Quality Assessment of Minced Poultry Products Including Black Fermented Garlic

Abstract

1. Introduction

2. Materials and Methods

2.1. Ingredients of Minced Poultry Products

2.2. Preparation of Minced Poultry Products

2.3. Assessment of Physicochemical Properties

2.4. Microbiological Analyses

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

3.1. Evaluation of Physicochemical Characteristics of Minced Poultry Product

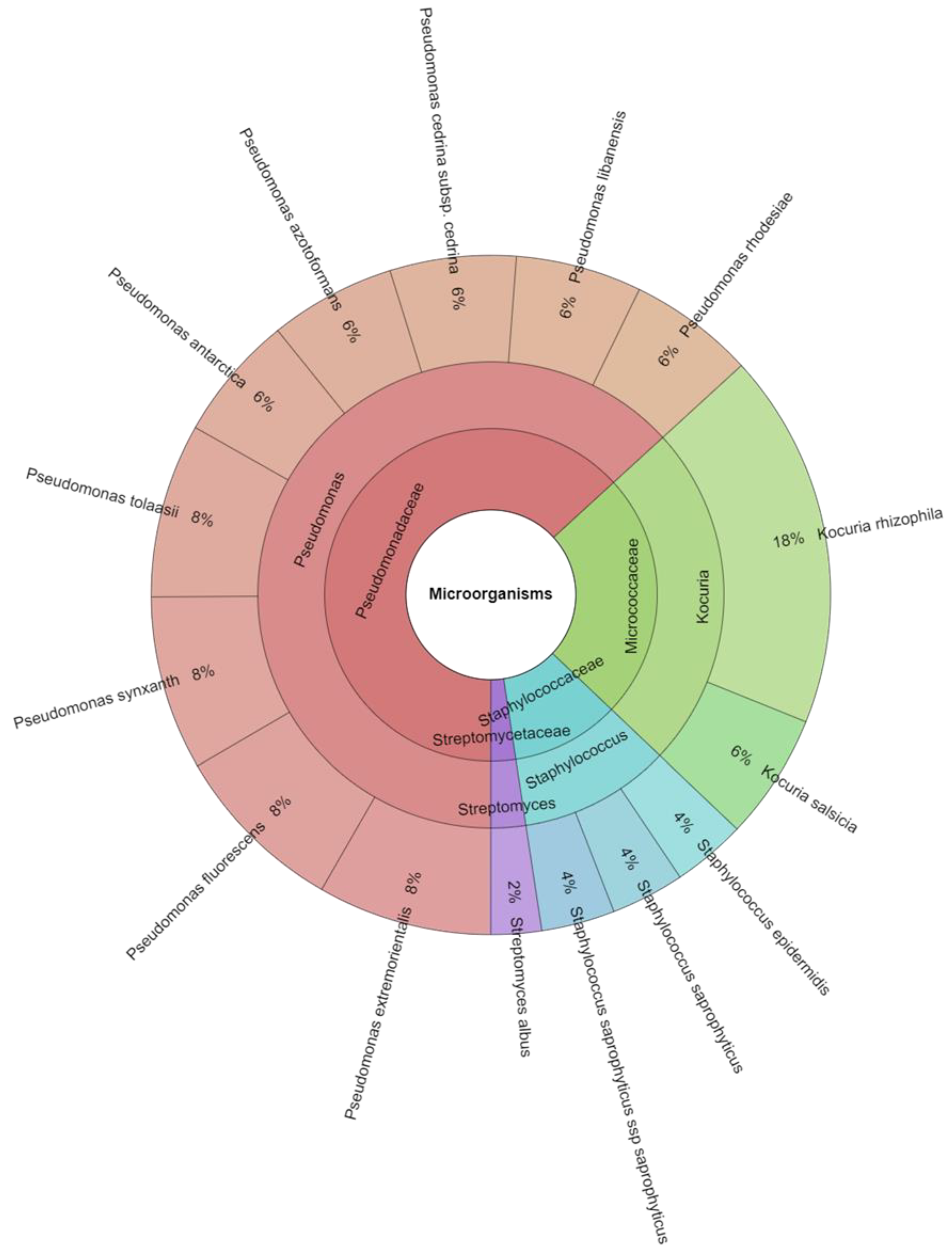

3.2. Microbiological Analyses of Minced Poultry Product

3.3. Sensory Analysis of Minced Poultry Product

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lei, F.C.; Hao, G.; Zhu, L.; Yang, Y.; Zhang, Y.L. Study progress on nutritional value and health effect of black garlic. Food Sci. Eng. 2012, 13, 429–432. [Google Scholar]

- Choi, I.S.; Cha, H.S.; Lee, Y.S. Physicochemical and antioxidant properties of black garlic. Molecules 2014, 19, 16811–16823. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, N.; Lu, X.; Liu, P.; Qiao, X. Effects of temperature on the quality of black garlic. J. Sci. Food Agric. 2016, 96, 2366–2372. [Google Scholar] [CrossRef] [PubMed]

- Kimura, S.; Tung, Y.C.; Pan, M.H.; Su, N.W.; Lai, Y.J.; Cheng, K.C. Black garlic: A critical review of its production, bioactivity, and application. J. Food Drug Anal. 2017, 25, 62–70. [Google Scholar] [CrossRef]

- Anoraga, S.B.; Ruspitasari, A.; Sabarisman, I.; Wikarta, J. Aging process of black garlic using natural material as spontaneous fermentation medium. J. Appl. Food Technol. 2020, 7, 38–40. [Google Scholar]

- Oktari, K.; Azizah, Z.; Chandra, B.; Asra, R. A Review: Antioxidant and immunomodulator effects of black garlic. EAS J. Pharm. Pharmacol. 2020, 2, 193–198. [Google Scholar] [CrossRef]

- Kim, J.H.; Jang, H.J.; Lee, C.H. Effect of aged garlic powder on physicochemical characteristics, texture profiles, and oxidative stability of ready-to-eat pork patties. Asian-Australas. J. Anim. Sci. 2019, 32, 1027–1035. [Google Scholar] [CrossRef]

- Angeles, T.M.M.; Jesus, P.A.; Rafael, M.R.; Tania, M.A. Evolution of some physicochemical and antioxidant properties of black garlic whole bulbs and peeled cloves. Food Chem. 2016, 199, 135–139. [Google Scholar] [CrossRef]

- Ammelia, S.M.; Suharti, R.; Retnosari, R.; Utomo, Y.; Sukarianingsih, D.; Wonorahardjo, S. The changing profiles of organosulfuric compounds during black garlic processing. International Conference on Green Agro-industry and Bioeconomy. IOP Conf. Ser. Earth Environ. Sci. 2020, 475, 012037. [Google Scholar] [CrossRef]

- Lizam, P.; Tragoolpua, Y.; Pandith, H.; Promputtha, I. Comparison of chemical profiles and bioactivities between fresh and black garlic extracts. In RSU International Research Conference 2022. Research and Innovation for Social and Economic Recovery in the New Normal Society; Suratthani Rajabhat University: Thani, Thailand, 2022; pp. 59–68. [Google Scholar]

- Nassur, R.C.M.R.; Boas, B.V.E.V.; Resende, F.V. Black garlic: Transformation effects, characterization and consumer purchase intention. Comun. Sci. 2017, 8, 444–451. [Google Scholar] [CrossRef]

- Ramli, N.K.C.M.; Ujang, S.; Ramli, N. Awareness of black garlic benefits to health: A preliminary study. GADING J. Sci. Technol. 2020, 3, 148–155. [Google Scholar]

- Najman, K.; Król, K.; Sadowska, A. The Physicochemical Properties, Volatile Compounds and Taste Profile of Black Garlic (Allium sativum L.) Cloves, Paste and Powder. Appl. Sci. 2022, 12, 4215. [Google Scholar] [CrossRef]

- Sunanta, P.; Chung, H.H.; Kunasakdakul, K.; Ruksiriwanich, W.; Juntrawutt, P.; Hongsibsong, S.; Sommano, S.R. Genomic relationship and physiochemical properties among raw materials used for Thai black garlic processing. Food Sci. Nutr. 2020, 8, 4534–4545. [Google Scholar] [CrossRef] [PubMed]

- Doronio, J.P.; Salazar, J.R.; Monserate, J.J.; Arevalo, B.J.A.; Eugenio, P.J.G.; Sarong, M.M. Nanoencapsulation of anthocyanin extract from fermented black garlic (FBG) based on biocompatible polymeric materials. Ann. Chim.-Sci. Des. Mater. 2022, 46, 37–43. [Google Scholar] [CrossRef]

- Halimah, L.S.; Nawangsih, E.N.; Hasan, K. Analysis of antibacterial and antioxidant activities of a single bulb of garlic fermented into black garlic. Adv. Health Sci. Res. 2021, 37, 83–87. [Google Scholar] [CrossRef]

- Sasaki, J.I. Overview of the black garlic movement in the fields of research and marketing. J. Life Sci. 2015, 9, 65–74. [Google Scholar] [CrossRef][Green Version]

- Toledano Medina, M.A.; Merinas-Amo, T.; Fernandez-Bedmar, Z.; Font, R.; del Rio-Colestino, M.; Perez-Aparicio, J.; Moreno-Ortenga, A.; Alonso-Moranga, A.; Moreno-Rojas, R. Physicochemical characterization and biological activities of black and white garlic: In vivo and in vitro assays. Foods 2019, 8, 220. [Google Scholar] [CrossRef]

- Arreola, R.; Quintero-Fabián, S.; López-Roa, R.I.; Flores-Gutiérrez, E.O.; Reyes-Grajeda, J.P.; Carrera-Quintanar, L.; Ortuño-Sahagún, D. Immunomodulation and anti-inflammatory effects of garlic compounds. J. Immunol. Res. 2015, 2015, 401630. [Google Scholar] [CrossRef]

- Lu, X.; Li, N.; Qiao, X.; Qiu, Z.; Liu, P. Composition analysis and antioxidant properties of black garlic extract. J. Food Drug Anal. 2017, 25, 340–349. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kang, D. Physicochemical properties, biological activity, health benefits, and general limitations of aged black garlic: A review. Molecules 2017, 22, 919. [Google Scholar] [CrossRef]

- Singhal, N.; Kumar, M.; Kanaujia, P.K.; Virdi, J.S. MALDI-TOF mass spectrometry: An emerging technology for microbial identification and diagnosis. Front. Microbiol. 2015, 6, 791. [Google Scholar] [CrossRef] [PubMed]

- Kačániová, M.; Mellen, M.; Vukovic, N.L.; Kluz, M.; Puchalski, C.; Haščík, P.; Kunová, S. Combined effect of vacuum packaging, fennel and savory essential oil treatment on the quality of chicken thighs. Microorganisms 2019, 7, 134. [Google Scholar] [CrossRef] [PubMed]

- PN-EN ISO 8589:2010; General Guidelines for the Design of a Sensory Analysis Laboratory. iTeh Standards: Newark, DE, USA, 2010.

- StatSoft Electronic Statistics Textbook. Data Analysis Software System, version 13.3; StatSoft, Inc.: Kraków, Poland, 2018.

- Barido, F.H.; Jang, A.; Pak, J.I.; Kim, Y.J.; Lee, S.K. Combined effects of processing method and black garlic extract on quality characteristics, antioxidative, and fatty acid profile of chicken breast. Poult. Sci. 2022, 101, 101723. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.K.; Kim, I.S.; Jeong, J.Y.; Kang, S.N.; Yang, H.S. Quality characteristics of low-salt and-fat meatball added black garlic (Allium sativum L.) during cold storage. Korean J. Food Sci. Anim. Resour. 2010, 30, 1031–1037. [Google Scholar] [CrossRef]

- Cayré, M.E.; Vignolo, G.; Garro, O. Modeling lactic acid bacteria growth in vacuum-packaged cooked meat emulsions stored at three temperatures. Food Microbiol. 2003, 20, 561–566. [Google Scholar] [CrossRef]

- Shin, J.H.; Kang, M.J.; Kim, R.J.; Sung, N.J. The quality characteristics of sausage with added black garlic extracts. Korean J. Food Cookery Sci. 2011, 27, 702–711. [Google Scholar] [CrossRef]

- Lishianawati, T.U.; Yusiati, L.M.; Jamhari, A. Antioxidants effects of black garlic powder on spent ducks meat nugget quality during storage. Food Sci. Technol. 2022, 42, e62220. [Google Scholar] [CrossRef]

- Yoon, H.S.; Shin, J.H.; Kang, M.J. Quality characteristics of sausage prepared with black garlic extract and dried powder of specialized crops cultivated in Namhae. Korean J. Food Cookery Sci. 2014, 30, 444–453. [Google Scholar] [CrossRef][Green Version]

- Huff-Lonergan, E.; Lonergan, S.M. Mechanisms of water holding capacity of meat: The role of postmortembiochemical and structural changes. Meat Sci. 2005, 71, 194–204. [Google Scholar] [CrossRef]

- Mancini, S.; Mattioli, S.; Nuvoloni, R.; Pedonese, F.; Dal Bosco, A.; Paci, G. Effects of garlic powder and salt on meat quality and microbial loads of rabbit burgers. Foods 2020, 9, 1022. [Google Scholar] [CrossRef]

- Fernandez-Lopez, J.; Zhi, N.; Aleson-Carbonell, L.; Perez-Alvarez, J.A.; Kuri, V. Antioxidant and antibacterial activities of natural extracts: Application in beef meatballs. Meat Sci. 2005, 69, 371–380. [Google Scholar] [CrossRef] [PubMed]

- Barido, F.H.; Kim, H.J.; Kang, S.M.; Jang, A.; Pak, J.I.; Lee, S.K. The effect of hydrolysis pre-treatment by flavourzyme on meat quality, antioxidative profiles, and taste-related compounds in samgyetang breast supplemented with black garlic. Food Sci. Anim. Resour. 2021, 42, 625–638. [Google Scholar] [CrossRef] [PubMed]

- Santhi, D.; Kalaikannan, A.; Sureshkumar, S. Factors influencing meat emulsion properties and product texture: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 2021–2027. [Google Scholar] [CrossRef] [PubMed]

- Lund, M.N.; Lametsch, R.; Hviid, M.S.; Jensen, O.N.; Skibsted, L.H. High-oxygen packaging atmosphere influences protein oxidation and tenderness of porcine longissimus dorsi during chill storage. Meat Sci. 2007, 77, 295–303. [Google Scholar] [CrossRef] [PubMed]

- Barido, F.H.; Jang, A.; Pak, J.I.; Kim, D.Y.; Lee, S.K. Investigation of taste-related compounds and antioxidative profiles of retorted samgyetang made from fresh and dried cordyceps militaris mushrooms. Food Sci. Anim. Resour. 2020, 40, 772–784. [Google Scholar] [CrossRef] [PubMed]

- Salejda, A.M.; Krasnowska, G.; Tril, U. Attempt to utilize antioxidant properties of green tea extract in the production of model meat products. ŻYWNOŚĆ Nauka Technologia Jakość 2011, 5, 107–118. [Google Scholar] [CrossRef]

- Mahros, M.; Eltanahy, A.; Abd-Elghany, S.; Sallam, K. The antimicrobial effect of fresh garlic and garlic oil supplemented with ground beef. Mansoura Vet. Med. J. 2021, 22, 48–51. [Google Scholar] [CrossRef]

- Javed, M.; Ahmed, W. Black garlic: A review of its biological significance. J. Food Biochem. 2022, 46, e14394. [Google Scholar] [CrossRef]

- Aydin, A.; Bostan, K.; Erkan, M.E.; Bingöl, B. The Antimicrobial Effects of Chopped Garlic in Ground Beef and Raw Meatball (Çiğ Köfte). J. Med. Food 2007, 10, 203–207. [Google Scholar] [CrossRef]

- Sallam, K.I.; Ishioroshi, M.; Samejima, K. Antioxidant and antimicrobial effects of garlic in chicken sausage. LWT-Food Sci. Technol. 2004, 37, 849–855. [Google Scholar] [CrossRef]

- Kim, J.W.; Kim, Y.S.; Kyung, K.H. Inhibitory Activity of Essential Oils of Garlic and Onion against Bacteria and Yeasts. J. Food Prot. 2004, 67, 499–504. [Google Scholar] [CrossRef] [PubMed]

- Fletcher, B.; Mullane, K.; Platts, P.; Todd, E.; Power, A.; Roberts, J.; Chapman, J.; Cozzolino, D.; Chandra, S. Advances in meat spoilage detection: A short focus on rapid methods and technologies. CYTA J. Food 2018, 16, 1037–1044. [Google Scholar] [CrossRef]

- Astal, Z. The Inhibitory Action of Aqueous Garlic Extract on the Growth of Certain Pathogenic Bacteria. East Cent. Afr. J. Pharm. Sci. 2005, 6, 9–14. [Google Scholar] [CrossRef]

- De Candia, S.; Quintieri, L.; Caputo, L.; Baruzzi, F. Antimicrobial Activity of Processed Spices Used in Traditional Southern Italian Sausage Processing. J. Food Process. Preserv. 2016, 41, e13022. [Google Scholar] [CrossRef]

- Cutler, R.R.; Wilson, P. Antibacterial activity of a new, stable, aqueous extract of allicin against methicillin-resistant Staphylococcus aureus. Br. J. Biomed. Sci. 2004, 61, 71–74. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Wang, C.; Zhou, G.; Li, C.; Ye, K. The effects of thermal treatment on the bacterial community and quality characteristics of meatballs during storage. Food Sci. Nutr. 2020, 9, 564–573. [Google Scholar] [CrossRef]

- Balamatsia, C.C.; Patsias, A.; Kontominas, M.G.; Savvaidis, I.N. Possible role of volatile amines as quality-indicating metabolites in modified atmosphere-packaged chicken fillets: Correlation with microbiological and sensory attributes. Food Chem. 2007, 104, 1622–1628. [Google Scholar] [CrossRef]

- Li, N.; Zhang, Y.X.; Wu, Q.P.; Gu, Q.H.; Chen, M.T.; Zhang, Y.Z.; Sun, X.; Zhang, J.M. High-throughput sequencing analysis of bacterial community composition and quality characteristics in refrigerated pork during storage. Food Microbiol. 2019, 83, 86–94. [Google Scholar] [CrossRef]

- Wang, H.H.; Zhang, X.X.; Wang, G.Y.; Jia, K.; Xu, X.L.; Zhou, G.H. Bacterial community and spoilage profiles shift in response to packaging in yellow-feather broiler, a highly popular meat in Asia. Front. Microbiol. 2017, 8, 2588. [Google Scholar] [CrossRef]

| Ingredients | Variants of Product | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Control Group | Group 1 | Group 1 | Group 3 | Group 4 | |||||

| fg | bg | fg | bg | fg | bg | fg | bg | ||

| breast muscle meat of turkeys for slaughter | 89.30 | 88.30 | 88.30 | 87.30 | 87.30 | 86.30 | 86.30 | 85.30 | 85.30 |

| water | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 | 10.00 |

| black garlic (bg) | 0 | 1.00 | 2.00 | 3.00 | 4.00 | ||||

| fresh garlic (fg) | 0 | 1.00 | 2.00 | 3.00 | 4.00 | ||||

| salt | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| pepper | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Day | Control Group | Addition Share | p-Value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||||||||

| fg | bg | fg | bg | fg | bg | fg | bg | ||||

| Wl (%) | 1 | 14.14 ± 1.21 a | 14.99 ± 0.9 9 | 14.79 ± 1.30 a | 13.04 ± 1.12 ab | 12.81 ± 0.98 ab | 12.58 ± 1.12 ab | 12.49 ± 1.12 ab | 12.18 ± 1.12 b | 12.05 ± 1.12 b | 0.0000 |

| pH | 1 | 6.16 ± 0.02 a | 6.10 ± 0.02 b | 6.05 ± 0.05 a | *6.08 ± 0.04 a | 6.03 ± 0.03 a | *6.06 ± 0.03 c | 6.01 ± 0.04 a | *6.02 ± 0.04 c | 5.98 ± 0.02 a | 0.0000 |

| 3 | 6.21 ± 0.02 a | 6.18 ± 0.06 b | 6.03 ± 0.04 bd | *6.03 ± 0.07 b | 6.04 ± 0.03 a | *6.00 ± 0.03 c | 5.97 ± 0.02 d | *5.78 ± 0.05 c | 5.92 ± 0.05 d | 0.0000 | |

| External colour | |||||||||||

| L* | 1 | *76.16 ± 0.94 a | *76.76 ± 1.79 a | 63.00 ± 2.79 d | *75.16 ± 2.25 ac | *53.56 ± 0.97 e | *72.40 ± 0.84 bc | *53.07 ± 3.53 e | *73.89 ± 0.58 ac | 48.03 ± 1.02 f | 0.0000 |

| 3 | *78.42 ± 0.96 a | *78.86 ± 0.99 a | 63.00 ± 1.61 b | *77.54 ± 1.07 a | *59.29 ± 0.78 c | *76.30 ± 1.09 a | *55.69 ± 1.53 d | *76.87 ± 1.15 a | 48.92 ± 2.38 e | 0.0000 | |

| a* | 1 | 10.05 ± 0.72 a | *7.94 ± 0.84 b | *8.13 ± 0.66 b | *7.22 ± 0.48 b | *8.19 ± 0.28 b | *7.28 ± 0.46 b | 7.12 ± 0.83 bc | *7.19 ± 0.14 b | *7.11 ± 0.28 c | 0.0000 |

| 3 | 9.11 ± 0.23 a | *5.62 ± 0.34 bd | *7.20 ± 0.44 cf | *5.16 ± 0.19 b | *6.93 ± 0.25 cf | *5.66 ± 0.42 bd | 6.24 ± 0.18 e | *5.40 ± 0.18 bd | *5.91 ± 0.30 de | 0.0000 | |

| b* | 1 | 12.59 ± 1.27 acd | *12.17 ± 0.74 a | *14.07 ± 1.24 ae | *14.49 ± 1.76 ce | *16.06 ± 0.31 be | *14.81 ± 1.09 be | *15.79 ± 1.09 be | 14.59 ± 0.91 de | *16.08 ± 0.76 be | 0.0000 |

| 3 | 10.19 ± 1.19 a | *9.93 ± 0.79 a | *11.80 ± 0.28 b | *11.77 ± 0.65 b | *12.14 ± 1.04 b | *11.22 ± 1.14 ab | *12.57 ± 0.72 b | *11.90 ± 0.36 b | *12.05 ± 0.71 b | 0.0000 | |

| Colour in cross-section | |||||||||||

| L* | 1 | 80.05 ± 1.49 a | 79.62 ± 1.34 a | 66.06 ± 3.28 c | *81.97 ± 2.67 b | *62.73 ± 1.04 d | *81.23 ± 0.96 ab | *59.42 ± 0.76 e | *81.50 ± 0.98 ab | 51.05 ± 1.11 f | 0.0000 |

| 3 | 81.16 ± 0.45 a | 77.93 ± 0.76 b | 66.50 ± 1.29 d | *79.81 ± 0.75 ac | *57.36 ± 0.43 ef | *80.22 ± 0.48 a | *55.84 ± 1.36 f | *78.13 ± 1.43 bc | 50.06 ± 0.47 f | 0.0000 | |

| a* | 1 | *8.81 ± 0.44 ac | *8.86 ± 0.48 c | 6.85 ± 0.37 b | 6.18 ± 0.22 b | 6.84 ± 0.82 b | 6.13 ± 0.51 b | 7.15 ± 0.55 b | *6.74 ± 1.62 b | 6.77 ± 0.19 b | 0.0000 |

| 3 | *7.86 ± 0.35 a | *7.47 ± 0.18 a | 6.70 ± 0.13 d | 5.52 ± 0.26 b | 6.26 ± 0.14 e | 5.58 ± 0.14 b | 6.58 ± 0.19 de | *4.35 ± 0.39 c | 6.83 ± 0.15 d | 0.0000 | |

| b* | 1 | 7.03 ± 0.12 a | 7.61 ± 0.27 a | 10.73 ± 0.42 c | 7.45 ± 0.36 a | 11.63 ± 0.29 d | 8.41 ± 0.19 b | *13.23 ± 0.35 e | *8.23 ± 0.22 b | 13.98 ± 0.34 f | 0.0000 |

| 3 | 6.27 ± 0.32 a | 8.21 ± 0.19 b | 10.62 ± 0.36 c | 8.04 ± 0.05 b | 11.56 ± 0.33 e | 10.00 ± 0.48 c | *12.48 ± 0.56 d | *10.70 ± 0.23 c | 13.10 ± 0.61 d | 0.0000 | |

| Sf (N) | 1 | 15.48 ± 1.53 a | 16.50 ± 1.88 a | 16.56 ± 2.20 a | 15.82 ± 1.65 a | 15.65 ± 2.30 a | 15.62 ± 0.98 a | 15.50 ± 2.02 a | 13.99 ± 1.96 ab | 13.20 ± 1.80 b | 0.0000 |

| 3 | 16.12 ± 2.02 a | 16.42 ± 1.60 a | 15.02 ± 1.89 a | 15.18 ± 1.50 a | 14.89 ± 21.93 a | 14.98 ± 1.18 a | 14.98 ± 1.86 a | 13.20 ± 1.89 b | 12.86 ± 1.95 b | 0.0000 | |

| Number of Bacteria (log cfu/g) | Day | Control Group | Addition Share | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Group 1 | Group 2 | Group 3 | Group 4 | |||||||

| fg | bg | fg | bg | fg | bg | fg | bg | |||

| EF | 1 | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| 3 | nd | nd | nd | nd | nd | nd | nd | nd | nd | |

| TCB | 1 | 1.25 a ± 0.05 | 1.15 ab ± 0.25 | 1.05 b ± 0.20 | 1.15 ab ± 0.05 | nd | 1.04 b ± 0.12 | nd | 1.05 b ± 0.08 | nd |

| 3 | 1.35 a ± 0.12 | 1.48 a ± 0.08 | 1.15 b ± 0.15 | 1.02 bc ± 0.10 | nd | nd | nd | 1.30 a ± 0.20 | nd | |

| LAB | 1 | nd | nd | 1.05 a ± 0.06 | 1.48 b ± 0.18 | nd | nd | nd | nd | 1.02 a ± 0.20 |

| 3 | 1.48 ± 0.32 | nd | nd | nd | nd | nd | nd | nd | nd | |

| P | 1 | 1.54 a ± 0.15 | 1.02 b ± 0.04 | nd | nd | nd | 0.98 b ± 0.08 | nd | nd | nd |

| 3 | 1.82 a ± 0.10 | 1.15 b ± 0.23 | nd | nd | nd | 1.12 b ± 0.15 | nd | nd | nd | |

| Control Group | Addition Share | Total | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Group 1 | Group 2 | Group 3 | Group 4 | |||||||

| fg | bg | fg | bg | fg | bg | fg | bg | |||

| Kocuria rhizophila | 10 | 5 | 5 | 20 | ||||||

| Kocuria salsicia | 6 | 6 | ||||||||

| Pseudomonas antarctica | 5 | 5 | 10 | |||||||

| Pseudomonas azotoformans | 12 | 12 | ||||||||

| Pseudomonas cedrina | 5 | 5 | ||||||||

| Pseudomonas cedrina subsp. cedrina | 7 | 5 | 12 | |||||||

| Pseudomonas extremorientalis | 7 | 5 | 12 | |||||||

| Pseudomonas fluorescens | 7 | 5 | 12 | |||||||

| Pseudomonas libanensis | 5 | 5 | 10 | |||||||

| Pseudomonas orientalis | 6 | 6 | ||||||||

| Pseudomonas rhodesiae | 6 | 5 | 11 | |||||||

| Pseudomonas synxantha | 7 | 6 | 13 | |||||||

| Pseudomonas tolaasii | 7 | 3 | 10 | |||||||

| Ralstonia pickettii | 2 | 2 | 3 | 3 | 10 | |||||

| Staphylococcus epidermidis | 3 | 3 | ||||||||

| Staphylococcus pasteuri | 3 | 3 | ||||||||

| Staphylococcus saprophyticus | 3 | 3 | ||||||||

| Staphylococcus saprophyticus subsp. saprophyticus | 3 | 3 | ||||||||

| Staphylococcus warneri | 3 | 3 | ||||||||

| Streptomyces albus | 2 | 2 | ||||||||

| Variovorax paradoxus | 5 | 5 | ||||||||

| Total | 171 | |||||||||

| Parameter | Day | Control Group | Addition Share | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Group 1 | Group 2 | Group 3 | Group 4 | |||||||

| fg | bg | fg | bg | fg | bg | fg | bg | |||

| Intensity of aroma | 1 | 4.40 a ± 0.52 | 4.70 a ± 0.48 | 4.20 a ± 0.63 | 4.20 a ± 0.42 | 4.50 a ± 0.53 | 4.40 a ± 0.52 | 4.20 a ± 0.42 | 3.50 b ± 0.53 | 3.40 b ± 0.52 |

| 3 | 4.20 a ± 0.42 | 4.50 a ± 0.48 | 4.00 a ± 0.42 | 4.40 a ± 0.52 | 4.70 a ± 0.48 | 4.00 a ± 0.47 | 3.70 ab ± 0.48 | 3.40 b ± 0.52 | 3.10 b ± 0.32 | |

| Desirability of aroma | 1 | 3.90 a ± 0.74 | 4.60 b ± 0.52 | 4.00 a ± 0.47 | 3.90 a ± 0.57 | 4.70 b ± 0.48 | 2.50 c ± 0.53 | 3.00 ab ± 0.67 | 1.80 c ± 0.63 | 2.40 c ± 0.52 |

| 3 | 3.70 b ± 0.48 | 4.25 a ± 0.27 | 3.80 ab ± 0.63 | 3.80 b ± 0.42 | 4.60 a ± 0.52 | 2.40 c ± 0.52 | 3.00 c ± 0.42 | 2.00 c ± 0.47 | 2.20 c ± 0.42 | |

| Taste intensity | 1 | 4.00 ab ± 0.50 | 4.70 a ± 0.40 | 4.40 a ± 0.42 | 3.20 b ± 0.30 | 4.75 a ± 0.53 | 3.00 b ± 0.52 | 4.20 a ± 0.42 | 1.80 c ± 0.50 | 2.40 c ± 0.40 |

| 3 | 3,80 b ± 0.36 | 4.45 a ± 0.40 | 4.20 a ± 0.40 | 3,00 b ± 0.36 | 4.70 a ± 0.48 | 3.00 b ± 0.40 | 3.70 b ± 0.48 | 1.60 c ± 0.32 | 2.10 c ± 0.51 | |

| Flavour intensity | 1 | 3.90 b ± 0.32 | 4.60 a ± 0.52 | 4.00 ab ± 0.63 | 3.70 b ± 0.48 | 4.70 a ± 0.48 | 2.50 c ± 0.53 | 4.40 a ± 0.32 | 1.90 c ± 0.57 | 2.00 c ± 0.47 |

| 3 | 3.90 b ± 0.74 | 4.20 ab ± 0.52 | 3.90 b ± 0.30 | 3.90 b ± 0.57 | 4.60 a ± 0.20 | 2.50 c ± 0.53 | 4.20 ab ± 0.67 | 1.80 c ± 0.63 | 2.40 c ± 0.52 | |

| Colour of cut section | 1 | 3.80 b ± 0.30 | 4.60 a ± 0.52 | 4.20 ab ± 0.40 | 3.90 b ± 0.57 | 3.80 b ± 0.48 | 2.50 c ± 0.53 | 3.00 ac ± 0.67 | 1.65 c ± 0.60 | 1.80 c ± 0.50 |

| 3 | 3.70 b ± 0.60 | 4.40 a ± 0.32 | 4.00 ab ± 0.47 | 3.80 b ± 0.50 | 3.60 b ± 0.40 | 2.00 c ± 0.42 | 2.80 c ± 0.40 | 1.60 c ± 0.63 | 1.60 c ± 0.32 | |

| Texture | 1 | 4.40 a ± 0.52 | 4.65 a ± 0.20 | 4.00 ab ± 0.47 | 4.20 ab ± 0.42 | 3.80 ab ± 0.48 | 4.00 ab ± 0.40 | 3.40 b ± 0.52 | 1.80 c ± 0.63 | 2.40 c ± 0.52 |

| 3 | 4.40 a ± 0.40 | 4.40 a ± 0.42 | 3.80 a ± 0.32 | 4.00 a ± 0.50 | 3.50 ab ± 0.53 | 2.50 b ± 0.53 | 3.00 ab ± 0.67 | 1.80 b ± 0.63 | 2.40 b ± 0.52 | |

| Overall desirability | 1 | 3.90 b ± 0.60 | 4.60 a ± 0.52 | 4.00 ab ± 0.47 | 3.90 b ± 0.30 | 4.60 a ± 0.48 | 2.40 c ± 0.50 | 3.60 b ± 0.67 | 1.80 d ± 0.63 | 2.00 cd ± 0.52 |

| 3 | 3.80 b ± 0.36 | 4.40 ab ± 0.30 | 3.90 b ± 0.30 | 3.80 b ± 0.50 | 4.20 ab ± 0.40 | 2.50 cd ± 0.53 | 3.00 c ± 0.42 | 1.80 d ± 0.63 | 1.80 d ± 0.52 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Augustyńska-Prejsnar, A.; Kačániová, M.; Ormian, M.; Topczewska, J.; Sokołowicz, Z.; Hanus, P. Quality Assessment of Minced Poultry Products Including Black Fermented Garlic. Foods 2024, 13, 70. https://doi.org/10.3390/foods13010070

Augustyńska-Prejsnar A, Kačániová M, Ormian M, Topczewska J, Sokołowicz Z, Hanus P. Quality Assessment of Minced Poultry Products Including Black Fermented Garlic. Foods. 2024; 13(1):70. https://doi.org/10.3390/foods13010070

Chicago/Turabian StyleAugustyńska-Prejsnar, Anna, Miroslava Kačániová, Małgorzata Ormian, Jadwiga Topczewska, Zofia Sokołowicz, and Paweł Hanus. 2024. "Quality Assessment of Minced Poultry Products Including Black Fermented Garlic" Foods 13, no. 1: 70. https://doi.org/10.3390/foods13010070

APA StyleAugustyńska-Prejsnar, A., Kačániová, M., Ormian, M., Topczewska, J., Sokołowicz, Z., & Hanus, P. (2024). Quality Assessment of Minced Poultry Products Including Black Fermented Garlic. Foods, 13(1), 70. https://doi.org/10.3390/foods13010070