Intensification of the SFE Using Ethanol as a Cosolvent and Integration of the SFE Process with sc-CO2 Followed by PLE Using Pressurized Ethanol of Black Soldier Fly (Hermetia illucens L.) Larvae Meal—Extract Yields and Characterization

Abstract

1. Introduction

2. Materials and Methods

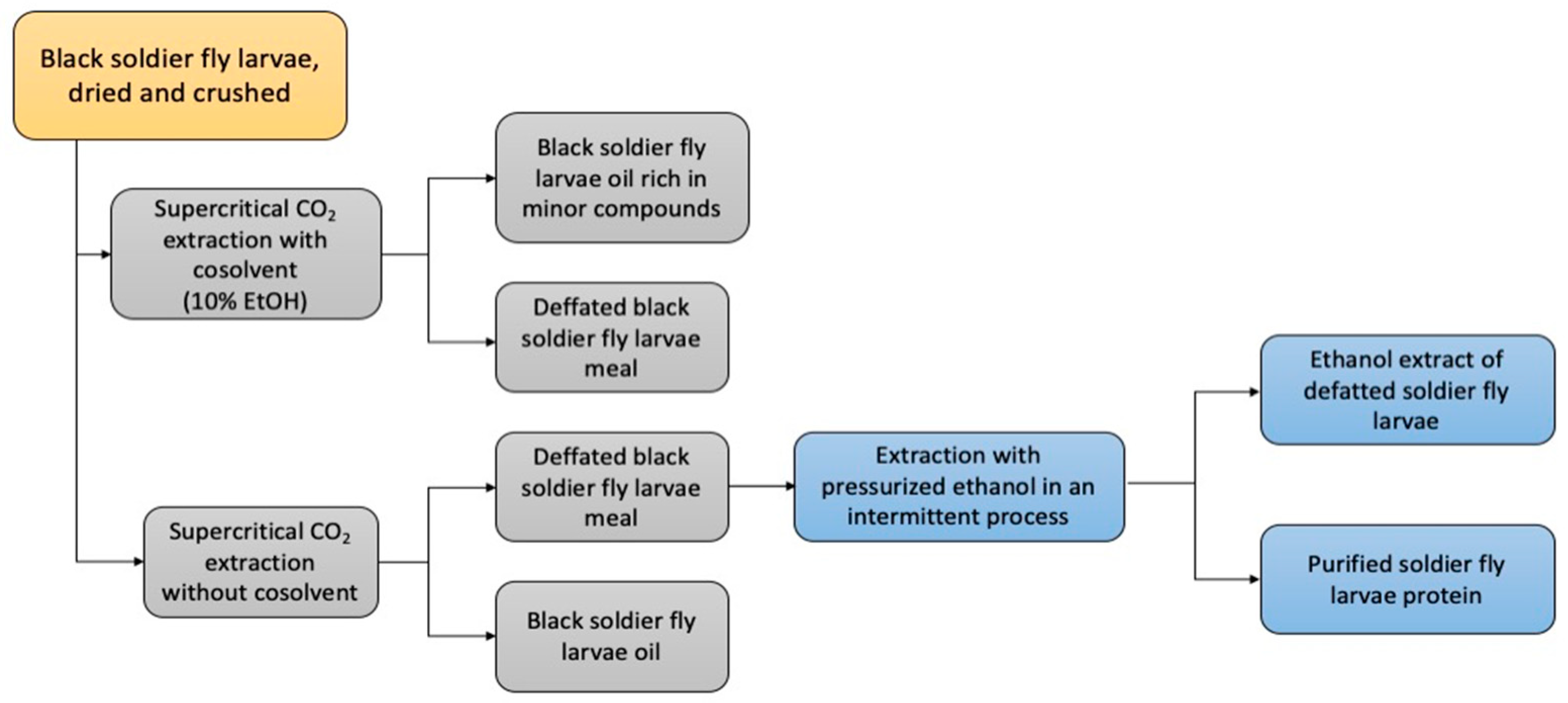

2.1. Purification of Black Soldier Fly Larvae Meal

2.1.1. Extraction with Supercritical CO2 (sc-CO2) Using Ethanol as a Cosolvent

2.1.2. Obtaining Defatted Black Soldier Fly Larvae Meal Extract via PLE in an Intermittent Process Using Ethanol as Solvent

2.2. Characterization of the Extracts

2.2.1. Fatty Acid Profile and Probable Triacylglycerols (TAGs) in the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent

2.2.2. Identification of Free Fatty Acids in the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent

2.2.3. Nutritional Quality Indices of the Lipids

2.2.4. Oxidative Stability of the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent

2.2.5. Determination of Acidity of the Oil Obtained via SFE with sc-CO2 and Ethanol as a Cosolvent and of the Ethanolic Extract Obtained via PLE

2.2.6. Total Phenolic Content (TPC) of the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent and the Ethanolic Extract Obtained via PLE

2.2.7. Determination of Carotenoid Content in the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent and in the Ethanolic Extract Obtained via PLE

2.2.8. Tocopherol Content in the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent and in the Ethanolic Extract Obtained via PLE

2.2.9. Determination of Phospholipid Content in the Oil Obtained via SFE with sc-CO2 Using Ethanol as a Cosolvent and in the Ethanolic Extract Obtained via PLE

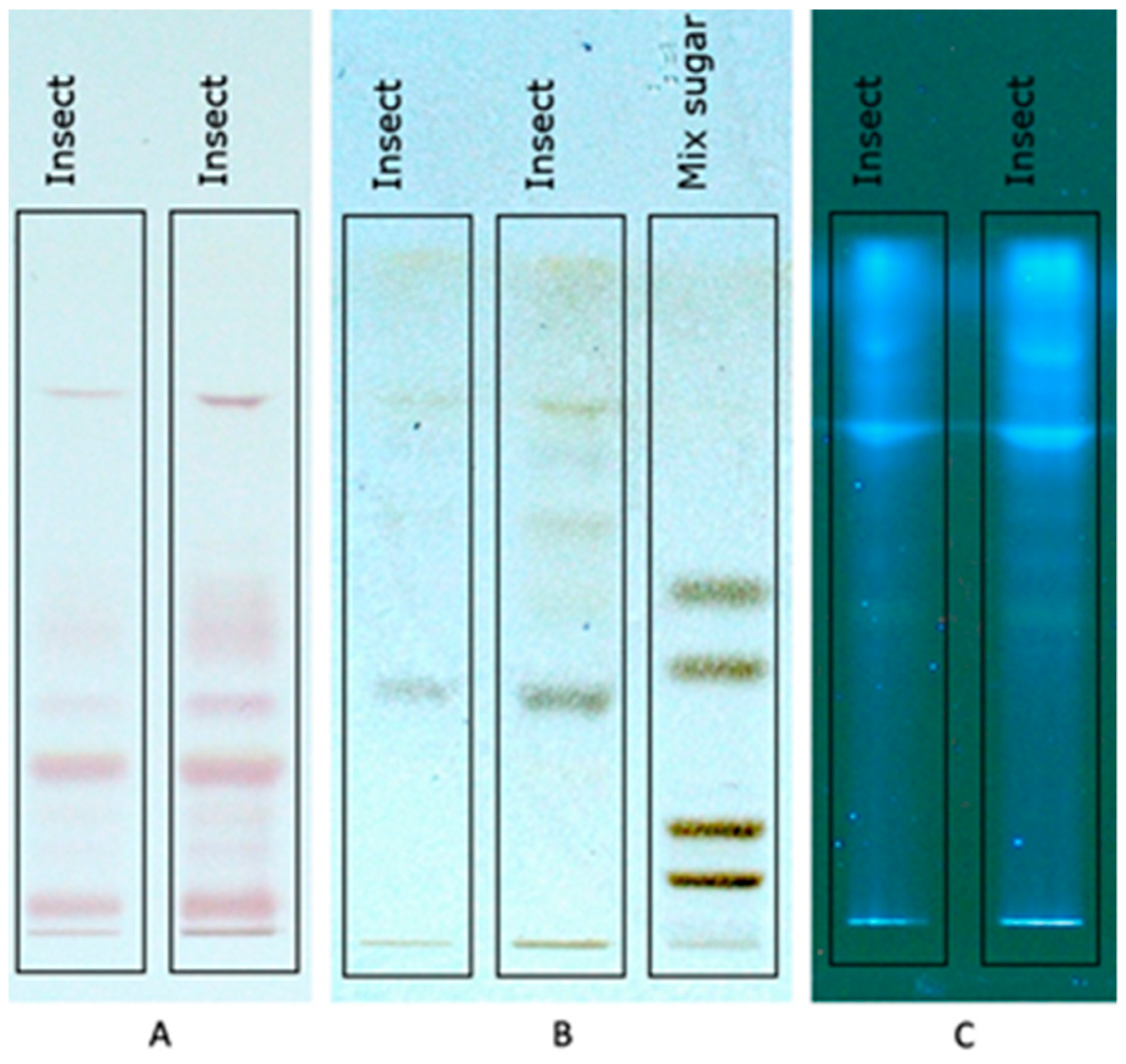

2.2.10. Preliminary Determination of the Classes of Compounds Present in the Ethanolic Extract of Defatted Black Soldier Fly Larvae Meal Obtained via PLE

2.3. Antioxidant Activity of the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent and the Ethanolic Extract Obtained via PLE

2.3.1. Antioxidant Activity Measured using the Reduction in the Free Radical DPPH

2.3.2. Antioxidant Activity Measured by the Reduction in the Free Radical ABTS

2.4. Statistical Analyses

3. Results

3.1. Yield of the Oil Obtained via SFE with sc-CO2 Using Ethanol as a Cosolvent

3.2. Yield of the Ethanolic Extract of the Defatted Meal Obtained via PLE

3.3. Characterization of the Extracts

3.3.1. Fatty Acid Profile and Probable Triacylglycerol (TAG) Content in the oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent

3.3.2. Identification of Free Fatty Acids in the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent

3.3.3. Nutritional Quality Indices of the Lipids

3.3.4. Determination of Acidity of the Oil Obtained via SFE with sc-CO2 and Ethanol as a Cosolvent and of the Ethanolic Extract Obtained via PLE

3.3.5. Total Phenolic Content (TPC) in the Oil Obtained via Extraction with sc-CO2 and Ethanol as a Cosolvent and of the Ethanolic Extract Obtained via PLE

3.3.6. Total Carotenoid Content in the Oil Obtained via Extraction with sc-CO2 and Ethanol as a Cosolvent and of the Ethanolic Extract Obtained via PLE

3.3.7. Tocopherol and Phospholipid Content in the Oil Obtained via SFE with sc-CO2 and Ethanol as a Cosolvent and of the Ethanolic Extract Obtained via PLE

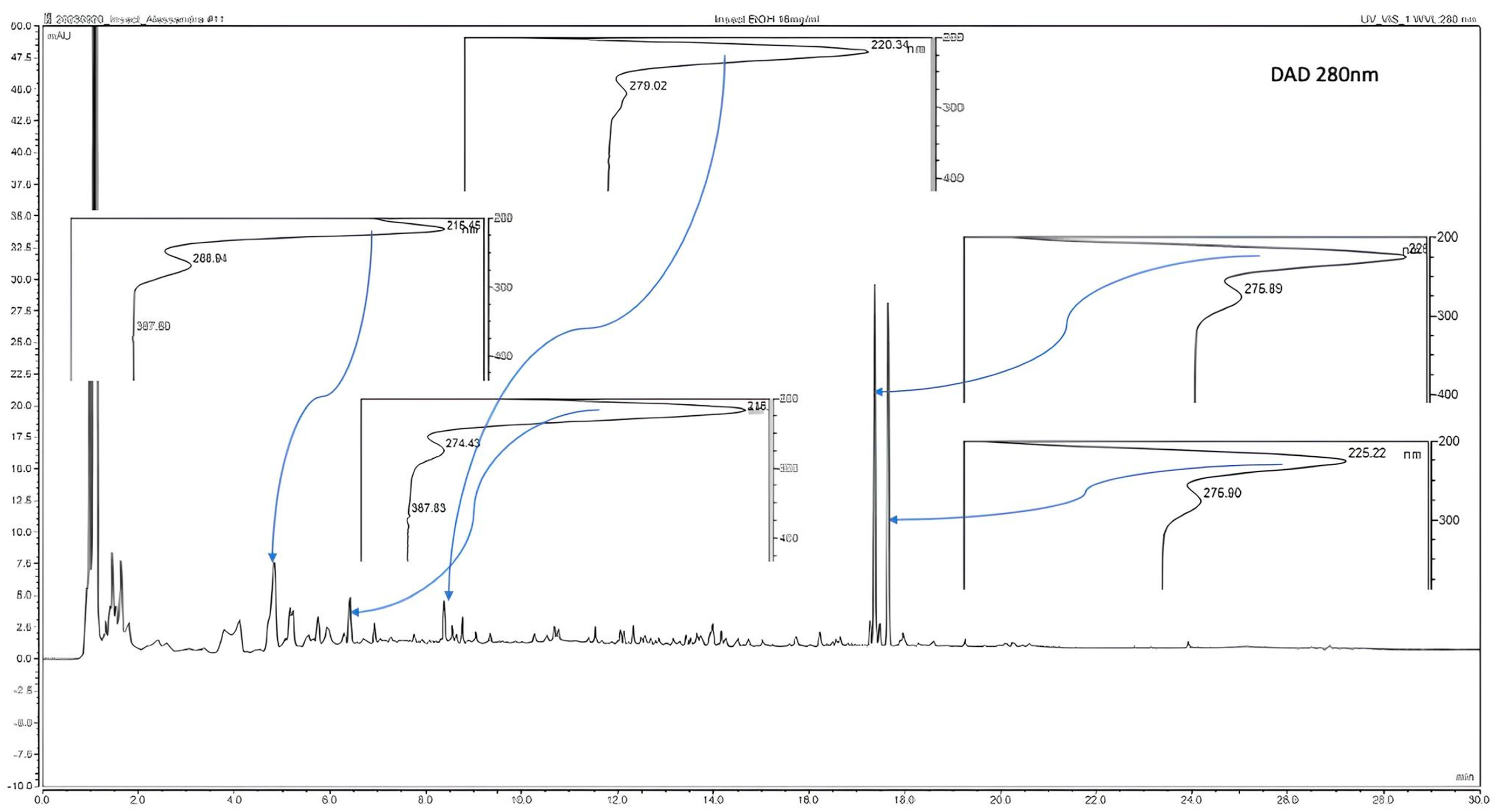

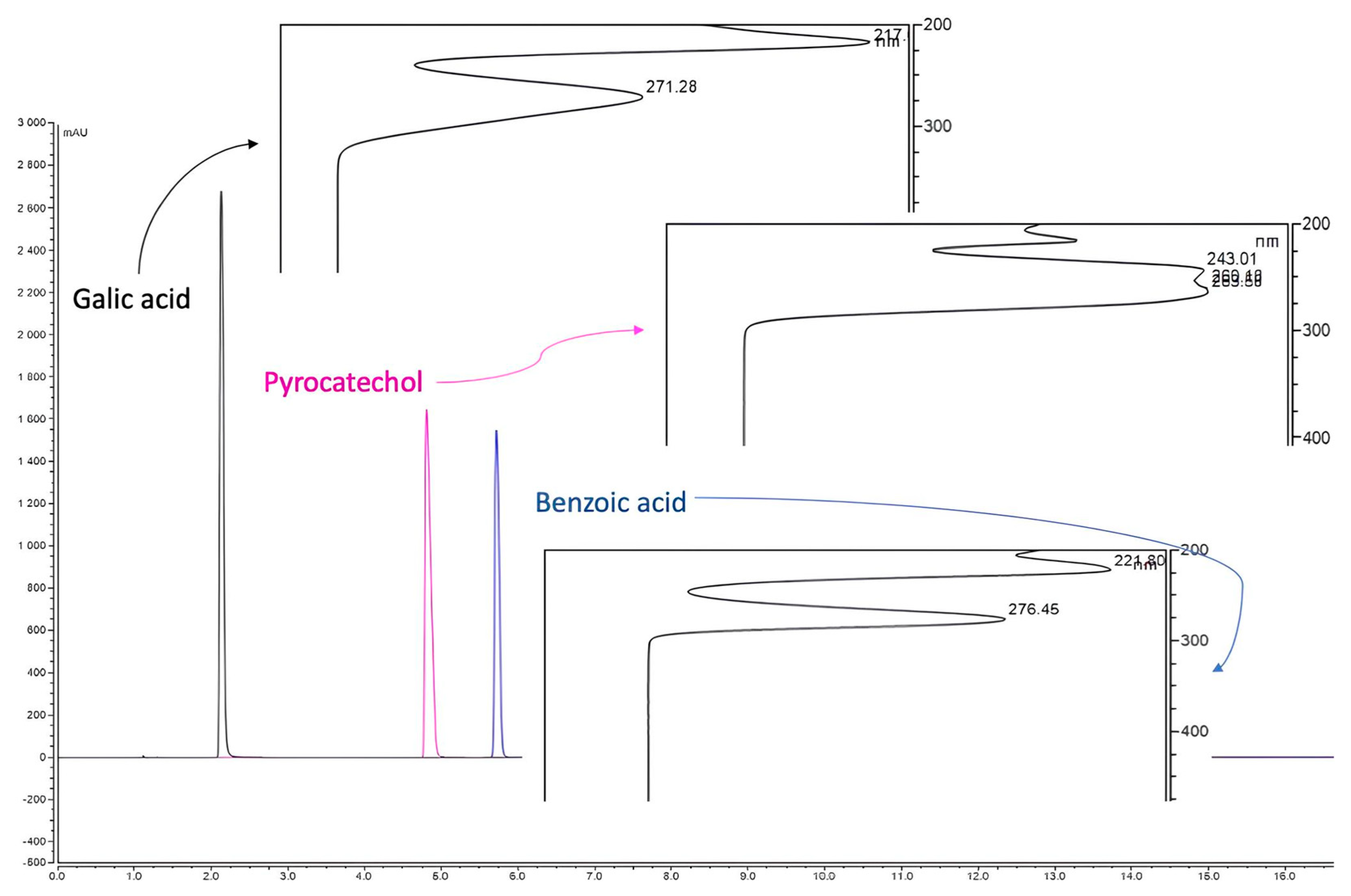

3.3.8. Preliminary Determination of the Class of Compounds Present in the Ethanolic Extract of Defatted Black Soldier Fly Larvae Meal Obtained via PLE

3.4. Antioxidant Activity of the Oil Obtained via Extraction with sc-CO2 Using Ethanol as a Cosolvent and the Ethanolic Extract Obtained via PLE

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). The Future of Food and Agriculture: Trends and Challenges; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017. [Google Scholar]

- de Souza-Vilela, J.; Andrew, N.R.; Ruhnke, I. Insect protein in animal nutrition. Anim. Prod. Sci. 2019, 59, 2029–2036. [Google Scholar] [CrossRef]

- EFSA Scientific Committee. Risk profile related to production and consumption of insects as food and feed. EFSA J. 2015, 13, 4257. [Google Scholar] [CrossRef]

- Cantero-Bahillo, E.; Del Hierro, J.N.; Hernández, D.M.; Fernández-Felipe, M.T.; Fornari, T.; Martin, D. Supercritical-CO2 for defatting and production of bioactive extracts from black soldier fly (Hermetia illucens) larvae. J. Insects Food Feed. 2022, 8, 1441–1453. [Google Scholar] [CrossRef]

- Cruz, V.A.; Ferreira, N.J.; Cornelio-Santiago, H.P.; Santos, G.M.T.; Oliveira, A.L. Oil extraction from black soldier fly (Hermetia illucens L.) larvae meal by dynamic and intermittent processes of supercritical CO2-Global yield, oil characterization, and solvent consumption. J. Supercrit. Fluids 2023, 195, 105861. [Google Scholar] [CrossRef]

- Tzompa-Sosa, D.A.; Yi, L.; van Valenberg, H.J.F.; van Boekel, M.A.J.S.; Lakemond, C.M.M. Insect lipid profile: Aqueous versus organic solvent-based extraction methods. Food Res. Int. 2014. 62, 1087–1094. [CrossRef]

- De Oliveira, N.A.; Mazzali, M.R.; Fukumasu, H.; Gonçalves, C.B.; de Oliveira, A.L. Composition and physical properties of babassu seed (Orbignya phalerata) oil obtained by supercritical CO2 extraction. J. Supercrit. Fluids 2019, 150, 21–29. [Google Scholar] [CrossRef]

- Capuzzo, A.; Maffei, M.E.; Occhipinti, A. Supercritical fluid extraction of plant flavors and fragrances. Molecules 2013, 18, 7194–7238. [Google Scholar] [CrossRef]

- Herrero, M.; Castro-Puyana, M.; Mendiola, J.A.; Ibañez, E. Compressed fluids for the extraction of bioactive compounds. TrAC Trends Anal. Chem. 2013, 43, 67–83. [Google Scholar] [CrossRef]

- Molino, A.; Mehariya, S.; Iovine, A.; Larocca, V.; Di Sanzo, G.; Martino, M.; Casella, P.; Chianese, S.; Musmarra, D. Extraction of astaxanthin and lutein from microalga Haematococcus pluvialis in the red phase using CO2 supercritical fluid extraction technology with ethanol as co-solvent. Mar. Drugs 2018, 16, 432. [Google Scholar] [CrossRef]

- Clark, R. Substances Generally Recognized as Safe (GRAS) Contents; Centre for Science in the Public Interest: Ottawa, ON, Canada, 2015. [Google Scholar]

- Navarro del Hierro, J.N.; Gutiérrez-Docio, A.; Otero, P.; Reglero, G.; Martin, D. Characterization, antioxidant activity, and inhibitory effect on pancreatic lipase of extracts from the edible insects Acheta domesticus and Tenebrio molitor. Food Chem. 2020, 309, 125742. [Google Scholar] [CrossRef]

- Capellini, M.C.; Giacomini, V.; Cuevas, M.S.; Rodrigues, C.E.C. Rice bran oil extraction using alcoholic solvents: Physicochemical characterization of oil and protein fraction functionality. Ind. Crops Prod. 2017, 104, 133–143. [Google Scholar] [CrossRef]

- Richter, B.E.; Jones, B.A.; Ezzell, J.L.; Porter, N.L.; Avdalovic, N.; Pohl, C. Accelerated solvent extraction: A technique for sample preparation. Anal. Chem. 1996, 68, 1033–1039. [Google Scholar] [CrossRef]

- Rodrigues, L.C.; Bodini, R.B.; Caneppele, F.D.L.; Dacanal, G.C.; Crevelin, E.J.; de Moraes, L.A.B.; de Oliveira, A.L. Pressurized Liquid Extraction (PLE) in an Intermittent Process as an Alternative for Obtaining Passion Fruit (Passiflora edulis) Leaf Hydroalcoholic Extract (Tincture). Processes 2023, 11, 2308. [Google Scholar] [CrossRef]

- AOAC. Official Analysis Methods International, 20th ed.; AOCS: Washington, DC, USA, 2016. [Google Scholar]

- Filho, N.R.A.; Mendes, O.L.; Lanças, F.M. Computer prediction of triacylglycerol composition of vegetable oils by HRGC. Chromatographia 1995, 40, 557–562. [Google Scholar] [CrossRef]

- Vicentini-Polette, C.M.; Ramos, P.R.; Gonçalves, C.B.; De Oliveira, A.L. Determination of free fatty acids in crude vegetable oil samples obtained by high-pressure processes. Food Chem. X 2021, 12, 100166. [Google Scholar] [CrossRef] [PubMed]

- Fatemi, S.H.; Hammond, E.G. Analysis of oleate, linoleate and linolenate hydroperoxides in oxidized ester mixtures. Lipids 1980, 15, 379–385. [Google Scholar] [CrossRef]

- Ulbricht, T.L.V.; Southgate, D.A.T. Coronary heart disease: Seven dietary factors. Lancet 1991, 338, 985–992. [Google Scholar] [CrossRef]

- Osmari, E.K.; Cecato, U.; Macedo, F.A.F.; Souza, N.E. Nutritional quality indices of milk fat from goats on diets supplemented with different roughages. Small Rumin. Res. 2011, 98, 128–132. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Altintas, Z. Lesser mealworm (Alphitobius diaperinus L.) larvae oils extracted by pure and binary mixed organic solvents: Physicochemical and antioxidant properties, fatty acid composition, and lipid quality indices. Food Chem. 2023, 408, 135209. [Google Scholar] [CrossRef]

- AOCS. Official Methods and Recommended Practices of the AOCS, 6th ed.; AOCS: Washington, DC, USA, 2009. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Rodriguez-Amaya, D.B.; Kimura, M. HarvestPlus Handbook for Carotenoid Analysis; International Food Policy Research Institute (IFPRI): Washington, DC, USA, 2004; Volume 2. [Google Scholar]

- Wagner, H.; Blat, S. Plant Drug Analysis: A Thin Layer Chromatography Atlas, 2nd ed.; Springer Science & Business Media: Berlin, Germany, 2001; Library of Congress Cataloging-in-Publication Data. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.-E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Altintas, Z. Ultrasound-assisted alcoholic extraction of lesser mealworm larvae oil: Process optimization, physicochemical characteristics, and energy consumption. Antioxidants 2022, 11, 1943. [Google Scholar] [CrossRef] [PubMed]

- Otero, P.; Gutierrez-Docio, A.; Del Hierro, J.N.; Reglero, G.; Martin, D. Extracts from the edible insects Acheta domesticus and Tenebrio molitor with improved fatty acid profile due to ultrasound assisted or pressurized liquid extraction. Food Chem. 2020, 314, 126200. [Google Scholar] [CrossRef] [PubMed]

- da Costa Rocha, A.C.; de Andrade, C.J.; de Oliveira, D. Perspective on integrated biorefinery for valorization of biomass from the edible insect Tenebrio molitor. Trends Food Sci. Technol. 2021, 116, 480–491. [Google Scholar] [CrossRef]

- Laroche, M.; Perreault, V.; Marciniak, A.; Gravel, A.; Chamberland, J.; Doyen, A. Comparison of conventional and sustainable lipid extraction methods for the production of oil and protein isolate from edible insect meal. Foods 2019, 8, 572. [Google Scholar] [CrossRef]

- Reverchon, E.; De Marco, I. Supercritical fluid extraction and fractionation of natural matter. J. Supercrit. Fluids 2006, 38, 146–166. [Google Scholar] [CrossRef]

- Asif, M. Chemical characteristics and nutritional potentials of unsaturated fatty acids. Chem. Int. 2015, 1, 118. [Google Scholar]

- Li, S.; Ji, H.; Zhang, B.; Tian, J.; Zhou, J.; Yu, H. Influence of black soldier fly (Hermetia illucens) larvae oil on growth performance, body composition, tissue fatty acid composition and lipid deposition in juvenile Jian carp (Cyprinus carpio var. Jian). Aquicultura 2016, 465, 43–52. [Google Scholar] [CrossRef]

- Mai, H.C.; Dao, N.D.; Lam, T.D.; Nguyen, B.V.; Nguyen, D.C.; Bach, L.G. Purification Process, Physicochemical Properties, and Fatty Acid Composition of Black Soldier Fly (Hermetia illucens Linnaeus) Larvae Oil. JAOCS J. Am. Oil Chem. Soc. 2019, 96, 1303–1311. [Google Scholar] [CrossRef]

- Atowa, C.O.; Okoro, B.C.; Umego, E.C.; Atowa, A.O.; Emmanuel, O.; Ude, V.C.; Ugbogu, E.A. Nutritional values of Zonocerus variegatus, Macrotermes bellicosus and Cirina forda insects: Mineral composition, fatty acids and amino acid profiles. Sci. Afr. 2021, 12, e00798. [Google Scholar] [CrossRef]

- Grzelczyk, J.; Gałkazka-Czarnecka, I.; Oracz, J. Potentiality Assessment of the Acetylcholinesterase-Inhibitory Activity of Olive Oil with an Additive Edible Insect Powder. Molecules 2023, 28, 5535. [Google Scholar] [CrossRef] [PubMed]

- Fornari, T.; Vázquez, L.; Villanueva-Bermejo, D.; Hurtado-Ribeira, R.; Martín Hernández, D.; Martin, D. Effect of Moisture and Oil Content in the Supercritical CO2 Defatting of Hermetia illucens Larvae. Foods 2023, 12, 490. [Google Scholar] [CrossRef]

- Rattana, M.; Yongyut, C.; Supachet, P. Drying treatment impact on oil yield extracted from black soldier fly larvae using supercritical carbon dioxide and its biological activities. J. Insects Food Feed 2023, 9, 1543–1563. [Google Scholar] [CrossRef]

- Mba, A.R.F.; Kansci, G.; Viau, M.; Ribourg, L.; Muafor, J.F.; Hafnaoui, N.; Le Gall, P.; Genot, C. Growing conditions and morphotypes of African palm weevil (Rhynchophorus phoenicis) larvae influence their lipophilic nutrient but not their amino acid compositions. J. Food Compos. Anal. 2018, 69, 87–97. [Google Scholar] [CrossRef]

- Chinarak, K.; Chaijan, M.; Panpipat, W. Farm-raised sago palm weevil (Rhynchophorus ferrugineus) larvae: Potential and challenges for promising source of nutrients. J. Food Compos. Anal. 2020, 92, 103542. [Google Scholar] [CrossRef]

- Onyeike, E.N.; Oguike, J.U. Influence of heat processing methods on the nutrient composition and lipid characterization of groundnut (Arachis hypogaea) seed pastes. Biokemistri 2003, 15, 34–43. [Google Scholar]

- Kinyuru, J.N. Oil characteristics and influence of heat processing on fatty acid profile of wild harvested termite (Macrotermes subhylanus) and long-horned grasshopper (Ruspolia differens). Int. J. Trop. Insect Sci. 2021, 41, 1427–1433. [Google Scholar] [CrossRef]

- Wołoszyn, J.; Haraf, G.; Okruszek, A.; Wereńska, M.; Goluch, Z.; Teleszko, M. Fatty acid profiles and health lipid indices in the breast muscles of local Polish goose varieties. Poult. Sci. 2020, 99, 1216–1224. [Google Scholar] [CrossRef]

- Chen, Y.; Qiao, Y.; Xiao, Y.; Chen, H.; Zhao, L.; Huang, M.; Zhou, G. Differences in physicochemical and nutritional properties of breast and thigh meat from crossbred chickens, commercial broilers, and spent hens. Asian-Australas. J. Anim. Sci. 2016, 29, 855. [Google Scholar] [CrossRef]

- Dorni, C.; Sharma, P.; Saikia, G.; Longvah, T. Fatty acid profile of edible oils and fats consumed in India. Food Chem. 2018, 238, 9–15. [Google Scholar] [CrossRef]

- Dos Santos da Silva, M.; Alves-Santos, A.M.; dos Santos, I.D.; Wagner, R.; Naves, M.M.V.; Cordeiro, M.W.S. A new population of pequi (Caryocar spp.) developed by Brazilian indigenous people has agro-industrial and nutraceutical advantages. Eur. Food Res. Technol. 2020, 246, 1715–1724. [Google Scholar] [CrossRef]

- Dos Santos, O.V.; Dias, P.C.S.; Soares, S.D.; da Conceição, L.R.V.; Teixeira-Costa, B.E. Artisanal oil obtained from insects’ larvae (Speciomerus ruficornis): Fatty acids composition, physicochemical, nutritional and antioxidant properties for application in food. Eur. Food Res. Tech. 2021, 247, 1803–1813. [Google Scholar] [CrossRef]

- Hassanien, M.M.M.; Abdel-Razek, A.G.; Rudzińska, M.; Siger, A.; Ratusz, K.; Przybylski, R. Phytochemical contents and oxidative stability of oils from non-traditional sources. Eur. J. Lipid Sci. Technol. 2014, 116, 1563–1571. [Google Scholar] [CrossRef]

- Sete da Cruz, R.M.; Da Silva, C.; Da Silva, E.A.; Hegel, P.; Barão, C.E.; Cardozo-Filho, L. Composition and oxidative stability of oils extracted from Zophobas morio and Tenebrio molitor using pressurized n-propane. J. Supercrit. Fluids 2022, 181, 105504. [Google Scholar] [CrossRef]

- Dalle Zotte, A.; Singh, Y.; Michiels, J.; Cullere, M. Black soldier fly (Hermetia illucens) as dietary source for laying quails: Live performance, and egg physico-chemical quality, sensory profile and storage stability. Animals 2019, 9, 115. [Google Scholar] [CrossRef]

- Turck, D.; Braegger, C.P.; Colombo, C.; Declercq, D.; Morton, A.; Pancheva, R.; Robberecht, E.; Stern, M.; Strandvik, B.; Wolfe, S.; et al. ESPEN-ESPGHAN-ECFS guidelines on nutrition care for infants, children, and adults with cystic fibrosis. Clin. Nutr. 2016, 35, 557–577. [Google Scholar] [CrossRef]

- Ochiai, M.; Komiya, Y. Detection of edible insect derived phospholipids with polyunsaturated fatty acids by thin-layer chromatography, gas chromatography, and enzymatic methods. J. Food Compos. Anal. 2021, 99, 103869. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, S.; Wei, X.; Xiao, J.; Huang, D. Characterization, Antioxidant Activities, and Pancreatic Lipase Inhibitory Effect of Extract From the Edible Insect Polyrhachis vicina. Front. Nut. 2022, 9, 860174. [Google Scholar] [CrossRef]

- Di Mattia, C.; Battista, N.; Sacchetti, G.; Serafini, M. Antioxidant activities in vitro of water and liposoluble extracts obtained by different species of edible insects and invertebrates. Front. Nutr. 2019, 6, 106. [Google Scholar] [CrossRef]

| SFE** (sc-CO2 + EtOH) | |||

| Yield (%) | Oil Recovery ***(%) | ||

| 32.5 b ± 0.1 (25 MPa, 60 °C) | 95.8 ± 0.3 b | ||

| 36.1 a ± 0.2 (30 MPa, 60 °C) | 106.5 ± 0.6 a | ||

| PLE (EtOH) | |||

| Yield PLE (%) | Total Yield (%) (Yeld by SFE*, 60 °C and 30 MPa [5] + Yield PLE) | Oil Recovery *** (%) (SFE* + PLE) | |

| 20.9 ± 0.5 | (33 + 20.9) 53.9 | 157 | |

| Fatty acid profile | ||||

| Pressures (MPa) | 25 | 30 | ||

| Peak | RT (min) | Fatty Acids | Area % | Area % |

| 1 | 15.81 | 10:0 (Capric) (C) | 0.59 ± 0.05 | 0.66 ± 0.03 |

| 2 | 19.10 | 12:0 (Lauric) (La) | 11.35 ± 0.32 | 13.00 ± 1.76 |

| 3 | 22.31 | 14:0 (Myristic) (M) | 8.63 ± 0.43 | 9.61 ± 0.14 |

| 4 | 25.65 | 16:0 (Palmitic) (P) | 21.09 ± 0.44 | 22.31 ± 0.16 |

| 5 | 29.07 | 18:0 (Stearic) (S) | 4.81 ± 0.07 | 4.92 ± 0.17 |

| SFA | 46.48 ± 1.24 a | 46.48 ± 1.24 a | ||

| 6 | 26.60 | 16:1 (Palmitoleic) (Po) | 6.11 ± 0.13 | 5.91 ± 0.22 |

| 7 | 29.76 | 18:1 ω-9 (Oleic) (O) | 24.64 ± 0.56 | 24.00 ± 0.31 |

| 8 | 31.60 | 18:2 ω-6 (Linoleic) (Li) | 19.94 ± 0.71 | 17.54 ± 0.83 |

| 9 | 33.52 | 18:3 ω-3 (Linolenic) (Ln) | 2.84 ± 0.10 | 2.21 ± 0.19 |

| MUFA | 30.74 ± 0.43 a | 29.79 ± 0.64 a | ||

| PUFA | 22.78 ± 1.24 a | 19.74 ± 1.02 a | ||

| Free Fatty Acids | ||||

| 2 | 19.56 | 12:0 (La) | 2.23 ± 0.31 | 5.86 ± 0.49 |

| 3 | 22.94 | 14:0 (M) | 0.35 ± 0.07 | 0.45 ± 0.07 |

| 4 | 26.47 | 16:0 (P) | 1.52 ± 0.25 | 4.17 ± 0.08 |

| 7 | 30.92 | 18:1 ω-9 (O) | 1.31 ± 0.27 | 2.87 ± 0.21 |

| 8 | 32.31 | 18:2 ω-6 (Li) | 1.24 ± 0.01 | 1.59 ± 0.02 |

| Group (X:Y) a | Triacylglycerol | Molar Mass (g/mol) | Molar (%) | Mass (%) |

|---|---|---|---|---|

| C40:1 | LaPoLa | 693.10 | 1.06 | 1.23 |

| C42:1 | LaOLa | 721.16 | 3.94 | 4.38 |

| C42:2 | LaLiLa | 719.14 | 2.13 | 2.37 |

| C44:1 | LaOM | 749.21 | 6.44 | 6.89 |

| C44:2 | LaLiM | 747.19 | 3.19 | 3.42 |

| C46:1 | LaOP | 777.26 | 10.84 | 11.18 |

| C46:2 | LaLiP | 775.25 | 7.97 | 8.24 |

| C46:3 | LaLnP | 773.23 | 1.82 | 1.89 |

| C48:1 | MOP | 805.32 | 8.56 | 8.52 |

| C48:2 | MLiP | 803.30 | 8.01 | 8.00 |

| C48:3 | LaLiO + LaOLi | 801.28 | 4.22 | 4.22 |

| C48:4 | LiLiLa | 799.27 | 1.57 | 1.58 |

| C50:1 | POP | 833.37 | 7.25 | 6.97 |

| C50:2 | PLiP | 831.35 | 7.90 | 7.62 |

| C50:3 | MOLi + MLiO | 829.34 | 3.91 | 3.77 |

| C50:4 | LiLiM | 827.32 | 1.22 | 1.18 |

| C52:1 | POS | 861.42 | 2.35 | 2.19 |

| C52:2 | POO | 859.41 | 4.97 | 4.64 |

| C52:3 | POLi + PLiO | 857.39 | 5.13 | 4.80 |

| C52:4 | LiLiP | 855.38 | 2.65 | 2.49 |

| C52:5 | PLiLn + PLnLi | 853.36 | 0.64 | 0.60 |

| C54:2 | OOS | 887.46 | 0.78 | 0.71 |

| C54:3 | SOLi + SLiO | 885.45 | 1.31 | 1.19 |

| C54:4 | OOLi | 883.43 | 1.31 | 1.19 |

| C54:5 | LiLiO | 881.41 | 0.83 | 0.76 |

| Nutritional Indices | Content * (%) | |

|---|---|---|

| Desirable Fatty Acids (DFAs) | 58.34 ± 1.24 a | 54.46 ± 1.76 b |

| PUFAs/SFAs | 0.49 ± 0.03 a | 0.39 ± 0.03 b |

| Hypercholesterolemic Fatty Acids (OFAs) | 41.08 ± 1.14 a | 44.88 ± 1.76 b |

| Nutritional Value Index (NVI) | 1.40 ± 1.24 a | 1.29 ± 0.03 b |

| Hipocholesterolemics/Hypercholesterolemics (h/HH) | 1.16 ± 0.07 a | 0.97 ± 0.07 b |

| Atherogenic Index (AI) | 1.25 ± 0.07 a | 1.49 ± 0.09 b |

| Thrombogenic Index (TI) | 0.73 ±0.04 a | 0.91 ± 0.09 b |

| PUFAs ω-6/ω-3 | 7.01 ± 0.05 a | 7.96 ± 0.33 b |

| COX | 2.91 ± 0.10 a | 2.52 ± 0.13 b |

| Oxidative Stability (h) | 0.02 ± 0.02 | |

| SFE (sc-CO2 + EtOH) 60 °C | PLE | ||

|---|---|---|---|

| 25 MPa | 30 MPa | ||

| Acidity index (mg KOH/g) | 8.01 ± 0.04 a | 9.36 ± 0.63 a | 48.79 ± 0.84 b |

| Total Phenolic Content (mg GAE/g) | 0.3 ± 0.0 b | 0.5 ± 0.0 b | 4.7 ± 0.3 a |

| Total carotenoids (mg/100 g) | 8.2 ± 0.0 b | 8.9 ± 0.5 b | 11.5 ± 0.9 a |

| Total tocopherols (mg/kg) | 65.45 | 68.87 | 0.94 |

| α-Tocopherol (mg/kg) | 36.18 | 40.47 | 0.94 |

| β-Tocopherol (mg/kg) | 10.68 | 11.14 | <0.50 (LQ) |

| γ-Tocopherol (mg/kg) | 1.72 | 1.58 | <0.50 (LQ) |

| δ-Tocopherol (mg/kg) | 16.87 | 15.68 | <0.50 (LQ) |

| Phospholipids (mg/100 g) | 2.4 ± 0.0 | 3.0 ± 0.0 | 1.50 |

| Method | SFE | PLE | ||

| sc-CO2 | sc-CO2 + EtOH | |||

| 30 MPa | 25 MPa | 30 MPa | ||

| DPPH (%) | 58.90 ± 2.71 c | 74.05 ± 2.18 b | 83.21 ± 0.93 a | 84.21 ± 1.50 a |

| ABTS (mMol TE/100 g) | 0.05 ± 0.00 d | 0.14 ± 0.01 c | 0.21 ± 0.00 b | 0.72 ± 0.01 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cruz, V.A.; Ferreira, N.J.; Le Roux, E.; Destandau, E.; de Oliveira, A.L. Intensification of the SFE Using Ethanol as a Cosolvent and Integration of the SFE Process with sc-CO2 Followed by PLE Using Pressurized Ethanol of Black Soldier Fly (Hermetia illucens L.) Larvae Meal—Extract Yields and Characterization. Foods 2024, 13, 1620. https://doi.org/10.3390/foods13111620

Cruz VA, Ferreira NJ, Le Roux E, Destandau E, de Oliveira AL. Intensification of the SFE Using Ethanol as a Cosolvent and Integration of the SFE Process with sc-CO2 Followed by PLE Using Pressurized Ethanol of Black Soldier Fly (Hermetia illucens L.) Larvae Meal—Extract Yields and Characterization. Foods. 2024; 13(11):1620. https://doi.org/10.3390/foods13111620

Chicago/Turabian StyleCruz, Vanessa Aparecida, Nilson José Ferreira, Elise Le Roux, Emilie Destandau, and Alessandra Lopes de Oliveira. 2024. "Intensification of the SFE Using Ethanol as a Cosolvent and Integration of the SFE Process with sc-CO2 Followed by PLE Using Pressurized Ethanol of Black Soldier Fly (Hermetia illucens L.) Larvae Meal—Extract Yields and Characterization" Foods 13, no. 11: 1620. https://doi.org/10.3390/foods13111620

APA StyleCruz, V. A., Ferreira, N. J., Le Roux, E., Destandau, E., & de Oliveira, A. L. (2024). Intensification of the SFE Using Ethanol as a Cosolvent and Integration of the SFE Process with sc-CO2 Followed by PLE Using Pressurized Ethanol of Black Soldier Fly (Hermetia illucens L.) Larvae Meal—Extract Yields and Characterization. Foods, 13(11), 1620. https://doi.org/10.3390/foods13111620