A Feasibility Study towards the On-Line Quality Assessment of Pesto Sauce Production by NIR and Chemometrics

Abstract

1. Introduction

2. Materials and Methods

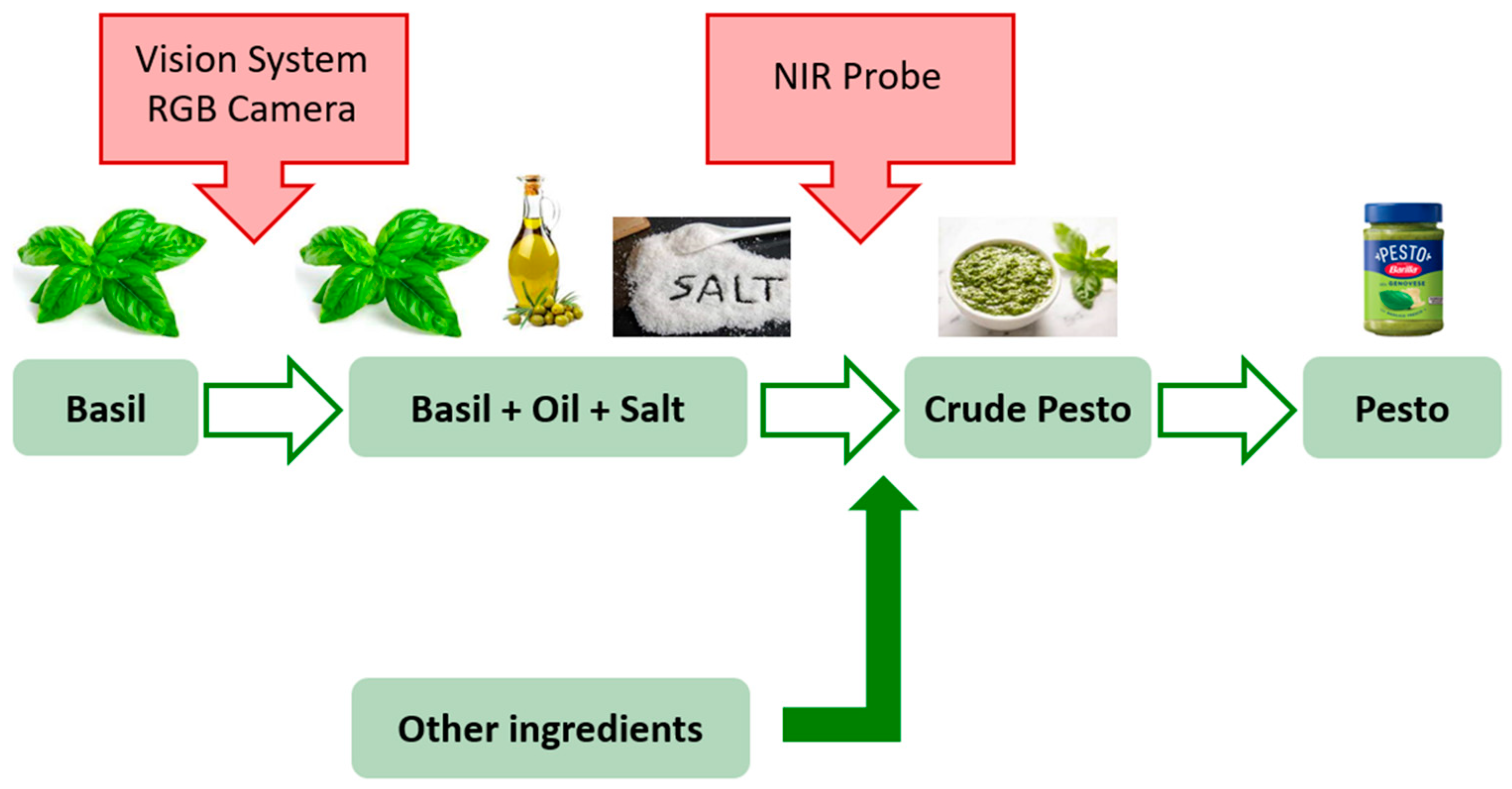

2.1. Process Description

2.2. Reference Analysis

2.3. On-Line Instrumentation

2.4. Data Analysis

2.4.1. Preprocessing

- Vision System Data

- NIR spectra prior to PCA and MSPC

- NIR spectra prior to PLS regression

2.4.2. Principal Component Analysis

2.4.3. Multivariate Control Charts

2.4.4. PLS Regression

3. Results and Discussion

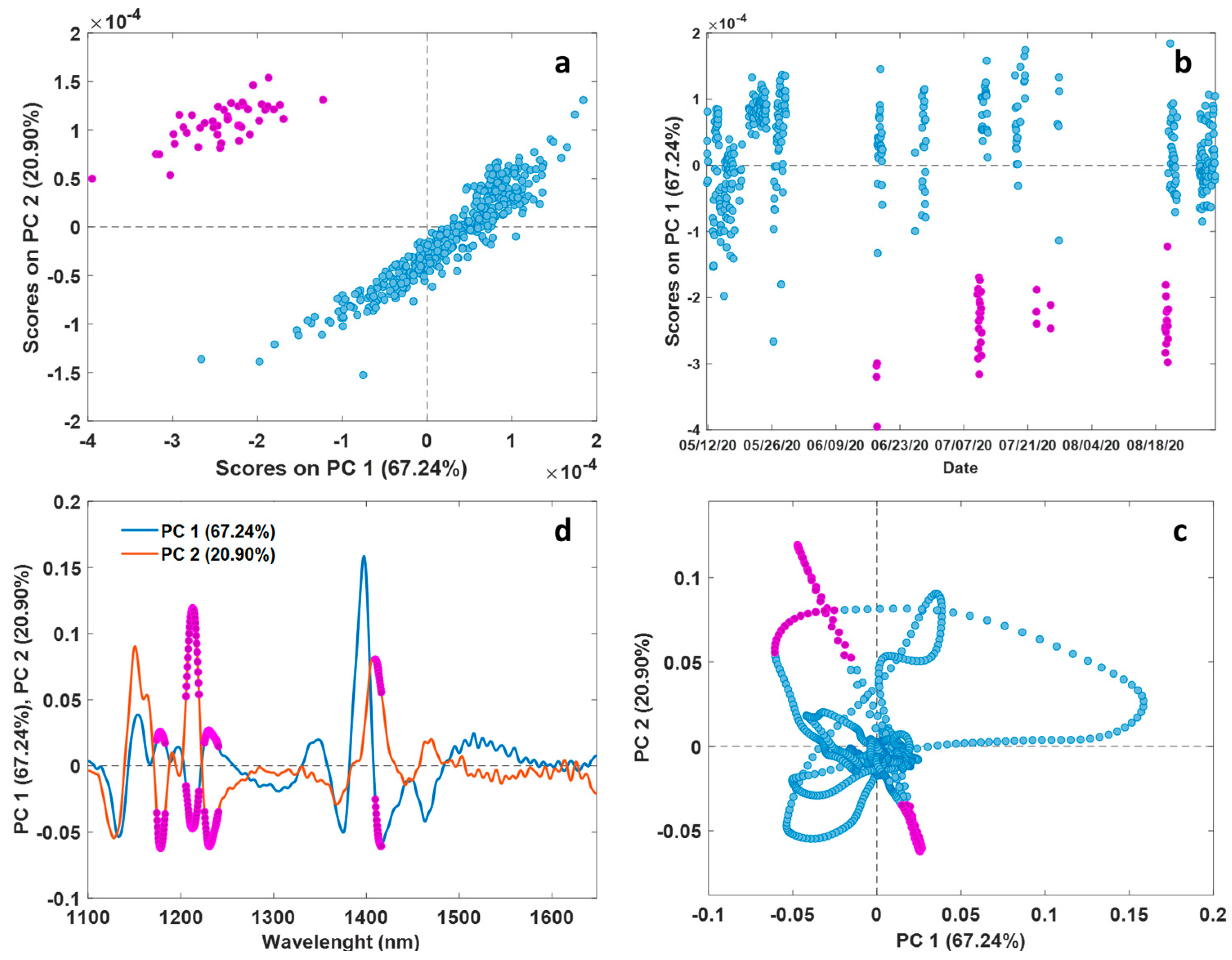

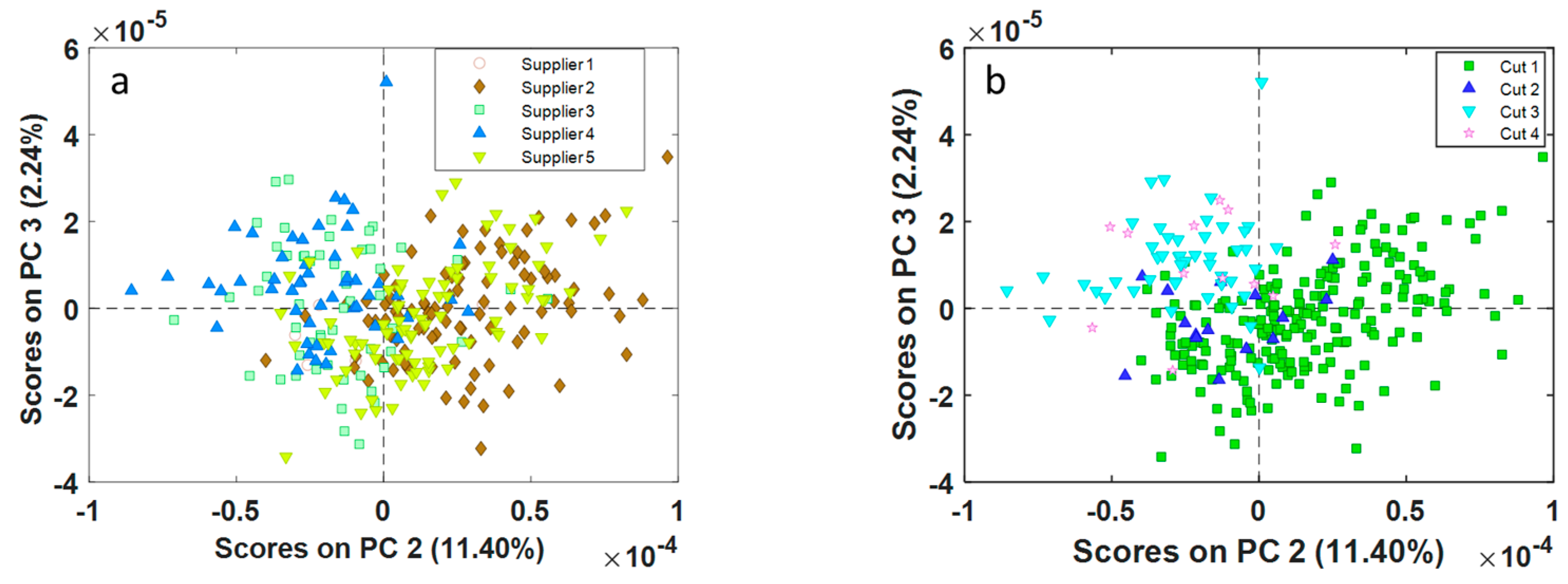

3.1. Exploratory Data Analysis

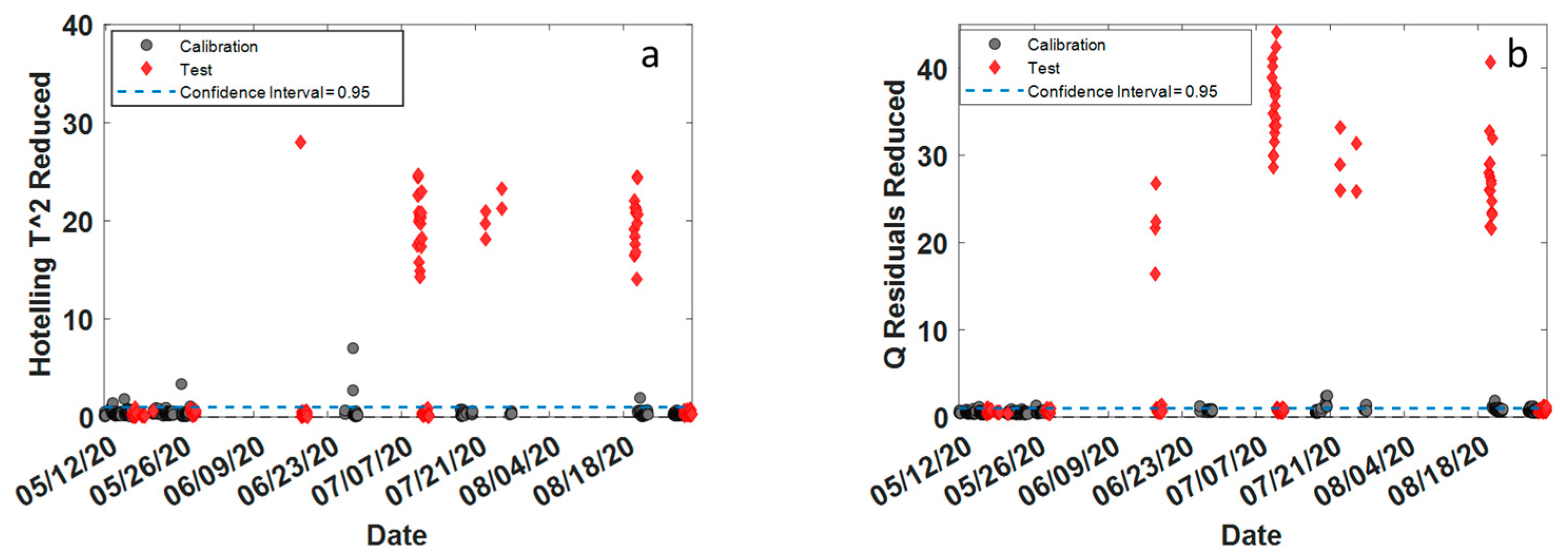

3.2. MSPC Charts

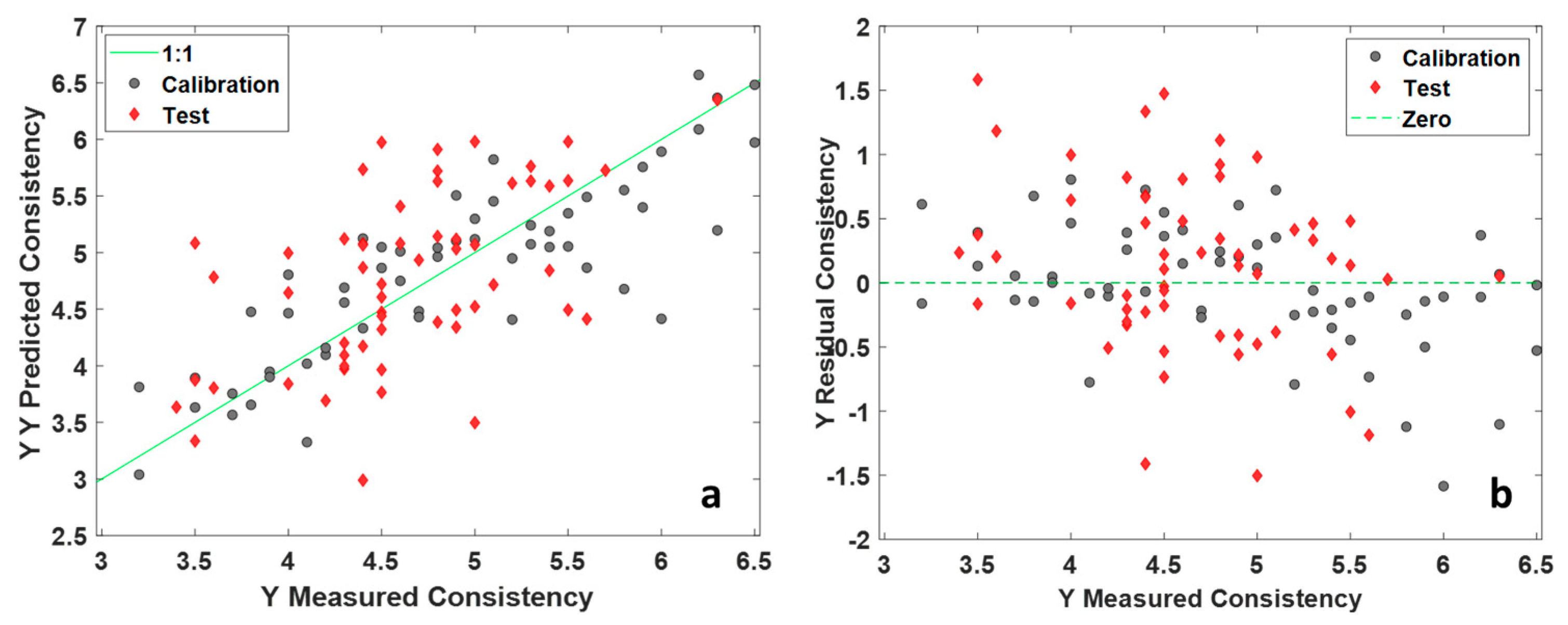

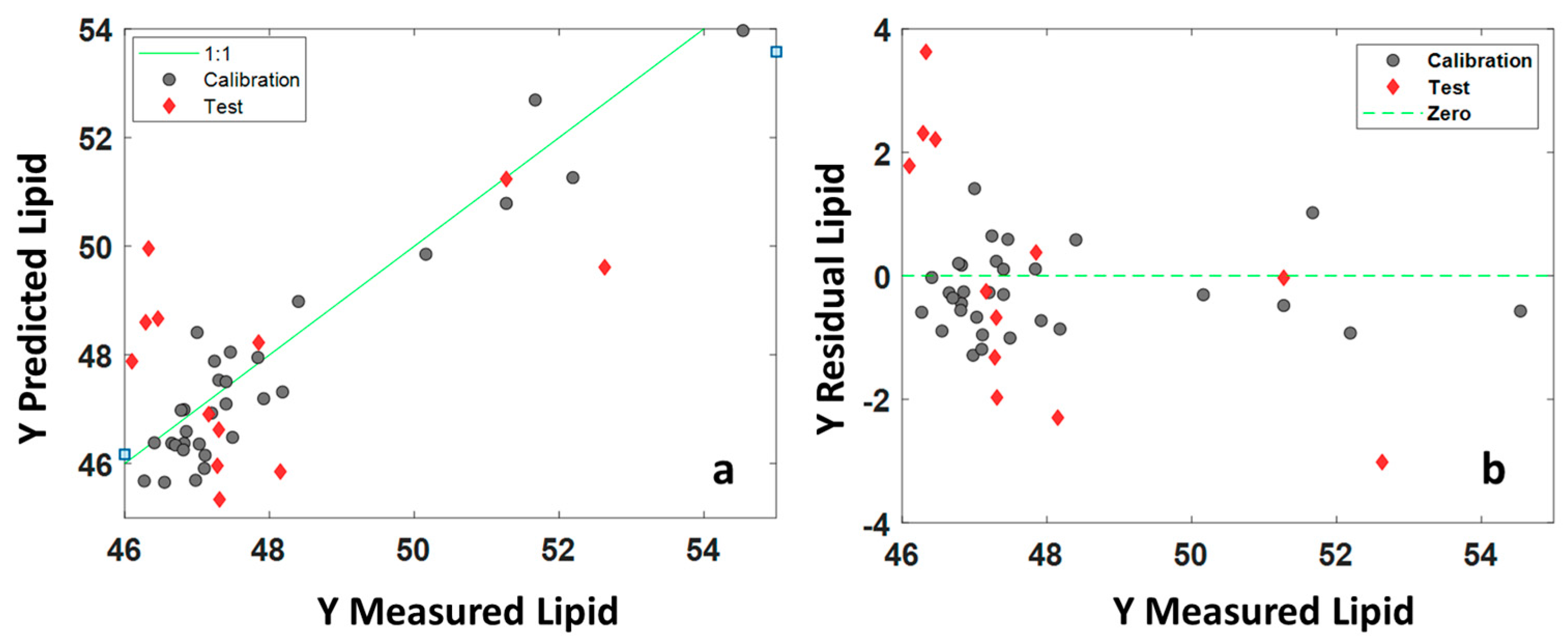

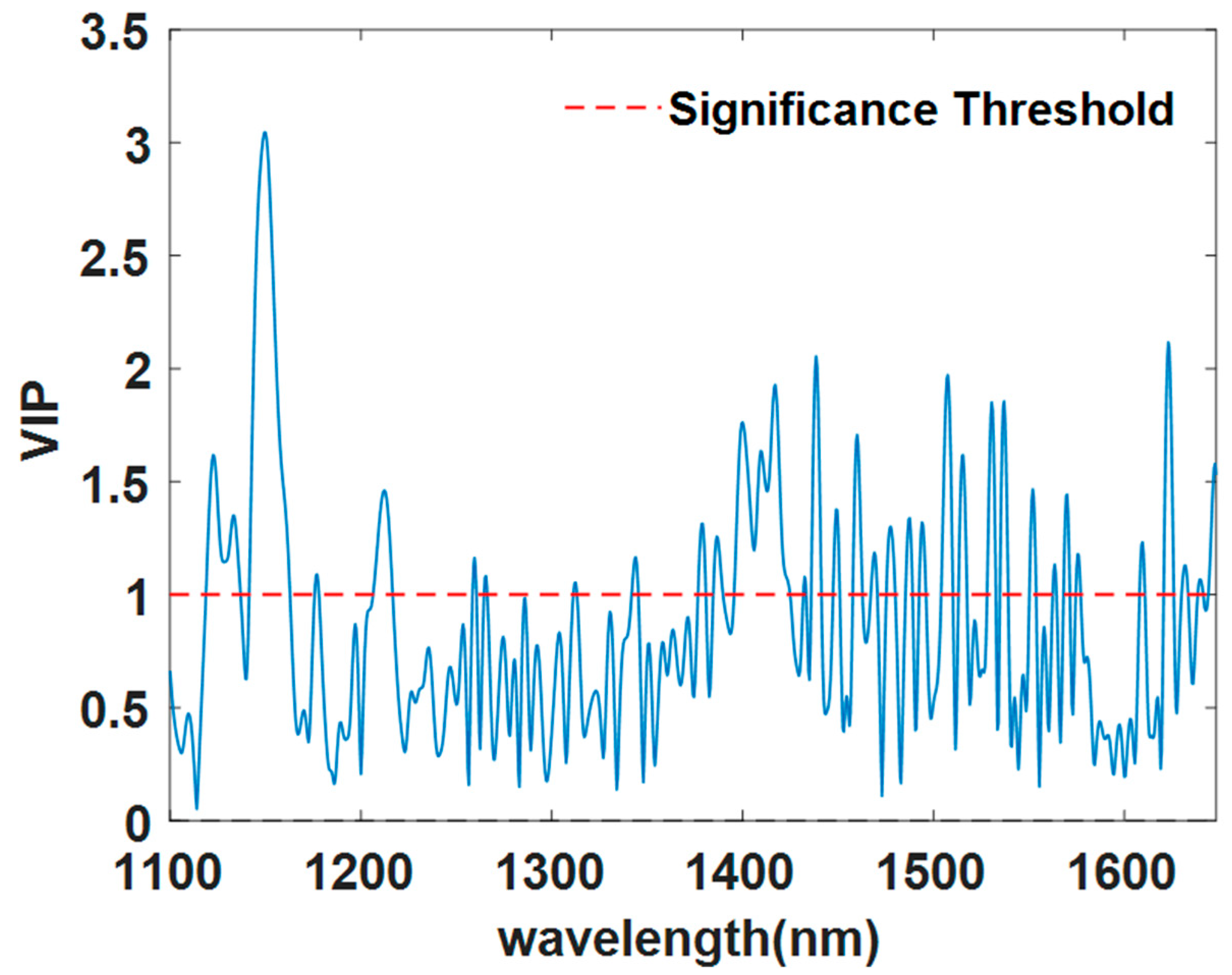

3.3. Predictive Models

4. Conclusions

4.1. MSPC Results

4.2. On-Line Predictive Models

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferrer-Riquelme, A. Statistical Control of Measures and Processes. In Comprehensive Chemometrics; Elsevier: Amsterdam, The Netherlands, 2009; pp. 97–126. [Google Scholar]

- Grassi, S.; Strani, L.; Alamprese, C.; Pricca, N.; Casiraghi, E.; Cabassi, G. A FT-NIR process analytical technology approach for milk renneting control. Foods 2022, 11, 33. [Google Scholar] [CrossRef] [PubMed]

- Franca, L.; Grassi, S.; Pimentel, M.F.; Amigo, J.M. A single model to monitor multistep craft beer manufacturing using near infrared spectroscopy and chemometrics. Food Bioprod. Process. 2021, 126, 95–103. [Google Scholar] [CrossRef]

- Zhou, Q.; Dai, Z.; Song, F.; Li, Z.; Song, C.; Ling, C. Monitoring black tea fermentation quality by intelligent sensors: Comparison of image, e-nose and data fusion. Food Biosci. 2023, 52, 102454. [Google Scholar] [CrossRef]

- Catelani, T.A.; Santos, J.R.; Páscoa, R.N.; Pezza, L.; Pezza, H.R.; Lopes, J.A. Real-time monitoring of a coffee roasting process with near infrared spectroscopy using multivariate statistical analysis: A feasibility study. Talanta 2018, 179, 292–299. [Google Scholar] [CrossRef]

- Hao, Y.; Lu, Y.; Li, X. Study on robust model construction method of multi-batch fruit online sorting by near-infrared spectroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2022, 280, 121478. [Google Scholar] [CrossRef]

- Strani, L.; Grassi, S.; Alamprese, C.; Casiraghi, E.; Ghiglietti, R.; Locci, F.; Pricca, N.; De Juan, A. Effect of physicochemical factors and use of milk powder on milk rennet-coagulation: Process understanding by near infrared spectroscopy and chemometrics. Food Control 2021, 119, 1074. [Google Scholar] [CrossRef]

- Maléchaux, A.; Le Dréau, Y.; Artaud, J.; Dupuy, N. Control chart and data fusion for varietal origin discrimination: Application to olive oil. Talanta 2020, 217, 121115. [Google Scholar] [CrossRef]

- Pérez-Beltrán, C.H.; Jiménez-Carvelo, A.M.; Torrente-López, A.; Navas, N.A.; Cuadros-Rodríguez, L. QbD/PAT—State of the Art of Multivariate Methodologies in Food and Food-Related Biotech Industries. Food Eng. Rev. 2023, 15, 24–40. [Google Scholar] [CrossRef]

- Grassi, S.; Alamprese, C. Advances in NIR spectroscopy applied to process analytical technology in food industries. Curr. Opin. Food Sci. 2018, 22, 17–21. [Google Scholar] [CrossRef]

- Pu, Y.Y.; O’Donnell, C.; Tobin, J.T.; O’Shea, N. Review of near-infrared spectroscopy as a process analytical technology for real-time product monitoring in dairy processing. Int. Dairy J. 2020, 103, 104623. [Google Scholar] [CrossRef]

- Baines, T.; Brown, S.; Benedettini, O.; Ball, P.D. Examining green production and its role within the competitive strategy of manufacturers. J. Ind. Eng. Manag. 2012, 5, 53–87. [Google Scholar] [CrossRef]

- Rico-Rodriguez, F.; Strani, L.; Grassi, S.; Lancheros, R.; Serrato, J.C.; Casiraghi, E. Study of Galactooligosaccharides production from dairy waste by FTIR and chemometrics as Process Analytical Technology. Food Bioprod. Process. 2021, 126, 113–120. [Google Scholar] [CrossRef]

- Strani, L.; Mantovani, E.; Bonacini, F.; Marini, F.; Cocchi, M. Fusing NIR and Process Sensors Data for Polymer Production Monitoring. Front. Chem. 2021, 9, 785. [Google Scholar] [CrossRef] [PubMed]

- Westerhuis, J.A.; Gurden, S.P.; Smilde, A.K. Generalized contribution plots in multivariate statistical process monitoring. Chemom. Intell. Lab. Syst. 2000, 51, 95–114. [Google Scholar] [CrossRef]

- Avila, C.; Mantzaridis, C.; Ferré, J.; de Oliveira, R.R.; Kantojärvi, U.; Rissanen, A.; Krassa, P.; De Juan, A.; Muller, F.L.; Hunter, T.; et al. Acid number, viscosity and end-point detection in a multiphase high temperature polymerisation process using an online miniaturised MEMS Fabry-Pérot interferometer. Talanta 2021, 224, 121735. [Google Scholar] [CrossRef] [PubMed]

- Macho, S.; Rius, A.; Callao, M.P.; Larrechi, M.S. Monitoring ethylene content in heterophasic copolymers by near-infrared spectroscopy: Standardisation of the calibration model. Anal. Chim. Acta 2001, 445, 213–220. [Google Scholar] [CrossRef]

- Joshi, K.; Patil, B. Multivariate statistical process monitoring and control of machining process using principal component-based Hotelling T2 charts: A machine vision approach. Int. J. Product. Qual. Manag. 2022, 35, 40–56. [Google Scholar] [CrossRef]

- Biancolillo, A.; Scappaticci, C.; Foschi, M.; Rossini, C.; Marini, F. Coupling of NIR Spectroscopy and Chemometrics for the Quantification of Dexamethasone in Pharmaceutical Formulations. Pharmaceuticals 2023, 16, 309. [Google Scholar] [CrossRef]

- de Oliveira, R.R.; Pedroza, R.H.; Sousa, A.O.; Lima, K.M.; de Juan, A. Process modeling and control applied to real-time monitoring of distillation processes by near-infrared spectroscopy. Anal. Chim. Acta 2017, 985, 41–53. [Google Scholar] [CrossRef]

- Kourti, T. Application of latent variable methods to process control and multivariate statistical process control in industry. Int. J. Adapt. Control Signal Process. 2005, 19, 213–246. [Google Scholar] [CrossRef]

- Strani, L.; Vitale, R.; Tanzilli, D.; Bonacini, F.; Perolo, A.; Mantovani, E.; Ferrando, A.; Cocchi, M. A Multiblock Approach to Fuse Process and Near-Infrared Sensors for On-Line Prediction of Polymer Properties. Sensors 2022, 22, 1436. [Google Scholar] [CrossRef]

- Zeaiter, M.; Roger, J.M.; Bellon-Maurel, V. Dynamic orthogonal projection. A new method to maintain the on-line robustness of multivariate calibrations. Application to NIR-based monitoring of wine fermentations. Chemom. Intell. Lab. Syst. 2006, 80, 227–235. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Bro, R.; Smilde, A.K. Principal component analysis. Anal. Methods 2014, 6, 2812–2831. [Google Scholar] [CrossRef]

- Jackson, J.E.; Hearne, F.T. Hotelling’s TM2 for Principal Components—What about Absolute Values? Technometrics 1979, 21, 253–255. [Google Scholar]

- Nomikos, P.; MacGregor, J.F. Multivariate SPC charts for monitoring batch processes. Technometrics 1995, 37, 41–59. [Google Scholar] [CrossRef]

- Wold, S.; Sjöström, M.; Eriksson, L. PLS-regression: A basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Snee, R.D. Validation of regression models: Methods and examples. Technometrics 1977, 19, 415–428. [Google Scholar] [CrossRef]

- Galtier, O.; Dupuy, N.; Le Dréau, Y.; Ollivier, D.; Pinatel, C.; Kister, J.; Artaud, J. Geographic origins and compositions of virgin olive oils determinated by chemometric analysis of NIR spectra. Anal. Chim. Acta 2007, 595, 136–144. [Google Scholar] [CrossRef]

- Casale, M.; Simonetti, R. Near infrared spectroscopy for analysing olive oils. J. Near Infrared Spectrosc. 2014, 22, 59–80. [Google Scholar] [CrossRef]

- Wold, S.; Johansson, E.; Cocchi, M. PLS: Partial least squares projections to latent structures. In 3D QSAR in Drug Design: Theory, Methods and Applications; Kluwer ESCOM Science Publisher: Dordrecht/Leiden, The Netherlands, 1993; pp. 523–550. [Google Scholar]

| Method | LVs | RMSECV | RMSEP |

|---|---|---|---|

| Consistency (cm) | 9 | 0.64 | 0.68 |

| Lipids (%) | 5 | 1.59 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanzilli, D.; D’Alessandro, A.; Tamelli, S.; Durante, C.; Cocchi, M.; Strani, L. A Feasibility Study towards the On-Line Quality Assessment of Pesto Sauce Production by NIR and Chemometrics. Foods 2023, 12, 1679. https://doi.org/10.3390/foods12081679

Tanzilli D, D’Alessandro A, Tamelli S, Durante C, Cocchi M, Strani L. A Feasibility Study towards the On-Line Quality Assessment of Pesto Sauce Production by NIR and Chemometrics. Foods. 2023; 12(8):1679. https://doi.org/10.3390/foods12081679

Chicago/Turabian StyleTanzilli, Daniele, Alessandro D’Alessandro, Samuele Tamelli, Caterina Durante, Marina Cocchi, and Lorenzo Strani. 2023. "A Feasibility Study towards the On-Line Quality Assessment of Pesto Sauce Production by NIR and Chemometrics" Foods 12, no. 8: 1679. https://doi.org/10.3390/foods12081679

APA StyleTanzilli, D., D’Alessandro, A., Tamelli, S., Durante, C., Cocchi, M., & Strani, L. (2023). A Feasibility Study towards the On-Line Quality Assessment of Pesto Sauce Production by NIR and Chemometrics. Foods, 12(8), 1679. https://doi.org/10.3390/foods12081679