Beef Toughness and the Amount of Greenhouse Gas Emissions as a Function of Localized Electrical Stimulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Animals and Treatment

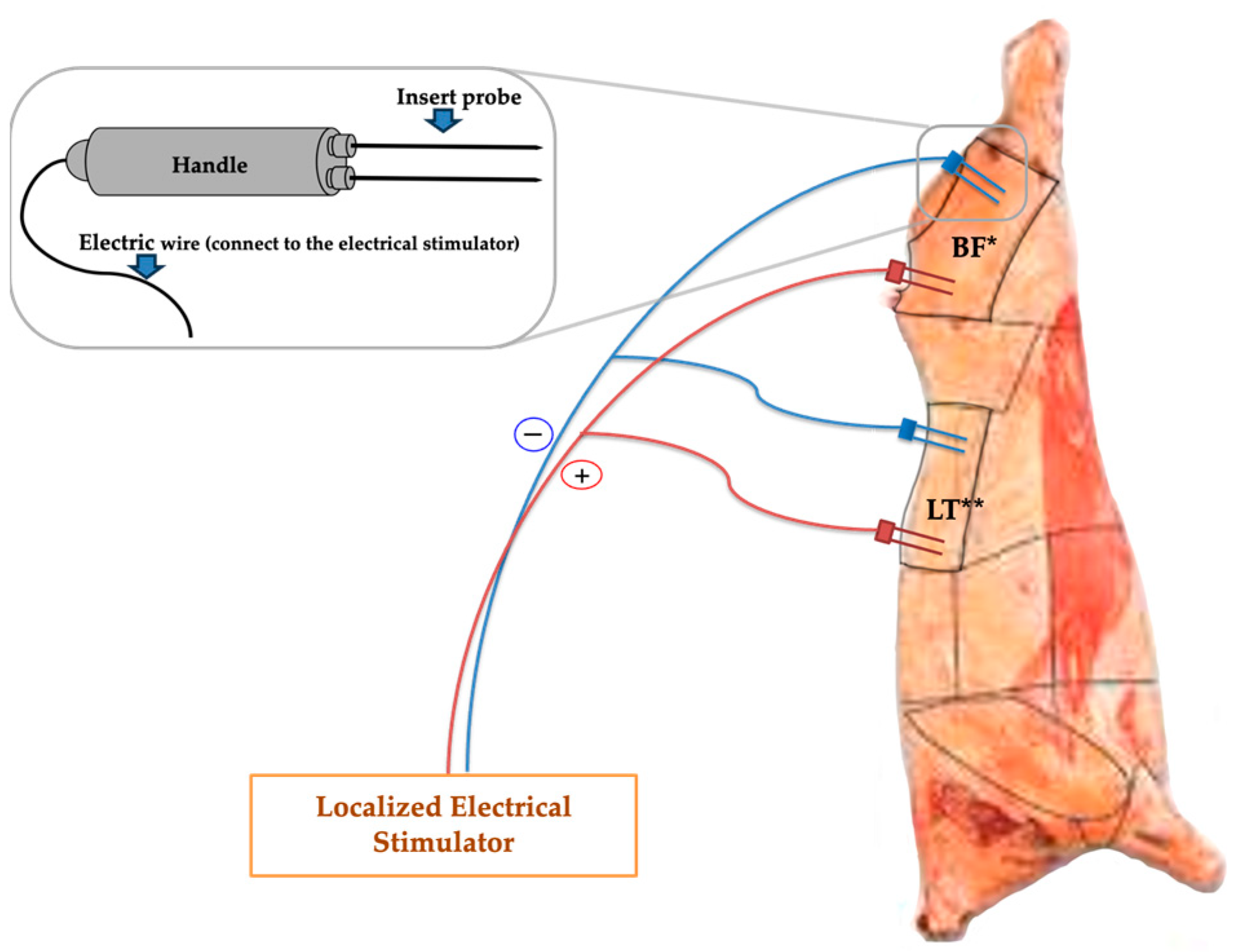

2.2. Aging Speeder through Localized Electrical Stimulation

2.3. pH and Color

2.4. Chemical Composition

2.5. 2-Thiobarbituric Acid Reactive Substances (TBARS) Value

2.6. Cooking Loss and Warner–Bratzler Shear Force (WBsf)

2.7. Calculation of CO2-eq Emission Mitigation Achieved by Reducing the Fattening Period

2.8. Statistical Analysis

3. Results

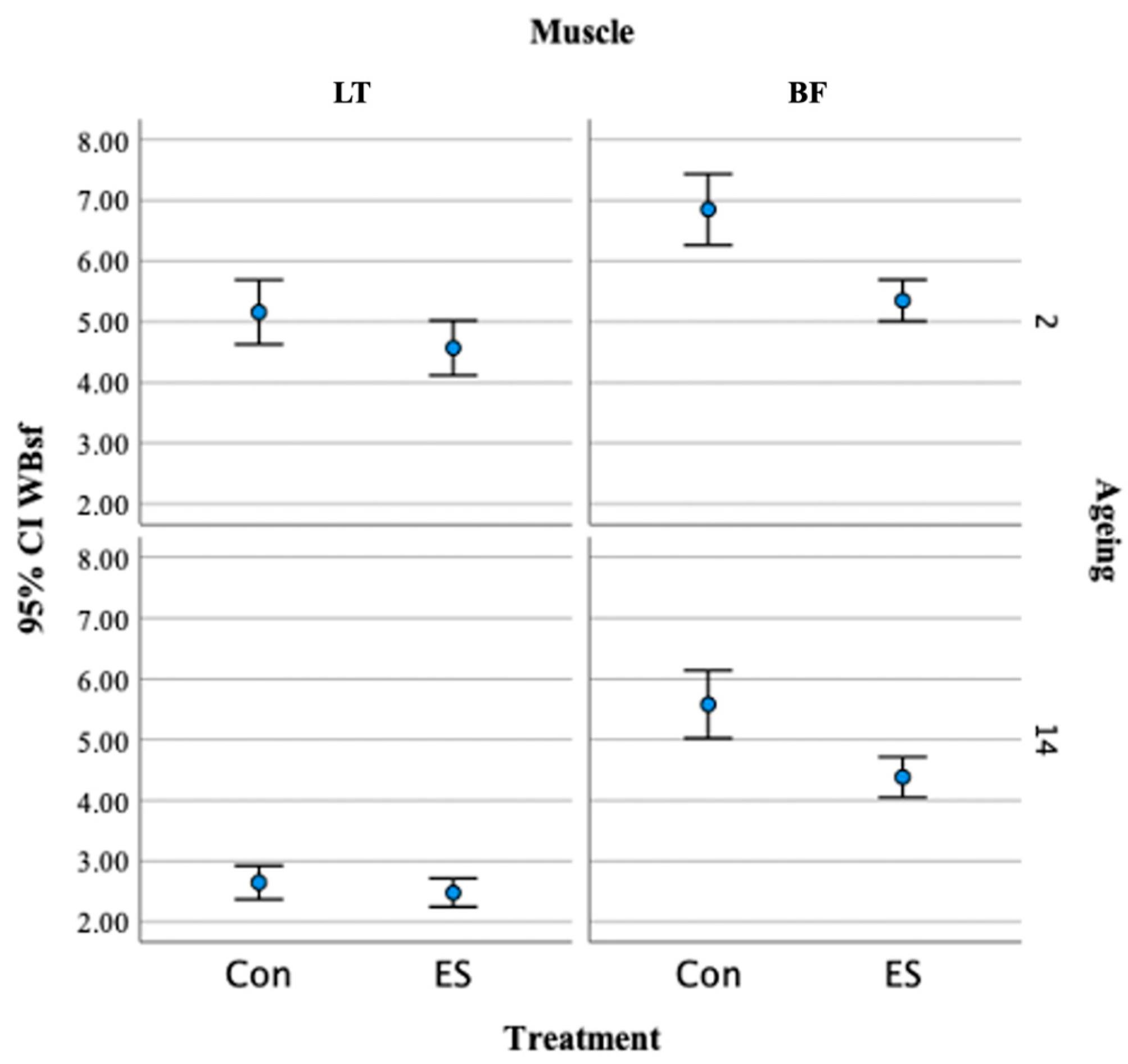

3.1. Effect of Localized Electrical Stimulation on Hanwoo Beef Quality

3.2. Effect of CO2 Emission Reduction from Hanwoo Meat through Localized Electrical Stimulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IPPC. Global Warming of 1.5 °C. Available online: https://www.ipcc.ch/sr15 (accessed on 21 November 2023).

- Gerber, P.J.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C.; Dijkman, J.; Falcucci, A.; Tempio, G. Tackling Climate Change through Livestock—A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013. [Google Scholar]

- Xiaogu, L.; Kimberly, L.J.; Christopher, D.C.; Dayton, M.L. Consumer willingness to pay for beef grown using climate friendly production practices. Food Policy 2016, 64, 93–106. [Google Scholar] [CrossRef]

- Capper, J.L. The Carbon Footprint of Beef Production. In Proceedings of the 64th Annual Reciprocal Meat Conference, Kansas State University, Manhattan, KS, USA, 19–22 June 2011. [Google Scholar]

- Garnett, T. Where are the best opportunities for reducing greenhouse gas emissions in the food system (including the food chain)? Food Policy 2011, 36, S23–S32. [Google Scholar] [CrossRef]

- Garnett, T.; (Centre for Environmental Strategy University of Surrey, Guildford, UK). Meat and Dairy Production and Consumption. Working Paper Produced a Part of the Work of the Food Climate Research Network. 2007. Available online: https://www.tabledebates.org/sites/default/files/2020-11/TGlivestock_env_sci_pol_paper.pdf (accessed on 21 November 2023).

- Cusack, D.F.; Kazanski, C.E.; Hedgpeth, A.; Chow, K.; Cordeiro, A.L.; Karpman, J.; Ryals, R. Reducing climate impacts of beef production: A synthesis of life cycle assessments across management systems and global regions. Glob. Chang. Biol. 2021, 27, 1721–1736. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.; Shin, J.S.; Seol, K.H.; Kim, Y.S.; Kang, S.M.; Seo, H.W. A study on the characteristics of purchasing propensity by preferences quality grade of Hanwoo beef. J. Korea Acad.-Ind. Coop. Soc. 2020, 21, 537–544. [Google Scholar] [CrossRef]

- Jo, C.; Cho, S.H.; Chang, J.; Nam, K.C. Keys to production and processing of Hanwoo beef: A perspective of tradition and science. Anim. Front. 2012, 2, 32–38. [Google Scholar] [CrossRef]

- Park, B.Y. A Report of Development for Hanwoo Steer Long Term Feeding System; Rural Development Administration: Jeonju-si, Republic of Korea, 2005; pp. 103–106. [Google Scholar]

- Ogino, A.; Kaku, K.; Osada, T.; Shimada, K. Environmental impacts of the Japanese beef-fattening system with different feeding lengths as evaluated by a life-cycle assessment method. J. Anim. Sci. 2004, 82, 2115–2122. [Google Scholar] [CrossRef]

- Hopkins, D.L.; Ertbjerg, P. Chapter 12—The eating quality of meat: II—Tenderness. In Lawrie’s Meat Science, 9th ed.; Toldrá, F., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2023; pp. 393–420. [Google Scholar] [CrossRef]

- Swatland, H. Cellular heterogeneity in the response of beef to electrical stimulation. Meat Sci. 1981, 5, 451–455. [Google Scholar] [CrossRef]

- Abhijith, A.; Dunshea, F.R.; Warner, R.D.; Leury, B.J.; Ha, M.; Chauhan, S.S. A meta-analysis of the effectiveness of high, medium, and low voltage electrical stimulation on the meat quality of small ruminants. Foods 2020, 9, 1587. [Google Scholar] [CrossRef]

- Hwang, I.; Thompson, J. The interaction between pH and temperature decline early postmortem on the calpain system and objective tenderness in electrically stimulated beef longissimus dorsi muscle. Meat Sci. 2001, 58, 167–174. [Google Scholar] [CrossRef]

- Yang, J.; Dashdorj, D.; Hwang, I. Volatile flavor components as a function of electrical stimulation and chiller aging form. longissimus and biceps femoris of Hanwoo beef. Food Sci. Anim. Resour. 2019, 39, 474–493. [Google Scholar] [CrossRef]

- Park, B. Establishment of Quality Differentiation Model Hanwoo Beef; Rural Development Administration: Jeonju-si, Republic of Korea, 2013; pp. 58–71. [Google Scholar]

- Claeys, E.; De Smet, S.; Balcaen, A.; Raes, K.; Demeyer, D. Quantification of fresh meat peptides by SDS–PAGE in relation to ageing time and taste intensity. Meat Sci. 2004, 67, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Jeremiah, L.; Gibson, L. The effects of postmortem product handling and aging time on beef palatability. Food Res. Int. 2003, 36, 929–941. [Google Scholar] [CrossRef]

- Adeyemi, K.D.; Sazili, A.Q. Efficacy of Carcass Electrical Stimulation in Meat Quality Enhancement: A Review. Asian-Australas. J. Anim. Sci. 2014, 27, 447–456. [Google Scholar] [CrossRef] [PubMed]

- KAPE (Korea Institute of Animal Products Quality Evaluation). 2017 The Beef Carcass Grading System. Available online: http://www.ekapepia.com/home/homeIndex.do (accessed on 20 May 2023).

- Horwitz, W. Official Methods of Analysis of AOAC, 17th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2000. [Google Scholar]

- Heinecke, J.; Rosen, H.; Suzuki, L.; Chait, A. The role of sulfur-containing amino acids in superoxide production and modification of low density lipoprotein by arterial smooth muscle cells. J. Biol. Chem. 1987, 262, 10098–10103. [Google Scholar] [CrossRef] [PubMed]

- Jeong, D.; Kim, Y.S.; Cho, S.; Hwang, I. A case study of CO2 emissions from beef and pork production in South Korea. J. Anim. Sci. Technol. 2023, 65, 427–440. [Google Scholar] [CrossRef] [PubMed]

- Jung, E.Y.; Hwang, Y.H.; Joo, S.T. Chemical components and meat quality traits related to palatability of ten primal cuts from Hanwoo carcasses. Korean J. Food Sci. Anim. Resour. 2015, 35, 859–866. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ji, X.; Mao, Y.; Luo, X.; Zhu, L.; Hopkins, D.L. Effect of new generation medium voltage electrical stimulation on the meat quality of beef slaughtered in a Chinese abattoir. Meat Sci. 2019, 149, 47–54. [Google Scholar] [CrossRef]

- Ho, C.Y.; Stromer, M.H.; Rouse, G.; Robson, R.M. Effects of electrical stimulation and postmortem storage on changes in titin, nebulin, desmin, troponin-T, and muscle ultrastructure in Bos indicus crossbred cattle. J. Anim. Sci. 1997, 75, 366–376. [Google Scholar] [CrossRef]

- Sleper, P.S.; Hunt, M.C.; Kropf, D.H.; Kastner, C.L.; Dikeman, M.E. Electrical stimulation effects on myoglobin properties of bovine longissimus muscle. J. Food Sci. 1983, 48, 479–483. [Google Scholar] [CrossRef]

- Aalhus, J.L.; Robertson, W.M.; Ye, J. Muscle fiber characteristics and their relation to meat quality. In Applied Muscle Biology and Meat Science; Du, M., McCormick, R.J., Eds.; CRC Press: London, UK, 2009; pp. 97–113. [Google Scholar]

- Ji, X.; Luo, X.; Zhu, L.; Mao, Y.; Lu, X.; Chen, X.; Hopkins, D.L.; Zhang, Y. Effect of medium voltage electrical stimulation and prior ageing on beef shear force during superchilled storage. Meat Sci. 2021, 172, 108320. [Google Scholar] [CrossRef]

- Biffin, T.E.; Smith, M.A.; Bush, R.D.; Collins, D.; Hopkins, D.L. The effect of electrical stimulation and tenderstretching on colour and oxidation traits of alpaca (Vicunga pacos) meat. Meat Sci. 2019, 156, 125–130. [Google Scholar] [CrossRef] [PubMed]

- Hwang, I.H.; Thompson, J.M. The effect of time and type of electrical stimulation on the calpain system and meat tenderness in beef longissimus dorsi muscle. Meat sci. 2001, 58, 135–144. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.; Kim, J.; Park, B.; Seong, P.; Kang, G.; Kim, J.; Jung, S.; Im, S.; Kim, D. Assessment of meat quality properties and development of a palatability prediction model for Korean Hanwoo steer beef. Meat Sci. 2010, 86, 236–242. [Google Scholar] [CrossRef] [PubMed]

- Voges, K.L.; Mason, C.L.; Brooks, J.C.; Delmore, R.J.; Griffin, D.B.; Hale, D.S.; Henning, W.R.; Johnson, D.D.; Lorenzen, C.L.; Maddok, R.J.; et al. National beef tenderness survey—2006: Assessment of Warner–Bratzler shear and sensory panel ratings for beef from US retail and foodservice establishments. Meat Sci. 2007, 77, 357–364. [Google Scholar] [CrossRef][Green Version]

- Cho, S. The Second National Research Establishment of Hanwoo and Pig’s Carcass Yield; Rural Development Administration (RDA): Jeonju-si, Republic of Korea, 2021; pp. 119–143. [Google Scholar]

- KAPE (Korea Institute of Animal Products Quality Evaluation). 2022 Animal Products Grading Statistical Yearbook. Available online: https://datalab.mtrace.go.kr/pdf/PUBLICATION/20230810/b441fe6f441249019efc87a3cb066b1a.pdf (accessed on 10 October 2023).

- Carlsson-Kanyama, A.; Faist, M. Energy Use in the Food Sector: A Data Survey; Swedish Environmental Protection Agency: Stockolm, Sweden, 2000; pp. 21–23. [Google Scholar]

- KEITI (Korea Environmental Industry and Technology Institute). Carbon Footprint Label. Available online: https://www.greenproduct.go.kr/epd/lci/lciDb (accessed on 25 June 2011).

| Properties of a Hanwoo Cattle/Carcass/Beef | Fattening Duration | References | ||

|---|---|---|---|---|

| 26 Months | 31 Months | 31–26 Months | ||

| A. Average intramuscular fat content (%) * | 14.83 | 18.61 | 4.23 | [10] |

| B. Average live weight (kg) ** | 655.9 | 776.8 | 121.0 | [10] |

| C. Amount of the trimmed meat (kg) *** | 259.65 | 321.98 | 62.33 | [10] |

| D. Trimmed meat yield (%) *** | 67.37 | 64.63 | −2.74 | [10] |

| E. WBsf of beef (kg of shear force) * | 4.44 | 3.46 | −0.98 | [10] |

| GHG emissions | CO2-eq | Functional unit | ||

| F. Hanwoo cattle | 16.55 | Kg of live weight | [24] | |

| Muscle | 2 Days Aging | 14 Days Aging | p Value | |||||

|---|---|---|---|---|---|---|---|---|

| Control | ES 1 | Control | ES | ES | Aging | Interaction | ||

| Longissimus thoracis | ||||||||

| pH | 5.53 | 5.53 | 5.50 | 5.50 | 0.888 | 0.003 | 0.844 | |

| Meat color | CIE L* | 39.63 | 41.68 | 40.8 | 41.3 | 0.129 | 0.636 | 0.353 |

| CIE a* | 16.69 | 17.39 | 20.54 | 20.93 | 0.415 | <0.001 | 0.819 | |

| CIE b* | 13.18 | 14.14 | 16.31 | 16.97 | 0.059 | <0.001 | 0.725 | |

| Moisture (%) | 56.47 | 54.71 | - | - | 0.360 | - | - | |

| Crude fat (%) | 23.79 | 21.81 | - | - | 0.465 | - | - | |

| TBARS (MA mg/kg) | 0.26 | 0.31 | 0.31 | 0.32 | 0.194 | 0.155 | 0.323 | |

| Biceps femoris | ||||||||

| pH | 5.53 | 5.56 | 5.50 | 5.52 | 0.117 | 0.003 | 0.618 | |

| Meat color | CIE L* | 37.79 | 38.82 | 38.03 | 38.57 | 0.147 | 0.989 | 0.656 |

| CIE a* | 19.33 | 20.84 | 23.38 | 25.69 | 0.012 | <0.001 | 0.588 | |

| CIE b* | 13.59 | 15.01 | 16.24 | 17.88 | <0.001 | <0001 | 0.785 | |

| Moisture (%) | 61.30 | 61.69 | - | - | 0.826 | - | - | |

| Crude fat (%) | 19.7 | 18.48 | - | - | 0.655 | - | - | |

| TBARS (MA mg/kg) | 0.36 | 0.38 | 0.36 | 0.41 | 0.303 | 0.673 | 0.683 | |

| Df 2 | 3/79 | |||||||

| Muscle | 2 Days Aging | 14 Days Aging | p Value | ||||

|---|---|---|---|---|---|---|---|

| Control | ES 1 | Control | ES | ES | Aging | Interaction | |

| Longissimus thoracis | |||||||

| Drip loss (%) | - | - | 20.92 | 16.79 | 0.346 | - | - |

| Cooking loss (%) | 13.79 | 15.48 | 14.26 | 15.57 | 0.021 | 0.660 | 0.765 |

| WBsf (kg) | 5.16 | 4.57 | 2.65 | 2.48 | 0.047 | <0.001 | 0.267 |

| Biceps femoris | |||||||

| Drip loss (%) | - | - | 7.40 | 7.34 | 0.950 | - | - |

| Cooking loss (%) | 18.21 | 19.05 | 23.75 | 23.76 | 0.528 | <0.001 | 0.532 |

| WBsf (kg) | 6.85 | 5.35 | 5.58 | 4.83 | <0.001 | <0.001 | 0.498 |

| Df 2 | 3/79 | ||||||

| Aging Days | Change in WBsf (kg) * | |||

|---|---|---|---|---|

| LT Muscle | BF Muscle | |||

| Control | ES | Control | ES | |

| 2 | 0 * | −0.59 | 0 * | −1.50 |

| 14 | −2.51 | −2.68 | −1.27 | −2.48 |

| Feeding Period | |||

|---|---|---|---|

| 26 Months | 31 Months | Additional 5 Months * | |

| Amount of CO2 emissions per 1 kg of the trimmed Hanwoo beef (CO2-eq) | 24.56 | 25.6 | 1.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, D.; Kim, Y.S.; Kim, H.-G.; Hwang, I. Beef Toughness and the Amount of Greenhouse Gas Emissions as a Function of Localized Electrical Stimulation. Foods 2024, 13, 37. https://doi.org/10.3390/foods13010037

Jeong D, Kim YS, Kim H-G, Hwang I. Beef Toughness and the Amount of Greenhouse Gas Emissions as a Function of Localized Electrical Stimulation. Foods. 2024; 13(1):37. https://doi.org/10.3390/foods13010037

Chicago/Turabian StyleJeong, Dawoon, Young Soon Kim, Hong-Gun Kim, and Inho Hwang. 2024. "Beef Toughness and the Amount of Greenhouse Gas Emissions as a Function of Localized Electrical Stimulation" Foods 13, no. 1: 37. https://doi.org/10.3390/foods13010037

APA StyleJeong, D., Kim, Y. S., Kim, H.-G., & Hwang, I. (2024). Beef Toughness and the Amount of Greenhouse Gas Emissions as a Function of Localized Electrical Stimulation. Foods, 13(1), 37. https://doi.org/10.3390/foods13010037