1. Introduction

By 2050, the global population is expected to reach 9 billion, and the demand for meat will increase by 75% compared to today [

1]. In addition, inefficient conversion causes animal meat production to occupy 83% of arable land and consume large amounts of water [

2]. As a result, global environmental and food security pressures are increasing. In particular, meat consumption is faced with severe challenges, and animal meat resources are increasingly unable to fully meet the meat demand of humans [

3]. Moreover, the increasing desire to address the health and ethical issues associated with the consumption of animal meat has led to a shift in dietary behavior toward vegetarianism [

4]. One potential solution, high-moisture texturized vegetable protein (HMTVP), has garnered attention due to its high production efficiency and low production costs [

5]. HMTVP is a meat analog that has a structure similar to meat fibers due to a four-stage formation process involving unfolding, association, aggregation, and crosslinking of vegetable protein molecular chains during the extrusion process under conditions of high moisture, high temperature, and high shear [

6]. Hitherto, most studies have aimed to improve the fiber structure of extrudates by optimizing the formula and process parameters [

7,

8,

9,

10,

11,

12,

13]. By contrast, few studies have examined the water distribution, despite the importance of water distribution for juiciness—a key characteristic of meat products [

14,

15,

16].

Differences in raw material characteristics can also lead to great fluctuations in the extruder response parameters during the extrusion process, thereby affecting the extrudate quality. A number of previous studies have described the relationship between process parameters, extruder response, and product characteristics during high moisture extrusion [

17,

18]. However, for a complex system composed of multiple proteins, the relationship between raw material characteristics, extruder response parameters, and product characteristics needs to be further clarified. Therefore, it is still difficult to systematically regulate the HMTVP product by adjusting the raw materials’ characteristics and extruder response in a targeted manner.

Currently, the most common protein sources for HMTVP products are soy protein (soy isolate protein and soy concentrate protein) [

19,

20,

21], wheat gluten [

22,

23], and pea protein (pea isolate protein) [

24,

25]. In order to improve the utilization of defatted peanut meal, peanut protein has been used in recent years. Of these, peanut protein is allergenic, with a prevalence of about 2% [

26]. However, peanut protein has an excellent amino acid profile, a desirable volatile profile, a low level of antinutritional factors, and a steady supply [

27]. PPP is the product of defatted peanut meal, a by-product of peanut oil production [

28]. The protein, mainly composed of arachin and conarachin, contains 8 essential amino acids necessary for the human diet and has a digestibility of up to 90%. However, the fiber structure of peanut protein still needs to be further improved. Many studies have reported on the fiber textural mechanism and fiber structure improvement of peanut-protein-based meat analogs [

29,

30]. The fibrous degree of PPP can be promoted by the addition of polysaccharides and transglutaminase, which induce conformational changes in the protein [

31,

32].

Wheat gluten (WG) is the primary storage protein group in wheat grains [

33,

34]. It forms a cohesive viscoelastic network that is important in producing meat analog products. It is mainly composed of glutenin, which forms polymer networks, and gliadin, which acts as a plasticizer to improve the viscosity and ductility of wheat doughs [

35]. WG can be extruded individually to form striking textures and is widely used to compound with other proteins to improve their fibrous structure. This is because it causes the mixture to form incompatibly independent phases, which are essential for the development of fibrous structures [

22,

36,

37]. From a protein conformation perspective, increasing the WG ratio increases the content of disulfide bonds and β-sheets, resulting in a dense and structurally strong gluten network [

10,

23,

38]. On the other hand, a strong fibrous structure can also result in a decrease in resemblance to real meat. In addition, juiciness has been neglected by many studies on the high water compression of wheat protein [

39]. In other words, the extrudates obtained by high-moisture extrusion of PPP or WG alone have shortcomings in simulating the fibrous structure and juiciness of real meat.

The aim of the present study was to explore the influence of mixing WG and PPP at different ratios on extrudate quality characteristics (texture, color, and moisture distribution) from the aspect of the extruder response. The goal of this work was to explain the relationships among raw material properties, extruder response parameters, and extrudate quality to provide a basis for systematic regulation of the protein fiber textural process. Our findings support the use of binary proteins to enhance the fibrous structure of meat analogs.

2. Materials and Methods

2.1. Materials

Peanut protein powder (PPP) and wheat gluten (WG) were supplied by Ouguo Co. (Yantai, China) and Feitian Co. (Hebi, China), respectively. The protein, starch, crude fiber, lipid, and water contents of the PPP employed in this study were 55.3% (dry basis), 5.2% (dry basis), 0.3% (dry basis), 8.8% (dry basis), and 6.1%, respectively. The protein, starch, crude fiber, lipid, and water contents of the WG employed in this study were 83.2% (dry basis), 5.7% (dry basis), 3.5% (dry basis), 1.0% (dry basis), and 8.96%, respectively. Deionized (DI) water was used throughout the experiment.

A three-dimensional movement mixer (SYH-15L, Shaoping, Wuxi, China) was used to mix the blends of PPP and WG at different ratios (dry basis). The tested WG:PPP ratios were 0:100, 30:70, 50:50, 70:30, and 100:0, respectively. A total of 12 kg of the mixture was prepared under each ratio. The conditioned mixtures were packed in plastic bags and kept at 4 °C overnight to equilibrate.

2.2. WAI and WSI

The water absorption index (WAI) and water solubility index (WSI) were determined using the method of Ding et al. [

40] and Hirunyophat et al. [

41], respectively, with appropriate modifications. A 2 g powder sample (m

0) was weighed and placed in a dry centrifuge tube (m

1). A 25 mL volume of distilled water was pipetted into the centrifuge tube, the tube was vortexed for 2 min and then placed in an oscillating water bath at 30 °C for 30 min, followed by centrifugation at 3500 r/min for 10 min. The tube was carefully removed from the centrifuge and placed vertically, and the supernatant was removed with a pipette gun. The supernatant was transferred to a weighing bottle (m

3) that had been dried to a constant weight, placed in a 105 °C oven to dry to a constant weight, and then weighed (m

4). The centrifuge tube and precipitate mass (m

2) were weighed at the same time. Each set of samples was measured three times and averaged.

The WAI and WSI were calculated using Equation (1) and Equation (2), respectively:

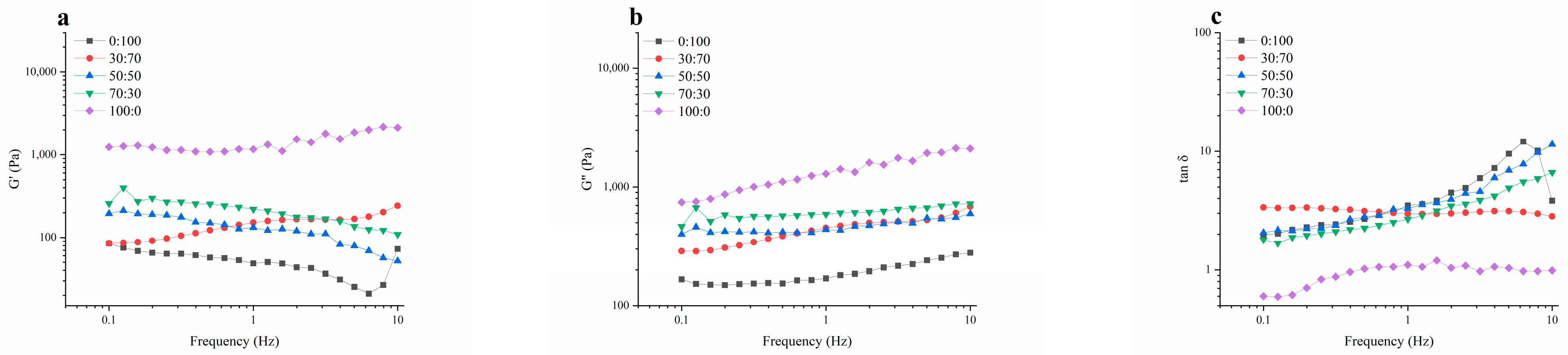

2.3. Rheological Properties of Raw Materials

A 3 g sample of raw material powder was accurately weighed into a small 50 mL beaker, and the water content was adjusted to 55% based on the water content measured in

Section 2.1 to simulate the hydration of raw materials in the mixing zone of the extruder. The material was thoroughly mixed, the cup was sealed with a sealing film to prevent water loss, and the powder was placed in a refrigerator at 4 °C overnight to balance the water.

The rheological properties of the samples were measured using a rotary rheometer (Discovery HR-3, TA Instruments, New Castle, DE, USA) using the following operational conditions: The mixture was placed between two 40 mm diameter plates, and the gap between the two plates was adjusted to 1050 μm. The excess sample was trimmed and removed, and a thin layer of silicone oil was applied to the edge of the sample to prevent water loss. The gap between the two plates was then adjusted to 1000 μm for the test.

2.3.1. Frequency Sweep

The sample was left for 60 s, and then the frequency was scanned at 25 °C, a strain degree of 0.5%, and a frequency of 0.1–10 Hz.

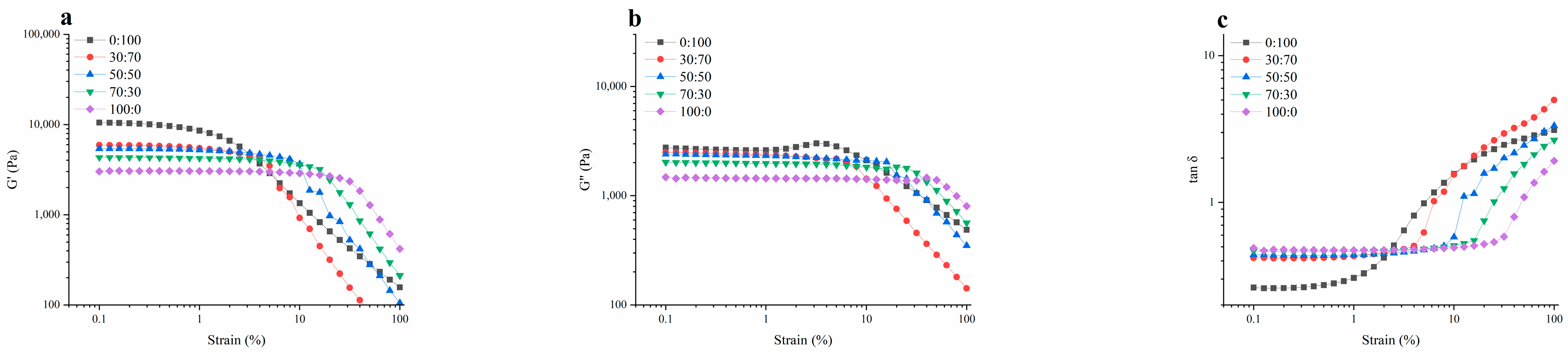

2.3.2. Strain Sweep

The sample was left for 60 s, and then the strain sweep was scanned at 25 °C, a vibration frequency of 1 Hz, and a strain degree of 0.1–100%.

2.3.3. Creep Recovery

The sample was left for 60 s, and then stress was applied at 10 Pa for 180 s. The stress was measured at 1 Hz and 25 °C at 360 s after the stress was withdrawn.

2.4. Extrusion Experiments and Sample Preparation

The raw materials were extruded with a co-rotating meshing twin-screw extruder (FMHE36-24, FUMACH, Changsha, China). The raw materials were fed into the extruder at a constant speed of 6 kg/h (dry basis) by a feeder and the process was controlled by the extruder operating system. Based on the moisture content of the mixture, water is added to the extruder through a pump so that the final feed moisture content is maintained at 55%. The processing parameters of the extruder are set according to the methods of Rehrah et al. [

42] and Zhang et al. [

32], and adjusted on the basis of a lot of pre-experiments. The screw speed was 210 rpm. From the first to the sixth zone, the temperature was maintained at 25 °C, 60 °C, 90 °C, 165 °C, 165 °C, and 120 °C. As shown in

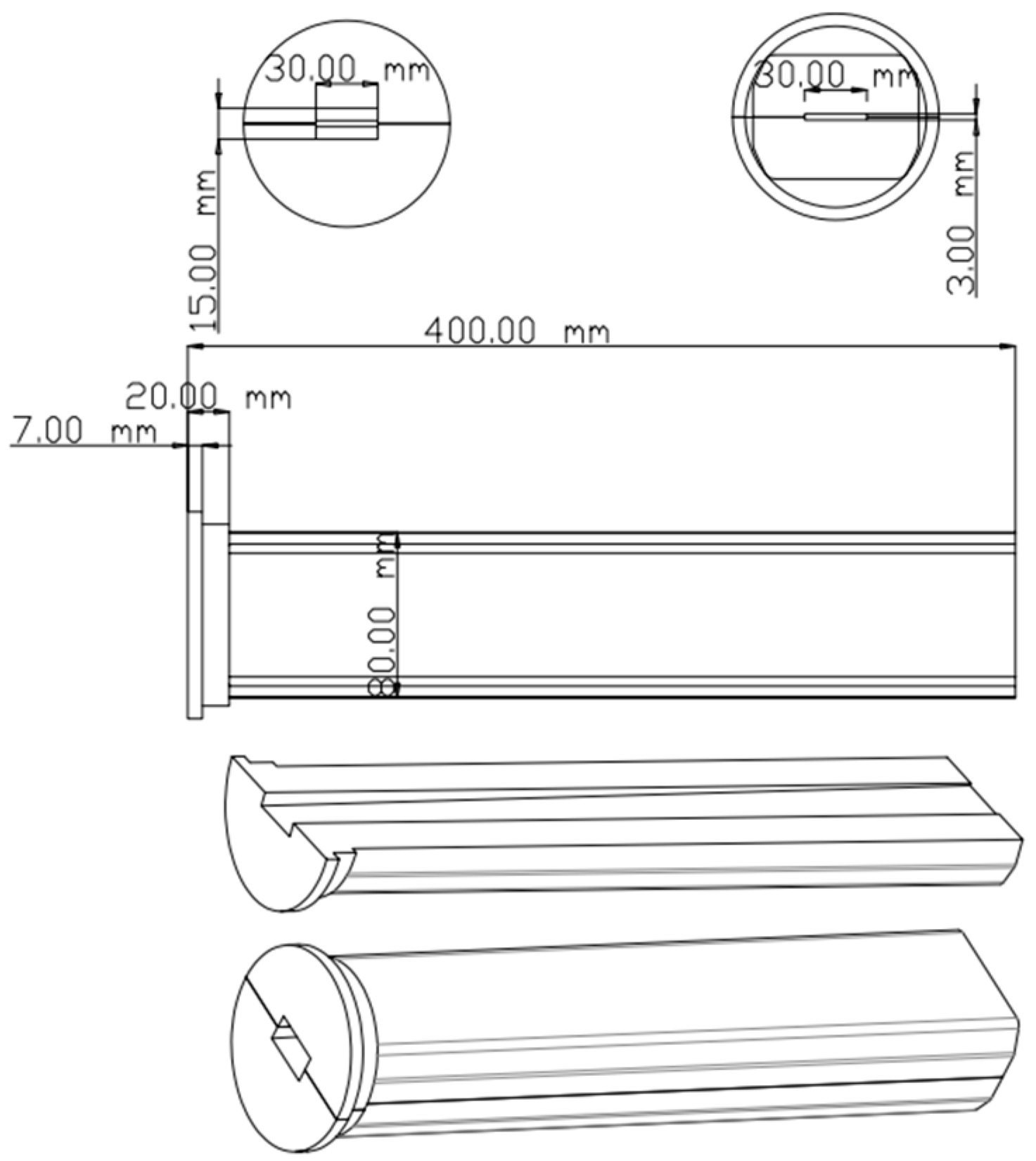

Figure 1, a long cooling die (including the connecting and cooling parts) was connected at the cylinder die mouth of the extruder, and the temperature was controlled at 70 °C.

Once the running state of the extruder stabilized, 20–30 continuous strips of extrudates per ratio were collected, cut into 20 cm lengths, immediately vacuum sealed, and frozen at −18 °C for future analysis.

2.5. Extruder Responses

After the extruder reached a stable running state, the real-time control software of the extruder was used to monitor the extruder response parameters online during the extrusion process. The extruder response parameters displayed on the extruder operating system were recorded every 5 min. These parameters included the torque, die pressure, die temperature, and mass flow rate (MFR). The specific mechanical energy (SME) was calculated using Equation (3) [

25]:

where n is the screw speed (rpm), and T is the torque (N·m).

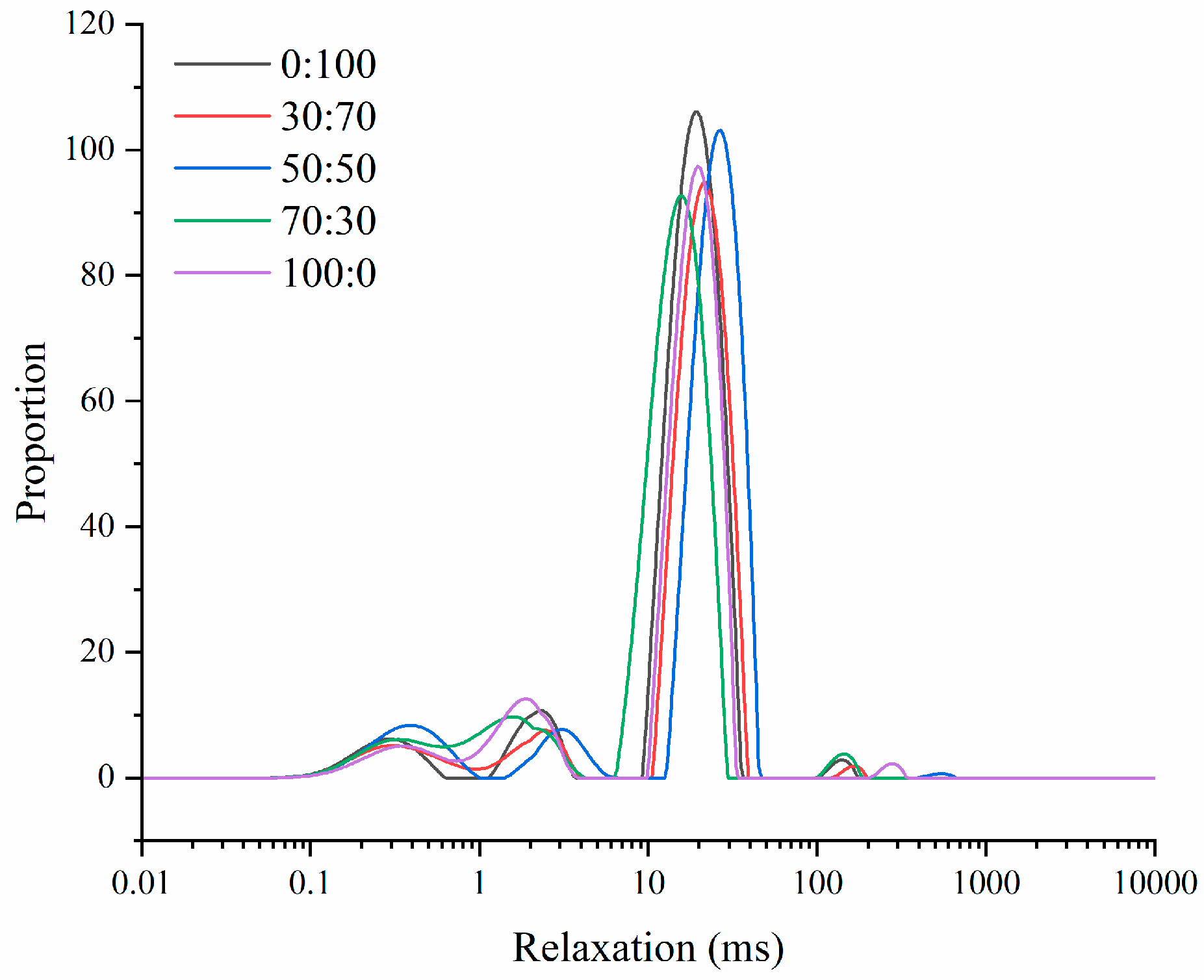

2.6. Low-Field Nuclear Magnetic Resonance

Extrudate samples were cut into 1 cm × 1 cm pieces for low-field nuclear magnetic resonance (NMR) analysis and nuclear magnetic resonance imaging (MRI).

2.6.1. Relaxation Time

We used the method of Sun et al. [

43], after some adjustments in the parameter settings. The block sample was placed into a cylindrical glass tube (diameter 15 mm). The sample relaxation time (T

2) was measured using a low-field NMR instrument (MicroMR20-030V-I, Suzhou Niumag Analytical Instrument Corporation, Suzhou, China). Carr–Purcell–Meiboom–Gill (CPMG) pulse trains were used to obtain decay signals. The main parameters of the signal acquisition were as follows: NS (scan times) = 32, NECH (echo number) = 10,000, TD (sampling point) = 249,990, TW (wait time) = 2000 ms, P2 (180° pulse time) = 12.48 μs, P1 (90° pulse time) = 6.52 μs, TE (time echo) = 0.25 ms, and SW (sampling frequency) = 100 kHz.

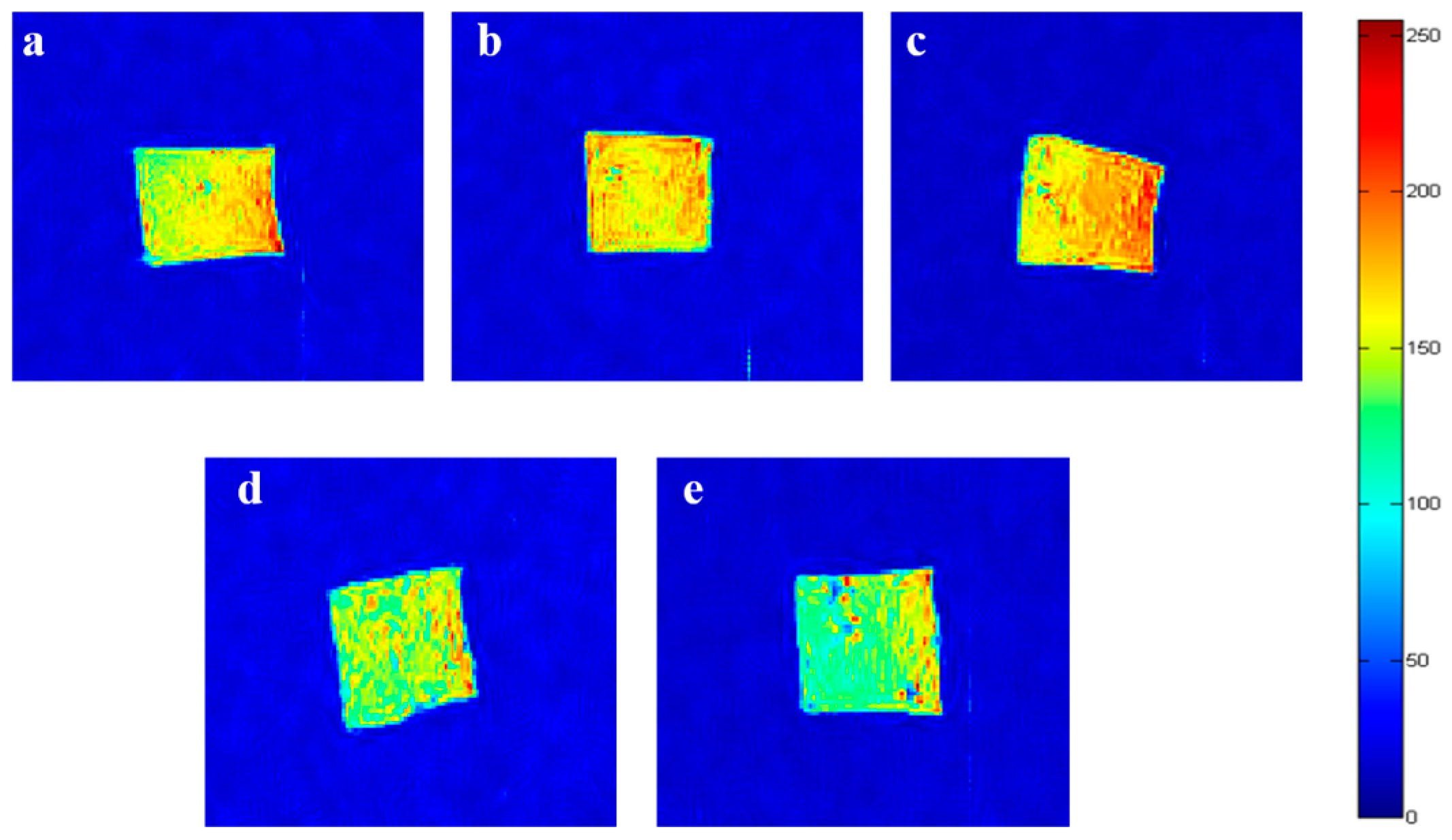

2.6.2. Magnetic Resonance Imaging

The block sample from

Section 2.2 was placed in a cylindrical glass tube (15 mm diameter) and subjected to MRI using the same low-field NMR analyzer (MicroMR20-030V-I, Suzhou Niumag Analytical Instrument Corporation, Suzhou, China). Proton density-weighted images were obtained using spin echo sequences. The echo time (TE) was 20 ms, the repetition time (TR) was 500 ms, the field of view (FOV) was 100 mm × 100 mm, and the slice width and slice gap were 1.9 mm and 2.0 mm, respectively. The pseudo-color image was obtained by software pseudo-color processing of the proton density-weighted images [

44].

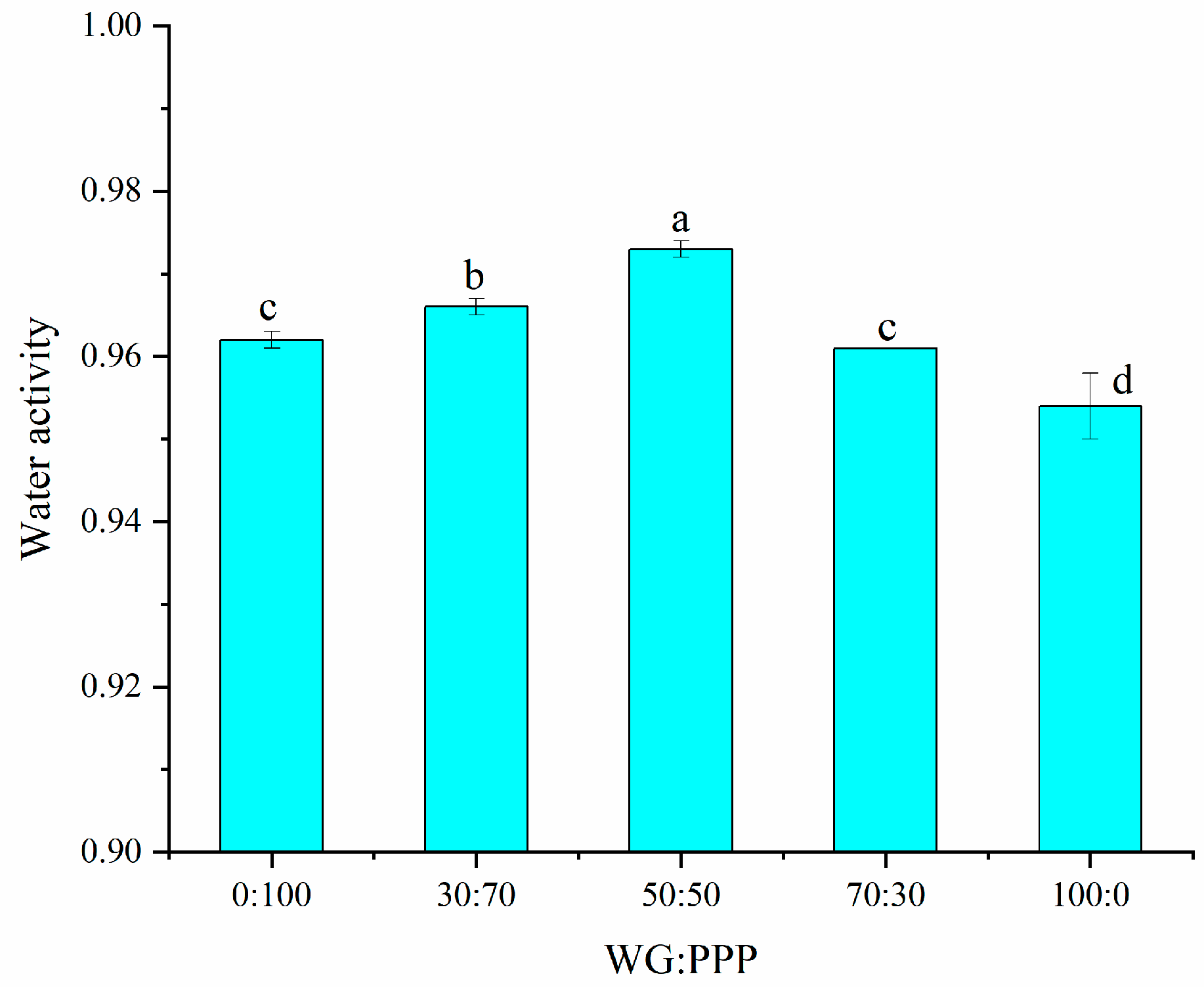

2.7. Water Activity

The water activity of the extrudates was determined using a water activity meter (FA-ST, GBX Scientific, Romans-sur-Isere, France) according to the method of Al-Jassar et al. [

45]. After cooling the extruded sample to room temperature, it was cut into uniform 0.5 cm × 0.5 cm × 0.5 cm pieces. After mixing, 2 g was transferred to a small plastic dish and placed in the water activity meter at room temperature until the indicator was stable. Each set of samples was measured three times, and the values were averaged.

2.8. Color

The color determination was based on the method of Lee et al. [

46] and Mazumder et al. [

47], respectively, with appropriate modifications. The color of the extrudates was measured with a handheld colorimeter (TES-135A, Herewith TES Electrical Electronic Crop, Taiwan, China) (CIE 2° standard observers, illuminant: white LED lamp). The sample (the extrudate sample was cut into small pieces with a side length of 20 mm and a thickness of 3 mm, the raw material was spread evenly in the test dish with a thickness of 3 mm) was placed in the test dish that accompanied the colorimeter and the test dish placed on 10 layers of white paper. The CIE

L*,

a*, and

b* values of the samples were recorded using 10 randomly chosen samples. The

L* value ranged from 5 to 100. The luminance (

L* value) ranged from total darkness (

L* = 5) to white (

L* = 100). The

a* value indicated red for a positive value and green for a negative value. The yellow

b* value was positive, and blue was the negative

b* value. The extrudates in each group were measured at least 10 times, and the values were averaged. A standard white plate (parameters of CIE LAB color space:

L* = 89.73,

a* = −0.78, and

b* = 1.88) was used to calculate the color difference between the samples and the white plate. The color difference value (Δ

E) of the extrudate was calculated using Equation (4) [

18,

31,

46].

2.9. Textural Properties

A texture analyzer (TA-XT plus, Stable Micro Systems, Godalming, UK) was used to determine the extrudate texture properties, including hardness, springiness, tensile properties, and shear properties (transverse shear force, longitudinal shear force, and fiber degree), following the methods of Fang et al. [

18] and Zhang et al. [

32].

2.9.1. Hardness and Springiness

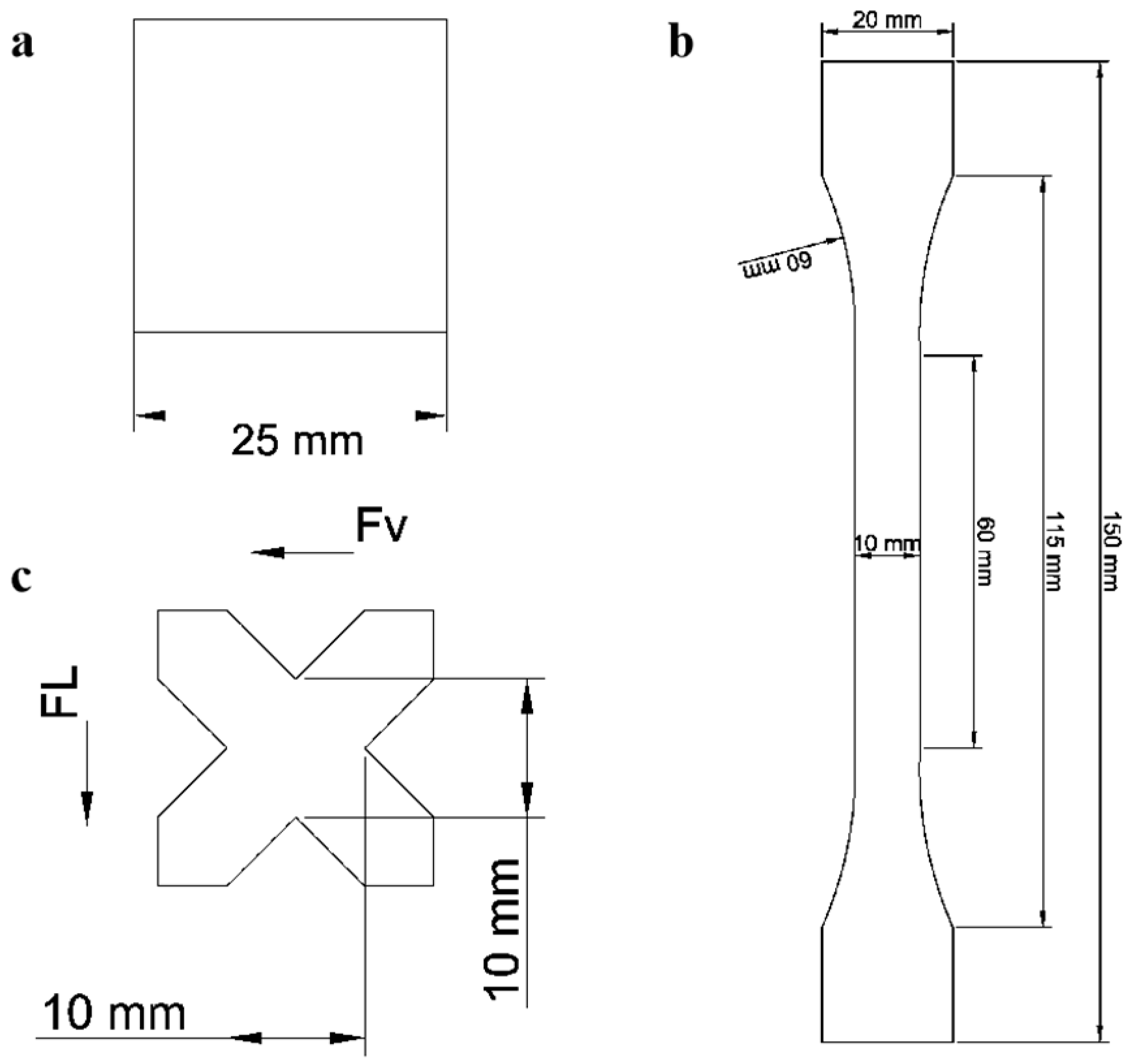

Square blocks with the shape shown in

Figure 2a were compressed to 50% of their original thickness with a P35 probe (cylinder, ∅35 mm) at a rate of 1 mm s

−1 for 5 s, and the hardness, springiness, and chewiness were recorded. All assays were repeated 10 times, and the recorded values were averaged.

2.9.2. Tensile Properties

Samples with the shape shown in

Figure 2b were pulled with an A/TG probe (rigs and clamps) at a speed of 0.5 mm s

−1. When the sample strip broke, the tensile force was recorded. All assays were repeated 10 times, and the recorded values were averaged.

2.9.3. Shear Properties

Samples with the shape shown in

Figure 2c were cut with an A/CKB probe (knife blade) to 75% of the original thickness at a speed of 1 mm s

−1. The force of the cut perpendicular to the extrusion direction was the crosswise shear force (FV), and the force of the cut parallel to the extrusion direction was the lengthwise shear force (FL). The fibrous degree was expressed as the ratio of FV to FL. All assays were repeated 10 times, and the recorded values were averaged.

2.10. Statistical Analysis

Statistical product and service solutions (SPSS) software (Version 24.0, SPSS Inc., Chicago, IL, USA) and Origin 2022 software (Origin-Lab, Inc., Northampton, MA, USA) were used to analyze the data. Analysis of variance (ANOVA) was used to make comparisons of means. Post hoc multiple comparisons were determined by Duncan’s test, and the significance level was set at p < 0.05. All results are expressed as mean ± standard deviation.

4. Conclusions

The proportions of continuous and dispersed phases in the process of high-moisture extrusion are of great significance to the mechanism that regulates the rheological properties of raw materials, the response parameters of the extruder, and the quality characteristics of the extrudates. In this study, the effects of different proportions of PPP and WG on extrudate quality characteristics were discussed from the perspective of the extruder response, and the causes of extruder response differences were discussed from the perspective of the raw material characteristics. The results support the idea that the good hydration ability of WG results in a more even distribution of water when added to the ingredients in moderation. The good moisture distribution also gives the extrudates a soft, elastic texture and white color. The introduction of glutenin also imparts a dense fiber structure and greater tensile strength to the extrudates. Conversely, when the WG ratio exceeds 50%, the good hydration ability of WG leads to the formation of dough with higher viscosity, and this prevents melt flow during extrusion, resulting in higher torque and higher SME. The large creep deformation and non-recoverable deformation of WG also lead to the accumulation of material at the die and increase the die pressure. In this case, a large amount of water evaporates at the die, the water distribution of the extrudates becomes uneven, and the extrudates become dry, hard, and dark in color. The extrudates also undergo longitudinal clearance due to the unstable discharge state, thus reducing the fibrous degree. This study found that the best quality parameters were achieved at a 50:50 balance of WG to PPP. Meanwhile, this study provides a new approach for the systematic regulation of the quality of meat analogs made from WG-PPP and other multiphase systems.