Impact of Ultrasound Pre-Treatment on the Drying Kinetics and Quality of Chicken Breast—A Comparative Study of Convective and Freeze-Drying Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ultrasound Pre-Treatment (US)

2.3. Drying Methods

2.3.1. Hot-Air Drying (HA)

2.3.2. Freeze-Drying (FD)

2.4. Drying Kinetics

2.5. Measurements of Quality Parameters

2.5.1. Water Content

2.5.2. Water Activity

2.5.3. Macrostructure and Internal Structure

2.5.4. Color Parameters

2.5.5. Rehydration Ratio

2.5.6. Hygroscopic Properties

2.6. Statistical Analyses

3. Results and Discussion

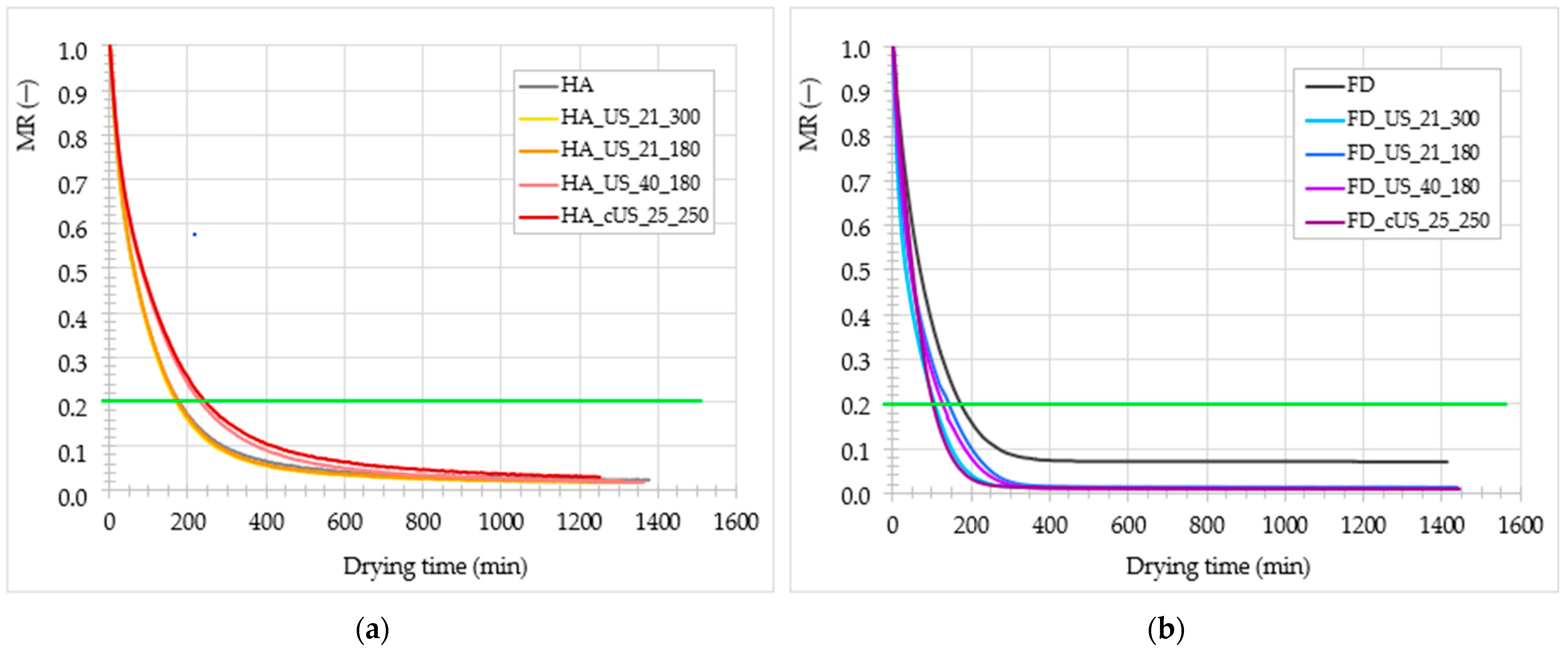

3.1. Influence of Ultrasound Pre-Treatment on the Drying Kinetics of Chicken Breast Meat

3.2. Influence of Ultrasound Pre-Treatment on the Water Content and Water Activity of Dried Chicken Breast Meat

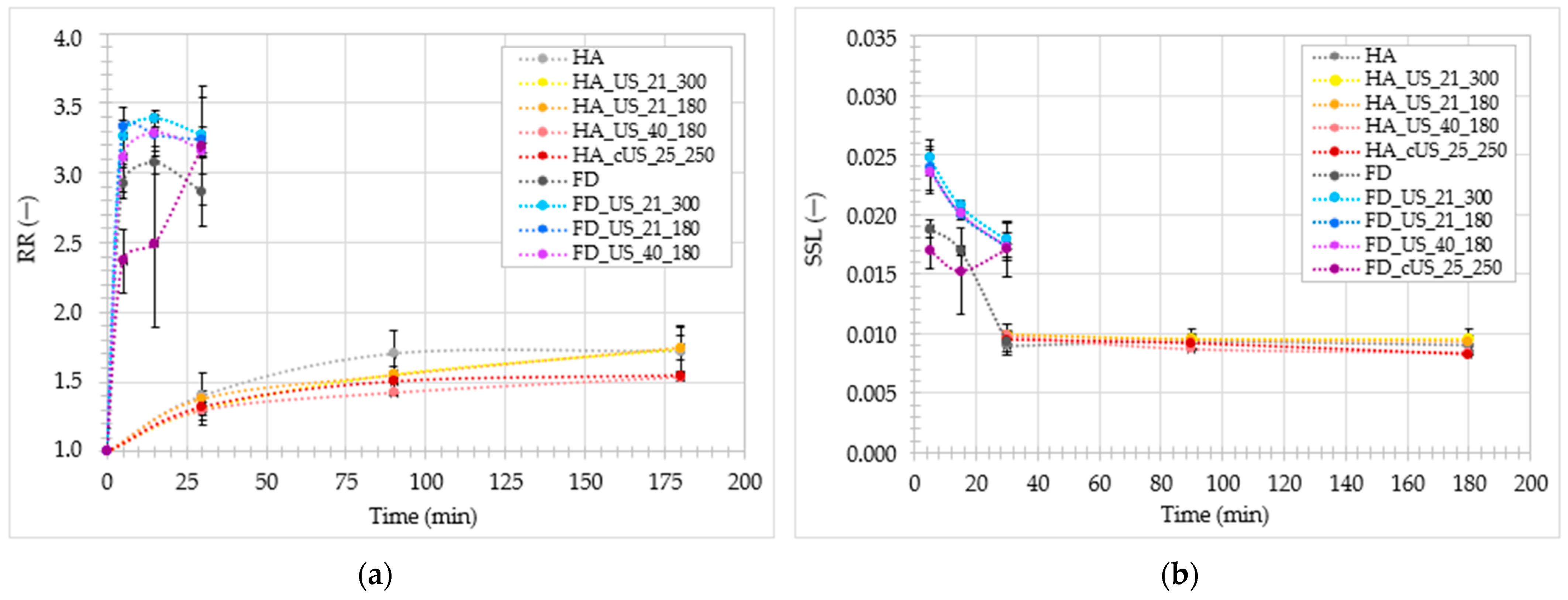

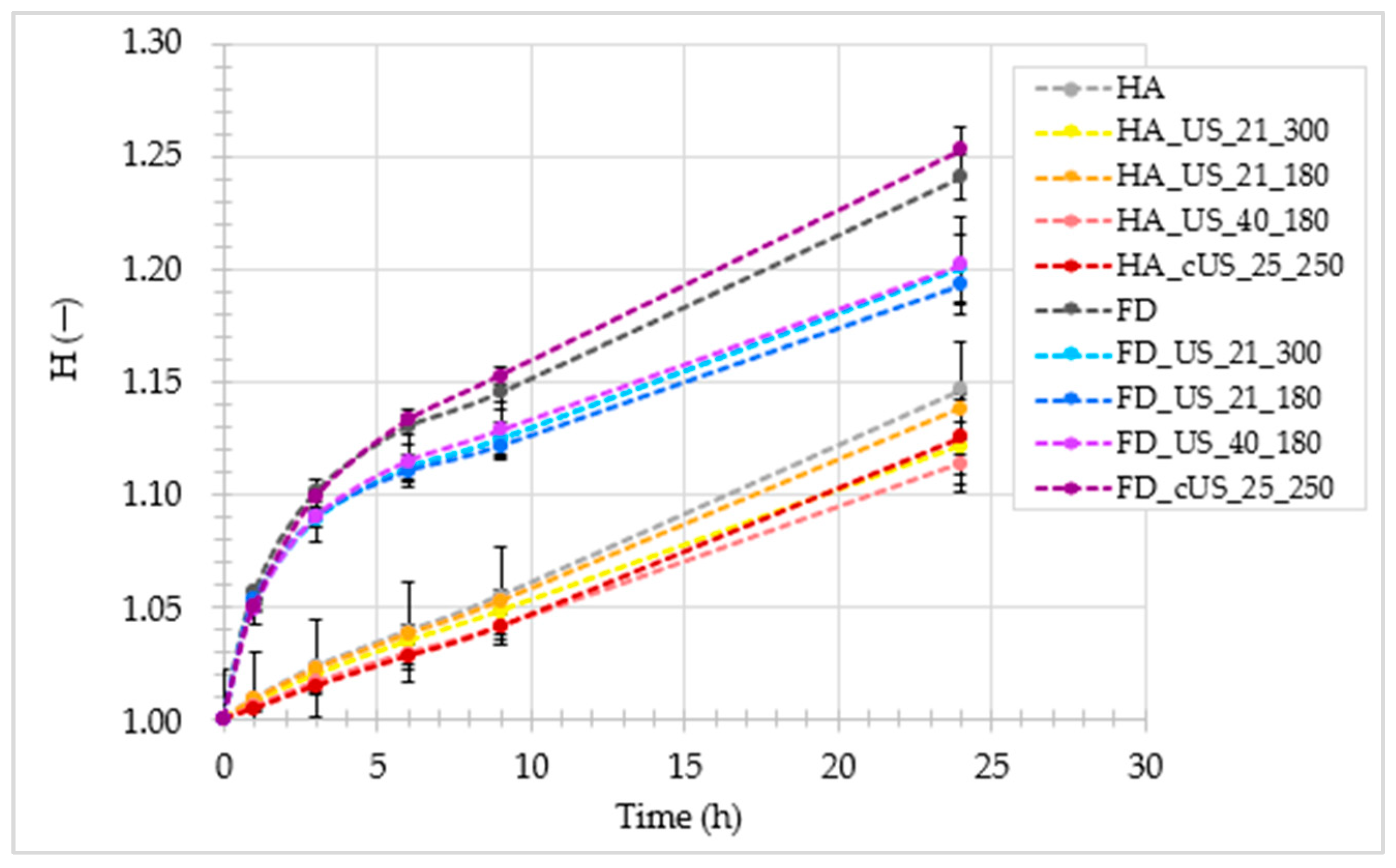

3.3. Influence of Ultrasound Pre-Treatment on the Rehydration Ratio and Hygroscopic Properties of Dried Chicken Breast Meat

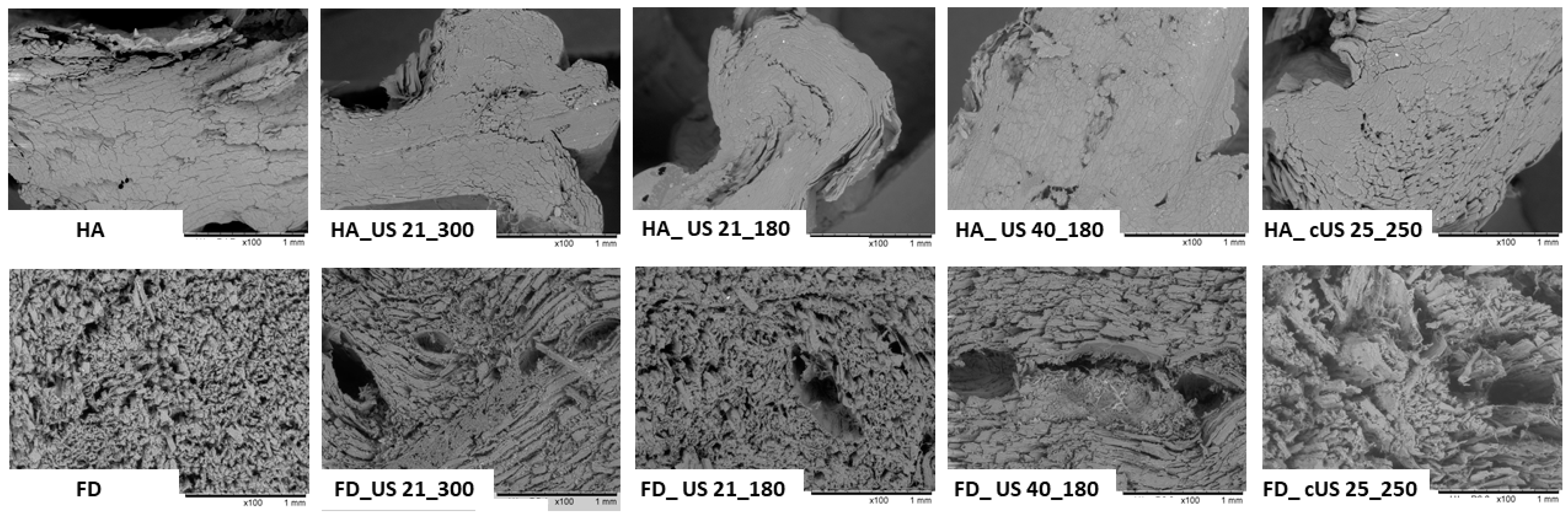

3.4. Influence of Ultrasound Pre-Treatment on the Structure of Chicken Breast Meat

3.5. Influence of Ultrasound Pre-Treatment on the Color Parameter of Chicken Breast Meat

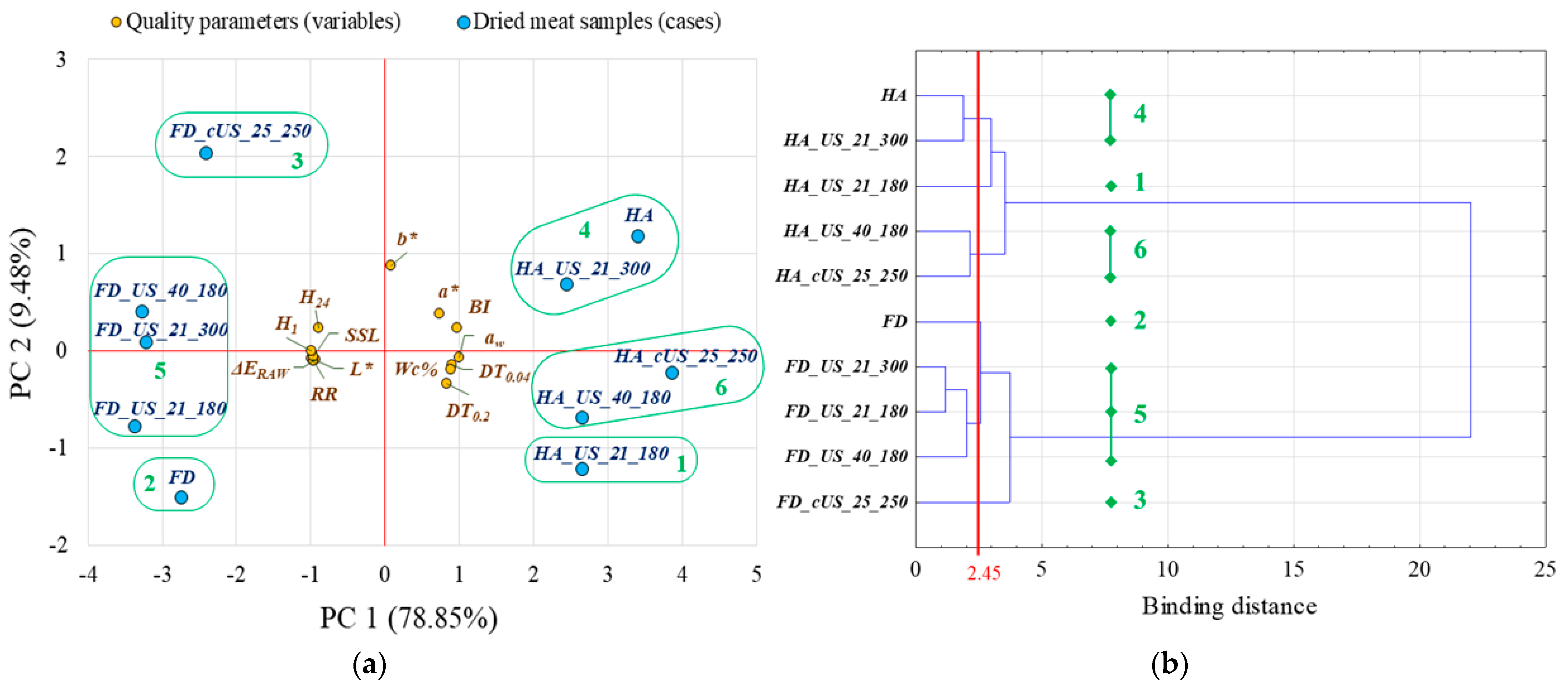

3.6. Multivariate Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OECD/FAO. OECD-FAO Agricultural Outlook 2023–2032; OECD Public: Paris, France, 2023. [Google Scholar] [CrossRef]

- Henchion, M.; Hayes, M.; Mullen, A.; Fenelon, M.; Tiwari, B. Future Protein Supply and Demand: Strategies and Factors Influencing a Sustainable Equilibrium. Foods 2017, 6, 53. [Google Scholar] [CrossRef]

- Tripathi, A.D.; Mishra, R.; Maurya, K.K.; Singh, R.B.; Wilson, D.W. Estimates for World Population and Global Food Availability for Global Health. In The Role of Functional Food Security in Global Health; Elsevier: Amsterdam, The Netherlands, 2019; pp. 3–24. ISBN 9780128131480. [Google Scholar]

- Ismail, B.P.; Senaratne-Lenagala, L.; Stube, A.; Brackenridge, A. Protein demand: Review of plant and animal proteins used in alternative protein product development and production. Anim. Front. 2020, 10, 53–63. [Google Scholar] [CrossRef]

- Rabeler, F.; Feyissa, A.H. Kinetic Modeling of Texture and Color Changes During Thermal Treatment of Chicken Breast Meat. Food Bioprocess Technol. 2018, 11, 1495–1504. [Google Scholar] [CrossRef]

- Livingston, M.L. Poultry optimum post-harvest meat quality. In Encyclopedia of Meat Sciences; Elsevier: Amsterdam, The Netherlands, 2024; pp. 28–36. [Google Scholar]

- Kim, H.-J.; Kim, H.-J.; Jeon, J.; Nam, K.-C.; Shim, K.-S.; Jung, J.-H.; Kim, K.S.; Choi, Y.; Kim, S.-H.; Jang, A. Comparison of the quality characteristics of chicken breast meat from conventional and animal welfare farms under refrigerated storage. Poult. Sci. 2020, 99, 1788–1796. [Google Scholar] [CrossRef]

- Demiray, E.; Ergezer, H.; Özünlü, O.; Gökçe, R. Influence of hot-air drying on drying kinetics and some quality parameters of sliced chicken breast meat. Res. Sq. 2022. [Google Scholar] [CrossRef]

- Sabikun, N.; Bakhsh, A.; Ismail, I.; Hwang, Y.-H.; Rahman, M.S.; Joo, S.-T. Changes in physicochemical characteristics and oxidative stability of pre- and post-rigor frozen chicken muscles during cold storage. J. Food Sci. Technol. 2019, 56, 4809–4816. [Google Scholar] [CrossRef]

- Banovic, M.; Arvola, A.; Pennanen, K.; Duta, D.E.; Brückner-Gühmann, M.; Lähteenmäki, L.; Grunert, K.G. Foods with increased protein content: A qualitative study on European consumer preferences and perceptions. Appetite 2018, 125, 233–243. [Google Scholar] [CrossRef]

- Barska, A. Millennial consumers in the convenience food market. Management 2018, 22, 251–264. [Google Scholar] [CrossRef]

- Imtiyaz, H.; Soni, P.; Yukongdi, V. Understanding Consumer’s purchase intention and consumption of convenience food in an emerging economy: Role of marketing and commercial determinants. J. Agric. Food Res. 2022, 10, 100399. [Google Scholar] [CrossRef]

- Statsenko, E.S.; Nizkiy, S.E.; Litvinenko, O.V.; Kodirova, G.A. Development of technology for food concentrates of culinary sauces of increased nutritional and biological value. AIMS Agric. Food 2020, 5, 137–149. [Google Scholar] [CrossRef]

- Adeyeye, S.A.O.; Ashaolu, T.J.; Babu, A.S. Food Drying: A Review. Agric. Rev. 2022. [Google Scholar] [CrossRef]

- Afolabi, I.S. Moisture Migration and Bulk Nutrients Interaction in a Drying Food Systems: A Review. Food Nutr. Sci. 2014, 05, 692–714. [Google Scholar] [CrossRef]

- Huang, D.; Men, K.; Li, D.; Wen, T.; Gong, Z.; Sunden, B.; Wu, Z. Application of ultrasound technology in the drying of food products. Ultrason. Sonochem. 2020, 63, 104950. [Google Scholar] [CrossRef]

- Daley, K. Sustainable food practices: Reducing food waste through dehydration. Afr. J. Food Sci. Technol. 2023, 14, 1–2. [Google Scholar] [CrossRef]

- Bampi, M.; Schmidt, F.C.; Laurindo, J.B. A fast drying method for the production of salted-and-dried meat. Food Sci. Technol. 2019, 39, 526–534. [Google Scholar] [CrossRef]

- Llavata, B.; García-Pérez, J.V.; Simal, S.; Cárcel, J.A. Innovative pre-treatments to enhance food drying: A current review. Curr. Opin. Food Sci. 2020, 35, 20–26. [Google Scholar] [CrossRef]

- Taormina, P.J.; Sofos, J.N. Low-Water Activity Meat Products. In The Microbiological Safety of Low Water Activity Foods and Spices; Springer: New York, NY, USA, 2014; pp. 127–164. [Google Scholar]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef]

- Mediani, A.; Hamezah, H.S.; Jam, F.A.; Mahadi, N.F.; Chan, S.X.Y.; Rohani, E.R.; Che Lah, N.H.; Azlan, U.K.; Khairul Annuar, N.A.; Azman, N.A.F.; et al. A comprehensive review of drying meat products and the associated effects and changes. Front. Nutr. 2022, 9, 1057366. [Google Scholar] [CrossRef]

- Loskota, E.; Gramatina, I.; Kince, T. A review: Application of freeze-drying in meat processing. In Proceedings of the Research for Rural Development 2023: Annual 29th International Scientific Conference Proceedings, Latvia, Jelgava, 12–14 April 2023; Volume 38, pp. 77–81. [Google Scholar]

- Deng, L.-Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.-H.; Wang, J.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Chemical and physical pre-treatments of fruits and vegetables: Effects on drying characteristics and quality attributes—A comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1408–1432. [Google Scholar] [CrossRef]

- Gao, J.; Chen, L.; Zeng, X.; Sun, X.; Bai, Y.; Wang, X.; Xu, X.; Han, M. Novel drying pre-treatment technologies and their applications in the food industry. Food Mater. Res. 2023, 3, 14. [Google Scholar] [CrossRef]

- Jadhav, H.B.; Annapure, U.S.; Deshmukh, R.R. Non-thermal Technologies for Food Processing. Front. Nutr. 2021, 8, 657090. [Google Scholar] [CrossRef]

- Chakka, A.K.; Sriraksha, M.S.; Ravishankar, C.N. Sustainability of emerging green non-thermal technologies in the food industry with food safety perspective: A review. LWT 2021, 151, 112140. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, L.; Zeng, X.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Int. J. Food Sci. Technol. 2019, 54, 1–13. [Google Scholar] [CrossRef]

- Chacha, J.S.; Zhang, L.; Ofoedu, C.E.; Suleiman, R.A.; Dotto, J.M.; Roobab, U.; Agunbiade, A.O.; Duguma, H.T.; Mkojera, B.T.; Hossaini, S.M.; et al. Revisiting Non-Thermal Food Processing and Preservation Methods—Action Mechanisms, Pros and Cons: A Technological Update (2016–2021). Foods 2021, 10, 1430. [Google Scholar] [CrossRef]

- Barbhuiya, R.I.; Singha, P.; Singh, S.K. A comprehensive review on impact of non-thermal processing on the structural changes of food components. Food Res. Int. 2021, 149, 110647. [Google Scholar] [CrossRef]

- Neoκleous, I.; Tarapata, J.; Papademas, P. Non-thermal Processing Technologies for Dairy Products: Their Effect on Safety and Quality Characteristics. Front. Sustain. Food Syst. 2022, 6, 856199. [Google Scholar] [CrossRef]

- Astráin-Redín, L.; Alejandre, M.; Raso, J.; Cebrián, G.; Álvarez, I. Direct Contact Ultrasound in Food Processing: Impact on Food Quality. Front. Nutr. 2021, 8, 633070. [Google Scholar] [CrossRef]

- Xu, B.; Sylvain Tiliwa, E.; Yan, W.; Roknul Azam, S.M.; Wei, B.; Zhou, C.; Ma, H.; Bhandari, B. Recent development in high quality drying of fruits and vegetables assisted by ultrasound: A review. Food Res. Int. 2022, 152, 110744. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Aydar, A.Y.; Kutlu, N.; Aslam, R.; Sahni, P.; Mitharwal, S.; Gavahian, M.; Kumar, M.; Raposo, A.; Yoo, S.; et al. Individual and interactive effect of ultrasound pre-treatment on drying kinetics and biochemical qualities of food: A critical review. Ultrason. Sonochem. 2023, 92, 106261. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Rodrigues, S. Ultrasound applications in drying of fruits from a sustainable development goals perspective. Ultrason. Sonochem. 2023, 96, 106430. [Google Scholar] [CrossRef]

- Royintarat, T.; Choi, E.H.; Boonyawan, D.; Seesuriyachan, P.; Wattanutchariya, W. Chemical-free and synergistic interaction of ultrasound combined with plasma-activated water (PAW) to enhance microbial inactivation in chicken meat and skin. Sci. Rep. 2020, 10, 1559. [Google Scholar] [CrossRef]

- Al-Hilphy, A.R.; Al-Temimi, A.B.; Al Rubaiy, H.H.M.; Anand, U.; Delgado-Pando, G.; Lakhssassi, N. Ultrasound applications in poultry meat processing: A systematic review. J. Food Sci. 2020, 85, 1386–1396. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Sardari, H.; Alikhani Chamgordani, P.; Behjati, M. Power ultrasound in the meat industry (freezing, cooking and fermentation): Mechanisms, advances and challenges. Ultrason. Sonochem. 2022, 86, 106027. [Google Scholar] [CrossRef]

- Alarcon-Rojo, A.D.; Janacua, H.; Rodriguez, J.C.; Paniwnyk, L.; Mason, T.J. Power ultrasound in meat processing. Meat Sci. 2015, 107, 86–93. [Google Scholar] [CrossRef]

- Aksoy, A.; Karasu, S.; Akcicek, A.; Kayacan, S. Effects of Different Drying Methods on Drying Kinetics, Microstructure, Color, and the Rehydration Ratio of Minced Meat. Foods 2019, 8, 216. [Google Scholar] [CrossRef]

- Aykın-Dinçer, E.; Kılıç-Büyükkurt, Ö.; Erbaş, M. Influence of drying techniques and temperatures on drying kinetics and quality characteristics of beef slices. Heat Mass Transf. 2020, 56, 315–320. [Google Scholar] [CrossRef]

- Afifah, N.; Ratnawati, L.; Indrianti, N.; Sarifudin, A. The effect of pre-drying treatments on the quality of dehydrated ground beef. IOP Conf. Ser. Earth Environ. Sci. 2021, 924, 012006. [Google Scholar] [CrossRef]

- ISO 1442:2023; Meat and Meat Products—Determination of Moisture Content—Reference Method. International Organization for Standardization: Geneva, Switzerland, 2023; Edition 3. Available online: https://www.iso.org/standard/82664.html (accessed on 3 August 2024).

- Gao, X.; Xie, Y.; Yin, T.; Hu, Y.; You, J.; Xiong, S.; Liu, R. Effect of high intensity ultrasound on gelation properties of silver carp surimi with different salt contents. Ultrason. Sonochem. 2021, 70, 105326. [Google Scholar] [CrossRef]

- von Gersdorff, G.J.E.; Kirchner, S.M.; Hensel, O.; Sturm, B. Impact of drying temperature and salt pre-treatments on drying behavior and instrumental color and investigations on spectral product monitoring during drying of beef slices. Meat Sci. 2021, 178, 108525. [Google Scholar] [CrossRef]

- Bozkir, H.; Ergün, A.R. Effect of sonication and osmotic dehydration applications on the hot air drying kinetics and quality of persimmon. LWT 2020, 131, 109704. [Google Scholar] [CrossRef]

- Wiktor, A.; Witrowa-Rajchert, D. Drying kinetics and quality of carrots subjected to microwave-assisted drying preceded by combined pulsed electric field and ultrasound treatment. Dry. Technol. 2020, 38, 176–188. [Google Scholar] [CrossRef]

- Granato, D.; de Araújo Calado, V.M.; Jarvis, B. Observations on the use of statistical methods in Food Science and Technology. Food Res. Int. 2014, 55, 137–149. [Google Scholar] [CrossRef]

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation Coefficients: Appropriate Use and Interpretation. Anesth. Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

- Granato, D.; Santos, J.S.; Escher, G.B.; Ferreira, B.L.; Maggio, R.M. Use of principal component analysis (PCA) and hierarchical cluster analysis (HCA) for multivariate association between bioactive compounds and functional properties in foods: A critical perspective. Trends Food Sci. Technol. 2018, 72, 83–90. [Google Scholar] [CrossRef]

- Jalilibal, Z.; Amiri, A.; Castagliola, P.; Khoo, M.B.C. Monitoring the coefficient of variation: A literature review. Comput. Ind. Eng. 2021, 161, 107600. [Google Scholar] [CrossRef]

- Konieczny, P.; Kowalski, R.; Pyrcz, J. Wybrane wyróżniki jakościowe suszonych produktów przekąskowych z mięsa wołowego. Żywność Nauka Technol. Jakość 2004, 11, 32–39. [Google Scholar]

- King, V.A.-E.; Chen, J.-F. Oxidation of controlled low-temperature vacuum dehydrated and freeze-dried beef and pork. Meat Sci. 1998, 48, 11–19. [Google Scholar] [CrossRef]

- Mulet, A.; Cárcel, J.A.; Sanjuán, N.; Bon, J. New Food Drying Technologies—Use of Ultrasound. Food Sci. Technol. Int. 2003, 9, 215–221. [Google Scholar] [CrossRef]

- Wang, K.; Liu, H.; Sun, J. Improved gelling and emulsifying properties of chicken wooden breast myofibrillar protein by high-intensity ultrasound combination with pH-shifting. Poult. Sci. 2023, 102, 103063. [Google Scholar] [CrossRef]

- Kumar, D.; Tarafdar, A.; Kumar, Y.; Badgujar, P.C. Intelligent modeling and detailed analysis of drying, hydration, thermal, and spectral characteristics for convective drying of chicken breast slices. J. Food Process Eng. 2019, 42, e13087. [Google Scholar] [CrossRef]

- Waghmare, R.; Kumar, M.; Yadav, R.; Mhatre, P.; Sonawane, S.; Sharma, S.; Gat, Y.; Chandran, D.; Radha; Hasan, M.; et al. Application of ultrasonication as pre-treatment for freeze drying: An innovative approach for the retention of nutraceutical quality in foods. Food Chem. 2023, 404, 134571. [Google Scholar] [CrossRef] [PubMed]

- Elmas, F.; Bodruk, A.; Köprüalan, Ö.; Arıkaya, Ş.; Koca, N.; Serdaroğlu, F.M.; Kaymak-Ertekin, F.; Koç, M. Drying kinetics behavior of turkey breast meat in different drying methods. J. Food Process Eng. 2020, 43, e13487. [Google Scholar] [CrossRef]

- Duan, X.; Yang, X.; Ren, G.; Pang, Y.; Liu, L.; Liu, Y. Technical aspects in freeze-drying of foods. Dry. Technol. 2016, 34, 1271–1285. [Google Scholar] [CrossRef]

- Park, Y. Moisture and Water Activity. In Handbook of Processed Meats and Poultry Analysis; CRC Press: Boca Raton, FL, USA, 2008; pp. 35–67. ISBN 9781420045338. [Google Scholar]

- Erkmen, O.; Bozoglu, T.F. Food Preservation by Reducing Water Activity. In Food Microbiology: Principles into Practice; Wiley: Hoboken, NJ, USA, 2016; pp. 44–58. [Google Scholar]

- Dave, D.; Ghaly, A.E. Meat Spoilage Mechanisms and Preservation Techniques: A Critical Review. Am. J. Agric. Biol. Sci. 2011, 6, 486–510. [Google Scholar] [CrossRef]

- Kim, S.-M.; Kim, T.-K.; Cha, J.Y.; Kang, M.-C.; Lee, J.H.; Yong, H.I.; Choi, Y.-S. Novel processing technologies for improving quality and storage stability of jerky: A review. LWT 2021, 151, 112179. [Google Scholar] [CrossRef]

- Rao, W.; Shi, Z.; Liu, S.; Shu, Y.; Chai, X.; Zhang, Z. Shrinkage Properties and Their Relationship with Degradation of Proteins Linking the Endomysium and Myofibril in Lamb Meat Submitted to Heating or Air Drying. Foods 2022, 11, 2242. [Google Scholar] [CrossRef]

- Witrowa-Rajchert, D.; Lewicki, P.P. Rehydration properties of dried plant tissues. Int. J. Food Sci. Technol. 2006, 41, 1040–1046. [Google Scholar] [CrossRef]

- Miraei Ashtiani, S.-H.; Sturm, B.; Nasirahmadi, A. Effects of hot-air and hybrid hot air-microwave drying on drying kinetics and textural quality of nectarine slices. Heat Mass Transf. 2018, 54, 915–927. [Google Scholar] [CrossRef]

- Dehghannya, J.; Farshad, P.; Khakbaz Heshmati, M. Three-stage hybrid osmotic–intermittent microwave–convective drying of apple at low temperature and short time. Dry. Technol. 2018, 36, 1982–2005. [Google Scholar] [CrossRef]

- Tepe, T.K.; Tepe, B. The comparison of drying and rehydration characteristics of intermittent-microwave and hot-air dried-apple slices. Heat Mass Transf. 2020, 56, 3047–3057. [Google Scholar] [CrossRef]

- Schössler, K.; Thomas, T.; Knorr, D. Modification of cell structure and mass transfer in potato tissue by contact ultrasound. Food Res. Int. 2012, 49, 425–431. [Google Scholar] [CrossRef]

- Wiktor, A.; Sledz, M.; Nowacka, M.; Rybak, K.; Witrowa-Rajchert, D. The influence of immersion and contact ultrasound treatment on selected properties of the apple tissue. Appl. Acoust. 2016, 103, 136–142. [Google Scholar] [CrossRef]

- Rahman, M.S.; Salman, Z.; Kadim, I.T.; Mothershaw, A.; Al-Riziqi, M.H.; Guizani, N.; Mahgoub, O.; Ali, A. Microbial and Physico-Chemical Characteristics of Dried Meat Processed by Different Methods. Int. J. Food Eng. 2005, 1. [Google Scholar] [CrossRef]

- Elmas, F.; Bodruk, A.; Köprüalan, Ö.; Arıkaya, Ş.; Koca, N.; Serdaroğlu, F.M.; Kaymak-Ertekin, F.; Koç, M. The effect of pre-drying methods on physicochemical, textural and sensory characteristics on puff dried Turkey breast meat. LWT 2021, 145, 111350. [Google Scholar] [CrossRef]

- Fijałkowska, A.; Nowacka, M.; Witrowa-Rajchert, D. The physical, optical and reconstitution properties of apples subjected to ultrasound before drying. Ital. J. Food Sci. 2017, 29, 343–356. [Google Scholar] [CrossRef]

- de Arruda, G.M.P.; Rupert Brandão, S.C.; da Silva Júnior, E.V.; da Silva, E.M.; Barros, Z.M.P.; da Silva, E.S.; Shinohara, N.K.S.; Azoubel, P.M. Influence of ultrasound and ethanol as a pre-treatment on papaya infrared and convective drying characteristics and quality parameters. J. Food Process Eng. 2023, 46, e14255. [Google Scholar] [CrossRef]

- Gu, C.; Ma, H.; Tuly, J.A.; Guo, L.; Zhang, X.; Liu, D.; Ouyang, N.; Luo, X.; Shan, Y. Effects of catalytic infrared drying in combination with hot air drying and freeze drying on the drying characteristics and product quality of chives. LWT 2022, 161, 113363. [Google Scholar] [CrossRef]

- Albrecht, A.; Dresch, L.C. Identification of influence factors on the quality and shelf life of fresh meat throughout the supply chain. In Living Handbook of Perishable Food Supply Chains; Publisso: Cologne, Germany, 2020; pp. 1–12. [Google Scholar]

- Tomasevic, I.; Djekic, I.; Font-i-Furnols, M.; Terjung, N.; Lorenzo, J.M. Recent advances in meat color research. Curr. Opin. Food Sci. 2021, 41, 81–87. [Google Scholar] [CrossRef]

- L’Eclairage-Cie, C.I.D. CIE Recommendations on Uniform Color Spaces, Color-Difference Equations, and Metric Color Terms. Color Res. Appl. 1977, 2, 5–6. [Google Scholar] [CrossRef]

- Mokrzycki, W.; Tatol, M. Color difference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Sun, Q.; Kong, B.; Liu, S.; Zheng, O.; Zhang, C. Ultrasound-assisted thawing accelerates the thawing of common carp (Cyprinus carpio) and improves its muscle quality. LWT 2021, 141, 111080. [Google Scholar] [CrossRef]

- Stadnik, J.; Dolatowski, Z.J. Influence of sonication on Warner-Bratzler shear force, colour and myoglobin of beef (m. semimembranosus). Eur. Food Res. Technol. 2011, 233, 553–559. [Google Scholar] [CrossRef]

- Sikes, A.L.; Mawson, R.; Stark, J.; Warner, R. Quality properties of pre- and post-rigor beef muscle after interventions with high frequency ultrasound. Ultrason. Sonochem. 2014, 21, 2138–2143. [Google Scholar] [CrossRef] [PubMed]

- Peña-González, E.M.; Alarcón-Rojo, A.D.; Rentería, A.; García, I.; Santellano, E.; Quintero, A.; Luna, L. Quality and sensory profile of ultrasound-treated beef. Ital. J. Food Sci. 2017, 29, 463–475. [Google Scholar]

- Alarcon-Rojo, A.D.; Carrillo-Lopez, L.M.; Reyes-Villagrana, R.; Huerta-Jiménez, M.; Garcia-Galicia, I.A. Ultrasound and meat quality: A review. Ultrason. Sonochem. 2019, 55, 369–382. [Google Scholar] [CrossRef]

- Hughes, J.M.; Oiseth, S.K.; Purslow, P.P.; Warner, R.D. A structural approach to understanding the interactions between colour, water-holding capacity and tenderness. Meat Sci. 2014, 98, 520–532. [Google Scholar] [CrossRef] [PubMed]

- Pujol, A.; Ospina-E, J.C.; Alvarez, H.; Muñoz, D.A. Myoglobin content and oxidative status to understand meat products’ color: Phenomenological based model. J. Food Eng. 2023, 348, 111439. [Google Scholar] [CrossRef]

- Mishra, B.; Mishra, J.; Pati, P.; Rath, P. Dehydrated Meat Products: A Review. Int. J. Livest. Res. 2017, 7, 10–22. [Google Scholar] [CrossRef]

- Kutlu, N.; Pandiselvam, R.; Kamiloglu, A.; Saka, I.; Sruthi, N.U.; Kothakota, A.; Socol, C.T.; Maerescu, C.M. Impact of ultrasonication applications on color profile of foods. Ultrason. Sonochem. 2022, 89, 106109. [Google Scholar] [CrossRef]

- Croguennec, T. Enzymatic Browning. In Handbook of Food Science and Technology 1; Wiley: Hoboken, NJ, USA, 2016; pp. 159–181. [Google Scholar]

| Treatment | US Method | Mass Changes (%) | Water Content (%) | Water Activity (─) |

|---|---|---|---|---|

| Raw | - | - | 75.19 ± 0.76 ab | 0.954 ± 0.025 a |

| US_21_300 | immersion | 3.28 ± 0.35 b | 76.41 ± 0.18 bc | 0.964 ± 0.016 ab |

| US_21_180 | 1.92 ± 0.31 b | 77.33 ± 0.16 c | 0.979 ± 0.003 b | |

| US_40_180 | 3.36 ± 1.06 b | 76.75 ± 0.78 c | 0.979 ± 0.003 b | |

| cUS_25_250 | contact | −5.07 ± 1.89 a | 74.03 ± 1.01 a | 0.973 ± 0.004 ab |

| Code | US Frequency (kHz) | US Power (W) | Drying Method |

|---|---|---|---|

| Raw | - | - | - |

| US_21_300 | 21 | 300 | - |

| US_21_180 | 21 | 180 | - |

| US_40_180 | 40 | 180 | - |

| cUS_25_250 | 25 | 250 | - |

| HA | - | - | Hot-air drying |

| HA_US_21_300 | 21 | 300 | |

| HA_US_21_180 | 21 | 180 | |

| HA_US_40_180 | 40 | 180 | |

| HA_cUS_25_250 | 25 | 250 | |

| FD | - | - | Freeze-drying |

| FD_US_21_300 | 21 | 300 | |

| FD_US_21_180 | 21 | 180 | |

| FD_US_40_180 | 40 | 180 | |

| FD_cUS_25_250 | 25 | 250 |

| Sample Code | Drying Time (min) | |

|---|---|---|

| MR = 0.20 | MR = 0.04 | |

| HA | 175.0 ± 7.1 bc | 607.5 ± 10.6 bc |

| HA_US_21_300 | 167.5 ± 24.7 bc | 465.0 ± 77.8 b |

| HA_US_21_180 | 172.5 ± 3.5 bc | 517.5 ± 17.7 bc |

| HA_US_40_180 | 227.5 ± 3.5 cd | 660.0 ± 56.6 c |

| HA_cUS_25_250 | 242.5 ± 10.6 d | 930.0 ± 42.4 d |

| FD | 146.9 ± 25.6 ab | 267.5 ± 31.8 a |

| FD_US_21_300 | 118.8 ± 19.4 ab | 222.5 ± 31.8 a |

| FD_US_21_180 | 137.5 ± 17.7 ab | 253.8 ± 23.0 a |

| FD_US_40_180 | 127.5 ± 10.6 ab | 245.0 ± 21.2 a |

| FD_cUS_25_250 | 102.5 ± 17.7 a | 181.3 ± 26.5 a |

| Sample Code | Water Content (%) | Water Activity (─) |

|---|---|---|

| HA | 7.39 ± 0.35 ef | 0.408 ± 0.039 bc |

| HA_US_21_300 | 5.91 ± 1.02 cd | 0.353 ± 0.052 b |

| HA_US_21_180 | 6.91 ± 0.13 def | 0.386 ± 0.028 bc |

| HA_US_40_180 | 6.17 ± 0.44 cde | 0.399 ± 0.039 bc |

| HA_cUS_25_250 | 8.20 ± 0.39 f | 0.436 ± 0.035 c |

| FD | 3.87 ± 0.47 ab | 0.101 ± 0.024 a |

| FD_US_21_300 | 5.03 ± 0.68 bc | 0.130 ± 0.030 a |

| FD_US_21_180 | 4.46 ± 1.43 b | 0.106 ± 0.041 a |

| FD_US_40_180 | 2.82 ± 0.49 a | 0.084 ± 0.028 a |

| FD_cUS_25_250 | 2.81 ± 0.40 a | 0.099 ± 0.028 a |

| Sample Code | RR (%) | H (─) | |

|---|---|---|---|

| After 30 min | After 1 h | After 24 h | |

| HA | 1.40 ± 0.13 a | 1.009 ± 0.002 a | 1.146 ± 0.011 a |

| HA_US_21_300 | 1.30 ± 0.11 a | 1.007 ± 0.002 a | 1.121 ± 0.021 a |

| HA_US_21_180 | 1.38 ± 0.05 a | 1.008 ± 0.001 a | 1.138 ± 0.006 a |

| HA_US_40_180 | 1.30 ± 0.04 a | 1.005 ± 0.002 a | 1.114 ± 0.005 a |

| HA_cUS_25_250 | 1.32 ± 0.04 a | 1.004 ± 0.001 a | 1.125 ± 0.020 a |

| FD | 2.92 ± 0.11 bc | 1.056 ± 0.003 b | 1.241 ± 0.010 c |

| FD_US_21_300 | 3.26 ± 0.20 c | 1.051 ± 0.002 b | 1.201 ± 0.015 b |

| FD_US_21_180 | 3.32 ± 0.25 c | 1.053 ± 0.002 b | 1.193 ± 0.009 b |

| FD_US_40_180 | 3.11 ± 0.24 c | 1.049 ± 0.007 b | 1.202 ± 0.022 b |

| FD_cUS_25_250 | 2.37 ± 0.22 b | 1.050 ± 0.003 b | 1.253 ± 0.011 c |

| Sample Code | L* (─) | a* (─) | b* (─) | BI (─) | ΔERAW (─) | ΔEHA/FD (─) |

|---|---|---|---|---|---|---|

| RAW | 53.1 ± 1.9 ab | −1.9 ± 0.4 a | 4.0 ± 1.7 a | - | - | - |

| US_21_300 | 54.9 ± 4.4 ab | −2.7 ± 0.3 a | 1.4 ± 0.2 a | - | 3.1 ± 0.2 a | - |

| US_21_180 | 59.1 ± 5.4 bc | −2.5 ± 0.5 a | 2.4 ± 0.9 a | - | 6.9 ± 3.8 ab | - |

| US_40_180 | 59.0 ± 4.9 bc | −2.5 ± 0.6 a | 1.0 ± 2.1 a | - | 7.2 ± 1.5 ab | - |

| cUS_25_250 | 53.4 ± 4.9 ab | −2.3 ± 0.5 a | 3.7 ± 3.8 a | - | 4.9 ± 2.0 a | - |

| HA | 44.4 ± 5.2 ab | 7.2 ± 1.5 c | 18.5 ± 1.3 b | 65.0 ± 5.3 d | 20.1 ± 1.3 cd | - |

| HA_US_21_300 | 44.4 ± 6.7 ab | 4.8 ± 1.6 bc | 18.1 ± 1.3 b | 59.2 ± 7.5 d | 18.5 ± 1.7 cd | 3.9 ± 0.2 a |

| HA_US_21_180 | 43.3 ± 5.9 a | 5.3 ± 1.8 bc | 15.1 ± 1.1 b | 51.2 ± 2.1 cd | 17.0 ± 0.3 cd | 6.2 ± 1.0 ab |

| HA_US_40_180 | 48.2 ± 6.3 ab | 3.1 ± 1.6 b | 17.4 ± 1.2 b | 48.5 ± 0.7 bcd | 16.3 ± 0.2 bc | 5.1 ± 0.3 a |

| HA_cUS_25_250 | 43.3 ± 5.3 a | 4.8 ± 2.2 bc | 18.0 ± 0.5 b | 60.8 ± 3.5 d | 19.0 ± 1.0 cd | 4.8 ± 2.0 a |

| FD | 81.0 ± 7.1 d | 2.9 ± 1.7 b | 15.2 ± 4.2 b | 23.7 ± 10.3 a | 31.2 ± 5.6 e | - |

| FD_US_21_300 | 82.1 ± 3.1 d | 1.9 ± 0.9 b | 18.2 ± 2.1 b | 26.2 ± 3.6 a | 33.8 ± 0.0 e | 7.6 ± 2.3 ab |

| FD_US_21_180 | 84.5 ± 3.7 d | 2.0 ± 1.2 b | 16.9 ± 0.3 b | 23.5 ± 0.2 a | 35.4 ± 0.4 e | 5.2 ± 0.1 a |

| FD_US_40_180 | 79.3 ± 7.9 d | 3.5 ± 2.6 b | 17.4 ± 2.0 b | 28.0 ± 8.1 ab | 31.5 ± 4.4 e | 9.6 ± 6.8 ab |

| FD_cUS_25_250 | 71.6 ± 6.7 cd | 4.1 ± 2.0 bc | 19.1 ± 1.2 b | 34.6 ± 0.8 abc | 26.1 ± 2.3 de | 16.9 ± 2.0 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szymanska, I.; Matys, A.; Rybak, K.; Karwacka, M.; Witrowa-Rajchert, D.; Nowacka, M. Impact of Ultrasound Pre-Treatment on the Drying Kinetics and Quality of Chicken Breast—A Comparative Study of Convective and Freeze-Drying Methods. Foods 2024, 13, 2850. https://doi.org/10.3390/foods13172850

Szymanska I, Matys A, Rybak K, Karwacka M, Witrowa-Rajchert D, Nowacka M. Impact of Ultrasound Pre-Treatment on the Drying Kinetics and Quality of Chicken Breast—A Comparative Study of Convective and Freeze-Drying Methods. Foods. 2024; 13(17):2850. https://doi.org/10.3390/foods13172850

Chicago/Turabian StyleSzymanska, Iwona, Aleksandra Matys, Katarzyna Rybak, Magdalena Karwacka, Dorota Witrowa-Rajchert, and Malgorzata Nowacka. 2024. "Impact of Ultrasound Pre-Treatment on the Drying Kinetics and Quality of Chicken Breast—A Comparative Study of Convective and Freeze-Drying Methods" Foods 13, no. 17: 2850. https://doi.org/10.3390/foods13172850

APA StyleSzymanska, I., Matys, A., Rybak, K., Karwacka, M., Witrowa-Rajchert, D., & Nowacka, M. (2024). Impact of Ultrasound Pre-Treatment on the Drying Kinetics and Quality of Chicken Breast—A Comparative Study of Convective and Freeze-Drying Methods. Foods, 13(17), 2850. https://doi.org/10.3390/foods13172850