Novel, Edible Melanin-Protein-Based Bioactive Films for Cheeses: Antimicrobial, Mechanical and Chemical Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of WPI Coatings and Films

2.2. Screening of WPI Films’ Antimicrobial Activity

2.2.1. Antibacterial Test

2.2.2. Antifungal Test

2.3. Physical Property Analysis

2.3.1. Mechanical Properties

2.3.2. Color Analysis Properties

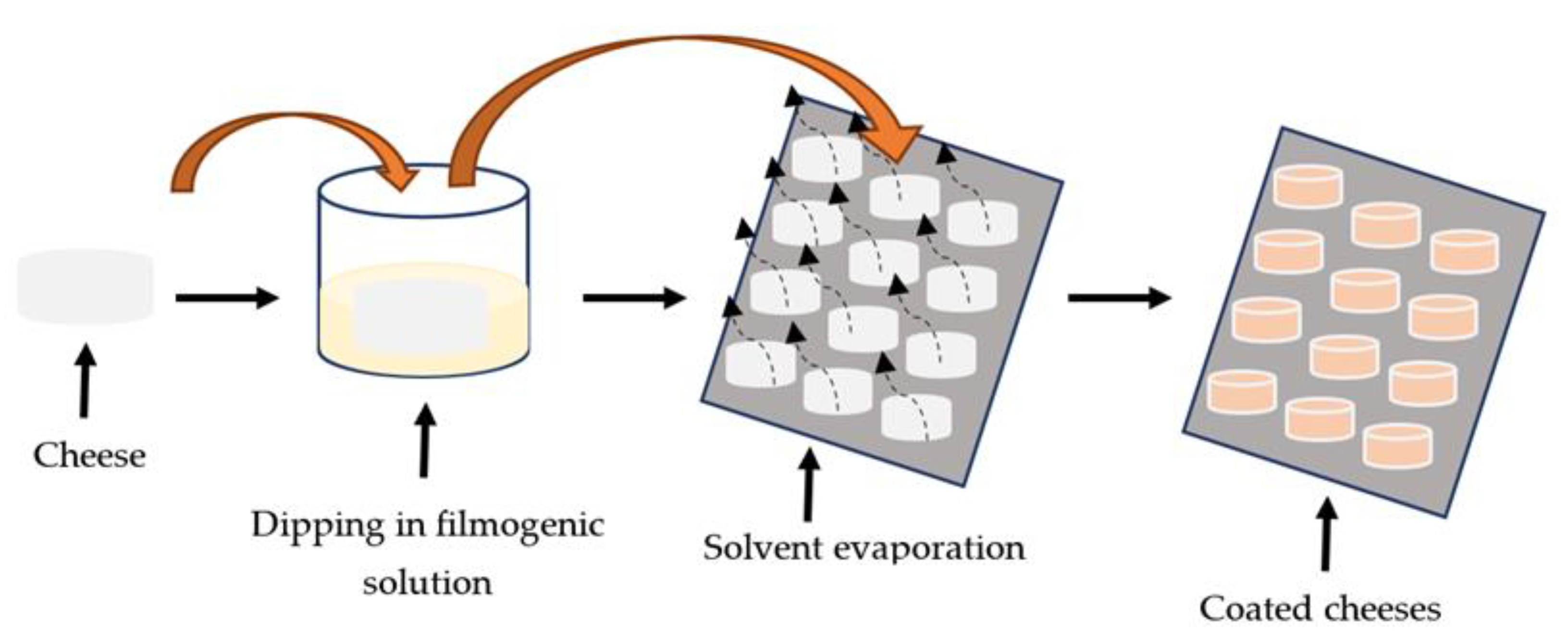

2.4. Application of Melanin WPI Coatings under Industrial Conditions

2.4.1. Melanin WPI Cheese Coatings

2.4.2. Melanin WPI Antimicrobial Activity

2.5. FTIR Analysis

2.6. Statistical Analysis

3. Results and Discussion

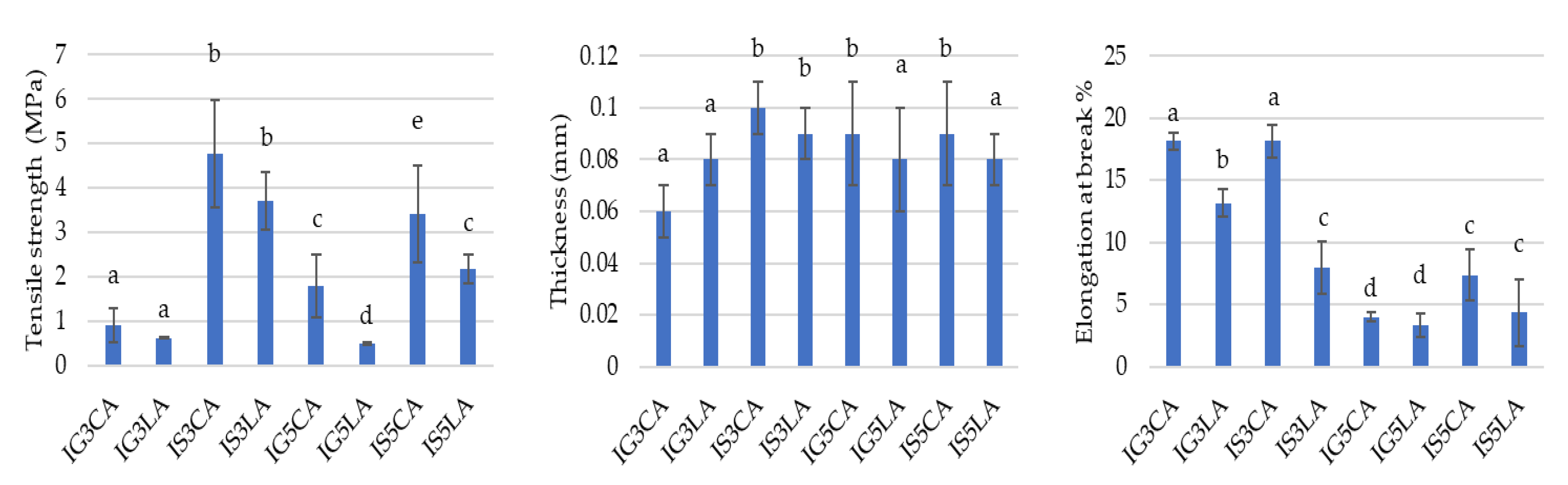

3.1. Screening of Mechanical Properties of WPI Films

3.1.1. Tensile Strength, Thickness and Extensibility of WPI Films

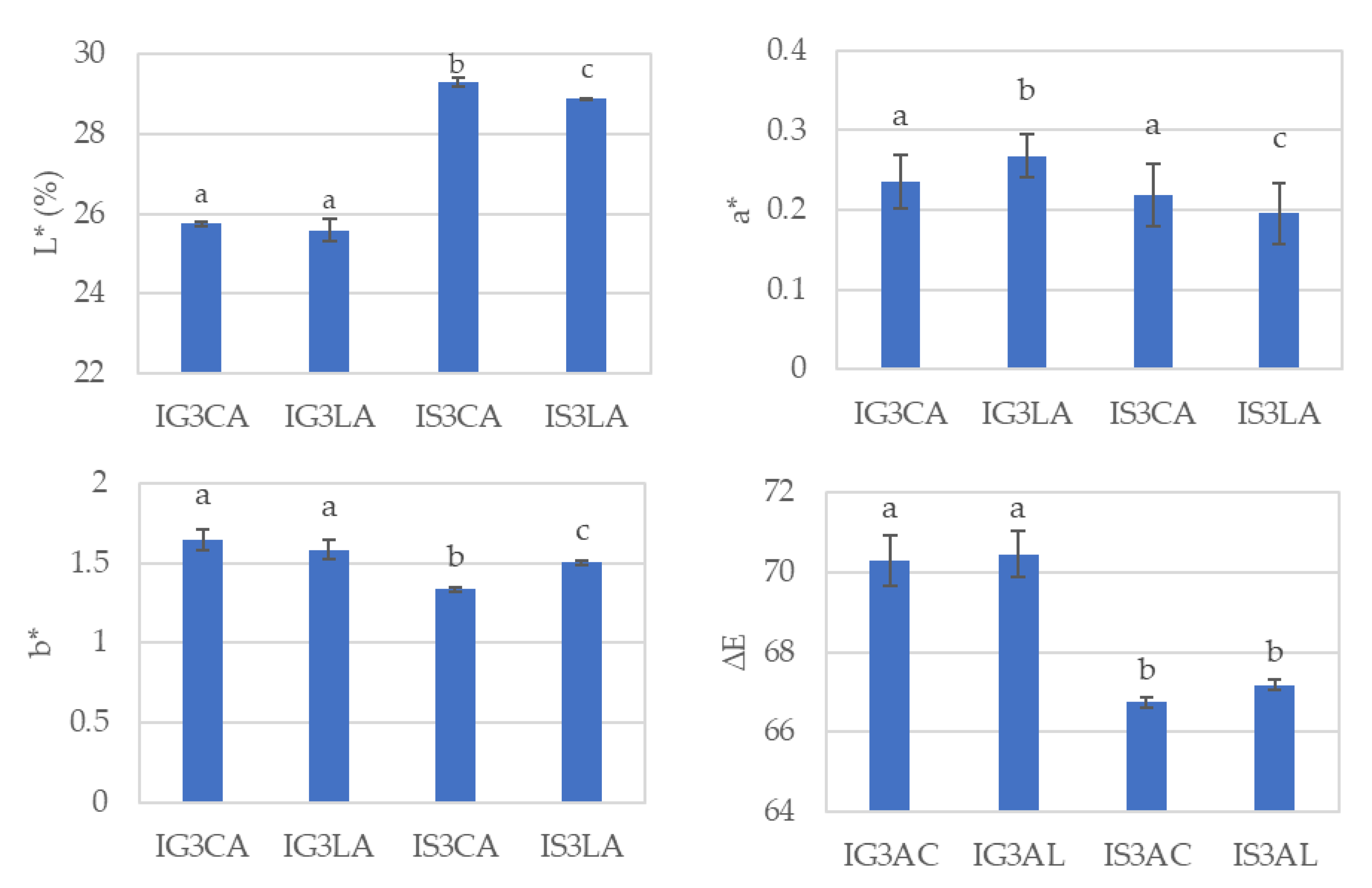

3.1.2. Color

3.2. Antimicrobial Activity of Melanin WPI Films

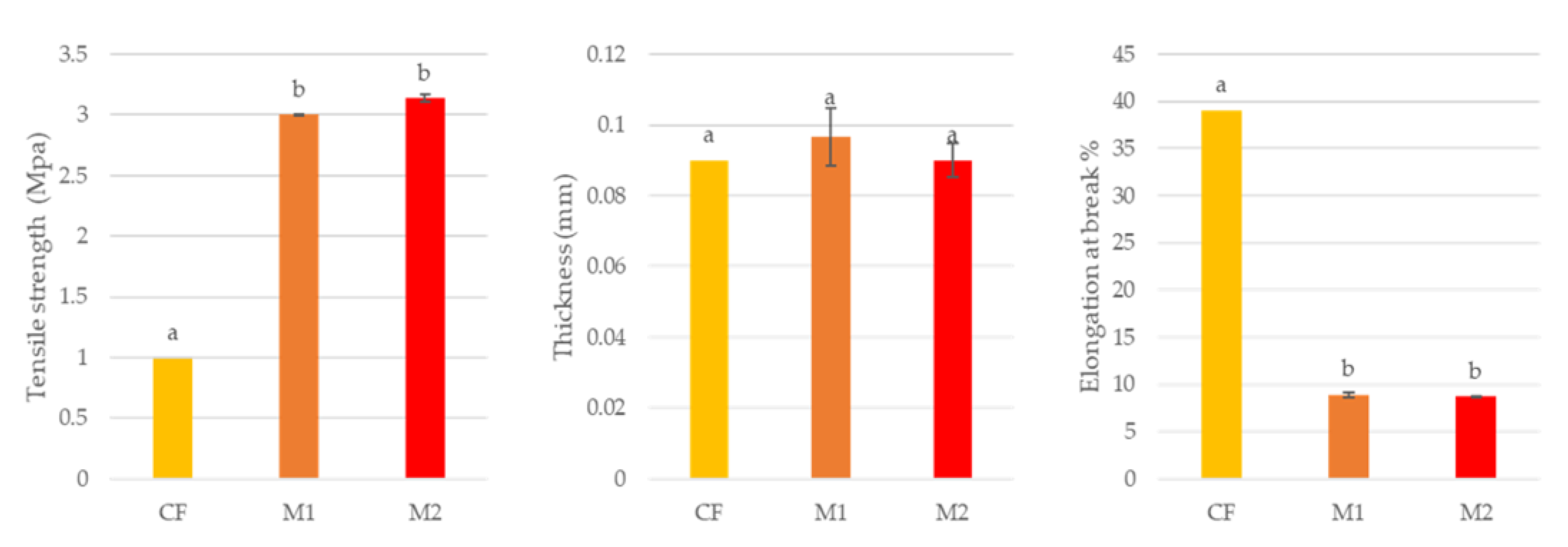

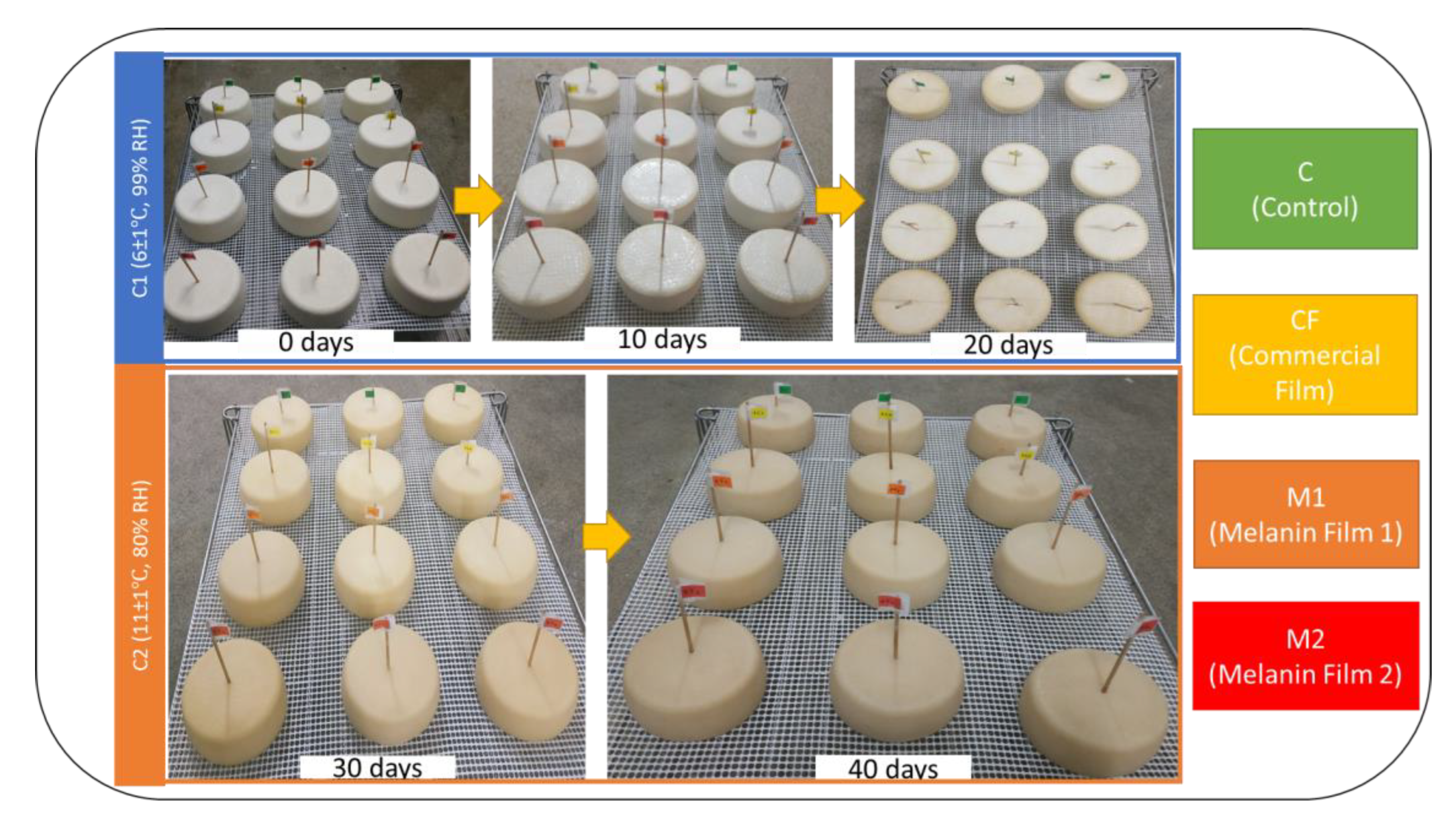

3.3. Novel Melanin Coatings in Cheese Maturation

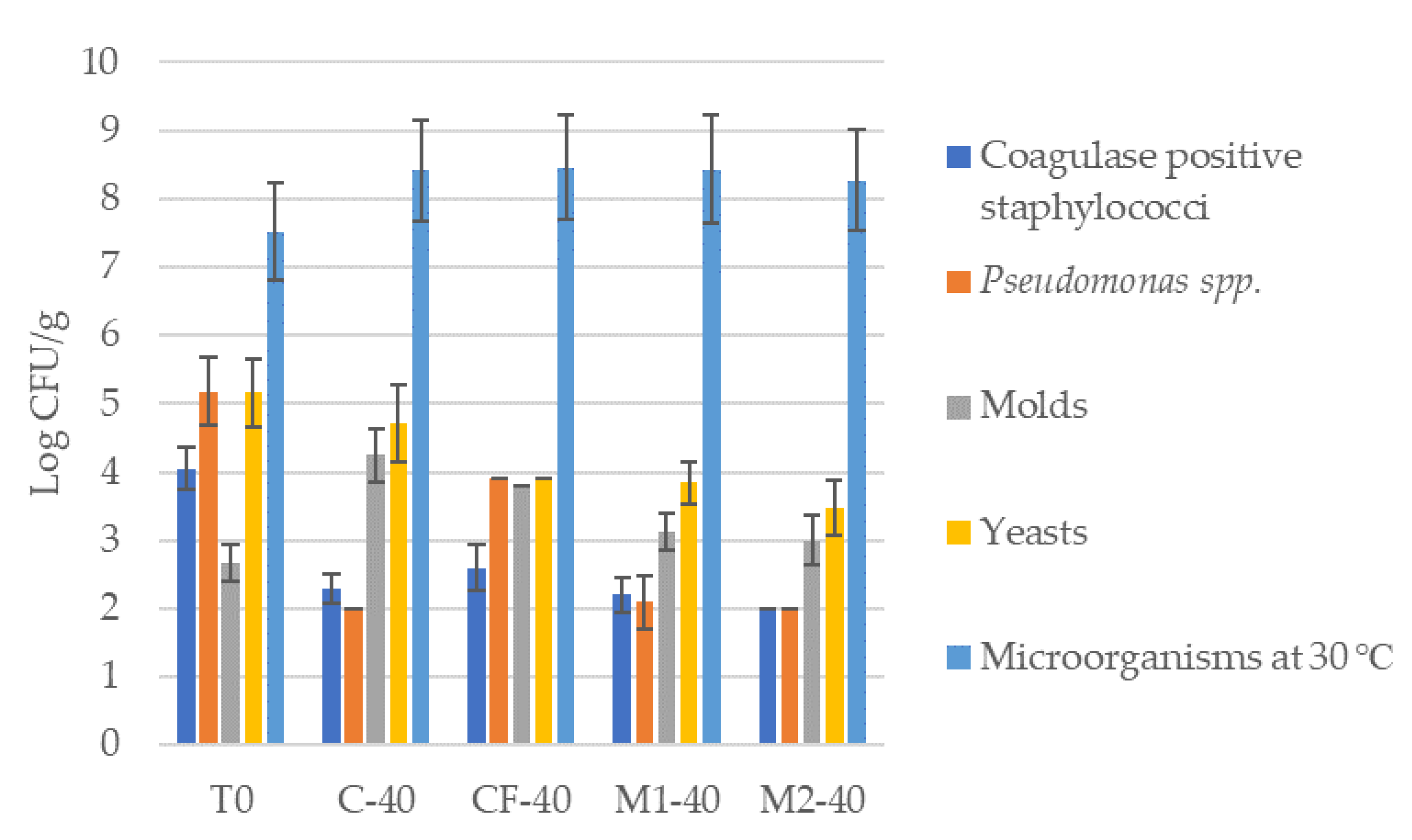

3.3.1. Film Antimicrobial Activity in Cheese

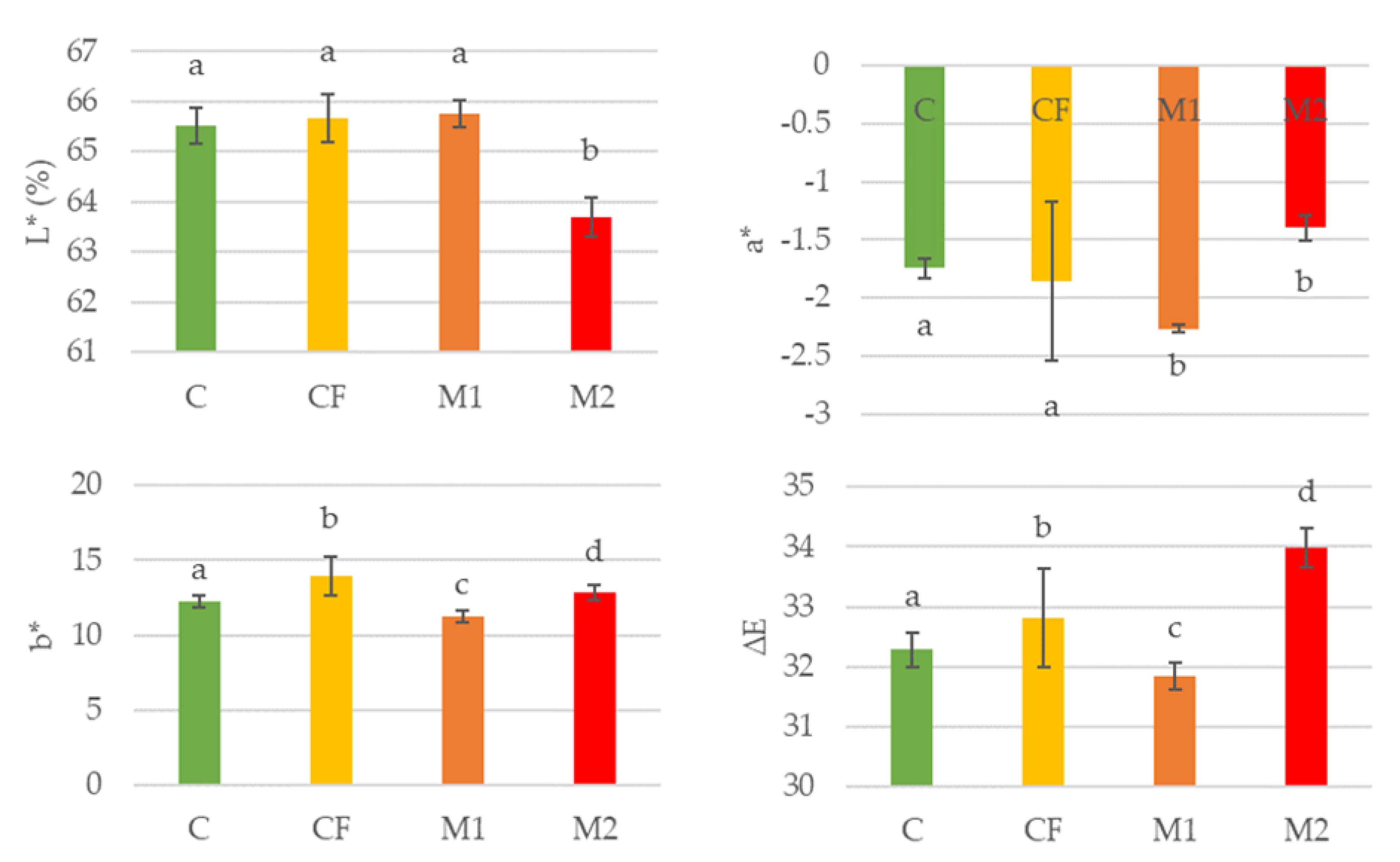

3.3.2. Color

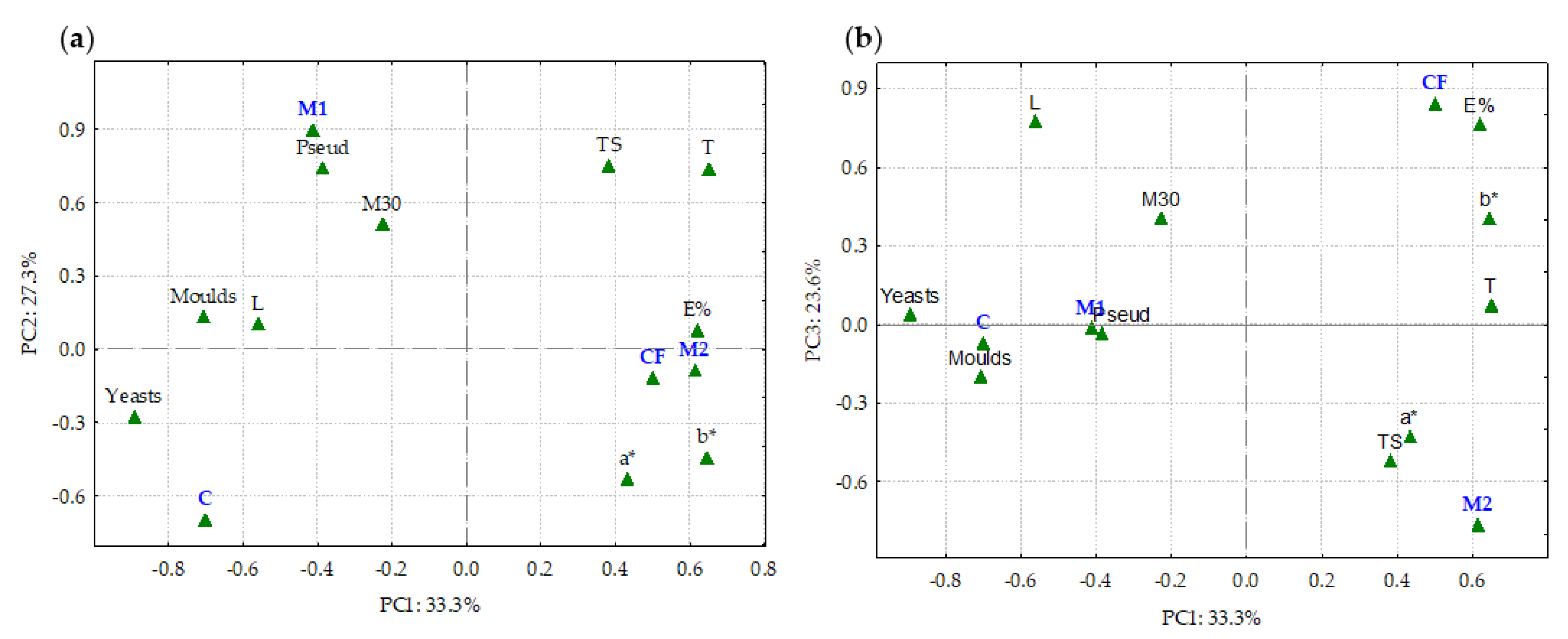

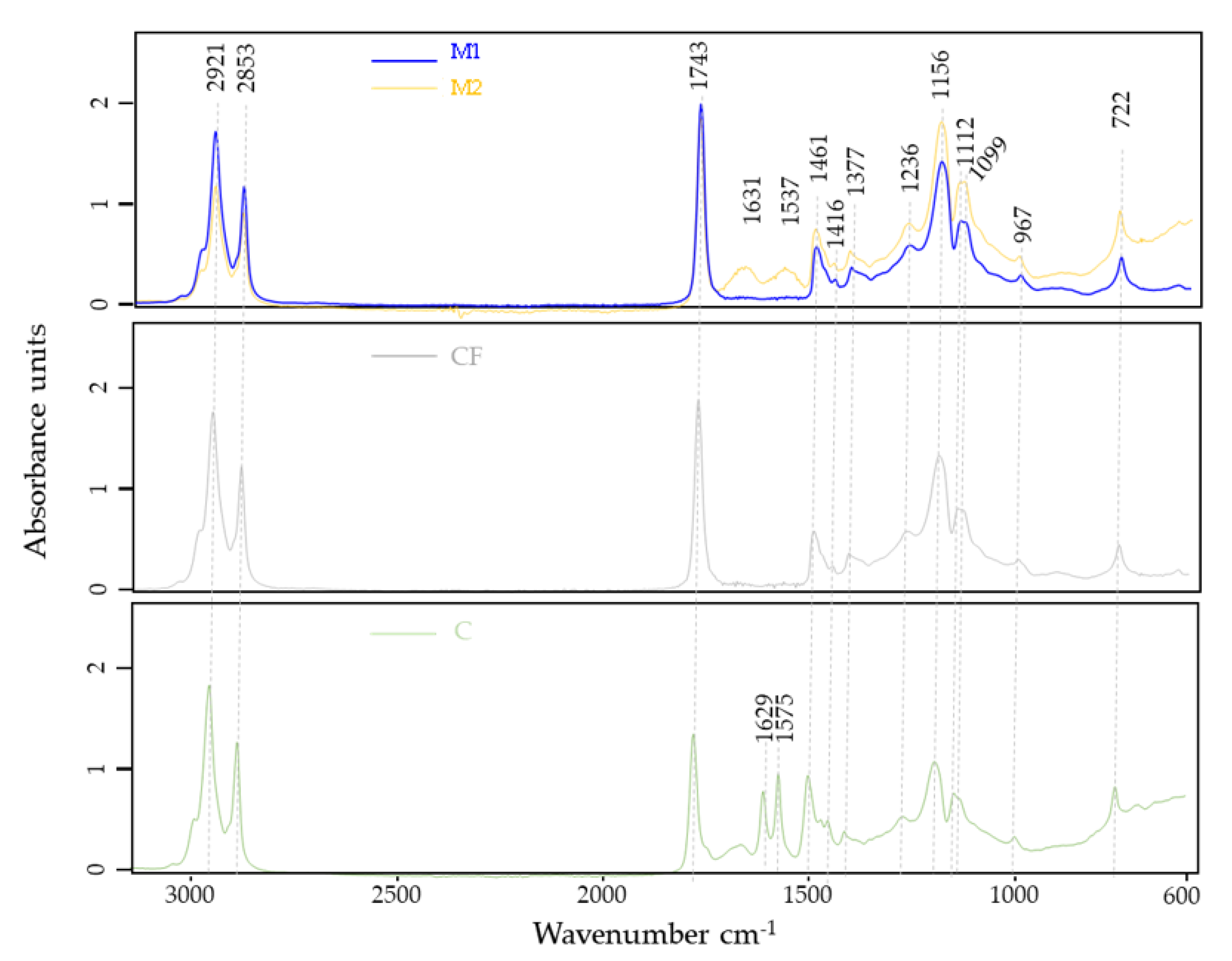

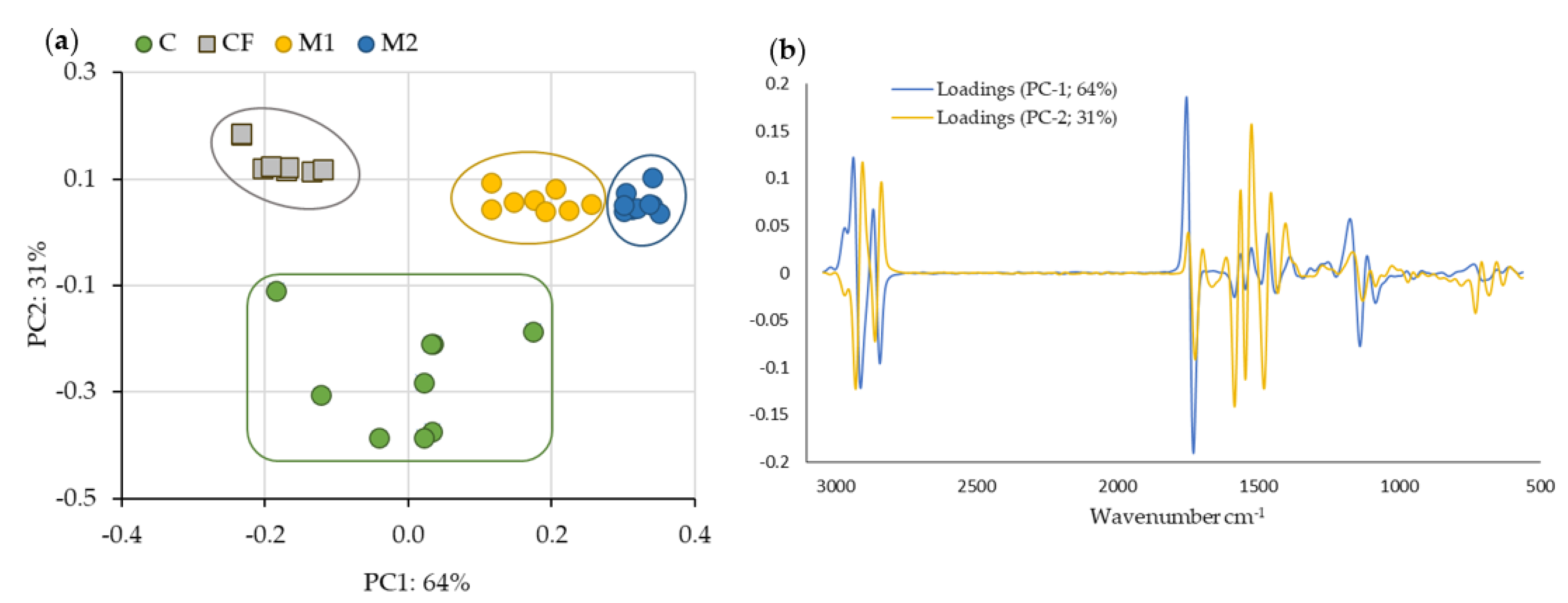

3.4. FTIR of Melanin WPI Cheese Coating

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nájera, A.I.; Nieto, S.; Barron, L.J.R.; Albisu, M. A review of the preservation of hard and semi-hard cheeses: Quality and safety. Int. J. Environ. Res. Public Health 2021, 18, 9789. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Salehabadi, A.; Mohammadi Nafchi, A.; Oladzadabbasabadi, N.; Jafari, S.M. Cheese packaging by edible coatings and biodegradable nanocomposites; improvement in shelf life, physicochemical and sensory properties. Trends Food Sci. Technol. 2021, 116, 218–231. [Google Scholar] [CrossRef]

- Asperger, H. Fermented milk products and influence of hygienic relevant microorganisms ± Part II: Quality defects and spoilage caused by micro-organisms. Nutrition 1986, 10, 227–232. [Google Scholar]

- Weichhold, U.; Seiler, H.; Busse, M.; Klostermeyer, H. Red discoloration of cheese and its causes. Dtsch. Milchwirtsch. 1986, 46, 1671–1765. [Google Scholar]

- Ferraz, A.R.; Pacheco, R.; Vaz, P.D.; Pintado, C.S.; Ascens, L.; Serralheiro, M.L. Melanin: Production from cheese bacteria, chemical characterization, and biological activities. Int. J. Environ. Res. Public Health 2021, 18, 10562. [Google Scholar] [CrossRef] [PubMed]

- Cantoni, C.; Soncini, G.; Milesi, S.; Cocolin, L.; Iacumin, L.; Comi, G. Additional data about some defects of cheeses: Discoloration and blowing. Ind. Aliment. 2006, 45, 276–281. [Google Scholar]

- Olmo, A.; Calzada, J.; Nu, M. The blue discoloration of fresh cheeses: A worldwide defect associated to specific contamination by Pseudomonas fluorescens. Food Control 2018, 86, 359–366. [Google Scholar] [CrossRef]

- Ferreira, A.R. Diversidade Genética de Isolados Bacterianos de Pseudomonas e Géneros Afins Relacionados com Defeitos de cor em Queijo. Final Master’s Degree Work in Innovation and Quality in Food Production. School of Agriculture of the Polytechnic Institute of Castelo Branco. 2017. Available online: http://hdl.handle.net/10400.11/5823 (accessed on 25 February 2023).

- Seydim, A.C.; Sarikus-Tutal, G.; Sogut, E. Effect of whey protein edible films containing plant essential oils on microbial inactivation of sliced kasar cheese. Food Packag. Shelf Life 2020, 26, 100567. [Google Scholar] [CrossRef]

- Ramos, Ó.L.; Santos, A.C.; Leão, M.V.; Pereira, J.O.; Silva, S.I.; Fernandes, J.C.; Franco, M.I.; Pintado, M.E.; Malcata, F.X. Antimicrobial activity of edible coatings prepared from whey protein isolate and formulated with various antimicrobial agents. Int. Dairy J. 2012, 25, 132–141. [Google Scholar] [CrossRef]

- Pintado, C.M.B.S.; Ferreira, M.A.S.S.; Sousa, I. Properties of whey protein-based films containing organic acids and nisin to control Listeria monocytogenes. J. Food Prot. 2009, 72, 1891–1896. [Google Scholar] [CrossRef]

- Balaguer, M.P.; Fajardo, P.; Gartner, H.; Gomez-Estaca, J.; Gavara, R.; Almenar, E.; Hernandez-Munoz, P. Functional properties and antifungal activity of films based on gliadins containing cinnamaldehyde and natamycin. Int. J. Food Microbiol. 2014, 173, 62–71. [Google Scholar] [CrossRef]

- Karaman, A.D.; Özer, B.; Pascall, M.A.; Alvarez, V. Recent advances in dairy packaging. Food Rev. Int. 2015, 31, 295–318. [Google Scholar] [CrossRef]

- Henriques, M.; Gomes, D.; Pereira, C. Whey protein edible coatings: Recent developments and applications. In Emerging and Traditional Technologies for Safe, Healthy and Quality Food; Food Engineering Series; Springer: Berlin/Heidelberg, Germany, 2016; pp. 177–196. [Google Scholar] [CrossRef]

- Costa, C.; Azoia, N.G.; Coelho, L.; Freixo, R.; Batista, P.; Pintado, M. Proteins derived from the dairy losses and by-products as raw materials for non-food applications. Foods 2021, 10, 135. [Google Scholar] [CrossRef]

- Costa, M.J.; Maciel, L.C.; Teixeira, J.A.; Vicente, A.A.; Cerqueira, M.A. Use of edible films and coatings in cheese preservation: Opportunities and challenges. Food Res. Int. 2018, 107, 84–92. [Google Scholar] [CrossRef]

- Davis, J.R. Introduction of Tensile Testing. In Tensile Testing; ASM International: Materials Park, OH, USA, 2004; pp. 1–13. [Google Scholar]

- Soliman, I.A.; Hasanien, Y.A.; Zaki, A.G.; Shawky, H.A.; Nassrallah, A.A. Irradiation impact on biological activities of anthraquinone pigment produced from talaromyces purpureogenus and its evaluation, characterization and application in beef burger as natural preservative. BMC Microbiol. 2022, 22, 325. [Google Scholar] [CrossRef] [PubMed]

- Hill, H.Z. The function of melanin or six blind people examine an elephant. Bioessays 1992, 14, 49–56. [Google Scholar] [CrossRef] [PubMed]

- European Committee on Antimicrobial Susceptibility Testing. EUCAST Disk Diffusion Method Version 8.0; European Society of Clinical Microbiology and Infectious Diseases: Basel, Switzerland, 2020; pp. 1–21. [Google Scholar]

- ASTM 882-02; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2002.

- Higueras, L.; López-Carballo, G.; Cerisuelo, J.P.; Gavara, R.; Hernández-Muñoz, P. Preparation and characterization of chitosan/hp-β-cyclodextrins composites with high sorption capacity for carvacrol. Carbohydr. Polym. 2013, 97, 262–268. [Google Scholar] [CrossRef]

- Hernández, B.; Sáenz, C.; Alberdi, C.; Diñeiro, J.M. CIELAB color coordinates versus relative proportions of myoglobin redox forms in the description of fresh meat appearance. J. Food Sci. Technol. 2016, 53, 4159–4167. [Google Scholar] [CrossRef]

- Arana, I. Physical Properties of Foods: Novel Measurement Techniques and Applications; Medical Diagnostic Theory Applied to Food Technology; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9781439835371. [Google Scholar]

- ISO Standard No. 4833-1; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization: Geneva, Switzerland, 2013.

- Norma Portuguesa NP 4400-1; Microbiologia Alimentar: Regras Gerais Para Contagem de Estafilococos Coagulase Positiva (Staphylococcus aureus e Outras Espécies), Parte 1: Técnica com Confirmação de Colónias (Método Corrente). Instituto Português da Qualidade: Almada, Portugal, 2002.

- ISO 11290-1:1996; Microbiology of Food and Animal Feeding Stuffs. Horizontal Method for the Detection and Enumeration of Listeria monocytogenes. Part 1: Detection Method. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO/TS 11059; Milk and Milk Products—Method for the Enumeration of Pseudomonas spp. International Organization for Standardization: Geneva, Switzerland, 2009.

- Norma Portuguesa NP 3277-1; Microbiologia Alimentar. Instituto Português da Qualidade: Almada, Portugal, 1987.

- Tafa, K.D.; Satheesh, N.; Abera, W. Mechanical properties of tef starch based edible films: Development and process optimization. Heliyon 2023, 9, 13160. [Google Scholar] [CrossRef]

- Khoiriyah, H.; Kurniawati, N.; Liviawaty, E. Junianto concentration addition of plasticizer sorbitol to the characteristics of carrageenan edible film. Glob. Sci. J. 2018, 6, 1–33. [Google Scholar]

- Rahmawati, M.; Arief, M.; Satyantini, W.H. The effect of sorbitol addition on the characteristic of carrageenan edible film. IOP Conf. Ser. Earth Environ. Sci. 2019, 236, 012129. [Google Scholar] [CrossRef]

- Fairley, P.; Monahan, F.J.; German, J.B.; Krochta, J.M. Mechanical properties and water vapor permeability of edible films from whey protein isolate and n-ethylmaleimide or cysteine. J. Agric. Food Chem. 1996, 44, 3789–3792. [Google Scholar] [CrossRef]

- Putra, A.D.; Johan, V.S.; Efendi, R. Penambahan sorbitol sebagai plasticizer dalam pembuatan edible film pati sukun. J. Online Mhs. Fak. Pertan. 2017, 4, 1–15. [Google Scholar]

- Arief, M.D.; Mubarak, A.S.; Pujiastuti, D.Y. The concentration of sorbitol on bioplastic. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 679, p. 012013. [Google Scholar] [CrossRef]

- Herliany, N.; Santoso, J.; Salamah, E. Karakteristik biofilm berbahan dasar karaginan. J. Akuatika Indones. 2013, 4, 10–20. [Google Scholar]

- Yulianti, R.; Ginting, E. Perbedaan Karakteristik fisik edible film dari umbi-umbian yang dibuat dengan penambahan Plasticizer. Balai Penelit. Tanam. Kacang-Kacangan Umbi-Umbian 2012, 31, 131–136. [Google Scholar]

- Cagri, A.; Ustunol, Z.; Ryser, E.T. Antimicrobial, mechanical, and moisture barrier properties of low ph whey protein-based edible films containing p-aminobenzoic or sorbic acids. J. Food Sci. 2001, 66, 865–870. [Google Scholar] [CrossRef]

- Garavaglia, J.; Pinto, L.M.N.; de Souza, D.; de Castilhos, J.; Rossi, R.C.; Machado, I.C.K.; de Souza Ramos, R.C.; Ziegler, D.D.R. Natamycin and nisin to improve shelf life and minimize benzene generation in lemon soft drinks. Food Sci. Technol. 2019, 39, 274–279. [Google Scholar] [CrossRef]

- Hu, G.; Chen, J.; Gao, J. Preparation and characteristics of oxidized potato starch films. Carbohydr. Polym. 2009, 76, 291–298. [Google Scholar] [CrossRef]

- González-Torres, B.; Robles-García, M.Á.; Gutiérrez-Lomelí, M.; Padilla-Frausto, J.J.; Navarro-Villarruel, C.L.; Del-Toro-sánchez, C.L.; Rodríguez-Félix, F.; Barrera-Rodríguez, A.; Reyna-Villela, M.Z.; Avila-Novoa, M.G. Combination of sorbitol and glycerol, as plasticizers, and oxidized starch improves the physicochemical characteristics of films for food preservation. Polymers 2021, 13, 3356. [Google Scholar] [CrossRef]

- Resch, J.J.; Daubert, C.R.; Foegeding, E.A. The effects of acidulant type on the rheological properties of beta-lactoglobulin gels and powders derived from these gels. Food Hydrocoll. 2005, 19, 851–860. [Google Scholar] [CrossRef]

- Dufossé, L.; Galaup, P.; Carlet, E.; Flamin, C.; Valla, A. Spectrocolorimetry in the CIE L*a*b* color space as useful tool for monitoring the ripening process and the quality of PDO red-smear soft cheeses. Food Res. Int. 2005, 38, 919–924. [Google Scholar] [CrossRef]

- Pinho, O.; Mendes, E.; Alves, M.M.; Ferreira, I.M.P.L.V.O. Chemical, physical, and sensorial characteristics of ‘terrincho’ ewe cheese: Changes during ripening and intravarietal comparison. J. Dairy Sci. 2004, 87, 249–257. [Google Scholar] [CrossRef] [PubMed]

- McDermott, A.; Visentin, G.; McParland, S.; Berry, D.; Fenelon, M.; De Marchi, M. Effectiveness of mid-infrared spectroscopy to predict the color of bovine milk and the relationship between milk color and traditional milk quality traits. J. Dairy Sci. 2016, 99, 3267–3273. [Google Scholar] [CrossRef] [PubMed]

- Licón, C.C.; Carmona, M.; Rubio, R.; Molina, A.; Berruga, M.I. Preliminary study of saffron (Crocus sativus L. stigmas) color extraction in a dairy matrix. Dye. Pigment. 2012, 92, 1355–1360. [Google Scholar] [CrossRef]

- Udovicki, B.; Andjelkovic, M.; Cirkovic-Velickovic, T.; Rajkovic, A. Microplastics in food: Scoping review on health effects, occurrence, and human exposure. Int. J. Food Contam. 2022, 9, 1–16. [Google Scholar] [CrossRef]

- Yao, Z.; Seong, H.J.; Jang, Y.S. Environmental toxicity and decomposition of polyethylene. Ecotoxicol. Environ. Saf. 2022, 242, 113933. [Google Scholar] [CrossRef]

- Rodriguez-Saona, L.E.; Koca, N.; Harper, W.J.; Alvarez, V.B. Rapid determination of swiss cheese composition by fourier transform infrared/attenuated total reflectance spectroscopy. J. Dairy Sci. 2006, 89, 1407–1412. [Google Scholar] [CrossRef]

- Andrade, J.; Pereira, C.G.; Ranquine, T.; Azarias, C.A.; Bell, M.J.V.; De Carvalho Dos Anjos, V. Long-term ripening evaluation of ewes’ cheeses by fourier-transformed infrared spectroscopy under real industrial conditions. J. Spectrosc. 2018, 2018, 1381864. [Google Scholar] [CrossRef]

- de Jesus, J.; Silva, G.; Gonçalves, B.-H.; de Souza, M.; Santos, L.; Ferrão, S. Quick identification of the time of maturation of artisanal minas cheese by FTIR-ATR spectroscopy and multivariate techniques. J. Braz. Chem. Soc. 2020, 31, 2000–2011. [Google Scholar] [CrossRef]

- Cevoli, C.; Gori, A.; Nocetti, M.; Cuibus, L.; Caboni, M.F.; Fabbri, A. FT-NIR and FT-MIR spectroscopy to discriminate competitors, non compliance and compliance grated Parmigiano Reggiano cheese. Food Res. Int. 2013, 52, 214–220. [Google Scholar] [CrossRef]

| Edible Films | WPI (w/v) | Plasticizers | Organic Acids | ||

|---|---|---|---|---|---|

| Glycerol (w/v) | Sorbitol (w/v) | Lactic Acid (w/v) | Citric Acid (w/v) | ||

| IG3LA | 5% | 3% | 0% | 3% | 3% |

| IG3CA | 5% | 3% | 0% | 3% | 3% |

| IG5LA | 5% | 5% | 0% | 3% | 3% |

| IG5CA | 5% | 5% | 0% | 3% | 3% |

| IS3LA | 5% | 0% | 3% | 3% | 3% |

| IS3CA | 5% | 0% | 3% | 3% | 3% |

| IS5LA | 5% | 0% | 5% | 3% | 3% |

| IS5CA | 5% | 0% | 5% | 3% | 3% |

| CF (Commercial Film) | M1 (Melanin Film 1) | M2 (Melanin Film 2) | |

|---|---|---|---|

| WPI | 5% | 5% | |

| Sorbitol | 3% | 3% | |

| Citric Acid | 3% | 3% | |

| Nisin | 50 IU/mL | 50 IU/mL | |

| Natamycin | 3.5 mg/mL | 3.5 mg/mL | |

| Melanin | 74 µg/mL | 500 µg/mL | |

| VIPLAST-1AX (Concentrol® Chemical Solutions, Girona, Spain) | 20% | ||

| RIOCOBERT (BecorBarbanza S.L.U., Coruña, Spain) | 30% |

| Strains | Origin | Inhibition Zone (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| IG3LA A | IG3CA A | IS3LA B | IS3CA C | IS3CAN D | IS3CAM E | M1 F | M2 G | RIOCOBERT D | VIPLAST-1AX D | ||

| Listeria monocytogenes NCTC 11944 | - | 13.0 a | 12.8 a | 15.1 b | 15.7 b | 13.0 a | 15.4 c | 16.8 d | 17.2 d | NI | 9.2 e |

| Staphylococcus aureus ATCC 25923 | - | 8.0 a | 7.9 a | 9.9 b | 10.3 b | 8.1 a | 10.5 b | 7.5 a | 8.5 a | NI | NI |

| Serratia marcescens ESACB 596 | Raw sheep’s milk | 9.9 a | 9.4 a | 11.1 b | 10.1 b | 8.1 a | 11.3 b | 10.1 b | 10.6 b | NI | NI |

| Serratia marcescens ESACB 734 | Raw sheep’s milk | 8.8 a | 8.4 a | 11.8 b | 12.8 a | 7.9 a | 12.9 a | 9.8 c | 9.1 c | NI | NI |

| Pseudomonas putida ESACB 27 | Goat’s cheese | 12.9 a | 12.7 a | 12.9 a | 13.6 b | 12.5 a | 15.8 c | 13.9 c | 14.5 c | NI | NI |

| Pseudomonas fluorescens ESACB 137 | Environment dairy factory | 12.8 a | 12.8 a | 14.3 b | 14.6 b | 14.8 b | 14.9 b | 15.6 c | 17.4 d | NI | NI |

| Pseudomonas putida ESACB 191 | The rind of goat´s cheese | 13.6 a | 13.3 a | 10.7 b | 13.9 a | 13.8 a | 13.9 a | 13.4 a | 14.4 c | 6.3 d | NI |

| Pseudomonas fluorescens ATCC 13525 | - | 11.8 a | 11.8 a | 12.8 b | 13.5 b | 12.4 b | 13.9 b | 14.1 b | 14.5 b | NI | NI |

| Pseudomonas aeruginosa ATCC 27853 | - | 12.9 a | 12.6 a | 12.9 a | 13.5 b | 13.2 b | 14.5 c | 14.8 c | 15.7 d | NI | NI |

| Penicillium chrysogenum | Cheese | NI | NI | NI | NI | 28.2 a | NI | 31.1 b | 32.9 b | 27.9 a | 31.1 b |

| Penicillium commune | Cheese | NI | NI | NI | NI | 27.9 a | NI | 25.1 a | 32.4 b | 27.9 a | 24.4 a |

| Penicillium roqueforti | Cheese | NI | NI | NI | NI | 30.1 a | NI | 25.1 b | 28.3 a | 24.7 b | 23.3 b |

| Grennish mould | Cheese | NI | NI | NI | NI | 27.2 a | NI | 23.7 b | 24.5 b | 18.9 c | 16.5 c |

| White mold | Cheese | NI | NI | NI | NI | 22.9 a | NI | 17.7 b | 19.6 a | 17.4 b | 13.0 b |

| Candida albicans ATCC 10231 | - | NI | NI | NI | NI | NI | NI | 20.2 a | 20.3 a | 15.3 c | 13.0 c |

| Yarrowia lipolytica | Cheese | NI | NI | NI | 8.70 a | 5.5 a | 6.7 a | 23.1 b | 23.9 b | 18.5 c | 14.4 c |

| Candida zeylanoides | Cheese | NI | NI | NI | NI | NI | NI | 7.4 a | 7.4 a | NI | 17.9 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferraz, A.R.; Goulão, M.; Santo, C.E.; Anjos, O.; Serralheiro, M.L.; Pintado, C.M.B.S. Novel, Edible Melanin-Protein-Based Bioactive Films for Cheeses: Antimicrobial, Mechanical and Chemical Characteristics. Foods 2023, 12, 1806. https://doi.org/10.3390/foods12091806

Ferraz AR, Goulão M, Santo CE, Anjos O, Serralheiro ML, Pintado CMBS. Novel, Edible Melanin-Protein-Based Bioactive Films for Cheeses: Antimicrobial, Mechanical and Chemical Characteristics. Foods. 2023; 12(9):1806. https://doi.org/10.3390/foods12091806

Chicago/Turabian StyleFerraz, Ana Rita, Manuela Goulão, Christophe E. Santo, Ofélia Anjos, Maria Luísa Serralheiro, and Cristina M. B. S. Pintado. 2023. "Novel, Edible Melanin-Protein-Based Bioactive Films for Cheeses: Antimicrobial, Mechanical and Chemical Characteristics" Foods 12, no. 9: 1806. https://doi.org/10.3390/foods12091806

APA StyleFerraz, A. R., Goulão, M., Santo, C. E., Anjos, O., Serralheiro, M. L., & Pintado, C. M. B. S. (2023). Novel, Edible Melanin-Protein-Based Bioactive Films for Cheeses: Antimicrobial, Mechanical and Chemical Characteristics. Foods, 12(9), 1806. https://doi.org/10.3390/foods12091806