Ready-to-Use Supplementary-Food Biscuit Production with Low-Cost Ingredients for Malnourished Children in Sub-Saharan Africa

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Plan

- Ingredient selection and preparation.

- Recipe development, with “La Nuova Dieta Ragionata—2003 (3.6.0)” software.

- Biscuit preparation.

- Chemical characterization and nutritional evaluation of two final prototypes.

- Sample production of two final prototypes for shelf-life trial.

- Monitoring time evolution for moisture, peroxide content, and texture.

- Evaluation of economic aspects.

2.2. Ingredient Selection and Preparation

2.3. Recipe Development and Preparation

2.4. Chemical and Nutritional Characterization

2.5. Shelf-Life Trial

2.6. Data Analysis

3. Results

3.1. Chemical and Nutritional Characterization

3.2. Economic Considerations

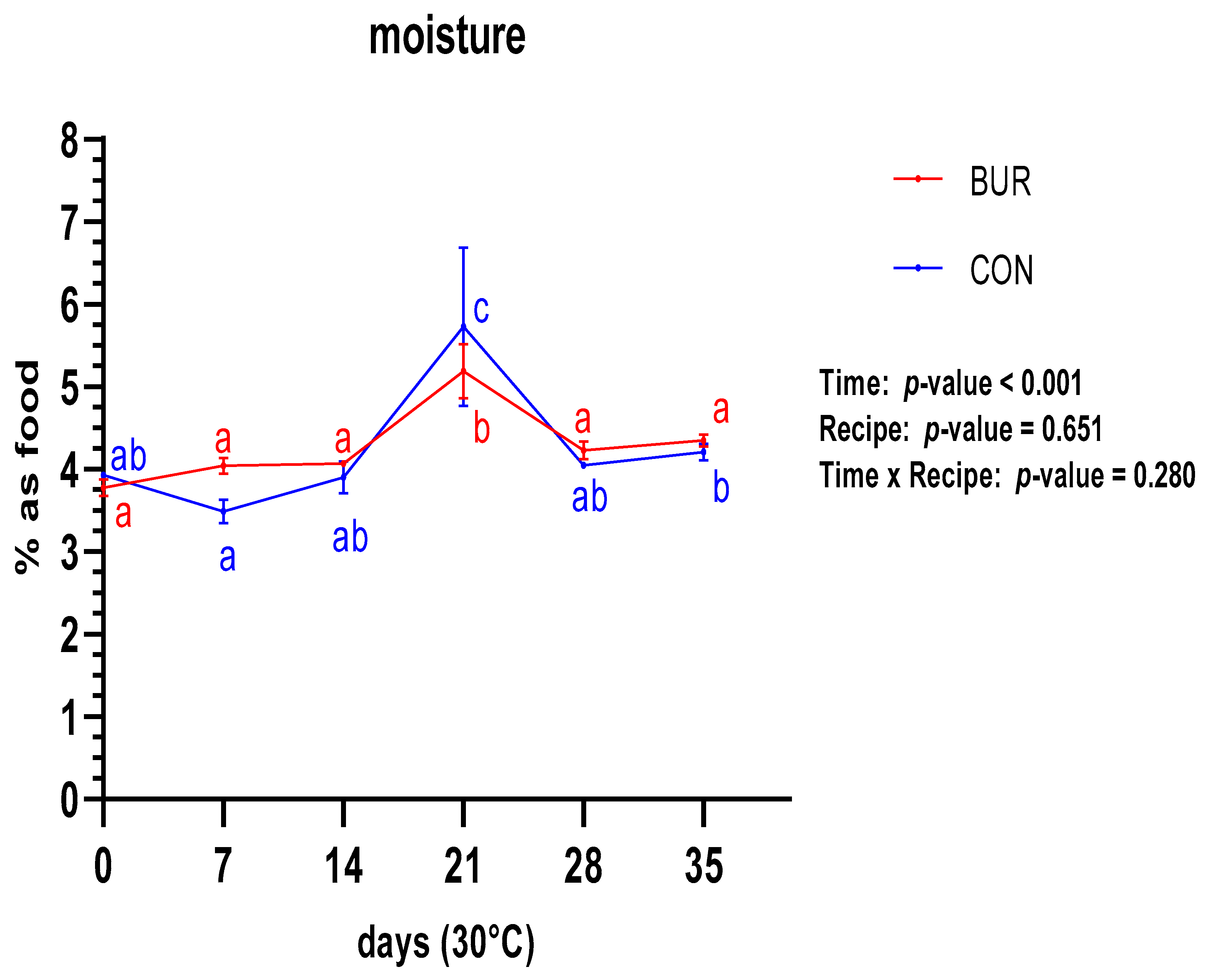

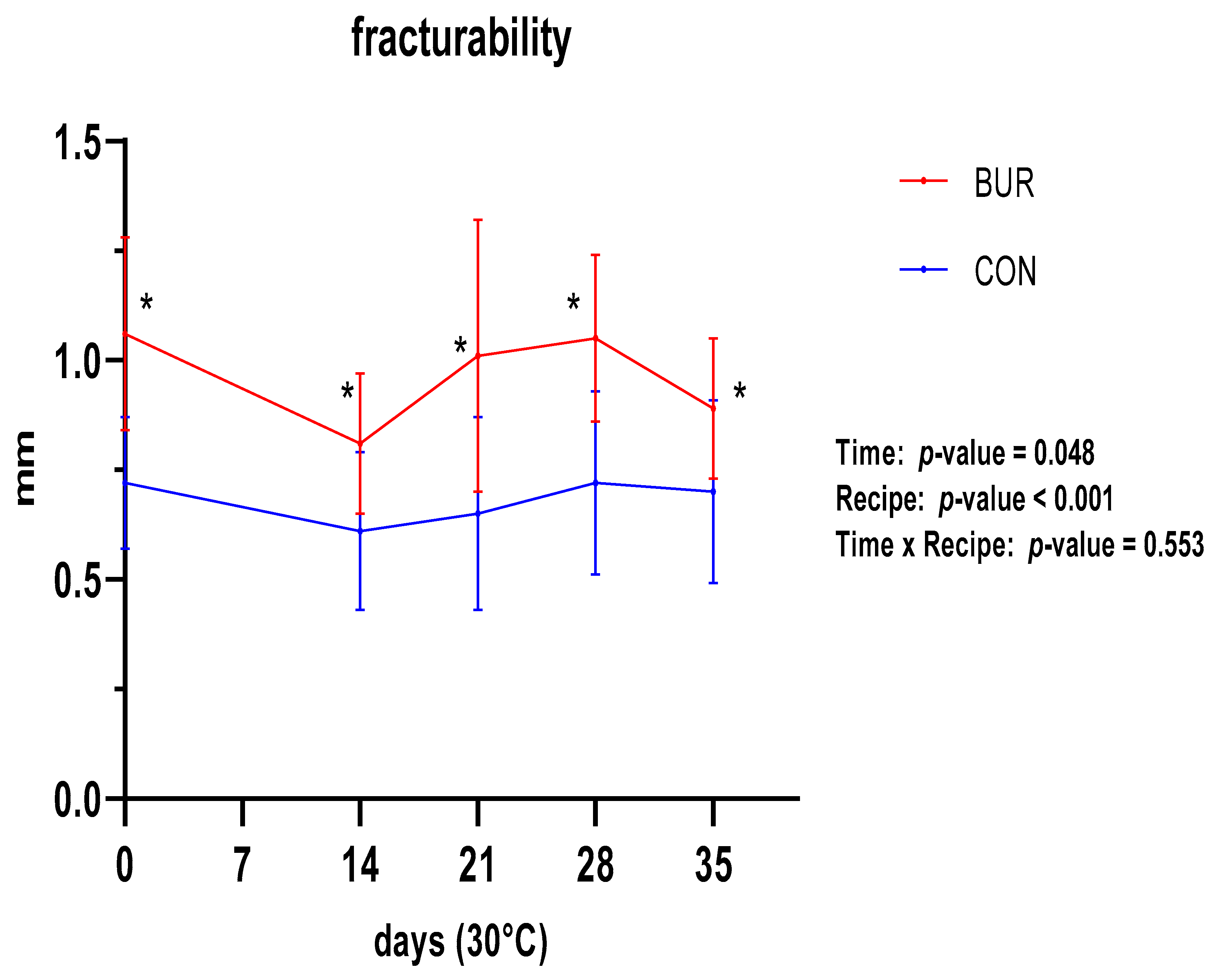

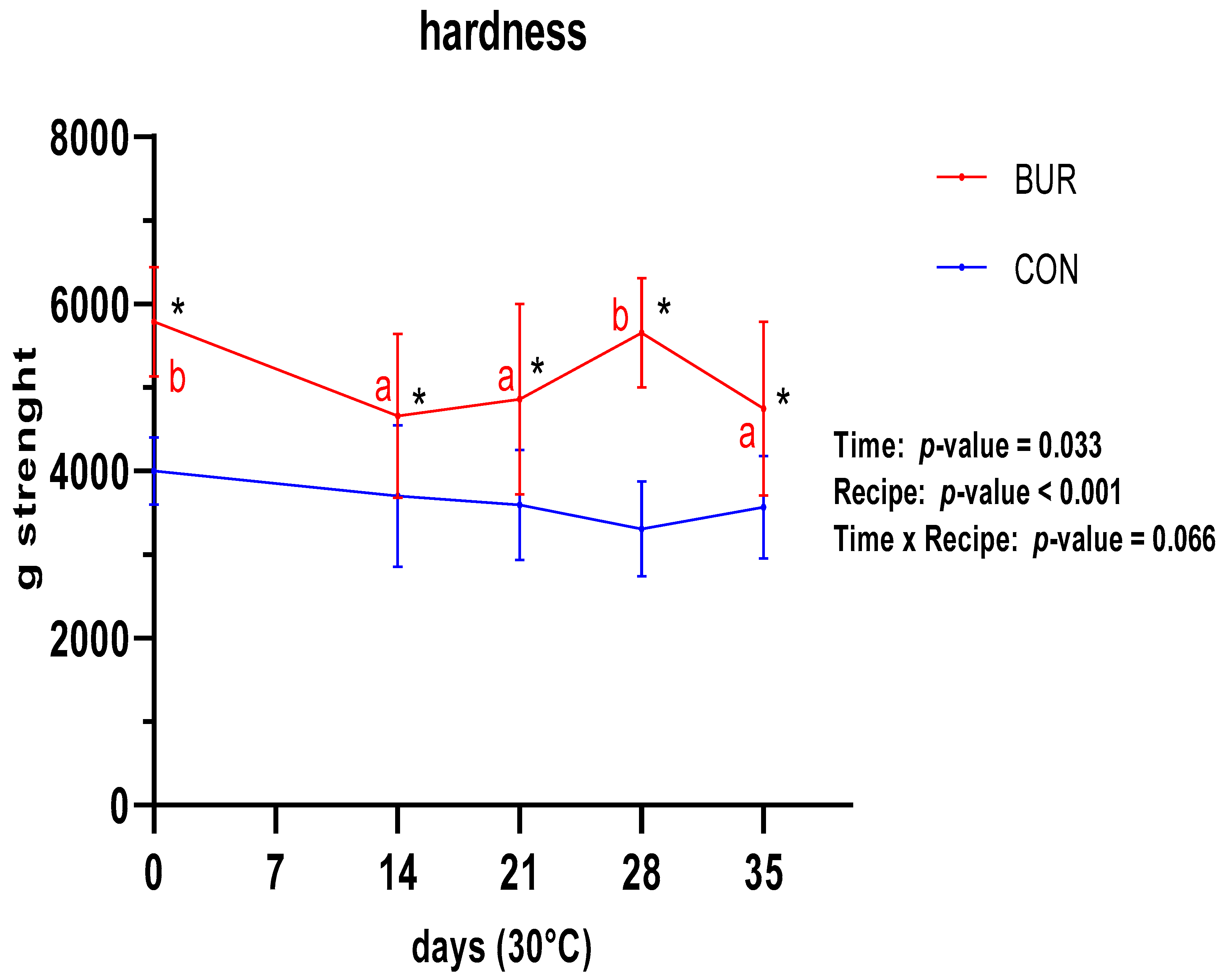

3.3. Shelf-Life Trials

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- WHO. Children: Reducing Mortality; WHO: Geneva, Switzerland, 2016; p. 178.

- Mc Donald, C.M.; Olofin, I.; Flaxman, S.; Fawzi, W.W.; Spiegelman, D.; Caufield, L.E.; Black, R.E.; Ezzati, M.; Danadei, G. Nutrition Impact Model Study. The effect of multiple anthropometric deficits on child mortality: Meta-analysis of individual data in 10 prospective studies from developing countries. Am. J. Clin. Nutr. 2013, 97, 896–901. [Google Scholar] [CrossRef]

- Kennedy, G.; Nantel, G.; Shetty, P. Globalization of Food Systems in Developing Countries: Impact on Food Security and Nutrition. FAO Food Nutr. Paper. Food Control. 2004, 19, 83. [Google Scholar]

- Black, R.; Victora, C.g.; Walker, S.P.; Bhutta, Z.A.; Christian, P.; de Onis, M.; Ezzati, M.; Grantham-McGregor, S.; Katz, J.; Martorell, R.; et al. Maternal and child undernutrition and overweight in low-income and middle-income countries. Lancet 2013, 382, 427. [Google Scholar] [CrossRef]

- Bhutta, Z.A.; Das, J.K.; Rizvi, A.; Gaffey, M.F.; Walker, N.; Horton, S.; Webb, P.; Lartey, A.; Black, R. Evidence-based interventions for improvement of maternal and child nutrition: What can be done and at what cost? Lancet 2013, 382, 452–477. [Google Scholar] [CrossRef] [PubMed]

- Victora, C.G.; Adair, L.; Fall, C.; Hallal, P.C.; Martorell, R.; Richter, L.; Sachdev, H.S.; Maternal and Child Undernutrition Study Group. Maternal and Child Undernutrition: Consequences for Adult Health and Human Capital. Lancet 2008, 371, 340–357. [Google Scholar] [CrossRef] [PubMed]

- Martins, V.J.B.; Florêncio, T.M.M.T.; Grillo, L.P.; Franco, M.D.C.P.; Martins, P.A.; Clemente, A.P.G.; Santos, C.D.L.; Vieira, M.d.F.A.; Sawaya, A.L. Long-Lasting Effects of Undernutrition. Int. J. Environ. Res. Public Health 2011, 8, 1817–1846. [Google Scholar] [CrossRef] [PubMed]

- Jyoti, D.F.; Frongillo, E.A.; Jones, S.J. Food Insecurity Affects School Children’s Academic Performance, Weight Gain, and Social Skills. J. Nutr. 2005, 135, 2831–2839. [Google Scholar] [CrossRef]

- FAO; IFAD; WFP. The Multiple Dimensions of Food Security. In The State of Food Insecurity in the World 2013; FAO: Rome, Italy, 2013. [Google Scholar]

- FAO; ECA; AUC. Africa Regional Overview of Food Security and Nutrition 2020: Transforming Food Systems for Affordable Healthy Diets; FAO: Accra, Ghana, 2021. [Google Scholar]

- UNICEF; WHO; The World Bank Group. Levels and Trends in Child Malnutrition; UNICEF: New York, NY, USA, 2017. [Google Scholar]

- UNICEF; WHO; The World Bank Group. Levels and Trends in Child Malnutrition: Key Findings of the 2021 Edition of the Joint Child Malnutrition Estimates; WHO: Geneva, Switzerland, 2021.

- WHO; UNICEF. WHO child growth standards and the identification of severe acute malnutrition in infants and children. In A Joint Statement by the World Health Organization and the United Nations Children’s Fund; WHO: Geneva, Switzerland, 2009. [Google Scholar]

- Cornelia, M.; Chandra, J. Utilization of white oyster mushroom powder (Pleurotus ostreatus (Jacq.) P. Kumm.) in the making of biscuit as emergency food product. EurAsian J. BioSciences 2019, 13, 1859–1866. [Google Scholar]

- Zoumas, B.L.; Armstrong, L.E.; Backstrand, J.R.; Chenoweth, W.L.; Chinachoti, P.; Klein, B.P.; Lane, H.; Marsh, K.; Tolvaven, M. High Energy, Nutrient-Dense Emergency Relief Product; National Academy Press: Washington, DC, USA, 2002. [Google Scholar] [CrossRef]

- Duclercq, M.-P. Production of Ready-to-Use Food (RUF): An Overview of the Steps and Challenges Involved in the “Local” Production of RUF. CMAM Forum Technical Brief; 2014. Available online: https://www.ennonline.net/productionofreadytousefoodruf (accessed on 28 April 2024).

- UNICEF. UNICEF ‘s Approach to Scaling up Nutrition; UNICEF: New York, NY, USA, 2012. [Google Scholar]

- Plumpy’NUT. [Online]. Available online: https://www.nutriset.fr/products/en/plumpy-nut (accessed on 28 April 2024).

- Scherbaum, V.; Purwestri, R.C.; Stuetz, W.; Inayati, D.A.; Suryantan, J.; Bloem, M.A.; Biesalski, H.K. Locally Produced Cereal/Nut/Legume-Based Biscuits versus Peanut/Milk-Based Spread for Treatment of Moderately to Mildly Wasted Children in Daily Programs on Nias Island, Indonesia: An Issue of Acceptance and Compliance? Asia Pac. J. Clin. Nutr. 2015, 24, 152–161. [Google Scholar] [CrossRef]

- Okafor, J.; Okafor, G.; Ozumba, A.; Elemo, G. Quality Characteristics of Bread Made from Wheat and Nigerian Oyster Mushroom (Pleurotus plumonarius) Powder. Pak. J. Nutr. 2012, 11, 5–10. [Google Scholar] [CrossRef]

- Agrahar-Murugkar, D.; Zaidi, A.; Gupta, C. Quality evaluation of composite flour laddoo containing sprouted and malted ingredients. Nutr. Food Sci. 2016, 46, 476–487. [Google Scholar] [CrossRef]

- Ubbor, S.; Akobundu, E. Quality characteristics of cookies from composite flours of watermelon seed, cassava and wheat. Pak. J. Nutr. 2009, 8, 1097–1102. [Google Scholar] [CrossRef]

- Fleet, A. High Energy Biscuits—Product Specification Sheet. 2017. Available online: https://www.ungm.org/Public/Notice/55262 (accessed on 28 April 2024).

- WHO. RUTF Biscuit (BP100). Product Specifications Sheet RUTF Biscuit (BP 100), BP100; WHO: Geneva, Switzerland, 2017.

- Varghese, C.; Srivastav, P.P. Formulation and sensory characterization of low-cost, high-energy, nutritious cookies for undernourished adolescents: An approach using linear programming and fuzzy logic. Innov. Food Sci. Emerg. Technol. 2022, 75, 102904. [Google Scholar] [CrossRef]

- Kouton, S.; Vodouhè, S.; Hounkpatin, W.A.; Soumanou, M.M. Formulated Therapeutic Food Fortified of Vegetable for Nutritional Recuperation of Undernourished Infants in Benin. J. Food Sci. Nutr. Res. 2020, 3, 092–101. [Google Scholar] [CrossRef]

- Fetriyuna, F.; Purwestri, R.C.; Susandy, M.; Köhler, R.; Jati, I.R.A.P.; Wirawan, N.N.; Biesalski, H.-K. Composite Flour from Indonesian Local Food Resources to Develop Cereal/Tuber Nut/Bean-Based Ready-to-Use Supplementary Foods for Prevention and Rehabilitation of Moderate Acute Malnutrition in Children. Foods 2021, 10, 3013. [Google Scholar] [CrossRef] [PubMed]

- Reggi, D. Sviluppo di Biscotti Proteici per Bambini del Burundi: Prospettive di Industrializzazione. Master’s Thesis, Università Cattolica del Sacro Cuore, Piacenza, Italy, 2020. [Google Scholar]

- Minardi, A. Food Security in Developing Countries: The Case Study of “Production of Appropriate Food: Sufficient, Safe and Sustainable” Project; AgriSystem; Università Cattolica del Sacro Cuore: Piacenza, Italy, 2018. [Google Scholar]

- Mourey, A. Nutrition Manual for Humanitarian Action; International Committee of the Red Cross Assistance Division: Geneva, Switzerland, 2008; pp. 76–96. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis; AOAC: Arlington, VA, USA, 2000. [Google Scholar]

- ISO 712:2009; Cereals and Cereal Products—Determination of Moisture Content—Reference Method. ISO: Geneva, Switzerland, 2009.

- EEC. Commission Directive (First) No 71/250 of 15 June 1971 Establishing Community Methods of Analysis for the Official Control of Feeding-Stuffs; EEC: Brussels, Belgium, 1971. [Google Scholar]

- Calligaris, S.; Manzocco, L.; Kravina, G.; Nicoli, M.C. Shelf-life modeling of bakery products by using oxidation indices. J. Agric. Food Chem. 2007, 55, 2004–2009. [Google Scholar] [CrossRef]

- EEC. Annex III—Regulation 2568/91/EEC; EEC: Brussels, Belgium, 1991. [Google Scholar]

- Kaur, M.; Sandhu, K.S.; Arora, A.; Sharma, A. Gluten free biscuits prepared from buckwheat flour by incorporation of various gums: Physicochemical and sensory properties. LWT Food Sci. Technol. 2015, 62, 628–632. [Google Scholar] [CrossRef]

- WHO. Global Panel on Agriculture and Food Systems for Nutrition. In Food Systems and Diets: Food Systems and Diets; WHO: London, UK, 2016. [Google Scholar]

- Kouakou, E.; Meite, A.; Kouamé, G. Traditional process for the production of therapeutic food for the nutritional care of the malnourished. Int. J. Curr. Res. 2016, 8, 39395–39398. [Google Scholar]

- Manary, M.J. Local Production and Provision of Ready-to-Use Therapeutic Food (RUTF) Spread for the Treatment of Severe Childhood Malnutrition. Food Nutr. Bull. 2006, 27 (Suppl. S3), S83–S89. [Google Scholar] [CrossRef]

- Arimond, M.; Hawkes, C.; Ruel, M.T.; Sifri, Z.; Berti, P.R.; Leroy, J.L.; Low, J.; Brown, L.; Frongillo, E. Agricultural Interventions and Nutrition: Lessons from the Past and New Evidence. In CAB International FAO; Thompson Amoroso, B., Ed.; FAO: Oxfordshire, UK, 2013; pp. 41–75. [Google Scholar]

- Beesabathuni, K.N.; Natchu, U. Production and distribution of a therapeutic nutritional product for severe acute malnutrition in India: Opportunities and challenges. Indian Pediatr. 2010, 47, 702–706. [Google Scholar] [CrossRef]

- Sandige, H.; Ndekha, M.J.; Briend, A.; Ashorn, P.; Manary, M.J. Home-based treatment of malnourished Malawian children with locally produced or imported ready-to-use food. J. Pediatr. Gastroenterol. Nutr. 2004, 39, 141–146. [Google Scholar] [CrossRef] [PubMed]

- Dibari, F.; Diop, E.H.I.; Collins, S.; Seal, A. Low-cost, ready-to-use therapeutic foods can be designed using locally available commodities with the aid of linear programming. J. Nutr. 2012, 142, 955–961. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, J.; Falvo, M. Protein—Which is Best? J. Sports Sci. Med. 2004, 3, 118–130. [Google Scholar]

- USAID. The United States Agency for International Development Commodity Specification for High-Energy Biscuits (HEB) for Use in International Food Assistance Programs; USAID: Washington, DC, USA, 2016.

- Camera di Commercio (CCIAA). Resolution n.6—Special Regulations Vegetable Extraction Flour (18/4/2011); CCIAA: Milano, Italy, 2011. [Google Scholar]

- Saini, H. Thermal stability of protease inhibitors in some cereals and legumes. Food Chem. 1989, 32, 59–67. [Google Scholar] [CrossRef]

- Romani, S.; Tappi, S.; Balestra, F.; Estrada, M.T.R.; Siracusa, V.; Rocculi, P.; Rosa, M.D. Effect of different new packaging materials on biscuit quality during accelerated storage. J. Sci. Food. Agric. 2015, 95, 1736–1746. [Google Scholar] [CrossRef] [PubMed]

- Beshir, E.O.; Khallaf, M.; El-Daim, Y.A.; Awad, R.; Kamel, M.A.-A. Sweet Lupin and Whey Protein Concentrate as Supplementants for Utilizing in Semi–Hard Biscuit and Its Chemical Properties. Egypt. J. Chem. 2021, 64, 7517–7527. [Google Scholar] [CrossRef]

- Calligaris, S.; Pieve, S.; Kravina, G.; Manzocco, L.; Nicoli, C. Shelf Life Prediction of Bread Sticks Using Oxidation Indices: A Validation Study. J. Food Sci. 2008, 73, E51–E56. [Google Scholar] [CrossRef]

- Rodrigues, L.L.; Hashimoto, J.M.; Nabeshima, E.H.; Gomes, F.d.O.; Silva, J.D.N.; Silva, K.J.D. Characteristics of biscuits containing different proportions of whole mung bean, wheat and rice brown flours. Food Sci. Technol. Int. 2022, 29, 818–830. [Google Scholar] [CrossRef]

| Product | Brand (In Piacenza Market) | Price Burundi (USD/kg) | Price DRCongo (USD/kg) |

|---|---|---|---|

| Whole chicken egg | Terra (Lidl) | 2.80 | 2.93 |

| Raw soy seeds | Calleris | 0.73 | 0.66 |

| Raw Niebè (Vigna unguiculata) | Calleris | 0.67 | 0.43 |

| Peanut flour | Kava Foods | 1.90 | 0.58 |

| Rice flour | Adea | 0.84 | 1.08 |

| Wheat flour (type 1) | Cerealpuglia | 0.73 | 2.00 |

| Brown sugar | Tate & Lyle Demerara | 0.88 | 1.40 |

| Palm oil | Blue Bay | 0.91 | 1.00 |

| Baking powder | Paneangeli | 1.48 | 2.11 |

| Ingredients | BUR (Burundi) | CON (DRCongo) |

|---|---|---|

| Whole chicken egg | 20 | 22 |

| Raw soy flour | 13 | 10 |

| Niebè flour | 10 | 15 |

| Peanut flour | 16 | 20 |

| Rice flour | 10 | 10 |

| Wheat flour (type 1) | 8 | -- |

| Brown sugar | 15 | 15 |

| Palm oil | 6 | 6 |

| Baking powder | 2 | 2 |

| Nutrients | BUR | CON |

|---|---|---|

| Dry matter | 94.35 ± 0.05 | 94.17 ± 0.02 |

| Ash | 3.06 ± 0.002 | 3.05 ± 0.004 |

| Protein | 17.81 ± 0.03 | 16.77 ± 0.12 |

| Fat | 19.69 ± 0.04 | 20.06 ± 0.02 |

| Starch | 26.37 ± 0.06 | 22.16 ± 0.01 |

| Fiber | 6.63 ± 0.04 | 6.95 ± 0.02 |

| Soluble fiber | 1.56 ± 0.05 | 1.11 ± 0.02 |

| Insoluble fiber | 5.07 ± 0.01 | 5.84 ± 0.04 |

| Redox sugars | 0.19 ± 0.02 | 0.34 ± 0.03 |

| Protein digestibility | 91.72 ± 0.01 | 92.01 ± 0.03 |

| Urease | 0.028 ± 0.003 | 0.020 ± 0.001 |

| Children’s Age | Protein Requirement (g/d) | BUR (g/d) | BUR (Number of Biscuits) | CON (g/d) | CON (Number of Biscuits) |

|---|---|---|---|---|---|

| 1–2 years | 4.3 | 24.14 | 3.44 | 25.64 | 3.61 |

| 2–3 years | 4.58 | 25.72 | 3.62 | 27.31 | 3.85 |

| 3–4 years | 5.39 | 30.26 | 4.31 | 32.14 | 4.53 |

| 4–5 years | 5.24 | 29.42 | 4.14 | 31.25 | 4.4 |

| 5–6 years | 6.27 | 35.20 | 4.96 | 37.39 | 5.27 |

| 6–7 years | 6.21 | 34.87 | 4.91 | 37.03 | 5.22 |

| 7–10 years | 8.18 | 45.93 | 6.47 | 48.78 | 6.87 |

| Children’s Age | Vit. A Needs (μg/Day) | Vit. A Covered (%) | Zn Needs (mg/Day) | Zn Covered (%) | Fe Needs (mg/Day) | Fe Covered (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| BUR | CON | BUR | CON | BUR | CON | ||||

| 1–3 years | 400 | 6.19 | 7.19 | 4 | 16 | 17.75 | 3.9 | 24.61 | 27.95 |

| 4–6 years | 400 | 7.67 | 8.94 | 6 | 13.16 | 14.66 | 4.2 | 28.33 | 32.14 |

| 7–10 years | 500 | 8.51 | 9.9 | 7 | 15.57 | 17.43 | 5.9 | 27.96 | 31.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reggi, D.; Alessio, G.; Ndereyimana, A.; Minuti, A.; Spigno, G.; Bertoni, G. Ready-to-Use Supplementary-Food Biscuit Production with Low-Cost Ingredients for Malnourished Children in Sub-Saharan Africa. Foods 2024, 13, 1614. https://doi.org/10.3390/foods13111614

Reggi D, Alessio G, Ndereyimana A, Minuti A, Spigno G, Bertoni G. Ready-to-Use Supplementary-Food Biscuit Production with Low-Cost Ingredients for Malnourished Children in Sub-Saharan Africa. Foods. 2024; 13(11):1614. https://doi.org/10.3390/foods13111614

Chicago/Turabian StyleReggi, Davide, Gaia Alessio, Andrè Ndereyimana, Andrea Minuti, Giorgia Spigno, and Giuseppe Bertoni. 2024. "Ready-to-Use Supplementary-Food Biscuit Production with Low-Cost Ingredients for Malnourished Children in Sub-Saharan Africa" Foods 13, no. 11: 1614. https://doi.org/10.3390/foods13111614

APA StyleReggi, D., Alessio, G., Ndereyimana, A., Minuti, A., Spigno, G., & Bertoni, G. (2024). Ready-to-Use Supplementary-Food Biscuit Production with Low-Cost Ingredients for Malnourished Children in Sub-Saharan Africa. Foods, 13(11), 1614. https://doi.org/10.3390/foods13111614