56 ± 2.81 a |

| Average gluten length (μm) | 54.45 ± 0.88 c | 103.24 ± 2.21 a | 79.28 ± 2.72 b |

| Lacunarity (×10−2) | 28.73 ± 2.02 a | 22.02 ± 1.28 b | 22.64 ± 2.31 b |

| Branching rate (×10−3) | 1.95 ± 0.23 b | 2.28 ± 0.22 a | 1.96 ± 0.27 b |

| 8 Min | Maximum Current | |

|---|---|---|

| Hardness | 3551.63 ± 276 b | 4197.60 ± 188 a |

| Adhesiveness | 4109.14 ± 140 a | 4157.73 ± 134 a |

| Resilience | 11.36 ± 0.96 a | 12.73 ± 0.82 a |

| Cohesion | 0.58 ± 0.07 b | 0.69 ± 0.02 a |

| Springiness | 73.47 ± 2.48 b | 89.14 ± 11.11 a |

| Gumminess | 2458.65 ± 321 a | 2519.63 ± 43 a |

| Chewiness | 1664.38 ± 206 b | 1847.58 ± 76 a |

| Gluten percentage area (%) | 21.16 ± 2.29 b | 25.92 ± 2.42 a |

| Gluten junctions | 315.30 ± 12.83 b | 338.75 ± 34.06 a |

| Total gluten length (×103 μm) | 17.42 ± 1.29 a | 18.20 ± 2.40 a |

| Average gluten length (μm) | 68.29 ± 10.74 b | 74.58 ± 7.34 a |

| Lacunarity (×10−2) | 26.79 ± 1.49 a | 28.73 ± 1.98 a |

| Branching rate (×10−3) | 1.86 ± 0.26 a | 2.13 ± 0.30 a |

| A21 (%) | 9.62 ± 1.18 b | 13.67 ± 0.82 a |

| A22 (%) | 89.23 ± 5.08 b | 85.12 ± 4.83 a |

| A23 (%) | 1.15 ± 0.14 a | 1.21 ± 0.19 a |

| Optimum Cooking Time (s) | Cooking Loss Rate (%) | |

|---|---|---|

| <Max. current | 210 | 13.86 ± 0.34 a |

| =Max. current | 280 | 8.34 ± 0.49 c |

| >Max. current | 280 | 9.73 ± 0.56 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Zhou, X.; Li, W.; Liang, J.; Huang, X.; Li, Z.; Zhang, X.; Zou, X.; Xu, B.; Shi, J. Real-Time Monitoring of Dough Quality in a Dough Mixer Based on Current Change. Foods 2024, 13, 504. https://doi.org/10.3390/foods13030504

Wang W, Zhou X, Li W, Liang J, Huang X, Li Z, Zhang X, Zou X, Xu B, Shi J. Real-Time Monitoring of Dough Quality in a Dough Mixer Based on Current Change. Foods. 2024; 13(3):504. https://doi.org/10.3390/foods13030504

Chicago/Turabian StyleWang, Wei, Xiaoling Zhou, Wenlong Li, Jing Liang, Xiaowei Huang, Zhihua Li, Xinai Zhang, Xiaobo Zou, Bin Xu, and Jiyong Shi. 2024. "Real-Time Monitoring of Dough Quality in a Dough Mixer Based on Current Change" Foods 13, no. 3: 504. https://doi.org/10.3390/foods13030504

APA StyleWang, W., Zhou, X., Li, W., Liang, J., Huang, X., Li, Z., Zhang, X., Zou, X., Xu, B., & Shi, J. (2024). Real-Time Monitoring of Dough Quality in a Dough Mixer Based on Current Change. Foods, 13(3), 504. https://doi.org/10.3390/foods13030504