Dynamic Changes in Volatiles, Soluble Sugars, and Fatty Acids in Glutinous Rice during Cooking

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Volatile Compounds Analysis

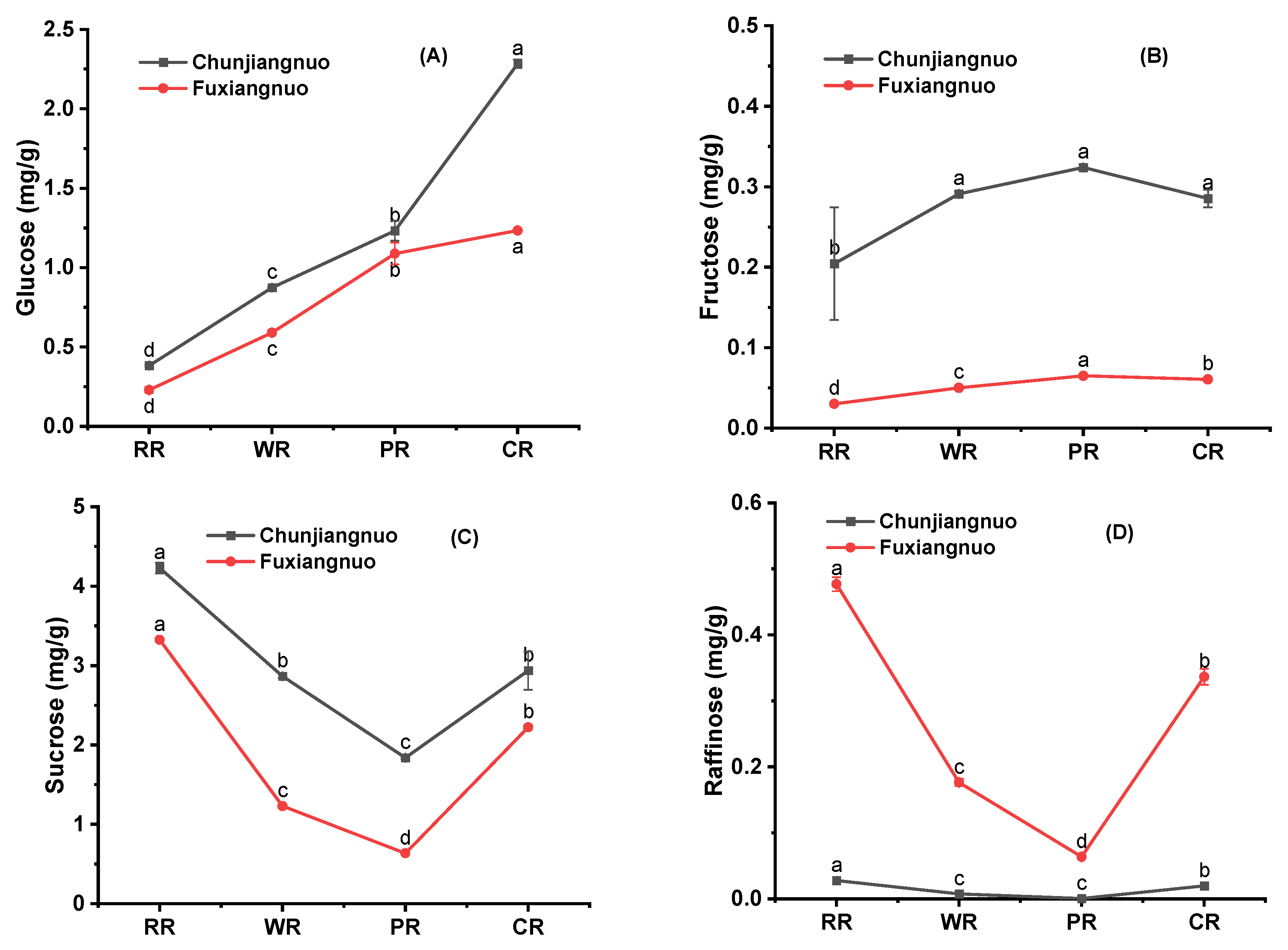

2.3. Soluble Sugars Analysis

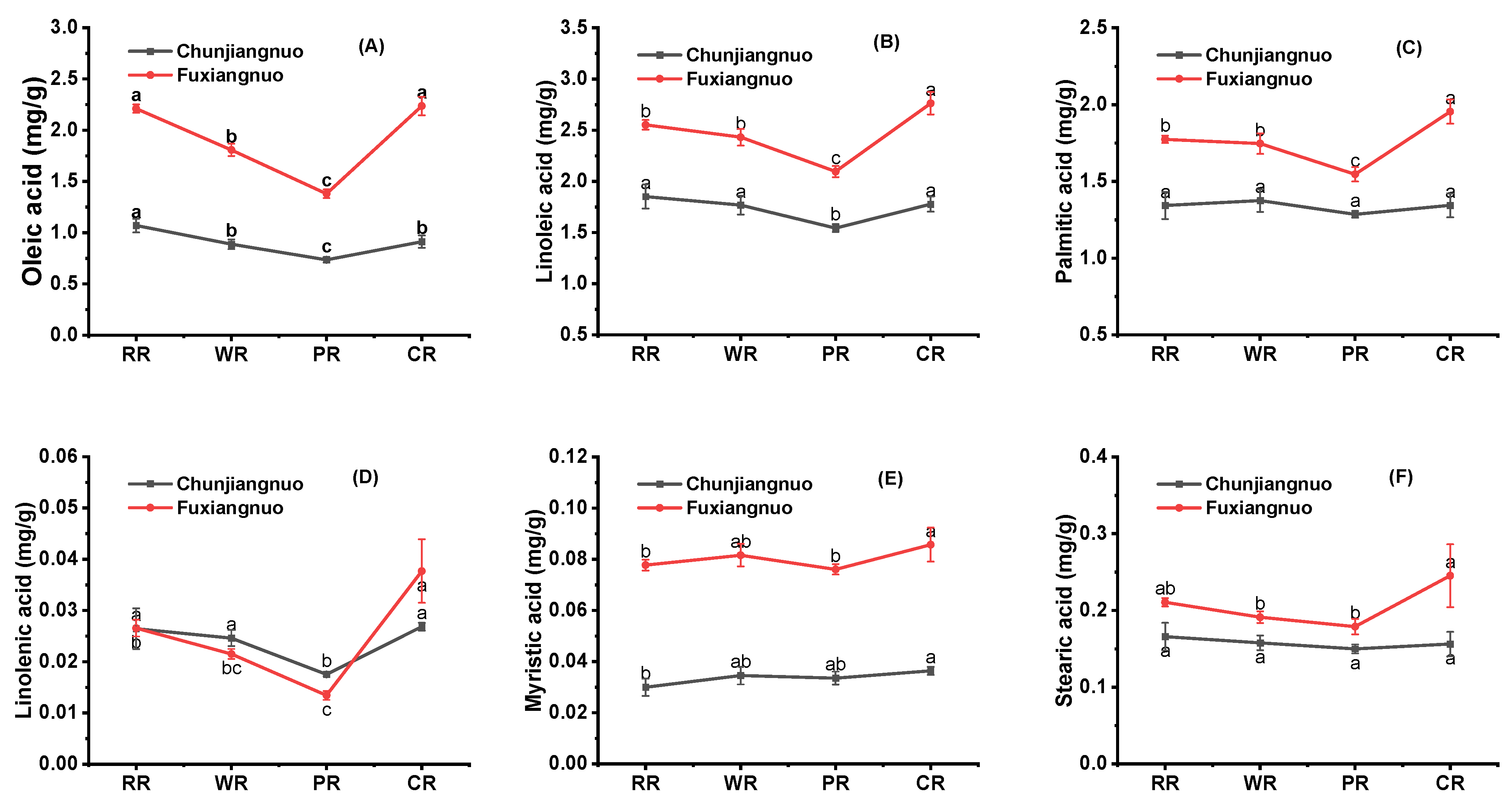

2.4. Fatty Acids Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Water Washing

3.2. Presoaking

3.3. Hydrothermal Cooking

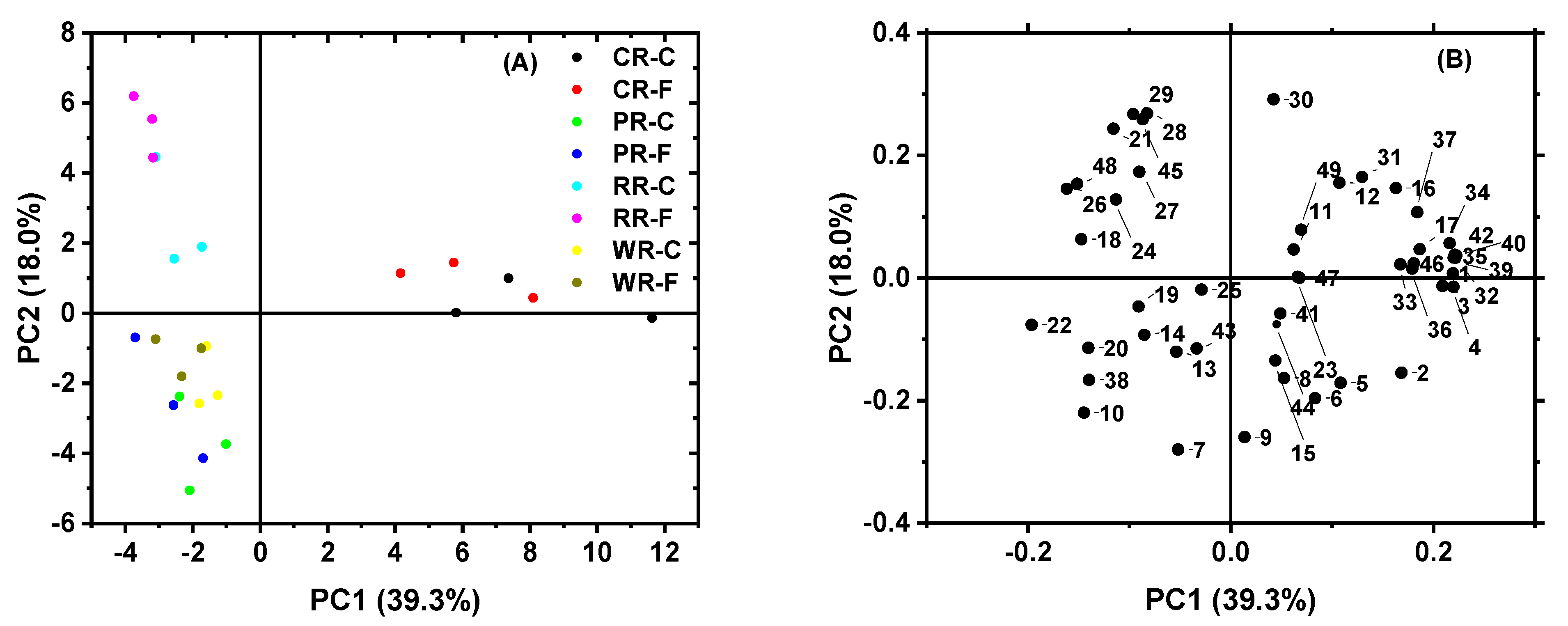

3.4. Principal Component Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guan, B.; Zhao, J.; Jin, H.; Lin, H. Determination of rice storage time with colorimetric sensor array. Food Anal. Methods 2017, 10, 1054–1062. [Google Scholar] [CrossRef]

- Hu, X.Q.; Lu, L.; Guo, Z.L.; Zhu, Z.W. Volatile compounds, affecting factors and evaluation methods for rice aroma: A review. Trends Food Sci. Technol. 2020, 97, 136–146. [Google Scholar] [CrossRef]

- Verma, D.K.; Srivastav, P.P. A paradigm of volatile aroma compounds in rice and their product with extraction and identification methods: A comprehensive review. Food Res. Int. 2020, 130, 108924. [Google Scholar] [CrossRef] [PubMed]

- Lina, G.; Min, Z. Formation and release of cooked rice aroma. J. Cereal Sci. 2022, 107, 103523. [Google Scholar] [CrossRef]

- Thi Uyen, T.; Suzuki, K.; Okadome, H.; Homma, S.; Ohtsubo, K. Analysis of the tastes of brown rice and milled rice with different milling yields using a taste sensing system. Food Chem. 2004, 88, 557–566. [Google Scholar] [CrossRef]

- Kasote, D.; Singh, V.K.; Bollinedi, H.; Singh, A.K.; Sreenivasulu, N.; Regina, A. Profiling of 2-acetyl-1-pyrroline and other volatile compounds in raw and cooked rice of traditional and improved varieties of India. Foods 2021, 10, 1917. [Google Scholar] [CrossRef]

- Zhao, Q.; Xi, J.; Xu, X.; Yin, Y.; Xu, D.; Jin, Y.; Tong, Q.; Dong, L.; Wu, F. Volatile fingerprints and biomarkers of Chinese fragrant and non-fragrant japonica rice before and after cooking obtained by untargeted GC/MS-based metabolomics. Food Biosci. 2022, 47, 101764. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, C.; Liu, K.; Liu, Q. Volatile organic compounds, evaluation methods and processing properties for cooked rice flavor. Rice 2022, 15, 53. [Google Scholar] [CrossRef]

- Yu, L.; Turner, M.S.; Fitzgerald, M.; Stokes, J.R.; Witt, T. Review of the effects of different processing technologies on cooked and convenience rice quality. Trends Food Sci. Technol. 2017, 59, 124–138. [Google Scholar] [CrossRef]

- Yamuangmorn, S.; Dell, B.; Prom-U-Thai, C. Effects of cooking on anthocyanin concentration and bioactive antioxidant capacity in glutinous and non-glutinous purple rice. Rice Sci. 2018, 25, 270–278. [Google Scholar] [CrossRef]

- Piyawanitpong, C.; Therdthai, N.; Ratphitagsanti, W. Effect of Precooking and Superheated Steam Treatment on Quality of Black Glutinous Rice. J. Food Qual. 2018, 2018, 8496723. [Google Scholar] [CrossRef]

- Monsoor, M.A.; Proctor, A. Volatile component analysis of commercially milled head and broken rice. J. Food Sci. 2004, 69, C632–C636. [Google Scholar] [CrossRef]

- Monsoor, M.A.; Proctor, A. Effect of water washing on the reduction of surface total lipids and FFA on milled rice. J. Am. Oil Chem. Soc. 2002, 79, 867–870. [Google Scholar] [CrossRef]

- Champagne, E.T.; Bett-Garber, K.L.; Thomson, J.L.; Shih, F.F.; Lea, J.; Daigle, K. Impact of presoaking on flavor of cooked rice. Cereal Chem. 2008, 85, 706–710. [Google Scholar] [CrossRef]

- Zhu, L.; Yu, C.; Yin, X.; Wu, G.; Zhang, H. Effects of soaking on the volatile compounds, textural property, phytochemical contents, and antioxidant capacity of brown rice. Foods 2022, 11, 3699. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhang, H.; Zhang, T.; Tamogami, S.; Chen, J.Y. Analysis of flavor volatiles of glutinous rice during cooking by combined gas chromatography-mass spectrometry with modified headspace solid-phase microextraction method. J. Food Compos. Anal. 2009, 22, 347–353. [Google Scholar] [CrossRef]

- Bett-Garber, K.L.; Champagne, E.T.; Ingram, D.A.; McClung, A.M. Influence of water-to-rice ratio on cooked rice flavor and texture. Cereal Chem. 2007, 84, 614–619. [Google Scholar] [CrossRef]

- Yu, C.; Zhu, L.; Zhang, H.; Bi, S.; Wu, G.; Qi, X.; Zhang, H.; Wang, L.; Qian, H.; Zhou, L. Effect of cooking pressure on phenolic compounds, gamma-aminobutyric acid, antioxidant activity and volatile compounds of brown. J. Cereal Sci. 2021, 97, 103127. [Google Scholar] [CrossRef]

- Ma, R.; Tian, Y.; Chen, L.; Jin, Z. Impact of cooling rates on the flavor of cooked rice during storage. Food Biosci. 2020, 35, 100563. [Google Scholar] [CrossRef]

- Hu, X.; Fang, C.; Zhang, W.; Lu, L.; Guo, Z.; Li, S.; Chen, M. Change in volatiles, soluble sugars and fatty acids of glutinous rice, japonica rice and indica rice during storage. LWT Food Sci. Technol. 2023, 174, 114416. [Google Scholar] [CrossRef]

- Fukuda, T.; Takeda, T.; Yoshida, S. Comparison of volatiles in cooked rice with various amylose contents. Food Sci. Technol. Res. 2014, 20, 1251–1259. [Google Scholar] [CrossRef]

- Xu, Y.; Jin, Y.; Su, J.; Yang, N.; Xu, X.; Jin, Z.; Cui, B.; Wu, F. Changes in the nutritional value, flavor, and antioxidant activity of brown glutinous rice during fermentation. Food Biosci. 2021, 43, 101273. [Google Scholar] [CrossRef]

- Hu, X.; Fang, C.; Lu, L.; Hu, Z.; Shao, Y.; Zhu, Z. Determination of soluble sugar profile in rice. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2017, 1058, 19–23. [Google Scholar] [CrossRef]

- Fukai, Y.; Tukada, K. Influence of pre-washing on quality of cooked rice maintained at a constant temperature—(Influence of cooking conditions on quality of cooked rice—Part 1). J. Jpn. Soc. Food Sci. Technol. Nippon. Shokuhin Kagaku Kogaku Kaishi 2006, 53, 587–591. [Google Scholar] [CrossRef]

- Yuan, B.; Zhao, C.; Yan, M.; Huang, D.; McClements, D.J.; Huang, Z.; Cao, C. Influence of gene regulation on rice quality: Impact of storage temperature and humidity on flavor profile. Food Chem. 2019, 283, 141–147. [Google Scholar]

- Yang, D.S.; Lee, K.-S.; Kays, S.J. Characterization and discrimination of premium-quality, waxy, and black-pigmented rice based on odor-active compounds. J. Sci. Food Agric. 2010, 90, 2595–2601. [Google Scholar] [CrossRef]

- Cheng, Y.; Huynh-Ba, T.; Blank, I.; Robert, F. Temporal changes in aroma release of Longjing tea infusion: Interaction of volatile and nonvolatile tea components and formation of 2-butyl-2-octenal upon aging. J. Agric. Food Chem. 2008, 56, 2160–2169. [Google Scholar] [CrossRef]

- Wang, K.; Arntfield, S.D. Binding of carbonyl flavours to canola, pea and wheat proteins using GC/MS approach. Food Chem. 2014, 157, 364–372. [Google Scholar] [CrossRef]

- Suzuki, Y.; Ise, K.; Li, C.Y.; Honda, I.; Iwai, Y.; Matsukura, U. Volatile components in stored rice Oryza sativa (L.) of varieties with and without lipoxygenase-3 in seeds. J. Agric. Food Chem. 1999, 47, 1119–1124. [Google Scholar] [CrossRef]

- Tran, T.U.; Suzuki, K.; Okadome, H.; Ikezaki, H.; Homma, S.; Ohtsubo, K. Detection of changes in taste of japonica and indica brown and milled rice (Oryza sativa L.) during storage using physicochemical analyses and a taste sensing system. J. Agric. Food Chem. 2005, 53, 1108–1118. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.; Zhang, W.; Lu, B.; Zhang, H.; Chi, G.; Mao, J.; Wang, D.; Sun, S.; Zong, Y.; et al. Sensory-oriented analysis of key sweet taste components in cured tobacco extract. Tob. Sci. Technol. 2016, 49, 58–64. [Google Scholar]

- Mestres, C.; Briffaz, A.; Valentin, D. Rice cooking and sensory quality. In Rice, 4th ed.; Bao, J.S., Ed.; AACC International Press: Washington, DC, USA, 2019; pp. 385–426. [Google Scholar]

- Choi, S.; Lee, J. Volatile and sensory profiles of different black rice (Oryza sativa L.) cultivars varying in milling degree. Food Res. Int. 2021, 141, 110150. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Li, Y.; Pan, Q.; Fan, M.; Wang, L.; Qian, H. Analysis of the key aroma volatile compounds in rice bran during storage and processing via HS-SPME GC/MS. J. Cereal Sci. 2021, 99, 103178. [Google Scholar] [CrossRef]

- Kasai, M.; Lewis, A.; Marica, F.; Ayabe, S.; Hatae, K.; Fyfe, C.A. NMR imaging investigation of rice cooking. Food Res. Int. 2005, 38, 403–410. [Google Scholar] [CrossRef]

- Xu, X.F.; Zhong, Y.J.; Liu, C.M.; Xia, W.; Liu, W.; Huang, Z.L. Formation pathways and influences of rice aroma. Sci. Technol. Food Ind. 2013, 13, 378–382+387. [Google Scholar]

- Shi, Y.; Wang, L.; Fang, Y.; Wang, H.; Tao, H.; Pei, F.; Li, P.; Xu, B.; Hu, Q. A comprehensive analysis of aroma compounds and microstructure changes in brown rice during roasting process. LWT Food Sci. Technol. 2018, 98, 613–621. [Google Scholar] [CrossRef]

- Lee, S.M.; Lim, H.J.; Chang, J.W.; Hurh, B.-S.; Kim, Y.-S. Investigation on the formations of volatile compounds, fatty acids, and gamma-lactones in white and brown rice during fermentation. Food Chem. 2018, 269, 347–354. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Fang, C.; Lu, L.; Hu, Z.; Zhang, W.; Chen, M. Dynamic Changes in Volatiles, Soluble Sugars, and Fatty Acids in Glutinous Rice during Cooking. Foods 2023, 12, 1700. https://doi.org/10.3390/foods12081700

Hu X, Fang C, Lu L, Hu Z, Zhang W, Chen M. Dynamic Changes in Volatiles, Soluble Sugars, and Fatty Acids in Glutinous Rice during Cooking. Foods. 2023; 12(8):1700. https://doi.org/10.3390/foods12081700

Chicago/Turabian StyleHu, Xianqiao, Changyun Fang, Lin Lu, Zhanqiang Hu, Weixing Zhang, and Mingxue Chen. 2023. "Dynamic Changes in Volatiles, Soluble Sugars, and Fatty Acids in Glutinous Rice during Cooking" Foods 12, no. 8: 1700. https://doi.org/10.3390/foods12081700

APA StyleHu, X., Fang, C., Lu, L., Hu, Z., Zhang, W., & Chen, M. (2023). Dynamic Changes in Volatiles, Soluble Sugars, and Fatty Acids in Glutinous Rice during Cooking. Foods, 12(8), 1700. https://doi.org/10.3390/foods12081700