Recent Advances in Halal Bioactive Materials for Intelligent Food Packaging Indicator

Abstract

:1. Introduction

2. Materials and Methods

3. Packaging for Food Safety and Quality

3.1. Food Packaging Materials

3.2. Petrochemical-Based Polymers

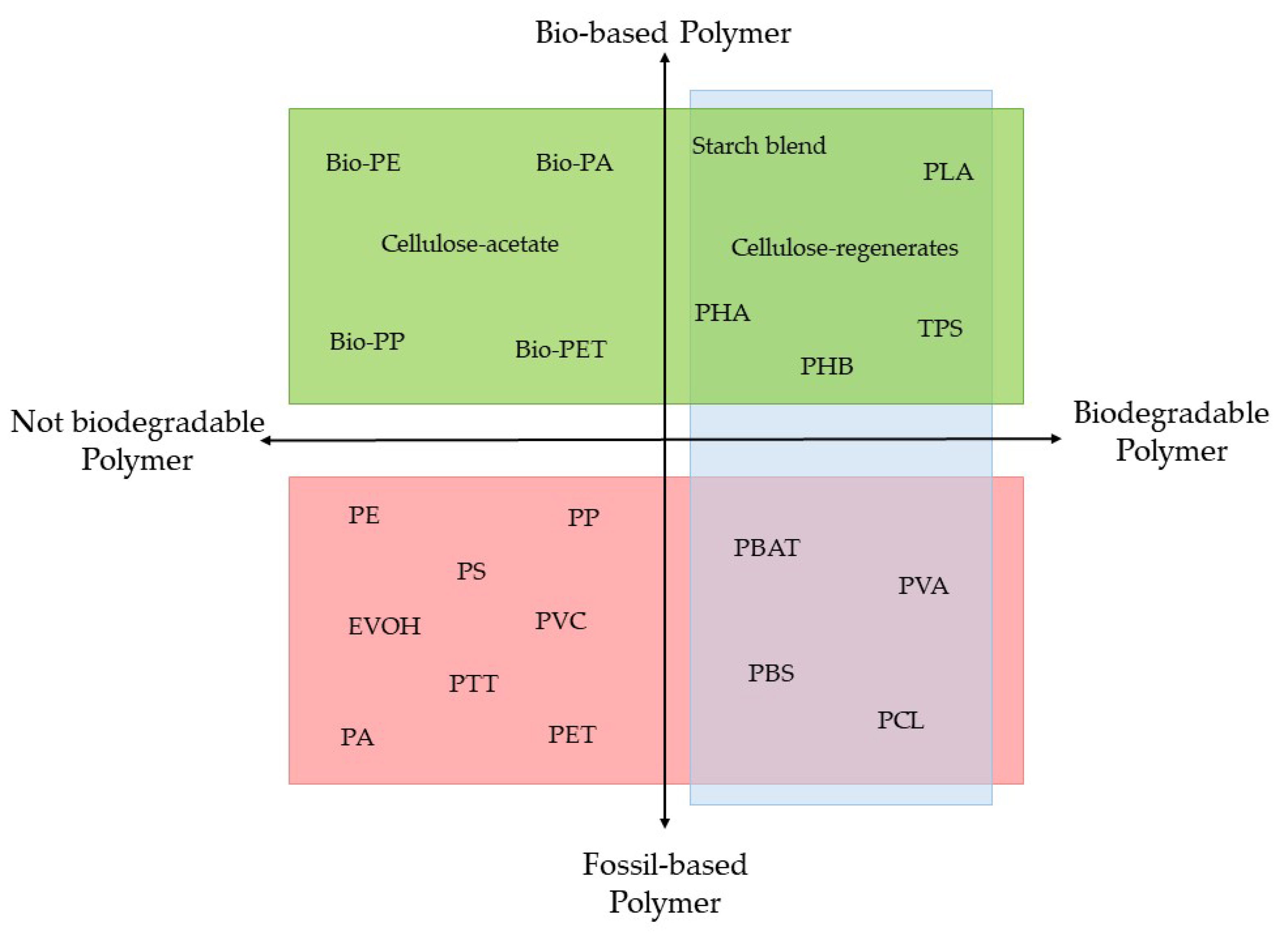

3.3. Bio-Based and Biodegradable Polymers

4. Intelligent Packaging

Intelligent Packaging Indicator

5. Active Materials for Intelligent Food Packaging Indicator

Halal Bioactive Materials for Intelligent Packaging

6. Recent Technologies

7. Recommendation

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Health Organization. Available online: https://www.who.int/publications/m/item/the-state-of-food-security-and-nutrition-in-the-world-2022. (accessed on 10 September 2022).

- Halonen, N.; Pálvölgyi, P.S.; Bassani, A.; Fiorentini, C.; Nair, R.; Spigno, G.; Kordas, K. Bio-Based Smart Materials for Food Packaging and Sensors–A Review. Front. Mater. 2020, 7, 82. [Google Scholar] [CrossRef] [Green Version]

- Mtolo, M.; Ruzengwe, F.; Ijabadeniyi, O.A. 14 Food packaging and packaging innovations. Food Science and Technology: Trends and Future. Prospects 2020, 1, 2. [Google Scholar]

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nogueira, G.F.; Oliveira, R.A.; Velasco, J.I.; Fakhouri, F.M. Methods of incorporating plant-derived bioactive compounds into films made with agro-based polymers for application as food packaging: A brief review. Polymers 2020, 12, 2518. [Google Scholar] [CrossRef] [PubMed]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties—From Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Vågsholm, I.; Arzoomand, N.S.; Boqvist, S. Food Security, Safety, and Sustainability—Getting the Trade-Offs Right. Front. Sustain. Food Syst. 2020, 4, 16. [Google Scholar] [CrossRef]

- Ghosh, S.; Sarkar, T.; Das, A.; Chakraborty, R. Natural colorants from plant pigments and their encapsulation: An emerging window for the food industry. LWT 2022, 153, 112527. [Google Scholar] [CrossRef]

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of fruits and vegetable wastes and by-products to produce natural pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563. [Google Scholar] [CrossRef]

- Tanna, B.; Choudhary, B.; Mishra, A.; Yadav, S.; Chauhan, O.; Elansary, H.O.; Shokralla, S.; El-Abedin, T.K.Z.; Mahmoud, E.A. Biochemical and Anti-proliferative activities of seven abundant tropical red seaweeds confirm nutraceutical potential of Grateloupia indica. Arab. J. Chem. 2022, 15, 103868. [Google Scholar] [CrossRef]

- Gallo, M.; Ferrara, L.; Calogero, A.; Montesano, D.; Naviglio, D. Relationships between food and diseases: What to know to ensure food safety. Food Res. Int. 2020, 137, 109414. [Google Scholar] [CrossRef]

- Jung, J.; Puligundla, P.; Ko, S. Proof-of-concept study of chitosan-based carbon dioxide indicator for food packaging applications. Food Chem. 2012, 135, 2170–2174. [Google Scholar] [CrossRef]

- Drago, E.; Campardelli, R.; Pettinato, M.; Perego, P. Innovations in Smart Packaging Concepts for Food: An Extensive Review. Foods 2020, 9, 1628. [Google Scholar] [CrossRef] [PubMed]

- Petrescu, D.C.; Vermeir, I.; Petrescu-Mag, R.M. Consumer Understanding of Food Quality, Healthiness, and Environmental Impact: A Cross-National Perspective. Int. J. Environ. Res. Public Health 2020, 17, 169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hong, L.G.; Yuhana, N.Y.; Zawawi, E.Z.E. Review of bioplastics as food packaging materials. AIMS Mater. Sci. 2021, 8, 166–184. [Google Scholar] [CrossRef]

- Ahmed, I.; Lin, H.; Zou, L.; Brody, A.L.; Li, Z.; Qazi, I.M.; Pavase, T.R.; Lv, L. A comprehensive review on the application of active packaging technologies to muscle foods. Food Control. 2017, 82, 163–178. [Google Scholar] [CrossRef]

- Majid, I.; Nayik, G.A.; Dar, S.M.; Nanda, V. Novel food packaging technologies: Innovations and future prospective. J. Saudi Soc. Agric. Sci. 2018, 17, 454–462. [Google Scholar] [CrossRef] [Green Version]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Muncke, J. Food Packaging Material. Available online: https://www.foodpackagingforum.org/food-packaging-health/food-packaging-materials (accessed on 17 May 2023).

- UN Environment Programme. Our Planet Is Choking on Plastics. Available online: https://www.unep.org/interactives/beat-plastic-pollution (accessed on 25 May 2023).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Domínguez, R.; Bohrer, B.; Pateiro, M.; Munekata, P.E.S.; Lorenzo, J.M. Packaging Systems. In Sustainable Production Technology in Food; Munekata, P.E.S., Lorenzo, J.M., Barba, F.J., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 49–69. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. Au 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Nagalakshmaiah, M.; Afrin, S.; Malladi, R.P.; Elkoun, S.; Robert, M.; Ansari, M.A.; Svedberg, A.; Karim, Z. Biocomposites: Present Trends and Challenges for the Future. In Green Composites for Automotive Applications; Woodhead Publishing: Sawston, UK, 2019; pp. 197–215. [Google Scholar] [CrossRef]

- Alim, A.A.; Shirajuddin, S.S.; Anuar, F.H. A review of nonbiodegradable and biodegradable composites for food packaging application. J. Chem. 2022, 2022, 7670819. [Google Scholar] [CrossRef]

- Stachowiak, T.; Łukasik, K. The Management of Polymer and Biodegradable Composite Waste in Relation to Petroleum-Based Thermoplastic Polymer Waste—In Terms of Energy Consumption and Processability. Sustainability 2021, 13, 3701. [Google Scholar] [CrossRef]

- Babu, R.P.; Oconnor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oyeoka, H.C.; Ewulonu, C.M.; Nwuzor, I.C.; Obele, C.M.; Nwabanne, J.T. Packaging and degradability properties of polyvinyl alcohol/gelatin nanocomposite films filled water hyacinth cellulose nanocrystals. J. Bioresour. Bioprod. 2021, 6, 168–185. [Google Scholar] [CrossRef]

- Sudesh, K.; Iwata, T. Sustainability of Biobased and Biodegradable Plastics. CLEAN Soil Air Water 2008, 36, 433–442. [Google Scholar] [CrossRef]

- Ramos, M.; Valdés, A.; Beltrán, A.; Garrigós, M.C. Gelatin-Based Films and Coatings for Food Packaging Applications. Coatings 2016, 6, 41. [Google Scholar] [CrossRef] [Green Version]

- Kizildag, N. Pullulan Films with PCMs: Recyclable Bio-Based Films with Thermal Management Functionality. Coatings 2023, 13, 414. [Google Scholar] [CrossRef]

- Trinetta, V.; Cutter, C.N. Pullulan: A Suitable Biopolymer for Antimicrobial Food Packaging Applications. In Antimicrobial Food Packaging; Barros-Velazquez, J., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 385–397. [Google Scholar]

- Getachew, A.T.; Ahmad, R.; Park, J.-S.; Chun, B.-S. Fish skin gelatin based packaging films functionalized by subcritical water extract from spent coffee ground. Food Packag. Shelf Life 2021, 29, 100735. [Google Scholar] [CrossRef]

- Chia, M.-R.; Ahmad, I.; Phang, S.-W. Starch/Polyaniline Biopolymer Film as Potential Intelligent Food Packaging with Colourimetric Ammonia Sensor. Polymers 2022, 14, 1122. [Google Scholar] [CrossRef]

- Smolander, M. Freshness indicators for food packaging. In Smart Packaging Technologies for Fast Moving Consumer Goods; Kerry, J., Butler, P., Eds.; John Wiley & Sons: West Sussex, UK, 2008; pp. 111–127. [Google Scholar]

- Kerry, J.; O’grady, M.; Hogan, S. Past, current and potential utilisation of active and intelligent packaging systems for meat and muscle-based products: A review. Meat Sci. 2006, 74, 113–130. [Google Scholar] [CrossRef] [PubMed]

- Kuswandi, B.; Wicaksono, Y.; Jayus, J.; Abdullah, A.; Heng, L.Y.; Ahmad, M. Smart packaging: Sensors for monitoring of food quality and safety. Sens. Instrum. Food Qual. Saf. 2011, 5, 137–146. [Google Scholar] [CrossRef]

- Mohebi, E.; Marquez, L. Intelligent packaging in meat industry: An overview of existing solutions. J. Food Sci. Technol. 2014, 52, 3947–3964. [Google Scholar] [CrossRef]

- Uçar, A.; Yilmaz, M.V.; Çakiroglu, F.P. Food Safety–Problems and Solutions. In Significance, Prevention and Control of Food Related Diseases; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Flórez, M.; Guerra-Rodríguez, E.; Cazón, P.; Vázquez, M. Chitosan for food packaging: Recent advances in active and intelligent films. Food Hydrocoll. 2022, 124, 107328. [Google Scholar] [CrossRef]

- Vilela, C.; Kurek, M.; Hayouka, Z.; Röcker, B.; Yildirim, S.; Antunes, M.D.C.; Nilsen-Nygaard, J.; Pettersen, M.K.; Freire, C.S.R. A concise guide to active agents for active food packaging. Trends Food Sci. Technol. 2018, 80, 212–222. [Google Scholar] [CrossRef]

- Carocho, M.; Barreiro, M.F.; Morales, P.; Ferreira, I.C. Adding Molecules to Food, Pros and Cons: A Review on Synthetic and Natural Food Additives. Compr. Rev. Food Sci. Food Saf. 2014, 13, 377–399. [Google Scholar] [CrossRef] [PubMed]

- Salgado, P.R.; Di Giorgio, L.; Musso, Y.S.; Mauri, A.N. Recent Developments in Smart Food Packaging Focused on Biobased and Biodegradable Polymers. Front. Sustain. Food Syst. 2021, 5, 630393. [Google Scholar] [CrossRef]

- Carpena, M.; Nuñez-Estevez, B.; Soria-Lopez, A.; Garcia-Oliveira, P.; Prieto, M.A. Essential Oils and Their Application on Active Packaging Systems: A Review. Resources 2021, 10, 7. [Google Scholar] [CrossRef]

- Mohd-Husni, N.; Amer, N.M.; Sofian-Seng, N.S.; Kasim, K.F. Development and characterization of antimicrobial film from Clinacanthus nutans and Polyvinyl Alcohol (PVA) mixture for food packaging. Malays. J. Microsc. 2020, 16, 1. [Google Scholar]

- Okafor, S.N.; Obonga, W.; Ezeokonkwo, M.A.; Nurudeen, J.; Orovwigho, U.; Ahiabuike, J. Assessment of the Health implications of Synthetic and Natural Food Colourants–A Critical Review. Pharm. Biosci. J. 2016, 4, 01–11. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, X.; Zhu, Y.; Zeng, Y.; Fang, C.; Liu, Y.; Hu, S.; Ge, Y.; Jiang, W. Preparation and application of a colorimetric film based on sodium alginate/sodium carboxymethyl cellulose incorporated with rose anthocyanins. Food Chem. 2022, 393, 133342. [Google Scholar] [CrossRef]

- Holck, A.L.; Pettersen, M.K.; Moen, M.H.; Sørheim, O. Prolonged Shelf Life and Reduced Drip Loss of Chicken Filets by the Use of Carbon Dioxide Emitters and Modified Atmosphere Packaging. J. Food Prot. 2014, 77, 1133–1141. [Google Scholar] [CrossRef]

- Filho, J.G.D.O.; Bertolo, M.R.V.; Rodrigues, M.V.; Silva, G.D.C.; de Mendonça, G.M.N.; Junior, S.B.; Ferreira, M.D.; Egea, M.B. Recent advances in the development of smart, active, and bioactive biodegradable biopolymer-based films containing betalains. Food Chem. 2022, 390, 133149. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, S.; Nazari, M.; Alizadeh, S.A.; Hamishehkar, H. Multifunctional betanin nanoliposomes-incorporated gelatin/chitosan nanofiber/ZnO nanoparticles nanocomposite film for fresh beef preservation. Meat Sci. 2020, 167, 108161. [Google Scholar] [CrossRef]

- Ardiyansyah; Apriliyanti, M.W.; Wahyono, A.; Fatoni, M.; Poerwanto, B.; Suryaningsih, W. The Potency of betacyanins extract from a peel of dragon fruits as a source of colourimetric indicator to develop intelligent packaging for fish freshness monitoring. IOP Conf. Series Earth Environ. Sci. 2018, 207, 012038. [Google Scholar] [CrossRef]

- Li, W.; Li, L.; Cao, Y.; Lan, T.; Chen, H.; Qin, Y. Effects of PLA Film Incorporated with ZnO Nanoparticle on the Quality Attributes of Fresh-Cut Apple. Nanomaterials 2017, 7, 207. [Google Scholar] [CrossRef] [Green Version]

- Suwanamornlert, P.; Kerddonfag, N.; Sane, A.; Chinsirikul, W.; Zhou, W.; Chonhenchob, V. Poly(lactic acid)/poly(butylene-succinate-co-adipate) (PLA/PBSA) blend films containing thymol as alternative to synthetic preservatives for active packaging of bread. Food Packag. Shelf Life 2020, 25, 100515. [Google Scholar] [CrossRef]

- Correa, J.P.; Molina, V.; Sanchez, M.; Kainz, C.; Eisenberg, P.; Massani, M.B. Improving ham shelf life with a polyhydroxybutyrate/polycaprolactone biodegradable film activated with nisin. Food Packag. Shelf Life 2017, 11, 31–39. [Google Scholar] [CrossRef]

- Capello, C.; Trevisol, T.C.; Pelicioli, J.; Terrazas, M.B.; Monteiro, A.R.; Valencia, G.A. Preparation and Characterization of Colorimetric Indicator Films Based on Chitosan/Polyvinyl Alcohol and Anthocyanins from Agri-Food Wastes. J. Polym. Environ. 2020, 29, 1616–1629. [Google Scholar] [CrossRef]

- Kharchoufi, S.; Parafati, L.; Licciardello, F.; Muratore, G.; Hamdi, M.; Cirvilleri, G.; Restuccia, C. Edible coatings incorporating pomegranate peel extract and biocontrol yeast to reduce Penicillium digitatum postharvest decay of oranges. Food Microbiol. 2018, 74, 107–112. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zou, X.; Zhai, X.D.; Huang, X.W.; Jiang, C.P.; Holmes, M. Preparation of an intelligent pH film based on biodegradable polymers and roselle anthocyanins for monitoring pork freshness. Food Chem. 2019, 272, 306–312. [Google Scholar] [CrossRef]

- Pereira, V.A.; de Arruda, I.N.Q.; Stefani, R. Active chitosan/PVA films with anthocyanins from Brassica oleraceae (Red Cabbage) as Time–Temperature Indicators for application in intelligent food packaging. Food Hydrocoll. 2015, 43, 180–188. [Google Scholar] [CrossRef]

- Yong, H.; Wang, X.; Zhang, X.; Liu, Y.; Qin, Y.; Liu, J. Effects of anthocyanin-rich purple and black eggplant extracts on the physical, antioxidant and pH-sensitive properties of chitosan film. Food Hydrocoll. 2019, 94, 93–104. [Google Scholar] [CrossRef]

- Ejaz, M.; Arfat, Y.A.; Mulla, M.; Ahmed, J. Zinc oxide nanorods/clove essential oil incorporated Type B gelatin composite films and its applicability for shrimp packaging. Food Packag. Shelf Life 2018, 15, 113–121. [Google Scholar] [CrossRef]

- Vo, T.-V.; Dang, T.-H.; Chen, B.-H. Synthesis of Intelligent pH Indicative Films from Chitosan/Poly(vinyl alcohol)/Anthocyanin Extracted from Red Cabbage. Polymers 2019, 11, 1088. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Merz, B.; Capello, C.; Leandro, G.C.; Moritz, D.E.; Monteiro, A.R.; Valencia, G.A. A novel colorimetric indicator film based on chitosan, polyvinyl alcohol and anthocyanins from jambolan (Syzygium cumini) fruit for monitoring shrimp freshness. Int. J. Biol. Macromol. 2020, 153, 625–632. [Google Scholar] [CrossRef] [PubMed]

- Padrão, J.; Gonçalves, S.; Silva, J.P.; Sencadas, V.; Lanceros-Méndez, S.; Pinheiro, A.C.; Vicente, A.A.; Rodrigues, L.R.; Dourado, F. Bacterial cellulose-lactoferrin as an antimicrobial edible packaging. Food Hydrocoll. 2016, 58, 126–140. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.; Sun, J.; Zheng, P.; Kang, X.; Chen, M.; Li, Y.; Ge, Y.; Hu, Y.; Pang, J. Preparation of an intelligent film based on chitosan/oxidized chitin nanocrystals incorporating black rice bran anthocyanins for seafood spoilage monitoring. Carbohydr. Polym. 2019, 222, 115006. [Google Scholar] [CrossRef]

- Abedi-Firoozjah, R.; Yousefi, S.; Heydari, M.; Seyedfatehi, F.; Jafarzadeh, S.; Mohammadi, R.; Garavand, F. Application of red cabbage anthocyanins as pH-sensitive pigments in smart food packaging and sensors. Polymers 2022, 14, 1629. [Google Scholar] [CrossRef]

- Dhall, R.K. Advances in Edible Coatings for Fresh Fruits and Vegetables: A Review. Crit. Rev. Food Sci. Nutr. 2013, 53, 435–450. [Google Scholar] [CrossRef]

- Martins, C.; Vilarinho, F.; Silva, A.S.; Andrade, M.; Machado, A.V.; Castilho, M.C.; Sá, A.; Cunha, A.; Vaz, M.F.; Ramos, F. Active polylactic acid film incorporated with green tea extract: Development, characterization and effectiveness. Ind. Crop. Prod. 2018, 123, 100–110. [Google Scholar] [CrossRef] [Green Version]

- Lisitsyn, A.; Semenova, A.; Nasonova, V.; Polishchuk, E.; Revutskaya, N.; Kozyrev, I.; Kotenkova, E. Approaches in animal proteins and natural polysaccharides application for food packaging: Edible film production and quality estimation. Polymers 2021, 13, 1592. [Google Scholar] [CrossRef]

- Khodaei, D.; Álvarez, C.; Mullen, A.M. Biodegradable packaging materials from animal processing co-products and wastes: An overview. Polymers 2021, 13, 2561. [Google Scholar] [CrossRef] [PubMed]

- MS 2565:2014; Halal Packaging-General Guidelines. Department of Standards Malaysia: Selangor, Malaysia, 2014.

- Mohamed Syazwan, A.T.; Mohd Remie, M.J. Issues in Halal Packaging: A Conceptual Paper. Int. Bus. Manag. 2012, 5, 94–98. [Google Scholar] [CrossRef]

- Evangelho, J.A.D.; Dannenberg, G.D.S.; Biduski, B.; el Halal, S.L.M.; Kringel, D.H.; Gularte, M.A.; Fiorentini, A.M.; Zavareze, E.D.R. Antibacterial activity, optical, mechanical, and barrier properties of corn starch films containing orange essential oil. Carbohydr. Polym. 2019, 222, 114981. [Google Scholar] [CrossRef] [PubMed]

- González, E.A.; García, E.M.; Nazareno, M.A. Free radical scavenging capacity and antioxidant activity of cochineal (Dactylopius coccus C.) extracts. Food Chem. 2010, 119, 358–362. [Google Scholar] [CrossRef]

- Al Kafi li al-Fatawi #505: Pewarna Merah Gincu Bibir Yang Diperbuat Daripada Cochineal. Adakah halal? Mufti of Federal Territory’s Office. Available online: https://muftiwp.gov.my/en/artikel/al-kafi-li-al-fatawi/2085-al-kafi-505-pewarna-merah-gincu-bibir-yag-diperbuat-daripada-cochineal-adakah-halal (accessed on 24 March 2023).

- Bayer, G.; Shayganpour, A.; Zia, J.; Bayer, I.S. Polyvinyl alcohol-based films plasticized with an edible sweetened gel enriched with antioxidant carminic acid. J. Food Eng. 2022, 323, 111000. [Google Scholar] [CrossRef]

- Nemes, S.A.; Szabo, K.; Vodnar, D.C. Applicability of Agro-Industrial By-Products in Intelligent Food Packaging. Coatings 2020, 10, 550. [Google Scholar] [CrossRef]

- Alam, A.U.; Rathi, P.; Beshai, H.; Sarabha, G.K.; Deen, M.J. Fruit Quality Monitoring with Smart Packaging. Sensors 2021, 21, 1509. [Google Scholar] [CrossRef]

- Fuertes, G.; Soto, I.; Carrasco, R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Dainelli, D.; Gontard, N.; Spyropoulos, D.; Zondervan-van den Beuken, E.; Tobback, P. Active and intelligent food packaging: Legal aspects and safety concerns. Trends Food Sci. Technol. 2008, 19, S103–S112. [Google Scholar] [CrossRef]

- Aday, M.S.; Yener, U. Assessing consumers’ adoption of active and intelligent packaging. Br. Food J. 2015, 117, 157–177. [Google Scholar] [CrossRef]

| Compound | Food | Function | References |

|---|---|---|---|

| Roses | Shrimp | Freshness indicator | [47] |

| Sodium bicarbonate and citric acid | Chicken | Gas indicator | [48] |

| Red beet | Fish/shrimp | Freshness indicator | [49] |

| Betalain | Meat | Freshness indicator | [50] |

| Dragon fruit | Fish | Freshness indicator | [51] |

| Zinc oxides | Apple | Microbial indicator | [52] |

| Thyme herb | Bread | Freshness indicator | [53] |

| Nisin | Ham | Microbial indicator | [54] |

| Purple sweet potato | Meat | Time–temperature indicator | [55] |

| Pomegranate | Orange fruit | Microbial indicator | [56] |

| Roselle | Pork | Freshness indicator | [57] |

| Red cabbage | Pasteurised Milk | Time–temperature indicator | [58] |

| Eggplant | Milk | Freshness indicator | [59] |

| Clove essential oil and zinc oxide | Shrimp | Microbial indicator | [60] |

| Red cabbage | Milk | Freshness indicator | [61] |

| Jambolan fruit | Shrimp | Time–temperature indicator | [62] |

| Lactoferrin | Fresh sausages | Microbial indicator | [63] |

| Black rice bran | Pomfret/shrimp | Freshness indicator | [64] |

| Manufacturer | Product Name | Indicator | Information |

|---|---|---|---|

| Mitsubishi Gas Chemical Inc. (Tokyo, Japan) | Ageless EyeTM | Gas | Notifies the presence/absence of oxygen by changing the colour from pink to blue when the oxygen level > 0.5%. |

| Freshpoint Lab (Epping, VIC, Australia) | O2 Sense | Gas | Colour changes when a package is damaged, or when oxygen is detected inside the packaging. |

| Insignia Technologies Ltd. (Scotland, United Kingdom) | Novas | Gas | Specially made for plastic packaging and detects packaging degradation by changing colour. |

| Ripesense Limited (Tauranga, New Zealand) | RipeSense | Gas | Colour changes from red to yellow when the fruit ripens. |

| Vanprob (Maharashtra, India) | Food FreshTM | Freshness | Colour changes when food is not fresh |

| DSM NV and Food Quality Sensor International (Lexington, MA, USA) | SensorQTM | Freshness | Used for poultry/meat products to detect bacteria growth. |

| Toxin Alert (Etobicoke, ON, Canada) | SIRA | Freshness | Barcode will indicate the presence of bacteria |

| COX Technologies (Belmont, North Carolina) | Fresh Tag | Freshness | Colour changes to intense pink when fish/seafood releases odour. |

| Timestrip UK Ltd. (Cambridge, United Kingdom) | Timestrip | Time–temperature | Can monitor time and temperature from days to months depending on the types of products. |

| 3M (St. Paul, MI, USA) | MonitormarkTM | Time–temperature | Monitor the temperature during storage and transportation starting from −15 °C to 26 °C |

| EVIGENCE SENSORS (Hoboken, NJ, USA) | Evigence sensors | Time–temperature | A silver colour indicator changes to white by increasing temperature; monitoring ranges from hours to years; have a SMARTDOTTM app for mobile usage. |

| Pymah Corp. (City of Los Angeles, CA, USA) | Cook-Chex | Time–temperature | A purple colour tag will turn green when exposed to pure steam atmosphere temperature. |

| Temptime Corp. (Morris Plains, NJ, USA) | Fresh-Check | Time–temperature/Freshness | Monitors food after purchasing in real-time. The circle darkens if the product is kept at an inappropriate temperature. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Hatta, F.A.; Mat Ali, Q.A.; Mohd Kashim, M.I.A.; Othman, R.; Abd Mutalib, S.; Mohd Nor, N.H. Recent Advances in Halal Bioactive Materials for Intelligent Food Packaging Indicator. Foods 2023, 12, 2387. https://doi.org/10.3390/foods12122387

Mohd Hatta FA, Mat Ali QA, Mohd Kashim MIA, Othman R, Abd Mutalib S, Mohd Nor NH. Recent Advances in Halal Bioactive Materials for Intelligent Food Packaging Indicator. Foods. 2023; 12(12):2387. https://doi.org/10.3390/foods12122387

Chicago/Turabian StyleMohd Hatta, Farah Ayuni, Qurratu Aini Mat Ali, Mohd Izhar Ariff Mohd Kashim, Rashidi Othman, Sahilah Abd Mutalib, and Nurul Hafizah Mohd Nor. 2023. "Recent Advances in Halal Bioactive Materials for Intelligent Food Packaging Indicator" Foods 12, no. 12: 2387. https://doi.org/10.3390/foods12122387

APA StyleMohd Hatta, F. A., Mat Ali, Q. A., Mohd Kashim, M. I. A., Othman, R., Abd Mutalib, S., & Mohd Nor, N. H. (2023). Recent Advances in Halal Bioactive Materials for Intelligent Food Packaging Indicator. Foods, 12(12), 2387. https://doi.org/10.3390/foods12122387