Mathematical Modeling of Goat Meat Drying Kinetics with Thermal Oscillations

Abstract

1. Introduction

2. Materials and Methods

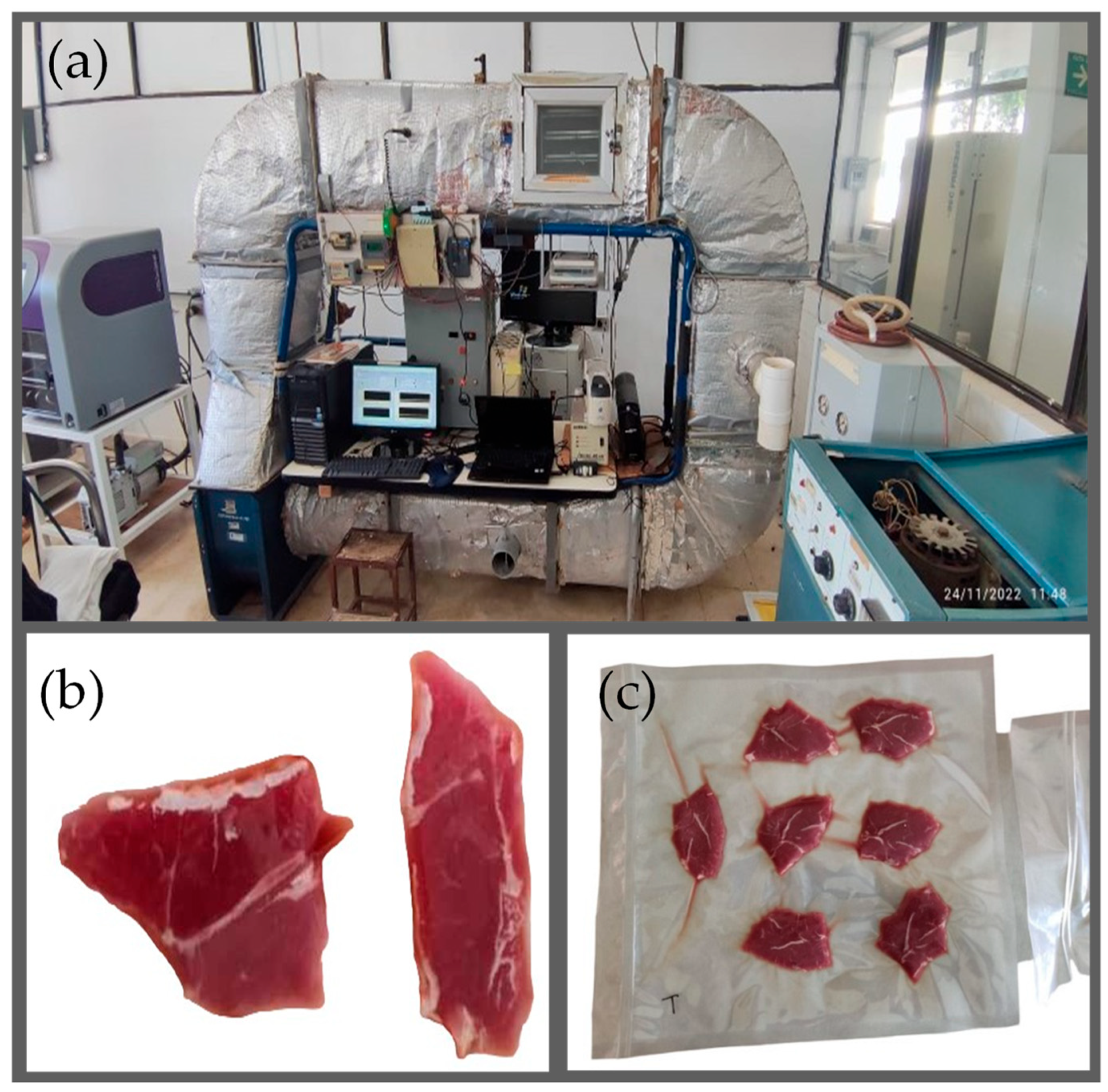

2.1. Meat Samples and Preparation

2.2. Drying

2.3. Drying Kinetics

2.4. Diffusion Coefficient

2.5. Activation Energy

2.6. Mathematical Models

3. Results and Discussion

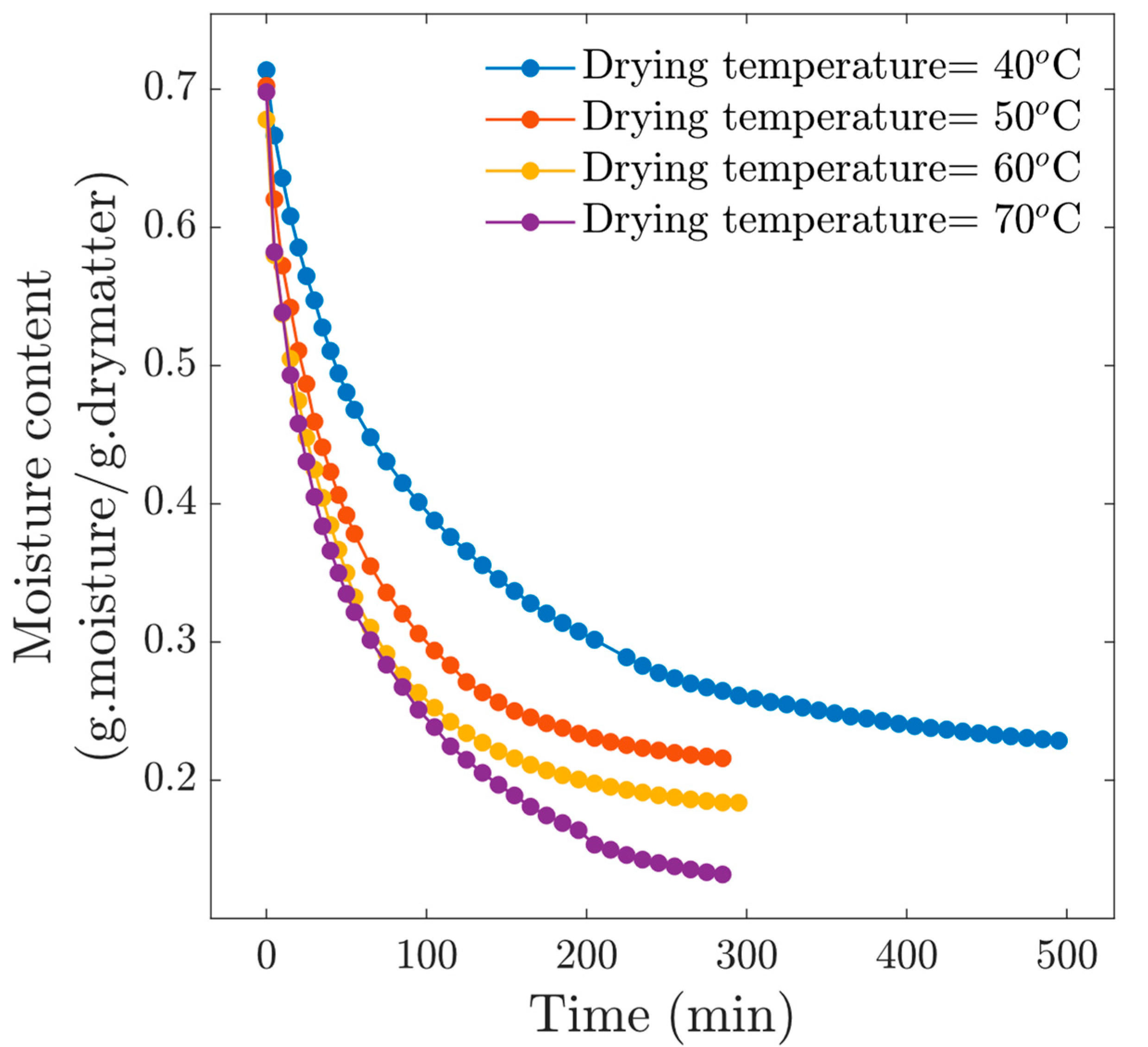

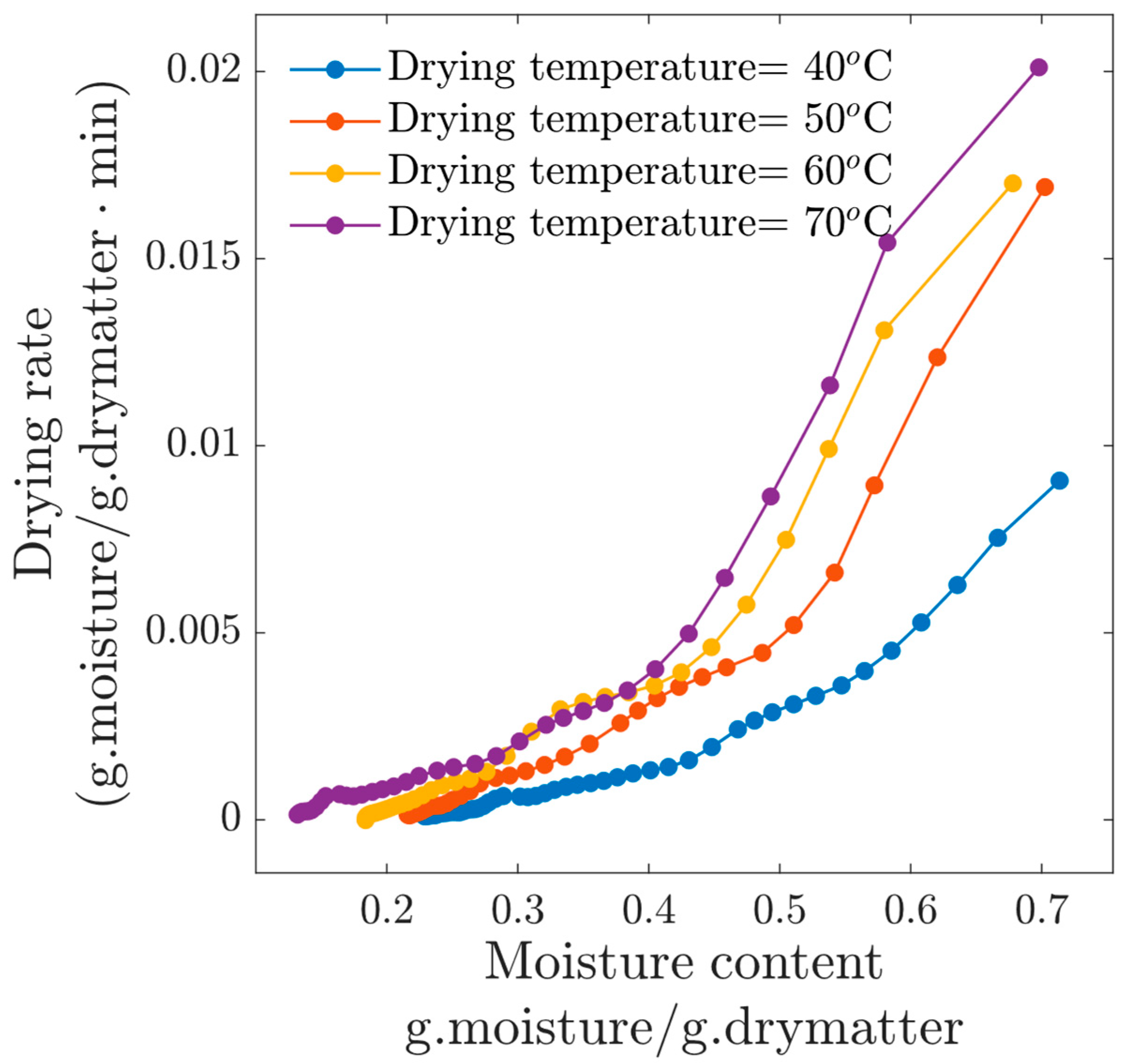

3.1. Convective Drying Kinetics Experiments

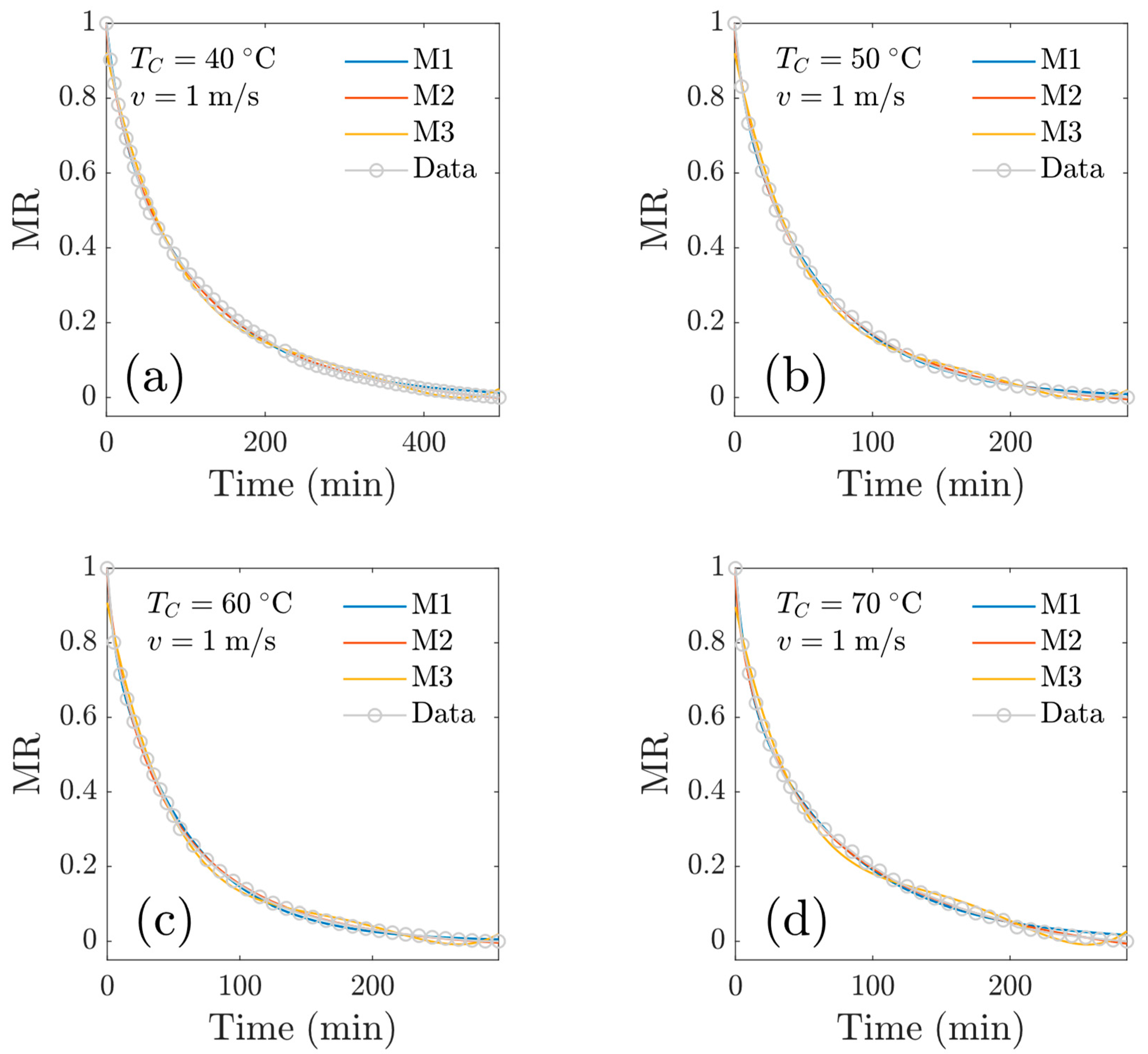

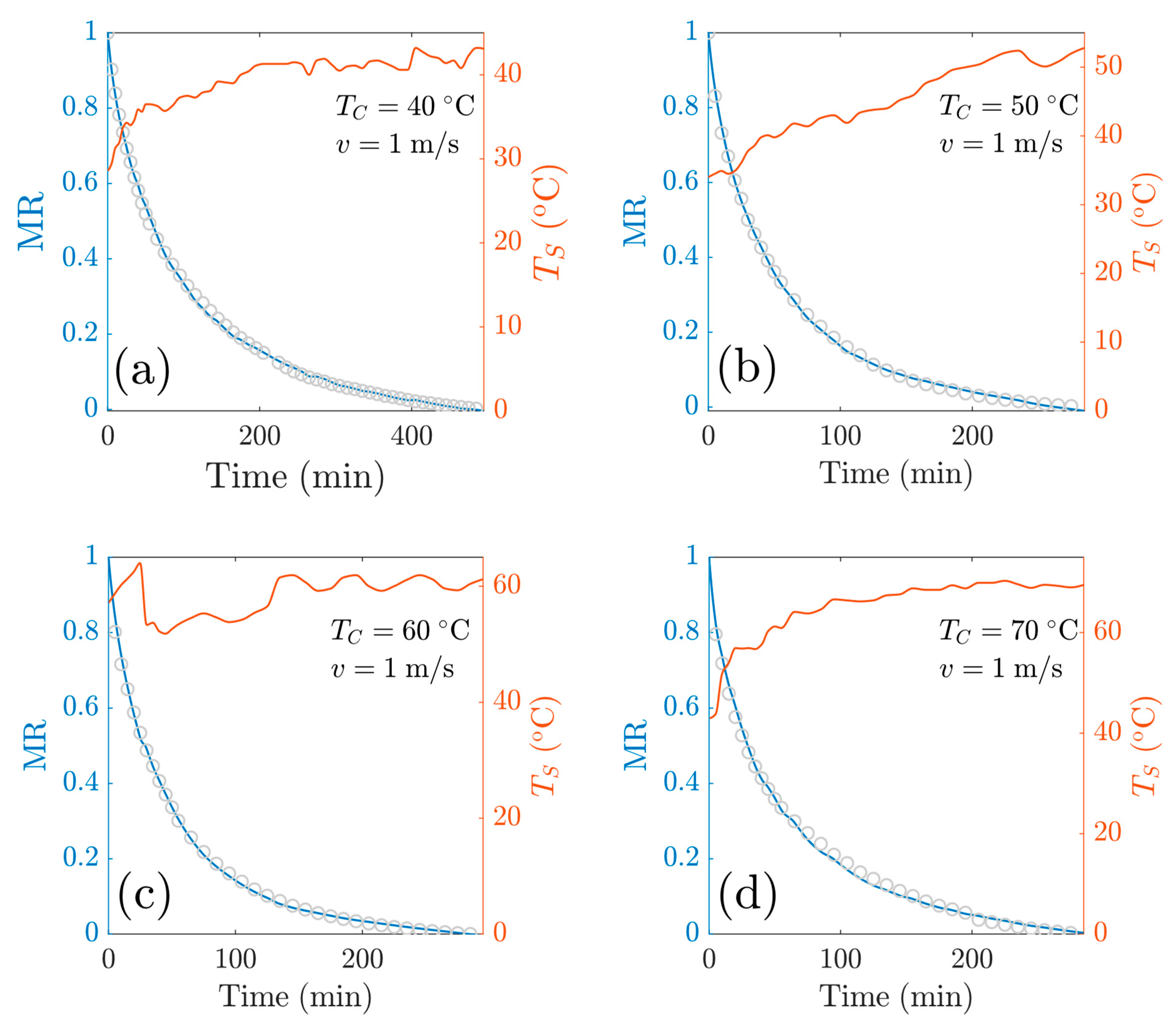

3.1.1. Experiments at v = 1 m/s Airflow

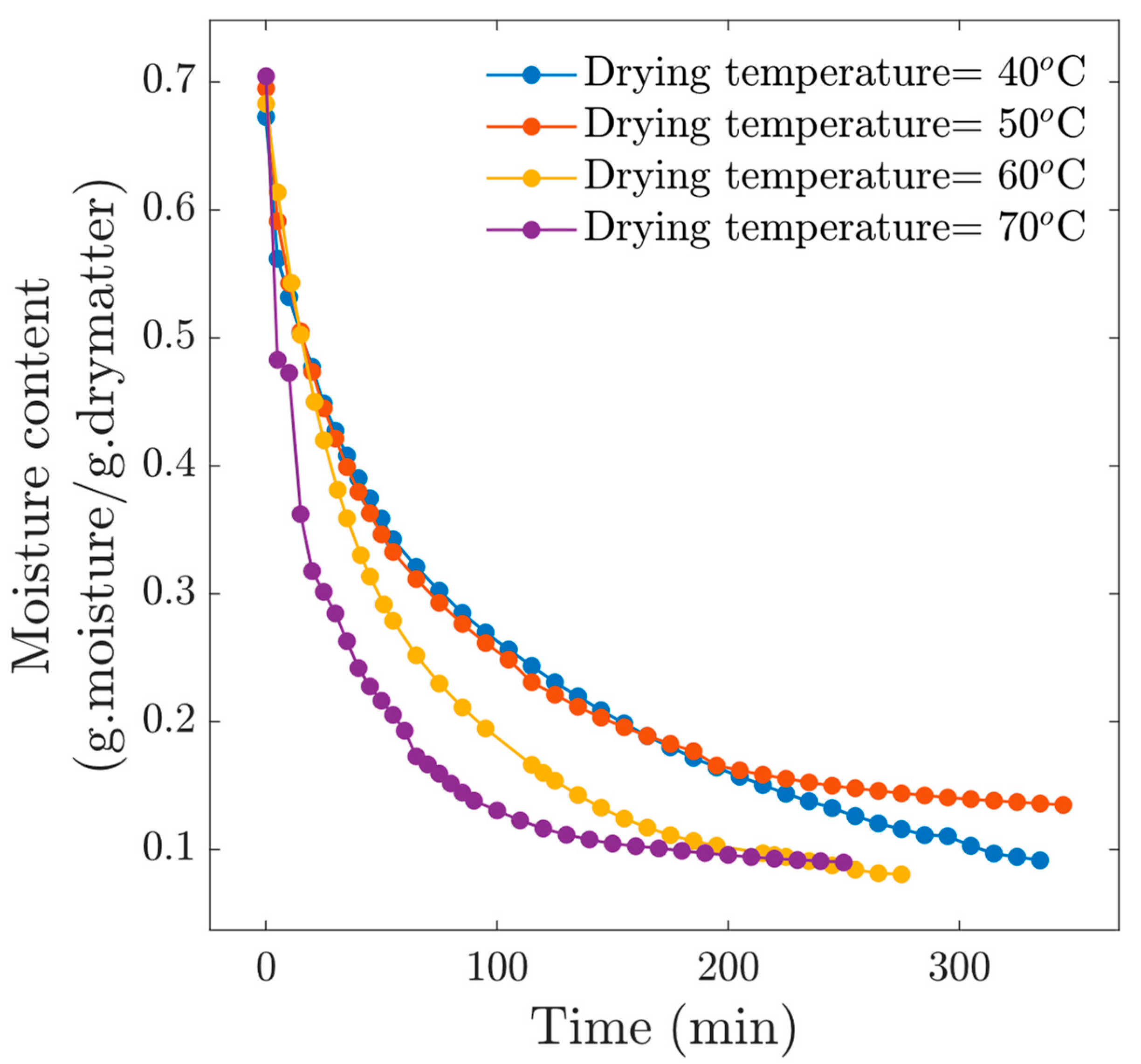

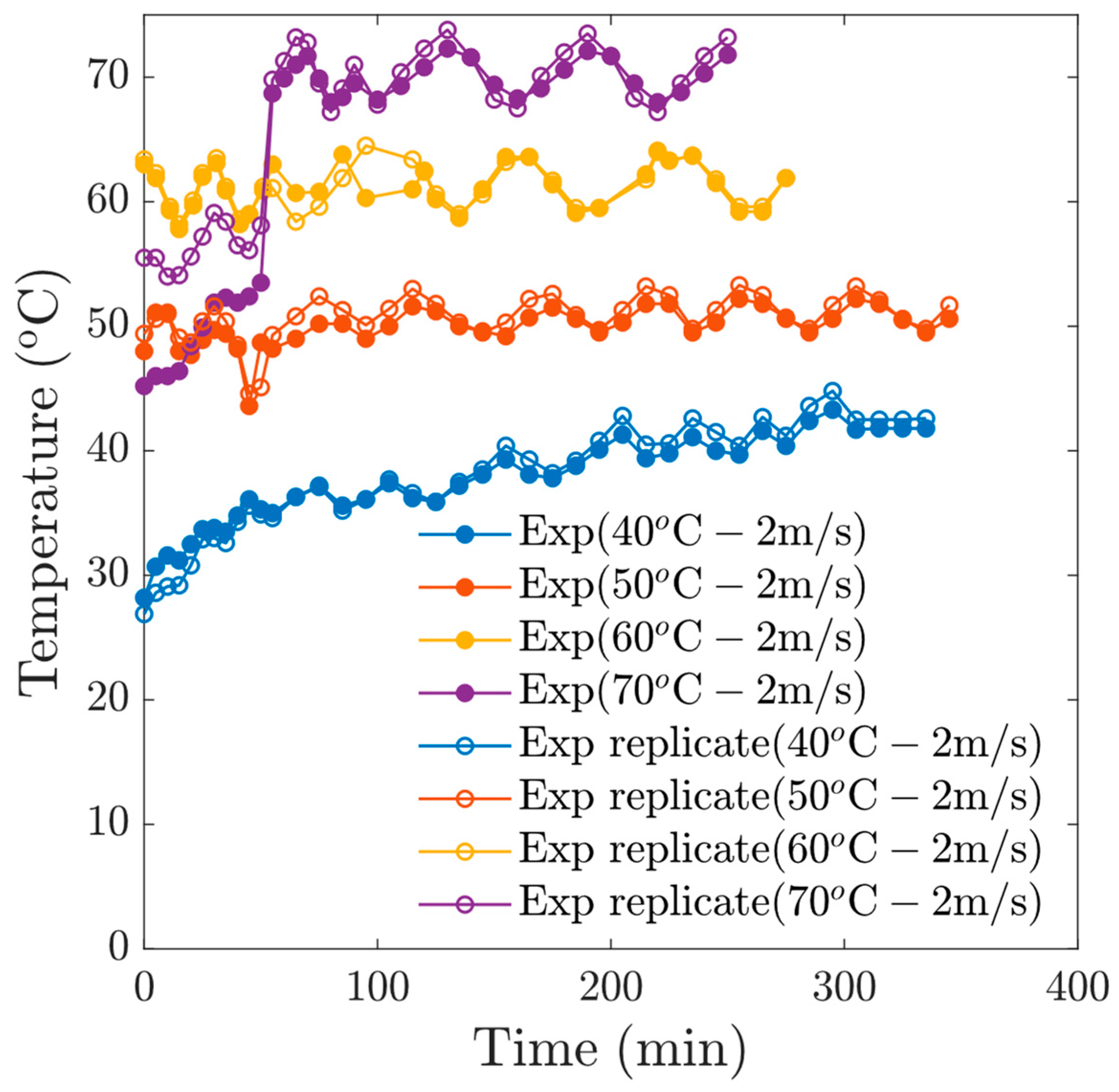

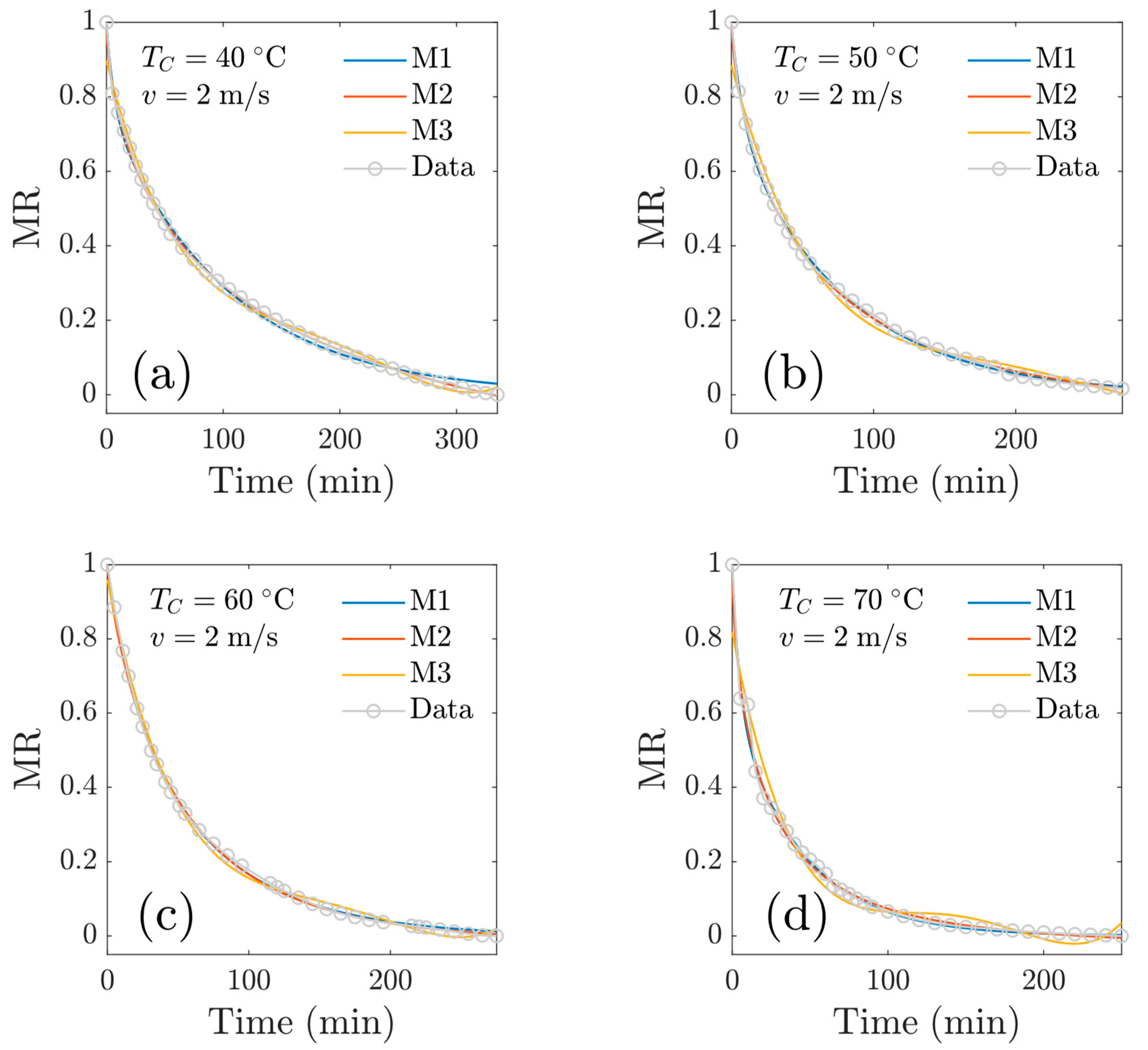

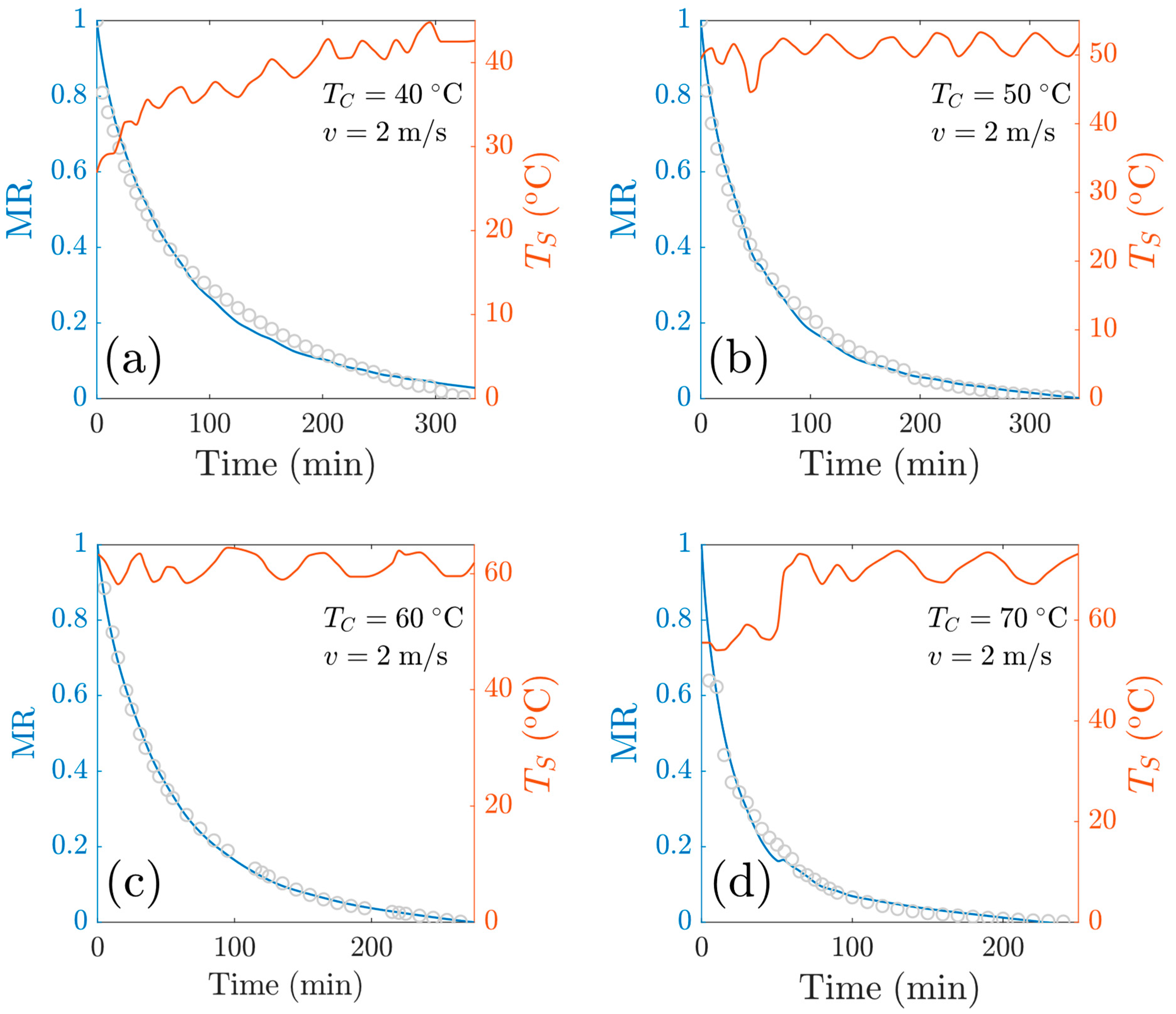

3.1.2. Experiments at v = 2 m/s Airflow

3.2. Implementation of Mathematical Models

3.3. Effective Diffusion Coefficients from the Analytical Solution

3.4. Heuristic Diffusion Model

3.4.1. Isothermal Model of MR

3.4.2. Temperature-Dependent Heuristic Model

4. Conclusions

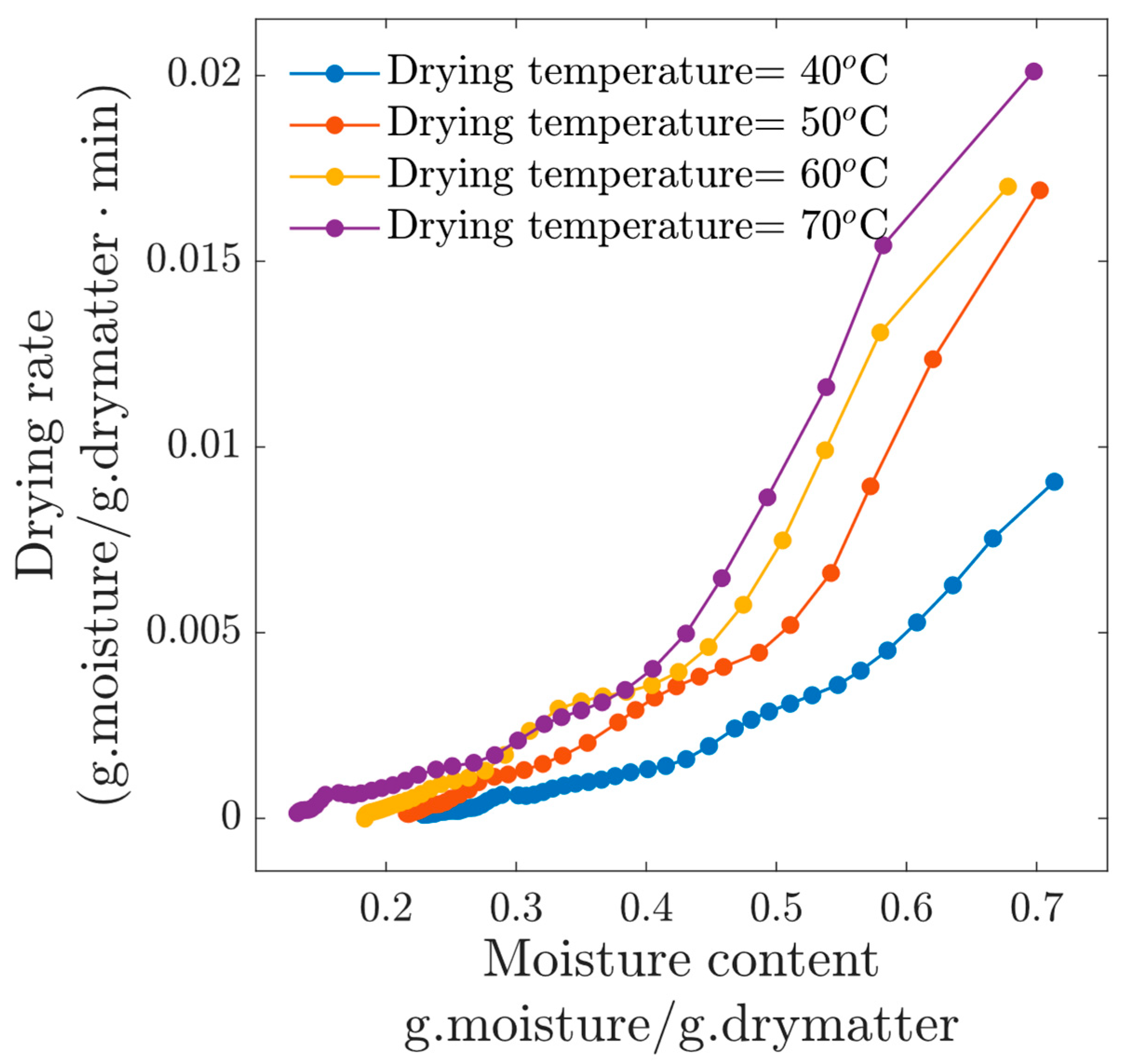

- According to our experimental results, the effect of air temperature on drying kinetics is very important. We observe the drying time decreases as temperature increases. For experiments at v = 1 m/s, we can observe that after 290 min, the samples subjected to Tc = 40 °C reached a moisture content of 0.26 (d.b), at Tc = 50 °C, a value of 0.22 (d.b), at Tc = 60 °C, a value of 0.18 (d.b) and for the conditions at Tc = 70 °C, a value of 0.07 (d.b). The temperature causes a very significant reduction in drying time. This was also corroborated by analyzing the drying rate curves, since it was observed that the initial drying rate for the drying condition at Tc = 70 °C was practically twice the rate at Tc = 40 °C. Furthermore, for experiments at 1 m/s, the constat drying rate was not observed.

- Regarding the drying kinetics for the four temperatures at v = 2 m/s, a second drying rule was confirmed: As airflow velocity increased, the drying rate increased. The final moisture content for this set of experiments was lower with respect to the experiments performed at v = 1 m/s; in fact, all the samples reached moisture contents below 0.2 (d.b). For these drying conditions, the falling drying rate period was always identified.

- Regarding the mathematical models, it was observed that they described the drying kinetics’ behavior with an accurate fitting of experimental data. The two-term models, the Midilli model and the Wang and Singh model showed very small RMSE values for all drying conditions. Also, the magnitude of the diffusion coefficients corresponded to the usual values for biological materials (~10−9 m2 s−1), which indicates the reliability of our calculations. In relation to the heuristic model, the drying curves for the four temperatures also showed a good prediction of data. This model considered the effect of temperature oscillation, which allows us to consider the thermal dynamics of the process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Field | Value | Description |

|---|---|---|

| RSS | Sum of squares due to error or residual sum of squares. Here is the estimator and is the sample size. | |

| ESS | Explained sum of squares. Here, is the arithmetic mean. | |

| TSS | Total sum of squares. | |

| RSQUARE () | R-squared (coefficient of determination). | |

| DFE | Degrees of freedom in the error, where is the number of predictors. | |

| ADJRSQUARE | Degree-of-freedom adjusted coefficient of determination. | |

| RMSE | Root mean square error (standard error). |

| Air Velocity | Coefficients * | Goodness | |||||||

|---|---|---|---|---|---|---|---|---|---|

| RSS | RSQUARE | DFE | ADJRSQUARE | RMSE | |||||

| 1 m/s | 40 | 0.0093 | 0.0003 | −1.4130 | 0.0029 | 0.9993 | 52 | 0.9993 | 0.0074 |

| 50 | 0.0164 | 0.0005 | −1.1000 | 0.0018 | 0.9993 | 32 | 0.9992 | 0.0076 | |

| 60 | 0.0256 | 0.0004 | 0.4998 | 0.0033 | 0.9986 | 33 | 0.9986 | 0.0101 | |

| 70 | 0.0156 | 0.0004 | −2.0000 | 0.0058 | 0.9974 | 33 | 0.9974 | 0.0133 | |

| 2 m/s | 40 | 0.0083 | 0.0006 | −3.3720 | 0.0172 | 0.9935 | 37 | 0.9993 | 0.0216 |

| 50 | 0.0188 | 0.0004 | −0.7729 | 0.0164 | 0.9939 | 38 | 0.9936 | 0.0207 | |

| 60 | 0.0206 | 0.0004 | −0.2490 | 0.0026 | 0.9990 | 31 | 0.9989 | 0.0091 | |

| 70 | 0.0347 | 0.0006 | −1.3720 | 0.0246 | 0.9854 | 32 | 0.9845 | 0.0278 | |

| Air Velocity | Coefficients * | Goodness | |||||||

|---|---|---|---|---|---|---|---|---|---|

| RSS | RSQUARE | DFE | ADJRSQUARE | RMSE | |||||

| 1 m/s | 40 | 0.2240 | 0.0082 | 0.0565 | 0.0019 | 0.9995 | 52 | 0.9995 | 0.0061 |

| 50 | 0.1910 | 0.0158 | 0.1459 | 0.0009 | 0.9996 | 32 | 0.9996 | 0.0053 | |

| 60 | 0.1830 | 0.0172 | 0.2165 | 0.0015 | 0.9994 | 33 | 0.9994 | 0.0068 | |

| 70 | 0.2923 | 0.0131 | 0.1230 | 0.0037 | 0.9984 | 32 | 0.9983 | 0.0107 | |

| 2 m/s | 40 | 0.2297 | 0.0097 | 0.1545 | 0.0077 | 0.9971 | 37 | 0.9969 | 0.0144 |

| 50 | 0.2639 | 0.0128 | 0.0128 | 0.0022 | 0.9992 | 38 | 0.9991 | 0.0076 | |

| 60 | 0.7201 | 0.0578 | 0.0147 | 0.0013 | 0.9995 | 31 | 0.9995 | 0.0065 | |

| 70 | 0.3808 | 0.0226 | 0.2104 | 0.0105 | 0.9938 | 32 | 0.9934 | 0.0181 | |

| Air Velocity | Coefficients * | Goodness | |||||||

|---|---|---|---|---|---|---|---|---|---|

| RSS | RSQUARE | DFE | ADJRSQUARE | RMSE | |||||

| 1 m/s | 40 | −0.0001 | 0.0318 | 0.7626 | 0.0012 | 0.9997 | 52 | 0.9997 | 0.0047 |

| 50 | −0.0001 | 0.0505 | 0.7658 | 0.0005 | 0.9998 | 32 | 0.9998 | 0.0041 | |

| 60 | −0.0001 | 0.0548 | 0.7629 | 0.0015 | 0.9994 | 33 | 0.9993 | 0.0068 | |

| 70 | −0.0002 | 0.0781 | 0.6482 | 0.0007 | 0.9997 | 32 | 0.9997 | 0.0048 | |

| 2 m/s | 40 | −0.0003 | 0.0667 | 0.6148 | 0.0012 | 0.9996 | 37 | 0.9995 | 0.0057 |

| 50 | −0.0001 | 0.0632 | 0.6933 | 0.0011 | 0.9996 | 38 | 0.9996 | 0.0054 | |

| 60 | −0.0000 | 0.0594 | 0.8267 | 0.0022 | 0.9991 | 31 | 0.9991 | 0.0084 | |

| 70 | −0.0001 | 0.1372 | 0.6325 | 0.0096 | 0.9943 | 32 | 0.9940 | 0.0173 | |

| Air Velocity | Coefficients * | Goodness | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RSS | RSQUARE | DFE | ADJRSQUARE | RMSE | |||||||

| 1 m/s | 40 | 0.0463 | −0.0980 | 0.0618 | −0.1124 | 0.1267 | 0.0728 | 0.9953 | 50 | 0.9949 | 0.0186 |

| 50 | 0.0488 | −0.1173 | 0.0861 | −0.1114 | 0.1167 | 0.0712 | 0.9947 | 30 | 0.9940 | 0.0195 | |

| 60 | 0.0535 | −0.1285 | 0.0829 | −0.0840 | 0.0946 | 0.0681 | 0.9939 | 30 | 0.9928 | 0.0205 | |

| 70 | 0.0601 | −0.1211 | 0.0409 | −0.0963 | 0.1487 | 0.0643 | 0.9903 | 30 | 0.9890 | 0.0251 | |

| 2 m/s | 40 | 0.0459 | −0.0946 | 0.0415 | 0.1300 | 0.1955 | 0.0658 | 0.9931 | 35 | 0.9923 | 0.0215 |

| 50 | 0.0567 | −0.1166 | 0.0530 | 0.0881 | 0.1108 | 0.0647 | 0.9898 | 36 | 0.9886 | 0.0259 | |

| 60 | 0.0530 | −0.1264 | 0.0843 | 0.1058 | 0.1242 | 0.0753 | 0.9967 | 36 | 0.9970 | 0.0157 | |

| 70 | 0.0633 | −0.1509 | 0.0571 | 0.0571 | 0.0639 | 0.0463 | 0.9588 | 30 | 0.9533 | 0.0446 | |

References

- Chen, C.; Pan, Z. An overview of progress, challenges, needs and trends in mathematical modeling approaches in food drying. Dry. Technol. 2023, 41, 2586–2605. [Google Scholar] [CrossRef]

- Álvarez, S.; Álvarez, C.; Hamill, R.; Mullen, A.M.; O’Neill, E. Drying dynamics of meat highlighting areas of relevance to dry-aging of beef. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5370–5392. [Google Scholar] [CrossRef] [PubMed]

- Baslar, M.; Yalınkılıc, B.; Erol, K.F.; Irkilmez, M.U. Evaluation of the Use of Vacuum-Dehydrated Minced Meat in Beef Patty Production. AgriEngineering 2024, 6, 1712–1724. [Google Scholar] [CrossRef]

- García-Pérez, J.; Carcel, J.; Mulet, A.; Riera, E.; Gallego-Juarez, J. Ultrasonic drying for food preservation. In Power Ultrasonics; Gallego-Juárez, J.A., Graff, K.F., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 875–910. [Google Scholar] [CrossRef]

- Mediani, A.; Hamezah, H.S.; Jam, F.A.; Mahadi, N.F.; Chan, S.X.Y.; Rohani, E.R.; Che Lah, N.H.; Azlan, U.K.; Khairul Annuar, N.A.; Azman, N.A.F.; et al. A comprehensive review of drying meat products and the associated effects and changes. Front. Nutr. 2022, 9, 1057366. [Google Scholar] [CrossRef]

- Ahmat, T.; Barka, M.; Aregba, A.W.; Bruneau, D. Convective Drying Kinetics of Fresh Beef: An Experimental and Modeling Approach. J. Food Process. Preserv. 2015, 39, 2581–2595. [Google Scholar] [CrossRef]

- Morales-Cruz, J.; Juárez-Canales, G.; Figueroa-González, J.; Mancillas-Medina, J. Evaluación de la Deshidratación solar en carne de cabra (Caprus dominiuniversi), determinación de su composición química y compararla con una comercial. Investig. Desarro. Cienc. Tecnol. Aliment. 2017, 2, 370–375. [Google Scholar]

- Chabbouh, M.; Hajji, W.; Ahmed, S.B.H.; Farhat, A.; Bellagha, S.; Sahli, A. Combined Effects of Osmotic Dehydration and Convective Air Drying on Kaddid Meats: Kinetics and Quality. Dry. Technol. 2011, 29, 1571–1579. [Google Scholar] [CrossRef]

- Aykin-Dinçer, E.; Kiliç-Büyükkurt, O.; Erbas, M. Influence of drying techniques and temperatures on drying kinetics and quality characteristics of beef slices. Heat Mass Transf. 2020, 56, 315–320. [Google Scholar] [CrossRef]

- Mewa, E.A.; Okoth, M.W.; Kunyanga, C.N.; Rugiri, M.N. Effect of drying air temperature and slice thickness on the physical and microbiological quality of dried beef. LWT 2018, 92, 484–489. [Google Scholar] [CrossRef]

- Kamiloğlu, A.; Elbir, T.; Dölek, M.; Eşrefoğlu, E.S. Comparative evaluation of different drying techniques for beef meat. J. Food Process Eng. 2023, 46, e14441. [Google Scholar] [CrossRef]

- Drãghici, O. Evaluation of mathematical models which describe the process of drying goat meat. Sci. Pap. Ser. 2021, 21, 237–240. Available online: https://managementjournal.usamv.ro/pdf/vol.21_1/volume_21_1_2021.pdf (accessed on 12 November 2024).

- Álvarez, S.; Álvarez, C.; Hamill, R.M.; O’Neill, E.; Mullen, A.M. Influence of meat sample geometry on dehydration dynamics during dry-aging of beef. Meat Sci. 2023, 202, 109216. [Google Scholar] [CrossRef] [PubMed]

- Zukál, E.; Incze, K. Drying. In Handbook of Meat Processing; Toldrá, F., Ed.; Wiley Blackwell: Hoboken, NJ, USA, 2010; pp. 219–229. [Google Scholar] [CrossRef]

- Nayak, A. A new regularization approach for numerical differentiation. Inverse Probl. Sci. Eng. 2020, 28, 1747–1772. [Google Scholar] [CrossRef]

- İrem Ş ahin, F.; Acaralı, N. Effective moisture diffusivity and activation energy during convective drying of bread containing clove oil/orange oil. J. Indian Chem. Soc. 2023, 100, 100952. [Google Scholar] [CrossRef]

- Barforoosh, M.Y.; Borghaee, A.M.; Rafiee, S.; Minaei, S.; Beheshti, B. Determining the effective diffusivity coefficient and activation energy in thin-layer drying of Haj Kazemi peach slices and modeling drying kinetics using ANFIS. Int. J. Low-Carbon Technol. 2024, 19, 192–206. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford University Press: London, UK, 1979. [Google Scholar]

- Juma Haydary, M.J.R.; Noori, A.W. Process conditions sensitive (PCS) thin-layer mathematical model of hot air convective drying. Chem. Eng. Commun. 2024, 211, 133–145. [Google Scholar] [CrossRef]

- Henderson, S. Progress in developing the thin layer drying equation. Trans. ASAE 1974, 17, 1167–1168. [Google Scholar] [CrossRef]

- Sharaf-Eldeen, Y.; Blaisdell, J.; Hamdy, M. A model for ear corn drying. Trans. ASAE 1981, 23, 1261–1265. [Google Scholar] [CrossRef]

- Demir, V.; Gunhan, T.; Yagcioglu, A. Mathematical modelling of convection drying of green table olives. Biosyst. Eng. 2007, 98, 47–53. [Google Scholar] [CrossRef]

- Verma, L.R.; Bucklin, R.; Endan, J.; Wratten, F. Effects of drying air parameters on rice drying models. Trans. ASAE 1985, 28, 296–0301. [Google Scholar] [CrossRef]

- Midilli, A.D.N.A.N.; Kucuk, H.A.Y.D.A.R.; Yapar, Z.İ.Y.A. A new model for single-layer drying. Dry. Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- Toğrul, İ.T.; Pehlivan, D. Mathematical modelling of solar drying of apricots in thin layers. J. Food Eng. 2002, 55, 209–216. [Google Scholar] [CrossRef]

- Henderson, S.; Pabis, S. Grain drying theory. I. Temperature effect on drying coefficients. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Popescu, M.; Iancu, P.; Plesu, V.; Bildea, C.S.; Manolache, F.A. Mathematical Modeling of Thin-Layer Drying Kinetics of Tomato Peels: Influence of Drying Temperature on the Energy Requirements and Extracts Quality. Foods 2023, 12, 3883. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic models for drying techniques—Food materials. ACES 2018, 8, 27–48. [Google Scholar] [CrossRef]

- Dinçer, I.; Zamfirescu, C. Drying Phenomena: Theory and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Bates, D.M.; Watts, D.G. Nonlinear Regression Analysis and Its Applications; Wiley: New York, NY, USA, 1988; Volume 2. [Google Scholar] [CrossRef]

- Jarantow, S.W.; Pisors, E.D.; Chiu, M.L. Introduction to the use of linear and nonlinear regression analysis in quantitative biological assays. Curr. Protoc. 2023, 3, e801. [Google Scholar] [CrossRef]

| Model | Name | Equation | References | |

|---|---|---|---|---|

| M1 | Two-term | [20] | ||

| Special case | Two-term exponential: | [21] | ||

| Diffusion: | [22] | |||

| Verma et al.: | [23] | |||

| M2 | Midilli (Extended) | [24] | ||

| Logarithmic: | [25] | |||

| Henderson and Pabis: | [26] | |||

| Special case | Page: | [27] | ||

| Modified Page: | [27] | |||

| Newton/Lewis: | [27,28] | |||

| M3 | Polynomial | |||

| Special case | Wang and Singh: | [28] | ||

| M4 | Heuristic+ | Current study | ||

| with | ||||

| M5 | Heuristic++ | Current study | ||

| with , . | ||||

| Model | Name | Equation | Parameter |

|---|---|---|---|

| M1 | Two-Term | ||

| M2 | Midilli (Extended) | ||

| M3 | Polynomial |

| Air Velocity | Coefficients | Central Drying Temperature Tc (°C) | |||

|---|---|---|---|---|---|

| 40 | 50 | 60 | 70 | ||

| 0.15 | 0.11 | 0.08 | 0.11 | ||

| 0.77 | 0.80 | 0.82 | 0.71 | ||

| 7–20 | 14–40 | 16–44 | 12–33 | ||

| 0.06 | 0.11 | 3.94 | 0.11 | ||

| 0.77 | 0.74 | 0.28 | 0.62 | ||

| 0.9–3 | 1–3 | 5–15 | 2–6 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrillo Luis, V.; Beristain Rios, D.; Hernández-Flores, O.A.; Romero-Salazar, C.; Sandoval-Torres, S. Mathematical Modeling of Goat Meat Drying Kinetics with Thermal Oscillations. Foods 2024, 13, 3836. https://doi.org/10.3390/foods13233836

Carrillo Luis V, Beristain Rios D, Hernández-Flores OA, Romero-Salazar C, Sandoval-Torres S. Mathematical Modeling of Goat Meat Drying Kinetics with Thermal Oscillations. Foods. 2024; 13(23):3836. https://doi.org/10.3390/foods13233836

Chicago/Turabian StyleCarrillo Luis, Valeria, Diego Beristain Rios, Omar Augusto Hernández-Flores, Carolina Romero-Salazar, and Sadoth Sandoval-Torres. 2024. "Mathematical Modeling of Goat Meat Drying Kinetics with Thermal Oscillations" Foods 13, no. 23: 3836. https://doi.org/10.3390/foods13233836

APA StyleCarrillo Luis, V., Beristain Rios, D., Hernández-Flores, O. A., Romero-Salazar, C., & Sandoval-Torres, S. (2024). Mathematical Modeling of Goat Meat Drying Kinetics with Thermal Oscillations. Foods, 13(23), 3836. https://doi.org/10.3390/foods13233836