Current Trends in Food Processing By-Products as Sources of High Value-Added Compounds in Food Fortification

Abstract

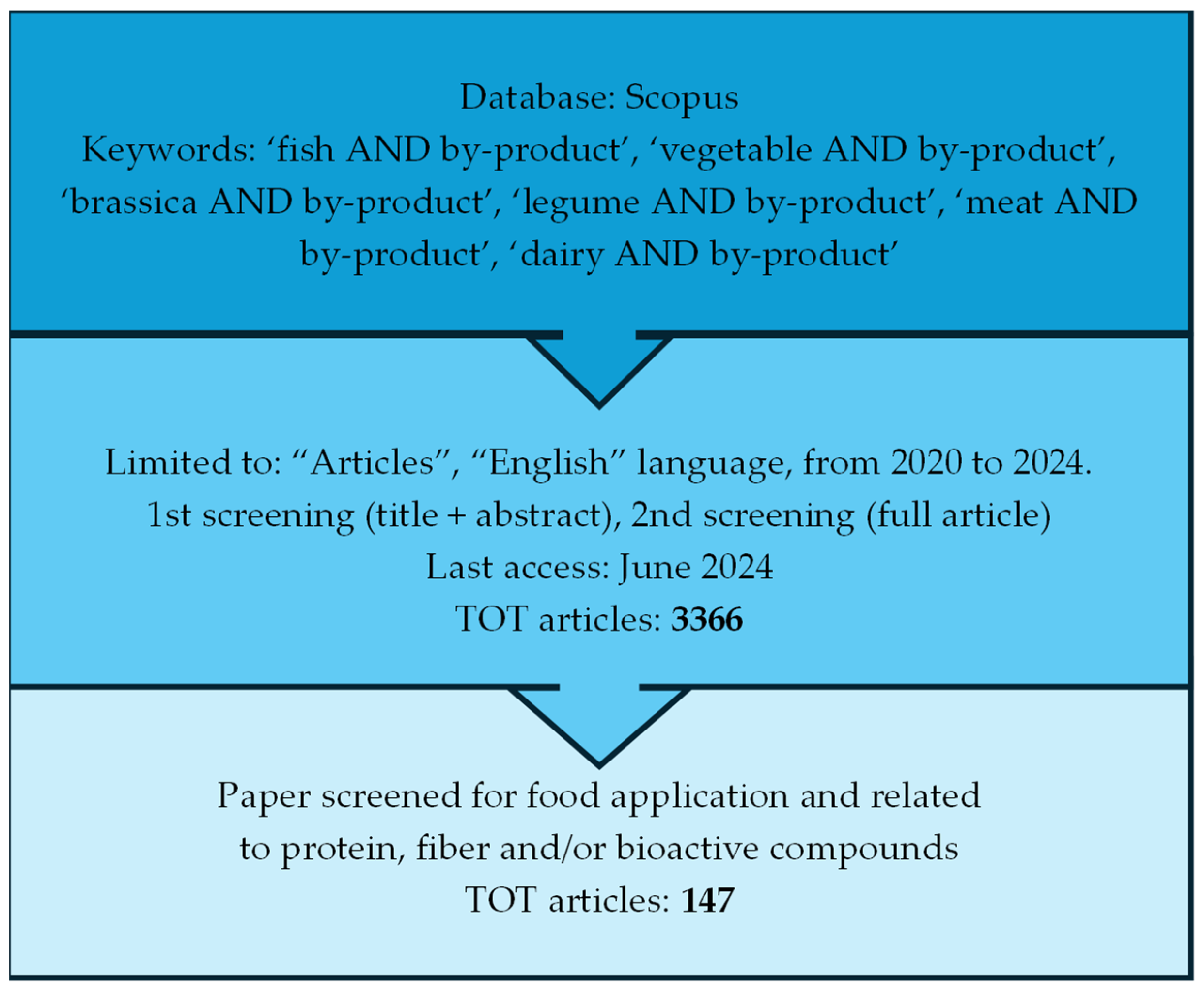

1. Introduction

2. Characterization of Food Processing By-Products Based on Their Nutritional Benefit, Treatment, and Food Application

2.1. Protein

2.2. Fiber

| By-Products | Ingredient Preparation | Food Application | Properties | References |

|---|---|---|---|---|

| Grape pomace | Addition (or not) of lyoprotectors → freeze drying → grinding | Gluten-free cookies (10–20% enrichment) Filling (17.2 g pomace flour) | ↑ Fiber, protein, fat; ↑ sensory properties | [114] |

| Carrot pomace | Air drying (60 °C, 12 h) → grinding (250 mm) | Muffins (5–20% enrichment) | ↑ Crude fiber, ↑ firmness, ↑ taste, ↑ appearance (10% the best sensory results) | [109] |

| Coconut residue | Drying → grinding | Spread (16% enrichment) | ↑ Protein, fiber, good spreadability, ↑ sensory acceptability | [92] |

| Banana peel | Disinfection → drying (63 °C, 24 h) → grinding (0.8 mm) | Biscuits (10–20% enrichment) | ↑ Fiber (+20% at 10%), ↑ dark color, good sensory acceptability (10% maximum) | [98] |

| Bread (10% enrichment) | ↑ Fiber (+12.5%) | |||

| Pasta (5–10% enrichment) | ↑ Fiber (+71.4% at 10%) | |||

| Hemp seed meal | Fat extraction (cold press) → grinding | Gnocchi (5–20% enrichment) | ↑ Fiber (source of fiber claim, >10%), ↑ cooking loss, ↓ cooking resistance, ↓ sensory acceptability (bitter taste, odor) | [100] |

| Pineapple peel, banana peel, and pumpkin seed | Banana, pineapple: cutting → sanitation → drying (60 °C, 8 h) → grinding Pumpkin seed: roasting (15 min) → grinding | Gluten-free muffins (17% enrichment) | ↑ Fiber, good sensory acceptability (100% pineapple peel; 50% pineapple peel; 50% pumpkin seed) | [97] |

| Grape pomace and skin | Grape by-products obtained commercially | Frankfurt and Spanish sausage (0.5% grape skin, 3–6% inulin, 0.5–1% β-glucan) | ↓ Fat reduction, ↓ boar taint, ↓ brightness, ↓ hardness | [115] |

| Male date palm flowers | Drying (40 °C, 24 h) → grinding | Biscuits (3–9% enrichment) | ↑ Fiber (source of fiber claim, >6%), darkness, hardness, good sensory acceptability (6% maximum) | [93] |

| Walnut oil cake | Fat extraction → grinding (0.8 mm) | Macarons (10–50% enrichment) | ↑ Fiber, TPC, antioxidant capacity; ↓ sensory acceptability (10% maximum) ↓ costs | [101] |

| Brewery bagasse | Cooking (20 min, 100 °C) → filtration (residue) → drying (60 °C) → grinding (1 mm) | Bread (6% enrichment) | ↑ Fiber | [80] |

| Jackfruit core | Pectin extraction: drying (60 °C, 20–24 h) → grinding → water dispersion (1:29) → acid extraction (pH 2, 80 °C, 105 min) → filtration → ethanol precipitation → drying (45 °C, overnight) → grinding | Vegetable soup | ↑ Sensory properties | [105] |

| Tomato seed and skin, peppers, placenta | Drying (30–40 °C, 17 h) → grinding (0.25 mm) | Bread (3–12% enrichment) | ↑ Fiber, WAC, dough development, softening; ↓ stability time, ↑ redness and yellowness | [96] |

| Celery root peel | Grinding → water dispersion (1:5) → homogenization → US extraction (25 kHz frequency, 40–60 °C, 40–60% power level, 10–30 min) → distillation (75–85 °C, 1–6 h) → refrigeration (4 °C) | Ayran Turkish beverage (15–62% enrichment) | ↑ Pectin, sensory and structural properties; ↑ flavor, WAC, viscosity; ↓ color, phase separation; ↑ shelf life | [102] |

| Sugar beet pulp | Sucrose extraction in water (75 °C, 45 min) → filtration → cooling → bleaching (pH 11, 120 min) → fiber extraction (pH 6.5) → saponins removal (water: ethanol dispersion 1:4, overnight) → pectin removal (pH 1.6, 90 °C, 3 h) → filtration → ethanol dispersion (1:4, pH 3, 24 h) → filtration, rinsing → boiling (20 min, pH 6.5) → air drying → grinding (1 mm) | Gluten-free muffins (0.2–0.4% enrichment) depectinized or not-depectinized ingredient | ↑ Viscosity, hardness (with pectin); ↑ fiber, swelling capacity, water and oil binding capacity (w/o pectin) | [104] |

| Paprika, pitted pepper, tomato pomace | Not specified | Bread (3–12% enrichment) | ↓ Gluten network strength | [108] |

| Carrot pomace and beetroot– apple (7:3) pomace | Drying (40 °C) → grinding (0.4 mm) | Pasta (10–30% enrichment) | ↑ Fiber, ↑ WAC (carrot pomace), ↑ technological and sensory (color, texture) properties | [94] |

| Apple and blackcurrant pomace | Obtained commercially | Freeze-dried snacks (2% enrichment) | ↓ Porosity, hygroscopicity; ↑ brittle and fragile texture, color changes | [110,111] |

| Non-compliant broccoli and carrots and pomace | Washing → cutting → steam-blanching → (juice extraction) → freeze drying → grinding (0.8 mm) | Extruded snacks (3% enrichment with pomace, 20–100% enrichment with whole vegetable powder) | ↓ Starch content, ↑ fiber, ↓ phenols, ↓ expansion volume | [99] |

| Orange and apple pomace, tomato peel, pepper peel, prickly pear peel, and prickly pear seed peel | Drying → grinding (0.5 mm) → pectin extraction: acid extraction (2 g sample +40 mL HCl, 90 °C, 45 min) → filtration (removal of insoluble material) → pectin precipitation: 95% ethanol dispersion (1:2), overnight → pectin purification: 70% ethanol dispersion (x2) → collection of the precipitate → drying (65 °C) | Gluten-free bread (2.5–7.5% enrichment) | ↑ Dough height, ↑ CO2 production and retention, ↑ specific volume | [103] |

| Pea | Pea fiber obtained commercially | Bread (3–7% enrichment) | ↑ Fermentation, ↑ CO2 production | [107] |

| Oil palm empty fruit bunch | Cleaning → drying (60 °C, 24 h) → grinding (0.2 mm) → α-cellulose extraction: NaCl dispersion + acetic acid (1:50, pH 4, 70–80 °C, 2 h, x 5) → rinsing→ drying (60 °C, overnight) → NaOH dispersion (1:25, 2 h, room T °C) → filtration→ washing→ drying (60 °C, 24 h) → carboxymethyl cellulose extraction: aqueous-alkaline dispersion (1:2), isopropyl alcohol addition (1 h, room T °C) → monochloroacetate addition (45 °C, 3 h) → pH adjustment with glacial acetic acid (neutral) → soaking in methanol (to remove impurities) → purification in ethanol | Low-fat ice cream (0.3% enrichment) | ↓ Viscosity, hardness; ↓ overrun | [106] |

| By-Products | Ingredient Preparation | Food Application | Properties | References |

|---|---|---|---|---|

| Shrimp and crab shells | Chitosan provided commercially with a deacetylation degree of 80–95% | Wine clarification | ↑ Faster and greater sedimentation | [112] |

| Asian tiger shrimp (Penaeus monodon) shells | Shells drying → milling (710 µm) → chitosan extraction → demineralization (1 M HCl) → centrifugation → deacetylation: chitin conversion to chitosan using 60% NaOH (w/v) Chitosan film: 1 g chitosan + water (containing 1% acetic acid) → glycerol (plasticizer) → protein hydrolysates → drying | Biodegradable film | Excellent lipid oxidation-delaying capacity | [44] |

2.3. Bioactive Compounds

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rao, M.; Bast, A.; de Boer, A. Valorized Food Processing By-Products in the EU: Finding the Balance between Safety, Nutrition, and Sustainability. Sustainability 2021, 13, 4428. [Google Scholar] [CrossRef]

- Orozco-Angelino, X.; Espinosa-Ramírez, J.; Serna-Saldívar, S.O. Extrusion as a Tool to Enhance the Nutritional and Bioactive Potential of Cereal and Legume By-Products. Food Res. Int. 2023, 169, 112889. [Google Scholar] [CrossRef]

- Delgado, L.; Schuster, M.; Torero, M. Quantity and Quality Food Losses across the Value Chain: A Comparative Analysis. Food Policy 2021, 98, 101958. [Google Scholar] [CrossRef]

- Chandrasekaran, M. Valorization of Food Processing By-Products: Fermented Foods and Beverages Series; Chandrasekaran, M., Ed.; CRC Press (Imprint of the Taylor and Francis Group): Boca Raton, FL, USA, 2012. [Google Scholar]

- Reguengo, L.M.; Salgaço, M.K.; Sivieri, K.; Maróstica Júnior, M.R. Agro-Industrial by-Products: Valuable Sources of Bioactive Compounds. Food Res. Int. 2022, 152, 110871. [Google Scholar] [CrossRef]

- Galali, Y.; Omar, Z.A.; Sajadi, S.M. Biologically Active Components in By-Products of Food Processing. Food Sci. Nutr. 2020, 8, 3004–3022. [Google Scholar] [CrossRef]

- Food Wastage Footprint (Project) Food Wastage Footprint: Impacts on Natural Resources. 2013. Available online: https://scholar.google.com/scholar_lookup?title=Food+Wastage+Footprint.+Impact+on+Natural+Resources&author=FAO&publication_year=2013 (accessed on 17 August 2024).

- Rațu, R.N.; Veleșcu, I.D.; Stoica, F.; Usturoi, A.; Arsenoaia, V.N.; Crivei, I.C.; Postolache, A.N.; Lipșa, F.D.; Filipov, F.; Florea, A.M.; et al. Application of Agri-Food By-Products in the Food Industry. Agriculture 2023, 13, 1559. [Google Scholar] [CrossRef]

- Dinkçi, N.; Akdeniz, V.; Akalın, A.S. Probiotic Whey-Based Beverages from Cow, Sheep and Goat Milk: Antioxidant Activity, Culture Viability, Amino Acid Contents. Foods 2023, 12, 610. [Google Scholar] [CrossRef]

- Toniasso, D.P.W.; Giacomelli da Silva, C.; de Souza Brum Junior, B.; Somacal, S.; Emanuelli, T.; Hashime Kubota, E.; Cristina Prestes Dornelles, R.; Mello, R. Collagen Extracted from Rabbit: Meat and by-Products: Isolation and Physicochemical Assessment. Int. Food Res. 2022, 162, 111967. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Díaz-Montes, E.; Gontarek-Castro, E.; Boczkaj, G.; Galanakis, C.M. A Comprehensive Review on Current and Emerging Technologies toward the Valorization of Bio-Based Wastes and by Products from Foods. Compr. Rev. Food Sci. Food Saf. 2022, 21, 46–105. [Google Scholar] [CrossRef]

- Varela-Ortega, C.; Blanco-Gutiérrez, I.; Manners, R.; Detzel, A. Life Cycle Assessment of Animal-Based Foods and Plant-Based Protein-Rich Alternatives: A Socio-Economic Perspective. J. Sci. Food Agric. 2022, 102, 5111–5120. [Google Scholar] [CrossRef]

- Castellanos-Fuentes, A.P.; Genevois, C.E.; Flores, S.K.; de Escalada Pla, M.F. Novel Application of a Food Ingredient Based on Soybean Extruded-Expelled Meal Containing Probiotics for Improving Gluten-Free Bread Quality. Int. J. Food Sci. 2023, 58, 6855–6861. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Avena-Bustillos, R.J.; Kahlon, A.K.; Brichta, J.L. Consumer Sensory Evaluation and Quality of Sorghum-Peanut Meal-Okra Snacks. Heliyon 2021, 7, e06874. [Google Scholar] [CrossRef]

- Leahu, A.; Ropciuc, S.; Ghinea, C.; Damian, C. Physico-Chemical, Textural and Sensory Evaluation of Emulsion Gel Formulated with By-Products from the Vegetable Oil Industry. Gels 2023, 9, 964. [Google Scholar] [CrossRef]

- Nartea, A.; Fanesi, B.; Pacetti, D.; Lenti, L.; Fiorini, D.; Lucci, P.; Frega, N.G.; Falcone, P.M. Cauliflower By-Products as Functional Ingredient in Bakery Foods: Fortification of Pizza with Glucosinolates, Carotenoids and Phytosterols. Curr. Res. Food Sci. 2023, 6, 100437. [Google Scholar] [CrossRef]

- Ahlström, C.; Thuvander, J.; Rayner, M.; Matos, M.; Gutiérrez, G.; Östbring, K. The Effect of Precipitation PH on Protein Recovery Yield and Emulsifying Properties in the Extraction of Protein from Cold-Pressed Rapeseed Press Cake. Molecules 2022, 27, 2957. [Google Scholar] [CrossRef]

- Ragonese, V.E.; Moscoso Ospina, Y.A.; Cabezas, D.M.; Kakisu, E.J. Effect of Ultrasound Treatment on the Composition and Emulsifying Properties of Quinoa Okara. Int. J. Food Sci. Technol. 2024, 59, 1481–1489. [Google Scholar] [CrossRef]

- López-García, A.; Moraga, G.; Hernando, I.; Quiles, A. Providing Stability to High Internal Phase Emulsion Gels Using Brewery Industry By-Products as Stabilizers. Gels 2021, 7, 245. [Google Scholar] [CrossRef]

- Kasapoglu, M.Z.; Sagdic, O.; Avci, E.; Tekin-Cakmak, Z.H.; Karasu, S.; Turker, R.S. The Potential Use of Cold-Pressed Coconut Oil By-Product as an Alternative Source in the Production of Plant-Based Drink and Plant-Based Low-Fat Ice Cream: The Rheological, Thermal, and Sensory Properties of Plant-Based Ice Cream. Foods 2023, 12, 650. [Google Scholar] [CrossRef]

- Sabater, C.; Ruiz, L.; Delgado, S.; Ruas-Madiedo, P.; Margolles, A. Valorization of Vegetable Food Waste and By-Products Through Fermentation Processes. Front. Microbiol. 2020, 11, 581997. [Google Scholar] [CrossRef]

- Squeo, G.; Latrofa, V.; Vurro, F.; De Angelis, D.; Caponio, F.; Summo, C.; Pasqualone, A. Developing a Clean Labelled Snack Bar Rich in Protein and Fibre with Dry-Fractionated Defatted Durum Wheat Cake. Foods 2023, 12, 2547. [Google Scholar] [CrossRef]

- Drabińska, N.; Nogueira, M.; Ciska, E.; Jeleń, H. Effect of Drying and Broccoli Leaves Incorporation on the Nutritional Quality of Durum Wheat Pasta. Pol. J. Food Nutr. Sci. 2022, 72, 273–285. [Google Scholar] [CrossRef]

- Krupa-Kozak, U.; Drabińska, N.; Baczek, N.; Šimková, K.; Starowicz, M.; Jeliński, T. Application of Broccoli Leaf Powder in Gluten-Free Bread: An Innovative Approach to Improve Its Bioactive Potential and Technological Quality. Foods 2021, 10, 819. [Google Scholar] [CrossRef]

- Tukassar, A.; Shukat, R.; Iahtisham-Ul-Haq, M.S.; Butt, M.S.; Nayik, G.A.; Ramniwas, S.; Al Obaid, S.; Ali Alharbi, S.; Ansari, M.J.; Konstantinos Karabagias, I.; et al. Compositional Profiling and Sensory Analysis of Cauliflower By-Products-Enriched Muffins. Food Sci. Nutr. 2023, 11, 6020–6031. [Google Scholar] [CrossRef] [PubMed]

- Kamani, M.H.; Luithui, Y.; Meera, M.S. Upgrading Black Gram By-Product to a New Texturized Vegetable Source by Extrusion: Evaluation of Functionality, Antinutrients and In Vitro Digestibility. Waste Biomass Valorization 2021, 12, 4319–4330. [Google Scholar] [CrossRef]

- la Gatta, B.; Rutigliano, M.; Dilucia, F.; Liberatore, M.T.; Viscecchia, R.; Bimbo, F.; Di Luccia, A. Protein Network Assessment and Sensory Characteristics of Durum Wheat Fresh Pasta Fortified with Artichoke Bracts and Tomato Powders. Food Biosci. 2023, 54, 102858. [Google Scholar] [CrossRef]

- Teterycz, D.; Sobota, A. Use of High-Protein and High-Dietary-Fibre Vegetable Processing Waste from Bell Pepper and Tomato for Pasta Fortification. Foods 2023, 12, 2567. [Google Scholar] [CrossRef]

- Aussanasuwannakul, A.; Teangpook, C.; Treesuwan, W.; Puntaburt, K.; Butsuwan, P. Effect of the Addition of Soybean Residue (Okara) on the Physicochemical, Tribological, Instrumental, and Sensory Texture Properties of Extruded Snacks. Foods 2022, 11, 2967. [Google Scholar] [CrossRef] [PubMed]

- Lima, J.R.; Araújo, Í.M.D.S.; Pinto, C.O.; Goiana, M.L.; Passos Rodrigues, M.D.C.; De Lima, L.V. Obtaining Cashew Kernel Protein Concentrate from Nut Processing By-Product and Its Use to Formulate Vegetal Burger. Braz. J. Food Technol. 2021, 24, e2020232. [Google Scholar] [CrossRef]

- Bovi Karatay, G.; Theóphilo Galvão, M.; Bhunia, A.K.; Amaral, J.S.; Byrne, D.V.; Varzakas, T.; Sendra, E.; Adhikari, B.P.; Grossi Bovi Karatay, G.; Maria Medeiros Theóphilo Galvão, A.; et al. Storage Stability of Conventional and High Internal Phase Emulsions Stabilized Solely by Chickpea Aquafaba. Foods 2022, 11, 1588. [Google Scholar] [CrossRef] [PubMed]

- Choya, F.; Combarros-Fuertes, P.; Camino, A.; Renes Bañuelos, D.; Prieto Gutiérrez, E.; Rodríguez, T.; Fresno Baro, M.E.; Fuentes Choya, P.; Combarros-Fuertes, P.; Camino, D.A.; et al. Study of the Technological Properties of Pedrosillano Chickpea Aquafaba and Its Application in the Production of Egg-Free Baked Meringues. Foods 2023, 12, 902. [Google Scholar] [CrossRef]

- Gawborisut, S.; Ketkaew, C.; Buasook, T. Production of Biocalcium from Fermented Fish Bone Residue for Fish Emulsion Sausage Fortification. Foods 2024, 13, 882. [Google Scholar] [CrossRef]

- Surasani, V.K.R.; Mandal, A.; Sofi, F.R.; Joshi, S. Utilization of Pangas Protein Isolates and By-Products in Fish Sausages: Effect on Quality Attributes and Acceptability. J. Food Process. Preserv. 2022, 46, e16798. [Google Scholar] [CrossRef]

- Honrado, A.; Ardila, P.; Leciñena, P.; Beltrán, J.A.; Calanche, J.B. Transforming ‘Bonito Del Norte’ Tuna By-Products into Functional Ingredients for Nutritional Enhancement of Cereal-Based Foods. Foods 2023, 12, 4437. [Google Scholar] [CrossRef] [PubMed]

- Kumari, A.; Kaushik, N.; Slizyte, R. Formulation of a Ready-to-Cook Soup Mix Using Microencapsulated Protein Hydrolysate Obtained from Pink Perch By-Product. Pol. J. Food Nutr. Sci. 2023, 73, 253–264. [Google Scholar] [CrossRef]

- Chew, R.M.; Mohd Zin, Z.; Ahmad, A.; Mohtar, N.F.; Rusli, N.D.; Zainol, M.K. Physicochemical and Sensory Properties of Deep Fried Battered Squid Containing Brownstripe Red Snapper (Lutjanus Vitta) Protein Hydrolysate. Food Res. 2020, 4, 1245–1253. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yang, Z.; Zhao, S.; Gai, J.; Wang, L.; Ning, X.; Tao, N. Quality Characteristics of Sardine (Sardina Pilchardus) Fish Sauce Produced Using Five Kinds of Material. Int. J. Gastron. Food Sci. 2023, 34, 100801. [Google Scholar] [CrossRef]

- Tkaczewska, J.; Kulawik, P.; Morawska-Tota, M.; Zając, M.; Guzik, P.; Tota, Ł.; Pająk, P.; Duliński, R.; Florkiewicz, A.; Migdał, W. Protocol for Designing New Functional Food with the Addition of Food Industry By-Products, Using Design Thinking Techniques—A Case Study of a Snack with Antioxidant Properties for Physically Active People. Foods 2021, 10, 694. [Google Scholar] [CrossRef]

- Zhang, L.; Shan, Y.; Hong, H.; Luo, Y.; Hong, X.; Ye, W. Prevention of Protein and Lipid Oxidation in Freeze-Thawed Bighead Carp (Hypophthalmichthys Nobilis) Fillets Using Silver Carp (Hypophthalmichthys Molitrix) Fin Hydrolysates. LWT 2020, 123, 109050. [Google Scholar] [CrossRef]

- Nurdiani, R.; Zahira, A.; Ainnayah, Q.; Rat, F.R.H.; Firdaus, M.; Astuti, R.T. Characteristics Of Yoghurt Enriched With Protein Hydrolysate From Parrotfish (Chlorurus Sordidus) Head. Carpathian J. Food Sci. Technol. 2023, 15, 184–196. [Google Scholar] [CrossRef]

- Unnikrishnan, P.; Puthenveetil Kizhakkethil, B.; Anant Jadhav, M.; Sivam, V.; Ashraf, P.M.; Ninan, G.; Aliyamveetil Abubacker, Z. Protein Hydrolysate from Yellowfin Tuna Red Meat as Fortifying and Stabilizing Agent in Mayonnaise. J. Food Sci. Technol. 2020, 57, 413–425. [Google Scholar] [CrossRef]

- Bruno Siewe, F.; Kudre, T.G.; Narayan, B. Optimisation of Ultrasound-Assisted Enzymatic Extraction Conditions of Umami Compounds from Fish by-Products Using the Combination of Fractional Factorial Design and Central Composite Design. Food Chem. 2021, 334, 127498. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.S.; Roy, V.C.; Park, J.S.; Haque, A.R.; Mok, J.H.; Zhang, W.; Chun, B.S. Protein and Polysaccharide Recovery from Shrimp Wastes by Natural Deep Eutectic Solvent Mediated Subcritical Water Hydrolysis for Biodegradable Film. Mar. Biotechnol. 2024. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Kan, G.; Peng, J.; Gong, H.; Zi, Y.; Shi, C.; Wang, X.; Zhong, J. Tilapia Head Gelatins to Stabilize Fish Oil Emulsions and the Effect of Extraction Methods. Int. J. Biol. Macromol. 2024, 269, 132137. [Google Scholar] [CrossRef]

- Yang, L.; Yang, M.; Xu, J.; Nie, Y.; Wu, W.; Zhang, T.; Wang, X.; Zhong, J. Structural and Emulsion Stabilization Comparison of Four Gelatins from Two Freshwater and Two Marine Fish Skins. Food Chem. 2022, 371, 131129. [Google Scholar] [CrossRef]

- Kumari, A.; Kaushik, N.; Slizyte, R.; Khushboo. Production and Microencapsulation of Protein Hydrolysate of Pink Perch (Nemipterus Japonicus) By-Products Obtained from Surimi Industry for Its Sustainable Utilization. Waste Biomass Valorization 2023, 14, 209–226. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Q.; Hong, H.; Luo, Y. Prevention of Protein Oxidation and Enhancement of Gel Properties of Silver Carp (Hypophthalmichthys Molitrix) Surimi by Addition of Protein Hydrolysates Derived from Surimi Processing by-Products. Food Chem. 2020, 316, 126343. [Google Scholar] [CrossRef] [PubMed]

- Steinsholm, S.; Oterhals, Å.; Underhaug, J.; Aspevik, T. Emulsion and Surface-Active Properties of Fish Solubles Based on Direct Extraction and after Hydrolysis of Atlantic Cod and Atlantic Salmon Backbones. Foods 2021, 10, 38. [Google Scholar] [CrossRef]

- Wang, K.; Ni, J.; Tian, X.; Xiang, S.; Li, H.; Shang, W.; Liu, B.; Tan, M.; Su, W. Survivability of Probiotics in Pickering Emulsion Gels Stabilized by Salmon By-Product Protein/Sodium Alginate Soluble Complexes at Neutral PH. Int. J. Biol. Macromol. 2024, 255, 128190. [Google Scholar] [CrossRef]

- Nasri, R.; Taktak, W.; Hamdi, M.; Ben Amor, N.; Kabadou, A.; Li, S.; Nasri, M. Sardinelle Protein Isolate as a Novel Material for Oil Microencapsulation: Novel Alternative for Fish by-Products Valorisation. Mater. Sci. Eng. C 2020, 116, 111164. [Google Scholar] [CrossRef]

- Syahrul, S.; Dewita, D.; Effendi, I.; Suwondo, S. The Use of Striped Catfish (Pangasianodon Hypophthalmus) Abdominal Fat as a Raw Material for Highly Nutritional Fish Oil. AACL Bioflux 2023, 16, 979–988. [Google Scholar]

- Ainsa, A.; Iranzo, L.; Honrado, A.; Marquina, P.; Roncalés, P.; Beltrán, J.A.; Calanche, J. Effects of Cooking over the Stability of Fatty Acids as Bioactive Compounds in Enriched Pasta with a Fish By-Product. Cereal Chem. 2022, 99, 286–294. [Google Scholar] [CrossRef]

- Ainsa, A.; Roldan, S.; Marquina, P.L.; Roncalés, P.; Beltrán, J.A.; Calanche Morales, J.B. Quality Parameters and Technological Properties of Pasta Enriched with a Fish By-Product: A Healthy Novel Food. J. Food Process. Preserv. 2022, 46, e16261. [Google Scholar] [CrossRef]

- Ainsa, A.; Marquina, P.L.; Roncalés, P.; Beltrán, J.A.; Calanche, M.J.B. Enriched Fresh Pasta with a Sea Bass By-Product, a Novel Food: Fatty Acid Stability and Sensory Properties throughout Shelf Life. Foods 2021, 10, 255. [Google Scholar] [CrossRef] [PubMed]

- Bonfim, B.d.C.; Monteiro, M.L.G.; Santos, A.F.G.N.d.; Vilar, J.d.S.; Conte-Junior, C.A. Nutritional Improvement and Consumer Perspective of Fish Nuggets with Partial Substitution of Wheat Flour Coating by Fish (Priacanthus Arenatus, Cuvier, 1829) Waste Flour. J. Aquat. Food Prod. 2020, 29, 28–42. [Google Scholar] [CrossRef]

- Vitorino, K.C.; Chambo, A.P.S.; Coradini, M.F.; Matiucci, M.A.; Graton Michka, J.M.; Goes, E.S.d.R.; Gonçalves, A.A.; de Souza, M.L.R. Cereal Bars Flavored with Fish Protein Concentrate from Different Species. J. Aquat. Food Prod. 2020, 29, 65–72. [Google Scholar] [CrossRef]

- Santos Corrêa, S.; Gonçalves Oliveira, G.; Coradini Franco, M.; Gasparino, E.; Feihrmann, A.C.; Siemer, S.; Vieira Dantas Filho, J.; Cavali, J.; de Vargas Schons, S.; Rodrigues de Souza, M.L. Quality of Oreochromis Niloticus and Cynoscion Virescens Fillets and Their By-Products in Flours Make for Inclusion in Instant Food Products. PLoS ONE 2023, 18, e0279351. [Google Scholar] [CrossRef] [PubMed]

- Long, J.M.; Mohan, A. Development of Meat Powder from Beef Byproduct as Value-Added Food Ingredient. LWT 2021, 146, 111460. [Google Scholar] [CrossRef]

- Usman, M.; Ishaq, A.; Regenstein, J.M.; Sahar, A.; Aadil, R.M.; Sameen, A.; Khan, M.I.; Alam, A. Valorization of Animal By-Products for Gelatin Extraction Using Conventional and Green Technologies: A Comprehensive Review. Biomass Convers. Biorefin. 2023, 1, 1–13. [Google Scholar] [CrossRef]

- de Souza Cunha, R.C.; de Carvalho, L.M.; de Sousa Fontes, V.M.; de Sousa Galvão, M.; Olegário, L.S.; de Medeiros, L.L.; Morgano, M.A.; Pacheco, M.T.B.; Madruga, M.S.; Bezerra, T.K.A. Volatilomic Evaluation of Protein Hydrolysates from Free-Range Chicken Bones Treated with Hot-Pressure Process. LWT 2023, 174, 114368. [Google Scholar] [CrossRef]

- Mattohti, W.; Rozi, P.; Ababakri, G.; Esmayil, Z.; Zhou, C.; Cao, B.; Yadikar, N.; Yang, X. Isolation and Structural Characterization of Antioxidant Peptides from Horse Bone Marrow Protein Hydrolysates. J. Food Meas. Charact. 2023, 17, 732–750. [Google Scholar] [CrossRef]

- da Silva Bambirra Alves, F.E.; Carpiné, D.; Teixeira, G.L.; Goedert, A.C.; de Paula Scheer, A.; Ribani, R.H. Valorization of an Abundant Slaughterhouse By-Product as a Source of Highly Technofunctional and Antioxidant Protein Hydrolysates. Waste Biomass Valorization 2021, 12, 263–279. [Google Scholar] [CrossRef]

- de Sousa Fontes, V.M.; de Sousa Galvão, M.; Moreira de Carvalho, L.; do Nascimento Guedes, F.L.; dos Santos Lima, M.; Alencar Bezerra, T.K.; Madruga, M.S. Thiamine, Cysteine and Xylose Added to the Maillard Reaction of Goat Protein Hydrolysate Potentiates the Formation of Meat Flavoring Compounds. Food Chem. 2024, 445, 138398. [Google Scholar] [CrossRef]

- Londoño-Zapata, L.; Franco-Cardona, S.; Restrepo-Manotas, S.; Gomez-Narvaez, F.; Suarez-Restrepo, L.; Nuñez-Andrade, H.; Valencia-Araya, P.; Simpson, R.; Vega-Castro, O. Valorization of the By-Products of Poultry Industry (Bones) by Enzymatic Hydrolysis and Glycation to Obtain Antioxidants Compounds. Waste Biomass Valorization 2022, 13, 4469–4480. [Google Scholar] [CrossRef]

- Song, Y.; Gu, H.; Jo, J.M.; Shin, M.; Kim, S.Y.; Gam, D.H.; Imamura, S.; Kim, J.W. Production of Functional Peptide with Anti-Obesity Effect from Defatted Tenebrio Molitor Larvae Using Proteolytic Enzyme. Biotechnol. Bioprocess Eng. 2020, 25, 374–383. [Google Scholar] [CrossRef]

- Tang, T.; Zhang, M.; Liu, Y. Valorization of Meat and Bone Residue by Ultrasound and High Voltage Electrostatic Field Assisted Two-Stage Enzymatic Hydrolysis: Nutritional Characteristics and Flavor Analysis. Food Biosci. 2023, 56, 103203. [Google Scholar] [CrossRef]

- Prokopová, A.; Gál, R.; Mokrejš, P.; Pavlačková, J. Preparation of Gelatin from Broiler Chicken Stomach Collagen. Foods 2022, 12, 127. [Google Scholar] [CrossRef]

- Lukin, A. On the Possibility of Obtaining High-Quality Lyophilized Collagen Hydrolysate and Its Applicability in the Sausage Production. Food Sci. Technol. 2019, 40, 721–728. [Google Scholar] [CrossRef]

- Toldrà, M.; Parés, D.; Saguer, E.; Carretero, C. Utilisation of Protein Fractions from Porcine Spleen as Technofunctional Ingredients in Emulsified Cooked Meat Sausages. Int. J. Food Sci. Technol. 2020, 55, 871–877. [Google Scholar] [CrossRef]

- Ananey-Obiri, D.; Matthews, L.; Tahergorabi, R. Chicken Processing By-Product: A Source of Protein for Fat Uptake Reduction in Deep-Fried Chicken. Food Hydrocoll. 2020, 101, 105500. [Google Scholar] [CrossRef]

- Akimova, D.; Suychinov, A.; Kakimov, A.; Kabdylzhar, B.; Zharykbasov, Y.; Yessimbekov, Z. Effect of Chicken By-Products on the Physicochemical Properties of Forcemeat Formulations. Future Foods 2023, 7, 100238. [Google Scholar] [CrossRef]

- Kusio, K.; Szafrańska, J.O.; Radzki, W.; Sołowiej, B.G. Effect of Whey Protein Concentrate on Physicochemical, Sensory and Antioxidative Properties of High-Protein Fat-Free Dairy Desserts. Appl. Sci. 2020, 10, 7064. [Google Scholar] [CrossRef]

- Pires, A.; Tan, G.; Gomes, D.; Pereira-Dias, S.; Díaz, O.; Cobos, A.; Pereira, C. Application of Ultrafiltration to Produce Sheep’s and Goat’s Whey-Based Synbiotic Kefir Products. Membranes 2023, 13, 473. [Google Scholar] [CrossRef] [PubMed]

- Pavoni, J.M.F.; Leidens, N.; Luchese, C.L.; Baldasso, C.; Tessaro, I.C. In Natura Ovine Whey Proteins Concentration by Ultrafiltration Combining Batch and Diafiltration Operating Modes. J. Food Process. Eng. 2020, 43, e13554. [Google Scholar] [CrossRef]

- Himashree, P.; Gokul Devi, E.; Hariharan, K.C.; Sunil, C.K. Impact of Whey Incorporation on Acrylamide Formation and the Quality of Bread. J. Food Meas. Charact. 2023, 17, 5748–5758. [Google Scholar] [CrossRef]

- la Gatta, B.; Rutigliano, M.; Liberatore, M.T.; Dilucia, F.; Spadaccino, G.; Quinto, M.; Di Luccia, A. Preservation of Bioactive Compounds Occurring in Fresh Pasta Fortified with Artichoke Bracts and Tomato Powders Obtained with a Novel Pre-Treatment. LWT 2023, 187, 115298. [Google Scholar] [CrossRef]

- Gunel, Z. Microencapsulation of Apricot Kernel Oil: Utilization of Mushroom by-Product as an Emulsifier in Oil-in-Water Emulsion. Acad Bras. Cienc. 2024, 96, e20220448. [Google Scholar] [CrossRef] [PubMed]

- Thi Minh Nguyet, N.; Pham Tan Quoc, L.; Gia Buu, T. Evaluation of Textural and Microstructural Properties of Vegan Aquafaba Whipped Cream from Chickpeas. Chem. Eng. Trans. 2021, 83, 421–426. [Google Scholar] [CrossRef]

- Lamas, D.L.; Gende, L.B. Valorisation of Brewers’ Spent Grain for the Development of Novel Beverage and Food Products. Appl. Food Res. 2023, 3, 100314. [Google Scholar] [CrossRef]

- Honrado, A.; Ardila, P.; Leciñena, P.; Beltrán, J.A.; Calanche, J. Nutritional Enrichment of Cereal Foods: Feasibility Study and Characterisation of Biscuits Fortified with Seabass by-Products. Int. J. Food Sci. Technol. 2024, 59, 5376–5388. [Google Scholar] [CrossRef]

- Vu, N.D.; Tran, T.T.; Nguyen, V.M. Effect of Cooking and Preservation Time on Fish Balls Quality Produced from Pangasius Hypophthalmus Meat By-Product. Squalen Bull. Mar. Fish. Postharvest Biotechnol. 2023, 18, 42–51. [Google Scholar] [CrossRef]

- Khodaei, D.; Forde, A.; Noci, F.; Ryan, L. Physicochemical and Sensory Characteristics of Pasta Enriched with Blue Whiting (Micromesistius Poutassou) Fish Protein Hydrolysate. Int. J. Food Sci. 2023, 58, 2782–2789. [Google Scholar] [CrossRef]

- Boronat, Ò.; Sintes, P.; Celis, F.; Díez, M.; Ortiz, J.; Aguiló-Aguayo, I.; Martin-Gómez, H. Development of Added-Value Culinary Ingredients from Fish Waste: Fish Bones and Fish Scales. Int. J. Gastron. Food Sci. 2023, 31, 100657. [Google Scholar] [CrossRef]

- Furey, A.E.; Hoeche, U.; McLaughlin, C.; Noci, F. Incorporation of Roe, Milt and Liver from Plaice (Pleuronectes Platessa), Herring (Clupea Harengus) and Cod (Gadus Morhua) in Newly Developed Seafood Pâtés: Sensory Evaluation by Teenage Consumers in Ireland and Their Attitudes to Seafood. Int. J. Gastron. Food Sci. 2022, 28, 100524. [Google Scholar] [CrossRef]

- Aínsa, A.; Vega, A.; Honrado, A.; Marquina, P.; Roncales, P.; Gracia, J.A.B.; Morales, J.B.C. Gluten-Free Pasta Enriched with Fish By-Product for Special Dietary Uses: Technological Quality and Sensory Properties. Foods 2021, 10, 3049. [Google Scholar] [CrossRef]

- Samarakoon, H.M.M.C.; Patabandi, P.P.S.K.; Walpita, C.N.; Priyadarshana, M.K.C.; Udayathilake, E. Development of Ready to Eat Fish Paste Using Chub Mackerel (Scomber Japonicus) Tail Offcuts. J. Agric. Sci. 2021, 16, 247–259. [Google Scholar] [CrossRef]

- Liu, J.; Shibata, M.; Ma, Q.; Liu, F.; Lu, Q.; Shan, Q.; Hagiwara, T.; Bao, J. Characterization of Fish Collagen from Blue Shark Skin and Its Application for Chitosan- Collagen Composite Coating to Preserve Red Porgy (Pagrus Major) Meat. J. Food Biochem. 2020, 44, e13265. [Google Scholar] [CrossRef]

- Jahan, K.; Qadri, O.S.; Younis, K. Dietary Fiber as a Functional Food. In Functional Food Products and Sustainable Health; Springer: Singapore, 2020; pp. 155–167. [Google Scholar] [CrossRef]

- Ye, S.; Shah, B.R.; Li, J.; Liang, H.; Zhan, F.; Geng, F.; Li, B. A Critical Review on Interplay between Dietary Fibers and Gut Microbiota. Trends Food Sci. 2022, 124, 237–249. [Google Scholar] [CrossRef]

- He, Y.; Wang, B.; Wen, L.; Wang, F.; Yu, H.; Chen, D.; Su, X.; Zhang, C. Effects of Dietary Fiber on Human Health. Food Sci. Hum. Wellness 2022, 11, 1–10. [Google Scholar] [CrossRef]

- Hitlamani, V.; Huded, P.; Kumar, G.S.; Chetana, R. Development of High-Fiber and High-Protein Virgin Coconut Oil-Based Spread and Its Physico-Chemical, and Sensory Qualities. J. Food Sci. Technol. 2024, 1, 1–9. [Google Scholar] [CrossRef]

- Karra, S.; Sebii, H.; Bouaziz, M.A.; Blecker, C.; Attia, H.; Besbes, S. Male Date Palm Flower Powder: Effect of Incorporation on Physico-Chemical, Textural, and Sensory Quality of Biscuits. J. Food Process. Preserv. 2020, 44, e14687. [Google Scholar] [CrossRef]

- Kultys, E.; Moczkowska-Wyrwisz, M. Effect of Using Carrot Pomace and Beetroot-Apple Pomace on Physicochemical and Sensory Properties of Pasta. LWT 2022, 168, 113858. [Google Scholar] [CrossRef]

- Mohamed, R.S.; Abozed, S.S.; El-Damhougy, S.; Salama, M.F.; Hussein, M.M. Efficiency of Newly Formulated Functional Instant Soup Mixtures as Dietary Supplements for Elderly. Heliyon 2020, 6, e03197. [Google Scholar] [CrossRef] [PubMed]

- Wirkijowska, A.; Zarzycki, P.; Teterycz, D.; Nawrocka, A.; Blicharz-Kania, A.; Łysakowska, P. The Influence of Tomato and Pepper Processing Waste on Bread Quality. Appl. Sci. 2023, 13, 9312. [Google Scholar] [CrossRef]

- Brigagão, T.C.S.; Fortes, R.R.; Lourenço, C.O.; Carvalho, E.E.N.; Cirillo, M.Â.; Nachtigall, A.M.; Vilas Boas, B.M. Optimization of Gluten-Free Muffins Made with Pineapple Peel, Banana Peel, and Pumpkin Seed Flours. J. Food Process. Preserv. 2021, 45, e16037. [Google Scholar] [CrossRef]

- Segura-Badilla, O.; Kammar-García, A.; Mosso-Vázquez, J.; Ávila-Sosa Sánchez, R.; Ochoa-Velasco, C.; Hernández-Carranza, P.; Navarro-Cruz, A.R. Potential Use of Banana Peel (Musa Cavendish) as Ingredient for Pasta and Bakery Products. Heliyon 2022, 8, e11044. [Google Scholar] [CrossRef]

- Ying, D.; Sanguansri, L.; Cheng, L.; Augustin, M.A. Nutrient-Dense Shelf-Stable Vegetable Powders and Extruded Snacks Made from Carrots and Broccoli. Foods 2021, 10, 2298. [Google Scholar] [CrossRef]

- Merlino, M.; Tripodi, G.; Cincotta, F.; Prestia, O.; Miller, A.; Gattuso, A.; Verzera, A.; Condurso, C. Technological, Nutritional, and Sensory Characteristics of Gnocchi Enriched with Hemp Seed Flour. Foods 2022, 11, 2783. [Google Scholar] [CrossRef]

- Pop, A.; Paucean, A.; Socaci, S.A.; Alexa, E.; Man, S.M.; Muresan, V.; Chis, M.S.; Salanta, L.; Popescu, I.; Berbecea, A.; et al. Quality Characteristics and Volatile Profile of Macarons Modified with Walnut Oilcake By-Product. Molecules 2020, 25, 2214. [Google Scholar] [CrossRef]

- Aşkın Uzel, R. Sustainable Green Technology for Adaptation of Circular Economy to Valorize Agri-Food Waste: Celery Root Peel as a Case Study. Manag. Environ. Qual. Int. J. 2023, 34, 1018–1034. [Google Scholar] [CrossRef]

- Djeghim, F.; Bourekoua, H.; Różyło, R.; Bieńczak, A.; Tanaś, W.; Zidoune, M.N. Effect of By-Products from Selected Fruits and Vegetables on Gluten-Free Dough Rheology and Bread Properties. Appl. Sci. 2021, 11, 4605. [Google Scholar] [CrossRef]

- Saeidy, S.; Nasirpour, A.; Barekat, S. Effect of Sugar Beet Fiber and Different Hydrocolloids on Rheological Properties and Quality of Gluten-Free Muffins. J. Sci. Food Agric. 2023, 103, 1404–1411. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.R.; Biswas, M.M.H.; Esham, M.K.H.; Roy, P.; Khan, M.R.; Hasan, S.M.K. Jackfruit (Artocarpus Heterophyllus) by-Products a Novel Source of Pectin: Studies on Physicochemical Characterization and Its Application in Soup Formulation as a Thickener. Food Chem. Adv. 2023, 2, 100273. [Google Scholar] [CrossRef]

- Parid, D.M.; Rahman, N.A.A.; Baharuddin, A.S.; Kadir Basha, R.P.; Mohammed, M.A.; Mat Johari, A.; Abd Razak, S.Z. Effects of Carboxymethyl Cellulose Extracted from Oil Palm Empty Fruit Bunch Stalk Fibres on the Physical Properties of Low-Fat Ice Cream. Food Res. 2021, 5, 1–7. [Google Scholar] [CrossRef]

- Silchuk, T.; Zuiko (Kulinich), V.; Nazar, M.; Tsirulnikova, V.; Tyshchenko (Usatiuk), O.; Pushka, O.; Kyrpichenkova, O.; Bortnichuk, O. Investigation of the Influence of Peas Dietary Fibers on the Process of Formation of Wheat Dough. J. Hyg. Eng. Des. 2021, 35, 56–60. [Google Scholar]

- Nawrocka, A.; Zarzycki, P.; Kłosok, K.; Welc, R.; Wirkijowska, A.; Teterycz, D. Effect of Dietary Fibre Waste Originating from Food Production on the Gluten Structure in Common Wheat Dough. Int. Agrophys. 2023, 37, 101–109. [Google Scholar] [CrossRef]

- Bamal, P.; Dhull, S.B. Development of Functional Muffins from Wheat Flour-Carrot Pomace Powder Using Fenugreek Gum as Fat Replacer. Curr. Res. Nutr. 2024, 12, 306–319. [Google Scholar] [CrossRef]

- Karwacka, M.; Ciurzyńska, A.; Galus, S.; Janowicz, M. Freeze-Dried Snacks Obtained from Frozen Vegetable by-Products and Apple Pomace—Selected Properties, Energy Consumption and Carbon Footprint. Innov. Food Sci. Emerg. Technol. 2022, 77, 102949. [Google Scholar] [CrossRef]

- Karwacka, M.; Rybak, K.; Smetana, S.; Galus, S.; Janowicz, M. Analysis of Selected Functional Properties, Resource Demands, and Energy Consumption of Freeze-Dried Vegetable Snacks. J. Food Process. Preserv. 2022, 46, e16721. [Google Scholar] [CrossRef]

- Vendramin, V.; Spinato, G.; Vincenzi, S.; Castro Marín, A.; Chinnici, F. Shellfish Chitosan Potential in Wine Clarification. Appl. Sci. 2021, 11, 4417. [Google Scholar] [CrossRef]

- Bastiaens, L.; Soetemans, L.; D’Hondt, E.; Elst, K. Sources of Chitin and Chitosan and Their Isolation. In Chitin and Chitosan; Broek, L.A.M., Boeriu, C.G., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2019; pp. 1–34. [Google Scholar] [CrossRef]

- Jofre, C.M.; Campderrós, M.E.; Rinaldoni, A.N. Integral Use of Grape: Clarified Juice Production by Microfiltration and Pomace Flour by Freeze-Drying. Development of Gluten-Free Filled Cookies. Food Chem. Adv. 2024, 4, 100583. [Google Scholar] [CrossRef]

- Egea, M.; Álvarez, D.; Peñaranda, I.; Panella-Riera, N.; Linares, M.B.; Garrido, M.D. Fat Replacement by Vegetal Fibres to Improve the Quality of Sausages Elaborated with Non-Castrated Male Pork. Animals 2020, 10, 1872. [Google Scholar] [CrossRef]

- Mahfoudhi, N.; Ksouri, R.; Hamdi, S. Nanoemulsions as Potential Delivery Systems for Bioactive Compounds in Food Systems: Preparation, Characterization, and Applications in Food Industry. Emulsions 2016, 3, 365–403. [Google Scholar] [CrossRef]

- Banwo, K.; Olojede, A.O.; Adesulu-Dahunsi, A.T.; Verma, D.K.; Thakur, M.; Tripathy, S.; Singh, S.; Patel, A.R.; Gupta, A.K.; Aguilar, C.N.; et al. Functional Importance of Bioactive Compounds of Foods with Potential Health Benefits: A Review on Recent Trends. Food Biosci. 2021, 43, 101320. [Google Scholar] [CrossRef]

- Jha, A.K.; Sit, N. Extraction of Bioactive Compounds from Plant Materials Using Combination of Various Novel Methods: A Review. Trends Food Sci. 2022, 119, 579–591. [Google Scholar] [CrossRef]

- Nartea, A.; Kuhalskaya, A.; Fanesi, B.; Orhotohwo, O.L.; Susek, K.; Rocchetti, L.; Di Vittori, V.; Bitocchi, E.; Pacetti, D.; Papa, R. Legume Byproducts as Ingredients for Food Applications: Preparation, Nutrition, Bioactivity, and Techno-Functional Properties. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1953–1985. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.; Abid, H.M.R.; Ahmad, A.; Khalid, N.; Shibli, S.; Amir, R.M.; Malik, A.M.; Asghar, M. Utilization of Mango Peel in Development of Instant Drink. Asian J. Agric. Biol. 2020, 8, 260–267. [Google Scholar] [CrossRef]

- Fanesi, B.; Ismaiel, L.; Nartea, A.; Orhotohwo, O.L.; Kuhalskaya, A.; Pacetti, D.; Lucci, P.; Falcone, P.M. Bioactives and Technological Quality of Functional Biscuits Containing Flour and Liquid Extracts from Broccoli By-Products. Antioxidants 2023, 12, 2115. [Google Scholar] [CrossRef] [PubMed]

- Naik, B.; Kumar, V.; Gupta, A.K. Valorization of Tender Coconut Mesocarp for the Formulation of Ready-to-Eat Dairy-Based Dessert (Kheer): Utilization of Industrial by-Product. J. Agric. Res. 2023, 12, 100572. [Google Scholar] [CrossRef]

- Pérez, P.; Hashemi, S.; Cano-Lamadrid, M.; Martínez-Zamora, L.; Gómez, P.A.; Artés-Hernández, F. Effect of Ultrasound and High Hydrostatic Pressure Processing on Quality and Bioactive Compounds during the Shelf Life of a Broccoli and Carrot By-Products Beverage. Foods 2023, 12, 3808. [Google Scholar] [CrossRef]

- Traffano-Schiffo, M.V.; Aguirre Calvo, T.R.; Avanza, M.V.; Santagapita, P.R. High-Intensity Ultrasound-Assisted Extraction of Phenolic Compounds from Cowpea Pods and Its Encapsulation in Hydrogels. Heliyon 2020, 6, e04410. [Google Scholar] [CrossRef]

- Difonzo, G.; Totaro, M.P.; Caponio, F.; Pasqualone, A.; Summo, C. Olive Leaf Extract (OLE) Addition as Tool to Reduce Nitrate and Nitrite in Ripened Sausages. Foods 2022, 11, 451. [Google Scholar] [CrossRef]

- Hue, H.T.; Tinh, H.T.; Van Bao, N.; Dao, P.T.A. Screening for Antioxidant Activity of Vegetable and Fruit By-Products and Evaluating the Ability of Coffee Sediment to Preserve Fish Meal. SN Appl. Sci. 2020, 2, 1282. [Google Scholar] [CrossRef]

- Tsai, S.Y.; Sun, W.J.; Wu, Y.C.; Lin, C.P. Peanut Skin Extracts Applied on Shelf Life of Button Mushrooms and Antioxidant Effect of Sacha Inchi Oil via Isothermal Calorimetry. J. Therm. Anal. Calorim. 2023, 148, 1629–1638. [Google Scholar] [CrossRef]

- Yu, J.; Xu, S.; Chen, R.; Shao, P. A Promising Bioactive Chitosan Film in Strawberry Fresh-Keeping: Plasticized with Tomato Processing by-Product Extract of Deep Eutectic Solvent. Food Hydrocoll. 2024, 151, 109859. [Google Scholar] [CrossRef]

- Benbouriche, A.; Haddadi-Guemghar, H.; Mehidi-Terki, D.; Boulekbache-Makhlouf, L.; Bachir-bey, M. Enrichment of Soybean Oil with Carotenoids from Chili Paste By-Product: Enhancement of Quality, Oxidative Stability, and Thermo-Resistance. J. Food Meas. Charact. 2024, 18, 1107–1120. [Google Scholar] [CrossRef]

- Cisneros-Yupanqui, M.; Chalova, V.I.; Kalaydzhiev, H.R.; Mihaylova, D.; Krastanov, A.I.; Lante, A. Ultrasound-Assisted Extraction of Antioxidant Bioactive Compounds from Wastes of Rapeseed Industry and Their Application in Delaying Rapeseed Oil Oxidation. Environ. Technol. Innov. 2023, 30, 103081. [Google Scholar] [CrossRef]

- Fernandez, M.V.; Bengardino, M.; Jagus, R.J.; Agüero, M.V. Enrichment and Preservation of a Vegetable Smoothie with an Antioxidant and Antimicrobial Extract Obtained from Beet By-Products. LWT 2020, 117, 108622. [Google Scholar] [CrossRef]

- Fotiadou, R.; Vougiouklaki, D.; Houhoula, D.; Stamatis, H. Improvement of the Oxidative Stability of Edible Oils through Enzymatic Esterification with Hydroxytyrosol-Rich Extract. Eur. J. Lipid Sci. Technol 2024, 126, 2400014. [Google Scholar] [CrossRef]

- De Leonardis, A.; Macciola, V.; Iftikhar, A.; Lopez, F. Characterization, Sensory and Oxidative Stability Analysis of Vegetable Mayonnaise Formulated with Olive Leaf Vinegar as an Active Ingredient. Foods 2022, 11, 4006. [Google Scholar] [CrossRef]

- Dzah, C.S.; Duan, Y.; Zhang, H.; Wen, C.; Zhang, J.; Chen, G.; Ma, H. The Effects of Ultrasound Assisted Extraction on Yield, Antioxidant, Anticancer and Antimicrobial Activity of Polyphenol Extracts: A Review. Food Biosci. 2020, 35, 100547. [Google Scholar] [CrossRef]

- Fernandez-Pan, I.; Horvitz, S.; Ibañez, F.C.; Arroqui, C.; Beriain, M.J.; Virseda, P. Extra-Virgin Olive Oil Enriched with Lycopene: From Industrial Tomato by-Products to Consumer. Food Sci. Nutr. 2024, 12, 5815–5823. [Google Scholar] [CrossRef] [PubMed]

- Michalak-Majewska, M.; Złotek, U.; Szymanowska, U.; Szwajgier, D.; Stanikowski, P.; Matysek, M.; Sobota, A. Antioxidant and Potentially Anti-Inflammatory Properties in Pasta Fortified with Onion Skin. Appl. Sci. 2020, 10, 8164. [Google Scholar] [CrossRef]

- Betrouche, A.; Estivi, L.; Colombo, D.; Pasini, G.; Benatallah, L.; Brandolini, A.; Hidalgo, A. Antioxidant Properties of Gluten-Free Pasta Enriched with Vegetable By-Products. Molecules 2022, 27, 8993. [Google Scholar] [CrossRef] [PubMed]

- Gumul, D.; Ziobro, R.; Korus, J.; Kruczek, M. Apple Pomace as a Source of Bioactive Polyphenol Compounds in Gluten-Free Breads. Antioxidants 2021, 10, 807. [Google Scholar] [CrossRef]

- Kaderides, K.; Mourtzinos, I.; Goula, A.M. Stability of Pomegranate Peel Polyphenols Encapsulated in Orange Juice Industry By-Product and Their Incorporation in Cookies. Food Chem. 2020, 310, 125849. [Google Scholar] [CrossRef]

- Lara-Abia, S.; Lobo, G.; Pérez-Pascual, N.; Welti-Chanes, J.; Cano, M.P. Improvement in the Stability and Bioaccessibility of Carotenoid and Carotenoid Esters from a Papaya By-Product Using O/W Emulsions. Foods 2023, 12, 2654. [Google Scholar] [CrossRef] [PubMed]

- Park, S.J.; Lee, M.J.; Choi, Y.J.; Yun, Y.R.; Lee, M.A.; Min, S.G.; Seo, H.Y.; Park, D.H.; Park, S.H. Optimization of Extraction and Nanoencapsulation of Kimchi Cabbage By-Products to Enhance the Simulated in Vitro Digestion of Glucosinolates. Heliyon 2023, 9, e16525. [Google Scholar] [CrossRef]

- Sanz, V.; Domínguez, H.; Torres, M.D. Formulation and Thermomechanical Characterization of Functional Hydrogels Based on Gluten Free Matrices Enriched with Antioxidant Compounds. Appl. Sci. 2021, 11, 1962. [Google Scholar] [CrossRef]

- Stoica, F.; Rațu, R.N.; Motrescu, I.; Cara, I.G.; Filip, M.; Țopa, D.; Jităreanu, G. Application of Pomace Powder of Black Carrot as a Natural Food Ingredient in Yoghurt. Foods 2024, 13, 1130. [Google Scholar] [CrossRef]

- Naurzbayeva, G.; Smolnikova, F.; Baytukenova, S.; Kapshakbayeva, Z.; Mustafayeva, A.; Baytukenova, S.; Smailova, Z.; Dikhanbayeva, F.; Temerbayeva, M.; Baybalinova, G. Incorporating Carrot Pomace-Based Emulsion to Enhance the Nutritional Value and Shelf Life of Butter. Int. J. Food Prop. 2023, 26, 2455–2475. [Google Scholar] [CrossRef]

- Kamiloglu, S.; Ozdal, T.; Tomas, M.; Capanoglu, E. Oil Matrix Modulates the Bioaccessibility of Polyphenols: A Study of Salad Dressing Formulation with Industrial Broccoli by-Products and Lemon Juice. J. Sci. Food Agric. 2022, 102, 5368–5377. [Google Scholar] [CrossRef]

- Akca, S.; Akpinar, A. The Effects of Grape, Pomegranate, Sesame Seed Powder and Their Oils on Probiotic Ice Cream: Total Phenolic Contents, Antioxidant Activity and Probiotic Viability. Food Biosci. 2021, 42, 101203. [Google Scholar] [CrossRef]

- Vlad, C.C.; Păcularu-Burada, B.; Vasile, A.M.; Milea, Ș.A.; Bahrim, G.E.; Râpeanu, G.; Stănciuc, N. Upgrading the Functional Potential of Apple Pomace in Value-Added Ingredients with Probiotics. Antioxidants 2022, 11, 2028. [Google Scholar] [CrossRef] [PubMed]

- Martin-Gómez, H.; Diez, M.; Abadias, M.; Rivera, A.; Aguiló-Aguayo, I. Promoting a Circular Economy by Developing New Gastronomic Products from Brassica Non-Edible Leaves. Int. J. Food Sci. Technol. 2024, 59, 1071–1079. [Google Scholar] [CrossRef]

- Ortinero, C.V.; Rafael, R.R.; Rayos, C.E.R.; Bautista, K.D.A.; Feliciano, M.A.M.; Natividad, L.R.; Natividad, G.M. Distilled Spirit Extraction of Phenolic Antioxidants from Fruit and Vegetable Residues. J. Ecol. Eng. 2021, 22, 125–131. [Google Scholar] [CrossRef]

- Salas-Millán, J.Á.; Aznar, A.; Conesa, E.; Conesa-Bueno, A.; Aguayo, E. Fruit Wine Obtained from Melon By-Products: Physico-Chemical and Sensory Analysis, and Characterization of Key Aromas by GC-MS. Foods 2022, 11, 3619. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Bravo, P.; Abellán, Á.; Zapata, P.J.; García-Viguera, C.; Domínguez-Perles, R.; Giménez, M.J. Broccoli Products Supplemented Beers Provide a Sustainable Source of Dietary Sulforaphane. Food Biosci. 2023, 51, 102259. [Google Scholar] [CrossRef]

- Rakariyatham, K.; Teerawutgulrag, A.; Laokuldilok, T.; Osiriphun, S.; Ackcharoensuk, N.; Tanbamrung, W. Combinatorial Effects of Longan (Dimocarpus Longan) Peel Extract and Lecithin on Stability of Soybean Oil and the Oxidative Stability of Fried Shrimp Crackers during Storage. Lebensm. Wiss. Und-Technol. 2024, 198, 116065. [Google Scholar] [CrossRef]

- Pereira, J.C.; Sivakanthan, S.; Vasantharuba, S. Effect of Star Fruit (Averrhoa Carambola L.) By-Product on Oxidative Stability of Sesame (Sesamum Indicum) Oil under Accelerated Oven Storage and during Frying. J. Oleo Sci. 2020, 69, 837–849. [Google Scholar] [CrossRef]

- Abeysinghe, A.M.A.K.; Ho, T.C.; Surendhiran, D.; Roy, V.C.; Park, J.S.; Han, J.M.; Chun, B.S. Oil Extraction and Methyl Esterification of Fatty Acids Obtained from Skipjack Tuna By-Products: Antimicrobial Property and Preservative Capability on Pork Sausage. Biomass Convers. Biorefin. 2024, 14, 1–11. [Google Scholar] [CrossRef]

- de la Fuente, B.; Pinela, J.; Mandim, F.; Heleno, S.A.; Ferreira, I.C.F.R.; Barba, F.J.; Berrada, H.; Caleja, C.; Barros, L. Nutritional and Bioactive Oils from Salmon (Salmo Salar) Side Streams Obtained by Soxhlet and Optimized Microwave-Assisted Extraction. Food Chem. 2022, 386, 132778. [Google Scholar] [CrossRef]

- Kalogianni, E.P.; Georgiou, D.; Charisis, A.; Exarhopoulos, S.; Tzika, P. Valorization of Mullet Roe By-Products for the Production of Polyunsaturated Fatty Acids Rich Oils. J. Am. Oil Chem. Soc. 2023, 100, 317–327. [Google Scholar] [CrossRef]

- Pinela, J.; de la Fuente, B.; Rodrigues, M.; Pires, T.C.S.P.; Mandim, F.; Almeida, A.; Dias, M.I.; Caleja, C.; Barros, L. Upcycling Fish By-Products into Bioactive Fish Oil: The Suitability of Microwave-Assisted Extraction. Biomolecules 2023, 13, 1. [Google Scholar] [CrossRef] [PubMed]

- Benkhoud, H.; Baâti, T.; Njim, L.; Selmi, S.; Hosni, K. Antioxidant, Antidiabetic, and Antihyperlipidemic Activities of Wheat Flour-Based Chips Incorporated with Omega-3-Rich Fish Oil and Artichoke Powder. J. Food Biochem. 2021, 45, e13297. [Google Scholar] [CrossRef]

- Phadtare, I.; Vaidya, H.; Hawboldt, K.; Cheema, S.K. Shrimp Oil Extracted from Shrimp Processing By-Product Is a Rich Source of Omega-3 Fatty Acids and Astaxanthin-Esters, and Reveals Potential Anti-Adipogenic Effects in 3T3-L1 Adipocytes. Mar. Drugs 2021, 19, 259. [Google Scholar] [CrossRef]

- Šimat, V.; Vlahović, J.; Soldo, B.; Generalić Mekinić, I.; Čagalj, M.; Hamed, I.; Skroza, D. Production and Characterization of Crude Oils from Seafood Processing By-Products. Food Biosci. 2020, 33, 100484. [Google Scholar] [CrossRef]

- Azmi, N.A.N.; Elgharbawy, A.A.M.; Salleh, H.M.; Moniruzzaman, M. Preparation, Characterization and Biological Activities of an Oil-in-Water Nanoemulsion from Fish By-Products and Lemon Oil by Ultrasonication Method. Molecules 2022, 27, 6725. [Google Scholar] [CrossRef]

- Murage, M.W.; Muge, E.K.; Mbatia, B.N.; Mwaniki, M.W. Development and Sensory Evaluation of Omega-3-Rich Nile Perch Fish Oil-Fortified Yogurt. Int. J. Food Sci. 2021, 2021, 8838043. [Google Scholar] [CrossRef]

- Alwohaibi, A.A.A.; Ali, A.A.; Sakr, S.S.; Mohamed Ahmed, I.A.; Alhomaid, R.M.; Alsaleem, K.A.; Aladhadh, M.; Barakat, H.; Hassan, M.F.Y. Valorization of Different Dairy By-Products to Produce a Functional Dairy–Millet Beverage Fermented with Lactobacillus Paracasei as an Adjunct Culture. Fermentation 2023, 9, 927. [Google Scholar] [CrossRef]

- Karwacka, M.; Galus, S.; Janowicz, M. Development and Physicochemical Characteristics of Multicomponent Freeze-Dried Snacks Obtained with Blackcurrant Pomace Powder and Calcium Ions as Structuring Agents. J. Food Sci. Technol. 2024, 61, 1363–1373. [Google Scholar] [CrossRef]

- Lordi, A.; Panza, O.; Conte, A.; Del Nobile, M.A. Best Combination of Vegetable By-Products for the Shelf-Life Extension of Fresh Pasta. Foods 2023, 13, 44. [Google Scholar] [CrossRef] [PubMed]

- Panza, O.; Lacivita, V.; Tarantino, F.; Manzi, A.; Conte, A.; Del Nobile, M.A. Fruit and Vegetable By-Products as Source of Bioactive Compounds to Preserve Handmade Fresh Pasta. LWT 2023, 190, 115584. [Google Scholar] [CrossRef]

- Long, J.M.; Mohan, A. Food Flavoring Prepared with Lemon By-Product. J. Food Process. Preserv. 2021, 45, e15462. [Google Scholar] [CrossRef]

- Giannoutsos, K.; Zalidis, A.P.; Koukoumaki, D.I.; Menexes, G.; Mourtzinos, I.; Sarris, D.; Gkatzionis, K. Production of Functional Crackers Based on Non-Conventional Flours. Study of the Physicochemical and Sensory Properties. Food Chem. Adv. 2023, 2, 100194. [Google Scholar] [CrossRef]

- García-Pastor, M.E.; Ródenas-Soriano, M.; Dobón-Suárez, A.; Zapata, P.J.; Giménez, M.J. Use of Olive Industry By-Products for Value-Added Food Development. Agronomy 2023, 13, 718. [Google Scholar] [CrossRef]

- Lipșa, F.D.; Stoica, F.; Rațu, R.N.; Veleșcu, I.D.; Cârlescu, P.M.; Motrescu, I.; Usturoi, M.G.; Râpeanu, G. Red Onion Peel Powder as a Functional Ingredient for Manufacturing Ricotta Cheese. Foods 2024, 13, 182. [Google Scholar] [CrossRef] [PubMed]

- Tonyali, B.; Sensoy, I.; Karakaya, S. Effects of Processing on Onion Skin Powder Added Extrudates. J. Food Sci. Technol. 2020, 57, 3426. [Google Scholar] [CrossRef]

- Cocan, I.; Cadariu, A.I.; Negrea, M.; Alexa, E.; Obistioiu, D.; Radulov, I.; Poiana, M.A. Investigating the Antioxidant Potential of Bell Pepper Processing By-Products for the Development of Value-Added Sausage Formulations. Appl. Sci. 2022, 12, 12421. [Google Scholar] [CrossRef]

- Nguyen, L.A.D.; Huynh, T.K.D.; Nguyen, T.N.H.; Nguyen, Q.T.; Tran, M.P. Effect of Rosemary (Rosmarinus Officinalis) Extract on the Protection of the Fishballs from Knife Fish (Chitala Chitala) and Striped Catfish by-Product (Pangasianodon Hypophthalmus) against Spoilage during Frozen Storage. Food Res. 2023, 7, 85–95. [Google Scholar] [CrossRef]

- Salas-Millán, J.Á.; Aznar, A.; Conesa, E.; Conesa-Bueno, A.; Aguayo, E. Functional Food Obtained from Fermentation of Broccoli By-Products (Stalk): Metagenomics Profile and Glucosinolate and Phenolic Compounds Characterization by LC-ESI-QqQ-MS/MS. LWT 2022, 169, 113915. [Google Scholar] [CrossRef]

- Bansal, U.; Bhardwaj, A.; Singh, S.N.; Khubber, S.; Sharma, N.; Bansal, V. Effect of Incorporating Plant-Based Quercetin on Physicochemical Properties, Consumer Acceptability and Sensory Profiling of Nutrition Bars. Funct. Foods Health Dis. 2022, 12, 116–127. [Google Scholar] [CrossRef]

- Ainsa, A.; Honrado, A.; Marquina, P.L.; Roncalés, P.; Beltrán, J.A.; Calanche, M.J.B. Innovative Development of Pasta with the Addition of Fish By-Products from Two Species. Foods 2021, 10, 1889. [Google Scholar] [CrossRef] [PubMed]

| By-Products | Ingredient Preparation | Food Application | Properties | References |

|---|---|---|---|---|

| Artichoke bracts and tomato | Non-thermal patented treatment (Patent n°001426984) → freeze drying | Fresh pasta (3% enrichment) | Good protein network, ↑ sensory acceptability | [77] |

| Pepper placenta, pepper defatted seeds, tomato seed/skin | Air drying (17 h, 30–40 °C) → fat extraction (from seeds, solvent) → grinding | Pasta (10–30% enrichment) | ↑ Protein, fiber | [28] |

| Broccoli leaf | Blanching (hot water, 1 min) → freeze drying → grinding | Pasta (2.5–5% enrichment) | ↑ AA composition, ↑ cooking loss | [23] |

| Broccoli leaf | Blanching (hot water, 1 min) → freeze drying → grinding (0.6 mm) | Gluten-free bread (5% enrichment) | ↑ Protein, minerals, ↑ antioxidant activity and anti-AGE activity, ↑ specific volume, bake loss | [24] |

| Cauliflower stems, leaves, stalks | Blanching (2–3 min) → drying (60 °C, 16 h) → grinding (0.8 mm) | Muffins (10–30% enrichment) | ↑ Protein, fiber, TPC, TFC, antioxidant activity, ↑ dark color, ↑ hardness, ↓ specific load volume, chewiness, springiness, cohesiveness, ↓ sensory acceptability (max 10%) | [25] |

| Mushroom stems | Freeze drying → grinding (0.25 mm) → ergosterol removal: dispersion (3:100) in 96% ethanol (residue) → drying (30 °C, 72 h) | Spray-dried emulsions (5% enrichment) | ↑ Viscosity, stability. ↑ yield, ↓ oxidation | [78] |

| Broken cashew kernels | Fat extraction (solvent) → grinding (0.25 mm) → water dispersion (1:15) → isoelectric precipitation (pH 3–4.5, 15 min) → drying | Vegan burgers (27% replacement) | ↓ Solubility, good sensory acceptability | [30] |

| Black gram by-product | Milling → fractionation (0.4–0.8 mm) | Extrudates | ↑ WAC, ↑ starch digestibility, ↓ phenolics (flavonoids, proanthocyanidins, saponins) | [26] |

| Quinoa okara | Water dispersion (1:10) → alkaline extraction (pH 9, 30 min, 55 °C) → US precipitation (75% amplitude, 30 s on—15 s off, 10 min) → air drying | Emulsions (2–6% enrichment) | ↑ Protein, fiber, ↑ ES, ↓ particle size | [18] |

| Soy okara | Drying (100 °C, 4 h) → grinding (0.3–0.6 mm) | Gluten-free extruded snacks (8–40% enrichment) | ↑ dark red color, ↓ expansion, ↑ nutritional/sensory quality (29–40%) | [29] |

| Aquafaba | Chickpea: broth, 1:2 (w/v) → cooking (100 kPa, 35 min) → freezing (liquid) | Meringue (egg white replacement) | ↑ Foaming and emulsifying properties, hardness, fracturability, similar color, ↓ alveoli | [32] |

| Aquafaba | Pre-soaking: chickpea: water, 1:3 (w/w) (5 °C, 16 h) → Cooking: chickpea: water, 1:2 (w/w) (118 °C, 70–80 kPa, 30 min) → filtration → freezing | Emulsion (25–35% replacement) | ↑ Gel-like behavior, ↓ cost | [31] |

| Aquafaba | Soaking (chickpea: water, 1:4, w/v, 8–10 h) → cooking (chickpea: water, 1–5, w/w, 45 min) → cooling → filtration (liquid) → freezing | Whipped cream (egg white replacement) | Good egg white replacer, ↑ foam particles, ↓ foam stability, ↓ hardness, gumminess | [79] |

| Walnut cake and sesame cake | Fat extraction → grinding | Low-fat mayonnaise (2–4%) | ↓ Carbohydrate, ↑ protein, fiber, ↑ ES, ↓ hardness, adhesiveness, ↑ sensory properties | [15] |

| Soybean extruded-expelled meal | Water dispersion (1:10) → sterilization (15 min, 120 °C) → fermentation → freeze drying | Gluten-free bread (6% enrichment) | ↑ Protein, fiber (cellulose lignin), ↑ specific volume, ↑ iron bio-accessibility, ↑ crumb color, ↑ aeration | [13] |

| Durum wheat cake | Fat extraction (solvent) → air classification (grader wheel speed 3000 rpm, airflow 50 m3/h) | Snack protein bar (10–50% enrichment) | ↑ Protein and fiber, ↓ fat, ↑ firmness, ↑ yellowness, ↑ caramel flavor | [22] |

| Coconut oil by-product | Fat extraction (cold press) → grinding → water dispersion (1:10) (60 °C, 1 h) → homogenization (10,000 rpm, 5 min) → US (405 W, 2.52 min) → filtrated liquid | Full-fat and low-fat vegan ice-cream (1–3% enrichment) | ↑ Protein and fat, ↓ cost | [20] |

| Peanut meal | Fat extraction (press) | Gluten-free snacks (26% enrichment) | ↑ Protein, ↑ shelf life, ↑ crispiness | [14] |

| Rapeseed press cake | Fat extraction (cold press) → water dispersion (1:9) → alkaline extraction (pH 10.5, 4 h) → isoelectric precipitation (pH 3–6.5) → freeze drying | Emulsions (0.05–5%) | ↑ ES (pH 5–6), ↑ protein yield (pH 4.2), ↓ droplet size (pH 6–6.5) | [17] |

| Spent brewer’s grain | Cooking (20 min, 100 °C) → filtration → homogenization → pasteurization (5 min, 80 °C) | Protein beverage | ↑ Protein | [80] |

| Spent brewer’s yeast | Vacuum drying (40 °C, −0.7 bar) → grinding → water dispersion (1 h) → alkaline treatment (pH 9–12, 20–25 °C, 2 h) | Emulsions (20% enrichment) | ↑ Mannoprotein solubility, ↑ viscosity, ↑ structure stability, color changes | [19] |

| By-Products | Ingredient Preparation | Food Application | Properties | References |

|---|---|---|---|---|

| Tilapia head | Removal of non-collagenous protein and fat with 1 mol/L of NaOH → mineral removal with 0.2 mol/L of EDTA → different extraction methods: (a) Hot water-pretreated gelatin (HWG) (b) Acetic acid-pretreated gelatin (AAG) (c) Sodium hydroxide-pretreated gelatin (SHG) (d) Pepsin enzyme-pretreated gelatin (PEG) | Fish oil emulsions with gelatin solutions (2–10 mg/mL) | (1) Gel strength: PEG > AAG > HWG > SHG (2) Foaming properties, emulsion viscosity, emulsion activity, and emulsion stabilization ability: PEG > HWG ≥ AAG > SHG | [45] |

| Fermented fish bone residue (FFBR) | Alkaline treatment (NaOH at 3–6%) and three soaking times (0, 1, and 2 h) | Fish sausage fortification with properly treated bio-calcium (0–36 g) | ↓ Salt content and intensity of fermented fish smell ↑ Calcium and phosphorus contents | [33] |

| Seabass (Dicentrarchus labrax) heads and bones | Hydrolysates production: alcalase (60 °C for 3 h/pH 7.6) → spray drying Fish meal production: steam boiling (20 min) → pressing → oven drying (60 °C for 30 h) → grinding | Biscuits (2.5–5% enrichment) | ↑ Intensities of color, toasted, and fish flavors; nutritional enrichment in protein and PUFAs | [81] |

| Asian tiger shrimp (Penaeus monodon) shells | Hot air oven drying → US and NADES → subcritical water hydrolysis (150–230 °C, 3 MPa, 20 min) → filtration | Biodegradable film (2–6%) for mackerel fish samples | ↑ Protein (391.96 mg BSA/g) obtained at 190 °C/UPT/NADES; average molecular size of protein molecules < 1000 Da | [44] |

| Salmon heads, fins, tails, and viscera | pH shifting: (2 mol/L NaOH) for 30 min/pH 11 → filtration → centrifugation → (2 mol/L HCl) pH 5.5 → precipitation → centrifugation → dialysis → freeze drying | Stabilized gels to encapsulate probiotic emulsions (4%, w/v complex protein solution; 2%, w/v alginate). | ↑ Emulsifying ability and emulsion stability | [50] |

| Tuna (Thunnus alalunga) heads | Hydrolysates production: alcalase (60 °C for 3 h/pH 7.6) → spray drying Fish meal production: steam boiled (20 min) → pressing → oven drying (60 °C for 30 h) → grinding | Biscuits (2.5–5% enrichment) | ↑ Protein and moisture | [35] |

| Canned sardine waste, mix of sardine meat, and by-products | Hydrolysates production: protamex, 0.50% → incubation (50 °C, 2.5 h) → addition of 0.7%; flavourzyme → adjusted to 15% salt and 14% Aspergillus oryzae koji → fermentation | Fermented fish sauce (50–100%) | No strong or unpleasant flavor, ↑ quality sauce | [38] |

| Tra fish (Pangasius hypophthalmus) | Washing (0.3% NaHCO3, 0.3% salt) → slicing → seasoning → grinding → balls forming → blanching (40 °C, 10 min → 2 cooking methods applied for 3–6 min, (1) steaming (100 °C) (2) blanching (80–100 °C) | Fish balls | ↑ Protein content, texture, color | [82] |

| Blue whiting (Micromesistius poutassou) | Protein isolate obtained commercially (92%) | Pasta (5–15% enrichment) | ↓ Optimal cooking time, swelling index, and water absorption; ↑ cooking loss; ↑ protein content, firmness, and adhesiveness | [83] |

| Abdominal fat of striped catfish (Pangasianodon hypophthalmus) | Oil extraction: Abdominal fat washing and draining → chopping → heating (5 h, 70 °C → filtration → oil purification → microencapsulation by spray drying | Microencapsulated fish oil enriched with fish protein concentrates and chlorella powders | Mix of catfish oil, chlorella powder, and striped catfish protein concentrate 40%, 20%, and 40% had the best protein content (17.02%) | [52] |

| Fish bones and scales | Scales demineralization of gelatin: washing (10% w/v NaCl) → washing → treated with 2 M lactic acid solution → washed (yield of 76%) Flour: boiling bones for 30 min → drying (90 °C, 24 h) → grinding (0.6 mm) | High-protein financier and deep-fried puffed (5 g gelatin), panna cotta (6 g gelatin), whipped cream (24.6 g gelatin) | ↑ Protein concentration | [84] |

| Nile tilapia (Oreochromis niloticus) and croaker (Cynoscion virescens) | Pressure-cooked → pressed → ground → drying → re-grinding | Instant food products and seasoned flours | ↑ Protein content (55.41–39.86%) of Nile tilapia backbone and head flour | [58] |

| Parrotfish (Chlorurus sordidus) head | Enzymatic hydrolysis (chopped head mixed with water (1:2), neutral pH with 0.2 N NaOH → conditioning (50 °C, 5 min) → flavourzyme (0.2 AU/g) addition → incubation → inactivation/heat → centrifugation → spray drying | Yoghurt (0.1–3% enrichment) | Best enrichment (0.15%) with a viscosity value of 2.432 N·s/m2, syneresis 49.67%, WHC 37.4%, pH 4.36, TTA 0.76%, color L* 74.55, color a* −3.76, color b* 8.2 | [41] |

| Pink perch (Nemipterus japonicus) head and viscera | Enzymatic hydrolysis (alcalase, 58 °C, 85 min → inactivation/heat → centrifugation → freeze drying → microencapsulation → freeze drying | Soup fortification (15% protein + 11% protein hydrolysate, microencapsulated protein hydrolysate (27%), and sun-dried whole fish powder (16%) | ↑ Overall acceptability | [36] |

| Pink perch (Nemipterus japonicus) | Enzymatic hydrolysis (alcalase, 57.9 °C, 85.8 min, 0.15% (v/w) E/S ratio) → freeze drying → microencapsulation | Microencapsulation of surimi by-product | High yield (17%), good functional properties, and moderate antioxidant activity;↑ amount of essential amino acid (35%), ↓ bitterness and odor | [47] |

| Pangas (Pangasius pangasius) | Alkaline extraction and precipitation | Fish sausages (2.5–10% enrichment) | ↑ Crude protein and lipid content, ↓ gel strength | [34] |

| Roe, milt, and liver of plaice (Pleuronectes platessa), herring (Clupea harengus), and cod (Gadus morhua) | Washing → mixing →cooking | Fish pate | ↑ Acceptability, ↑ protein content (21%) in roe pate | [85] |

| Sea bass (Dicentrarchus labrax) | Dipped in saline solution 8% → dried (60 °C/24 h) | Pasta (10% enrichment) | ↑ Protein, fat, fiber, EPA, DHA; ↑ nutritional availability after cooking | [54] |

| Sea bass (Dicentrarchus labrax) | Dipped in saline solution 8% → dried (60 °C/24 h) | Pasta (10% enrichment) | ↓ Texture properties except for adhesiveness, ↑ Nutritional profile, low impact on the technological quality | [86] |

| Chub mackerel (Scomber japonicus) tail | Minced fresh tail offcuts | Ready-to-eat fish paste (3.5–61.1%) | Paste with 61.1%: ↑ overall acceptability, flavor, color, texture, crude protein; ↓ crude fat percentage | [87] |

| Carp skins (Cyprinus carpio) | Gelatin extraction: 2.6% NaCl → filtration → freeze dying Hydrolysate production: protamex, alcalase, neutrase and flavourzyme → enzyme inactivation → centrifugation → SDS-PAGE separation → freeze drying | Snack | ↑ Nutritional value and antioxidant power, good sensory qualities | [39] |

| Sea bass (Dicentrarchus labrax) | Dipped in saline solution 8% → drying (60 °C/24 h) | Fresh pasta (10% enrichment) | ↑ Nutritional values, ↑ protection against oxidation, ↑ ω-3 and ω-6, adequate sensory profiles | [55] |

| Atlantic salmon (Salmo salar) and cod (Gadus morhua) backbones | Enzymatic hydrolysis, direct protein extracts by thermal coagulation without enzyme | Emulsions | ↑ Emulsion activity in the products based on direct protein extraction | [49] |

| Abeo rohita head | US enzymatic extraction: mincing → pH adjusted (2 M NaOH) → US → pH 7.5 (2 M NaOH or 2 M HCl) → protamex incubation → inactivation → centrifugation → freeze drying | Umami compounds | ↑ Efficiency of extraction best results at degree hydrolysis (22.73%) and extraction yield (76.34%) of umami extract achieved with a liquid/solid ratio of 3 (v/w), US time 19.20 min, hydrolysis time 140.45 min | [43] |

| Sardinella aurita | Protein isolates by alkaline process: homogenization → adjusting pH 11.0 (2 N NaOH) → centrifugation → precipitation (2 N HCl) → centrifugation → adjusting pH 7 → spray drying | Stabilized microencapsulated corn oil | ↑ Encapsulation efficiency, ↑ protection of corn oil, ↑ best ratio protein isolates and maltodextrin 1:4 | [51] |

| Brown stripe red snapper (Lutjanus vitta) protein hydrolysate | Enzymatic hydrolysis by alcalase → freeze drying | Deep-fried battered squid with hydrolysate (2–6% and 8%) | ↑ Hardness and crispness, ↓ fat content at 8%, ↓ oil binding capacity, maximum acceptability scores at 4% | [37] |

| Surimi by-products | Lyophilized by-product (25 g protein) → alcalase 2.4 L (270,000 U/g) and trypsin (200,000 U/g) → inactivate protease → centrifuge → freeze drying | Gel for silver carb surimi | ↑ Delaying protein oxidation, ↑ initial gelation properties, ↓ loss in gelation and water-holding capacity | [48] |

| Silver carp (Hypophthalmichthys molitrix) fin | Hydrolysate by four enzymes (trypsin, alcalase, papain, and neutrase) → freeze drying | Bighead carp (Hypophthalmichthys nobilis) fillets fortified | Trypsin and alcalase hydrolysates had strong ABTS scavenging activity and inhibition of protein oxidation, ↓ lipid oxidation | [40] |

| Yellow fin tuna red (Thunnus albacares) | Hydrolysate by papain enzyme: E/S ratio and hydrolysis time as 0.34% and 30 min, respectively at 60 °C and pH of 6.5 → spray drying | Mayonnaise | (50%) Replacement of egg yolk with protein hydrolysate: ↑ desirability, ↑ quality of emulsion, ↓ particle size, ↑ oxidative and physicochemical stability | [42] |

| Tilapia, salmon, and tuna | Thawing → washing → cooking (BHT at 0.5 mg/kg) → draining → pressing → milling → oven (60 °C, 24 h) | Cereal bars (90% tilapia protein concentrate and 10% salmon or tuna protein concentrate) | No change in the nutrients, sensory and microbiological profile ↑ mineral matter | [57] |

| Priacanthus arenatus | 1st Heating (180 °C, 100 min) → milling → 2nd heating (200 °C, 40 min) → milling | Fish nuggets (10–40%) | 40% fish waste flour: ↑ protein, lipid, and ash ↓ carbohydrate ↑ hue angle, a*, and b* values ↑ overall liking and preference | [56] |

| Chinese long snout catfish skin, silver carp skin, salmon skin, and Alaska pollack skin | Soaking with 0.1 M NaOH (pH 7) → soaking in 0.05 M acetic acid (pH 7) → incubation (55 °C) → filtration → freeze drying | Fish oil-loaded gelatin-stabilized emulsions (2–10 mg/mL gelatin) | ↑ Gel strength of catfish and silver carp gelatins than marine fish skin gelatins, ↑ amino acids, ↑ contents of hydrophobic amino acids, ↑ molecular weights | [46] |

| Blue shark (Prionace glauca) skin | Pepsin soluble collagen extraction: shark skin mixed with 0.1 M NaOH (remove non-collagenous proteins) → fat removal → extraction (0.5 M acetic acid + 0.2% pepsin) → centrifugation → dialysation → freeze drying | Chitosan–collagen composite coating for red porgy (Pagrus major) meat | ↑ Deterioration indexes at a ratio of 1:0.8 chitosan/pepsin, soluble collagen, ↑ physicochemical indexes | [88] |

| By-Products | Ingredient Preparation | Food Application | Properties | References |

|---|---|---|---|---|

| Porcine spleens | Soluble proteins extraction (sodium citrate buffer 0.1 M, pH 5) → centrifuging→ spray drying → washing of insoluble fraction → Pasteurization (80 °C, 45 min) | Sausages | Good functional properties | [70] |

| Broiler chicken stomachs | Separation of organic matter (0.2 mol/L NaCl, 0.06 mol/L NaOH, 1:1 petroleum ether/ethanol) → conditioning of collagen (protamex, pH 6.5, 0.1–0.2 wt%) → hot water | Gelatins | ↑ Gelatin yield (65%), gel strength (25–439 Bloom), digestibility (100%), melting point, ↓ ash | [68] |

| Trimmings, skin, meat-left-on-bone of chicken drumstick | Homogenization → alkaline extraction (pH 11.5, 10 min) → centrifugation → isoelectric precipitation (pH 5.5, 10 min) → centrifugation | Edible coating | ↑ Moisture content, ↓ fat uptake, ↑frying yield in coated samples | [71] |

| Chicken bones | High pressure pretreatment (121 °C, 4 h) → oven drying (55 °C, 5 h) → enzymatic hydrolysis → Maillard reaction → autoclaving (113 °C, 10 min). | Flavoring agents | ↑ Protein and lipid content | [61] |

| Chicken feet and head | Grinding → dispersion (1:1) in 10% solution of ascorbic acid → drying | Forcemeat | ↑ Protein, ash content | [72] |

| Cattle lips and ears | Cleaning → crushing → enzymatic hydrolysis (protepsin, 1:2 E/S, 0.5–1.5 h, 17–22 °C) → filtration → freeze drying | Forcemeats (5–20% enrichment) | ↑ Moisture-retaining capacity | [69] |

| Goat viscera | Cleaning → crushing → homogenization → enzymes inactivation (90 °C, 15 min) → cooling → enzymatic hydrolysis (alcalase, 0.8% E/S), 240 min) → inactivation (90 °C, 15 min) → cooling → Maillard reaction → homogenization → autoclaving (121 °C, 60 min) | Meat flavorings | ↑ Meat aroma | [64] |

| By-Products | Ingredient Preparation | Food Application | Properties | References |

|---|---|---|---|---|

| Whey | Heating of milk (70 °C, 20 min) → coagulation (1% citric acid) → filtration | Bread (0–100% water substitution) | ↑ Protein, fat | [76] |

| Whey | Whey-protein concentrate (76.8%) obtained commercially | High-protein fat-free dairy desserts | ↑ Texture and appearance, ↓ water activity | [73] |

| Sheep and goat cheese whey | Ultrafiltration (40–45 °C, 3.0–3.5 bar → pasteurization (65 °C, 30 min) → homogenization → freezing | Symbiotic kefir | ↑ Protein concentration | [74] |

| Cow, sheep, and goat whey | Whey-protein concentrate (>60%) obtained commercially | Probiotic beverages | ↑ Protein, free amino acids, TPC, antioxidant activity | [9] |

| By-Products | Ingredient Preparation | Food Application | Properties | References |

|---|---|---|---|---|

| Longan peel | Fat extraction → freeze drying → 80% ethanolic extraction → solvent evaporation | Soybean oil | ↑ Oxidative stability during frying, tocopherols; ↓ peroxides, conjugated dienes, TBARS | [152] |

| Black currant pomace | Obtained commercially | Freeze-dried vegetable snacks (1–5% enrichment) | ↑ TPC, antioxidant activity; ↑ dark color, ↓ water activity, ↓ porosity, ↑ hardness, crispiness | [164] |

| Pomegranate peels, olive oil pomace, broccoli root and leaves | Broccoli: drying (35 °C, 48 h) → grinding (0.5 mm) pomegranate: washing and disinfection → drying (50 °C, 48 h) → grinding (0.5 mm) olive: drying (35 °C, 72 h) → grinding (0.5 mm) | Fresh pasta (10% broccoli and 3–6% olive and pomegranate by-products enrichment) | ↑ Phenols, flavonoids; ↓ microbial growth; ↑ shelf life | [165] |

| Pomegranate peels, olive oil pomace, broccoli root and leaves | Pomegranate, broccoli: washing → disinfection → cutting → drying (45 °C) → grinding (0.5 mm) Olive: drying (45 °C) → grinding (0.5 mm) | Fresh pasta (3–8% enrichment each) | ↑ Phenols, flavonoids, antioxidant activity, shelf life (especially pomegranates) | [166] |

| Papaya peel | Washing → cutting → freeze-drying → grinding (<2 mm) → carotenoid extraction: dispersion (1:20) in THF+0.01% BHT+ magnesium carbonate →homogenization → US treatment (30 min) → centrifugation → re-extraction with acetone (pellet) → supernatant collection → diethyl ether addition → organic phase collection → filtration → vacuum drying | HPP-treated microemulsions (7 mg/g soybean/sunflower/coconut oil) | ↓ Particle size, ↑ carotenoid bio-accessibility (sunflower, soybean oil) | [140] |

| Coconut husk | Washing → cutting → grinding → MW blanching (2450 MHz–900 W, 40–160 s) → cooling → grinding | Kheer dairy-based dessert (5–15% enrichment) | ↑ Flavor, color (10% maximum) | [122] |

| Apple pomace | Drying → milling | Gluten-free bread (5–15% enrichment) | ↑ Phenols, flavonoids, chlorogenic acid, phlorizin; ↑ antioxidant activity; ↑ sensory acceptability | [138] |

| Apple pomace | Freeze drying → UV sterilization | Fermented soy milk | ↑ Phenols, ↑ antioxidant activity, ↑ viable cell count | [147] |

| Lemon peel | Grinding | Flavoring gel | ↑ thermal stability ↑ safety, quality | [167] |

| Mango peel | Cutting → blanching (98 °C, 1 min) → drying (50 °C, 4 h) | Instant drink (2–6% enrichment) | ↑ TPC, vitamin C, ↑ antioxidant activity, ↑ acidity | [120] |

| Pomegranate peel, orange juice residue | Pomegranate: drying (40 °C, 48 h) → grinding (0.1 mm) → water dispersion (1:32) → US treatment (50 W, 35 °C, pulse 7 s on—6 s off, 10 min) → homogenization with hydrated orange fibers (1:9) → encapsulation (spray drying) | Cookies (enrichment at 5000 ppm of phenolic concentration) | ↑ Retention of encapsulated phenolics, ↑ antioxidant activity, ↑ bitterness, astringency, ↑ color, odor, ↓ texture | [139] |

| Banana, pineapple, squash, mango, calamansi, potato peels | Washing → cutting → drying | Distilled spirit (sample-to-solvent, 1:10, solvent: 40% ethanol/gin/vodka/tequila) | ↑ TPC, DPPH (mango), gin/vodka good substitute for food-compatible solvents | [149] |

| Star fruit peel | Drying (40 °C, 24 h) → grinding → phenol extraction (sample: acetone, 1:20, 4–24 h, 30 °C, x2) > solvent evaporation | Sesame oil (200–1000 ppm) | ↑ Oxidative stability during storage and frying (1000 ppm), good alternative to synthetic antioxidants | [153] |

| Non-compliant melon | Washing → peeling → deseeding → cutting → juice extraction → decantation (1 °C, 24 h, SO2 addition) → must | Melon-based wine | ↑ TPC, antioxidants, ↑ fruity, floral aroma | [150] |

| Grape seed, olive stone | Flour obtained commercially | Crackers (10–30% enrichment) | ↑ TPC, ↑ dark color, ↓ sensory acceptance, ↓ hardness (olive stone) | [168] |

| Olive mill wastewater | Filtration → liquid-liquid extraction with ethyl acetate (1:1–5, 4–70 °C, 0.25–24 h) → organic phase separation → solvent evaporation | Olive and sunflower oil (0.3% enrichment) | ↑ lipophilicity and bioactivity of phenols, ↑ thermal stability, ↓ oxidation | [132] |

| Olive wastewater (oil + brine) | Centrifugation | Stuffing or paste for olives (63% enrichment oil fraction) and pickled vegetable (brine) | ↑ Phenols, ↑ sensory properties | [169] |

| Olive leaf | Drying (T °C room, 15 d) → dispersion (1:10) in vinegar → homogenization → maceration (T °C room, 5 d) → filtration | Low-fat vegan mayonnaise | ↑ Phenols (oleuropein), ↑ oxidative stability, ↑ shelf life, ↑ color, taste | [133] |

| Olive leaf | Washing → drying (120 °C, 8 min) → grinding → water dispersion (1:20→ US extraction → filtration (liquid extract) → freeze drying | Ripened sausage (0.02–0.08%) | ↑ Weight loss, ↑ oxidative stability, ↓ hardness, ↑ microbial safety, natural additives (nitrite substitute) | [125] |

| Red onion peel | Washing → drying (40 °C) → grinding (1 mm) → UV sterilization → dispersion (1:14) in 70% acidified ethanol → US treatment (40 kHz, 25 °C, 40 min, 100 W) → centrifugation (liquid extract) | Ricotta cheese (1–3% enrichment) | ↑ Phytochemical content, ↑ antioxidant activity ↑ texture, color | [170] |

| Onion skin | Washing → drying (50 °C, 12 h) → grinding (0.5 mm) | Pasta (2.5–7.5% enrichment) | ↑ Phenol (quercetin, phenolic acids), ↑ antioxidant, anti-inflammatory activity | [136] |

| Onion skin | Washing → drying (T °C room, 14 d) → grinding (0.2 mm) | Extrudates (3–9% enrichment) | ↑ Quercetin, ↑ TPC, antioxidant activity | [171] |

| Tomato by-products | Dispersion (1:10) in DES-LA (deep eutectic solvents/lactic acid, 1:2) → US (40 kHz, 30 °C, 1–2 h) → centrifugation (liquid extract) → extract: chitosan solution (40:60, w/w) | Edible films (40% liquid extract) | ↑ Thermal stability, hydrophilicity; ↑ free radical scavenging rate, ↓ oxidation, ↑ shelf life | [128] |

| Tomato seeds and skin | Blanching → freezing → HPP extraction (by-product+ oil, 300–600 Mpa, 10 min) → agitation (45 °C, 45 min) | Extra virgin olive oil (10–20% enrichment) | ↑ Lycopene recovery, good sensory acceptability (10%) | [135] |

| Tomato pomace, linseed meal | Tomato: grinding → drying (45 °C, 10 h) Linseed: cold pressing | Gluten-free pasta (10–15% enrichment) | ↑ Fiber, lipid, tocols, phenols, ↑ antioxidant capacity | [137] |

| Artichoke bracts and tomato | Non-thermal patented treatment (Patent n°001426984) → freeze drying | Fresh pasta (3% enrichment) | ↑ Phenols, antioxidant activity | [77] |

| Black carrot pomace | Freeze drying → grinding → UV sterilization → dispersion (1:10) in 70% acidified ethanol → US treatment (40 kHz, 25 °C, 40 min, 100 W) → centrifugation (liquid extract) | Yoghurt (1–2% enrichment) | ↑ Nutritional quality, ↑ phytochemicals, antioxidant activity, ↑ color, appealing (2% best formulation) | [143] |