Quality Characteristics of Meat Analogs through the Incorporation of Textured Vegetable Protein: A Systematic Review

Abstract

:1. Introduction

2. Materials Methods

2.1. Data Sources and Searches

2.2. Study Selection

2.3. Data Extraction

2.4. Data Synthesis and Analysis

3. Results

3.1. Study Selection Workflow

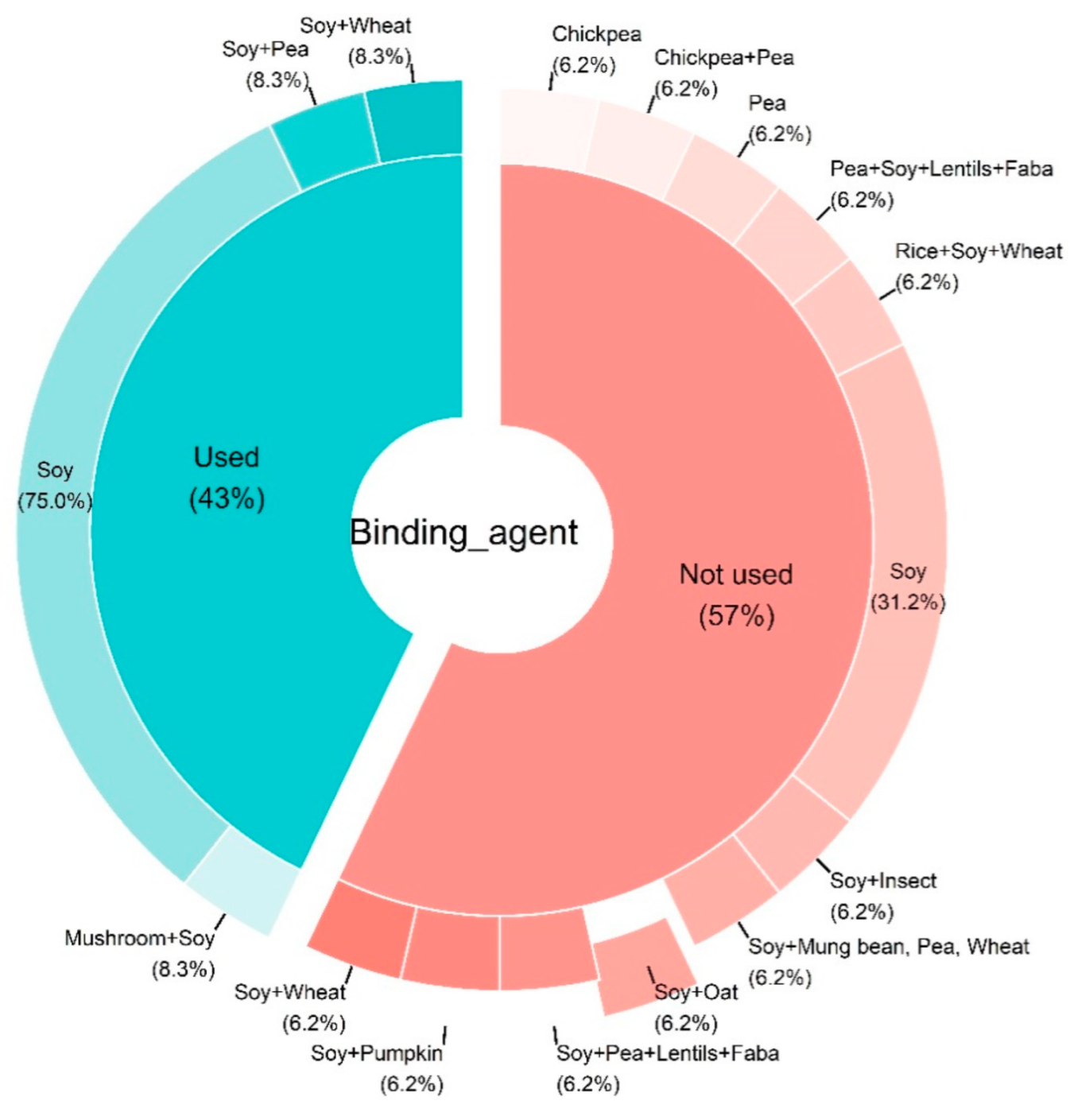

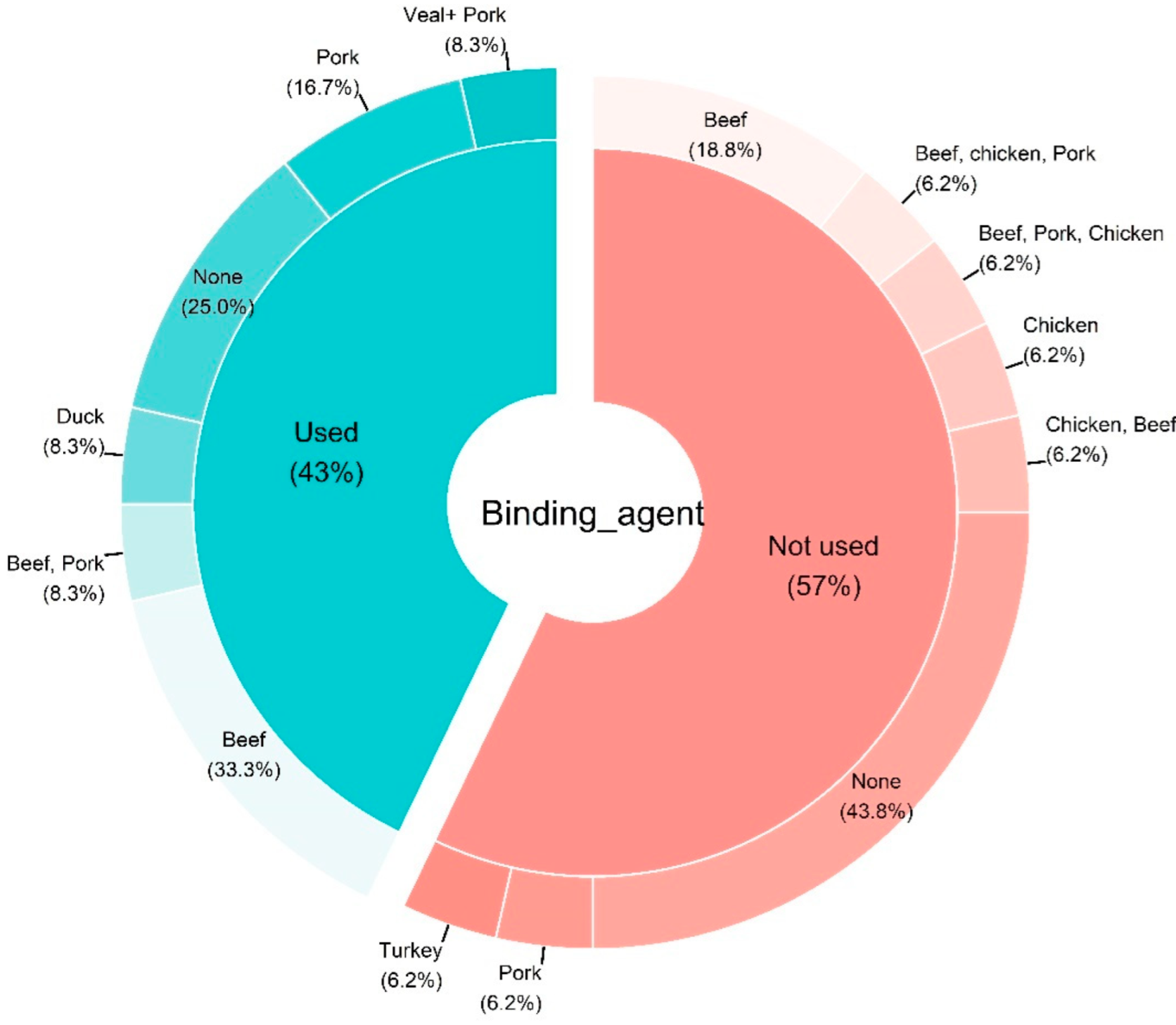

3.2. Study Characteristics

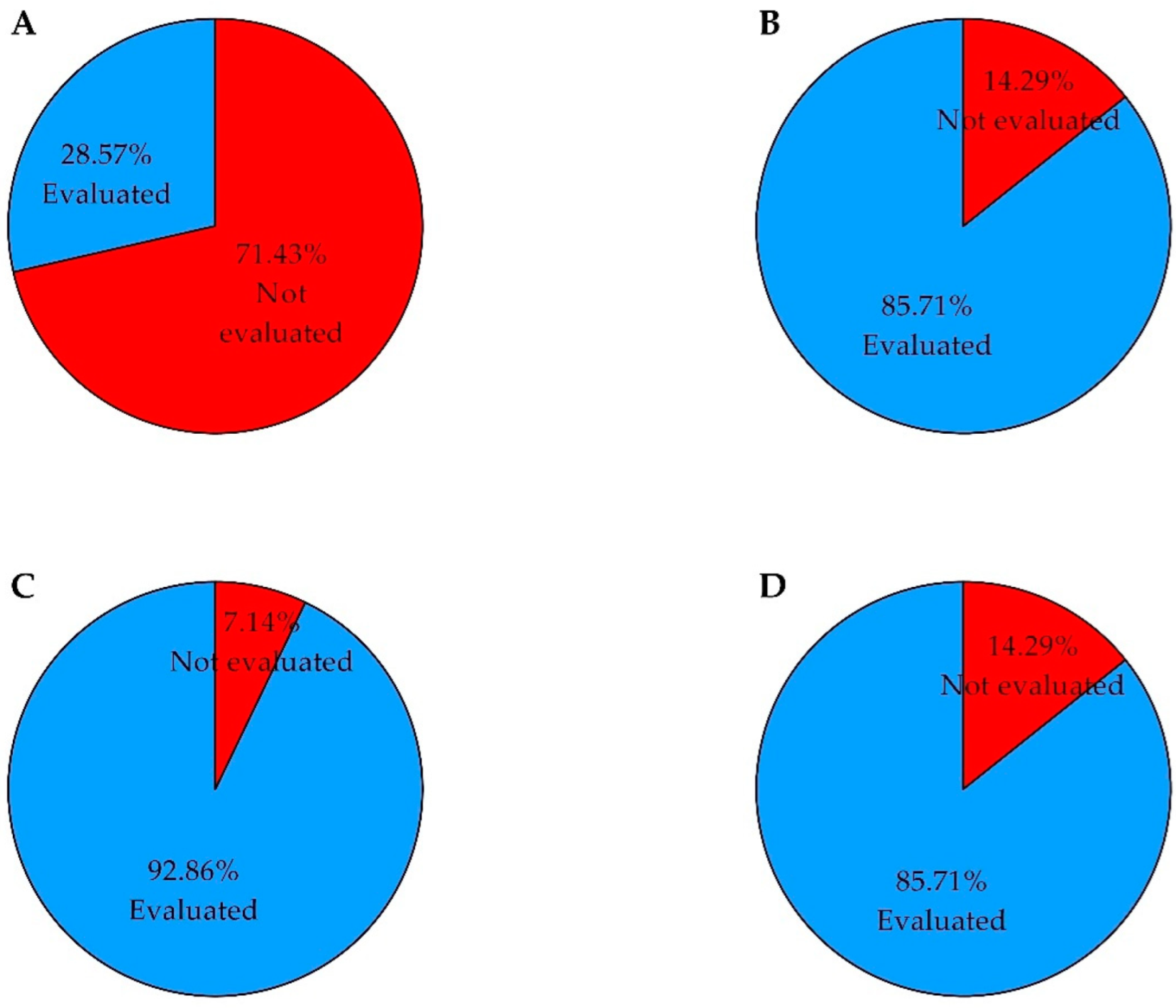

3.3. Quality Assessment

4. Discussion

5. Limitations and Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wild, F. Manufacture of Meat Analogues through High Moisture Extrusion; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–9. [Google Scholar]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Hwang, Y.-H.; Jo, S. Traditional plant-based meat alternatives, current and a future perspective: A review. J. Agric. Life Sci. 2021, 55, 1–10. [Google Scholar] [CrossRef]

- Troy, D.J.; Kerry, J. Consumer perception and the role of science in the meat industry. Meat Sci. 2010, 86, 214–226. [Google Scholar] [CrossRef] [PubMed]

- Melina, V.; Craig, W.; Levin, S. Position of the Academy of Nutrition and Dietetics: Vegetarian diets. J. Acad. Nutr. Diet. 2016, 116, 1970–1980. [Google Scholar] [CrossRef] [PubMed]

- Yoo, S.S.; Kook, S.H.; Park, S.Y.; Shim, J.H.; Chin, K.B. Physicochemical characteristics, textural properties and volatile compounds in comminuted sausages as affected by various fat levels and fat replacers. Int. J. Food Sci. 2007, 42, 1114–1122. [Google Scholar] [CrossRef]

- Forghani, Z.; Eskandari, M.H.; Aminlari, M.; Shekarforoush, S.S. Effects of microbial transglutaminase on physicochemical properties, electrophoretic patterns and sensory attributes of veggie burger. J. Food Sci. Technol. 2017, 54, 2203–2213. [Google Scholar] [CrossRef]

- Asgar, M.; Fazilah, A.; Huda, N.; Bhat, R.; Karim, A. Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Food Saf. 2010, 9, 513–529. [Google Scholar] [CrossRef]

- McMichael, A.J.; Powles, J.W.; Butler, C.D.; Uauy, R. Food, livestock production, energy, climate change, and health. Lancet 2007, 370, 1253–1263. [Google Scholar] [CrossRef]

- Singh, M.; Trivedi, N.; Enamala, M.K.; Kuppam, C.; Parikh, P.; Nikolova, M.P.; Chavali, M. Plant-based meat analogue (PBMA) as a sustainable food: A concise review. Eur. Food Res. Technol. 2021, 247, 2499–2526. [Google Scholar] [CrossRef]

- Machovina, B.; Feeley, K.J.; Ripple, W.J. Biodiversity conservation: The key is reducing meat consumption. Sci. Total Environ. 2015, 536, 419–431. [Google Scholar] [CrossRef]

- He, J.; Evans, N.M.; Liu, H.; Shao, S. A review of research on plant-based meat alternatives: Driving forces, history, manufacturing, and consumer attitudes. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2639–2656. [Google Scholar] [CrossRef]

- Whitnall, T.; Pitts, N. Global trends in meat consumption. Agric. Commod. 2019, 9, 96–99. [Google Scholar]

- Bouvard, V.; Loomis, D.; Guyton, K.Z.; Grosse, Y.; El Ghissassi, F.; Benbrahim-Tallaa, L.; Guha, N.; Mattock, H.; Straif, K.; Corpet, D.E. Carcinogenicity of consumption of red and processed meat. Lancet Oncol. 2015, 16, 1599–1600. [Google Scholar] [CrossRef] [Green Version]

- De Boer, I.H.; Bangalore, S.; Benetos, A.; Davis, A.M.; Michos, E.D.; Muntner, P.; Rossing, P.; Zoungas, S.; Bakris, G. Diabetes and hypertension: A position statement by the American Diabetes Association. Diabetes Care 2017, 40, 1273–1284. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fehér, A.; Gazdecki, M.; Véha, M.; Szakály, M.; Szakály, Z. A comprehensive review of the benefits and barriers to the switch to a plant-based diet. Sustainability 2020, 12, 4136. [Google Scholar] [CrossRef]

- Joo, S.-T.; Choi, J.-S.; Hur, S.-J.; Kim, G.-D.; Kim, C.-J.; Lee, E.-Y.; Bakhsh, A.; Hwang, Y.-H. A Comparative Study on the Taste Characteristics of Satellite Cell Cultured Meat Derived from Chicken and Cattle Muscles. Food Sci. Anim. Resour. 2022, 42, 175. [Google Scholar] [CrossRef] [PubMed]

- Hocquette, J.-F. Is in vitro meat the solution for the future? Meat Sci. 2016, 120, 167–176. [Google Scholar] [CrossRef] [PubMed]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Sabikun, N.; Hwang, Y.-H.; Joo, S.-T. A novel approach for tuning the physicochemical, textural, and sensory characteristics of plant-based meat analogs with different levels of methylcellulose concentration. Foods 2021, 10, 560. [Google Scholar] [CrossRef] [PubMed]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Hwang, Y.-H.; Joo, S.-T. Characteristics of Beef Patties Substituted by Different Levels of Textured Vegetable Protein and Taste Traits Assessed by Electronic Tongue System. Foods 2021, 10, 2811. [Google Scholar] [CrossRef]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Hwang, Y.-H.; Joo, S.-T. Evaluation of Rheological and Sensory Characteristics of Plant-Based Meat Analog with comparison to Beef and Pork. Food Sci. Anim. Resour. 2021, 41, 983–996. [Google Scholar] [CrossRef]

- Ismail, I.; Hwang, Y.-H.; Joo, S.-T. Meat analog as future food: A review. J. Anim. Sci. Technol. 2020, 62, 111. [Google Scholar] [CrossRef] [Green Version]

- Malav, O.; Talukder, S.; Gokulakrishnan, P.; Chand, S. Meat analog: A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1241–1245. [Google Scholar] [CrossRef] [PubMed]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-based meat analogues. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–126. [Google Scholar]

- Joshi, V.; Kumar, S. Meat Analogues: Plant based alternatives to meat products—A review. Int. J. Food Ferment. Technol. 2015, 5, 107–119. [Google Scholar] [CrossRef]

- Wild, F.; Czerny, M.; Janssen, A.M.; Kole, A.P.; Zunabovic, M.; Domig, K.J. The evolution of a plant-based alternative to meat. Agro. Food Ind. Hi Tech. 2014, 25, 45–49. [Google Scholar]

- Hoek, A.C.; Luning, P.A.; Weijzen, P.; Engels, W.; Kok, F.J.; De Graaf, C. Replacement of meat by meat substitutes. A survey on person-and product-related factors in consumer acceptance. Appetite 2011, 56, 662–673. [Google Scholar] [CrossRef]

- Graça, J.; Godinho, C.A.; Truninger, M. Reducing meat consumption and following plant-based diets: Current evidence and future directions to inform integrated transitions. Trends Food Sci. Technol. 2019, 91, 380–390. [Google Scholar] [CrossRef] [Green Version]

- Boatright, W.; Lu, G. Hexanal synthesis in isolated soy proteins. J. Am. Oil Chem. Soc. 2007, 84, 249–257. [Google Scholar] [CrossRef]

- Fiorentini, M.; Kinchla, A.J.; Nolden, A.A. Role of sensory evaluation in consumer acceptance of plant-based meat analogs and meat extenders: A scoping review. Foods 2020, 9, 1334. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef] [Green Version]

- Ncho, C.M.; Gupta, V.; Goel, A. Effect of thermal conditioning on growth performance and thermotolerance in broilers: A systematic review and meta-analysis. J. Therm. Biol. 2021, 98, 102916. [Google Scholar] [CrossRef]

- Ncho, C.M.; Jeong, C.; Gupta, V.; Goel, A. The effect of gamma-aminobutyric acid supplementation on growth performances, immune responses, and blood parameters of chickens reared under stressful environment: A meta-analysis. Environ. Sci. Pollut. Res. 2021, 28, 45019–45028. [Google Scholar] [CrossRef]

- Higgins, J.P.; Thomas, J.; Chandler, J.; Cumpston, M.; Li, T.; Page, M.J.; Welch, V.A. Cochrane Handbook for Systematic Reviews of Interventions; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Sunchaleev, O.A.; Zhuravskaia, N.K. Changes in the qualitative characteristics of ground beef patties containing textured soy flour. Vopr. Pitan. 2001, 70, 38–41. [Google Scholar] [PubMed]

- Kim, K.; Choi, B.; Lee, I.; Lee, H.; Kwon, S.; Oh, K.; Kim, A.Y. Bioproduction of mushroom mycelium of Agaricus bisporus by commercial submerged fermentation for the production of meat analogue. J. Sci. Food Agric. 2011, 91, 1561–1568. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Peng, M.; Tu, S.; Li, H.; Cai, L.; Yu, X. Development of a new meat analog through twin-screw extrusion of defatted soy flour-lean pork blend. Food Sci. Technol. Int. 2005, 11, 463–470. [Google Scholar] [CrossRef]

- Katayama, M.; Wilson, L.A. Utilization of soybeans and their components through the development of textured soy protein foods. J. Food Sci. 2008, 73, S158–S164. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Hsieh, F.-H. Protein–protein interactions during high-moisture extrusion for fibrous meat analogues and comparison of protein solubility methods using different solvent systems. J. Agric. Food Chem. 2008, 56, 2681–2687. [Google Scholar] [CrossRef] [PubMed]

- Pereira, C.; Marques, M.; Hatano, M.; Castro, I. Effect of the partial substitution of soy proteins by highly methyl-esterified pectin on chemical and sensory characteristics of sausages. Food Sci. Technol. Int. 2010, 16, 401–407. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, C.; Neidhart, S.; Carle, R. Application and sensory evaluation of enzymatically texturised vegetable proteins in food models. Eur. Food Res. Technol. 2011, 232, 1043–1056. [Google Scholar] [CrossRef]

- Gao, X.Q.; Zhang, W.G.; Zhou, G.H. Emulsion stability, thermo-rheology and quality characteristics of ground pork patties prepared with soy protein isolate and carrageenan. J. Sci. Food Agric. 2015, 95, 2832–2837. [Google Scholar] [CrossRef]

- Hidayat, B.; Wea, A.; Andriat, N. Physicochemical, sensory attributes and protein profile by SDS-PAGE of beef sausage substituted with texturized vegetable proteins. Food Res. 2018, 2, 20–31. [Google Scholar] [CrossRef]

- Ghribi, A.M.; Amira, A.B.; Gafsi, I.M.; Lahiani, M.; Bejar, M.; Triki, M.; Zouari, A.; Attia, H.; Besbes, S. Toward the enhancement of sensory profile of sausage “Merguez” with chickpea protein concentrate. Meat Sci. 2018, 143, 74–80. [Google Scholar] [CrossRef]

- Sah, W.I.; Alisha, N. The Influences of transglutaminase enzyme dosage on the meat characteristic from restructuring the animal and vegetable protein sources. In Proceedings of the 3rd International Tropical Renewable Energy Conference “Sustainable Development of Tropical Renewable Energy”, i-TREC 2018, Bali, Indonesia, 6–8 September 2018; p. 03043. [Google Scholar]

- Samard, S.; Ryu, G.H. A comparison of physicochemical characteristics, texture, and structure of meat analogue and meats. J. Sci. Food Agric. 2019, 99, 2708–2715. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.H. Physicochemical and functional characteristics of plant protein-based meat analogs. J. Food Process. Preserv. 2019, 43, e14123. [Google Scholar] [CrossRef]

- Murillo, J.S.; Osen, R.; Hiermaier, S.; Ganzenmüller, G. Towards understanding the mechanism of fibrous texture formation during high-moisture extrusion of meat substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Webb, D.; Plattner, B.J.; Donald, E.; Funk, D.; Plattner, B.S.; Alavi, S. Role of chickpea flour in texturization of extruded pea protein. J. Food Sci. 2020, 85, 4180–4187. [Google Scholar] [CrossRef] [PubMed]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ball, J.J.; Wyatt, R.P.; Coursen, M.M.; Lambert, B.D.; Sawyer, J.T. Meat Substitution with Oat Protein Can Improve Ground Beef Patty Characteristics. Foods 2021, 10, 3071. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Miller, R.; Laird, H.; Riaz, M.N. Beef flavor vegetable hamburger patties with high moisture meat analogs (HMMA) with pulse proteins-peas, lentils, and faba beans. Food Sci. Nutr. 2021, 9, 4048–4056. [Google Scholar] [CrossRef]

- Kim, T.; Riaz, M.N.; Awika, J.; Teferra, T.F. The effect of cooling and rehydration methods in high moisture meat analogs with pulse proteins-peas, lentils, and faba beans. J. Food Sci. 2021, 86, 1322–1334. [Google Scholar] [CrossRef]

- Saerens, W.; Smetana, S.; Van Campenhout, L.; Lammers, V.; Heinz, V. Life cycle assessment of burger patties produced with extruded meat substitutes. J. Clean. Prod. 2021, 306, 127177. [Google Scholar] [CrossRef]

- Sakai, K.; Sato, Y.; Okada, M.; Yamaguchi, S. Improved functional properties of meat analogs by laccase catalyzed protein and pectin crosslinks. Sci. Rep. 2021, 11, 16631. [Google Scholar] [CrossRef]

- Samard, S.; Gu, B.-Y.; Kim, M.-H.; Ryu, G.-H. Influences of extrusion parameters on physicochemical properties of textured vegetable proteins and its meatless burger patty. Food Sci. Biotechnol. 2021, 30, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.K.; Yong, H.I.; Cha, J.Y.; Park, S.Y.; Jung, S.; Choi, Y.S. Drying-induced restructured jerky analog developed using a combination of edible insect protein and textured vegetable protein. Food Chem. 2022, 373, 131519. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Oh, H.; Choi, I.; Yoon, C.S.; Han, J. Physico-chemical characteristics of rice protein-based novel textured vegetable proteins as meat analogues produced by low-moisture extrusion cooking technology. LWT-Food Sci. Technol. 2022, 157, 113056. [Google Scholar]

- Yuan, X.; Zhu, X.; Sun, R.; Jiang, W.; Zhang, D.; Liu, H.; Sun, B. Sensory attributes and characterization of aroma profiles of fermented sausages based on fibrous-like meat substitute from soybean protein and Coprinus comatus. Food Chem. 2022, 373, 131537. [Google Scholar] [CrossRef] [PubMed]

- Kmet, L.M.; Cook, L.S.; Lee, R.C. Standard Quality Assessment Criteria for Evaluating Primary Research Papers from a Variety of Fields; AHFMR, Alberta Heritage Foundation for Medical Research, University of Calgary Factutly of Medicne: Calgary, AB, Canada, 2004. [Google Scholar]

- Samard, S.; Gu, B.Y.; Ryu, G.H. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; van den Berg, F.W.; Zhang, W.; Czaja, T.P.; Zhang, L.; Jespersen, B.M.; Lametsch, R. Differences in physicochemical properties of high-moisture extrudates prepared from soy and pea protein isolates. Food Hydrocoll. 2022, 128, 107540. [Google Scholar] [CrossRef]

- Anjum, F.M.; Naeem, A.; Khan, M.I.; Nadeem, M.; Amir, R.M. Development of texturized vegetable protein using indigenous sources. Pak. J. Food Sci. 2011, 21, 33–44. [Google Scholar]

- Siddique, U. The Substitution of Textured Soy-Protein with Red Meat in Pizza Topping. Master’s Thesis, Department of Food Technology, University of Agriculture, Faisalabad, Pakistan, 2000. [Google Scholar]

- Arora, B.; Kamal, S.; Sharma, V. Effect of binding agents on quality characteristics of mushroom based sausage analogue. J. Food Process. Preserv. 2017, 41, e13134. [Google Scholar] [CrossRef]

- Bertolo, A.P.; Kempka, A.P.; Rigo, E.; Sehn, G.A.R.; Cavalheiro, D. Incorporation of natural and mechanically ruptured brewing yeast cells in beef burger to replace textured soy protein. J. Food Sci. Technol. 2022, 59, 935–943. [Google Scholar] [CrossRef]

- Kassama, L.; Ngadi, M.; Raghavan, G. Structural and instrumental textural properties of meat patties containing soy protein. Int. J. Food Prop. 2003, 6, 519–529. [Google Scholar] [CrossRef]

- De Angelis, D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.-L.; Squeo, G.; Summo, C. Physicochemical and sensorial evaluation of meat analogues produced from dry-fractionated pea and oat proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef]

- Qammar, G.; Mohyud Din, G.; Huma, N.; Sameen, A.; Khan, M.I. Textured soy protein (TSP) as pizza topping. Nutr. Food Sci. 2010, 40, 551–556. [Google Scholar] [CrossRef]

- Barnard, N.; Levin, S.; Trapp, C. Meat consumption as a risk factor for type 2 diabetes. Nutrients 2014, 6, 897–910. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leahy, E.; Lyons, S.; Tol, R.S. An Estimate of the Number of Vegetarians in the World; ESRI Working Paper; The Economic and Social Research Institute (ESRI): Dublin, Ireland, 2010. [Google Scholar]

- Riaz, M.N. Textured soy protein and its uses. Agro. Food Ind. Hi Tech. 2001, 12, 28–31. [Google Scholar]

- Riaz, M. Texturized soy protein as an ingredient. In Proteins Food Processing; Woodhead Publishing Ltd.: Cambridge, UK, 2004; pp. 517–558. [Google Scholar]

- Riaz, M.N. Soy Applications in Food; CRC Press: Boca Raton, FL, USA; Taylor & Francis, Inc.: Abingdon, UK, 2005; pp. 155–184. [Google Scholar]

- Ranasinghesagara, J.; Hsieh, F.H.; Yao, G. An image processing method for quantifying fiber formation in meat analogs under high moisture extrusion. J. Food Sci. 2005, 70, 450–454. [Google Scholar] [CrossRef]

- Egbert, R.; Borders, C. Achieving success with meat analogs. Food Technol. 2006, 60, 28–34. [Google Scholar]

- Singh, P.; Kumar, R.; Sabapathy, S.; Bawa, A. Functional and edible uses of soy protein products. Compr. Rev. Food Sci. Food Saf. 2008, 7, 14–28. [Google Scholar] [CrossRef]

- Imeson, A. Food Stabilisers, Thickeners and Gelling Agents; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Demirci, Z.O.; Yılmaz, I.; Demirci, A.Ş. Effects of xanthan, guar, carrageenan and locust bean gum addition on physical, chemical and sensory properties of meatballs. J. Food Sci. Technol. 2014, 51, 936–942. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Articles | Type of TVP Used | Binding Agent | Meat Type | Product Type | Quality Characteristics Evaluated |

|---|---|---|---|---|---|

| Sunchaleev et al., 2001 [34] | Soy | None | Beef | Patty | Physicochemical, organoleptic |

| Kim et al., 2011 [35] | Mushroom, Soy | Yes | Beef | Patty | Texture, Physiochemical |

| Liu et al., 2005 [36] | Soy | None | Pork | None | Texture, extrusion |

| Katayama et al., 2008 [37] | Soy | None | Chicken | None | Sensory, Texture, Physiochemical |

| Liu et al., 2008 [38] | Soy | None | None | None | Extrusion, Protein solubility |

| Pereira et al., 2011 [39] | Soy | Yes | Pork | Sausage | Texture, Physiochemical, sensory |

| Schäfer et al., 2011 [40] | Soy, Pea | Yes | Veal+ Pork | Sausage | Texture, Sensory, Gel strength |

| Gao et al., 2015 [41] | Soy | Yes | Pork | Patty | Texture, Thermo-rheology, chemical |

| Hidayat et al., 2018 [42] | Soy | Yes | Beef | Sausage | Physiochemical, Sensory, Texture |

| Ghribi et al., 2018 [43] | Chickpea | None | Turkey | Sausage | Physicochemical, Sensory, texture |

| Setiadi et al., 2018 [44] | Soy | Yes | Duck | None | Physicochemical, Texture |

| Samard et al., 2019a [45] | Soy, Wheat | None | Beef, Pork, Chicken | None | Physicochemical, Texture |

| Samard et al., 2019b [46] | Soy, Mung bean, Pea, Wheat | None | None | None | Physicochemical, Texture |

| Murillo et al., 2019 [47] | Pea | None | None | None | Diffusivity, Thermodynamics |

| Webb et al., 2020 [48] | Chickpea, Pea | None | Chicken, Beef | None | Physicochemical, Texture |

| Wi et al. et al., 2020 [49] | Soy | Yes | None | None | Physiochemical, Sensory, Texture |

| Bakhsh et al., 2021a [18] | Soy | Yes | Beef | Patty | Physiochemical, Sensory, Texture |

| Bakhsh et al., 2021b [20] | Soy | Yes | Beef, Pork | Patty | Physiochemical, Sensory, Texture |

| Bakhsh et al., 2021c [19] | Soy | Yes | Beef | Patty | Physiochemical, Sensory, Texture |

| Ball et al., 2021 [50] | Soy, Oat | None | Beef | Patty | Physicochemical, storage |

| Kim et al., 2021a [51] | Soy, Pea Lentils, Faba bean | None | Beef | Patty | Physiochemical, Sensory, Texture |

| Kim et al., 2021b [52] | Pea, Soy, Lentils, Faba beans | None | None | None | Physicochemical, Texture |

| Saerens et al., 2021 [53] | Soy, Pumpkin seed | None | Beef, chicken, Pork | Patty | Extrusion, Climate change, |

| Sakai et al., 2021 [54] | Soy | Yes | None | Patty | Physicochemical, Texture |

| Samard et al., 2021 [55] | Soy, Wheat gluten | Yes | None | Patty | Physicochemical, Texture |

| Kim et al., 2022 [56] | Soy, Insect | None | None | Jerky | Physicochemical, Tenderness |

| Lee et al., 2022 [57] | Rice, Soy, Wheat | None | None | None | Physiochemical, Texture, Extrusion |

| Yuan et al., 2022 [58] | Soy | None | None | Sausage | Physiochemical, Sensory, Texture |

| Articles | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sunchaleev et al.2001 [34] | No | Partial | Partial | partial | N/A | N/A | N/A | Partial | Partial | Partial | No | No | Partial | Yes |

| Kim et al., 2011 [35] | Partial | Yes | Partial | Yes | N/A | N/A | N/A | Yes | Partial | Yes | No | No | Yes | Yes |

| Liu et al., 2005 [36] | Partial | Yes | Partial | Yes | N/A | N/A | N/A | Partial | Partial | Partial | yes | yes | Yes | Yes |

| Katayama et al., 2008 [37] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | Yes | Partial | Yes | yes | Yes | Yes | Yes |

| Liu et al., 2008 [38] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | Yes | Partial | Yes | No | No | Partial | Partial |

| Pereira et al., 2011 [39] | Yes | Yes | Partial | No | N/A | N/A | N/A | Partial | Partial | Yes | yes | yes | Yes | Yes |

| Schäfer et al., 2011 [40] | Partial | Yes | Yes | Yes | N/A | N/A | N/A | No | Partial | Partial | Partial | yes | Yes | Yes |

| Gao et al., 2015 [41] | Yes | Yes | Partial | Yes | N/A | N/A | N/A | Partial | Partial | Partial | No | yes | Yes | Yes |

| Hidayat et al., 2018 [42] | Yes | Yes | Partial | partial | N/A | N/A | N/A | No | Yes | Partial | No | yes | Yes | Yes |

| Ghribi et al., 2018 [43] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | No | Yes | Yes | Partial | yes | Partial | Yes |

| Setiadi et al., 2018 [44] | No | Partial | Partial | No | N/A | N/A | N/A | No | Partial | No | No | yes | Partial | Yes |

| Samard et al., 2019a [45] | No | Yes | Yes | partial | N/A | N/A | N/A | No | Yes | Yes | yes | yes | Yes | Yes |

| Samard et al., 2019b [46] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | Partial | Partial | Yes | yes | No | Yes | Yes |

| Murillo et al., 2019 [47] | No | Yes | Partial | Yes | N/A | N/A | N/A | Yes | Partial | Yes | yes | No | Yes | Yes |

| Webb et al., 2020 [48] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | Partial | Partial | Yes | No | No | No | Yes |

| Wi et al. et al., 2020 [49] | Yes | yes | Yes | Partial | N/A | N/A | N/A | Partial | Yes | Yes | No | No | Yes | Yes |

| Bakhsh et al., 2021a [18] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | Partial | Yes | Partial | No | yes | Yes | Yes |

| Bakhsh et al., 2021b [20] | Yes | Partial | No | Yes | N/A | N/A | N/A | Partial | Yes | Partial | yes | No | Yes | Yes |

| Bakhsh et al., 2021c [19] | Yes | Yes | No | Yes | N/A | N/A | N/A | Partial | Yes | Partial | yes | yes | Yes | yes |

| Ball et al., 2021 [50] | Yes | Yes | No | Yes | N/A | N/A | N/A | Partial | No | Partial | yes | yes | yes | Yes |

| Kim et al., 2021a [51] | Yes | Yes | Partial | Yes | N/A | N/A | N/A | Partial | Partial | Yes | yes | yes | Yes | No |

| Kim et al., 2021b [52] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | Partial | No | Partial | No | yes | Partial | Yes |

| Saerens et al., 2021 [53] | Yes | Yes | Yes | Yes | N/A | N/A | N/A | Partial | Partial | Partial | yes | No | Yes | Yes |

| Sakai et al., 2021 [54] | Yes | Partial | Partial | Yes | N/A | N/A | N/A | Partial | Partial | Yes | yes | yes | Partial | Yes |

| Samard et al., 2021 [55] | Yes | Yes | Partial | Yes | N/A | N/A | N/A | Yes | No | Yes | No | yes | Yes | Yes |

| Kim et al., 2022 [56] | Yes | Yes | Partial | partial | N/A | N/A | N/A | Partial | No | Yes | No | No | Yes | Yes |

| Lee et al., 2022 [57] | Partial | Yes | Partial | Yes | N/A | N/A | N/A | Yes | No | Yes | No | yes | Yes | Yes |

| Yuan et al., 2022 [58] | Partial | Yes | Yes | Yes | N/A | N/A | N/A | Partial | Yes | No | No | No | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakhsh, A.; Lee, E.-Y.; Ncho, C.M.; Kim, C.-J.; Son, Y.-M.; Hwang, Y.-H.; Joo, S.-T. Quality Characteristics of Meat Analogs through the Incorporation of Textured Vegetable Protein: A Systematic Review. Foods 2022, 11, 1242. https://doi.org/10.3390/foods11091242

Bakhsh A, Lee E-Y, Ncho CM, Kim C-J, Son Y-M, Hwang Y-H, Joo S-T. Quality Characteristics of Meat Analogs through the Incorporation of Textured Vegetable Protein: A Systematic Review. Foods. 2022; 11(9):1242. https://doi.org/10.3390/foods11091242

Chicago/Turabian StyleBakhsh, Allah, Eun-Yeong Lee, Chris Major Ncho, Chan-Jin Kim, Yu-Min Son, Young-Hwa Hwang, and Seon-Tea Joo. 2022. "Quality Characteristics of Meat Analogs through the Incorporation of Textured Vegetable Protein: A Systematic Review" Foods 11, no. 9: 1242. https://doi.org/10.3390/foods11091242

APA StyleBakhsh, A., Lee, E.-Y., Ncho, C. M., Kim, C.-J., Son, Y.-M., Hwang, Y.-H., & Joo, S.-T. (2022). Quality Characteristics of Meat Analogs through the Incorporation of Textured Vegetable Protein: A Systematic Review. Foods, 11(9), 1242. https://doi.org/10.3390/foods11091242