Preliminary Investigation of Fruit Mash Inoculation with Pure Yeast Cultures: A Case of Volatile Profile of Industrial-Scale Plum Distillates

Abstract

1. Introduction

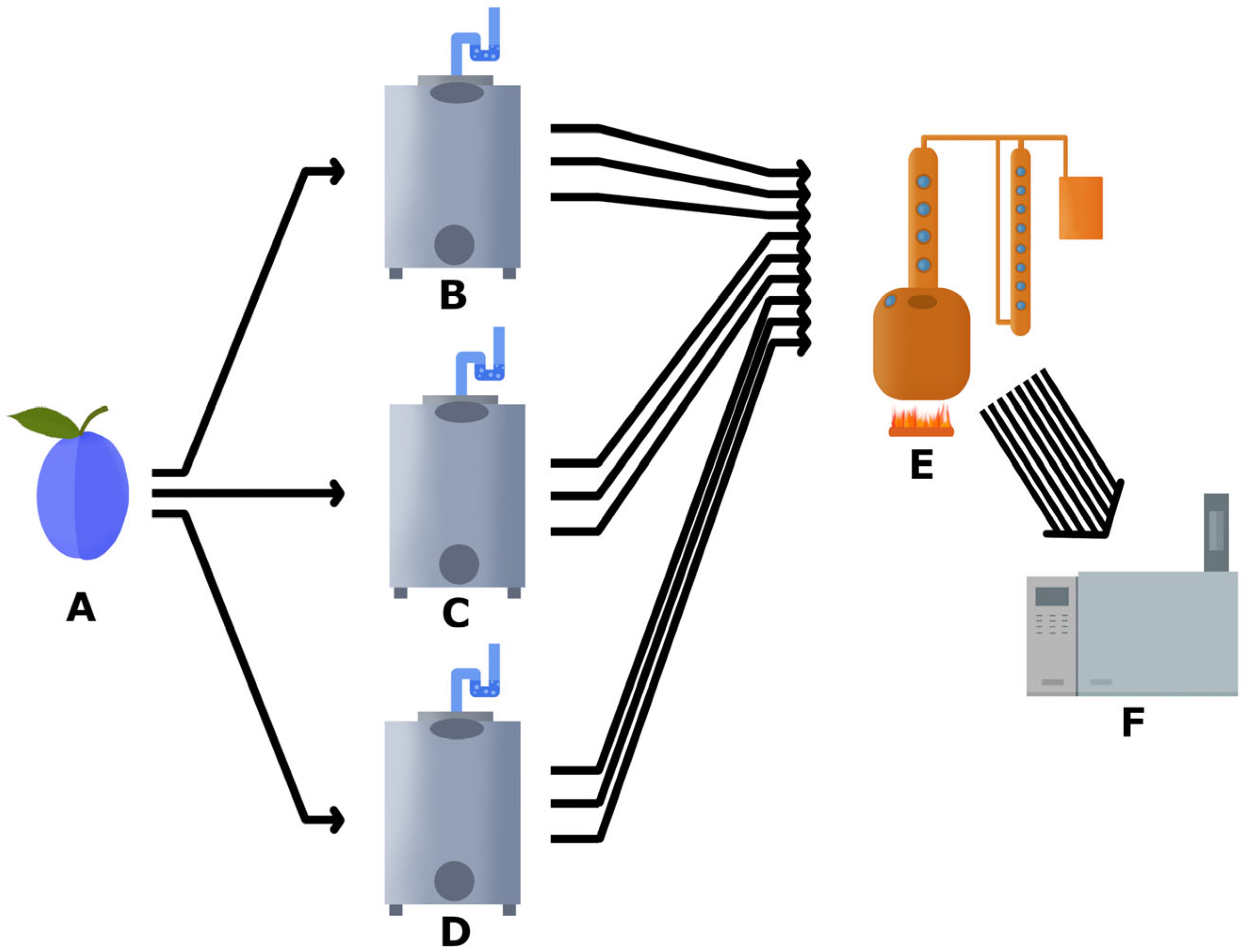

2. Materials and Methods

2.1. Samples of Plum Brandy

2.2. Chemicals and Reagents

2.3. Determination of Aroma Substances

2.4. Sensory Evaluation

2.5. Statistical Analysis

3. Results and Discussion

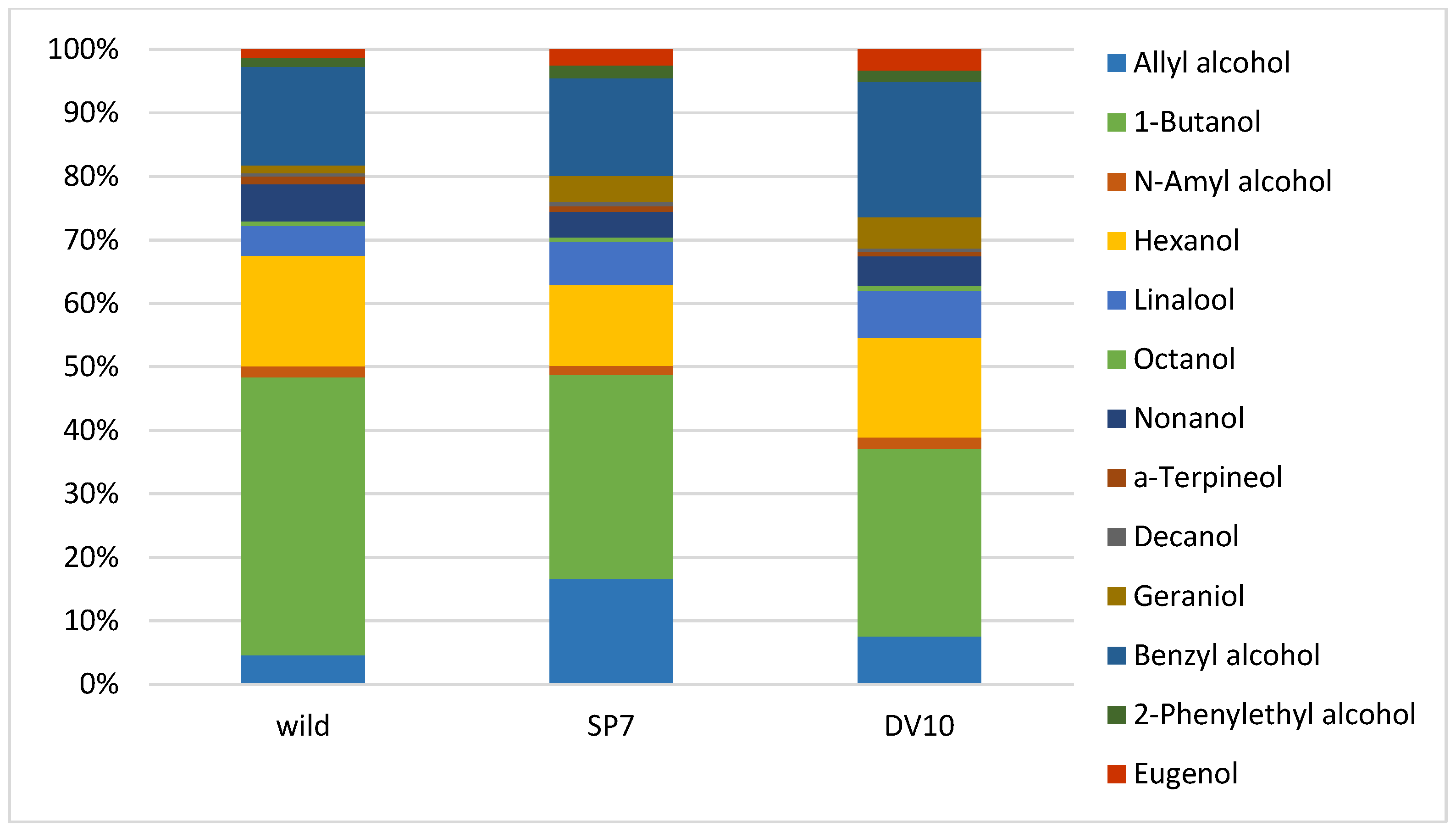

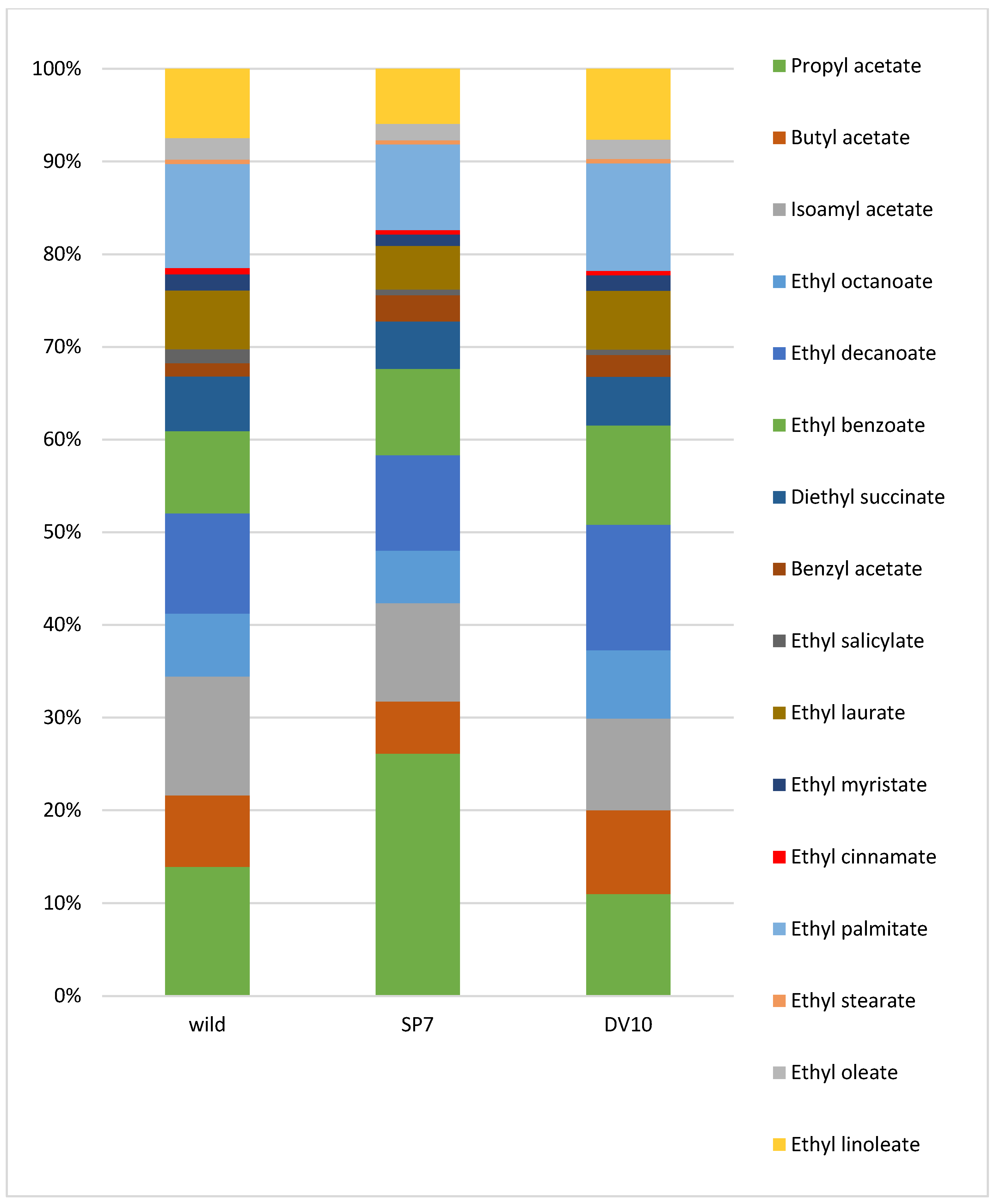

3.1. Effect of Fermentation Type on the Analytical Profile of Plum Brandies

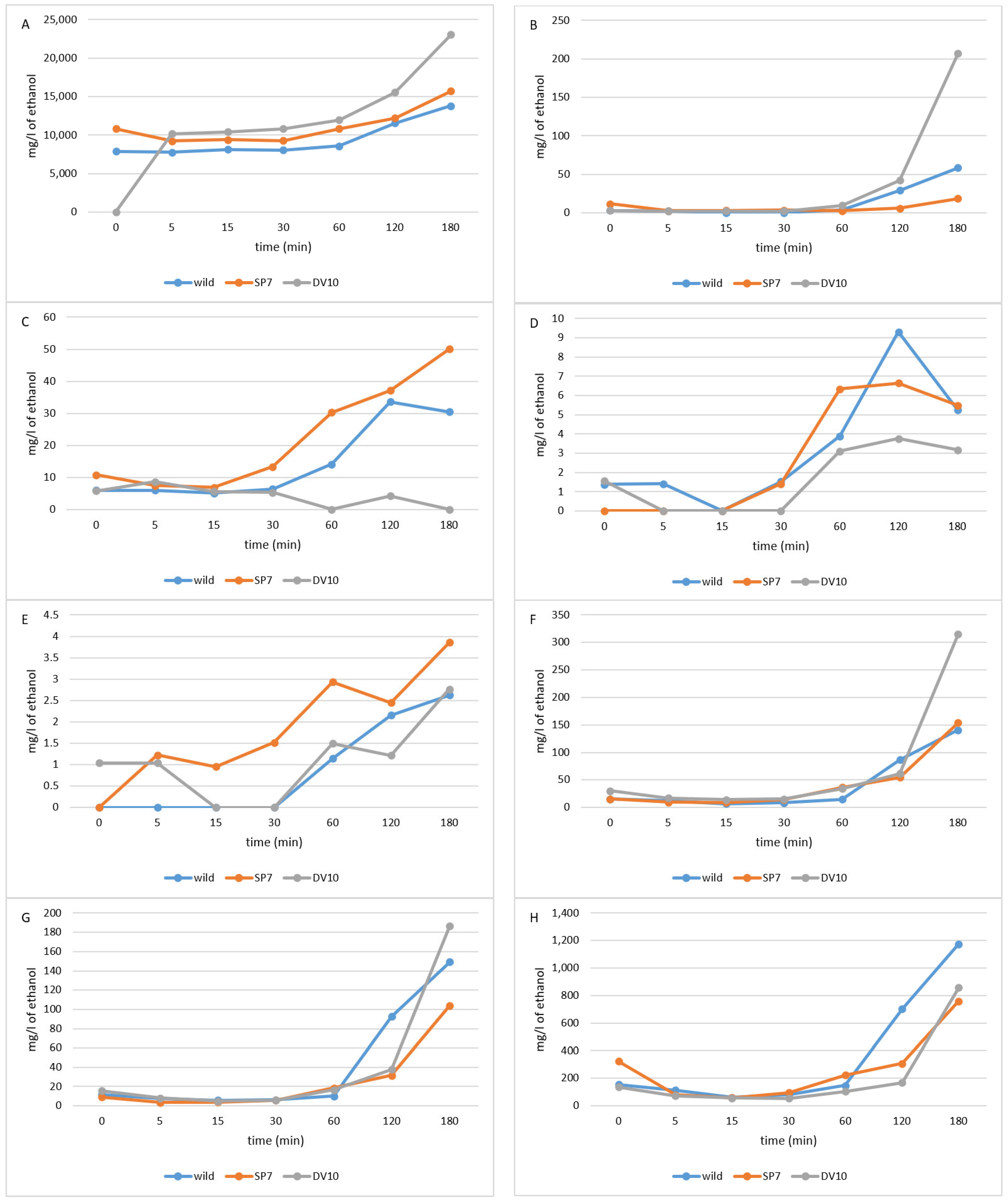

3.2. Changes in the Analytical Profiles of Plum Brandies during Distillation

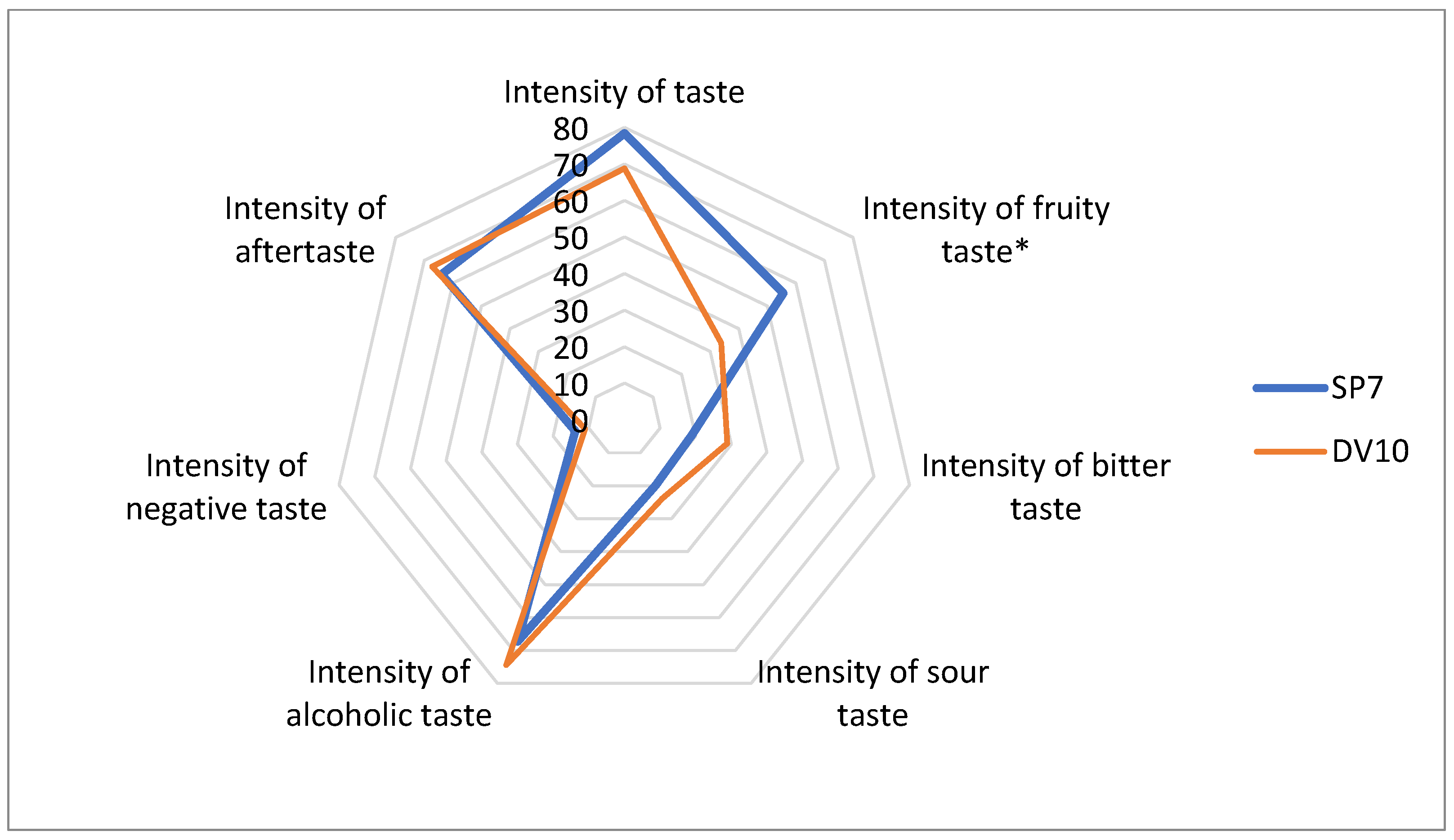

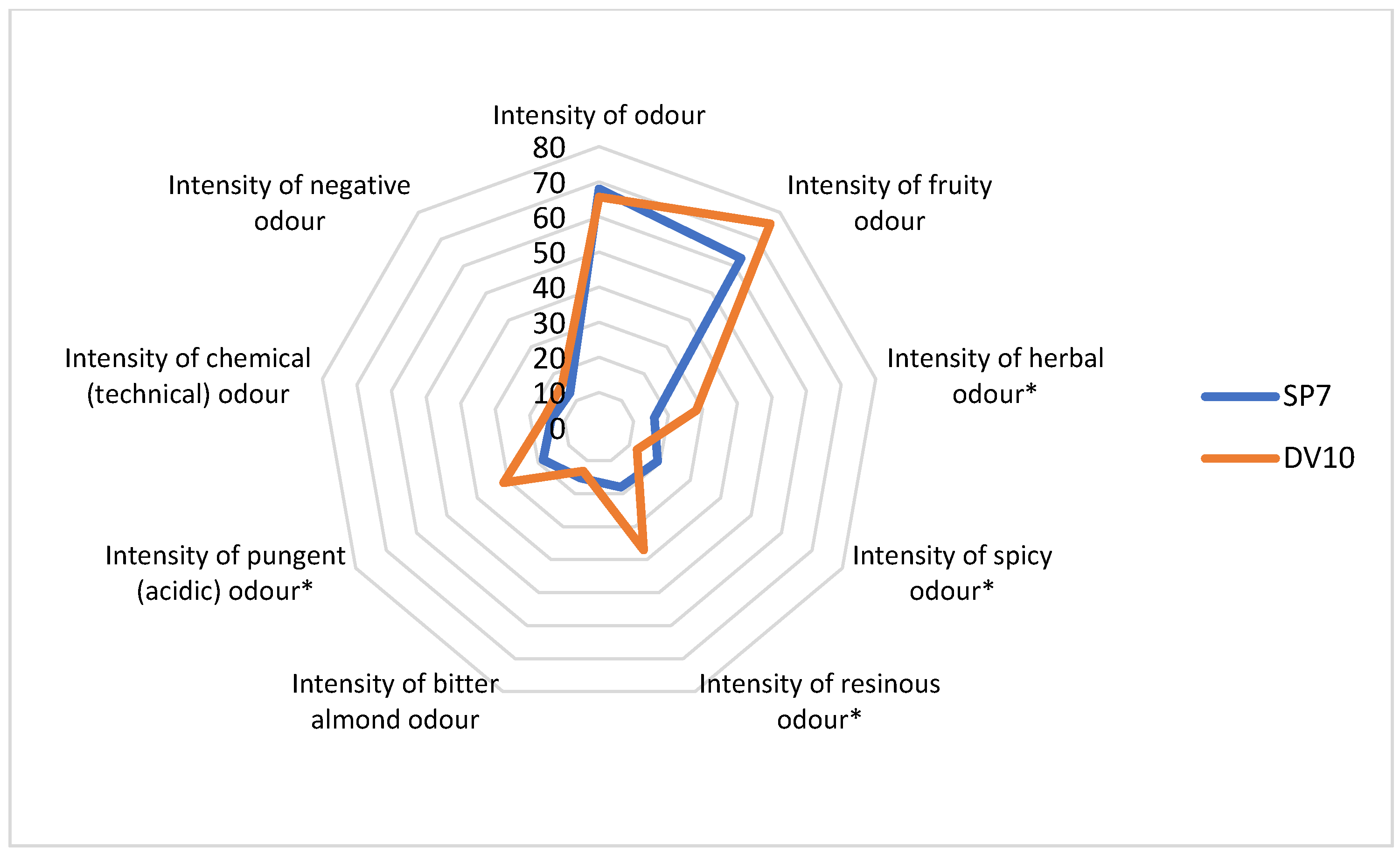

3.3. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heller, D.; Einfalt, D. Reproducibility of Fruit Spirit Distillation Processes. Beverages 2022, 8, 20. [Google Scholar] [CrossRef]

- Christoph, N.; Bauer-Christoph, C. Flavour of Spirit Drinks: Raw Materials. Fermentation, Distillation, and Ageing. In Flavours and Fragrances: Chemistry. Bioprocessing and Sustainability; Berger, R.G., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 219–239. [Google Scholar]

- Querol, A.; Fleet, G.H. Yeasts in Food and Beverages; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- El Hadi, M.A.; Zhang, F.J.; Wu, F.F.; Zhou, C.H.; Tao, J. Advances in fruit aroma volatile research. Molecules 2013, 18, 8200–8229. [Google Scholar] [CrossRef] [PubMed]

- Walker, G.M.; Stewart, G.G. Saccharomyces cerevisiae in the production of fermented beverages. Beverages 2016, 2, 30. [Google Scholar] [CrossRef]

- Spaho, N. Distillation techniques in the fruit spirits production. In Distillation—Innovative Applications and Modeling; IntechOpen: Rijeka, Croatia, 2017; p. 246. [Google Scholar] [CrossRef]

- Satora, P.; Tuszyński, T. Influence of indigenous yeasts on the fermentation and volatile profile of plum brandies. Food Microbiol. 2010, 27, 418–424. [Google Scholar] [CrossRef] [PubMed]

- Fleet, G.H. Wine yeasts for the future. FEMS Yeast Res. 2008, 8, 979–995. [Google Scholar] [CrossRef] [PubMed]

- Taiwo, A.E.; Madzimbamuto, T.N.; Ojumu, T.V. Optimization of Corn Steep Liquor Dosage and Other Fermentation Parameters for Ethanol Production by Saccharomyces cerevisiae Type 1 and Anchor Instant Yeast. Energies 2018, 11, 1740. [Google Scholar] [CrossRef]

- Krapfenbauer, G.; Suman, H.; Karner, M.; Gössinger, M. Effect of several parameters of harvesting and processing of fruit mashes on the methanol content and the sensory profile of distillates. Mitteilungen Klosterneuburg 2007, 57, 94–107. [Google Scholar]

- Zhang, H.; Woodams, E.E.; Hang, Y.D. Influence of pectinase treatment on fruit spirits from apple mash, juice and pomace. Process Biochem. 2011, 46, 1909–1913. [Google Scholar] [CrossRef]

- Hang, Y.D.; Woodams, E.E. Influence of apple cultivar and juice pasteurization on hard cider and eau-de-vie methanol content. Bioresour. Technol. 2010, 101, 1396–1398. [Google Scholar] [CrossRef]

- Tuszyński, T. Changes in the degree of pectin demethylation during fermentation of fruit musts. Food/Nahrung 1989, 33, 183–189. [Google Scholar] [CrossRef]

- Nikićević, N.; Tešević, V. Possibilities for methanol content reduction in plum brandy. J. Agric. Sci. 2005, 50, 49–60. [Google Scholar]

- Popović, B.; Mitrović, O.; Nikićević, N.; Tešević, V.; Urošević, I.; Miletić, N.; Milojević, S. Influence of Different Pre-Distillation Steps on Aromatic Profile of Plum Spirits Produced by Traditional and Modified Methods. Processes 2023, 11, 863. [Google Scholar] [CrossRef]

- Alimardani-Theuil, P.; Gainvors-Claisse, A.; Duchiron, F. Yeasts: An attractive source of pectinases—From gene expression to potential applications: A review. Process Biochem. 2011, 46, 1525–1537. [Google Scholar] [CrossRef]

- Regulation (EU) 2019/787; Regulation on the Definition, Description, Presentation and Labelling of Spirit Drinks, the Use of the Names of Spirit Drinks in the Presentation and Labelling of Other Foodstuffs, the Protection of Geographical Indications for Spirit Drinks, the Use of Ethyl alcohol and Distillates of Agricultural Origin in Alcoholic Beverages, and Repealing Regulation (EC) No 110/2008. Available online: http://data.europa.eu/eli/reg/2019/787/oj (accessed on 26 April 2024).

- Stanzer, D.; Hanousek Čiča, K.; Blesić, M.; Smajić Murtić, M.; Mrvčić, J.; Spaho, N. Alcoholic Fermentation as a Source of Congeners in Fruit Spirits. Foods 2023, 12, 1951. [Google Scholar] [CrossRef] [PubMed]

- Eden, A.; Van Nedervelde, L.; Drukker, M.; Benvenisty, N.; Debourg, A. Involvement of branched-chain amino acid aminotransferases in the production of fusel alcohols during fermentation in yeast. Appl. Microbiol. Biotechnol. 2001, 55, 296–300. [Google Scholar] [CrossRef] [PubMed]

- Hazelwood, L.A.; Daran, J.-M.; Van Maris, A.J.; Pronk, J.T.; Dickinson, J.R. The Ehrlich pathway for fusel alcohol production: A century of research on Saccharomyces cerevisiae metabolism. Appl. Environ. Microbiol. 2008, 74, 2259–2266. [Google Scholar] [CrossRef] [PubMed]

- Spaho, N.; Dürr, P.; Grba, S.; Velagić-Habul, E.; Blesić, M. Effects of distillation cut on the distribution of higher alcohols and esters in brandy produced from three plum varieties. J. Inst. Brew. 2013, 119, 48–56. [Google Scholar] [CrossRef]

- Belda, I.; Ruiz, J.; Esteban-Fernández, A.; Navascués, E.; Marquina, D.; Santos, A.; Moreno-Arribas, M.V. Microbial contribution to wine aroma and its intended use for wine quality improvement. Molecules 2017, 22, 189. [Google Scholar] [CrossRef] [PubMed]

- Vyviurska, O.; Matura, F.; Furdíková, K.; Špáni, I. Volatile fingerprinting of the plum brandies produced from different fruit varieties. J. Food Sci. Technol. 2017, 54, 4284–4301. [Google Scholar] [CrossRef]

- Logistica Fruit. European Statistics Handbook 2024; Fruit Logistica: Berlin, Germany, 2024. [Google Scholar]

- Solís-Solís, H.; Calderón-Santoyo, M.; Schorr-Galindo, S.; Luna-Solano, G.; Ragazzo-Sánchez, J. Characterization of aroma potential of apricot varieties using different extraction techniques. Food Chem. 2007, 105, 829–837. [Google Scholar] [CrossRef]

- Pino, J.A.; Quijano, C.E. Study of the volatile compounds from plum (Prunus domestica L. cv. Horvin) and estimation of their contribution to the fruit aroma. Food Sci. Technol. 2012, 32, 76–83. [Google Scholar] [CrossRef]

- Léauté, R. Distillation in alambic. Am. J. Enol. Vitic. 1990, 41, 90–103. [Google Scholar] [CrossRef]

- Kroh, L.W. Caramelisation in food and beverages. Food Chem. 1994, 51, 373–379. [Google Scholar] [CrossRef]

- Mesias, M.; Delgado-Andrade, C.; Gómez-Narváez, F.; Contreras-Calderón, J.; Morales, F.J. Formation of acrylamide and other heat-induced compounds during panela production. Foods 2020, 9, 531. [Google Scholar] [CrossRef] [PubMed]

- Nikićević, N. Effects of some production factors on chemical composition and sensory qualities of Williams pear brandy. J. Agric. Sci. 2005, 50, 193–206. [Google Scholar]

- Satora, P.; Kostrz, M.; Sroka, P.; Tarko, T. Chemical profile of spirits obtained by spontaneous fermentation of different varieties of plum fruits. Eur. Food Res. Technol. 2017, 243, 489–499. [Google Scholar] [CrossRef]

- Czerny, M.; Christlbauer, M.; Christlbauer, M.; Fischer, A.; Granvogl, M.; Hammer, M.; Hartl, C.; Hernandez, N.M.; Schieberle, P. Re-investigation on odour thresholds of key food aroma compounds and development of an aroma language based on odour qualities of defined aqueous odorant solutions. Eur. Food Res. Technol. 2008, 228, 265–273. [Google Scholar] [CrossRef]

- Singh, V.; Murphy, N.R.; Balasubramanian, V.; Mainland, J.D. Competitive binding predicts nonlinear responses of olfactory receptors to complex mixtures. Proc. Natl. Acad. Sci. USA 2019, 116, 9598–9603. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Xie, T.; Xie, J.; Chen, C.; Ai, L.; Tian, H. Aroma perceptual interactions of benzaldehyde, furfural, and vanillin and their effects on the descriptor intensities of Huangjiu. Food Res. Int. 2020, 129, 108808. [Google Scholar] [CrossRef]

- Zierer, B.; Schieberle, P.; Granvogl, M. Aroma-active compounds in Bartlett pears and their changes during the manufacturing process of Bartlett pear brandy. J. Agric. Food Chem. 2016, 64, 9515–9522. [Google Scholar] [CrossRef]

- Butac, M.; Bozhkova, V.; Zhivondov, A.; Milosevic, N.; Bellini, E.; Nencetti, V.; Blazek, J.; Balsemin, E.; Lafarque, B.; Kaufmane, E. Overview of plum breeding in Europe. In Proceedings of the II Balkan Symposium on Fruit Growing 981, Pitesti, Romania, 5–7 September 2011; pp. 91–98. [Google Scholar]

- Popović, B.T.; Mitrović, O.V.; Leposavić, A.P.; Paunović, S.A.; Jevremović, D.R.; Nikićević, N.J.; Tesević, V.V. Chemical and sensory characterization of plum spirits obtained from cultivar Čačanska Rodna and its parent cultivars. J. Serb. Chem. Soc. 2019, 84, 1381–1390. [Google Scholar] [CrossRef]

- Ivanović, S.; Simić, K.; Tešević, V.; Vujisić, L.; Ljekočević, M.; Gođevac, D. GC-FID-MS based metabolomics to access plum brandy quality. Molecules 2021, 26, 1391. [Google Scholar] [CrossRef] [PubMed]

- Filatova, M.; Bechynska, K.; Hajslova, J.; Stupak, M. A comprehensive characterization of volatile profiles of plum brandies using gas chromatography coupled to high resolution mass spectrometry. LWT 2022, 167, 113864. [Google Scholar] [CrossRef]

- Balcerek, M.; Pielech-Przybylska, K.; Patelski, P.; Dziekońska-Kubczak, U.; Strąk, E. The effect of distillation conditions and alcohol content in ‘heart’ fractions on the concentration of aroma volatiles and undesirable compounds in plum brandies. J. Inst. Brew. 2017, 123, 452–463. [Google Scholar] [CrossRef]

- Skotniczny, M.; Satora, P.; Pańczyszyn, K.; Cioch-Skoneczny, M. Growth dynamics and diversity of yeasts during spontaneous plum mash fermentation of different varieties. Foods 2020, 9, 1054. [Google Scholar] [CrossRef]

- Liebminger, A.; Philipp, C.; Sari, S.; Holstein, M.; Dietrich, V.; Goessinger, M. In-line conductivity measurement to select the best distillation technique for improving the quality of apricot brandies. Eur. Food Res. Technol. 2021, 247, 1987–1997. [Google Scholar] [CrossRef]

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 8586:2012; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 5496:2014; Sensory Analysis—Methodology—Initiation and Training of Assessors in the Detection and Recognition of Odours. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 3972:2011; Sensory Analysis—Methodology—Method of Investigating Sensitivity of Taste. International Organization for Standardization: Geneva, Switzerland, 2011.

- ISO 4120:2004; Sensory Analysis—Methodology—Triangle Test. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 5495:2005; Sensory Analysis—Methodology—Paired Comparison Test. International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 13299:2016; Sensory analysis—Methodology—General guidance for establishing a sensory profile. International Organization for Standardization: Geneva, Switzerland, 2016.

- Suomalainen, H. Yeast esterases and aroma esters in alcoholic beverages. J. Inst. Brew. 1981, 87, 296–300. [Google Scholar] [CrossRef]

- Jones, D.T.; Woods, D.R. Acetone-butanol fermentation revisited. Microbiol. Rev. 1986, 50, 484–524. [Google Scholar] [CrossRef]

- Pielech-Przybylska, K.; Balcerek, M.; Nowak, A.; Patelski, P.; Dziekońska-Kubczak, U. Influence of yeast on the yield of fermentation and volatile profile of ‘Węgierka Zwykła’plum distillates. J. Inst. Brew. 2016, 122, 612–623. [Google Scholar] [CrossRef]

- Si, T.; Luo, Y.; Xiao, H.; Zhao, H. Utilizing an endogenous pathway for 1-butanol production in Saccharomyces cerevisiae. Metab. Eng. 2014, 22, 60–68. [Google Scholar] [CrossRef]

- Wu, Y.-H.; Kyung, K.-H. Allyl alcohol found in heated garlic is a potent selective inhibitor of yeasts. J. Microbiol. Biotechnol. 2006, 16, 1236–1239. [Google Scholar]

- Tsakiris, A.; Kallithraka, S.; Kourkoutas, Y. Grape brandy production. composition and sensory evaluation. J. Sci. Food Agric. 2014, 94, 404–414. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez Madrera, R.; García Hevia, A.; Suárez Valles, B. Comparative study of two aging systems for cider brandy making. Changes in chemical composition. LWT Food Sci. Technol. 2013, 54, 513–520. [Google Scholar] [CrossRef]

- Apostolopoulou, A.A.; Flouros, A.I.; Demertzis, P.G.; Akrida-Demertzi, K. Differences in concentration of principal volatile constituents in traditional Greek distillates. Food Control 2005, 16, 157–164. [Google Scholar] [CrossRef]

- Bečvářová, H.; Hanč, O.; Macek, K. Course of transformation of benzaldehyde by Saccharomyces cerevisiae. Folia Microbiol. 1963, 8, 165–169. [Google Scholar] [CrossRef]

- Delfini, C.; Gaia, P.; Bardi, L.; Mariscalco, G.; Contiero, M.; Pagliara, A. Production of benzaldehyde, benzyl alcohol and benzoic acid by yeasts and Botrytis cinerea isolated from grape musts and wines. Vitis 1991, 30, 263. [Google Scholar]

- Carrau, F.M.; Medina, K.; Boido, E.; Farina, L.; Gaggero, C.; Dellacassa, E.; Versini, G.; Henschke, P.A. De novo synthesis of monoterpenes by Saccharomyces cerevisiae wine yeasts. FEMS Microbiol. Lett. 2005, 243, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Krammer, G.; Winterhalter, P.; Schwab, M.; Schreier, P. Glycosidically bound aroma compounds in the fruits of Prunus species: Apricot (P. armeniaca, L.). peach (P. persica, L.). yellow plum (P. domestica, L. ssp. Syriaca). J. Agric. Food Chem. 1991, 39, 778–781. [Google Scholar] [CrossRef]

- Velíšek, J.; Pudil, F.; Davídek, J.; Kubelka, V. The neutral volatile components of Czechoslovak plum brandy. Z. Lebensm.—Unters. Forsch. 1982, 174, 463–466. [Google Scholar] [CrossRef]

- Miličević, B.; Lukić, I.; Babić, J.; Šubarić, D.; Miličević, R.; Ačkar, Đ.; Miličević, D. Aroma and sensory characteristics of Slavonian plum brandy. Technol. Acta 2012, 5, 1–7. [Google Scholar]

- Beckner Whitener, M.E.; Carlin, S.; Jacobson, D.; Weighill, D.; Divol, B.; Conterno, L.; Du Toit, M.; Vrhovsek, U. Early fermentation volatile metabolite profile of non-Saccharomyces yeasts in red and white grape must: A targeted approach. LWT—Food Sci. Technol. 2015, 64, 412–422. [Google Scholar] [CrossRef]

- Silva, M.L.; Malcata, F.X. Effects of time of grape pomace fermentation and distillation cuts on the chemical composition of grape marcs. Z. Lebensm.—Unters. Forsch. A 1999, 208, 134–143. [Google Scholar] [CrossRef]

- García-Llobodanin, L.; Achaerandio, I.; Ferrando, M.; Güell, C.; López, F. Pear distillates from pear juice concentrate: Effect of lees in the aromatic composition. J. Agric. Food Chem. 2007, 55, 3462–3468. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Gómez, L.F.; Úbeda, J.; Briones, A. Melon fruit distillates: Comparison of different distillation methods. Food Chem. 2003, 82, 539–543. [Google Scholar] [CrossRef]

- Lea, A.G.; Lea, A.G.H.; Piggott, J.R. Fermented Beverage Production; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Horvat, R.J.; Chapman, G.W., Jr.; Senter, S.D.; Norton, J.D.; Okie, W.R.; Robertson, J.A. Comparison of the volatile compounds from several commercial plum cultivars. J. Sci. Food Agric. 1992, 60, 21–23. [Google Scholar] [CrossRef]

- Satora, P.; Tuszyński, T. Chemical characteristics of Śliwowica Łącka and other plum brandies. J. Sci. Food Agric. 2008, 88, 167–174. [Google Scholar] [CrossRef]

- Gomez, E.; Ledbetter, C.A.; Hartsell, P.L. Volatile compounds in apricot, plum, and their interspecific hybrids. J. Agric. Food Chem. 1993, 41, 1669–1676. [Google Scholar] [CrossRef]

- Ledauphin, J.; Le Milbeau, C.; Barillier, D.; Hennequin, D. Differences in the volatile compositions of French labeled brandies (Armagnac, Calvados, Cognac, and Mirabelle) using GC-MS and PLS-DA. J. Agric. Food Chem. 2010, 58, 7782–7793. [Google Scholar] [CrossRef]

- Spaho, N.; Blesić, M.; Kurtović, M.; Borovac, B. Content of Harmful Chemical Compounds That May Persist in Plum Spirits. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2022, 23, 307–320. [Google Scholar]

- Urošević, I.; Nikićević, N.; Stanković, L.; Andjelković, B.; Urošević, T.; Krstić, G.; Tešević, V. Influence of yeast and nutrients on the quality of apricot brandy. J. Serb. Chem. Soc. 2014, 79, 1223–1234. [Google Scholar] [CrossRef]

- Januszek, M.; Satora, P.; Tarko, T. Oenological characteristics of fermented apple musts and volatile profile of brandies obtained from different apple cultivars. Biomolecules 2020, 10, 853. [Google Scholar] [CrossRef] [PubMed]

- De-La-Fuente-Blanco, A.; Sáenz-Navajas, M.-P.; Ferreira, V. On the effects of higher alcohols on red wine aroma. Food Chem. 2016, 210, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Herrero, M.; García, L.A.; Díaz, M. The Effect of SO2 on the Production of Ethanol, Acetaldehyde, Organic Acids, and Flavor Volatiles during Industrial Cider Fermentation. J. Agric. Food Chem. 2003, 51, 3455–3459. [Google Scholar] [CrossRef] [PubMed]

- Cortés, S.; Gil, M.L.; Fernández, E. Volatile composition of traditional and industrial Orujo spirits. Food Control 2005, 16, 383–388. [Google Scholar] [CrossRef]

- Cordente, A.G.; Curtin, C.D.; Varela, C.; Pretorius, I.S. Flavour-active wine yeasts. Appl. Microbiol. Biotechnol. 2012, 96, 601–618. [Google Scholar] [CrossRef] [PubMed]

- Plutowska, B.; Biernacka, P.; Wardencki, W. Identification of Volatile Compounds in Raw Spirits of Different Organoleptic Quality. J. Inst. Brew. 2010, 116, 433–439. [Google Scholar] [CrossRef]

- Mangas Alonso, J.J.; Rodríguez, R.; Moreno Fernández, J.; Blanco-Gomis, D. Changes in the Major Volatile Compounds of Cider Distillates During Maturation. Food Sci. Thecnol. 1996, 29, 357–364. [Google Scholar] [CrossRef]

- Claus, M.J.; Berglund, K.A. Fruit brandy production by batch column distillation with reflux. J. Food Process Eng. 2005, 28, 53–67. [Google Scholar] [CrossRef]

| Major Compounds | RT (min) | Wild (mg/le) | SP7 (mg/le) | DV10 (mg/le) | p |

|---|---|---|---|---|---|

| Methyl acetate | 4.81 | 1256 | 1500 | 1383 | 0.0144 * |

| Ethyl acetate | 6.02 | 3354 | 4215 | 3078 | 0.0006 * |

| Methanol | 6.31 | 10,954 | 11,715 | 13,188 | 0.0103 * |

| 2-Butanol | 11.5 | 105 | 834 | 149 | 4.74 × 10−8 * |

| 1-Propanol | 12.1 | 4395 | 17,287 | 4635 | 1.39 × 10−7 * |

| Isobutyl alcohol | 14.3 | 330 | 456 | 357 | 0.0005 * |

| Isoamyl alcohol | 18.4 | 850 | 932 | 855 | 0.1079 |

| Ethyl (-)-L-lactate | 22.7 | 1086 | 1318 | 1138 | 0.0070 * |

| Acetic acid | 25.6 | 11.7 | 69.7 | 56.6 | 3.96 × 10−7 * |

| Minor alcohols | p | ||||

| 1-Butanol | 16.2 | 118 | 108 | 70.8 | 6 × 10−5 * |

| N-Amylalcohol | 19.2 | 4.85 | 5.03 | 4.16 | 0.0091 * |

| Hexanol | 22.9 | 47.2 | 42.6 | 37.6 | 0.0043 * |

| Linalool | 28.0 | 12.6 | 23.0 | 17.6 | 2.59 × 10−5 * |

| Octanol | 28.3 | 1.93 | 2.03 | 1.78 | 0.055566 |

| Nonanol | 30.7 | 16.0 | 13.7 | 11.3 | 0.0005 * |

| Decanol | 33.0 | 1.40 | 2.17 | 1.25 | 1.99 × 10−5 * |

| α-Terpineol | 31.7 | 3.25 | 2.84 | 1.66 | 4.47 × 10−5 * |

| Geraniol | 34.9 | 3.27 | 13.9 | 11.8 | 7.2 × 10−7 * |

| Benzyl alcohol | 35.7 | 42.0 | 51.4 | 50.8 | 0.0054 * |

| 2-Phenylethanol | 36.4 | 3.63 | 6.91 | 4.36 | 1.06 × 10−5 * |

| Eugenol | 41.41 | 3.76 | 8.47 | 7.98 | 6.09 × 10−6 * |

| Allyl alcohol | 15.1 | 12.5 | 55.7 | 18.0 | 1.55 × 10−7 * |

| Minor esters | RT (min) | wild (mg/le) | SP7 (mg/le) | DV10 (mg/le) | p |

| Propyl acetate | 9.36 | 34.8 | 91.0 | 33.2 | 5.29 × 10−7 * |

| Butyl acetate | 13.5 | 19.1 | 19.5 | 27.2 | 0.0002 * |

| Isoamyl acetate | 15.3 | 32.0 | 37.1 | 30.0 | 0.0050 * |

| Ethyl octanoate | 25.1 | 16.9 | 19.7 | 22.2 | 0.0019 * |

| Ethyl decanoate | 30.2 | 27.1 | 35.9 | 40.8 | 0.0002 * |

| Ethyl benzoate | 31.1 | 22.1 | 32.5 | 32.3 | 0.0002 * |

| Diethyl succinate | 31.2 | 14.8 | 17.9 | 15.9 | 0.0100 * |

| Ethyl salicylate | 34.4 | 3.79 | 2.20 | 1.75 | 4.03 × 10−6 * |

| Benzyl acetate | 32.5 | 3.55 | 9.77 | 7.11 | 2.42 × 10−6 * |

| Ethyl laurate | 34.8 | 15.8 | 16.4 | 19.1 | 0.0070 * |

| Ethyl myristate | 39.0 | 4.34 | 4.23 | 4.96 | 0.0151 * |

| Ethyl cinnamate | 40.7 | 1.68 | 1.67 | 1.51 | 0.0724 |

| Ethyl palmitate | 42.8 | 28.0 | 32.2 | 35.0 | 0.0047 * |

| Ethyl stearate | 46.3 | 1.24 | 1.57 | 1.41 | 0.0033 * |

| Ethyl oleate | 46.7 | 5.76 | 6.21 | 6.28 | 0.1568 |

| Ethyl linoleate | 47.5 | 18.7 | 20.6 | 23.0 | 0.0061 * |

| Carbonyl compounds | RT (min) | wild (mg/le) | SP7 (mg/le) | DV10 (mg/le) | p |

| Acetaldehyde | 3.54 | 105 | 91.4 | 93.4 | 0.0293 * |

| Acetone | 4.61 | 3.21 | 4.02 | 5.25 | 6.75 × 10−5 * |

| 2.3-Butandione | 9.61 | 12.8 | 13.2 | 23.7 | 7.31 × 10−6 * |

| Furfural | 26.1 | 13.3 | 6.16 | 23.2 | 6.11 × 10−7 * |

| Benzaldehyde | 27.7 | 8.37 | 13.1 | 18.2 | 7.25 × 10−6 * |

| Samples | Number of Respondents | Correct Answers | p |

|---|---|---|---|

| SP7 vs. “wild” sample | 39 | 32 | <1 × 10−6 * |

| DV vs. “wild” sample | 39 | 25 | 8 × 10−5 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balák, J.; Drábová, L.; Ilko, V.; Maršík, D.; Jarošová Kolouchová, I. Preliminary Investigation of Fruit Mash Inoculation with Pure Yeast Cultures: A Case of Volatile Profile of Industrial-Scale Plum Distillates. Foods 2024, 13, 1955. https://doi.org/10.3390/foods13121955

Balák J, Drábová L, Ilko V, Maršík D, Jarošová Kolouchová I. Preliminary Investigation of Fruit Mash Inoculation with Pure Yeast Cultures: A Case of Volatile Profile of Industrial-Scale Plum Distillates. Foods. 2024; 13(12):1955. https://doi.org/10.3390/foods13121955

Chicago/Turabian StyleBalák, Josef, Lucie Drábová, Vojtěch Ilko, Dominik Maršík, and Irena Jarošová Kolouchová. 2024. "Preliminary Investigation of Fruit Mash Inoculation with Pure Yeast Cultures: A Case of Volatile Profile of Industrial-Scale Plum Distillates" Foods 13, no. 12: 1955. https://doi.org/10.3390/foods13121955

APA StyleBalák, J., Drábová, L., Ilko, V., Maršík, D., & Jarošová Kolouchová, I. (2024). Preliminary Investigation of Fruit Mash Inoculation with Pure Yeast Cultures: A Case of Volatile Profile of Industrial-Scale Plum Distillates. Foods, 13(12), 1955. https://doi.org/10.3390/foods13121955