Discrimination of Inner Injury of Korla Fragrant Pear Based on Multi-Electrical Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Korla Fragrant Pear

2.2. Inner-Injury Samples

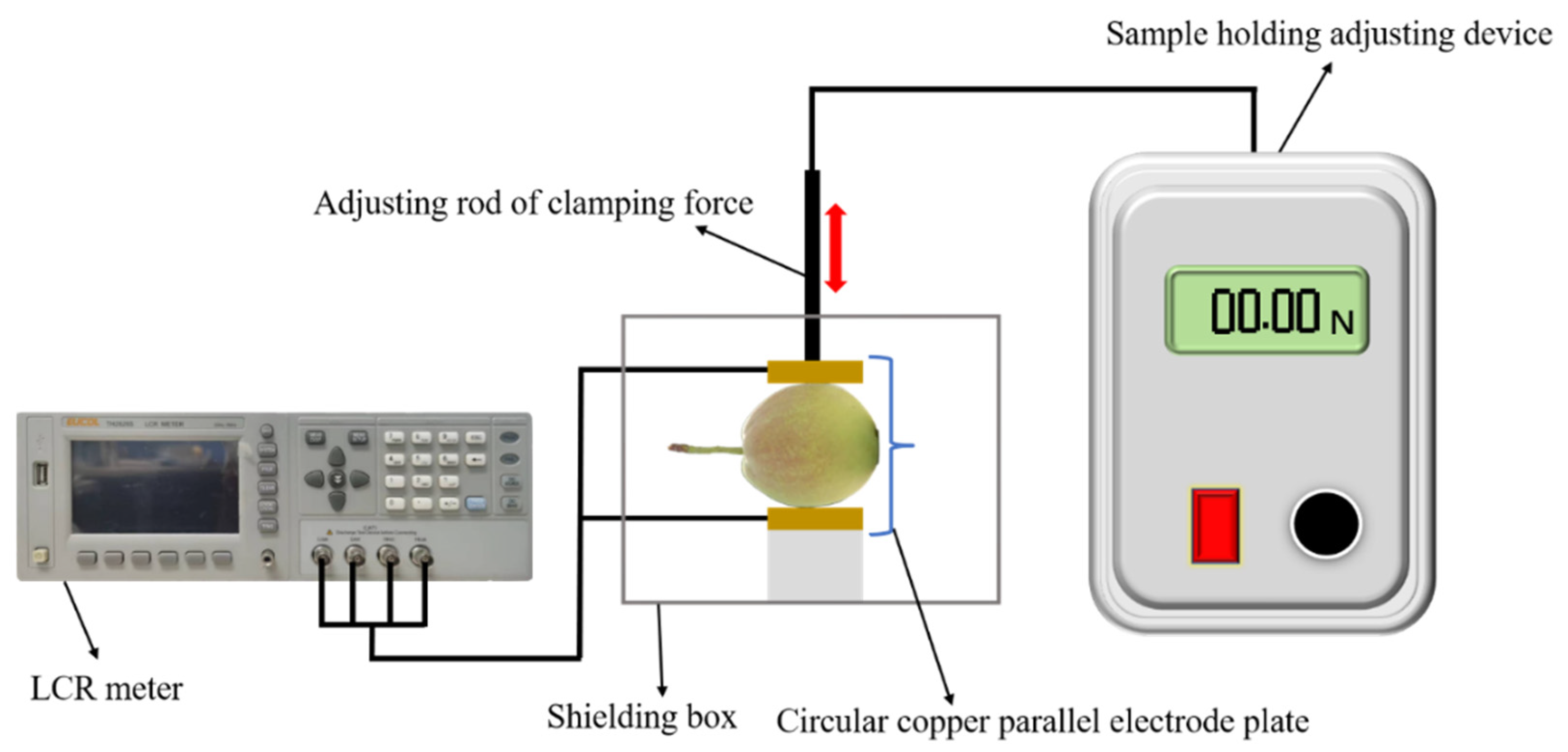

2.3. Experimental Equipment and Data Acquisition

2.4. Circuit Model

2.5. Data Processing and Analysis

2.6. Classification Modeling Method

2.7. Model Evaluation

3. Results

3.1. Electrical Parameters

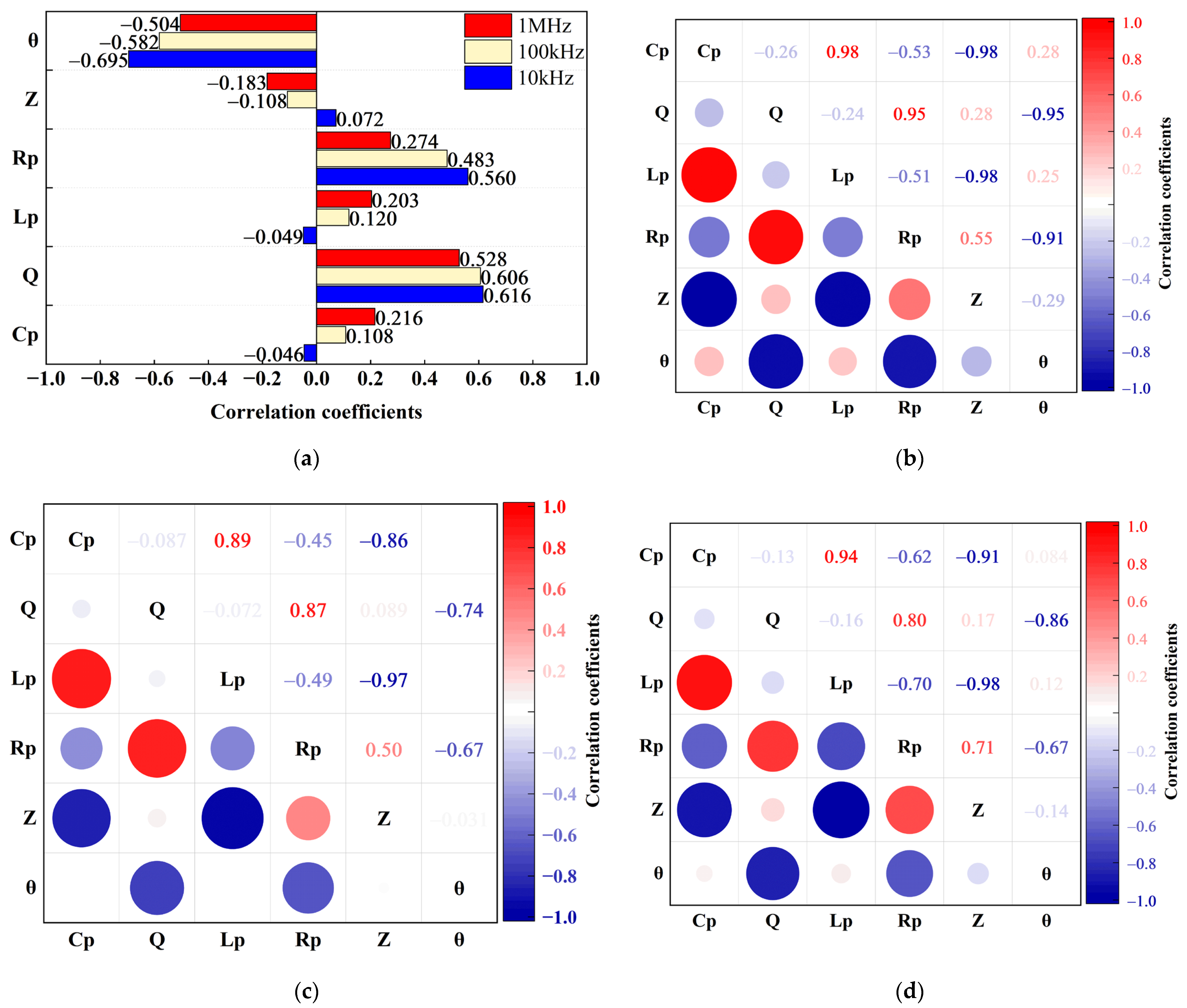

3.2. Correlation Analysis

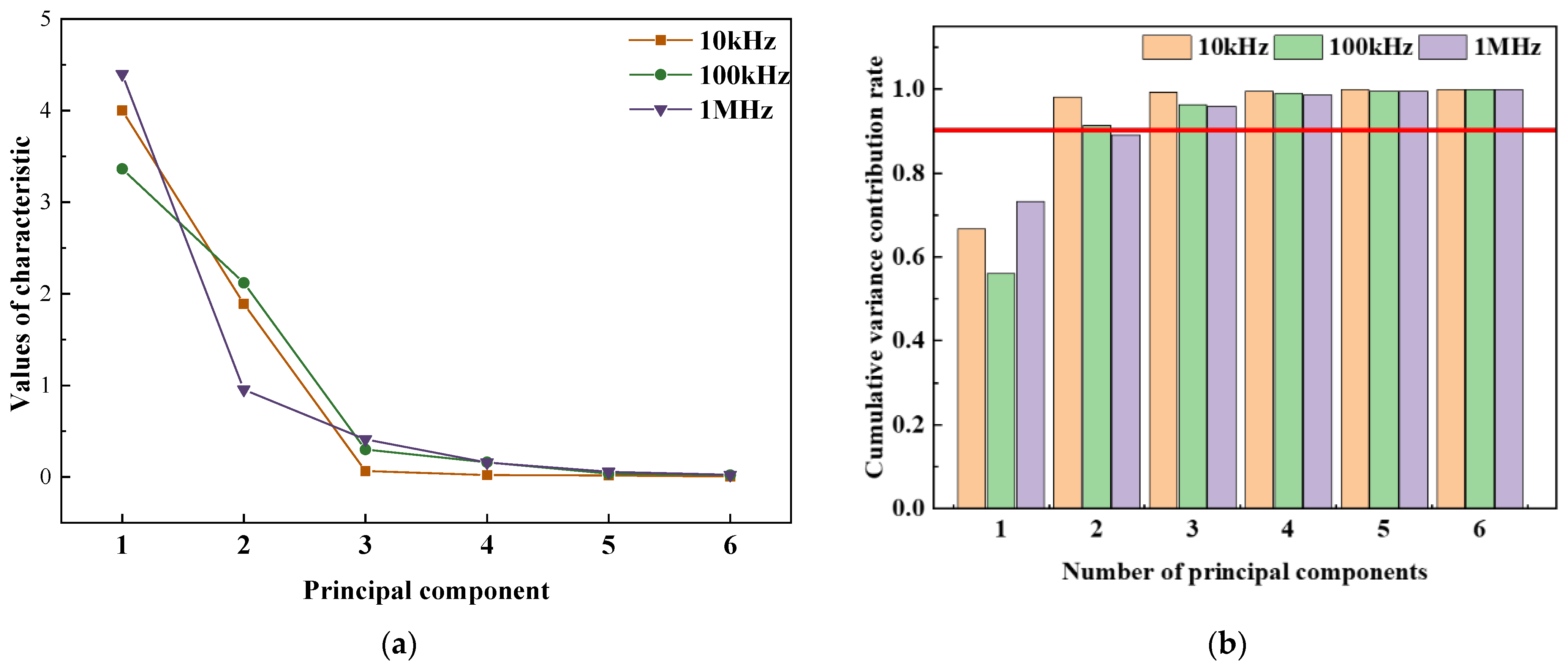

3.3. Principal Component Analysis

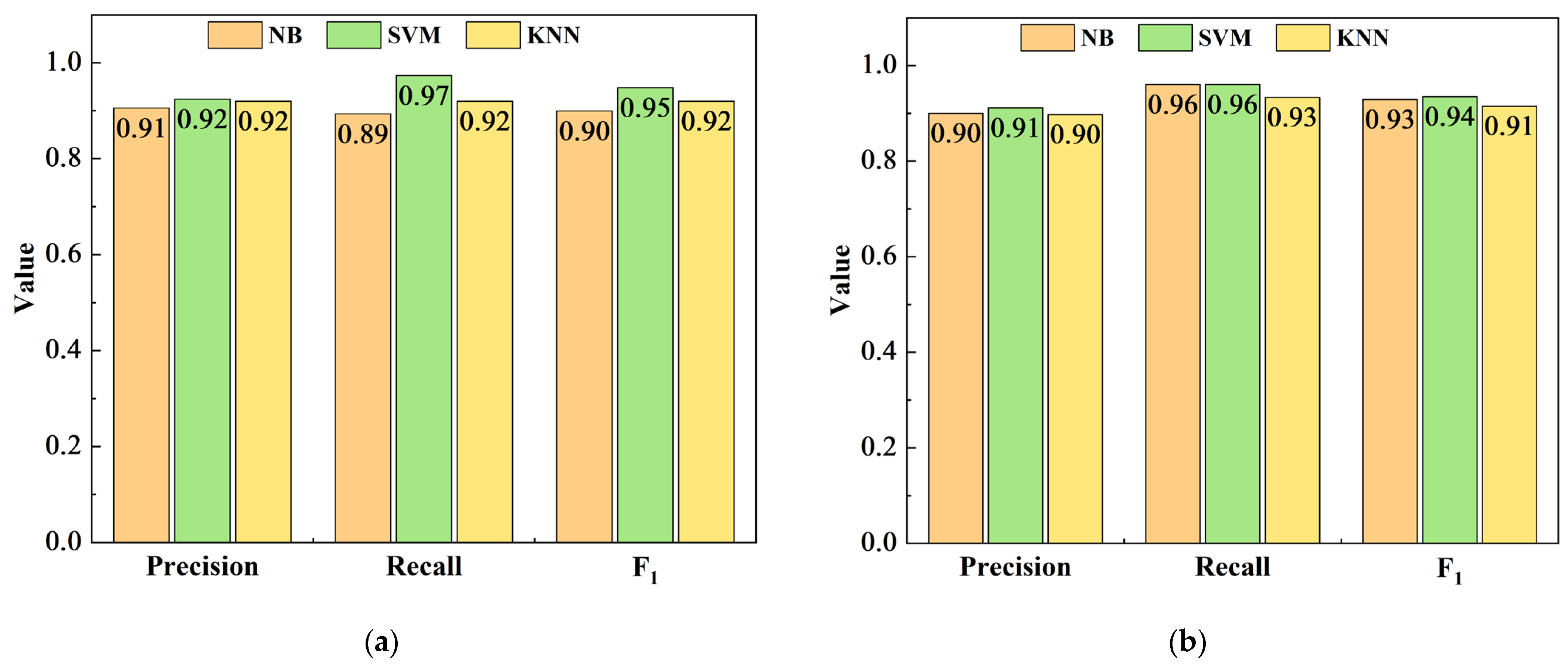

3.4. Modeling and Model Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, X.; Wang, W.; Li, S.; Du, Y.; Yu, Q.; Zhang, F.; He, Z. Investigation on storage and freshness of Xinjiang Korla fragrant pear. China Fruits 2014, 5, 75–78. [Google Scholar] [CrossRef]

- Liu, Y. Study on Mechanical Damage Mechanism and Effect Evaluation on Storage of Korla Fragrant Pear. Ph.D. Thesis, Northeast Agricultural University, Harbin City, China, 2021. [Google Scholar]

- Zhang, P.; Shen, B.; Ji, H.; Wang, H.; Liu, Y.; Zhang, X.; Ren, C. Nondestructive prediction of mechanical parameters to apple using hyperspectral imaging by support vector machine. Food Anal. Methods 2022, 15, 1397–1406. [Google Scholar] [CrossRef]

- Yuan, R.; Guo, M.; Li, C.; Chen, S.; Liu, G.; He, J.; Wan, G.; Fan, N. Detection of early bruises in jujubes based on reflectance, absorbance and Kubelka-Munk spectral data. Postharvest Biol. Technol. 2022, 185, 111810. [Google Scholar] [CrossRef]

- Pang, Q.; Huang, W.; Fan, S.; Zhou, Q.; Wang, Z.; Tian, X. Detection of early bruises on apples using hyperspectral imaging combining with YOLOv3 deep learning algorithm. J. Food Process Eng. 2022, 45, e13952. [Google Scholar] [CrossRef]

- Rivera, N.V.; Gomez-Sanchis, J.; Chanona-Perez, J.; Carrasco, J.J.; Millan-Giralolo, M.; Lorente, D.; Cubero, S.; Blasco, J. Early detection of mechanical damage in mango using NIR hyperspectral images and machine learning. Biosyst. Eng. 2014, 122, 91–98. [Google Scholar] [CrossRef]

- Lü, Q.; Tang, M. Detection of hidden bruise on Kiwi fruit using hyperspectral imaging and parallelepiped classification. Procedia Environ. Sci. 2012, 12, 1172–1179. [Google Scholar] [CrossRef]

- ElMasry, G.; Wang, N.; Vigneault, C.; Qiao, J.; El Sayed, A. Early detection of apple bruises on different background colors using hyperspectral imaging. LWT-Food Sci. Technol. 2008, 41, 337–345. [Google Scholar] [CrossRef]

- Ariana, D.; Guyer, D.E.; Shrestha, B. Integrating multispectral reflectance and fluorescence imaging for defect detection on apples. Comput. Electron. Agric. 2006, 50, 148–161. [Google Scholar] [CrossRef]

- Bhargava, A.; Bansal, A. Fruits and vegetables quality evaluation using computer vision: A review. J. King Saud Univ. 2021, 33, 243–257. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, W.; Li, J.; Zhao, C.; Fan, S.; Wu, J.; Liu, C. Principles, developments and applications of computer vision for external quality inspection of fruits and vegetables: A review. Food Res. Int. 2014, 62, 326–343. [Google Scholar] [CrossRef]

- Dong, Y.; Huang, Y.; Xu, B.; Li, B.; Guo, B. Bruise detection and classification in jujube using thermal imaging and DenseNet. J. Food Process Eng. 2022, 45, e13981. [Google Scholar] [CrossRef]

- Bizzani, M.; Menezes Flores, D.W.; Moraes, T.B.; Colnago, L.A.; Ferreira, M.D.; Fillet Spoto, M.H. Non-invasive detection of internal flesh breakdown in intact Palmer mangoes using time-domain nuclear magnetic resonance relaxometry. Microchem. J. 2020, 158, 105208. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Y.; Lin, M.; Wu, D.; Chen, K. Non-destructive detection of damaged strawberries after impact based on analyzing volatile organic compounds. Sensors 2022, 22, 427. [Google Scholar] [CrossRef] [PubMed]

- Arendse, E.; Fawole, O.A.; Magwaza, L.S.; Opara, U.L. Non-destructive prediction of internal and external quality attributes of fruit with thick rind: A review. J. Food Eng. 2018, 217, 11–23. [Google Scholar] [CrossRef]

- Julrat, S.; Trabelsi, S. Measuring dielectric properties for sensing foreign material in peanuts. IEEE Sens. J. 2019, 19, 1756–1766. [Google Scholar] [CrossRef]

- Trabelsi, S. Measuring changes in radio-frequency dielectric properties of chicken meat during storage. J. Food Meas. Charact. 2018, 12, 683–690. [Google Scholar] [CrossRef]

- Bian, H.; Tu, P. The simultaneous monitoring of physiological change of apple based on dielectric parameters in static pressure. J. Chin. Inst. Food Sci. Technol. 2019, 19, 279–285. [Google Scholar] [CrossRef]

- Tu, P.; Bian, H. The influence of static pressure on dielectric property and intracellular moisture of apple. Sci. Technol. Food Ind. 2017, 38, 30–34. [Google Scholar] [CrossRef]

- Lan, H.; Wang, Z.; Niu, H.; Zhang, H.; Zhang, Y.; Tang, Y.; Liu, Y. A nondestructive testing method for soluble solid content in Korla fragrant pears based on electrical properties and artificial neural network. Food Sci. Nutr. 2020, 8, 5172–5181. [Google Scholar] [CrossRef]

- Zhu, X.; Fang, L.; Gu, J.; Guo, W. Feasibility Investigation on Determining Soluble Solids Content of Peaches Using Dielectric Spectra. Food Anal. Method 2016, 9, 1789–1798. [Google Scholar] [CrossRef]

- Guo, W.; Fang, L.; Liu, D.; Wang, Z. Determination of soluble solids content and firmness of pears during ripening by using dielectric spectroscopy. Comput. Electron. Agric. 2015, 117, 226–233. [Google Scholar] [CrossRef]

- Guo, W.; Zhu, X.; Liu, Y.; Zhuang, H. Sugar and water contents of honey with dielectric property sensing. J. Food Eng. 2010, 97, 275–281. [Google Scholar] [CrossRef]

- Guo, W.; Zhu, X.; Nelson, S.O.; Yue, R.; Liu, H.; Liu, Y. Maturity effects on dielectric properties of apples from 10 to 4500 MHz. LWT-Food Sci. Technol. 2011, 44, 224–230. [Google Scholar] [CrossRef]

- Castro-Giraldez, M.; Fito, P.J.; Chenoll, C.; Fito, P. Development of a dielectric spectroscopy technique for the determination of apple (Granny Smith) maturity. Innov. Food Sci. Emerg. 2010, 11, 749–754. [Google Scholar] [CrossRef]

- Tu, P.; Bian, H. Prediction of damage volume on apple basing the dielectric property. Sci. Technol. Food Ind. 2018, 39, 226–229. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Tang, Y.; Lan, H.; Niu, H. Non-destructive detection of the fruit firmness of Korla fragrant pear based on electrical properties. Int. J. Agric. Biol. Eng. 2022, 15, 216–221. [Google Scholar] [CrossRef]

- Shi, G.; Liu, Y.; Zhao, J.; Xu, P.; Zhang, H.; Lan, H. Study on the influence of preload and electrode diameter on electric parameter measurement of Korla pear. J. Chin. Agric. Mech. 2019, 40, 112–117. [Google Scholar] [CrossRef]

- Guo, H. Research on the Gooseberries’ Electric Characteristic and the Non-Destructive Determination Technology. Master’s Thesis, Northwest A&F University, Yangling, China, 2004. [Google Scholar]

- Dong, C.; An, T.; Zhu, H.; Wang, J.; Hu, B.; Jiang, Y.; Yang, Y.; Li, J. Rapid sensing of key quality components in black tea fermentation using electrical characteristics coupled to variables selection algorithms. Sci. Rep. 2020, 10, 1598. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Y.; Sun, F.; Wang, S. A Method for determining index weights based on principal component analysis. J. Ordnance Eq. Eng. 2012, 33, 124–126. [Google Scholar]

- Bro, R.; Smilde, A.K. Principal component analysis. Anal. Methods 2014, 6, 2812–2831. [Google Scholar] [CrossRef]

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation coefficients: Appropriate use and interpretation. Anesth. Anal. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

- Cover, T.M.; Hart, P.E. Nearest neighbor pattern classification. IEEE Trans. Inf. Theory 1967, 13, 21–27. [Google Scholar] [CrossRef]

- Fan, S.; Li, C.; Shen, A. Class-specific attribute weighted Naive Bayes improvement for imbalanced data classification. Math. Appl. 2022, 35, 463–468. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Takahashi, K.; Yamamoto, K.; Kuchiba, A.; Koyama, T. Confidence interval for micro-averaged F-1 and macro-averaged F-1 scores. Appl. Intell. 2022, 52, 4961–4972. [Google Scholar] [CrossRef] [PubMed]

- Lan, H. Research on Maturity Characteristics and Maturity Evaluation of Korla Fragrant Pear. Ph.D. Thesis, Northeast Agricultural University, Harbin City, China, 2017. [Google Scholar]

- Lin, H.; Du, Z. Some problems in comprehensive evaluation in the principal component analysis. Stat. Res. 2013, 30, 25–31. [Google Scholar] [CrossRef]

- Rajasekar, L.; Sharmila, D. Performance analysis of soft computing techniques for the automatic classification of fruits dataset. Soft Comput. 2019, 23, 2773–2788. [Google Scholar] [CrossRef]

- Gopika, N.; Kowshalaya, A.M. Correlation based feature selection algorithm for machine learning. In Proceedings of the 2018 3rd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 15–16 October 2018; IEEE: New York, NY, USA, 2018; pp. 692–695. [Google Scholar]

| D (mm) | Cp (pF) | Q | Lp (H) | Rp (MΩ) | Z (MΩ) | θ (°) |

|---|---|---|---|---|---|---|

| 0 | 9.005 ± 0.801 a | 12.777 ± 1.473 d | −28.336 ± 2.514 a | 22.864 ± 3.988 d | 1.729 ± 0.156 a | −85.321 ± 0.554 a |

| 3 | 8.949 ± 0.895 a | 15.605 ± 2.054 c | −28.607 ± 3.07 a | 28.317 ± 6.247 c | 1.745 ± 0.187 a | −86.139 ± 0.491 b |

| 5 | 8.917 ± 0.945 a | 19.69 ± 3.156 b | −28.666 ± 3.209 a | 35.989 ± 8.826 b | 1.763 ± 0.19 a | −86.92 ± 0.541 c |

| 7 | 8.882 ± 0.671 a | 25.108 ± 2.208 a | −28.673 ± 2.228 a | 45.249 ± 5.511 a | 1.764 ± 0.139 a | −87.599 ± 0.251 d |

| D (mm) | Cp (pF) | Q | Lp (mH) | Rp (MΩ) | Z (kΩ) | θ (°) |

|---|---|---|---|---|---|---|

| 0 | 8.171 ± 0.848 a | 18.324 ± 2.64 d | −314.777 ± 52.355 b | 3.679 ± 1.295 d | 192.093 ± 32.768 a | −86.524 ± 1.216 d |

| 3 | 8.313 ± 0.785 a | 22.258 ± 3.153 c | −307.617 ± 31.131 b,a | 4.348 ± 0.985 c | 186.894 ± 20.451 a | −87.248 ± 0.402 c |

| 5 | 8.385 ± 0.904 a | 28.247 ± 4.919 b | −305.701 ± 35.003 b,a | 5.35 ± 1.293 b | 187.495 ± 20.534 a | −87.821 ± 0.318 b |

| 7 | 8.44 ± 0.803 a | 34.766 ± 3.634 a | −300.051 ± 23.581 a | 6.547 ± 0.86 a | 184.619 ± 14.479 a | −88.251 ± 0.237 a |

| D (mm) | Cp (pF) | Q | Lp (mH) | Rp (kΩ) | Z (kΩ) | θ (°) |

|---|---|---|---|---|---|---|

| 0 | 8.114 ± 0.792 c | 13.344 ± 1.789 d | −3.167 ± 0.489 c | 268.599 ± 84.7 b | 19.195 ± 3.065 a | −85.536 ± 0.579 a |

| 3 | 8.321 ± 0.767 b,c | 14.664 ± 1.753 c | −3.061 ± 0.316 b,c | 285.794 ± 57.86 b | 18.598 ± 1.759 b,a | −85.885 ± 0.566 b |

| 5 | 8.52 ± 0.893 a,b | 16.536 ± 1.848 b | −3.006 ± 0.335 a,b | 314.699 ± 64.43 a | 18.361 ± 1.955 b | −86.342 ± 0.455 c |

| 7 | 8.706 ± 0.646 a | 18.428 ± 1.778 a | −2.92 ± 0.226 a | 337.754 ± 47.079 a | 17.864 ± 1.366 b | −86.79 ± 0.393 d |

| Parameter | 10 kHz | 100 kHz | 1 MHz | |||

|---|---|---|---|---|---|---|

| PC1 | PC2 | PC1 | PC2 | PC1 | PC2 | |

| Cp | −0.41914 | 0.38758 | −0.45083 | 0.31033 | −0.4265 | 0.36479 |

| Q | 0.36809 | 0.48569 | 0.29302 | 0.54503 | 0.35387 | 0.56292 |

| Lp | −0.41294 | 0.40082 | −0.47113 | 0.32675 | −0.41169 | 0.40611 |

| Rp | 0.45025 | 0.30226 | 0.45876 | 0.33487 | 0.45276 | 0.22491 |

| Z | 0.42464 | −0.37592 | 0.4694 | −0.31681 | 0.446 | −0.32307 |

| θ | −0.36779 | −0.46963 | −0.24108 | −0.53606 | −0.34566 | −0.47975 |

| Actual | 10 kHz | 100 kHz | 1 MHz | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Prediction | ACC | Prediction | ACC | Prediction | ACC | |||||

| Model | 0 | 1 | 0 | 1 | 0 | 1 | ||||

| NB | 0 (N = 25) | 24 | 1 | 86.00% | 18 | 7 | 85.00% | 15 | 10 | 75.00% |

| 1 (N = 75) | 13 | 62 | 8 | 67 | 12 | 63 | ||||

| SVM | 0 (N = 25) | 18 | 7 | 88.00% | 19 | 6 | 92.00% | 16 | 9 | 83.00% |

| 1 (N = 75) | 5 | 70 | 2 | 73 | 8 | 67 | ||||

| KNN | 0 (N = 25) | 20 | 5 | 89.00% | 19 | 6 | 88.00% | 16 | 9 | 86.00% |

| 1 (N = 75) | 6 | 69 | 6 | 69 | 5 | 70 | ||||

| 10 kHz | 100 kHz | 1 MHz | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Prediction | ACC | Prediction | ACC | Prediction | ACC | |||||

| Model | Actual | 0 | 1 | 0 | 1 | 0 | 1 | |||

| NB | 0 (N = 25) | 14 | 11 | 85.00% | 17 | 8 | 89.00% | 12 | 13 | 81.00% |

| 1 (N = 75) | 4 | 71 | 3 | 72 | 6 | 69 | ||||

| SVM | 0 (N = 25) | 20 | 5 | 90.00% | 18 | 7 | 90.00% | 13 | 12 | 82.00% |

| 1 (N = 75) | 5 | 70 | 3 | 72 | 6 | 69 | ||||

| KNN | 0 (N = 25) | 19 | 6 | 90.00% | 17 | 8 | 87.00% | 16 | 9 | 81.00% |

| 1 (N = 75) | 4 | 71 | 5 | 70 | 10 | 65 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.; Luo, X.; Xiong, L.; Tang, X.; Lan, H. Discrimination of Inner Injury of Korla Fragrant Pear Based on Multi-Electrical Parameters. Foods 2023, 12, 1805. https://doi.org/10.3390/foods12091805

An J, Luo X, Xiong L, Tang X, Lan H. Discrimination of Inner Injury of Korla Fragrant Pear Based on Multi-Electrical Parameters. Foods. 2023; 12(9):1805. https://doi.org/10.3390/foods12091805

Chicago/Turabian StyleAn, Jing, Xiuzhi Luo, Lijian Xiong, Xiuying Tang, and Haipeng Lan. 2023. "Discrimination of Inner Injury of Korla Fragrant Pear Based on Multi-Electrical Parameters" Foods 12, no. 9: 1805. https://doi.org/10.3390/foods12091805

APA StyleAn, J., Luo, X., Xiong, L., Tang, X., & Lan, H. (2023). Discrimination of Inner Injury of Korla Fragrant Pear Based on Multi-Electrical Parameters. Foods, 12(9), 1805. https://doi.org/10.3390/foods12091805