Quantitative Assessment of Volatile Profile and Sensory Perception of Artisan Bread Made in the City of Valencia

Abstract

1. Introduction

2. Materials and Methods

2.1. Bakeries and Samples Collection

2.2. Determination of pH, TTA, and Organic Acids

2.3. Volatile Compounds Analysis

2.4. Descriptive Analysis

2.4.1. Selection of Terms

2.4.2. Panel Training

2.4.3. Formal Assessment

2.5. Statistical Analysis

3. Results and Discussion

3.1. Recipes of Artisan Breads

3.2. Biochemical Characterization of Bread Dough

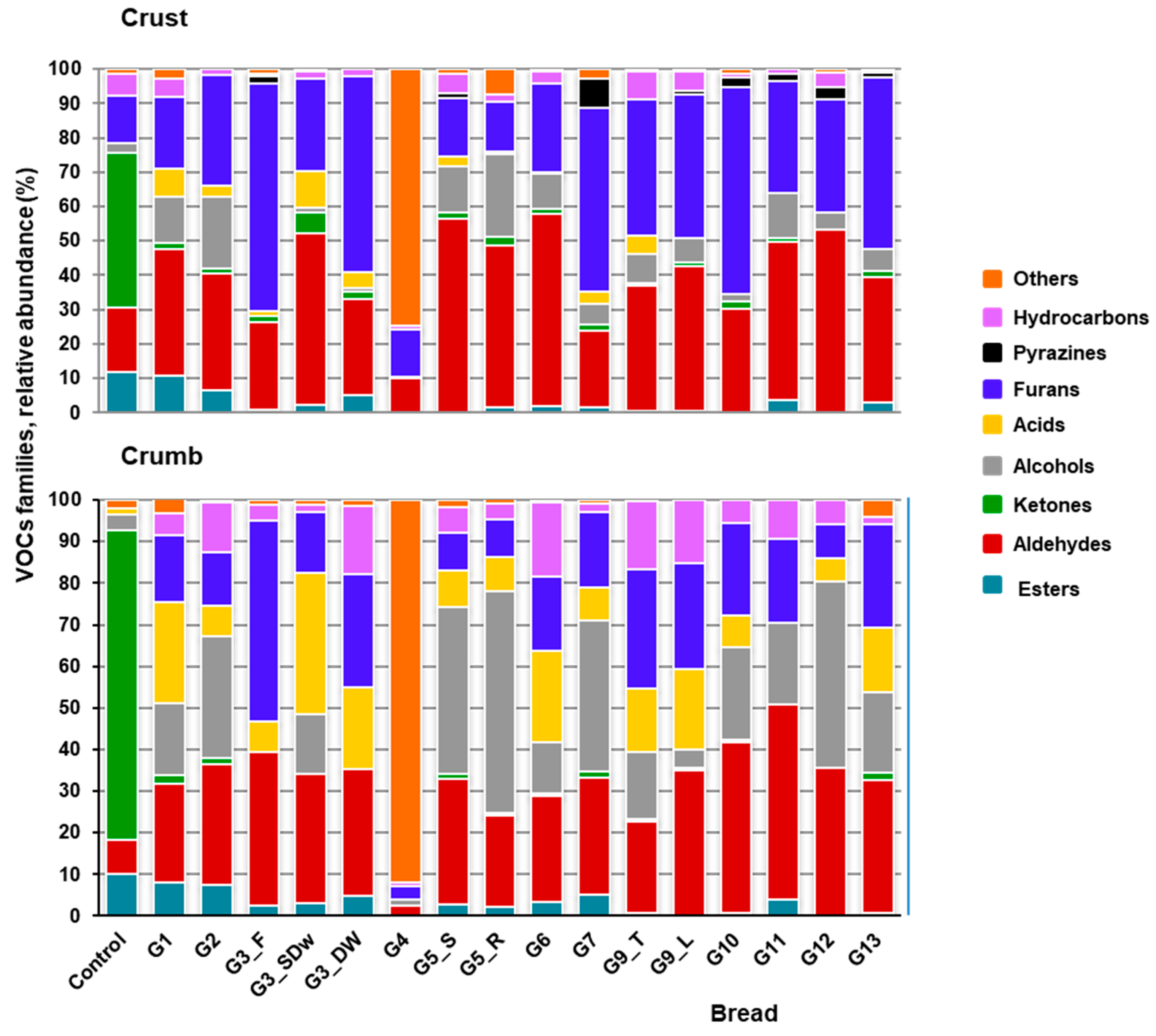

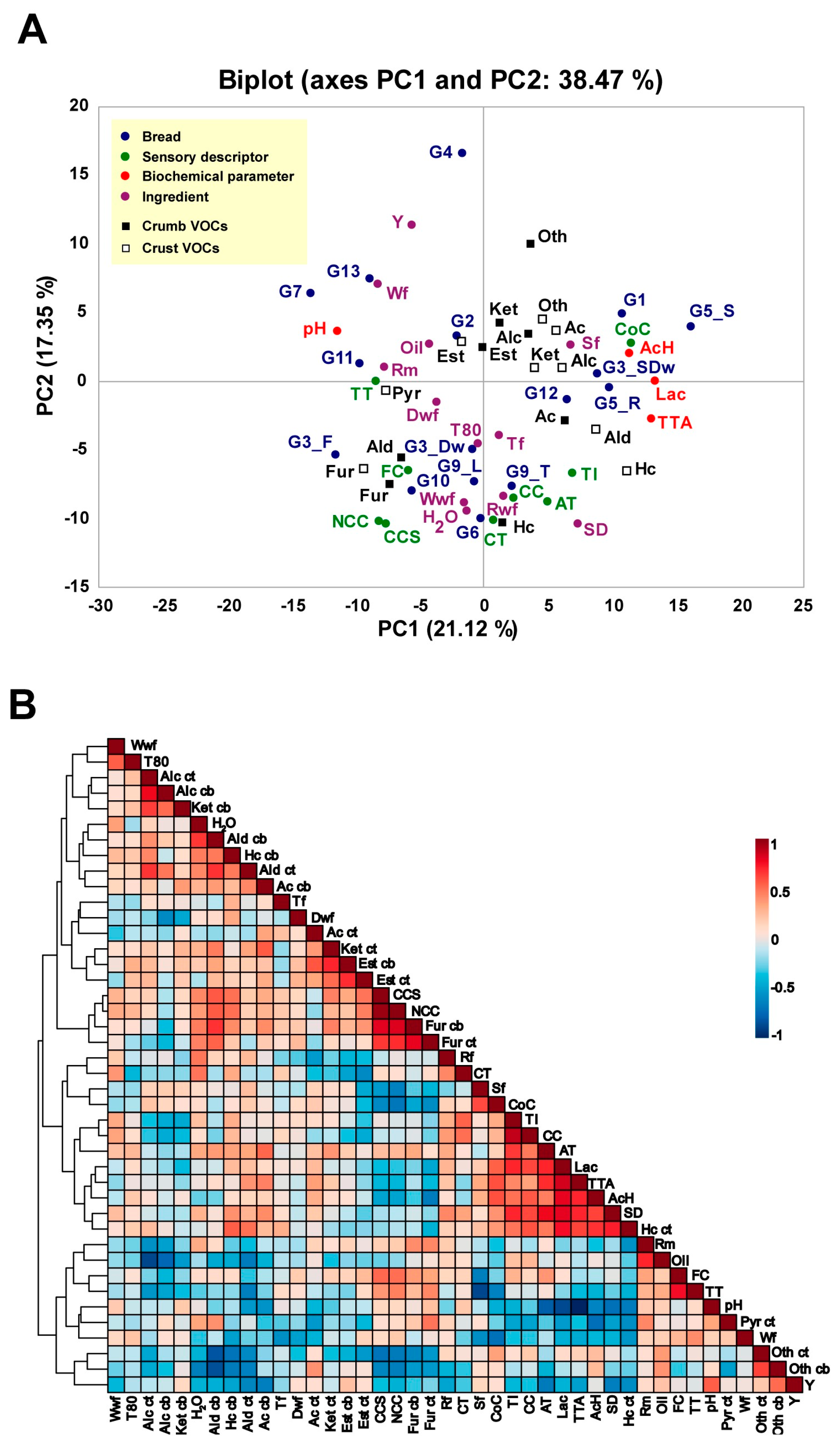

3.3. Volatile Profile of Artisan Bread: From Crumb to Crust

3.4. Influence of Ingredients on Volatile Profile

3.5. Sensory Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Escurriol Martinez, V.; Binimelis, R.; Rivera-Ferre, M.G. The Situation of rural women in Spain: The case of small-scale artisan food producers. Athenea Digit.—Rev. De Pensam. E Investig. Soc. 2014, 14, 3–22. [Google Scholar] [CrossRef][Green Version]

- Lingham, S.; Hill, I.; Manning, L. Artisan Food Production: What Makes Food ‘Artisan’? In Artisan and Handicraft Entrepreneurs; Dana, L.P., Ramadani, V., Palalic, R., Salamzadeh, A., Eds.; Contributions to Management Science; Springer: Cham, Switzerland, 2022; pp. 101–117. [Google Scholar] [CrossRef]

- Ross, A.S. Flour Quality and Artisan Bread. Cereal Foods World 2018, 63, 56–62. [Google Scholar] [CrossRef]

- Nicolosi, A.; Laganà, V.R.; Di Gregorio, D. Habits, Health and Environment in the Purchase of Bakery Products: Consumption Preferences and Sustainable Inclinations before and during COVID-19. Foods 2023, 12, 1661. [Google Scholar] [CrossRef] [PubMed]

- Heenan, S.P.; Dufour, J.P.; Hamid, N.; Harvey, W.; Delahunty, C.M. Characterisation of fresh bread flavour: Relationships between sensory characteristics and volatile composition. Food Chem. 2009, 116, 249–257. [Google Scholar] [CrossRef]

- Pico, J.; Bernal, J.; Gómez, M. Wheat bread aroma compounds in crumb and crust: A review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef]

- Pétel, C.; Onno, B.; Prost, C. Sourdough volatile compounds and their contribution to bread: A review. Trends Food Sci. Technol. 2017, 59, 105–123. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Hansen, Å.S. Aroma of Wheat Bread Crumb. Cereal Chem. 2014, 91, 105–114. [Google Scholar] [CrossRef]

- Cho, I.H.; Peterson, D.G. Chemistry of bread aroma: A review. Food Sci. Biotechnol. 2010, 19, 575–582. [Google Scholar] [CrossRef]

- Prost, C.; Poinot, P.; Arvisenet, G.; Rannou, C. Bread aroma. In Woodhead Publishing Series in Food Science, Technology and Nutrition, Breadmaking, 3rd ed.; Cauvain, S.P., Ed.; Woodhead Publishing: Sawston, UK, 2020; pp. 467–515. [Google Scholar] [CrossRef]

- Makhoul, S.; Romano, A.; Capozzi, V.; Spano, G.; Aprea, E.; Cappellin, L.; Benozzi, E.; Scampicchio, M.; Märk, T.D.; Gasperi, F.; et al. Volatile Compound Production During the Bread-Making Process: Effect of Flour, Yeast and Their Interaction. Food Bioproc. Technol. 2015, 8, 1925–1937. [Google Scholar] [CrossRef]

- Heitmann, M.; Zannini, E.; Axel, C.; Arendt, E. Correlation of Flavor Profile to Sensory Analysis of Bread Produced with Different Saccharomyces cerevisiae Originating from the Baking and Beverage Industry. Cerea Chem. 2017, 94, 746–751. [Google Scholar] [CrossRef]

- Sánchez-Adriá, I.E.; Sanmartín, G.; Prieto, J.A.; Estruch, F.; Fortis, E.; Randez-Gil, F. Technological and acid stress performance of yeast isolates from industrial sourdough. LWT 2023, 184, 114957. [Google Scholar] [CrossRef]

- Sanmartín, G.; Sánchez-Adriá, I.E.; Prieto, J.A.; Estruch, F.; Randez-Gil, F. Bioprospecting of sourdough microbial species from artisan bakeries in the city of Valencia. Food Microbiol. 2024, 120, 104474. [Google Scholar] [CrossRef] [PubMed]

- Venturi, F.; Sanmartin, C.; Taglieri, I.; Nari, A.; Andrich, G.; Zinnai, A. Effect of the baking process on artisanal sourdough bread-making: A technological and sensory evaluation. Agrochimica 2016, 60, 222–234. [Google Scholar] [CrossRef]

- Annett, L.E.; Spaner, D.; Wismer, W.V. Sensory profiles of bread made from paired samples of organic and conventionally grown wheat grain. J. Food Sci. 2007, 72, S254–S260. [Google Scholar] [CrossRef]

- Longin, C.F.H.; Afzal, M.; Pfannstiel, J.; Bertsche, U.; Melzer, T.; Ruf, A.; Heger, C.; Pfaff, T.; Schollenberger, M.; Rodehutscord, M. Mineral and Phytic Acid Content as Well as Phytase Activity in Flours and Breads Made from Different Wheat Species. Int. J. Mol. Sci. 2023, 24, 2770. [Google Scholar] [CrossRef]

- Rapp, M.; Beck, H.; Gütler, H.; Heilig, W.; Starck, N.; Römer, P.; Cuendet, C.; Uhlig, F.; Kurz, H.; Würschum, T.; et al. Spelt: Agronomy.; quality, and flavor of its breads from 30 varieties tested across multiple environments. Crop Sci. 2017, 57, 739–747. [Google Scholar] [CrossRef]

- Raffo, A.; Carcea, M.; Moneta, E.; Narducci, V.; Nicoli, S. Influence of different levels of sodium chloride of a reduced sodium salt substitute on volatiles formation and sensory quality of wheat bread. J. Cereal Sci. 2018, 79, 519–526. [Google Scholar] [CrossRef]

- Belz, M.C.E.; Axel, C.; Beauchamp, J.; Zannini, E.; Arendt, E.K.; Czerny, M. Sodium Chloride and Its Influence on the Aroma Profile of Yeasted Bread. Foods 2017, 6, 66. [Google Scholar] [CrossRef]

- Barbarisi, C.; De Vito, V.; Pellicano, M.P.; Boscaino, F.; Balsamo, S.; Laurino, C.; Sorrentino, G.; Volpe, M.G. Bread chemical and nutritional characteristics as influenced by food grade sea water. Int. J. Food Prop. 2019, 22, 280–289. [Google Scholar] [CrossRef]

- Chambers, E., 4th; Koppel, K. Associations of volatile compounds with sensory aroma and flavor: The complex nature of flavor. Molecules 2013, 18, 4887–4905. [Google Scholar] [CrossRef]

- Alfonzo, A.; Ventimiglia, G.; Corona, O.; Di Gerlando, R.; Gaglio, R.; Francesca, N.; Moschetti, G.; Settanni, L. Diversity and technological potential of lactic acid bacteria of wheat flours. Food Microbiol. 2013, 36, 343–354. [Google Scholar] [CrossRef] [PubMed]

- Stone, H.; Sidel, J. Sensory Evaluation Practices, 3rd ed.; Academic Press: London, UK, 2004; p. 408. [Google Scholar]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; Volume 2. [Google Scholar]

- Pang, Z.; Lu, Y.; Zhou, G.; Hui, F.; Xu, L.; Viau, C.; Spigelman, A.F.; MacDonald, P.E.; Wishart, D.S.; Li, S.; et al. MetaboAnalyst 6.0: Towards a unified platform for metabolomics data processing, analysis and interpretation. Nucleic Acids Res. 2024, 52, W398–W406. [Google Scholar] [CrossRef]

- Maurice, B.; Saint-Eve, A.; Pernin, A.; Leroy, P.; Souchon, I. How Different Are Industrial, Artisanal and Homemade Soft Breads? Foods 2022, 11, 1484. [Google Scholar] [CrossRef] [PubMed]

- Gobbetti, M.; De Angelis, M.; Di Cagno, R.; Calasso, M.; Archetti, G.; Rizzello, C.G. Novel insights on the functional/nutritional features of the sourdough fermentation. Int. J. Food Microbiol. 2019, 302, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Calvert, M.D.; Madden, A.A.; Nichols, L.M.; Haddad, N.M.; Lahne, J.; Dunn, R.R.; McKenney, E.A. A review of sourdough starters: Ecology, practices, and sensory quality with applications for baking and recommendations for future research. Peer J. 2021, 9, e11389. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Alvarado, O.; Zepeda-Hernández, A.; Garcia-Amezquita, L.E.; Requena, T.; Vinderola, G.; García-Cayuela, T. Role of lactic acid bacteria and yeasts in sourdough fermentation during bread making: Evaluation of postbiotic-like components and health benefits. Front. Microbiol. 2022, 13, 969460. [Google Scholar] [CrossRef]

- De Vuyst, L.; Comasio, A.; Kerrebroeck, S.V. Sourdough production: Fermentation strategies, microbial ecology, and use of non-flour ingredients. Crit. Rev. Food Sci. Nutr. 2023, 63, 2447–2479. [Google Scholar] [CrossRef]

- Arora, K.; Ameur, H.; Polo, A.; Di Cagno, R.; Rizzello, C.G.; Gobbetti, M. Thirty years of knowledge on sourdough fermentation: A systematic review. Trend Food Sci. Tech. 2021, 108, 71–83. [Google Scholar] [CrossRef]

- Buehler, E. Bread Science: The Chemistry and Craft of Making Bread; Two Blue Books publishing: Hillsborough, NC, USA, 2021; Available online: https://www.goodreads.com/book/show/23981874-bread-science (accessed on 2 September 2024).

- Siepmann, F.; Sousa de Almeida, B.; Waszczynskyj, N.; Spier, M.R. Influence of Temperature and of Starter Culture on Biochemical Characteristics and the Aromatic Compounds Evolution on Type II Sourdough and Wheat Bread. LWT 2019, 108, 199–206. [Google Scholar] [CrossRef]

- Ren, A.; Zhang, Y.; Bian, Y.; Liu, Y.J.; Zhang, Y.X.; Ren, C.J.; Zhou, Y.; Zhang, T.; Feng, X.S. Pyrazines in food samples: Recent update on occurrence, formation, sampling, pretreatment and analysis methods. Food Chem. 2024, 430, 137086. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Mathematical and statistical properties of sample principal components. In Principal Component Analysis; Springer Series in Statistics; Springer: New York, NY, USA, 2002. [Google Scholar] [CrossRef]

- Lawless, H.; Heymann, H. Sensory Evaluation of Food; Springer: New York, NY, USA, 2010; Volume 1. [Google Scholar]

- Ficco, D.B.M.; Saia, S.; Beleggia, R.; Fragasso, M.; Giovanniello, V.; De Vita, P. Milling overrides cultivar, leavening agent and baking mode on chemical and rheological traits and sensory perception of durum wheat breads. Sci. Rep. 2017, 7, 13632. [Google Scholar] [CrossRef]

- Su, X.; Wu, F.; Zhang, Y.; Yang, N.; Chen, F.; Jin, Z.; Xu, X. Effect of organic acids on bread quality improvement. Food Chem. 2019, 278, 267–275. [Google Scholar] [CrossRef]

| Bread 1 | Denomination 2 | Origin | N° Ingredients | Bakery | Ingredients 3,4 | % (f.b.) |

|---|---|---|---|---|---|---|

| Control | Común (Standard bread) | Industrial | 4 | Unknown | Wheat flour | Not available |

| Tap water | ||||||

| Yeast | ||||||

| Table salt | ||||||

| G1 | Huerta | Artisanal | 6 | Llàtcer | 160 W wheat flour (Harinas Santamaría) | 75 |

| Bio T80 flour (Harinera Roca) | 25 | |||||

| Tap water | 62 | |||||

| Sourdough | 20 | |||||

| Compressed yeast | 0.4 | |||||

| Table salt | 1.8 | |||||

| G2 | Pueblo | Artisanal | 5 | San Pablo | >120 W wheat flour (Panificadora Conquense) | 100 |

| Tap water | 75 | |||||

| Sourdough | 20 | |||||

| Compressed yeast | 1.0 | |||||

| Table salt | 1.75 | |||||

| G3_F | Francés (French baguette) | Artisanal | 8 | La Tahona del Abuelo | 320 W wheat flour (Harinas Vicente Bosque) | 80 |

| Whole rye flour Type 170 (Dossche Mills) | 20 | |||||

| Tap water | 85 | |||||

| Sourdough | 20 | |||||

| Olive oil | 5.0 | |||||

| Table salt | 1.8 | |||||

| Roasted malt (Bayogar) | 0.5 | |||||

| Compressed yeast | 0.3 | |||||

| G3_SDw | Masa madre trigo (Wheat sourdough bread) | Artisanal | 4 | La Tahona del Abuelo | 200 W wheat flour (Harinas Vicente Bosque) | 100 |

| Tap water | 70 | |||||

| Sourdough | 20 | |||||

| Table salt | 1.7 | |||||

| G3_DW | Trigo duro (Durum wheat bread) | Artisanal | 5 | La Tahona del Abuelo | Durum wheat flour (Harinas Belda) | 100 |

| Tap water | 80 | |||||

| Sourdough | 20 | |||||

| Compressed yeast | 0.3 | |||||

| Table salt | 1.8 | |||||

| G4 | Pascua (Easter bread) | Artisanal | 9 | Marco artesans | 90–100 W wheat flour (Harinas Santamaría) | 100 |

| Tap water | 56 | |||||

| Raisins | 8.0 | |||||

| Sourdough | 5.0 | |||||

| Walnuts | 4.0 | |||||

| Montanejos Honey (Casa Bautista) | 2.5 | |||||

| Refined sunflower oil (High oleic, Casalbert) | 2.0 | |||||

| Compressed yeast | 4.0 | |||||

| Table salt | 1.8 | |||||

| G5_S | Espelta (Spelt bread) | Artisanal | 6 | Valencia | Whole spelt flour (El Molino de Cerecinos) | 100 |

| Tap water | 80 | |||||

| Sourdough | 20 | |||||

| Compressed yeast | 0.8 | |||||

| Table salt | 1.7 | |||||

| G5_R | Centeno (Rye bread) | Artisanal | 6 | Valencia | Whole rye flour (Harivasa) | 60 |

| 180–220 W wheat flour (Harinas Santamaría) | 40 | |||||

| Tap water | 80 | |||||

| Sourdough | 20 | |||||

| Table salt | 1.7 | |||||

| Compressed yeast | 0.8 | |||||

| G6 | Carrasca | Artisanal | 7 | Monpla | 180 W wheat flour (Harinas Molí de Picó) | 70 |

| Bio T80 flour (Moulin de Colagne) | 10 | |||||

| Whole wheat flour (Harinera Coromina) | 10 | |||||

| Whole rye flour (Harinas Molí de Picó) | 10 | |||||

| Tap water | 85 | |||||

| Sourdough | 30 | |||||

| Table salt | 1.8 | |||||

| G7 | Chapata (Ciabatta bread) | Artisanal | 7 | Masanet | 380–400 W wheat flour (Harinas Saiz) | 60 |

| 220–260 W wheat flour (Harinas Saiz) | 40 | |||||

| Tap water | 80 | |||||

| Table salt | 1.1 | |||||

| Compressed yeast | 1.8 | |||||

| Bread improver (T500, Puratos) | 0.4 | |||||

| Roasted malt (Bayogar) | 0.1 | |||||

| G9_T | Tritordeum (Tritordeum bread) | Artisanal | 6 | La Tahona del Boni | T72 tritordeum flour (Molinos del Duero) | 100 |

| Tap water | 75 | |||||

| Sourdough | 20 | |||||

| Compressed yeast | 0.08 | |||||

| Table salt | 1.7 | |||||

| Seeds mix (Molí de Picó) | 1.8 | |||||

| G9_L | Llesca | Artisanal | 5 | La Tahona del Boni | 200 W wheat flour (Molinos del Duero) | 90 |

| Whole rye flour (Molinos del Duero) | 10 | |||||

| Tap water | 75 | |||||

| Sourdough | 20 | |||||

| Table salt | 1.7 | |||||

| G10 | Moruno | Artisanal | 7 | Vicente Raimundo | 200 W wheat flour (Harinas Saiz) | 90 |

| Whole wheat flour (Harinera Segorbina) | 5 | |||||

| Whole rye flour (Harivasa) | 5 | |||||

| Tap water | 83 | |||||

| Sourdough | 25 | |||||

| Table salt | 0.2 | |||||

| Compressed yeast | 1.8 | |||||

| G11 | Chapata (Ciabatta bread) | Artisanal | 8 | Velarte | 220–260 W wheat flour (Harinas Saiz) | 67.5 |

| 380–400 W wheat flour (Harinas Saiz) | 25 | |||||

| Bio T80 flour (Moulin de Colagne) | 3.75 | |||||

| Durum wheat flour (Molí de Picó) | 3.75 | |||||

| Tap water | 71.25 | |||||

| Compressed yeast | 1.25 | |||||

| Table salt | 1.8 | |||||

| Dried sourdough (Sapore Tosca, Puratos) | 1.0 | |||||

| Bread improver (T500, Puratos) | 1.0 | |||||

| G12 | Pa de la casa (House bread) | Artisanal | 5 | Forn d’En Rausell | Whole rye flour (Harinas Santamaría) | 60 |

| 380 W wheat flour (Harinas Vicente Bosque) | 40 | |||||

| Tap water | 80 | |||||

| Sourdough | 35 | |||||

| Table salt | 1.7 | |||||

| G13 | Pa de la casa (House bread) | Artisanal | 4 | Forn, Pa i Dolços | 220 W wheat flour (Harinas Molí de Picó) | 100 |

| Tap water | 70 | |||||

| Table salt | 1.0 | |||||

| Compressed yeast | 1.7 |

| Bread Dough | SD (%) 1 | pH | TTA 2 | Organic Acid (mg/g Dough 3) | FQ 4 | |

|---|---|---|---|---|---|---|

| Lactic Acid | Acetic Acid | |||||

| G1 | 20 | 4.23 ± 0.07 h | 8.55 ± 0.07 b | 11.2 ± 1.0 a | 3.2 ± 0.7 a | 2.32 |

| G2 | 20 | 5.01 ± 0.02 def | 2.92 ± 0.04 h | 2.5 ± 0.6 efg | 0.9 ± 0.4 c | 1.85 |

| G3_F | 20 | 4.93 ± 0.11 ef | 4.57 ± 0.10 e | 4.7 ± 0.6 bcde | 0.99 ± 0.16 c | 3.16 |

| G3_SDw | 20 | 3.76 ± 0.08 i | 9.8 ± 0.3 a | 8.1 ± 2.1 ab | 1.0 ± 0.3 c | 5.40 |

| G3_DW | 20 | 4.66 ± 0.04 g | 5.18 ± 0.12 d | 5.2 ± 1.1 bcde | 0.93 ± 0.13 c | 3.73 |

| G4 | 5 | 5.38 ± 0.05 b | 3.04 ± 0.04 h | 2.9 ± 0.9 efg | 1.11 ± 0.12 c | 1.74 |

| G5_S | 14 | 4.68 ± 0.03 g | 8.53 ± 0.04 b | 8.0 ± 1.6 ab | 2.13 ± 0.06 b | 2.50 |

| G5_R | 20 | 4.54 ± 0.03 g | 6.35 ± 0.05 c | 7.67 ± 1.14 abc | 2.5 ± 0.5 ab | 2.05 |

| G6 | 30 | 5.15 ± 0.04 cd | 3.4 ± 0.2 g | 2.2 ± 0.6 efg | 0.7 ± 0.3 c | 2.10 |

| G7 | 0 | 5.58 ± 0.02 a | 2.30 ± 0.08 i | 0.26 ± 0.04 fg | 0.16 ± 0.12 c | 1.08 |

| G9_T | 20 | 4.87 ± 0.05 f | 4.71 ± 0.10 e | 4.2 ± 1.1 cde | 1.1 ± 0.4 c | 2.55 |

| G9_L | 20 | 4.53 ± 0.03 g | 5.12 ± 0.05 d | 4.5 ± 1.2 def | 0.8 ± 0.3 c | 3.75 |

| G10 | 25 | 5.09 ± 0.12 cde | 4.25 ± 0.05 f | 3.3 ± 0.9 defg | 0.9 ± 0.4 c | 2.44 |

| G11 | 0 | 5.25 ± 0.02 bc | 2.45 ± 0.03 i | 1.9 ± 0.5 efg | 0.5 ± 0.2 c | 2.53 |

| G12 | 35 | 4.35 ± 0.05 h | 6.60 ± 0.14 c | 6.7 ± 1.8 bcd | 0.6 ± 0.3 c | 7.44 |

| G13 | 0 | 5.58 ± 0.02 a | 2.34 ± 0.07 i | 0.19 ± 0.02 g | 0.4 ± 0.2 c | 0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanmartín, G.; Sánchez-Adriá, I.E.; Salvador, A.; Prieto, J.A.; Estruch, F.; Randez-Gil, F. Quantitative Assessment of Volatile Profile and Sensory Perception of Artisan Bread Made in the City of Valencia. Foods 2024, 13, 3872. https://doi.org/10.3390/foods13233872

Sanmartín G, Sánchez-Adriá IE, Salvador A, Prieto JA, Estruch F, Randez-Gil F. Quantitative Assessment of Volatile Profile and Sensory Perception of Artisan Bread Made in the City of Valencia. Foods. 2024; 13(23):3872. https://doi.org/10.3390/foods13233872

Chicago/Turabian StyleSanmartín, Gemma, Isabel Elena Sánchez-Adriá, Ana Salvador, Jose A. Prieto, Francisco Estruch, and Francisca Randez-Gil. 2024. "Quantitative Assessment of Volatile Profile and Sensory Perception of Artisan Bread Made in the City of Valencia" Foods 13, no. 23: 3872. https://doi.org/10.3390/foods13233872

APA StyleSanmartín, G., Sánchez-Adriá, I. E., Salvador, A., Prieto, J. A., Estruch, F., & Randez-Gil, F. (2024). Quantitative Assessment of Volatile Profile and Sensory Perception of Artisan Bread Made in the City of Valencia. Foods, 13(23), 3872. https://doi.org/10.3390/foods13233872