Physicochemical Quality Retention during Cold Storage of Prepackaged Barramundi Meat Processed with a New Microwave-Assisted Induction Heating Technology

Abstract

:1. Introduction

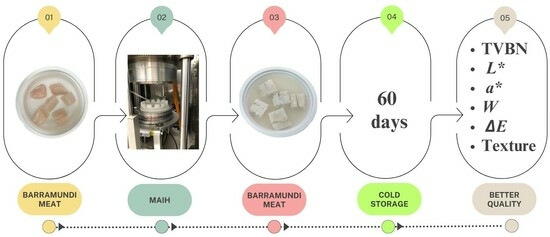

2. Materials and Methods

2.1. Preparing Barramundi Meat Samples

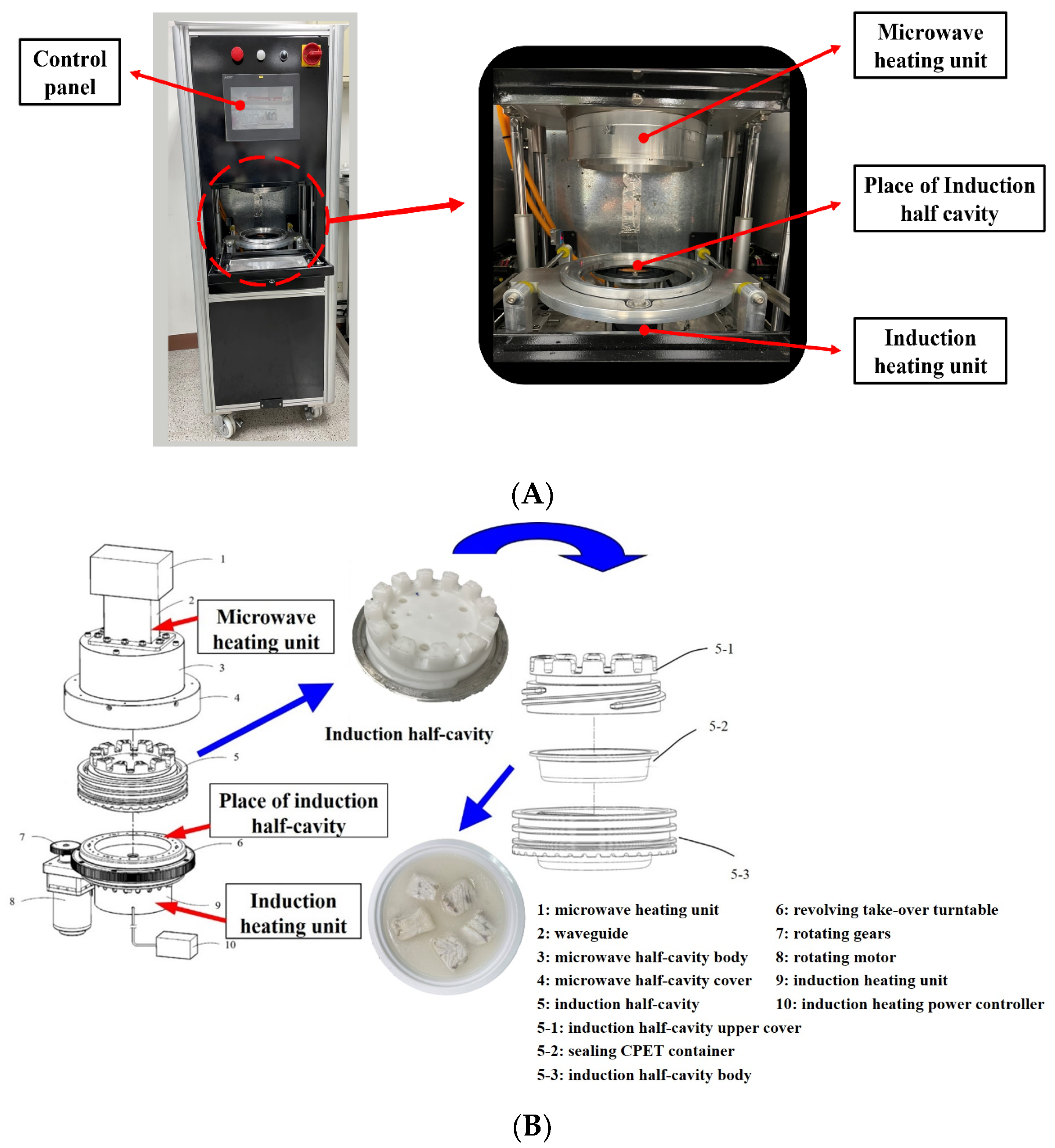

2.2. Conditions for Heating Barramundi Meat with MAIH and Boiling

2.3. Storage Test

2.4. Testing the Microbial Quality

2.5. Numeric Analysis of Colors

2.6. Texture Analysis

2.7. TVBN Content and pH Value

2.8. Statistical Analysis

3. Results and Discussion

3.1. Changes in the Microbial Count of the Barramundi Meat Heated with Different Methods during Cold Storage

3.2. Changes in the Color Values of the Barramundi Meat Heated with Different Methods during Cold Storage

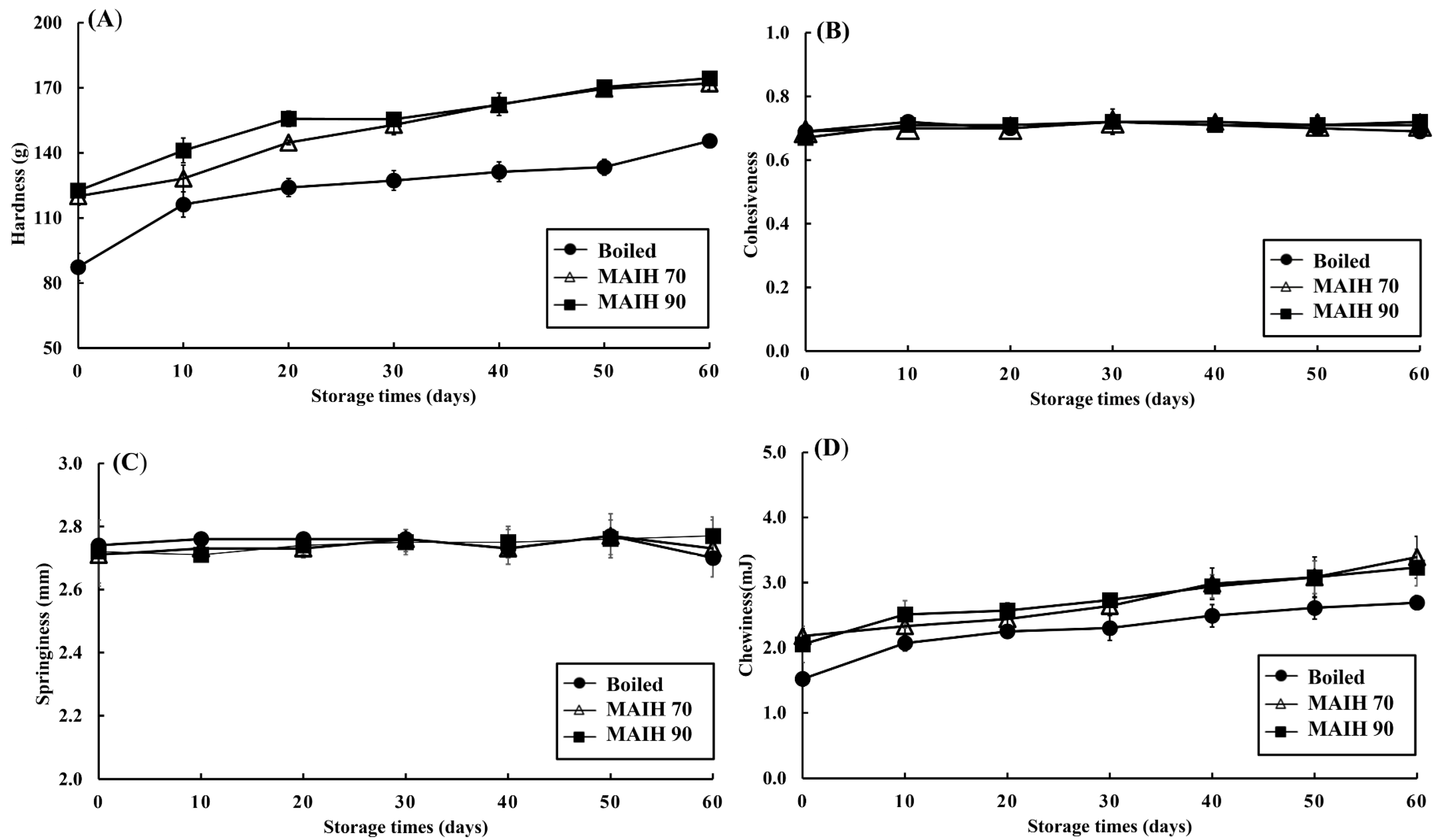

3.3. Changes in the Texture of the Barramundi Meat Heated Using Different Methods during Cold Storage

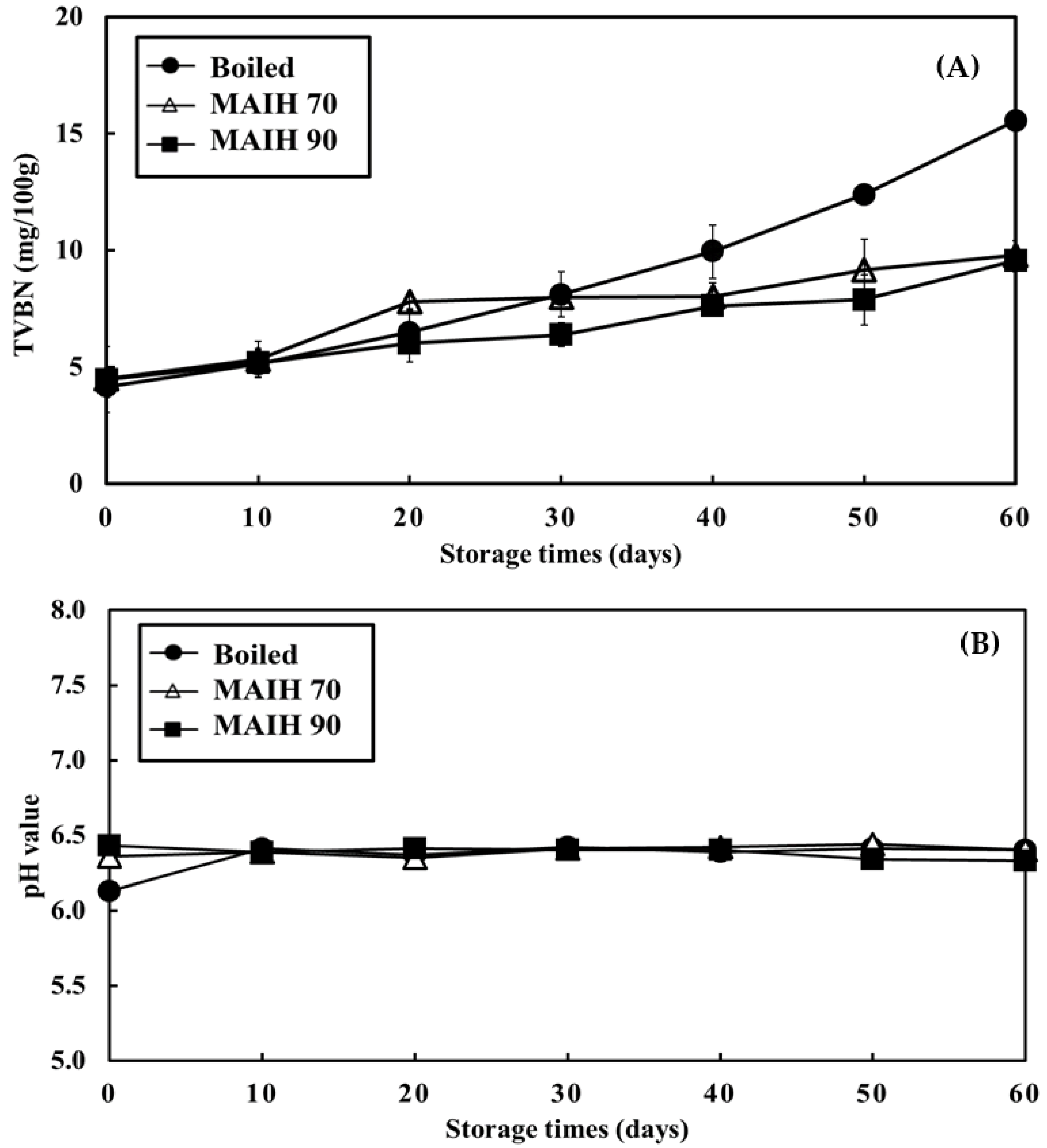

3.4. Changes in TVBN Content and pH Value of the Barramundi Meat Heated Using Different Methods during Cold Storage

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tang, J. Unlocking potentials of microwaves for food safety and quality. J. Food Sci. 2015, 80, E1776–E1793. [Google Scholar] [CrossRef] [PubMed]

- Datta, A.K.; Davidson, P.M. Microwave and radio frequency processing. J. Food Sci. 2000, 65, 32–41. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave food processing—A review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Non-uniform temperature distribution during microwave heating of food materials—A review. Food Bioprocess Technol. 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Chizoba Ekezie, F.G.C.; Sun, D.W.; Han, Z.; Cheng, J.H. Microwave-assisted food processing technologies for enhancing product quality and process efficiency: A review of recent developments. Trends Food Sci. Technol. 2017, 67, 58–69. [Google Scholar] [CrossRef]

- Tang, J.; Hong, Y.K.; Inanoglu, S.; Liu, F. Microwave pasteurization for ready-to-eat meals. Curr. Opin. Food Sci. 2018, 23, 133–141. [Google Scholar] [CrossRef]

- Bornhorst, E.R.; Liu, F.; Tang, J.; Sablani, S.S.; Barbosa-Canovas, G.V. Food quality evaluation using model foods: A comparison study between microwave-assisted and conventional thermal pasteurization process. Food Bioprocess Technol. 2017, 10, 1248–1256. [Google Scholar] [CrossRef]

- Guo, Q.; Sun, D.W.; Cheng, J.H.; Han, Z. Microwave processing techniques and their recent applications in the food industry. Trends Food Sci. Technol. 2017, 67, 236–247. [Google Scholar] [CrossRef]

- Tsai, Y.H.; Hwang, C.C.; Lin, C.S.; Lin, C.Y.; Ou, T.Y.; Chang, T.H.; Lee, Y.C. Comparison of microwave-assisted induction heating system (MAIH) and individual heating methods on the quality of pre-packaged white shrimp. Innov. Food Sci. Emerg. Technol. 2021, 73, 102787. [Google Scholar] [CrossRef]

- Chang, H.I.; Chin, K.T.; Yu, Y.C.; Hsieh, J.K.; Lin, C.H. Cavity Detachable Modular Composite Microwave Heating System. Taiwan Patent No. I614457, 2 November 2018. [Google Scholar]

- Lee, Y.C.; Lin, C.S.; Zeng, W.H.; Hwang, C.C.; Chiu, K.; Ou, T.Y.; Chang, T.H.; Tsai, Y.H. Effect of a novel microwave-assisted induction heating (MAIH) technology on the quality of prepackaged Asian hard clam (Meretrix lusoria). Foods 2021, 10, 2299. [Google Scholar] [CrossRef]

- Tsai, Y.H.; Hwang, C.C.; Zeng, W.H.; Huang, Y.R.; Ou, T.Y.; Chang, T.H.; Lee, S.H.; Lee, Y.C. Retardation of quality loss and extension of shelf life of prepackaged hard clam heating by a novel microwave-assisted induction heating (MAIH) during refrigerated storage. Food Control 2022, 141, 109187. [Google Scholar] [CrossRef]

- Tsai, Y.H.; Hwang, C.C.; Kao, J.C.; Ou, T.Y.; Chang, T.H.; Lee, S.H.; Lee, Y.C. Cooking and pasteurizing evaluation of Barramundi (Lates calcarifer) meats subjected to an emerging microwave-assisted induction heating (MAIH) technology. Innov. Food Sci. Emerg. Technol. 2022, 80, 103089. [Google Scholar] [CrossRef]

- Cobb, B.F.; Alaniz, I.; Thompson, C.A. Biochemical and microbial studies on shrimp: Volatile nitrogen and amino nitrogen analysis. J. Food Sci. 1973, 38, 431–435. [Google Scholar] [CrossRef]

- Lee, Y.C.; Tsai, Y.H.; Hwang, C.C.; Lin, C.Y.; Huang, Y.R. Evaluating the effect of an emerging microwave-assisted induction heating (MAIH) on the quality and shelf life of prepackaged Pacific white shrimp Litopenaeus vannamei stored at 4 °C in Taiwan. Food Control 2022, 133, 108509. [Google Scholar] [CrossRef]

- Li, C.H.; Bland, J.M.; Bechtel, P.J. Effect of precooking and polyphosphate treatment on the quality of microwave cooked catfish fillets. Food Sci. Nutr. 2017, 5, 812–819. [Google Scholar] [CrossRef]

- Xue, Q.; Xue, C.; Luan, D.; Wen, Y.; Bi, S.; Wei, Z.; Mou, H. Comprehensive investigation into quality of pasteurized Oncorhynchus keta Walbaum fillets and non-thermal effects of microwave. LWT Food Sci. Technol. 2021, 146, 111466. [Google Scholar] [CrossRef]

- Islam, M.A.; Mohibbullah, M.; Suraiya, S.; Sarower-E-Mahfuj, M.; Ahmed, S.; Haq, M. Nutritional characterization of freshwater mud eel (Monopterus cuchia) muscle cooked by different thermal processes. Food Sci. Nutr. 2020, 8, 6247–6258. [Google Scholar] [CrossRef]

- Connell, J.J. Methods of assessing and selecting for quality. In Control of Fish Quality, 3rd ed.; Fishing News Books: Oxford, UK, 1990; pp. 122–150. [Google Scholar]

- Pivarnik, L.F.; Thiam, M.; Christopher Ellis, P. Rapid determination of volatile bases in fish by using an ammonia ion-selective electrode. J. AOAC Int. 1998, 81, 1011–1022. [Google Scholar] [CrossRef]

- Bekhit, A.E.-D.A.; Holman, B.W.B.; Giteru, S.G.; Hopkins, D.L. Total volatile basic nitrogen (TVB-N) and its role in meat spoilage: A review. Trends Food Sci. Technol. 2021, 109, 280–302. [Google Scholar] [CrossRef]

- Sibirny, V.; Demkiv, O.; Pavlishko, H.M.; Honchar, T.; Gonchar, M. Alcohol oxidase- and formaldehyde dehydrogenase-based enzymatic methods for formaldehyde assay in fish food products. Food Chem. 2011, 127, 774–779. [Google Scholar] [CrossRef]

- Lin, J.K.; Hurng, D.C. Thermal conversion of trimethylamine-N-oxide to trimethylamine and dimethylamine in squids. Food Chem. Toxicol. 1985, 23, 579–583. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Li, J.; Jia, J. Effects of thermal processing and various chemical substances on formaldehyde and dimethylamine formation in squid Dosidicus gigas. J. Sci. Food Agric. 2012, 92, 2436–2442. [Google Scholar] [CrossRef] [PubMed]

| Treatments | Storage Time (Days) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | 40 | 50 | 60 | ||

| APC | Boiled | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| (log CFU/g) | MAIH 70 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| MAIH 90 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | |

| PBC | Boiled | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| (log CFU/g) | MAIH 70 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| MAIH 90 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | |

| HBC | Boiled | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| (log CFU/g) | MAIH 70 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| MAIH 90 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | |

| V. parahaemolyticus | Boiled | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| (log CFU/g) | MAIH 70 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| MAIH 90 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | |

| Coliform | Boiled | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| (log CFU/g) | MAIH 70 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| MAIH 90 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | |

| E. coli | Boiled | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| (log CFU/g) | MAIH 70 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| MAIH 90 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | |

| Color | Treatments | Storage Time (Days) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | 40 | 50 | 60 | ||

| L* | Boiled | 81.74 ± 0.08 aA *1 | 78.64 ± 0.12 bC | 78.77 ± 0.26 bC | 77.68 ± 0.30 cC | 76.37 ± 0.27 eC | 76.87 ± 0.08 dB | 75.81 ± 0.18 fC |

| MAIH 70 | 81.88 ± 0.22 aA | 80.89 ± 0.04 bA | 79.93 ± 0.06 cA | 79.45 ± 0.07 dA | 79.46 ± 0.47 dA | 78.76 ± 0.37 eA | 79.18 ± 0.21 deA | |

| MAIH 90 | 81.19 ± 0.77 aA | 80.61 ± 0.16 aB | 79.36 ± 0.17 bB | 78.60 ± 0.38 bcB | 78.54 ± 0.58 bcB | 78.14 ± 0.99 cA | 78.31 ± 0.63 dB | |

| a* | Boiled | 1.53 ± 0.15 aB | 1.20 ± 0.15 bB | 1.07 ± 0.03 bB | 0.69 ± 0.03 cB | 0.64 ± 0.06 cB | 0.58 ± 0.04 cB | 0.57 ± 0.01 cB |

| MAIH 70 | 2.00 ± 0.11 aA | 1.53 ± 0.05 bA | 1.36 ± 0.21 bcA | 1.16 ± 0.09 cdA | 1.08 ± 0.05 dA | 0.94 ± 0.24 dA | 0.95 ± 0.11 dA | |

| MAIH 90 | 1.60 ± 0.03 aB | 1.49 ± 0.04 aA | 1.27 ± 0.03 bAB | 1.12 ± 0.02 cA | 1.08 ± 0.08 cdA | 1.06 ± 0.11 cdA | 0.93 ± 0.16 dA | |

| b* | Boiled | 10.61 ± 0.13 eB | 11.62 ± 0.16 dA | 11.39 ± 0.31 dB | 11.85 ± 0.58 cdB | 12.23 ± 0.19 cB | 13.45 ± 0.04 bA | 14.18 ± 0.03 aA |

| MAIH 70 | 11.02 ± 0.07 fA | 11.58 ± 0.17 eA | 12.12 ± 0.07 dA | 13.15 ± 0.11 cA | 13.27 ± 0.30 cA | 13.59 ± 0.16 bA | 14.32 ± 0.21 aA | |

| MAIH 90 | 11.24 ± 0.14 dA | 11.47 ± 0.01 dA | 12.14 ± 0.08 cA | 13.26 ± 0.16 bA | 13.57 ± 0.14 bA | 13.81 ± 0.73 bA | 14.43 ± 0.45 aA | |

| W | Boiled | 78.53 ± 0.36 aA | 74.18 ± 0.05 eB | 75.85 ± 0.27 cB | 74.58 ± 0.19 dC | 74.16 ± 0.18 eB | 74.46 ± 0.13 bC | 74.37 ± 0.14 deB |

| MAIH 70 | 78.54 ± 0.07 aA | 78.62 ± 0.47 aA | 76.72 ± 0.52 bA | 75.70 ± 0.15 cA | 75.72 ± 0.57 cA | 75.25 ± 0.07 cA | 75.36 ± 0.31 cA | |

| MAIH 90 | 78.79 ± 0.07 aA | 77.99 ± 0.63 bA | 76.48 ± 0.31 cAB | 75.25 ± 0.08 deB | 75.75 ± 0.12 dA | 75.30 ± 0.05 fB | 75.05 ± 0.25 eA | |

| ΔE | Boiled | - | 3.28 ± 0.18 dA | 3.11 ± 0.17 dA | 4.33 ± 0.45 cA | 5.68 ± 0.19 bA | 5.71 ± 0.04 bA | 6.98 ± 0.14 aA |

| MAIH 70 | - | 1.24 ± 0.02 dB | 2.33 ± 0.04 cB | 3.34 ± 0.01 bB | 3.45 ± 0.15 bB | 4.18 ± 0.44 aB | 4.40 ± 0.06 aB | |

| MAIH 90 | - | 0.64 ± 0.15 cC | 2.07 ± 0.12 bC | 3.33 ± 0.20 aB | 3.57 ± 0.53 aB | 4.04 ± 1.20 aB | 4.36 ± 0.73 aB | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, C.-C.; Chien, H.-I.; Lee, Y.-C.; Kao, J.-C.; Huang, Y.-R.; Huang, Y.-L.; Huang, C.-Y.; Tsai, Y.-H. Physicochemical Quality Retention during Cold Storage of Prepackaged Barramundi Meat Processed with a New Microwave-Assisted Induction Heating Technology. Foods 2023, 12, 3140. https://doi.org/10.3390/foods12163140

Hwang C-C, Chien H-I, Lee Y-C, Kao J-C, Huang Y-R, Huang Y-L, Huang C-Y, Tsai Y-H. Physicochemical Quality Retention during Cold Storage of Prepackaged Barramundi Meat Processed with a New Microwave-Assisted Induction Heating Technology. Foods. 2023; 12(16):3140. https://doi.org/10.3390/foods12163140

Chicago/Turabian StyleHwang, Chiu-Chu, Hung-I Chien, Yi-Chen Lee, Jun-Cheng Kao, Yu-Ru Huang, Ya-Ling Huang, Chun-Yung Huang, and Yung-Hsiang Tsai. 2023. "Physicochemical Quality Retention during Cold Storage of Prepackaged Barramundi Meat Processed with a New Microwave-Assisted Induction Heating Technology" Foods 12, no. 16: 3140. https://doi.org/10.3390/foods12163140

APA StyleHwang, C.-C., Chien, H.-I., Lee, Y.-C., Kao, J.-C., Huang, Y.-R., Huang, Y.-L., Huang, C.-Y., & Tsai, Y.-H. (2023). Physicochemical Quality Retention during Cold Storage of Prepackaged Barramundi Meat Processed with a New Microwave-Assisted Induction Heating Technology. Foods, 12(16), 3140. https://doi.org/10.3390/foods12163140