Effect of High-Hydrostatic-Pressure Processing and Storage Temperature on Sliced Iberian Dry-Cured Sausage (“Salchichón”) from Pigs Reared in Montanera System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experimental Design

2.3. High-Pressure Processing Conditions

2.4. Initial Characterization (Water Activity, pH, Protein, Moisture, and Fat Content)

2.5. Fatty Acid Profile

2.6. Microbiological Analysis

2.7. Instrumental Color

2.8. Lipid Oxidation

2.9. Protein Oxidation

2.10. Sensory Analysis

2.11. Statistical Analysis

3. Results and Discussion

3.1. Initial Characterization

3.2. Effect of HHP and Storage on the Microbiology

3.3. Effect of HHP and Storage on the Instrumental Color and Lipid and Protein Oxidation

3.4. Effect of HHP and Storage on the Sensory Analysis

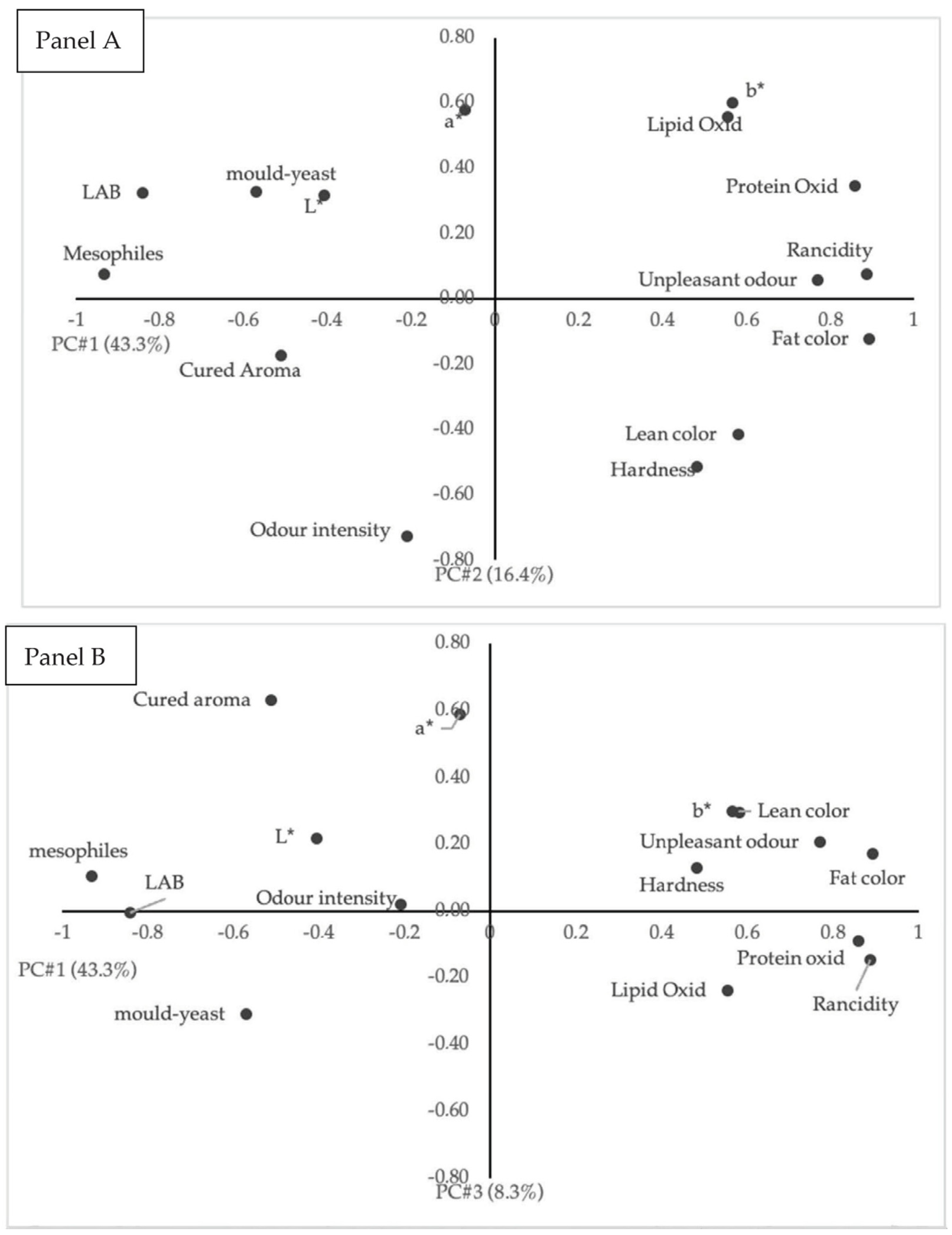

3.5. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cava, R.; Ventanas, J.; Ruiz-Carrascal, J.; Andres, A.; Antequera, T. Sensory characteristics of Iberian ham: Influence of rearing system and muscle location/ Caracteristicas sensoriales del jamón Ibérico: Influencia del sistema de engorde y del músculo. Food Sci. Technol. Int. 2000, 6, 235–242. [Google Scholar] [CrossRef]

- Contador, R.; Ortiz, A.; del Rosario Ramírez, M.; García-Torres, S.; López-Parra, M.M.; Tejerina, D. Physico-chemical and sensory qualities of Iberian sliced dry-cured loins from various commercial categories and the effects of the type of packaging and refrigeration time. Lwt 2021, 141, 110876. [Google Scholar] [CrossRef]

- Beriain, M.J.; Peña, M.P.; Bello, J. A study of the chemical components which characterize Spanish saucisson. Food Chem. 1993, 48, 31–37. [Google Scholar] [CrossRef]

- Ministerio de Agricultura. Últimos datos de consumo alimentario. Informe del Consumo de Alimentación en España. 2020. Available online: https://www.mapa.gob.es/es/alimentacion/temas/consumo-tendencias/panel-de-consumo-alimentario/ultimos-datos/ (accessed on 18 April 2022).

- Amaro-Blanco, G.; Delgado-Adamez, J.; Martín, M.J.; Ramírez, R. Active packaging using an olive leaf extract and high pressure processing for the preservation of sliced dry-cured shoulders from Iberian pigs. Innov. Food Sci. Emerg. Technol. 2018, 45, 1–9. [Google Scholar] [CrossRef]

- Lin, C.-M.; Takeuchi, K.; Zhang, L.; Dohm, C.B.; Meyer, J.D.; Hall, P.A.; Doyle, M.P. Cross-Contamination between Processing Equipment and Deli Meats by Listeria monocytogenes. J. Food Prot. 2006, 69, 71–79. [Google Scholar] [CrossRef]

- Cava, R.; García-Parra, J.; Ladero, L. Effect of high hydrostatic pressure processing and storage temperature on food safety, microbial counts, colour and oxidative changes of a traditional dry-cured sausage. LWT 2020, 128, 109462. [Google Scholar] [CrossRef]

- Cava, R.; Higuero, N.; Ladero, L. High-pressure processing and storage temperature on Listeria monocytogenes, microbial counts and oxidative changes of two traditional dry-cured meat products. Meat Sci. 2021, 171, 108273. [Google Scholar] [CrossRef]

- Martín, M.J.; García-Parra, J.; Trejo, A.; Gómez-Quintana, A.; Miguel-Pintado, C.; Riscado, A.; Paulo, L.; Bernabé, R.R. Comparative effect of high hydrostatic pressure treatment on Spanish and Portuguese traditional chorizos and evolution at different storage temperatures. J. Food Process. Preserv. 2020, 45, e15082. [Google Scholar] [CrossRef]

- Martínez-Onandi, N.; Sánchez, C.; Nuñez, M.; Picon, A. Microbiota of Iberian dry-cured ham as influenced by chemical composition, high pressure processing and prolonged refrigerated storage. Food Microbiol. 2019, 80, 62–69. [Google Scholar] [CrossRef]

- Real Decreto 4/2014, de 10 de enero, por el que se aprueba la norma de calidad para la carne, el jamón, la paleta y la caña de lomo ibérico. Boletín Of. Del Estado 2014, 171, 1569–1585. Available online: https://www.boe.es/eli/es/rd/2014/01/10/4 (accessed on 18 April 2022).

- Buzrul, S.; Alpas, H.; Largeteau, A.; Bozoglu, F.; Demazeau, G. Compression heating of selected pressure transmitting fluids and liquid foods during high hydrostatic pressure treatment. J. Food Eng. 2008, 85, 466–472. [Google Scholar] [CrossRef]

- Trejo, A.; Martín, M.J.; Gómez-Quintana, A.; Cava, R.; García-Parra, J.J.; Ramírez, M.R. Effect of slicing of top quality (Montanera) Iberian dry-cured chorizo on the stability to high pressure treatment and storage. J. Food Sci. 2021, 86, 1963–1978. [Google Scholar] [CrossRef] [PubMed]

- Sørensen, G.; Jørgensen, S.S. A critical examination of some experimental variables in the 2-thiobarbituric acid (TBA) test for lipid oxidation in meat products. Eur. Food Res. Technol. 1996, 202, 205–210. [Google Scholar] [CrossRef]

- Oliver, C.N.; Ahn, B.W.; Moerman, E.J.; Goldstein, S.; Stadtman, E.R. Age-related changes in oxidized proteins. J. Biol. Chem. 1987, 262, 5488–5491. [Google Scholar] [CrossRef]

- Cava, R.; Ruiz, J.; López-Bote, C.; Martín, L.; Garcia, C.; Ventanas, J.; Antequera, T. Influence of finishing diet on fatty acid profiles of intramuscular lipids, triglycerides and phospholipids in muscles of the Iberian pig. Meat Sci. 1997, 45, 263–270. [Google Scholar] [CrossRef]

- Tejerina, D.; García-Torres, S.; de Vaca, M.C.; Vázquez, F.; Cava, R. Acorns (Quercus rotundifolia Lam.) and grass as natural sources of antioxidants and fatty acids in the “montanera” feeding of Iberian pig: Intra- and inter-annual variations. Food Chem. 2011, 124, 997–1004. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [Green Version]

- Balamurugan, S.; Gemmell, C.; Lau, A.T.Y.; Arvaj, L.; Strange, P.; Gao, A.; Barbut, S. High pressure processing during drying of fermented sausages can enhance safety and reduce time required to produce a dry fermented product. Food Control 2020, 113, 107224. [Google Scholar] [CrossRef]

- Alpas, H.; Bozoglu, F. The combined effect of high hydrostatic pressure, heat and bacteriocins on inactivation of foodborne pathogens in milk and orange juice. World J. Microbiol. Biotechnol. 2000, 16, 387–392. [Google Scholar] [CrossRef]

- Gill, A.; Ramaswamy, H.S. Application of High Pressure Processing To Kill Escherichia coli O157 in Ready-to-Eat Meats. J. Food Prot. 2008, 71, 2182–2189. [Google Scholar] [CrossRef]

- Yuste, J.; Capellas, M.; Fung, D.Y.; Mor-Mur, M. Inactivation and sublethal injury of foodborne pathogens by high pressure processing: Evaluation with conventional media and thin agar layer method. Food Res. Int. 2004, 37, 861–866. [Google Scholar] [CrossRef]

- Rubio, B.; Martínez, B.; García-Cachán, M.D.; Rovira, J.; Jaime, I. The effects of high pressure treatment and of storage periods on the quality of vacuum-packed “salchichón” made of raw material enriched in monounsaturated and polyunsaturated fatty acids. Innov. Food Sci. Emerg. Technol. 2007, 8, 180–187. [Google Scholar] [CrossRef]

- Garriga, M.; Marcos, B.; Martin, B.; Veciana-Nogués, M.T.; Bover-Cid, S.; Hugas, M.; Aymerich, T. Starter Cultures and High-Pressure Processing To Improve the Hygiene and Safety of Slightly Fermented Sausages. J. Food Prot. 2005, 68, 2341–2348. [Google Scholar] [CrossRef] [PubMed]

- Possas, A.; Valdramidis, V.; García-Gimeno, R.M.; Pérez-Rodríguez, F. High hydrostatic pressure processing of sliced fermented sausages: A quantitative exposure assessment for Listeria monocytogenes. Innov. Food Sci. Emerg. Technol. 2019, 52, 406–419. [Google Scholar] [CrossRef]

- Rubio, B.; Martínez, B.; García-Cachán, M.D.; Rovira, J.; Jaime, I. Effect of high pressure preservation on the quality of dry cured beef “Cecina de Leon”. Innov. Food Sci. Emerg. Technol. 2007, 8, 102–110. [Google Scholar] [CrossRef]

- Mor-Mur, M.; Escriu, R.; Yuste, J. Microbiological Aspects of High-Pressure Processing, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Serra-Castelló, C.; Jofré, A.; Garriga, M.; Bover-Cid, S. Modeling and designing a Listeria monocytogenes control strategy for dry-cured ham taking advantage of water activity and storage temperature. Meat Sci. 2020, 165, 108131. [Google Scholar] [CrossRef]

- Møller, J.K.S.; Skibsted, L.H. Mechanism of Nitrosylmyoglobin Autoxidation: Temperature and Oxygen Pressure Effects on the Two Consecutive Reactions. Chem.—A Eur. J. 2004, 10, 2291–2300. [Google Scholar] [CrossRef]

- García-Esteban, M.; Ansorena, D.; Astiasarán, I. Comparison of modified atmosphere packaging and vacuum packaging for long period storage of dry-cured ham: Effects on colour, texture and microbiological quality. Meat Sci. 2004, 67, 57–63. [Google Scholar] [CrossRef]

- Jin, G.; He, L.; Zhang, J.; Yu, X.; Wang, J.; Huang, F. Effects of temperature and NaCl percentage on lipid oxidation in pork muscle and exploration of the controlling method using response surface methodology (RSM). Food Chem. 2012, 131, 817–825. [Google Scholar] [CrossRef]

- Janero, D.R. Malondialdehyde and thiobarbituric acid-reactivity as diagnostic indices of lipid peroxidation and peroxidative tissue injury. Free Radic. Biol. Med. 1990, 9, 515–540. [Google Scholar] [CrossRef]

- Fuentes, V.; Ventanas, J.; Morcuende, D.; Estévez, M.; Ventanas, S. Lipid and protein oxidation and sensory properties of vacuum-packaged dry-cured ham subjected to high hydrostatic pressure. Meat Sci. 2010, 85, 506–514. [Google Scholar] [CrossRef] [PubMed]

- Rubio, B.; Martínez, B.; García-Cachán, M.D.; Rovira, J.; Jaime, I. Effect of the packaging method and the storage time on lipid oxidation and colour stability on dry fermented sausage salchichón manufactured with raw material with a high level of mono and polyunsaturated fatty acids. Meat Sci. 2008, 80, 1182–1187. [Google Scholar] [CrossRef] [PubMed]

- Park, D.; Xiong, Y.L.; Alderton, A.L. Concentration effects of hydroxyl radical oxidizing systems on biochemical properties of porcine muscle myofibrillar protein. Food Chem. 2007, 101, 1239–1246. [Google Scholar] [CrossRef]

- Guyon, C.; Meynier, A.; de Lamballerie, M. Protein and lipid oxidation in meat: A review with emphasis on high-pressure treatments. Trends Food Sci. Technol. 2016, 50, 131–143. [Google Scholar] [CrossRef]

- Tejerina, D.; García-Torres, S.; Cabeza de Vaca, M.; Vázquez, F.M.; Cava, R. Effect of production system on physical–chemical, antioxidant and fatty acids composition of Longissimus dorsi and Serratus ventralis muscles from Iberian pig. Food Chem. 2012, 133, 293–299. [Google Scholar] [CrossRef] [PubMed]

- Carrapiso, A.I.; Amaro-Blanco, G.; Manzano, R.; Delgado-Adámez, J.; Ramírez, R. Volatile compounds of sliced high quality (Montanera) dry-cured Iberian shoulder subjected to high pressure processing and/or with an active packaging of olive leaf extract. Food Packag. Shelf Life 2020, 27, 100606. [Google Scholar] [CrossRef]

- Ramírez, R.; Cava, R. Volatile Profiles of Dry-Cured Meat Products from Three Different Iberian X Duroc Genotypes. J. Agric. Food Chem. 2007, 55, 1923–1931. [Google Scholar] [CrossRef]

- Rivas-Cañedo, A.; Nuñez, M.; Fernández-García, E. Volatile compounds in Spanish dry-fermented sausage ‘salchichón’ subjected to high pressure processing. Effect of the packaging material. Meat Sci. 2009, 83, 620–626. [Google Scholar] [CrossRef]

- Ramírez, R.; Cava, R. Effect of Iberian× Duroc genotype on composition and sensory properties of dry-cured ham. J. Sci. Food Agric. 2008, 88, 667–675. [Google Scholar] [CrossRef]

- Zhao, C.J.; Schieber, A.; Gänzle, M.G. Formation of taste-active amino acids, amino acid derivatives and peptides in food fermentations—A review. Food Res. Int. 2016, 89, 39–47. [Google Scholar] [CrossRef]

| S1 | S2 | |

|---|---|---|

| Pig breed | 100% Iberian | 100% Iberian |

| Rearing system | Feeding in freedom with feed and supplemented with some acorn | Feeding in freedom with feed and supplemented with some acorn |

| Lean/fat proportion | 63/37 | 75/25 |

| Slice diameter | 60 mm | 50–55 mm |

| Slice thickness | ≈1.6 mm | 1.5 mm |

| Spices | Sodium chloride, black pepper, nutmeg | Sodium Chloride, black pepper |

| Preservatives | E250, E252 | E250, E252 |

| Other ingredients | Dextrose, corn dextrin, E331 | Dextrose, glucose, Soya protein, E331, emulsifiers |

| Starters | None | Lactobacillus delbrueki |

| Ripening time | 120 days, 75–85% RH; 7–15 °C in progressive increase | At least 120 days, 75–80% to 55–65% RH; 3–5 °C and 20–22 °C final storage. |

| Casing thickness | Unavailable | 60–65 mm |

| Packaging characteristics | Plastic composite bags PET-PE 190 μm, 205 × 250 mm Oxygen permeability ≤100 cm3/m2/24 h (23 °C, 0% RH) | Plastic composite bags PA/PE 160 μm Oxygen permeability ≤ 46 cm3/m2 bar 24 h (75% RH) |

| S1 | S2 | p-Value | |

|---|---|---|---|

| pH | 6.34 ± 0.21 | 5.60 ± 0.18 | *** |

| aw | 0.83 ± 0.01 | 0.80 ± 0.00 | ** |

| %Moisture | 26.31 ± 1.72 | 21.23 ± 1.09 | ** |

| %Protein | 31.59 ± 4.40 | 25.81 ± 0.74 | * |

| %Fat | 27.30 ± 6.33 | 29.72 ± 1.98 | ns |

| S1 | S2 | p-Value | |

|---|---|---|---|

| C12:0 | 0.06 ± 0.01 | 0.03 ± 0.03 | ns |

| C14:0 | 1.40 ± 0.03 | 1.19 ± 0.01 | *** |

| C16:0 | 24.96 ± 0.35 | 23.42 ± 0.19 | *** |

| C16:1 | 2.93 ± 0.05 | 2.56 ± 0.08 | *** |

| C17:0 | 0.26 ± 0.01 | 0.25 ± 0.01 | ns |

| C17:1 | 0.26 ± 0.03 | 0.21 ± 0.01 | ** |

| C18:0 | 12.17 ± 0.23 | 11.58 ± 0.12 | ** |

| C18:1 | 51.25 ± 0.41 | 53.06 ± 0.18 | *** |

| C18:2 | 5.24 ± 0.25 | 6.20 ± 0.13 | *** |

| C18:3 | 0.33 ± 0.04 | 0.38 ± 0.01 | * |

| C20:0 | 0.18 ± 0.01 | 0.31 ± 0.36 | ns |

| C20:1 | 0.97 ± 0.03 | 0.79 ± 0.29 | ns |

| 4 °C | 20 °C | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Storage (Days) | Control | HHP | Control | HHP | T | ST | T × ST | |

| Mesophilic aerobic counts | 0 | 7.5 ± 0.3 | 7.1 ± 0.1 b | 7.5 ± 0.3 a | 7.1 ± 0.1 a | ** | ns | ns |

| S1 | 90 | 7.1 ± 0.3 | 7.7 ± 0.1 a | 6.3 ± 0.3 b | 6.0 ± 0.4 b | ns | *** | ** |

| 180 | 7.1 ± 0.3 | 6.9 ± 0.2 b | 6.3 ± 0.3 b | 5.3 ± 0.6 c | ** | *** | * | |

| P-storage | ns | *** | *** | *** | ||||

| 0 | 7.8 ± 0.2 a | 7.8 ± 0.1 a | 7.8 ± 0.2 a | 7.8 ± 0.1 a | ns | ns | ns | |

| S2 | 90 | 7.0 ± 0.4 b | 6.7 ± 0.4 b | 4.8 ± 1.1 b | 3.4 ± 0.7 b | * | *** | ns |

| 180 | 6.7 ± 0.4 b | 6.0 ± 0.4 c | 3.5 ± 0.3 c | 3.7 ± 0.2 b | * | *** | ** | |

| P-storage | ** | *** | *** | *** | ||||

| P S1-S2 | 0 | ns | *** | ns | *** | |||

| 90 | ns | ** | * | *** | ||||

| 180 | * | ** | *** | *** | ||||

| Lactic acid bacteria | 0 | 7.1 ± 0.3 | 6.9 ± 0.1 b | 7.1 ± 0.3 a | 6.9 ± 0.1 a | ns | ns | ns |

| S1 | 90 | 6.8 ± 0.2 | 7.7 ± 0.1 a | 5.9 ± 0.3 b | 5.6 ± 0.3 b | ns | *** | ns |

| 180 | 7.2 ± 0.9 | 6.3 ± 0.3 c | 3.0 ± 0.5 c | 1.6 ± 0.9 c | ** | *** | ns | |

| P-storage | ns | *** | *** | *** | ||||

| 0 | 7.5 ± 0.3 a | 7.6 ± 0.1 a | 7.5 ± 0.3 a | 7.6 ± 0.1 a | ns | ns | ns | |

| S2 | 90 | 6.8 ± 0.5 b | 6.3 ± 0.5 b | 5.2 ± 0.6 b | 2.4 ± 0.2 b | *** | ** | *** |

| 180 | 6.4 ± 0.3 b | 5.3 ± 0.4 c | 2.7 ± 0.3 c | 1.2 ± 0.7 c | *** | *** | ns | |

| P-storage | ** | *** | *** | |||||

| P S1-S2 | 0 | ns | *** | ns | *** | |||

| 90 | ns | *** | * | *** | ||||

| 180 | ns | ** | ns | ns | ||||

| S. aureus | 0 | 2.5 ± 0.4 a | 2.0 ± 0.2 | 2.5 ± 0.4 a | 2.0 ± 0.2 | ** | ns | ns |

| S1 | 90 | <2 b | <2 | <2 b | <2 | ns | ns | ns |

| 180 | <2 b | <2 | <2 b | <2 | ns | ns | ns | |

| P-storage | ** | ns | ** | ns | ||||

| 0 | <2 | <2 | <2 | <2 | ns | ns | ns | |

| S2 | 90 | <2 | <2 | <2 | <2 | ns | ns | ns |

| 180 | <2 | 2.0 ± 0.3 | <2 | <2 | ns | ns | ns | |

| P-storage | ns | ns | ns | ns | ||||

| P S1-S2 | 0 | * | ns | * | ns | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | ns | ns | ns | ns | ||||

| Cl. perfringens | 0 | 0.9 ± 0 | <1 | 0.9 ± 0 | <1 | ns | ns | ns |

| S1 | 90 | <1 | 1 ± 0.2 | <1 | 1.0 ± 0.2 | ns | ns | ns |

| 180 | 0.9 ± 0.1 | 1 ± 0.3 | <1 | <1 | ns | ns | ns | |

| P-storage | ns | ns | ns | ns | ||||

| 0 | <1 | <1 | <1 | <1 | ns | ns | ns | |

| S2 | 90 | <1 | <1 | <1 | <1 | ns | ns | ns |

| 180 | <1 | <1 | <1 | <1 | ns | ns | ns | |

| P-storage | ns | ns | ns | ns | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | ns | ns | ns | ns | ||||

| Yeast and molds | 0 | 2.0 ± 0.6 | 1.6 ± 0.4 b | 2.0 ± 0.6 a | 1.6 ± 0.4 a | ns | ns | ns |

| S1 | 90 | 1.4 ± 0.5 | 2.3 ± 0.4 a | 1.0 ± 0.1 b | 0.9 ± 0 b | ns | *** | ns |

| 180 | 1.7 ± 0.6 | 1.1 ± 0.3 b | 0.9 ± 0.1 b | 0.9 ± 0.1 b | ns | ** | ns | |

| P-storage | ns | ** | ** | ** | ||||

| 0 | 2.3 ± 0.7 | 1.3 ± 0.4 | 2.3 ± 0.7 a | 1.3 ± 0.4 a | ** | ns | ** | |

| S2 | 90 | 1.6 ± 0.7 | 0.9 ± 0.1 | 1.2 ± 0.4 b | 0.9 ± 0 b | * | ns | ns |

| 180 | 1.8 ± 0.6 | 1.2 ± 0.4 | 0.9 ± 0 b | 0.9 ± 0.1 b | ns | ** | * | |

| P-storage | ns | ns | ** | * | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | *** | *** | *** | ||||

| 180 | ns | ns | ns | ns | ||||

| Coliforms | 0 | 3.3 ± 0.7 | 2.2 ± 0.5 b | 3.3 ± 0.7a | 2.2 ± 0.5 | ** | ns | ns |

| S1 | 90 | 3.6 ± 0.9 | 4.2 ± 0.5 a | 2.5 ± 0.7a | 3.1 ± 0.7 | ns | *** | ns |

| 180 | 3.3 ± 0.5 | 2.8 ± 0.7 b | 1.2 ± 0.6 b | 1.8 ± 1.2 | ns | *** | ns | |

| P-storage | ns | *** | *** | ns | ||||

| 0 | <1 | 1.1 ± 0.2 b | <1 | 1.1 ± 0.2 | * | ns | * | |

| S2 | 90 | 0.9 ± 0.1 | 1.8 ± 0.5 a | <1 | <1 | ** | ** | ** |

| 180 | 1.2 ± 0.4 | 0.9 ± 0 b | 1 ± 0.3 | <1 | ns | ns | ns | |

| P-storage | ns | ** | ns | ns | ||||

| P S1-S2 | 0 | *** | ** | *** | ** | |||

| 90 | *** | *** | *** | *** | ||||

| 180 | *** | *** | ns | ns | ||||

| E. coli | 0 | 1.4 ± 0.2 a | 1.2 ± 0.4 | 1.4 ± 0.2 a | 1.2 ± 0.4 | ns | ns | ns |

| S1 | 90 | <1 b | <1 | <1 b | <1 | ns | ns | ns |

| 180 | 0.9 ± 0.0 b | <1 | <1 b | <1 | ns | ns | ns | |

| P-storage | *** | ns | *** | ns | ||||

| 0 | <1 | <1 | <1 | <1 | ns | ns | ns | |

| S2 | 90 | <1 | <1 | <1 | <1 | ns | ns | ns |

| 180 | <1 | <1 | <1 | <1 | ns | ns | ns | |

| P-storage | ns | ns | ns | ns | ||||

| P S1-S2 | 0 | ** | ns | ** | ns | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | ns | ns | ns | ns | ||||

| 4 °C | 20 °C | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Storage (Days) | Control | HHP | Control | HHP | T | ST | T × ST | |

| CIE L* | 0 | 36.7 ± 3.1 | 33.3 ± 2.6 b | 36.7 ± 3.2 | 33.3 ± 2.6 | * | ns | ns |

| S1 | 90 | 35.5 ± 3.7 | 37.0 ± 4.3 ab | 33.6 ± 2.5 | 33.2 ± 1.4 | ns | ns | ns |

| 180 | 36.6 ± 2.4 | 40.3 ± 3.1 a | 31.4 ± 4.2 | 32.6 ± 2.5 | ns | *** | ns | |

| P-storage | ns | * | ns | ns | ||||

| 0 | 35.8 ± 1.6 | 36.8 ± 2.7 | 35.8 ± 1.6 b | 36.8 ± 2.2 b | ns | ns | ns | |

| S2 | 90 | 36.3 ± 2.9 | 35.0 ± 2.7 | 42.1 ± 2.8 a | 42.0 ± 1.2 a | ns | *** | ns |

| 180 | 36.4 ± 3.0 | 35.1 ± 2.7 | 31.1 ± 3.3 c | 31.7 ± 2.2 c | ns | ** | ns | |

| P-storage | ns | ns | *** | *** | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ns | ** | *** | ||||

| 180 | ns | * | ns | ns | ||||

| CIE a* | 0 | 11.8 ± 1.7 | 12.0 ± 1.2 | 11.8 ± 1.7 | 12.0 ± 1.2 b | ns | ns | ns |

| S1 | 90 | 13.0 ± 1.3 | 11.6 1.1 | 13.4 ± 2.2 | 14.4 ± 0.7 a | ns | * | ns |

| 180 | 14.1 ± 1.9 | 13.2 ± 0.9 | 11.4 ± 0.8 | 12.8 ± 1.0 b | ns | * | ns | |

| P-storage | ns | ns | ns | ** | ||||

| 0 | 15.9 ± 1.2 | 15.1 ± 2.1 | 15.9 ± 1.2 a | 15.1 ± 2.1 | ns | ns | ns | |

| S2 | 90 | 15.2 ± 1.6 | 14.4 ± 1.3 | 14.9 ± 1.5 ab | 14.7 ± 1.8 | ns | ns | ns |

| 180 | 13.5 ± 2.0 | 14.6 ± 1.5 | 12.8 ± 1.5 b | 13.6 ± 0.7 | ns | ns | ns | |

| P-storage | ns | ns | * | ns | ||||

| P S1-S2 | 0 | ** | * | ** | * | |||

| 90 | * | ** | ns | ns | ||||

| 180 | ns | ns | ns | ns | ||||

| CIE b* | 0 | 5.2 ± 0.4 | 4.6 ± 0.5 b | 5.2 ± 0.4 | 4.6 ± 0.5 b | ** | ns | ns |

| S1 | 90 | 5.5 ± 0.7 | 4.9 ± 0.5 b | 5.3 ± 0.3 | 5.6± 0.5 a | ns | ns | ns |

| 180 | 5.4 ± 0.4 | 6.0 ± 0.4 a | 5.0 ± 0.7 | 6.1 ± 0.9 a | ** | ns | ns | |

| P-storage | ns | ** | ns | ** | ||||

| 0 | 6.2 ± 0.7 | 6.8 ± 0.4 | 6.2 ± 0.7 b | 6.8 ± 0.4 b | * | ns | ns | |

| S2 | 90 | 6.8 ± 0.6 | 6.0 ± 0.5 | 7.8 ± 0.9 a | 8.2 ± 0.7 a | ns | *** | ns |

| 180 | 7.2 ± 0.7 | 6.8 ± 0.7 | 8.0 ± 1.4 a | 7.7 ± 0.8 ab | ns | ns | ns | |

| P-storage | ns | ns | * | * | ||||

| P S1-S2 | 0 | * | *** | * | *** | |||

| 90 | * | * | *** | *** | ||||

| 180 | ** | ns | ** | * | ||||

| 4 °C | 20 °C | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Storage (Days) | Control | HHP | Control | HHP | T | ST | T × ST | |

| Lipid oxidation | 0 | 0.4 ± 0.1 a | 0.5 ± 0.1 b | 0.4 ± 0.1 a | 0.5 ± 0.1 | ns | ns | ns |

| S1 | 90 | 0.3 ± 0.1 b | 0.8 ± 0.2 a | 0.3 ± 0.0 b | 0.5 ± 0.0 | *** | * | * |

| 180 | 0.3 ± 0.1 ab | 0.8 ± 0.1 a | 0.3± 0.1 b | 0.5 ± 0.2 | *** | ** | * | |

| P-storage | * | ** | * | ns | ||||

| 0 | 1.3 ± 0.5 | 1.0 ± 0.1 b | 1.3 ± 0.5 | 1.0 ± 0.1 b | ns | ns | ns | |

| S2 | 90 | 1.4 ± 0.3 | 1.4 ± 0.4 b | 1.5 ± 0.3 | 1.4 ± 0.1 b | ns | ns | ns |

| 180 | 2.0 ± 0.5 | 2.3 ± 0.4 a | 1.5 ± 0.3 | 2.0 ± 0.5 a | ns | * | ns | |

| P-storage | ns | *** | ns | *** | ||||

| P S1-S2 | 0 | ** | *** | ** | *** | |||

| 90 | *** | * | *** | *** | ||||

| 180 | *** | *** | *** | *** | ||||

| Protein oxidation | 0 | 4.7 ± 1.2 | 3.9 ± 1.2 b | 4.7 ± 1.2 | 3.9 ± 1.2 | ns | ns | ns |

| S1 | 90 | 4.4 ± 1.7 | 5.6 ± 2.7 ab | 4.8 ± 1.4 | 5.9 ± 2.3 | ns | ns | ns |

| 180 | 5.4 ± 1.1 | 7.8 ± 2.1 a | 5.1 ± 1.6 | 6.1 ± 1.5 | * | ns | ns | |

| P-storage | ns | * | ns | ns | ||||

| 0 | 6.2 ± 0.8 b | 6.3 ± 1.5 b | 6.2 ± 0.8 b | 6.3 ± 1.5 b | ns | ns | ns | |

| S2 | 90 | 6.8 ± 1.9 b | 7.4 ± 1.7 b | 5.5 ± 2.4 b | 8.2 ± 2.3 b | ns | ns | ns |

| 180 | 10.7 ± 1.7 a | 10.6 ± 2.1 a | 17.9 ± 3.0 a | 21.7 ± 3.8 a | ns | *** | ns | |

| P-storage | ** | ** | *** | *** | ||||

| P S1-S2 | 0 | * | * | * | * | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | *** | ns | *** | *** | ||||

| 4 °C | 20 °C | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Storage (Days) | Control | HHP | Control | HHP | T | ST | T × ST | |

| Lean color | 0 | 6.9 ± 0.6 | 7.2 ± 0.4 ab | 6.9 ± 0.6 | 7.2 ± 0.4 b | ns | ns | ns |

| S1 | 90 | 7.2 ± 0.3 | 6.7 ± 0.2 b | 6.8 ± 0.4 | 6.8 ± 0.3 b | ns | ns | ns |

| 180 | 7.1 ± 0.6 | 7.4 ± 0.2 a | 6.9 ± 0.2 | 7.7 ± 0.2 a | ** | ns | ns | |

| P-storage | ns | * | ns | ** | ||||

| 0 | 6.7 ± 0.5 | 7.0 ± 0.4 a | 6.7 ± 0.5 b | 7.0 ± 0.4 b | ns | ns | ns | |

| S2 | 90 | 6.5 ± 0.2 | 6.7 ± 0.2 ab | 6.9 ± 0.4 b | 7.0 ± 0.4 b | ns | * | ns |

| 180 | 6.5 ± 0.3 | 6.3 ± 0.1 b | 7.8 ± 0.2 a | 7.8 ± 0.4 a | ns | *** | ns | |

| P-storage | ns | ** | ** | * | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ** | ns | ns | ns | ||||

| 180 | ns | *** | *** | ns | ||||

| Fat color | 0 | 1.5 ± 0.1 | 1.5 ± 0.2 b | 1.5 ± 0.1 c | 1.5 ± 0.2 c | ns | ns | ns |

| S1 | 90 | 2.0 ± 0.2 | 2.2 ± 0.3 a | 2.0 ± 0.1 b | 2.4 ± 0.3 b | * | ns | ns |

| 180 | 3.2 ± 2.3 | 2.5 ± 0.3 a | 3.0 ± 0.2 a | 3.3 ± 0.3 a | ns | ns | ns | |

| P-storage | ns | *** | *** | *** | ||||

| 0 | 1.7 ± | 1.8 ± 0.4 | 1.7 ± 0.2 c | 1.8 ± 0.4 c | ns | ns | ns | |

| S2 | 90 | 2.3 ± 0.2 | 2.3 ± 0.3 | 3.0 ± 0.4 b | 3.0 ± 0.5 b | ns | ns | ns |

| 180 | 2.6 ± 0.8 | 2.3 ± 0.4 | 3.9 ± 0.7 a | 4.1 ± 0.9 a | ns | ** | ns | |

| P-storage | ns | ns | *** | ** | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ns | *** | ns | ||||

| 180 | ns | ns | * | ns | ||||

| Odor intensity | 0 | 6.2 ± 0.4 | 6.2 ± 0.4 a | 6.2 ± 0.4 b | 6.2 ± 0.4 ab | ns | ns | ns |

| S1 | 90 | 5.7 ± 0.5 | 5.6 ± 0.3 b | 5.7 ± 0.3 b | 5.9 ± 0.5 b | ns | ns | ns |

| 180 | 5.6 ± 2.0 | 6.2 ± 0.2 a | 6.8 ± 0.2 a | 6.7 ± 0.3 a | ns | ns | ns | |

| P-storage | ns | * | ** | * | ||||

| 0 | 5.7 ± 0.2 | 5.8 ± 0.5 | 5.7 ± 0.2 | 5.8 ± 0.5 | ns | ns | ns | |

| S2 | 90 | 6.0 ± 0.2 | 6.0 ± 0.4 | 6.0 ± 0.5 | 6.3 ± 0.6 | ns | ns | ns |

| 180 | 6.1 ± 0.5 | 5.6 ± 0.3 | 5.8 ± 0.3 | 5.5 ± 0.4 | ns | ns | ns | |

| P-storage | ns | ns | ns | ns | ||||

| P S1-S2 | 0 | * | ns | * | ns | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | ns | * | ** | ** | ||||

| Unpleasant odor | 0 | 0.1 ± 0.1 | 0.0 ± 0.1 b | 0.1 ± 0.1 | 0.0 ± 0.1 b | ns | ns | ns |

| S1 | 90 | 0.4 ± 0.4 | 0.2 ± 0.1 b | 0.1 ± 0.1 | 0.2 ± 0.1 b | ns | ns | ns |

| 180 | 0.5 ± 0.4 | 0.7 ± 0.2 a | 0.4 ± 0.3 | 0.4 ± 0.3 a | ns | ns | ns | |

| P-storage | ns | *** | ns | ** | ||||

| 0 | 0.1 ± 0.1 b | 0.3 ± 0.3 | 0.1 ± 0.1 b | 0.3 ± 0.3 b | ns | ns | ns | |

| S2 | 90 | 0.5 ± 0.2 a | 0.5 ± 0.1 | 0.5 ± 0.3 ab | 0.4 ± 0.2 b | ns | ns | ns |

| 180 | 0.2 ± 0.1 b | 0.4 ± 0.1 | 1.0 ± 0.6 a | 1.0 ± 0.5 a | ns | ** | ns | |

| P-storage | ** | ns | ** | * | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ** | * | ns | ||||

| 180 | ns | * | ns | ns | ||||

| Hardness | 0 | 6.0 ± 0.7 | 6.1 ± 0.5 | 6.0 ± 0.7 | 6.1 ± 0.5 ab | ns | ns | ns |

| S1 | 90 | 6.1 ± 0.5 | 5.5 ± 0.6 | 5.4 ± 0.3 | 5.9 ± 0.3 b | ns | ns | * |

| 180 | 4.2 ± 2.3 | 6.3 ± 0.6 | 6.0 ± 0.4 | 6.7 ± 0.6 a | ns | ns | ns | |

| P-storage | ns | ns | ns | * | ||||

| 0 | 5.3 ± 0.4 | 5.4 ± 0.3 | 5.3 ± 0.4 b | 5.4 ± 0.3 b | ns | ns | ns | |

| S2 | 90 | 4.8 ± 0.2 | 5.2 ± 0.4 | 5.1 ± 0.2 b | 5.8 ± 0.5 b | ** | * | ns |

| 180 | 5.4 ± 0.4 | 5.7 ± 0.5 | 6.1 ± 0.3 a | 6.5 ± 0.4 a | ns | ** | ns | |

| P-storage | ns | ns | ** | ** | ||||

| P S1-S2 | 0 | ns | * | ns | * | |||

| 90 | ** | ns | ns | ns | ||||

| 180 | ns | ns | ns | ns | ||||

| Juiciness | 0 | 4.2 ± 0.6 | 4.3 ± 0.6 | 4.2 ± 0.6 | 4.3 ± 0.6 | ns | ns | ns |

| S1 | 90 | 4.4 ± 0.7 | 4.6 ± 0.2 | 4.8 ± 0.3 | 4.4 ± 0.2 | ns | ns | ns |

| 180 | 5.6 ± 1.2 | 4.8 ± 0.3 | 4.5 ± 0.3 | 4.0 ± 0.2 | ns | * | ns | |

| P-storage | * | ns | ns | ns | ||||

| 0 | 4.9 ± 0.5 | 4.6 ± 0.4 | 4.9 ± 0.5 a | 4.6 ± 0.4 a | ns | ns | ns | |

| S2 | 90 | 4.9 ± 0.3 | 4.7 ± 0.6 | 4.6 ± 0.6 a | 4.2 ± 0.3 a | ns | ns | ns |

| 180 | 4.6 ± 0.3 | 4.2 ± 0.5 | 3.7 ± 0.4 b | 3.3 ± 0.4 b | ns | ** | ns | |

| P-storage | ns | ns | ** | *** | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | ns | ns | * | * | ||||

| Saltiness | 0 | 4.5 ± 0.2 b | 4.5 ± 0.3 | 4.5 ± 0.2 | 4.5 ± 0.3 | ns | ns | ns |

| S1 | 90 | 4.8 ± 0.2 ab | 4.6 ± 0.2 | 4.6 ± 0.1 | 4.7 ± 0.2 | ns | ns | ns |

| 180 | 4.9 ± 0.3 a | 4.9 ± 0.3 | 4.8 ± 0.5 | 4.6 ± 0.5 | ns | ns | ns | |

| P-storage | * | ns | ns | ns | ||||

| 0 | 4.4 ± 0.2 | 4.6 ± 0.1 a | 4.4 ± 0.2 a | 4.6 ± 0.1 a | ** | ns | ns | |

| S2 | 90 | 4.2 ± 0.2 | 4.3 ± 0.2 b | 4.1 ± 0.2 b | 4.3 ± 0.2 b | ns | ns | ns |

| 180 | 4.5 ± 0.2 | 4.5 ± 0.1 ab | 4.4 ± 0.1 a | 4.5 ± 0.2 ab | ns | ns | ns | |

| P-storage | ns | ** | * | * | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ** | * | ** | * | ||||

| 180 | * | * | ns | ns | ||||

| Acid taste | 0 | 2.5 ± 0.2 ab | 2.6 ± 0.3 a | 2.5 ± 0.2 a | 2.6 ± 0.3 a | ns | ns | ns |

| S1 | 90 | 1.6 ± 0.3 b | 1.5 ± 0.1 b | 1.4 ± 0.1 b | 1.5 ± 0.2 b | ns | ns | ns |

| 180 | 3.2 ± 1.2 a | 2.9 ± 0.5 a | 2.8 ± 0.4 a | 2.5 ± 0.6 a | ns | ns | ns | |

| P-storage | * | *** | *** | ** | ||||

| 0 | 2.5 ± 0.3 | 2.5 ± 0.3 | 2.5 ± 0.3 b | 2.5 ± 0.3 | ns | ns | ns | |

| S2 | 90 | 3.2 ± 0.6 | 2.9 ± 0.6 | 3.0 ± 0.5 ab | 3.0 ± 0.4 | ns | ns | ns |

| 180 | 2.8 ± 0.5 | 3.0 ± 0.3 | 3.2 ± 0.1 a | 2.9 ± 0.6 | ns | ns | ns | |

| P-storage | ns | ns | * | ns | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ** | ** | *** | *** | ||||

| 180 | ns | ns | ns | ns | ||||

| Sweet taste | 0 | 2.6 ± 0.1 a | 2.7 ± 0.2 a | 2.6 ± 0.1 | 2.7 ± 0.2 | ns | ns | ns |

| S1 | 90 | 2.6 ± 0.2 a | 2.7 ± 0.3 a | 2.6 ± 0.3 | 2.7 ± 0.3 | ns | ns | ns |

| 180 | 2.3 ± 0.1 b | 2.1 ± 0.3 b | 2.2 ± 0.4 | 2.2 ± 0.5 | ns | ns | ns | |

| P-storage | ** | ** | ns | ns | ||||

| 0 | 2.4 ± 0.2 | 2.5 ± 0.1 | 2.4 ± 0.2 b | 2.5 ± 0.1 | ns | ns | ns | |

| S2 | 90 | 2.9 ± 0.3 | 2.9 ± 0.3 | 3.0 ± 0.4 a | 2.8 ± 0.3 | ns | ns | ns |

| 180 | 2.8 ± 0.4 | 2.8 ± 0.3 | 2.8 ± 0.3 ab | 2.5 ± 0.2 | ns | ns | ns | |

| P-storage | ns | ns | * | ns | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | ns | * | * | ns | ||||

| Spicy taste | 0 | 2.6 ± 0.4 ab | 2.9 ± 0.4 b | 2.6 ± 0.4 b | 2.9 ± 0.4 a | ns | ns | ns |

| S1 | 90 | 1.9 ± 0.3 b | 1.8 ± 0.2 c | 1.9 ± 0.2 c | 2.0 ± 0.6 b | ns | ns | ns |

| 180 | 3.3 ± 0.9 a | 4.2 ± 0.7 a | 3.7 ± 0.5 a | 3.3 ± 0.3 a | ns | ns | ns | |

| P-storage | ** | *** | *** | ** | ||||

| 0 | 2.8 ± 0.3 | 2.9 ± 0.3 | 2.8 ± 0.3 a | 2.9 ± 0.3 | ns | ns | ns | |

| S2 | 90 | 2.4 ± 0.4 | 2.4 ± 0.2 | 2.3 ± 0.3 ab | 2.3 ± 0.4 | ns | ns | ns |

| 180 | 2.5 ± 0.2 | 2.8 ± 0.3 | 2.2 ± 0.4 b | 2.5 ± 0.2 | ns | ns | ns | |

| P-storage | ns | ns | * | ns | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | * | ** | * | ns | ||||

| 180 | ns | * | ** | ** | ||||

| Flavor intensity | 0 | 6.1 ± 0.2 | 6.1 ± 0.4 | 6.1 ± 0.2 | 6.1 ± 0.4 | ns | ns | ns |

| S1 | 90 | 6.3 ± 0.3 | 6.4 ± 0.3 | 6.5 ± 0.3 | 6.5 ± 0.2 | ns | ns | ns |

| 180 | 5.9 ± 1.2 | 6.7 ± 0.4 | 6.6 ± 0.4 | 6.5 ± 0.3 | ns | ns | ns | |

| P-storage | ns | ns | ns | ns | ||||

| 0 | 5.9 ± 0.1 b | 6.1 ± 0.1 | 5.9 ± 0.1 | 6.1 ± 0.1 | * | ns | ns | |

| S2 | 90 | 6.4 ± 0.1 a | 6.4 ± 0.3 | 6.0 ± 0.2 | 6.2 ± 0.3 | ns | * | ns |

| 180 | 6.2 ± 0.3 ab | 6.1 ± 0.4 | 5.9 ± 0.2 | 6.0 ± 0.2 | ns | ns | ns | |

| P-storage | * | ns | ns | ns | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ns | * | ns | ||||

| 180 | ns | ns | * | * | ||||

| Cured aroma | 0 | 4.7 ± 0.2 b | 4.7 ± 0.7 | 4.7 ± 0.2 ab | 4.7 ± 0.7 b | ns | ns | ns |

| S1 | 90 | 4.6 ± 0.3 b | 4.5 ± 0.2 | 4.6 ± 0.3 b | 4.6 ± 0.1 b | ns | ns | ns |

| 180 | 5.3 ± 0.5 a | 5.4 ± 0.3 | 5.1 ± 0.3 a | 5.4 ± 0.2 a | ns | ns | ns | |

| P-storage | * | ns | * | * | ||||

| 0 | 5.1 ± 0.1 a | 5.1 ± 0.4 | 5.1 ± 0.1 a | 5.1 ± 0.4 a | ns | ns | ns | |

| S2 | 90 | 4.6 ± 0.3 b | 4.8 ± 0.3 | 4.6 ± 0.4 b | 4.6 ± 0.5 ab | ns | ns | ns |

| 180 | 4.8 ± 0.1 ab | 4.8 ± 0.3 | 4.1 ± 0.4 b | 4.2 ± 0.3 b | ns | ** | ns | |

| P-storage | ** | ns | ** | * | ||||

| P S1-S2 | 0 | ** | ns | ** | ns | |||

| 90 | ns | ns | ns | ns | ||||

| 180 | ns | ns | ** | ** | ||||

| Rancidity | 0 | 0.8 ± 0.6 | 0.8 ± 0.6 | 0.8 ± 0.6 | 0.8 ± 0.6 | ns | ns | ns |

| S1 | 90 | 0.8 ± 0.3 | 0.5 ± 0.2 | 0.6 ± 0.3 | 1.0 ± 0.4 | ns | ns | * |

| 180 | 0.7 ± 0.5 | 0.7 ± 0.2 | 1.0 ± 0.5 | 1.3 ± 0.8 | ns | ns | ns | |

| P-storage | ns | ns | ns | ns | ||||

| 0 | 0.6 ± 0.2 | 0.8 ± 0.3 b | 0.6 ± 0.2 c | 0.8 ± 0.3 b | ns | ns | ns | |

| S2 | 90 | 1.2 ± 0.4 | 1.1 ± 0.2 ab | 1.4 ± 0.6 b | 1.2 ± 0.5 b | ns | ns | ns |

| 180 | 0.9 ± 0.3 | 1.5 ± 0.4 a | 2.4 ± 0.5 a | 2.7 ± 0.6 a | ns | *** | ns | |

| P-storage | ns | * | *** | *** | ||||

| P S1-S2 | 0 | ns | ns | ns | ns | |||

| 90 | ns | ** | * | ns | ||||

| 180 | ns | * | ** | * | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez, R.; Trejo, A.; Delgado-Adámez, J.; Martín-Mateos, M.J.; García-Parra, J. Effect of High-Hydrostatic-Pressure Processing and Storage Temperature on Sliced Iberian Dry-Cured Sausage (“Salchichón”) from Pigs Reared in Montanera System. Foods 2022, 11, 1338. https://doi.org/10.3390/foods11091338

Ramírez R, Trejo A, Delgado-Adámez J, Martín-Mateos MJ, García-Parra J. Effect of High-Hydrostatic-Pressure Processing and Storage Temperature on Sliced Iberian Dry-Cured Sausage (“Salchichón”) from Pigs Reared in Montanera System. Foods. 2022; 11(9):1338. https://doi.org/10.3390/foods11091338

Chicago/Turabian StyleRamírez, Rosario, Antonia Trejo, Jonathan Delgado-Adámez, María Jesús Martín-Mateos, and Jesús García-Parra. 2022. "Effect of High-Hydrostatic-Pressure Processing and Storage Temperature on Sliced Iberian Dry-Cured Sausage (“Salchichón”) from Pigs Reared in Montanera System" Foods 11, no. 9: 1338. https://doi.org/10.3390/foods11091338

APA StyleRamírez, R., Trejo, A., Delgado-Adámez, J., Martín-Mateos, M. J., & García-Parra, J. (2022). Effect of High-Hydrostatic-Pressure Processing and Storage Temperature on Sliced Iberian Dry-Cured Sausage (“Salchichón”) from Pigs Reared in Montanera System. Foods, 11(9), 1338. https://doi.org/10.3390/foods11091338