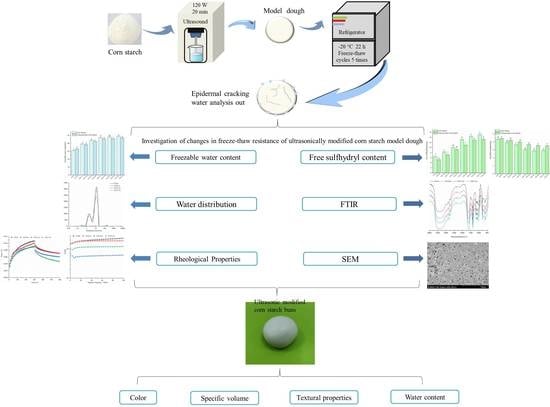

Ultrasonic Treatment of Corn Starch to Improve the Freeze-Thaw Resistance of Frozen Model Dough and Its Application in Steamed Buns

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Ultrasonically Modified Corn Starch and Frozen Model Dough

2.2.1. Preparation of Ultrasonically Modified Corn Starch

2.2.2. Preparation of Frozen Model Dough

2.3. Determination of Freezable Water Content of Model Dough

2.4. Determination of Moisture Distribution in Model Dough

2.5. Determination of Texture Properties of Model Dough

2.6. Measurement of Rheological Properties of Model Dough

2.6.1. Dynamic Rheology Measurement

2.6.2. Creep Recovery Measurement

2.7. Determination of Free Sulfhydryl Content and Disulfide Bond Content of Model Doughs

2.8. Determination of FTIR Spectra of Model Doughs

2.9. Determination of the Microscopic Morphology of the Model Dough

2.10. Model Dough for Steamed Buns

2.11. Apparent Characteristics of Steamed Buns

2.11.1. The Color and Specific Volume of the Bun

2.11.2. Textural Properties of Buns

2.12. Determination of Moisture Content in Steamed Buns

2.13. Statistical Analysis

3. Results

3.1. Analysis of Freezable Water Content of Model Dough

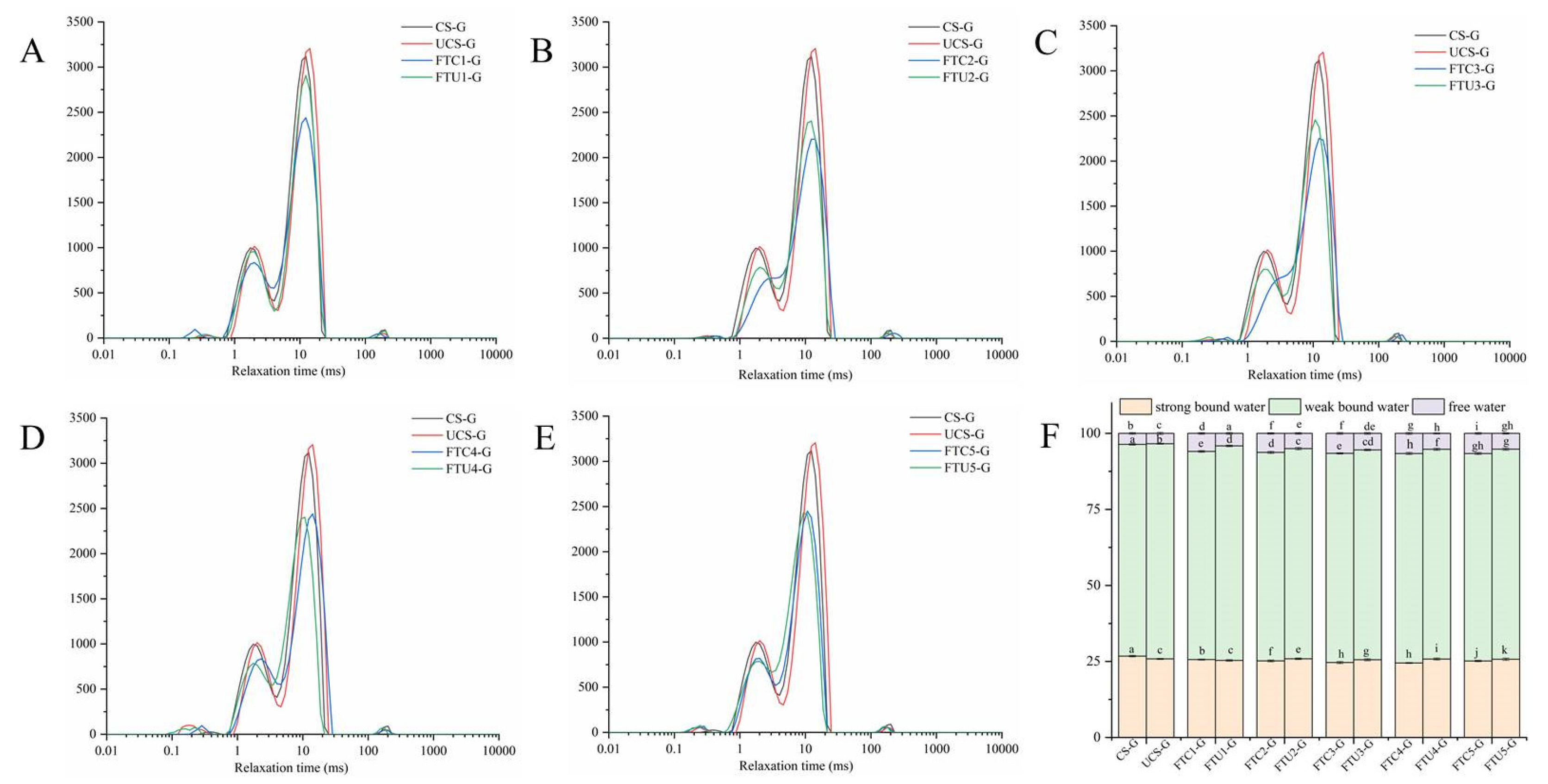

3.2. Analysis of Model Dough Moisture Distribution Results

3.3. Analysis of the Results of the Qualitative Properties of the Model Dough

3.4. Analysis of Rheological Properties of Model Dough Results

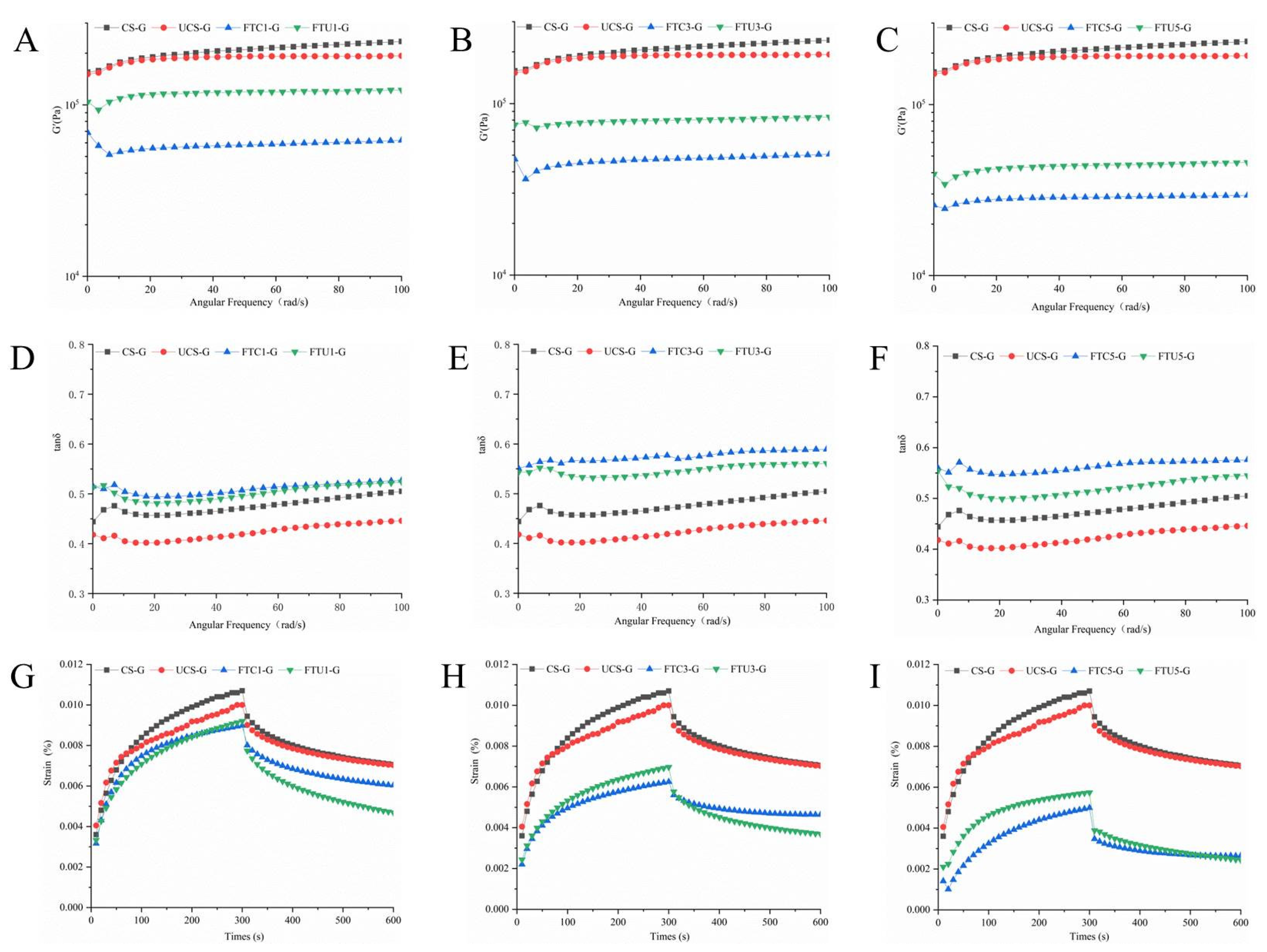

3.4.1. Analysis of Dynamic Rheological Results

3.4.2. Creep Recovery Characteristics Results Analysis

3.5. Analysis of the Results of Free Sulfhydryl Content and Disulfide Bond Content of Model Doughs

3.6. Analysis of FTIR Results of Model Dough

3.7. Analysis of Microstructure Results of Model Dough

3.8. Apparent Characteristics of Buns

3.8.1. The Color of the Bun

3.8.2. Specific Volume of the Bun

3.8.3. Textural Properties of Buns

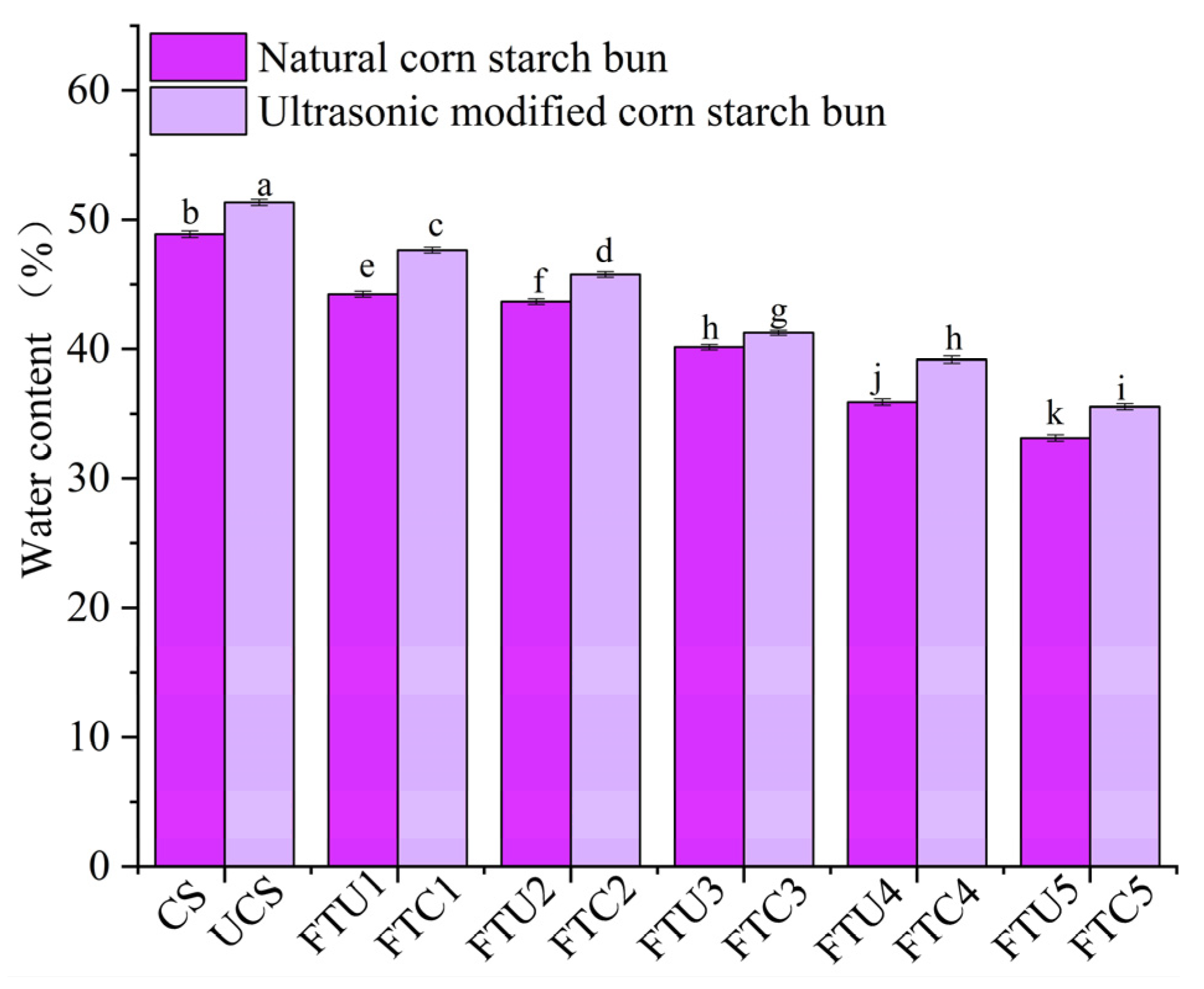

3.9. Water Content of Buns

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Giannou, V.; Tzia, C. Addition of Vital Wheat Gluten to Enhance the Quality Characteristics of Frozen Dough Products. Foods 2016, 5, 6. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, L.; Zhao, R.; Liu, Q.; Liu, W.; Hu, H. Effects of particle size distribution of potato starch granules on rheological properties of model dough underwent multiple freezing-thawing cycles. Food Res. Int. 2022, 156, 111112. [Google Scholar] [CrossRef]

- Tao, H.; Wang, P.; Wu, F.; Jin, Z.; Xu, X. Particle size distribution of wheat starch granules in relation to baking properties of frozen dough. Carbohydr. Polym. 2016, 137, 147–153. [Google Scholar] [CrossRef]

- Oladele, A.K.; Duodu, K.G.; Emmambux, N.M. Pasting, flow, thermal and molecular properties of maize starch modified with crude phenolic extracts from grape pomace and sorghum bran under alkaline conditions. Food Chem. 2019, 297, 124879. [Google Scholar] [CrossRef]

- Maphalla, T.G.; Emmambux, M.N. Functionality of maize, wheat, teff and cassava starches with stearic acid and xanthan gum. Carbohydr. Polym. 2016, 136, 970–978. [Google Scholar] [CrossRef]

- Guo, L.; Yuan, Y.; Li, J.; Tan, C.; Janaswamy, S.; Lu, L.; Fang, Y.; Cui, B. Comparison of functional properties of porous starches produced with different enzyme combinations. Int. J. Biol. Macromol. 2021, 174, 110–119. [Google Scholar] [CrossRef]

- Woo, S.-H.; Kim, J.-S.; Jeong, H.-M.; Shin, Y.-J.; Hong, J.-S.; Choi, H.-D.; Shim, J.-H. Development of Freeze-Thaw Stable Starch through Enzymatic Modification. Foods 2021, 10, 2269. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Q.; Zhao, Y.; Qin, Z.; Zheng, M.; Liu, H.; Liu, J. Preparation and characterization of low oil absorption corn starch by ultrasonic combined with freeze–thaw treatment. Food Chem. X 2022, 15. [Google Scholar] [CrossRef]

- Chan, H.-T.; Bhat, R.; Karim, A.A. Effects of sodium dodecyl sulphate and sonication treatment on physicochemical properties of starch. Food Chem. 2010, 120, 703–709. [Google Scholar] [CrossRef]

- López-Méndez, E.; Ortiz-García-Carrasco, B.; Ruiz-Espinosa, H.; Sampieri-Croda, A.; García-Alvarado, M.; Ochoa-Velasco, C.; Escobedo-Morales, A.; Ruiz-López, I. Effect of shape change and initial geometry on water diffusivity estimation during drying of gel model systems. J. Food Eng. 2018, 216, 52–64. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Wang, H.; Oladejo, A.O.; Zhang, H.; Liu, X. Effects of ultrasound-assisted freezing on the water migration of dough and the structural characteristics of gluten components. J. Cereal Sci. 2019, 94, 102893. [Google Scholar] [CrossRef]

- Lu, L.; Yang, Z.; Guo, X.-N.; Xing, J.-J.; Zhu, K.-X. Effect of NaHCO3 and freeze–thaw cycles on frozen dough: From water state, gluten polymerization and microstructure. Food Chem. 2021, 358, 129869. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, B.; Huang, W.; Ma, Z.; Zhang, F.; Wang, F.; Zou, Q.; Zheng, J. Hydration, water distribution and microstructure of gluten during freeze thaw process: Role of a high molecular weight dextran produced by Weissella confusa QS813. Food Hydrocoll. 2018, 90, 377–384. [Google Scholar] [CrossRef]

- Bai, N.; Guo, X.-N.; Xing, J.-J.; Zhu, K.-X. Effect of freeze-thaw cycles on the physicochemical properties and frying performance of frozen Youtiao dough. Food Chem. 2022, 386. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Zhang, B.; Zhang, Y.; Rasheed, M.; Gu, S.; Guo, B. Effect of freezing rate and frozen storage on the rheological properties and protein structure of non-fermented doughs. J. Food Eng. 2020, 293, 110377. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Q.; Hu, N.; Yin, H.; Wang, T.; Dai, X.; Zheng, M.; Liu, J. Improvement of structural characteristics and in vitro digestion properties of zein by controlling postharvest ripening process of corn. Food Control. 2022, 142. [Google Scholar] [CrossRef]

- Fan, J.-L.; Han, N.; Chen, H.-Q. Physicochemical and structural properties of wheat gluten/rice starch dough-like model. J. Cereal Sci. 2021, 98, 103181. [Google Scholar] [CrossRef]

- Akbarian, M.; Koocheki, A.; Mohebbi, M.; Milani, E. Rheological properties and bread quality of frozen sweet dough with added xanthan and different freezing rate. J. Food Sci. Technol.-Mysore 2016, 53, 3761–3769. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, H.; Wang, L.; Qian, H.; Qi, X.; Xiao, J. Effect of barley antifreeze protein on thermal properties and wa-ter state of dough during freezing and freeze-thaw cycles. Food Hydrocoll. 2015, 47, 32–40. [Google Scholar] [CrossRef]

- Han, C.; Ma, M.; Li, M.; Sun, Q. Further interpretation of the underlying causes of the strengthening effect of alkali on gluten and noodle quality: Studies on gluten, gliadin, and glutenin. Food Hydrocoll. 2020, 103, 105661. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, D.; Zhou, H.; Wu, F.; Xu, X. New insight into the contribution of wheat starch and gluten to frozen dough bread quality. Food Biosci. 2022, 48. [Google Scholar] [CrossRef]

- Peng, B.; Li, Y.; Ding, S.; Yang, J. Characterization of textural, rheological, thermal, microstructural, and water mobility in wheat flour dough and bread affected by trehalose. Food Chem. 2017, 233, 369–377. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, Y.; Liu, Y.; Zhang, H. Effects of multiple freeze-thaw cycles on the quality of frozen dough. Cereal Chem. 2018, 95, 499–507. [Google Scholar] [CrossRef]

- Liu, R.; Sun, W.; Zhang, Y.; Huang, Z.; Hu, H.; Zhao, M.; Li, W. Development of a novel model dough based on mechanically activated cassava starch and gluten protein: Application in bread. Food Chem. 2019, 300, 125196. [Google Scholar] [CrossRef]

- Wang, P.; Lee, T.-C.; Xu, X.; Jin, Z. The contribution of glutenin macropolymer depolymerization to the deterioration of frozen steamed bread dough quality. Food Chem. 2016, 211, 27–33. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Guida, M.; Danza, A.; Laverse, J.; Frisullo, P.; Lampignano, V.; Del Nobile, M.A. Rheological, microstructural and sensorial properties of durum wheat bread as affected by dough water content. Food Res. Int. 2013, 51, 458–466. [Google Scholar] [CrossRef]

- Li, M.; Liu, C.; Zheng, X.; Hong, J.; Bian, K.; Li, L. Interaction between A-type/B-type starch granules and gluten in dough during mixing. Food Chem. 2021, 358, 129870. [Google Scholar] [CrossRef]

- Zhang, D.; Mu, T.; Sun, H. Comparative study of the effect of starches from five different sources on the rheological properties of gluten-free model doughs. Carbohydr. Polym. 2017, 176, 345–355. [Google Scholar] [CrossRef]

- Skendi, A.; Papageorgiou, M.; Biliaderis, C. Effect of barley β-glucan molecular size and level on wheat dough rheological properties. J. Food Eng. 2009, 91, 594–601. [Google Scholar] [CrossRef]

- Rombouts, I.; Jansens, K.J.; Lagrain, B.; Delcour, J.A.; Zhu, K.-X. The impact of salt and alkali on gluten polymerization and quality of fresh wheat noodles. J. Cereal Sci. 2014, 60, 507–513. [Google Scholar] [CrossRef]

- Lu, Z.-H.; Donner, E.; Yada, R.Y.; Liu, Q. Physicochemical properties and in vitro starch digestibility of potato starch/protein blends. Carbohydr. Polym. 2016, 154, 214–222. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Hu, X.; Wang, Z.; Bao, Q.; Zhou, B.; Li, T.; Li, S. Preparation and characterization of highly lipophilic modified potato starch by ultrasound and freeze-thaw treatments. Ultrason. Sonochem. 2020, 64, 105054. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Zhou, Q.; Sun, D.-W. Measuring and controlling ice crystallization in frozen foods: A review of recent developments. Trends Food Sci. Technol. 2019, 90, 13–25. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, L.; Liu, Q.; Liu, W.; Hu, H. Rheological behaviors and physicochemical changes of doughs reconstituted from potato starch with different sizes and gluten. Food Res. Int. 2021, 145, 110397. [Google Scholar] [CrossRef] [PubMed]

- Esteller, M.S.; de Lima, A.C.O.; Lannes, S. Color measurement in hamburger buns with fat and sugar replacers. LWT 2006, 39, 184–187. [Google Scholar] [CrossRef]

- Belorio, M.; Sahagún, M.; Gómez, M. Influence of Flour Particle Size Distribution on the Quality of Maize Gluten-Free Cookies. Foods 2019, 8, 83. [Google Scholar] [CrossRef]

- Zhang, D. Effect of Proofing on the Rheology and Moisture Distribution of Corn Starch-Hydroxypropylmethylcellulose Gluten-Free Dough. Foods 2023, 12, 695. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, Y.; Yuan, J.; Yang, M.; Yang, R.; Gu, Z.; Xie, C.; Zhou, Q.; Jiang, D.; Zhou, J.; et al. Impact of Different Frozen Dough Technology on the Quality and Gluten Structure of Steamed Buns. Foods 2022, 11, 3833. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, H.; Tang, S.; Gu, Z. Study on the Thermal and Water Migration of Chinese steamed buns during cooling process after steam cooking. LWT 2021, 145. [Google Scholar] [CrossRef]

- Besbes, E.; Jury, V.; Monteau, J.-Y.; Le Bail, A. Effect of baking conditions and storage with crust on the moisture profile, local textural properties and staling kinetics of pan bread. LWT 2014, 58, 658–666. [Google Scholar] [CrossRef]

- Vasafi, P.S.; Hamdami, N.; Keramat, J. Quality and microbial stability of part-baked ‘Barbari bread’ during freezing storage. LWT 2019, 104, 173–179. [Google Scholar] [CrossRef]

- Li, Q.; Liu, R.; Wu, T.; Zhang, M. Interactions between soluble dietary fibers and wheat gluten in dough studied by confocal laser scanning microscopy. Food Res. Int. 2017, 95, 19–27. [Google Scholar] [CrossRef] [PubMed]

| Freezable Water Content (%) | A21 (%) | A22 (%) | A23 (%) | |

|---|---|---|---|---|

| CS-G | 31.12 ± 0.56 a | 26.749 ± 0.25 e | 69.654 ± 0.25 f | 3.597 ± 0.28 b |

| UCS-G | 33.01 ± 0.51 b | 25.836 ± 0.18 f | 70.777 ± 0.16 h | 3.387 ± 0.36 a |

| FTC1-G | 39.34 ± 0.45 d | 25.619 ± 0.18 d | 68.456 ± 0.29 b | 5.925 ± 0.26 g |

| FTU1-G | 38.15 ± 0.46 c | 25.345 ± 0.26 c | 70.548 ± 0.25 h | 4.107 ± 0.30 c |

| FTC2-G | 43.78 ± 0.58 ef | 25.187 ± 0.30 b | 68.568 ± 0.34 b | 6.245 ± 0.23 h |

| FTU2-G | 42.61 ± 0.38 e | 25.896 ± 0.25 f | 69.105 ± 0.39 g | 4.999 ± 0.27 d |

| FTC3-G | 47.56 ± 0.39 b | 24.658 ± 0.35 a | 68.781 ± 0.21 c | 6.561 ± 0.31 i |

| FTU3-G | 45.62 ± 0.39 g | 25.569 ± 0.34 d | 69.008 ± 0.26 f | 5.423 ± 0.29 f |

| FTC4-G | 48.29 ± 0.43 i | 24.514 ± 0.16 a | 68.884 ± 0.36 d | 6.602 ± 0.34 i |

| FTU4-G | 45.77 ± 0.41 g | 25.793 ± 0.33 e | 68.993 ± 0.34 e | 5.214 ± 0.18 e |

| FTC5-G | 49.15 ± 0.50 j | 25.161 ± 0.22 b | 68.241 ± 0.33 a | 6.598 ± 0.30 i |

| FTU5-G | 46.94 ± 0.46 gh | 25.721 ± 0.38 e | 69.101 ± 0.33 f | 5.178 ± 0.20 e |

| Hardness(g) | Springiness | Cohesiveness | Resilience | |

|---|---|---|---|---|

| CS-G | 1573.22 ± 4.21 b | 0.458 ± 0.11 g | 0.266 ± 0.01 f | 0.075 ± 0.01 e |

| UCS-G | 1233.70 ± 3.75 a | 0.342 ± 0.09 c | 0.294 ± 0.01 g | 0.073 ± 0.01 d |

| FTC1-G | 1705.42 ± 3.33 d | 0.403 ± 0.04 f | 0.307 ± 0.02 h | 0.089 ± 0.01 f |

| FTU1-G | 1543.07 ± 3.56 b | 0.382 ± 0.06 d | 0.254 ± 0.01 e | 0.085 ± 0.02 ef |

| FTC2-G | 1778.43 ± 4.00 d | 0.379 ± 0.03 d | 0.269 ± 0.01 f | 0.073 ± 0.01 d |

| FTU2-G | 1676.62 ± 4.15 c | 0.386 ± 0.04 e | 0.299 ± 0.01 g | 0.077 ± 0.01 e |

| FTC3-G | 1913.41 ± 3.88 f | 0.319 ± 0.01 a | 0.217 ± 0.02 c | 0.067 ± 0.01 c |

| FTU3-G | 1653.09 ± 3.75 c | 0.375 ± 0.03 d | 0.241 ± 0.03 e | 0.073 ± 0.02 d |

| FTC4-G | 1956.35 ± 4.25 f | 0.326 ± 0.05 b | 0.191 ± 0.01 a | 0.061 ± 0.02 a |

| FTU4-G | 1814.49 ± 2.88 e | 0.377 ± 0.01 d | 0.245 ± 0.02 d | 0.064 ± 0.01 b |

| FTC5-G | 2084.02 ± 4.50 g | 0.309 ± 0.03 a | 0.201 ± 0.01 b | 0.061 ± 0.01 a |

| FTU5-G | 1813.63 ± 3.90 f | 0.324 ± 0.02 b | 0.216 ± 0.01 c | 0.065 ± 0.01 bc |

| k′ | n′ | k″ | n″ | Creep Phase | Recovery Phase | |||

|---|---|---|---|---|---|---|---|---|

| Jmax (10−4Pa−1) | η0 (10−4Pa−1) | Je/Jmax (%) | Jv/Jmax (%) | |||||

| CS-G | 2.85 ± 0.08 a | 0.14 ± 0.02 g | 1.90 ± 0.11 d | 0.12 ± 0.01 b | 35.27 ± 0.25 a | 1.62 ± 0.08 h | 47.26 ± 0.33 a | 52.73 ± 0.36 h |

| UCS-G | 2.74 ± 0.10 d | 0.13 ± 0.05 f | 1.74 ± 0.12 b | 0.13 ± 0.05 c | 33.15 ± 0.27 c | 1.53 ± 0.12 fg | 45.14 ± 0.21 b | 54.85 ± 0.31 g |

| FTC1-G | 2.56 ± 0.11 f | 0.15 ± 0.06 h | 1.78 ± 0.20 a | 0.16 ± 0.06 a | 32.18 ± 0.21 d | 1.71 ± 0.11 gh | 43.35 ± 0.38 c | 56.64 ± 0.22 f |

| FTU1-G | 2.63 ± 0.15 ab | 0.15 ± 0.03 e | 1.83 ± 0.16 e | 0.15 ± 0.04 fg | 33.89 ± 0.18 b | 1.65 ± 0.13 fg | 44.76 ± 0.25 b | 55.23 ± 0.29 g |

| FTC2-G | 2.51 ± 0.21 c | 0.17 ± 0.03 g | 1.77 ± 0.23 g | 0.18 ± 0.03 e | 30.64 ± 0.30 e | 1.84 ± 0.07 def | 41.46 ± 0.22 de | 58.53 ± 0.15 e |

| FTU2-G | 2.56 ± 0.19 e | 0.16 ± 0.04 f | 1.74 ± 0.18 h | 0.16 ± 0.10 gh | 30.97 ± 0.33 e | 1.76 ± 0.06 efg | 43.15 ± 0.26 c | 56.84 ± 0.27 f |

| FTC3-G | 2.21 ± 0.16 f | 0.19 ± 0.06 e | 1.55 ± 0.22 f | 0.19 ± 0.11 a | 25.41 ± 0.29 g | 1.92 ± 0.10 bcd | 40.57 ± 0.37 e | 59.42 ± 0.22 d |

| FTU3-G | 2.22 ± 0.15 h | 0.17 ± 0.09 c | 1.62 ± 0.14 d | 0.18 ± 0.13 h | 28.73 ± 0.45 f | 1.87 ± 0.14 cde | 41.35 ± 0.31 d | 58.64 ± 0.19 e |

| FTC4-G | 2.16 ± 0.14 g | 0.20 ± 0.10 a | 1.54 ± 0.19 g | 0.21 ± 0.07 g | 23.49 ± 0.13 h | 2.05 ± 0.09 ab | 37.99 ± 0.25 g | 62.00 ± 0.35 b |

| FTU4-G | 2.13 ± 0.22 ab | 0.19 ± 0.08 b | 1.57 ± 0.15 h | 0.18 ± 0.08 a | 26.88 ± 0.22 g | 1.98 ± 0.07 bc | 39.54 ± 0.33 f | 60.45 ± 0.41 c |

| FTC5-G | 1.88 ± 0.13 e | 0.23 ± 0.07 d | 1.23 ± 0.16 f | 0.24 ± 0.04 c | 21.87 ± 0.19 j | 2.16 ± 0.11 a | 36.13 ± 0.36 h | 63.86 ± 0.33 a |

| FTU5-G | 1.95 ± 0.17 cd | 0.21 ± 0.06 c | 1.24 ± 0.23 c | 0.22 ± 0.06 d | 24.26 ± 0.16 i | 2.07 ± 0.08 ab | 38.31 ± 0.28 g | 61.68 ± 0.39 b |

| α-Helix (%) | β-Sheet (%) | β-Turn (%) | Random Coil (%) | |

|---|---|---|---|---|

| CS-G | 21.65 ± 0.21 k | 28.32 ± 0.21 b | 30.84 ± 0.23 k | 19.19 ± 0.16 a |

| UCS-G | 20.49 ± 0.18 h | 28.09 ± 0.14 a | 30.34 ± 0.16 j | 21.08 ± 0.18 d |

| FTC1-G | 20.87 ± 0.16 j | 30.49 ± 0.15 e | 28.73 ± 0.18 h | 19.91 ± 0.15 b |

| FTU1-G | 20.85 ± 0.23 i | 29.47 ± 0.22 c | 29.68 ± 0.16 i | 20.00 ± 0.21 c |

| FTC2-G | 20.11 ± 0.25 g | 30.02 ± 0.19 d | 27.85 ± 0.19 e | 22.02 ± 0.19 g |

| FTU2-G | 20.39 ± 0.15 h | 30.21 ± 0.16 d | 28.43 ± 0.14 g | 20.97 ± 0.14 d |

| FTC3-G | 19.24 ± 0.16 c | 30.87 ± 0.17 f | 26.59 ± 0.20 b | 23.30 ± 0.13 i |

| FTU3-G | 19.80 ± 0.23 f | 30.90 ± 0.13 g | 28.11 ± 0.12 f | 21.19 ± 0.18 e |

| FTC4-G | 19.61 ± 0.22 d | 31.18 ± 0.20 h | 26.78 ± 0.26 c | 22.43 ± 0.19 h |

| FTU4-G | 19.68 ± 0.15 e | 31.50 ± 0.23 i | 27.20 ± 0.22 d | 21.62 ± 0.21 f |

| FTC5-G | 19.12 ± 0.14 a | 30.44 ± 0.14 e | 26.88 ± 0.16 c | 23.56 ± 0.22 j |

| FTU5-G | 19.15 ± 0.17 b | 31.87 ± 0.21 j | 26.30 ± 0.18 a | 22.68 ± 0.14 h |

| L* | a* | b* | △E | |

|---|---|---|---|---|

| CS | 77.6 ± 0.05 a | 5.3 ± 0.04 b | 13.2 ± 0.02 b | 30.70 ± 0.05 b |

| UCS | 77.4 ± 0.04 a | 5.0 ± 0.02 a | 12.9 ± 0.04 a | 30.49 ± 0.03 a |

| FTC1 | 73.2 ± 0.07 c | 6.9 ± 0.01 d | 14.8 ± 0.02 c | 31.45 ± 0.04 c |

| FTU1 | 75.1 ± 0.09 b | 6.3 ± 0.03 c | 14.2 ± 0.01 b | 33.42 ± 0.08 d |

| FTC2 | 71.7 ± 0.05 e | 7.2 ± 0.03 f | 15.4 ± 0.03 e | 33.81 ± 0.06 d |

| FTU2 | 73.1 ± 0.07 c | 7.1 ± 0.03 e | 15.1 ± 0.03 d | 36.39 ± 0.02 f |

| FTC3 | 70.1 ± 0.06 f | 7.6 ± 0.02 h | 15.9 ± 0.02 f | 35.65 ± 0.07 e |

| FTU3 | 72.1 ± 0.07 d | 7.4 ± 0.04 g | 15.4 ± 0.02 e | 37.11 ± 0.03 g |

| FTC4 | 69.8 ± 0.08 g | 7.8 ± 0.03 j | 16.2 ± 0.02 g | 36.12 ± 0.11 f |

| FTU4 | 71.9 ± 0.05 e | 7.7 ± 0.02 i | 15.8 ± 0.01 f | 39.47 ± 0.08 i |

| FTC5 | 69.5 ± 0.09 g | 8.0 ± 0.03 k | 16.5 ± 0.03 h | 38.12 ± 0.05 h |

| FTU5 | 70.1 ± 0.06 f | 7.6 ± 0.04 h | 16.1 ± 0.01 g | 39.89 ± 0.04 i |

| Specific Volume (cm3/g) | Hardness (g) | Springiness | Chewiness | |

|---|---|---|---|---|

| CS | 1.64 ± 0.02 g | 1956.27 ± 30.15 d | 1.09 ± 0.05 f | 1124.18 ± 13.41 b |

| UCS | 1.69 ± 0.04 g | 1339.87 ± 20.19 a | 1.11 ± 0.02 g | 910.59 ± 24.15 a |

| FTC1 | 1.36 ± 0.01 e | 2312.56 ± 25.48 e | 1.00 ± 0.06 e | 1638.74 ± 18.94 d |

| FTU1 | 1.50 ± 0.02 f | 1589.12 ± 41.38 b | 1.01 ± 0.04 e | 1356.71 ± 16.23 c |

| FTC2 | 1.25 ± 0.02 c | 2580.34 ± 52.13 f | 0.91 ± 0.02 c | 1920.64 ± 20.13 e |

| FTU2 | 1.31 ± 0.03 d | 1834.25 ± 31.49 c | 0.94 ± 0.04 cd | 1709.59 ± 25.47 d |

| FTC3 | 1.24 ± 0.03 c | 2663.44 ± 8.79 f | 0.86 ± 0.03 b | 2135.38 ± 11.23 f |

| FTU3 | 1.29 ± 0.01 d | 1904.81 ± 34.65 d | 0.95 ± 0.02 d | 1801.48 ± 15.61 de |

| FTC4 | 1.18 ± 0.04 b | 2966.13 ± 38.94 g | 0.87 ± 0.03 b | 2514.32 ± 21.45 g |

| FTU4 | 1.19 ± 0.02 bc | 2470.84 ± 29.16 e | 0.93 ± 0.03 c | 2261.15 ± 19.78 f |

| FTC5 | 1.12 ± 0.01 a | 3071.96 ± 33.71 h | 0.88 ± 0.04 b | 2978.45 ± 12.11 h |

| FTU5 | 1.18 ± 0.03 b | 2746.74 ± 44.21 f | 0.79 ± 0.02 a | 2499.38 ± 17.45 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, R.; Lin, J.; Hou, J.; Xu, X.; Bao, S.; Wei, C.; Xing, J.; Wu, Y.; Liu, J. Ultrasonic Treatment of Corn Starch to Improve the Freeze-Thaw Resistance of Frozen Model Dough and Its Application in Steamed Buns. Foods 2023, 12, 1962. https://doi.org/10.3390/foods12101962

Han R, Lin J, Hou J, Xu X, Bao S, Wei C, Xing J, Wu Y, Liu J. Ultrasonic Treatment of Corn Starch to Improve the Freeze-Thaw Resistance of Frozen Model Dough and Its Application in Steamed Buns. Foods. 2023; 12(10):1962. https://doi.org/10.3390/foods12101962

Chicago/Turabian StyleHan, Rui, Jiaqi Lin, Jingyao Hou, Xiuying Xu, Saruna Bao, Chaoyue Wei, Jiayue Xing, Yuzhu Wu, and Jingsheng Liu. 2023. "Ultrasonic Treatment of Corn Starch to Improve the Freeze-Thaw Resistance of Frozen Model Dough and Its Application in Steamed Buns" Foods 12, no. 10: 1962. https://doi.org/10.3390/foods12101962

APA StyleHan, R., Lin, J., Hou, J., Xu, X., Bao, S., Wei, C., Xing, J., Wu, Y., & Liu, J. (2023). Ultrasonic Treatment of Corn Starch to Improve the Freeze-Thaw Resistance of Frozen Model Dough and Its Application in Steamed Buns. Foods, 12(10), 1962. https://doi.org/10.3390/foods12101962