Hazelnut Skin Waste as a Functional Ingredient to Nutritionally Improve a Classic Shortbread Cookie Recipe

Abstract

1. Introduction

2. Materials and Methods

2.1. Hazelnut Skins and Chemicals

2.2. Proximate Composition

2.3. Experimental Cookies’ Preparation

2.4. Fatty Acid (FA) Profile

2.5. Sensory Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. HS Varieties’ Proximate Composition

3.2. Formulation of Isolipidic Experimental Cookie Recipes

3.3. Nutritional Evaluation of Experimental Cookies

3.4. Fatty Acid Content of Experimental Cookies

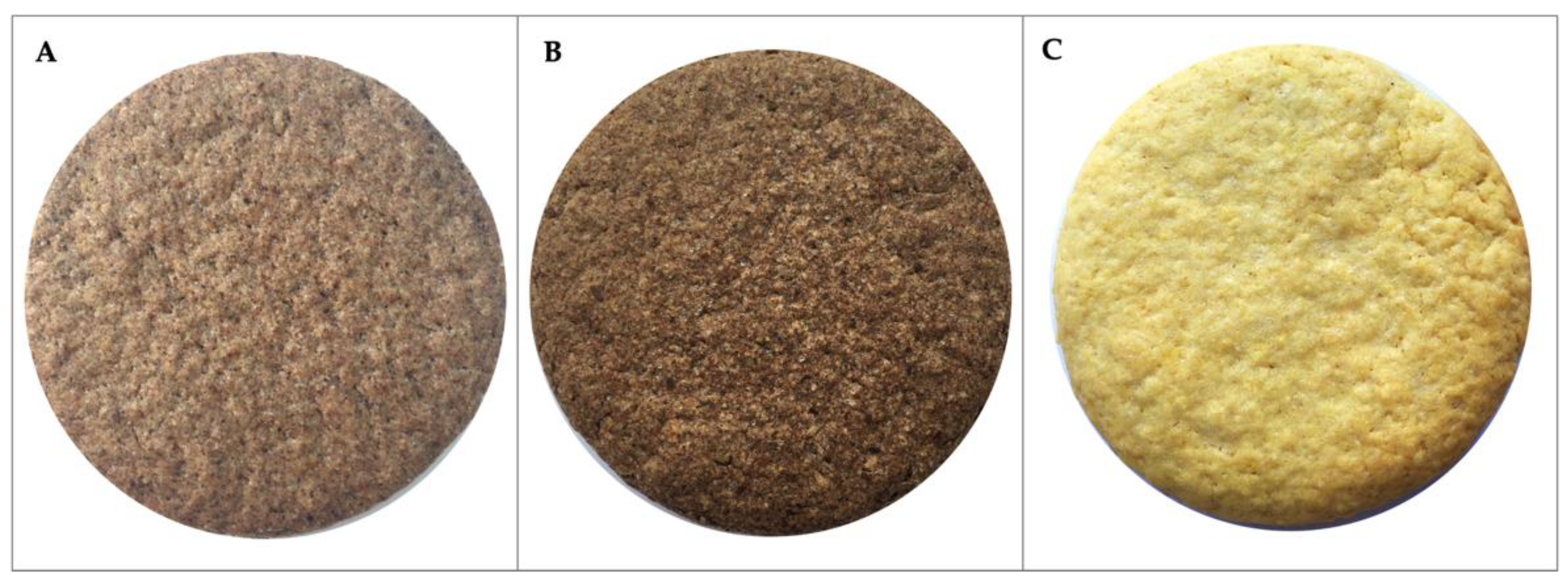

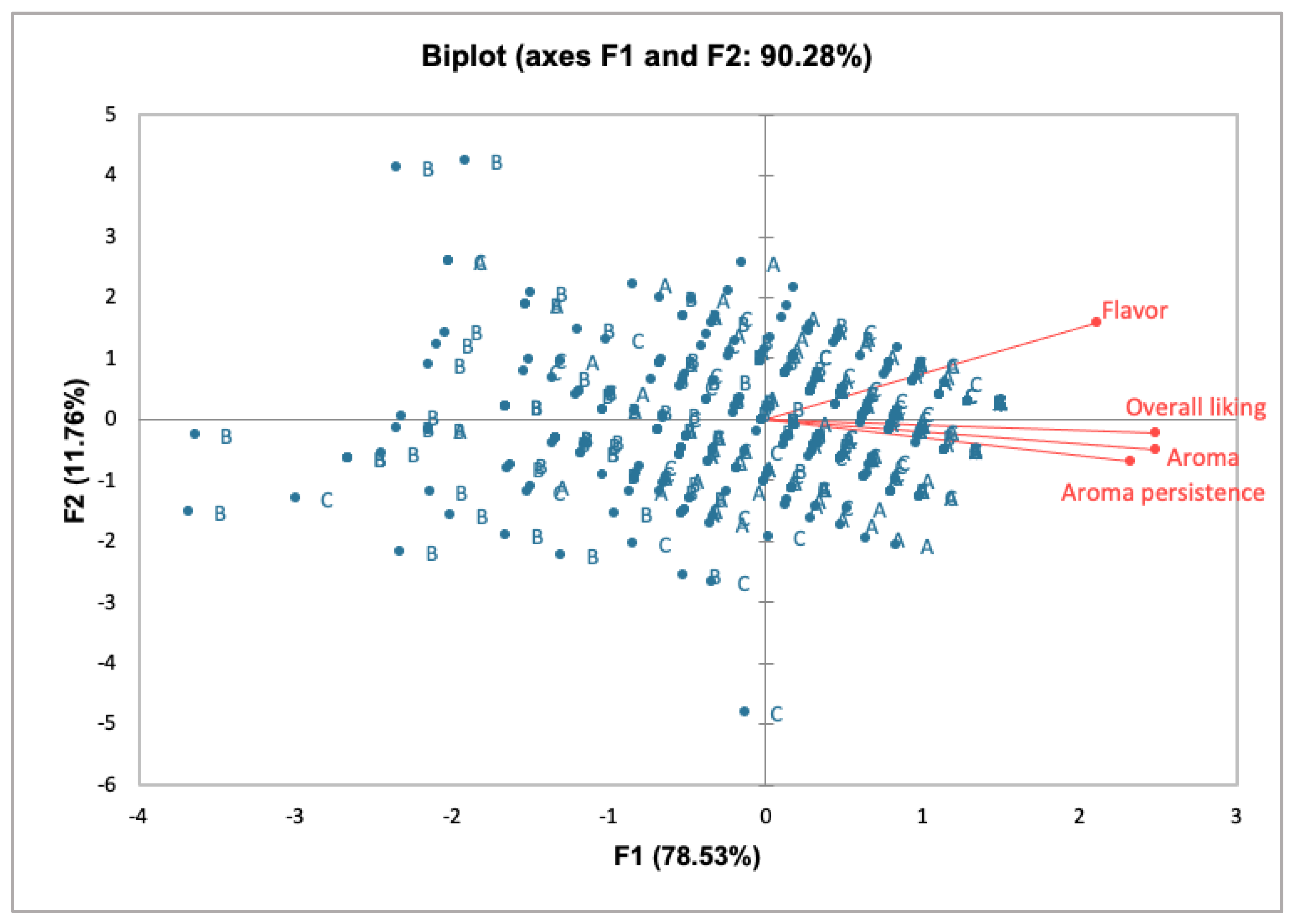

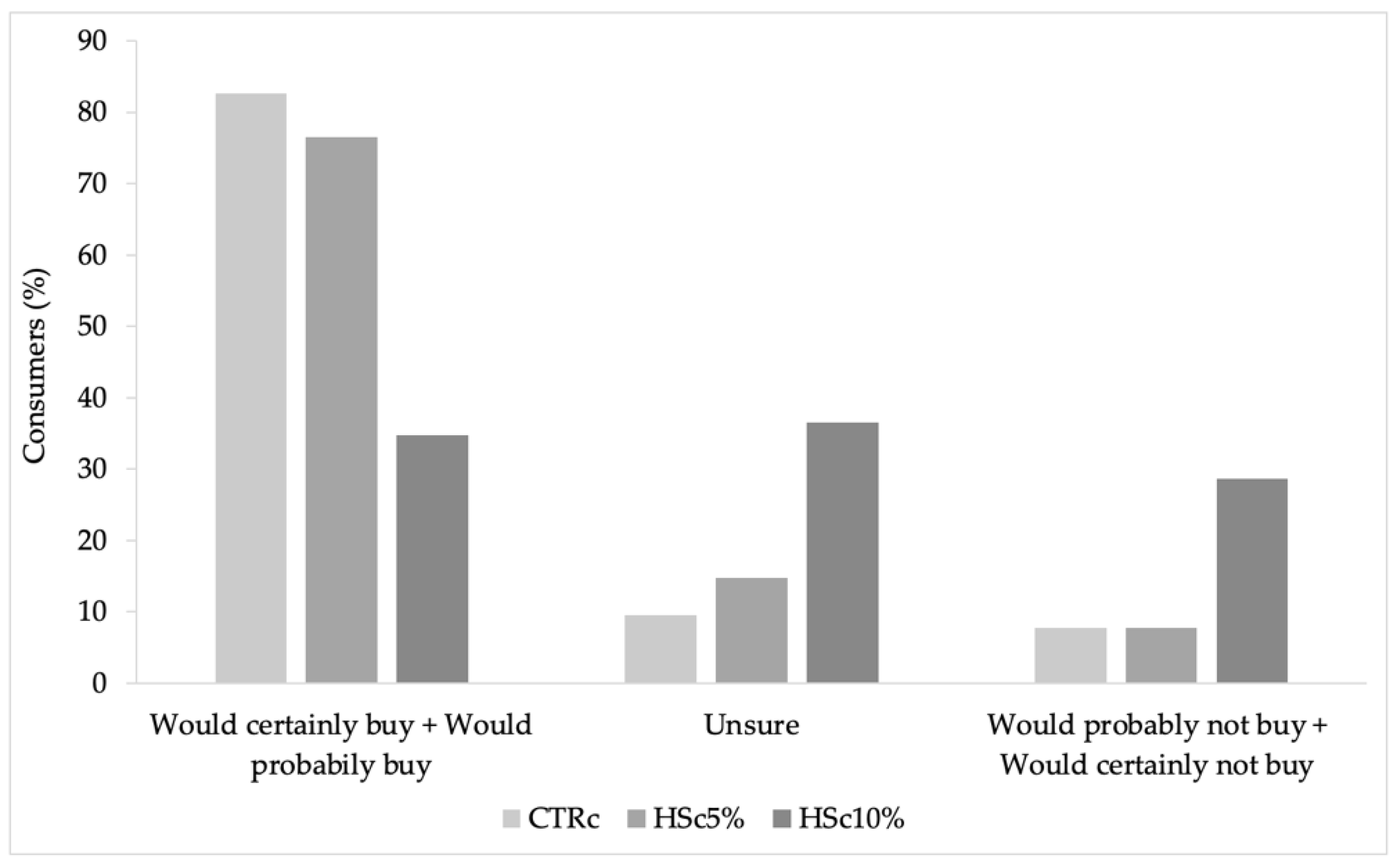

3.5. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAOSTAT. 2023. Available online: https://www.fao.org/faostat/en/#home (accessed on 23 June 2023).

- Alasalvar, C.; Karamać, M.; Kosińska, A.; Rybarczyk, A.; Shahidi, F.; Amarowicz, R. Antioxidant Activity of Hazelnut Skin Phenolics. J. Agric. Food Chem. 2009, 57, 4645–4650. [Google Scholar] [CrossRef] [PubMed]

- Del Rio, D.; Calani, L.; Dall’Asta, M.; Brighenti, F. Polyphenolic Composition of Hazelnut Skin. J. Agric. Food Chem. 2011, 59, 9935–9941. [Google Scholar] [CrossRef]

- Tunçil, Y.E. Dietary Fibre Profiles of Turkish Tombul Hazelnut (Corylus avellana L.) and Hazelnut Skin. Food Chem. 2020, 316, 126338. [Google Scholar] [CrossRef]

- Bertolino, M.; Belviso, S.; Dal Bello, B.; Ghirardello, D.; Giordano, M.; Rolle, L.; Gerbi, V.; Zeppa, G. Influence of the Addition of Different Hazelnut Skins on the Physicochemical, Antioxidant, Polyphenol and Sensory Properties of Yogurt. LWT—Food Sci. Technol. 2015, 63, 1145–1154. [Google Scholar] [CrossRef]

- Özdemir, K.S.; Yılmaz, C.; Durmaz, G.; Gökmen, V. Hazelnut Skin Powder: A New Brown Colored Functional Ingredient. Food Res. Int. 2014, 65, 291–297. [Google Scholar] [CrossRef]

- Locatelli, M.; Travaglia, F.; Coïsson, J.D.; Martelli, A.; Stévigny, C.; Arlorio, M. Total Antioxidant Activity of Hazelnut Skin (Nocciola Piemonte PGI): Impact of Different Roasting Conditions. Food Chem. 2010, 119, 1647–1655. [Google Scholar] [CrossRef]

- Available online: https://www.unioneitalianafood.it/en/baked-goods/ (accessed on 4 July 2023).

- Kozlowska, M.; Zbikowska, A.; Marciniak-Lukasiak, K.; Kowalska, M. Herbal Extracts Incorporated into Shortbread Cookies: Impact on Color and Fat Quality of the Cookies. Biomolecules 2019, 9, 858. [Google Scholar] [CrossRef] [PubMed]

- WHO. 2018. Available online: http://www.who.int/mediacentre/factsheets/fs394/en/ (accessed on 23 June 2023).

- Manohar, R.S.; Rao, P.H. Effect of emulsifiers, fat level and type on the rheological characteristics of biscuit dough and quality of biscuits. J. Sci. Food Agric. 1999, 79, 1223–1231. [Google Scholar] [CrossRef]

- Onacik-Gür, S.; Żbikowska, A.; Jaroszewska, A. Effect of High-Oleic Sunflower Oil and Other pro-Health Ingredients on Physical and Sensory Properties of Biscuits. CyTA—J. Food 2015, 13, 621–628. [Google Scholar] [CrossRef]

- Vieira, S.A.; McClements, D.J.; Decker, E.A. Challenges of Utilizing Healthy Fats in Foods. Adv. Nutr. 2015, 6, 309S–317S. [Google Scholar] [CrossRef]

- AOAC International (Ed.) Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Gaithersburg, MD, USA, 2006. [Google Scholar]

- Costantini, L.; Lukšič, L.; Molinari, R.; Kreft, I.; Bonafaccia, G.; Manzi, L.; Merendino, N. Development of Gluten-Free Bread Using Tartary Buckwheat and Chia Flour Rich in Flavonoids and Omega-3 Fatty Acids as Ingredients. Food Chem. 2014, 165, 232–240. [Google Scholar] [CrossRef]

- Farinon, B.; Costantini, L.; Molinari, R.; Di Matteo, G.; Garzoli, S.; Ferri, S.; Ceccantoni, B.; Mannina, L.; Merendino, N. Effect of Malting on Nutritional and Antioxidant Properties of the Seeds of Two Industrial Hemp (Cannabis sativa L.) Cultivars. Food Chem. 2022, 370, 131348. [Google Scholar] [CrossRef]

- Awobusuyi, T.D.; Pillay, K.; Siwela, M. Consumer Acceptance of Biscuits Supplemented with a Sorghum–Insect Meal. Nutrients 2020, 12, 895. [Google Scholar] [CrossRef]

- Cayres, C.A.; Ascheri, J.L.R.; Couto, M.A.P.G. Evaluation of Nutritional Characteristics and Consumers’ Acceptance of Gluten-Free Sweet Biscuits Made from Rice-Based Pregelatinized Composite Flours Containing Orange Pomace and Soy Protein Isolate. SN Appl. Sci. 2021, 3, 183. [Google Scholar] [CrossRef]

- Lelli, V.; Molinari, R.; Merendino, N.; Timperio, A.M. Detection and Comparison of Bioactive Compounds in Different Extracts of Two Hazelnut Skin Varieties, Tonda Gentile Romana and Tonda Di Giffoni, Using a Metabolomics Approach. Metabolites 2021, 11, 296. [Google Scholar] [CrossRef]

- Zeppa, G.; Belviso, S.; Bertolino, M.; Cavallero, M.C.; Dal Bello, B.; Ghirardello, D.; Giordano, M.; Giorgis, M.; Grosso, A.; Rolle, L.; et al. The Effect of Hazelnut Roasted Skin from Different Cultivars on the Quality Attributes, Polyphenol Content and Texture of Fresh Egg Pasta. J. Sci. Food Agric. 2015, 95, 1678–1688. [Google Scholar] [CrossRef]

- Paciulli, M.; Littardi, P.; Carini, E.; Paradiso, V.M.; Castellino, M.; Chiavaro, E. Inulin-Based Emulsion Filled Gel as Fat Replacer in Shortbread Cookies: Effects during Storage. LWT Food Sci. Technol. 2020, 133, 109888. [Google Scholar] [CrossRef]

- Curti, E.; Federici, E.; Diantom, A.; Carini, E.; Pizzigalli, E.; Wu Symon, V.; Pellegrini, N.; Vittadini, E. Structured Emulsions as Butter Substitutes: Effects on Physicochemical and Sensory Attributes of Shortbread Cookies: Fibre-Water-Fat Systems as Butter Substitutes in Shortbread Cookies. J. Sci. Food Agric. 2018, 98, 3836–3842. [Google Scholar] [CrossRef]

- Dziki, D.; Lisiecka, K.; Gawlik-Dziki, U.; Różyło, R.; Krajewska, A.; Cacak-Pietrzak, G. Shortbread Cookies Enriched with Micronized Oat Husk: Physicochemical and Sensory Properties. Appl. Sci. 2022, 12, 12512. [Google Scholar] [CrossRef]

- Sileoni, V.; Alfeo, V.; Bravi, E.; Belardi, I.; Marconi, O. Upcycling of a By-Product of the Brewing Production Chain as an Ingredient in the Formulation of Functional Shortbreads. J. Funct. Foods 2022, 98, 105292. [Google Scholar] [CrossRef]

- Velioglu, S.D.; Guner, K.G.; Velioglu, H.M.; Gulnaz, C. The use of hazelnut testa in bakery products. J. Tekirdag Agric. Fac. 2017, 14, 127–139. [Google Scholar]

- Lucchetti, S.; Ambra, R.; Pastore, G. Effects of Peeling and/or Toasting on the Presence of Tocopherols and Phenolic Compounds in Four Italian Hazelnut Cultivars. Eur. Food Res. Technol. 2018, 244, 1057–1064. [Google Scholar] [CrossRef]

- Ivanović, S.; Avramović, N.; Dojčinović, B.; Trifunović, S.; Novaković, M.; Tešević, V.; Mandić, B. Chemical Composition, Total Phenols and Flavonoids Contents and Antioxidant Activity as Nutritive Potential of Roasted Hazelnut Skins (Corylus avellana L.). Foods 2020, 9, 430. [Google Scholar] [CrossRef] [PubMed]

- Dervisoglu, M. Influence of Hazelnut Flour and Skin Addition on the Physical, Chemical and Sensory Properties of Vanilla Ice Cream. Int. J. Food Sci. Technol. 2006, 41, 657–661. [Google Scholar] [CrossRef]

| Moisture | Protein 1 | Fat | Carbohydrates 2 | Ash | kcal/100 g 3 | kJ/100 g 3 | |

|---|---|---|---|---|---|---|---|

| HSR | 6.31 ± 0.02 a | 9.70 ± 0.14 a | 26.71 ± 0.04 b | 60.41 | 3.19 ± 0.02 a | 487.91 | 2041.43 |

| HSG | 3.13 ± 0.02 d | 9.57 ± 0.09 b | 28.98 ± 0.12 a | 58.59 | 2.85 ± 0.04 b | 516.78 | 2101.09 |

| HSL | 3.44 ± 0.05 c | 6.94 ± 0.03 d | 26.30 ± 0.14 c | 63.90 | 2.86 ± 0.03 c | 502.17 | 2161.20 |

| HST | 5.83 ± 0.04 b | 7.90 ± 0.06 c | 20.36 ± 0.17 d | 69.49 | 2.25 ± 0.04 d | 464.07 | 1941.67 |

| CSc | HSc5% | HSc10% | |

|---|---|---|---|

| flour | 48.3% | 43.9% | 40.5% |

| HSR | - | 5% | 10% |

| butter | 20.2% | 19.6% | 18% |

| sugar | 19% | 19% | 19% |

| eggs | 11.6% | 11.6% | 11.6% |

| vanillin | 0.1% | 0.1% | 0.1% |

| baking powder | 0.8% | 0.8% | 0.8% |

| Moisture | Protein 1 | Fat | Carbohydrates 2 | Ash | kcal/100 g 3 | kJ/100 g 3 | |

|---|---|---|---|---|---|---|---|

| CSc | 4.79 ± 0.06 b | 7.86 ± 0.06 a | 21.09 ± 0.21 a | 70.50 | 1.14 ± 0.02 b | 474.11 | 1983.69 |

| HSc5% | 3.18 ± 0.34 c | 7.96 ± 0.29 a | 21.44 ± 0.67 a | 69.21 | 1.39 ± 0.02 a | 485.72 | 2032.24 |

| HSc10% | 5.71 ± 0.04 a | 7.34 ± 0.23 b | 21.31 ± 0.46 a | 69.97 | 1.39 ± 0.01 a | 472.40 | 1976.54 |

| HSR | CSc | HSc5% | HSc10% | |

|---|---|---|---|---|

| Caprylic acid, C8:0 | n.d. | 0.35 ± 0.07 | 0.30 ± 0.14 | n.d. |

| Capric acid, C10:0 | n.d. | 1.40 ± 0.71 | 2.10 ± 0.14 | 1.85 ± 0.21 |

| Undecanoic acid, C11:0 | n.d. | n.d. | 0.45 ± 0.07 | 0.55 ± 0.07 |

| Lauric acid, C12:0 | n.d. | 2.95 ± 0.50 | 3.35 ± 0.21 | 3.45 ± 0.07 |

| Tridecanoic acid, C13:0 | n.d. | n.d. | 0.15 ± 0.07 | 0.25 ± 0.07 |

| Myristic acid, C14:0 | n.d. | 12.15 ± 0.07 b | 12.75 ± 0.07 a | 12.15 ± 0.21 b |

| Pentadecanoic acid, C15:0 | n.d. | 0.85 ± 0.07 | 0.85 ± 0.07 | 0.90 ± 0.01 |

| Palmitic acid, C16:0 | 6.60 ± 0.57 c | 40.05 ± 3.04 a | 39.10 ± 1.13 a | 33.75 ± 0.64 b |

| Palmitoleic acid, C16:1n7 | n.d. | 0.95 ± 0.07 | 1.05 ± 0.07 | 1.10 ± 0.14 |

| Stearic acid, C18:0 | 1.85 ± 0.07 b | 8.20 ± 0.01 a | 7.25 ± 0.07 a | 5.90 ± 1.14 a |

| Oleic acid, C18:1n9 | 80.50 ± 0.14 a | 28.65 ± 1.48 c | 28.00 ± 0.28 c | 34.35 ± 1.20 b |

| Linolelaidic acid, C18:2 n6,9 all trans | 11.05 ± 0.49 a | 4.45 ± 0.50 c | 4.60 ± 0.14 bc | 5.75 ± 0.49 b |

| Total saturated FA (SFA) | 8.50 | 66.00 | 66.30 | 58.80 |

| Total unsaturated FA (UFA) | 80.50 | 29.60 | 29.05 | 35.45 |

| UFA/SFA | 9.53 | 0.45 | 0.44 | 0.60 |

| UFA/TFA | 7.29 | 6.65 | 6.32 | 6.17 |

| Acceptance Means | Cookies | ||

|---|---|---|---|

| CSc | HSc5% | HSc10% | |

| Overall liking | 7.68 ± 1.61 a | 7.31 ± 1.62 b | 6.20 ± 1.58 c |

| Flavor | 7.39 ± 1.63 a | 7.29 ± 1.63 a | 6.40 ± 1.60 b |

| Aroma | 7.80 ± 1.75 a | 7.59 ± 1.76 b | 6.03 ± 1.72 c |

| Aroma persistence | 7.46 ± 1.85 a | 7.41 ± 1.84 a | 5.85 ± 1.81 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costantini, L.; Frangipane, M.T.; Molinari, R.; Garzoli, S.; Massantini, R.; Merendino, N. Hazelnut Skin Waste as a Functional Ingredient to Nutritionally Improve a Classic Shortbread Cookie Recipe. Foods 2023, 12, 2774. https://doi.org/10.3390/foods12142774

Costantini L, Frangipane MT, Molinari R, Garzoli S, Massantini R, Merendino N. Hazelnut Skin Waste as a Functional Ingredient to Nutritionally Improve a Classic Shortbread Cookie Recipe. Foods. 2023; 12(14):2774. https://doi.org/10.3390/foods12142774

Chicago/Turabian StyleCostantini, Lara, Maria Teresa Frangipane, Romina Molinari, Stefania Garzoli, Riccardo Massantini, and Nicolò Merendino. 2023. "Hazelnut Skin Waste as a Functional Ingredient to Nutritionally Improve a Classic Shortbread Cookie Recipe" Foods 12, no. 14: 2774. https://doi.org/10.3390/foods12142774

APA StyleCostantini, L., Frangipane, M. T., Molinari, R., Garzoli, S., Massantini, R., & Merendino, N. (2023). Hazelnut Skin Waste as a Functional Ingredient to Nutritionally Improve a Classic Shortbread Cookie Recipe. Foods, 12(14), 2774. https://doi.org/10.3390/foods12142774