Impact of Starch Concentration on the Pasting and Rheological Properties of Gluten-Free Gels. Effects of Amylose Content and Thermal and Hydration Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Moisture Content

2.3. Amylose Determination

2.4. Hydration Properties

2.5. Thermal Properties

2.6. Pasting Properties

2.7. Rheological Properties of Gels

2.8. Statistical Analysis

3. Results and Discussion

3.1. Amylose Content and Hydration Properties

3.2. Thermal Properties

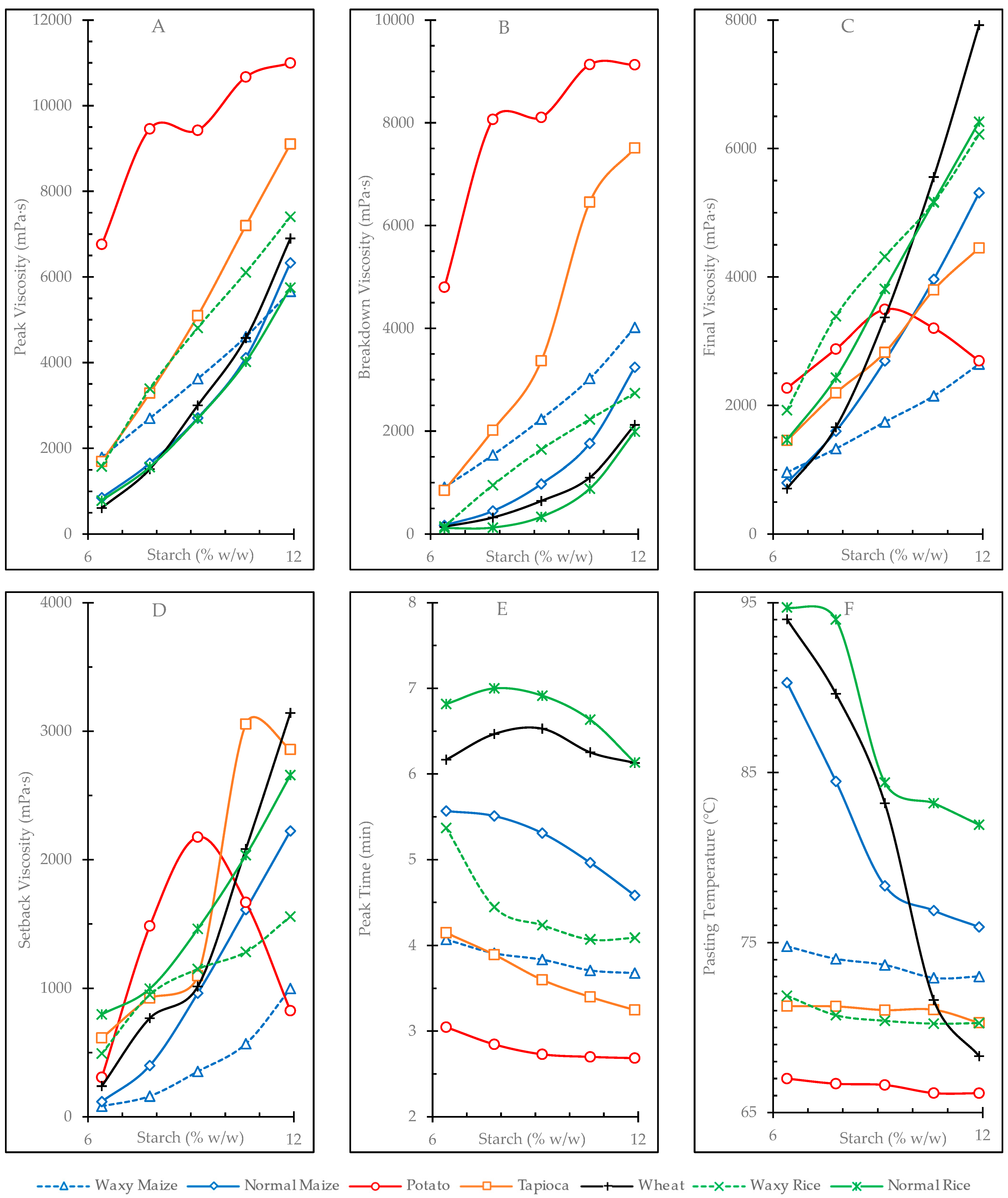

3.3. Pasting Profiles

3.4. Rheological Properties of Gels

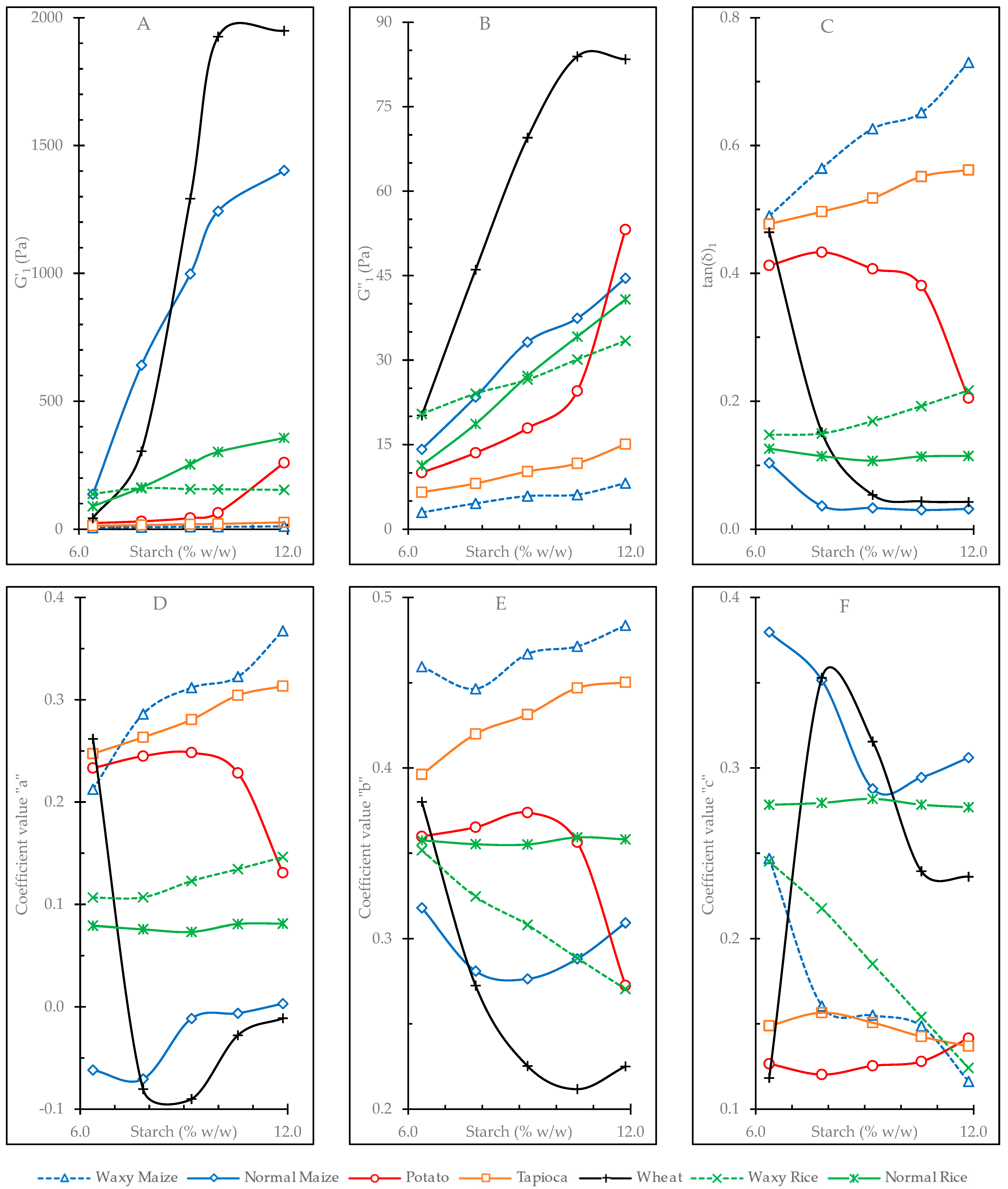

3.4.1. Oscillatory Frequency Sweep Tests

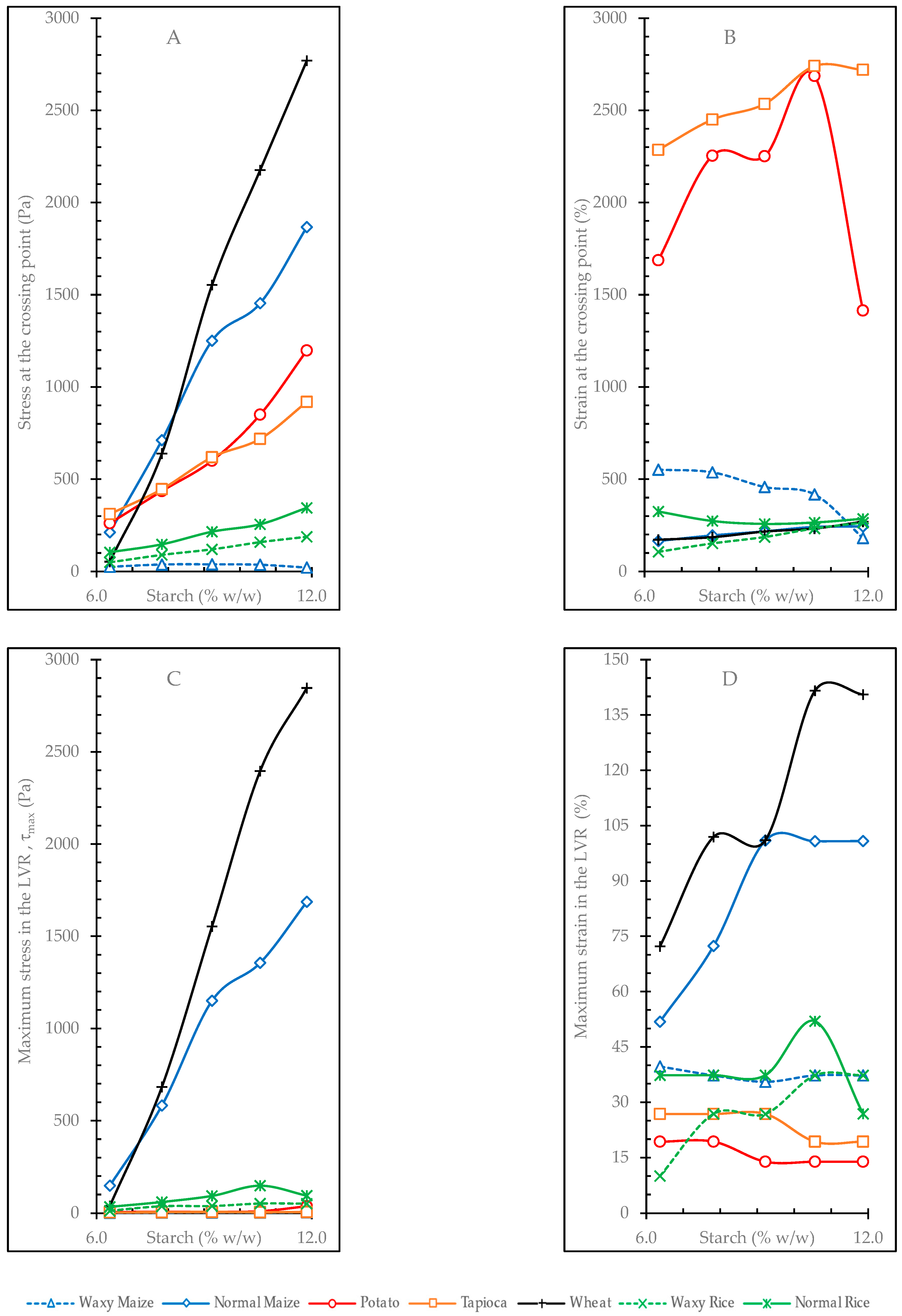

3.4.2. Oscillatory Deformation Sweep Tests

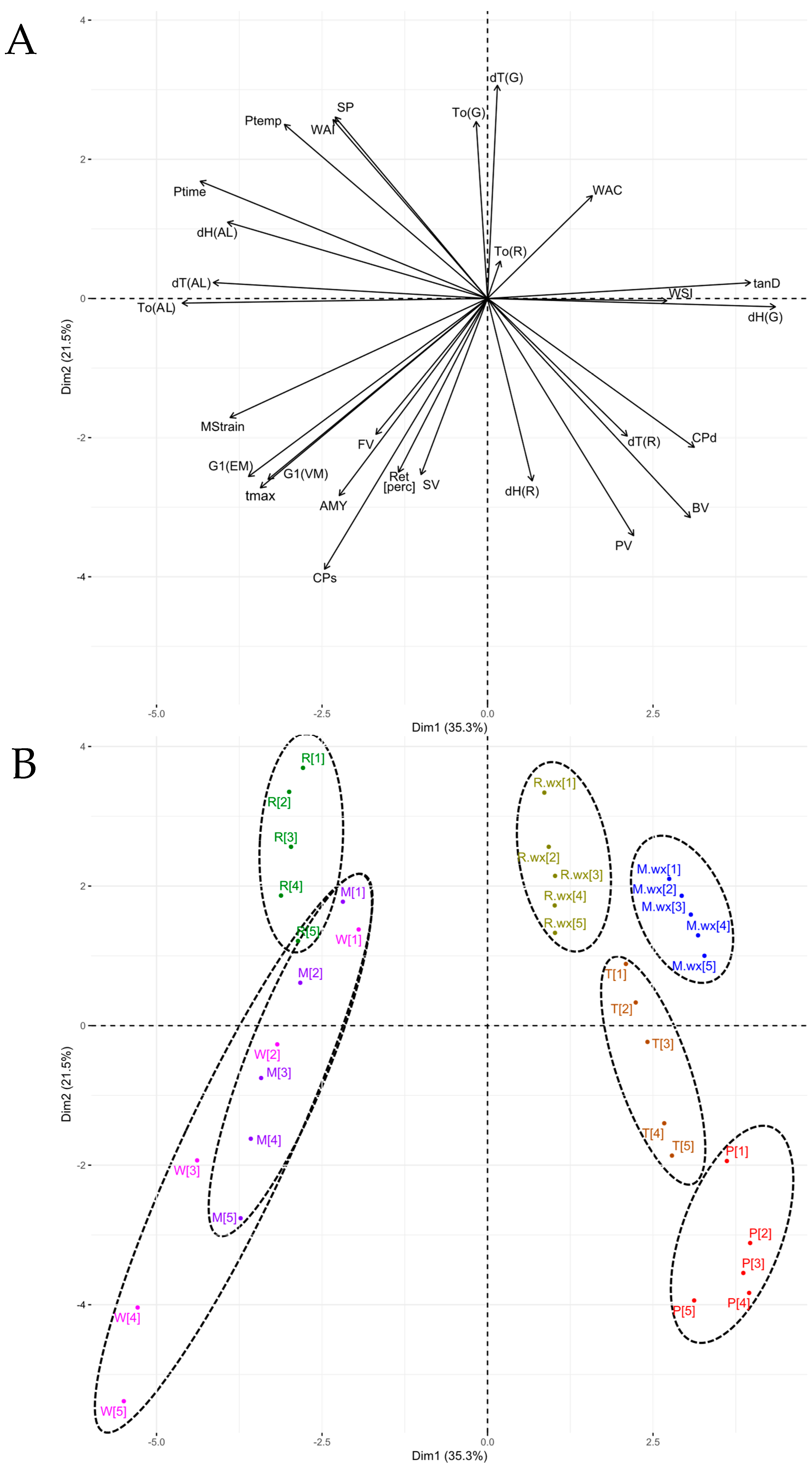

3.5. Principal Components Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hedayati, S.; Shahidi, F.; Koocheki, A.; Farahnaky, A.; Majzoobi, M. Functional properties of granular cold-water swelling maize starch: Effect of sucrose and glucose. Int. J. Food Sci. Technol. 2016, 51, 2416–2423. [Google Scholar] [CrossRef]

- Hong, E.M.; Rho, S.J.; Kim, U.; Kim, Y.R. Physicochemical properties and freeze–thaw stability of rice flour blends among rice cultivars with different amylose contents. Food Sci. Biotechnol. 2021, 30, 1347–1356. [Google Scholar] [CrossRef] [PubMed]

- Luallen, T. Chapter 13—Utilizing Starches in Product Development. In Starch in Food, 2nd ed.; Sjöö, M., Nilsson, L., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 545–579. [Google Scholar]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT—Food Sci. Technol. 2011, 44, 681–686. [Google Scholar] [CrossRef]

- Bourekoua, H.; Benatallah, L.; Zidoune, M.N.; Rosell, C.M. Developing gluten free bakery improvers by hydrothermal treatment of rice and corn flours. LWT—Food Sci. Technol. 2016, 73, 342–350. [Google Scholar] [CrossRef] [Green Version]

- Dudu, O.E.; Ma, Y.; Olurin, T.O.; Oyedeji, A.B.; Oyeyinka, S.A.; Ogungbemi, J.W. Changes in structural and functional characteristics of cassava flour by additive complexations stimulated by hydrothermal conditions. Food BioSci. 2021, 43, 101289. [Google Scholar] [CrossRef]

- Blennow, A. Chapter 4—Starch Bioengineering. In Starch in Food, 2nd ed.; Sjöö, M., Nilsson, L., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 179–222. [Google Scholar]

- Li, C.; Hu, Y. Antagonistic effects of amylopectin and amylose molecules on the starch inter- and intramolecular interactions during retrogradation. LWT 2021, 148, 111942. [Google Scholar] [CrossRef]

- Ma, M.; Liu, Y.; Chen, X.; Brennan, C.; Xu, X.; Sui, Z.; Corke, H. Thermal and pasting properties and digestibility of blends of potato and rice starches differing in amylose content. Int. J. Biol. Macromol. 2020, 165, 321–332. [Google Scholar] [CrossRef]

- Deriu, A.G.; Vela, A.J.; Ronda, F. Techno-Functional and Gelling Properties of Acha (Fonio) (Digitaria exilis stapf) Flour: A Study of Its Potential as a New Gluten-Free Starch Source in Industrial Applications. Foods 2022, 11, 183. [Google Scholar] [CrossRef]

- Abebe, W.; Collar, C.; Ronda, F. Impact of variety type and particle size distribution on starch enzymatic hydrolysis and functional properties of tef flours. Carbohydr. Polym. 2015, 115, 260–268. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.B.; Lu, Q.Y.; Yang, H.; Meng, D.D. Effects of protein content, glutenin-to-gliadin ratio, amylose content, and starch damage on textural properties of chinese fresh white noodles. Cereal Chem. 2011, 88, 296–301. [Google Scholar] [CrossRef] [Green Version]

- Rudra, S.G.; Anand, V.; Kaur, C.; Bhooshan, N.; Bhardwaj, R. Hydrothermal Treatment to Improve Processing Characteristics of Flour for Gluten-Free Pasta. Starch 2020, 72, 1900320. [Google Scholar] [CrossRef]

- Tao, K.; Li, C.; Yu, W.; Gilbert, R.G.; Li, E. How amylose molecular fine structure of rice starch affects functional properties. Carbohydr. Polym. 2019, 204, 24–31. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Cheng, B.; Zhang, W.; Shu, Z.; Wang, P.; Zeng, X. Structural and functional characteristics of Japonica rice starches with different amylose contents. CYTA J. Food 2021, 19, 532–540. [Google Scholar] [CrossRef]

- Dennett, A.L.; Schofield, P.R.; Roake, J.E.; Howes, N.K.; Chin, J. Starch swelling power and amylose content of triticale and Triticum timopheevii germplasm. J. Cereal Sci. 2009, 49, 393–397. [Google Scholar] [CrossRef]

- Guo, G.; Jackson, D.S.; Graybosch, R.A.; Parkhurst, A.M. Wheat tortilla quality: Impact of amylose content adjustments using waxy wheat flour. Cereal Chem. 2003, 80, 427–436. [Google Scholar] [CrossRef]

- Le-Bail, P.; Hesso, N.; Le-Bail, A. Chapter 15—Starch in Baked Products. In Starch in Food, 2nd ed.; Sjöö, M., Nilsson, L., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 595–632. [Google Scholar]

- Cereals & Grains Association. AACC International Method 44-19.01. Moisture—Air-Oven Method, Drying at 135°. In AACC Approved Methods of Analysis, 11th ed.; American Association of Cereal Chemists International: St. Paul, MN, USA, 2010. [Google Scholar]

- Gibson, T.S.; Solah, V.A.; McCleary, B.V. A procedure to measure amylose in cereal starches and flours with concanavalin A. J. Cereal Sci. 1997, 25, 111–119. [Google Scholar] [CrossRef]

- Kumar, Y.; Singh, L.; Sharanagat, V.S.; Patel, A.; Kumar, K. Effect of microwave treatment (low power and varying time) on potato starch: Microstructure, thermo-functional, pasting and rheological properties. Int. J. Biol. Macromol. 2020, 155, 27–35. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Liu, Y.; Ouyang, J. Effect of ultrasonic and microwave dual-treatment on the physicochemical properties of chestnut starch. Polymers 2020, 12, 1718. [Google Scholar] [CrossRef]

- Rico, D.; Villaverde, A.; Martinez-Villaluenga, C.; Gutierrez, A.L.; Caballero, P.A.; Ronda, F.; Peñas, E.; Frias, J.; Diana, A.B.M. Application of autoclave treatment for development of a natural wheat bran antioxidant ingredient. Foods 2020, 9, 781. [Google Scholar] [CrossRef]

- Mukwevho, P.; Emmambux, M.N. Effect of infrared and microwave treatments alone and in combination on the functional properties of resulting flours from bambara groundnut seeds. LWT 2022, 153, 112448. [Google Scholar] [CrossRef]

- Acevedo, B.A.; Villanueva, M.; Chaves, M.G.; Avanza, M.V.; Ronda, F. Modification of structural and physicochemical properties of cowpea (Vigna unguiculata) starch by hydrothermal and ultrasound treatments. Food Hydrocoll. 2022, 124, 107266. [Google Scholar] [CrossRef]

- Ronda, F.; Roos, Y.H. Staling of fresh and frozen gluten-free bread. J. Cereal Sci. 2011, 53, 340–346. [Google Scholar] [CrossRef]

- Eliasson, A.C. Interactions between starch and lipids studied by DSC. Thermochim. Acta 1994, 246, 343–356. [Google Scholar] [CrossRef]

- Cereals & Grains Association. AACC International Method 76–21.02. General pasting method for wheat or rye flour of starch using the Rapid Visco analyser. In AACC Approved Methods of Analysis, 11th ed.; American Association of Cereal Chemists International: St. Paul, MN, USA, 2010. [Google Scholar]

- Biliaderis, C.G. Chapter 8—Structural Transitions and Related Physical Properties of Starch. In Starch, 3rd ed.; BeMiller, J., Whistler, R., Eds.; Academic Press: San Diego, CA, USA, 2009; pp. 293–372. [Google Scholar]

- Bao, J.; Bergman, C.J. Chapter 10—Rice Flour and Starch Functionality. In Starch in Food, 2nd ed.; Sjöö, M., Nilsson, L., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 373–419. [Google Scholar]

- Vamadevan, V.; Bertoft, E. Structure-function relationships of starch components. Starch 2015, 67, 55–68. [Google Scholar] [CrossRef]

- Hellemans, T.; Nekhudzhiga, H.; Van Bockstaele, F.; Wang, Y.J.; Emmambux, M.N.; Eeckhout, M. Variation in amylose concentration to enhance wheat flour extrudability. J. Cereal Sci. 2020, 95, 102992. [Google Scholar] [CrossRef]

- Wikman, J.; Blennow, A.; Bertoft, E. Effect of amylose deposition on potato tuber starch granule architecture and dynamics as studied by lintnerization. Biopolymers 2013, 99, 73–83. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, C.; Jiang, S.; Xiong, L.; Sun, Q. Characterization of starch nanoparticles prepared by nanoprecipitation: Influence of amylose content and starch type. Ind. Crops Prod. 2016, 87, 182–190. [Google Scholar] [CrossRef]

- Maurer, H.W. Chapter 18—Starch in the Paper Industry. In Starch, 3rd ed.; BeMiller, J., Whistler, R., Eds.; Academic Press: San Diego, CA, USA, 2009; pp. 657–713. [Google Scholar]

- Wang, K.; Hasjim, J.; Wu, A.C.; Henry, R.J.; Gilbert, R.G. Variation in amylose fine structure of starches from different botanical sources. J. Agric. Food Chem. 2014, 62, 4443–4453. [Google Scholar] [CrossRef]

- Charles, A.L.; Chang, Y.H.; Ko, W.C.; Sriroth, K.; Huang, T.C. Influence of amylopectin structure and amylose content on the gelling properties of five cultivars of cassava starches. J. Agric. Food Chem. 2005, 53, 2717–2725. [Google Scholar] [CrossRef]

- Jane, J.-L. Chapter 6—Structural Features of Starch Granules II. In Starch, 3rd ed.; BeMiller, J., Whistler, R., Eds.; Academic Press: San Diego, CA, USA, 2009; pp. 193–236. [Google Scholar]

- Pulido Díaz, A.; Lourdin, D.; Della Valle, G.; Fernández Quintero, A.; Ceballos, H.; Tran, T.; Dufour, D. Thermomechanical characterization of an amylose-free starch extracted from cassava (Manihot esculenta, Crantz). Carbohydr. Polym. 2017, 157, 1777–1784. [Google Scholar] [CrossRef] [Green Version]

- Gani, A.; Ashwar, B.A.; Akhter, G.; Shah, A.; Wani, I.A.; Masoodi, F.A. Physico-chemical, structural, pasting and thermal properties of starches of fourteen Himalayan rice cultivars. Int. J. Biol. Macromol. 2017, 95, 1101–1107. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, N.; Xu, Y.; Huang, J.; Yuan, M.; Wu, D.; Shu, X. Physicochemical properties of hydroxypropylated and cross-linked rice starches differential in amylose content. Int. J. Biol. Macromol. 2019, 128, 775–781. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Q.; Wu, H.; Su, C.; Ge, X.; Shen, H.; Han, L.; Yu, X.; Li, W. The influence of repeated versus continuous dry-heating on the performance of wheat starch with different amylose content. LWT 2021, 136, 110380. [Google Scholar] [CrossRef]

- Oyeyinka, S.A.; Singh, S.; Adebola, P.O.; Gerrano, A.S.; Amonsou, E.O. Physicochemical properties of starches with variable amylose contents extracted from bambara groundnut genotypes. Carbohydr. Polym. 2015, 133, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Srichuwong, S.; Sunarti, T.C.; Mishima, T.; Isono, N.; Hisamatsu, M. Starches from different botanical sources II: Contribution of starch structure to swelling and pasting properties. Carbohydr. Polym. 2005, 62, 25–34. [Google Scholar] [CrossRef]

- Kong, X.; Zhu, P.; Sui, Z.; Bao, J. Physicochemical properties of starches from diverse rice cultivars varying in apparent amylose content and gelatinisation temperature combinations. Food Chem. 2015, 172, 433–440. [Google Scholar] [CrossRef] [PubMed]

- Selma-Gracia, R.; Laparra, J.M.; Haros, C.M. Potential beneficial effect of hydrothermal treatment of starches from various sources on in vitro digestion. Food Hydrocoll. 2020, 103, 105687. [Google Scholar] [CrossRef] [Green Version]

- Jeong, D.; Lee, J.H.; Chung, H.J. Effect of molecular structure on phase transition behavior of rice starch with different amylose contents. Carbohydr. Polym. 2021, 259, 117712. [Google Scholar] [CrossRef] [PubMed]

- Trinh, K.S. Recrystallization of starches by hydrothermal treatment: Digestibility, structural, and physicochemical properties. J. Food Sci. Technol. 2015, 52, 7640–7654. [Google Scholar] [CrossRef] [Green Version]

- Ishiguro, K.; Noda, T.; Kitahara, K.; Yamakawa, O. Retrogradation of Sweetpotato Starch. Starch 2000, 52, 13–17. [Google Scholar] [CrossRef]

- Yang, X.; Bi, J.; Gilbert, R.G.; Li, G.; Liu, Z.; Wang, S.; Ding, Y. Amylopectin chain length distribution in grains of japonica rice as affected by nitrogen fertilizer and genotype. J. Cereal Sci. 2016, 71, 230–238. [Google Scholar] [CrossRef] [Green Version]

- Zhu, L.J.; Liu, Q.Q.; Wilson, J.D.; Gu, M.H.; Shi, Y.C. Digestibility and physicochemical properties of rice (Oryza sativa L.) flours and starches differing in amylose content. Carbohydr. Polym. 2011, 86, 1751–1759. [Google Scholar] [CrossRef]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT—Food Sci. Technol. 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- Yoo, S.H.; Perera, C.; Shen, J.; Ye, L.; Suh, D.S.; Jane, J.L. Molecular structure of selected tuber and root starches and effect of amylopectin structure on their physical properties. J. Agric. Food Chem. 2009, 57, 1556–1564. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ronda, F.; Roos, Y.H. Gelatinization and freeze-concentration effects on recrystallization in corn and potato starch gels. Carbohydr. Res. 2008, 343, 903–911. [Google Scholar] [CrossRef] [PubMed]

- Acevedo, B.A.; Avanza, M.V.; Cháves, M.G.; Ronda, F. Gelation, thermal and pasting properties of pigeon pea (Cajanus cajan L.), dolichos bean (Dolichos lablab L.) and jack bean (Canavalia ensiformis) flours. J. Food Eng. 2013, 119, 65–71. [Google Scholar] [CrossRef]

- Becker, A.; Hill, S.E.; Mitchell, J.R. Relevance of amylose-lipid complexes to the behaviour of thermally processed starches. Starch 2001, 53, 121–130. [Google Scholar] [CrossRef]

- Karakelle, B.; Kian-Pour, N.; Toker, O.S.; Palabiyik, I. Effect of process conditions and amylose/amylopectin ratio on the pasting behavior of maize starch: A modeling approach. J. Cereal Sci. 2020, 94, 102998. [Google Scholar] [CrossRef]

- Mun, S.; Shin, M. Molecular structures of rice starch to investigate the differences in the processing quality of rice flours. Food Sci. Biotechnol. 2018, 27, 1007–1014. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, Y.; Chen, X.; Zhang, L.; Li, H.; Sui, Z.; Corke, H. Polishing conditions in rice milling differentially affect the physicochemical properties of waxy, low- and high-amylose rice starch. J. Cereal Sci. 2021, 99, 103183. [Google Scholar] [CrossRef]

- Acevedo, B.A.; Villanueva, M.; Chaves, M.G.; Avanza, M.V.; Ronda, F. Starch enzymatic hydrolysis, structural, thermal and rheological properties of pigeon pea (Cajanus cajan) and dolichos bean (Dolichos lab-lab) legume starches. Int. J. Food Sci. Technol. 2020, 55, 712–719. [Google Scholar] [CrossRef] [Green Version]

- Alvarez-Jubete, L.; Auty, M.; Arendt, E.K.; Gallagher, E. Baking properties and microstructure of pseudocereal flours in gluten-free bread formulations. Eur. Food Res. Technol. 2010, 230, 437–445. [Google Scholar] [CrossRef]

- Villanueva, M.; Harasym, J.; Muñoz, J.M.; Ronda, F. Rice flour physically modified by microwave radiation improves viscoelastic behavior of doughs and its bread-making performance. Food Hydrocoll. 2019, 90, 472–481. [Google Scholar] [CrossRef] [Green Version]

- Morante, N.; Ceballos, H.; Sánchez, T.; Rolland-Sabaté, A.; Calle, F.; Hershey, C.; Gibert, O.; Dufour, D. Discovery of new spontaneous sources of amylose-free cassava starch and analysis of their structure and techno-functional properties. Food Hydrocoll. 2016, 56, 383–395. [Google Scholar] [CrossRef]

- Hsu, R.J.C.; Lu, S.; Chang, Y.H.; Chiang, W. Effects of added water and retrogradation on starch digestibility of cooked rice flours with different amylose content. J. Cereal Sci. 2015, 61, 1–7. [Google Scholar] [CrossRef]

- Li, C.; Wu, A.; Yu, W.; Hu, Y.; Li, E.; Zhang, C.; Liu, Q. Parameterizing starch chain-length distributions for structure-property relations. Carbohydr. Polym. 2020, 241, 116390. [Google Scholar] [CrossRef]

- Bertoft, E.; Källman, A.; Koch, K.; Andersson, R.; Åman, P. The cluster structure of barley amylopectins of different genetic backgrounds. Int. J. Biol. Macromol. 2011, 49, 441–453. [Google Scholar] [CrossRef]

- Bertoft, E. Composition of clusters and their arrangement in potato amylopectin. Carbohydr. Polym. 2007, 68, 433–446. [Google Scholar] [CrossRef]

- Mar, N.N.; Umemoto, T.; Abdulah, S.N.A.; Maziah, M. Chain Length Distribution of Amylopectin and Physicochemical Properties of Starch in Myanmar Rice Cultivars. Int. J. Food Prop. 2015, 18, 1719–1730. [Google Scholar] [CrossRef] [Green Version]

| Starch Weight (1) | Paste Concentration (2) |

|---|---|

| 2.0 | 6.4 |

| 2.5 | 7.8 |

| 3.0 | 9.2 |

| 3.5 | 10.6 |

| 4.0 | 11.9 |

| Sample | Amylose (%) | WAC (1) | WAI (2) | WSI (3) | SP (4) |

|---|---|---|---|---|---|

| Wheat | 22.1 ± 0.3 a | 0.82 ± 0.01 b | 8.0 ± 0.4 b | 1.8 ± 0.5 c | 8.2 ± 0.4 b |

| Normal maize | 19.8 ± 0.8 a,b | 0.82 ± 0.03 b | 7.0 ± 0.1 c | 0.7 ± 0.1 d,e | 7.0 ± 0.1 c |

| Waxy maize | 2.8 ± 0.1 d | 1.07 ± 0.02 a | 4.2 ± 0.1 d | 7.1 ± 0.8 a | 4.4 ± 0.1 d |

| Normal rice | 15.0 ± 1.0 c | 1.08 ± 0.01 a | 12.5 ± 0.1 a | 0.12 ± 0.05 e | 12.5 ± 0.1 a |

| Waxy rice | 2.8 ± 0.2 d | 0.89 ± 0.01 b | 12.4 ± 0.1 a | 0.03 ± 0.02 e | 12.4 ± 0.1 a |

| Potato | 17.9 ± 0.1 b,c | 1.01 ± 0.06 a | 4.3 ± 0.1 d | 1.7 ± 0.2 c,d | 4.3 ± 0.1 d |

| Tapioca | 18.7 ± 0.2 b | 0.83 ± 0.01 b | 7.4 ± 0.4 b,c | 4.5 ± 0.4 b | 7.7 ± 0.4 b,c |

| Wheat | Normal Maize | Waxy Maize | Normal Rice | Waxy Rice | Potato | Tapioca | |

|---|---|---|---|---|---|---|---|

| Gelatinization | |||||||

| ΔH (J/g) | 10.7 ± 0.1 e | 12.4 ± 0.1 d | 15.7 ± 0.1 b,c | 13.0 ± 0.5 d | 16.2 ± 0.8 b | 18.0 ± 0.1 a | 14.6 ± 0.1 c |

| To (°C) | 53.1 ± 0.1 e | 63.1 ± 0.1 b | 63.4 ± 0.1 b | 67.9 ± 0.1 a | 57.5 ± 0.2 d | 57.4 ± 0.1 d | 61.3 ± 0.1 c |

| Tp (°C) | 58.6 ± 0.1 f | 68.7 ± 0.1 b | 69.0 ± 0.1 b | 74.9 ± 0.1 a | 66.5 ± 0.1 c | 61.4 ± 0.1 e | 65.9 ± 0.1 d |

| Te (°C) | 63.5 ± 0.1 e | 75.3 ± 0.2 b | 76.4 ± 0.2 b | 80.4 ± 0.2 a | 77 ± 1 b | 66.6 ± 0.1 d | 72.5 ± 0.1 c |

| ΔT (°C) | 10.4 ± 0.1 b,c | 12.2 ± 0.2 b | 13.0 ± 0.2 b | 12.5 ± 0.3 b | 19 ± 1 a | 9.2 ± 0.1 c | 11.2 ± 0.1 b,c |

| Retrogradation | |||||||

| ΔH (J/g) | 5.6 ± 0.9 b | 6.7 ± 0.3 b | 5.9 ± 0.1 b | 6 ± 1 b | 1.3 ± 0.5 c | 11.4 ± 0.1 a | 4 ± 1 b,c |

| To (°C) | 35 ± 2 a | 35.2 ± 0.4 a | 37.9 ± 0.3 a | 37 ± 1 a | 27.0 ± 0.7 b | 34 ± 2 a | 36.7 ± 0.1 a |

| Tp (°C) | 49.4 ± 0.1 b | 50.2 ± 0.2 b | 49.6 ± 0.7 b | 51.6 ± 0.9 b | 52 ± 4 b | 61 ± 1 a | 50 ± 2 b |

| Te (°C) | 63.8 ± 0.3 b | 63.9 ± 0.8 b | 63.2 ± 0.2 b | 63.5 ± 0.2 b | 63.3 ± 0.2 b | 72.8 ± 0.3 a | 64 ± 2 b |

| ΔT (°C) | 29.0 ± 0.9 b | 28.6 ± 0.3 b | 25.4 ± 0.5 b | 26 ± 1 b | 36.2 ± 0.9 a | 39 ± 2 a | 27 ± 2 b |

| DR (%) | 52 ± 7 a,b | 54 ± 2 a,b | 38 ± 1 c,d | 49 ± 7 b,c | 8 ± 3 e | 63 ± 1 a | 26 ± 7 d |

| Amylose–lipid complex | |||||||

| ΔH (J/g) | 1.1 ± 0.1 b | 1.4 ± 0.1 b | - | 2.6 ± 0.1 a | - | - | - |

| To (°C) | 96.7 ± 0.4 a | 85 ± 1 c | - | 92.3 ± 0.1 b | - | - | - |

| Tp (°C) | 102.0 ± 0.2 a | 96 ± 1 b | - | 99.9 ± 0.3 a | - | - | - |

| Te (°C) | 104.7 ± 0.5 a | 102.5 ± 0.1 b | - | 104.6 ± 0.1 a | - | - | - |

| ΔT (°C) | 8.0 ± 0.1 c | 17 ± 1 a | - | 12.3 ± 0.2 b | - | - | - |

| Wheat | Normal Maize | Waxy Maize | Normal Rice | Waxy Rice | Potato | Tapioca | |

|---|---|---|---|---|---|---|---|

| Peak Viscosity (PV) | |||||||

| k | 2.9 ± 2 | 1.9 ± 0.5 | 67 ± 6 | 2.9 ± 0.4 | 46 ± 24 | 2165 ± 784 | 21 ± 7 |

| e | 3.2 ± 0.2 | 3.3 ± 0.1 | 1.8 ± 0.1 | 3.1 ± 0.1 | 2.1 ± 0.2 | 0.7 ± 0.1 | 2.5 ± 0.1 |

| R2 | 98.4 | 97.6 | 99.9 | 99.9 | 97.6 | 86.3 | 99.4 |

| Trough Viscosity (TV) | |||||||

| k | 5 ± 3 | 10 ± 1 | 160 ± 42 | 12 ± 7 | 70 ± 21 | 2024 ± 1822 | 402 ± 727 |

| e | 2.9 ± 0.2 | 2.4 ± 0.01 | 1.0 ± 0.1 | 2.4 ± 0.2 | 1.7 ± 0.1 | −0.2 ± 0.4 | 0.6 ± 0.7 |

| R2 | 97.8 | 99.8 | 96.3 | 97.5 | 98.7 | 1.8 | 12.8 |

| Breakdown Viscosity (BV) | |||||||

| k | 0.10 ± 0.01 | 0.10 ± 0.01 | 12.8 ± 1.3 | 0.10 ± 0.01 | 4 ± 4 | 1341 ± 836 | 4 ± 4 |

| e | 4.4 ± 0.4 | 4.9 ± 0.1 | 2.40 ± 0.01 | 6.9 ± 0.3 | 2.8 ± 0.4 | 0.8 ± 0.2 | 3.1 ± 0.4 |

| R2 | 97.8 | 99.8 | 99.9 | 99.7 | 94.5 | 76.4 | 96.4 |

| Final Viscosity (FV) | |||||||

| k | 3 ± 2 | 5 ± 1 | 47 ± 3 | 24 ± 7 | 108 ± 39 | 1533 ± 1172 | 58 ± 10 |

| e | 3.2 ± 0.2 | 2.9 ± 0.1 | 1.7 ± 0.1 | 2.3 ± 0.1 | 1.7 ± 0.1 | 0.3 ± 0.3 | 1.8 ± 0.1 |

| R2 | 98.8 | 99.7 | 99.9 | 99.5 | 97.9 | 21.2 | 99.6 |

| Setback Viscosity (SV) | |||||||

| k | 0.3 ± 0.1 | 0.3 ± 0.2 | 0.10 ± 0.01 | 13 ± 4 | 40 ± 22 | 346 ± 1030 | 4 ± 7 |

| e | 3.9 ± 0.2 | 3.7 ± 0.3 | 4.3 ± 0.1 | 2.2 ± 0.1 | 1.5 ± 0.2 | 0.6 ± 1.3 | 2.8 ± 0.8 |

| R2 | 99.2 | 98.5 | 99.7 | 99.2 | 94.1 | 9.3 | 83.4 |

| Peak Time (Pt) | |||||||

| k | 6.7 ± 0.9 | 10 ± 2 | 5.6 ± 0.1 | 9 ± 2 | 12 ± 3 | 4.5 ± 0.3 | 8.8 ± 0.2 |

| e | −0.10 ± 0.01 | −0.30 ± 0.01 | −0.2 ± 0.01 | −0.20 ± 0.01 | −0.5 ± 0.1 | −0.3 ± 0.01 | −0.5 ± 0.01 |

| R2 | 3.5 | 85.3 | 98.4 | 51.5 | 85.1 | 90.5 | 99.6 |

| Pasting Temperature (PT) | |||||||

| k | 246 ± 36 | 156 ± 13 | 81 ± 1 | 158 ± 19 | 77 ± 2 | 70.0 ± 0.5 | 74 ± 1 |

| e | −0.60 ± 0.01 | −0.30 ± 0.01 | −0.10 ± 0.01 | −0.30 ± 0.01 | −0.10 ± 0.01 | −0.10 ± 0.01 | −0.10 ± 0.01 |

| R2 | 94.9 | 95.3 | 95.2 | 88.1 | 81.7 | 93.4 | 64 |

| Wheat | Normal Maize | Waxy Maize | Normal Rice | Waxy Rice | Potato | Tapioca | |

|---|---|---|---|---|---|---|---|

| G′1 (Elastic Modulus) | |||||||

| k | 1 ± 3 | 6 ± 7 | 1.4 ± 0.4 | 3 ± 2 | 118 ± 28 | 0.10 ± 0.01 | 1.9 ± 0.6 |

| e | 3.1 ± 0.9 | 2.3 ± 0.5 | 0.9 ± 0.1 | 2.0 ± 0.2 | 0.2 ± 0.1 | 9.5 ± 1.9 | 1.1 ± 0.1 |

| R2 | 85.4 | 90.3 | 91.6 | 96.7 | 29.9 | 94.3 | 94.5 |

| G″1 (Viscous Modulus) | |||||||

| k | 2 ± 1 | 0.8 ± 0.3 | 0.4 ± 0.1 | 0.4 ± 0.1 | 4.7 ± 0.2 | 0.10 ± 0.01 | 0.6 ± 0.1 |

| e | 1.7 ± 0.4 | 1.7 ± 0.1 | 1.3 ± 0.2 | 2.0 ± 0.1 | 0.80 ± 0.01 | 3.7 ± 0.7 | 1.4 ± 0.1 |

| R2 | 86.3 | 97.2 | 90.9 | 98.9 | 99.8 | 91.1 | 97.5 |

| tan(δ)1 | |||||||

| k | 103 ± 93 | 17 ± 27 | 0.20 ± 0.01 | 0.20 ± 0.01 | 0.10 ± 0.01 | 2 ± 1 | 0.30 ± 0.01 |

| e | −5.4 ± 0.5 | −2.8 ± 0.8 | 0.6 ± 0.1 | −0.2 ± 0.1 | 0.7 ± 0.1 | −0.7 ± 0.4 | 0.30 ± 0.01 |

| R2 | 99.2 | 83.5 | 91.7 | 38.0 | 92.9 | 49.0 | 97.7 |

| Wheat | Normal Maize | Waxy Maize | Normal Rice | Waxy Rice | Potato | Tapioca | |

|---|---|---|---|---|---|---|---|

| Crossing Point Stress | |||||||

| k | 1 ± 1 | 5.0 ± 5.1 | 25 ± 43 | 2.9 ± 0.8 | 1.7 ± 0.5 | 3.0 ± 0.8 | 14 ± 3 |

| e | 3.2 ± 0.5 | 2.5 ± 0.4 | 0.2 ± 0.7 | 2.0 ± 0.1 | 2.0 ± 0.1 | 2.5 ± 0.1 | 1.7 ± 0.1 |

| R2 | 94.8 | 94.1 | 1.2 | 99.0 | 98.7 | 99.5 | 99.1 |

| Crossing Point Deformation | |||||||

| k | 41 ± 8 | 53 ± 8 | 33 ± 43 | 481 ± 179 | 8 ± 1 | 23 ± 33 | 1.33 ± 0.13 |

| e | 0.80 ± 0.01 | 0.70 ± 0.01 | −0.8 ± 0.6 | −0.3 ± 0.1 | 1.50 ± 0.01 | 0.1 ± 0.6 | 0.30 ± 0.01 |

| R2 | 96.8 | 96.6 | 35.7 | 39.3 | 99.5 | 0.3 | 94.6 |

| Max Stress (τmax) | |||||||

| k | 1 ± 2 | 4 ± 4 | 0.3 ± 0.1 | 3 ± 6 | 1 ± 1 | 0.10 ± 0.01 | 1.8 ± 0.9 |

| e | 3.2 ± 0.6 | 2.6 ± 0.5 | 1.3 ± 0.2 | 1.6 ± 0.8 | 1.6 ± 0.4 | 9 ± 2 | 0.6 ± 0.2 |

| R2 | 93.9 | 92.8 | 93.6 | 57.6 | 82.5 | 89.1 | 59.4 |

| Max Strain | |||||||

| k | 11 ± 6 | 11 ± 7 | 48 ± 3 | 43 ± 52 | 1 ± 1 | 67 ± 28 | 79 ± 40 |

| e | 1.1 ± 0.2 | 1.0 ± 0.2 | −0.20 ± 0.01 | −0.1 ± 0.5 | 1.5 ± 0.4 | −0.7 ± 0.1 | −0.6 ± 0.2 |

| R2 | 89.4 | 80.4 | 81.2 | 0.3 | 82.8 | 78.7 | 66.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mauro, R.R.; Vela, A.J.; Ronda, F. Impact of Starch Concentration on the Pasting and Rheological Properties of Gluten-Free Gels. Effects of Amylose Content and Thermal and Hydration Properties. Foods 2023, 12, 2281. https://doi.org/10.3390/foods12122281

Mauro RR, Vela AJ, Ronda F. Impact of Starch Concentration on the Pasting and Rheological Properties of Gluten-Free Gels. Effects of Amylose Content and Thermal and Hydration Properties. Foods. 2023; 12(12):2281. https://doi.org/10.3390/foods12122281

Chicago/Turabian StyleMauro, Raúl Ricardo, Antonio José Vela, and Felicidad Ronda. 2023. "Impact of Starch Concentration on the Pasting and Rheological Properties of Gluten-Free Gels. Effects of Amylose Content and Thermal and Hydration Properties" Foods 12, no. 12: 2281. https://doi.org/10.3390/foods12122281

APA StyleMauro, R. R., Vela, A. J., & Ronda, F. (2023). Impact of Starch Concentration on the Pasting and Rheological Properties of Gluten-Free Gels. Effects of Amylose Content and Thermal and Hydration Properties. Foods, 12(12), 2281. https://doi.org/10.3390/foods12122281