Reformulation of Traditional Fermented Tea Sausage Utilizing Novel (Digital) Methods of Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Survey

2.2. Sausage Production

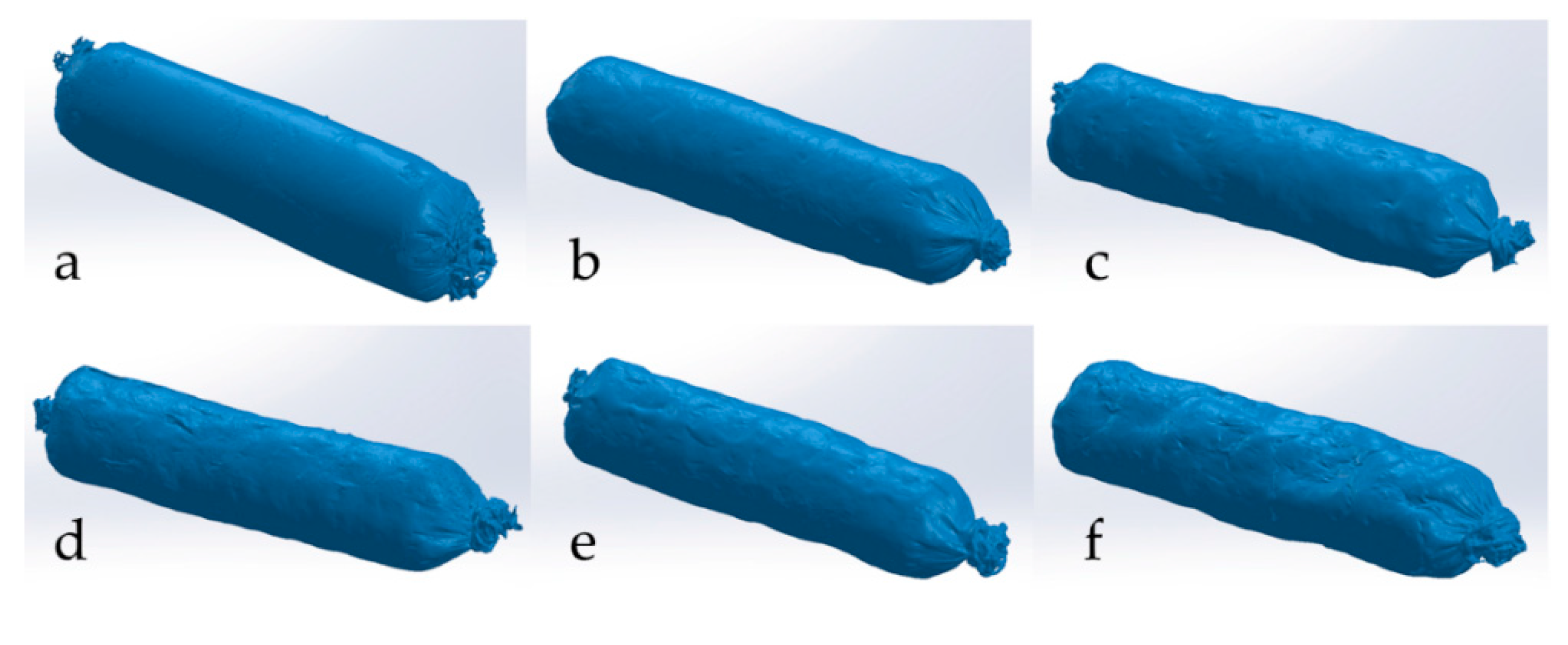

2.3. 3D Laser Imaging

2.4. CVS Analysis

2.5. TPA Analysis

2.6. Physicochemical Analyses

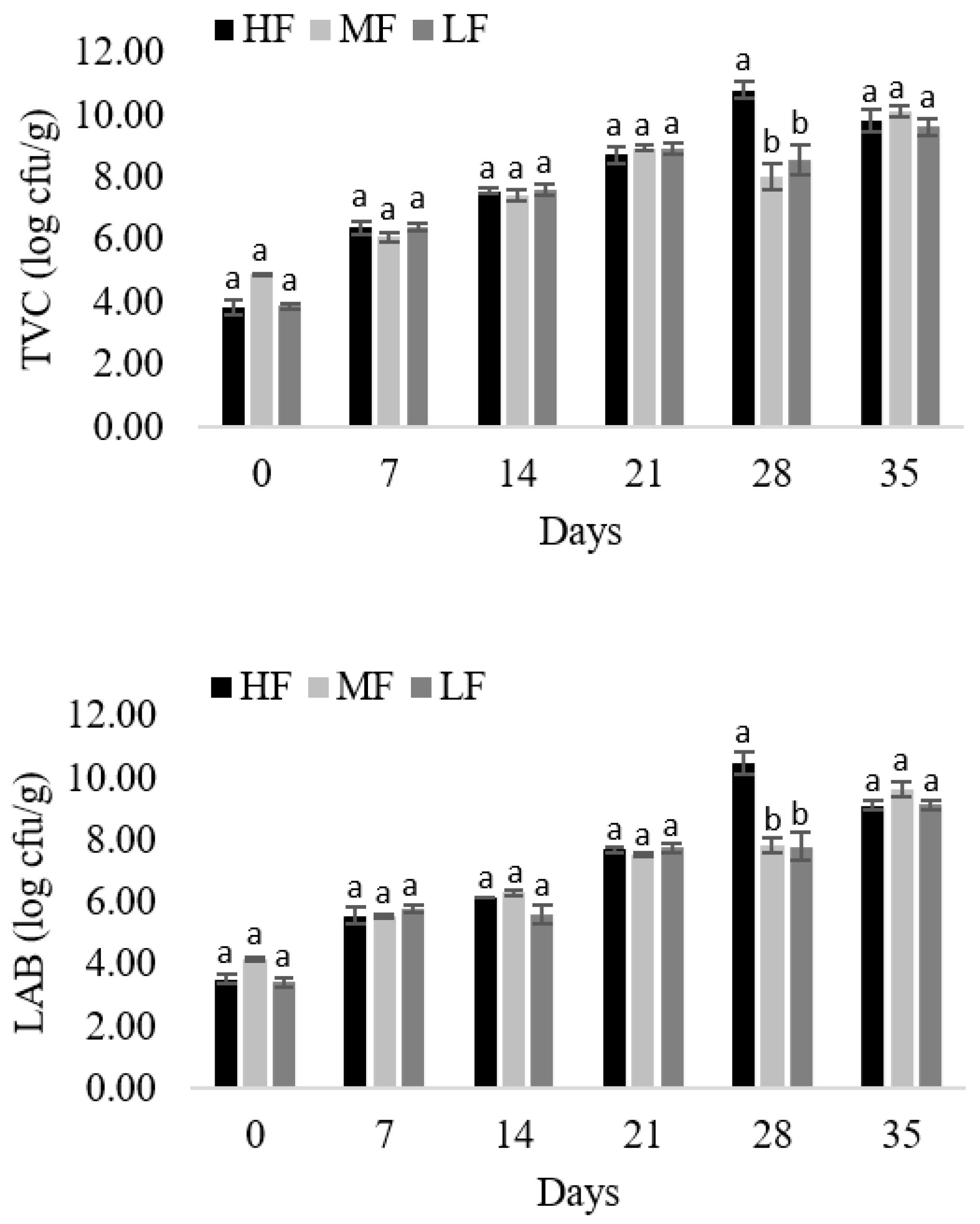

2.7. Microbiological Analyses

2.8. Descriptive Sensory Analysis

2.9. Oral Processing

2.10. Statistical Analysis

3. Results and Discussion

3.1. Survey

3.2. 3D Laser Imaging

3.3. CVS

3.4. TPA

3.5. Physicochemical Analysis

3.6. Oxidative Stability

3.7. Microbiological Analysis

3.8. Descriptive Sensory Analysis

3.9. Oral Processing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement:

Conflicts of Interest

References

- Tomasevic, I.; Simunovic, S.; Đorđević, V.; Djekic, I.; Tomovic, V. Traditional Pork Sausages in Serbia. In Pork-Meat Quality and Processed Meat Products; Munekata, P.E.S., Pateiro, M., Franco, D., Lorenzo, J., Eds.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Forouhi, N.G.; Krauss, R.M.; Taubes, G.; Willett, W. Dietary fat and cardiometabolic health: Evidence, controversies, and consensus for guidance. BMJ 2018, 361, k2139. [Google Scholar] [CrossRef] [PubMed]

- Lahoz, C.; Alonso, R.; Ordovás, J.M.; López-Farré, A.; De Oya, M.; Mata, P. Effects of dietary fat saturation on eicosanoid production, platelet aggregation and blood pressure. Eur. J. Clin. Investig. 1997, 27, 780–787. [Google Scholar] [CrossRef] [PubMed]

- Micha, R.; Mozaffarian, D. Saturated fat and cardiometabolic risk factors, coronary heart disease, stroke, and diabetes: A fresh look at the evidence. Lipids 2010, 45, 893–905. [Google Scholar] [CrossRef] [PubMed]

- Potvin Kent, M.; Pauzé, E.; Guo, K.; Kent, A.; Jean-Louis, R. The physical activity and nutrition-related corporate social responsibility initiatives of food and beverage companies in Canada and implications for public health. BMC Public Health 2020, 20, 890. [Google Scholar] [CrossRef]

- Rajic, S.; Đorđević, V.; Tomasevic, I.; Djekic, I. The role of food systems in achieving the sustainable development goals: Environmental perspective. Bus. Strategy Environ. 2022, 31, 988–1001. [Google Scholar] [CrossRef]

- Hamilton, J.; Knox, B.; Hill, D.; Parr, H. Reduced fat products-Consumer perceptions and preferences. Br. Food J. 2000, 102, 494–506. [Google Scholar] [CrossRef]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Purriños, L.; Cerqueira, M.A.; Vicente, A.A.; Pastrana, L.M.; Zapata, C.; Lorenzo, J.M. Strategy towards Replacing Pork Backfat with a Linseed Oleogel in Frankfurter Sausages and Its Evaluation on Physicochemical, Nutritional, and Sensory Characteristics. Foods 2019, 8, 366. [Google Scholar] [CrossRef]

- Muguerza, E.; Fista, G.; Ansorena, D.; Astiasaran, I.; Bloukas, J.G. Effect of fat level and partial replacement of pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 2002, 61, 397–404. [Google Scholar] [CrossRef]

- Pintado, T.; Cofrades, S. Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer. Foods 2020, 9, 830. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Franco, D. Fat effect on physico-chemical, microbial and textural changes through the manufactured of dry-cured foal sausage Lipolysis, proteolysis and sensory properties. Meat Sci. 2012, 92, 704–714. [Google Scholar] [CrossRef]

- Israel, G.D. Determining Sample Size; University of Florida: Gainesville, FL, USA, 1992. [Google Scholar]

- Vaskoska, R.; Ha, M.; Tran, H.T.T.; Khoshelham, K.; White, J.D.; Warner, R.D. Evaluation of 3D Laser Scanning for Estimation of Heating-Induced Volume Shrinkage and Prediction of Cooking Loss of Pork Cuboids Compared to Manual Measurements. Food Bioprocess. Technol. 2020, 13, 938–947. [Google Scholar] [CrossRef]

- Wong, J.M.; Elwood, D.; Fredlund, D.G. Use of a three-dimensional scanner for shrinkage curve tests. Can. Geotech. J. 2019, 56, 526–535. [Google Scholar] [CrossRef]

- Zhang, R.; Li, F.; Tang, J.; Koral, T.; Jiao, Y. Improved accuracy of radio frequency (RF) heating simulations using 3D scanning techniques for irregular-shape food. LWT 2020, 121, 108951. [Google Scholar] [CrossRef]

- Tomasevic, I.; Tomovic, V.; Milovanovic, B.; Lorenzo, J.; Đorđević, V.; Karabasil, N.; Djekic, I. Comparison of a computer vision system vs. traditional colorimeter for color evaluation of meat products with various physical properties. Meat Sci. 2019, 148, 5–12. [Google Scholar] [CrossRef]

- Simunovic, S.; Đorđević, V.; Barba, F.J.; Lorenzo, J.M.; Rašeta, M.; Janković, S.; Tomasevic, I. Characterisation of changes in physicochemical, textural and microbiological properties of Njeguška sausage during ripening. J. Food Sci. Technol. 2021, 58, 3993–4001. [Google Scholar] [CrossRef]

- Djekic, I.; Lorenzo, J.M.; Munekata, P.E.S.; Gagaoua, M.; Tomasevic, I. Review on characteristics of trained sensory panels in food science. J. Texture Stud. 2021, 52, 501–509. [Google Scholar] [CrossRef]

- Djekic, I.; Ilic, J.; Guiné, R.P.F.; Tomasevic, I. Can we understand food oral processing using Kano model? Case study with confectionery products. J. Texture Stud. 2020, 51, 861–869. [Google Scholar] [CrossRef]

- Goñi, S.; Purlis, E.; Salvadori, V. Three-dimensional reconstruction of irregular foodstuffs. J. Food Eng. 2007, 82, 536–547. [Google Scholar] [CrossRef]

- Tomašević, I.; Putnik, P.; Valjak, F.; Pavlić, B.; Šojić, B.; Bebek Markovinović, A.; Bursać Kovačević, D. 3D printing as novel tool for fruit-based functional food production. Curr. Opin. Food Sci. 2021, 41, 138–145. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, X.; Qiu, Z.; He, Y. A novel method for measuring the volume and surface area of egg. J. Food Eng. 2016, 170, 160–169. [Google Scholar] [CrossRef]

- Uyar, R.; Erdoğdu, F. Potential use of 3-dimensional scanners for food process modeling. J. Food Eng. 2009, 93, 337–343. [Google Scholar] [CrossRef]

- Bolumar, T.; Toepfl, S.; Heinz, V. Fat Reduction and Replacement in Dry-Cured Fermented Sausage by Using High Pressure Processing Meat as Fat Replacer and Olive Oil. Pol. J. Food Nutr. Sci. 2015, 65, 175–182. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Serra, X.; Guàrdia, M.D.; Arnau, J. Effect of reducing and replacing pork fat on the physicochemical, instrumental and sensory characteristics throughout storage time of small caliber non-acid fermented sausages with reduced sodium content. Meat Sci. 2014, 97, 62–68. [Google Scholar] [CrossRef]

- Yim, D.-G.; Jang, K.-H.; Chung, K.-Y. Effect of Fat Level and the Ripening Time on Quality Traits of Fermented Sausages. Asian-Australas. J. Anim. Sci. 2016, 29, 119–125. [Google Scholar] [CrossRef][Green Version]

- Lorenzo, J.M.; Temperán, S.; Bermúdez, R.; Cobas, N.; Purriños, L. Changes in physico-chemical, microbiological, textural and sensory attributes during ripening of dry-cured foal salchichón. Meat Sci. 2012, 90, 194–198. [Google Scholar] [CrossRef]

- Altmanna, B.; Gertheiss, J.; Tomasevic, I.; Engelkes, C.; Glaesener, T.; Meye, J.; Schäfer, A.; Wiesen, R.; Mörlein, D. Human perception of color differences using computer vision system measurements of raw pork loin. Meat Sci. 2022, 188, 108766. [Google Scholar] [CrossRef]

- Simunovic, S.; Djordjevic, V.; Bogdanovic, S.; Dimkic, I.; Stankovic, S.; Novakovic, S.; Tomasevic, I. Changes in chemical attributes during ripening of traditional fermented sausage, “Pirot ironed”. IOP Conf. Ser. Earth Environ. Sci. 2019, 333, 012100. [Google Scholar] [CrossRef]

- Cullere, M.; Novelli, E.; Dalle Zotte, A. Fat Inclusion Level, NaCl Content and LAB Starter Cultures in the Manufacturing of Italian-Type Ostrich Salami: Weight Loss and Nutritional Traits. Foods 2020, 9, 476. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef]

- Hospital, X.F.; Hierro, E.; Fernández, M. Survival of Listeria innocua in dry fermented sausages and changes in the typical microbiota and volatile profile as affected by the concentration of nitrate and nitrite. Int. J. Food Microbiol. 2012, 153, 395–401. [Google Scholar] [CrossRef]

- Hospital, X.F.; Hierro, E.; Fernández, M. Effect of reducing nitrate and nitrite added to dry fermented sausages on the survival of Salmonella Typhimurium. Food Res. Int. 2014, 62, 410–415. [Google Scholar] [CrossRef]

- Hospital, X.F.; Hierro, E.; Stringer, S.; Fernández, M. A study on the toxigenesis by Clostridium botulinum in nitrate and nitrite-reduced dry fermented sausages. Int. J. Food Microbiol. 2016, 218, 66–70. [Google Scholar] [CrossRef]

- Wirth, F. Technologies for making fat-reduce meat products. What possibilities are there? Fleisechwirtschaf 1988, 68, 1153–1156. [Google Scholar]

- Koç, H.; Çakir, E.; Vinyard, C.J.; Essick, G.; Daubert, C.R.; Drake, M.A.; Osborne, J.; Foegeding, E.A. Adaptation of Oral Processing to the Fracture Properties of Soft Solids. J. Texture Stud. 2014, 45, 47–61. [Google Scholar] [CrossRef]

- Peyron, M.A.; Lassauzay, C.; Woda, A. Effects of increased hardness on jaw movement and muscle activity during chewing of visco-elastic model foods. Exp. Brain Res. 2002, 142, 41–51. [Google Scholar] [CrossRef]

| Processing Time (Days) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | SEM | 7 | SEM | 14 | SEM | ||||||||

| HF | MF | LF | HF | MF | LF | HF | MF | LF | |||||

| Shrinkage (%) | 17.71 1a | 22.51 2a | 23.55 3a | 22.66 1b | 30.74 2b | 35.63 3b | 1.92 | ||||||

| Chemical parameters | |||||||||||||

| pH | 5.39 1a | 5.39 1a | 5.40 1a | 0.00 | 4.95 1b | 5.05 2b | 5.13 3b | 0.03 | 4.93 1b | 4.99 2c | 5.11 3c | 0.03 | |

| aw | 0.939 1a | 0.943 1a | 0.943 1a | 0.00 | 0.931 1b | 0.930 1b | 0.932 1b | 0.00 | 0.915 1c | 0.901 2c | 0.894 3c | 0.00 | |

| Protein (% DM) | 33.14 1a | 39.70 2a | 46.17 3a | 1.89 | 34.15 1a | 39.13 2a | 46.10 3a | 1.74 | 33.91 1a | 39.00 2a | 45.27 3a | 1.65 | |

| Fat (% DM) | 59.00 1a | 55.59 2a | 44.46 3a | 2.20 | 56.60 1b | 52.61 2b | 43.48 3ab | 1.95 | 58.98 1a | 54.00 2ab | 45.82 3a | 1.92 | |

| Moisture (%) | 54.94 1a | 58.40 2a | 61.93 3a | 1.01 | 45.09 1b | 50.35 2b | 53.97 3b | 1.29 | 42.48 1 c | 41.73 2c | 40.27 3c | 0.32 | |

| Ash (%) | 3.02 12a | 2.95 1a | 3.16 2a | 0.03 | 3.54 1b | 3.71 2b | 3.78 2b | 0.04 | 3.66 1b | 4.16 2c | 4.83 3c | 0.17 | |

| Weight loss (%) | 16.511a | 22.84 2a | 26.04 3a | 22.34 1b | 32.08 2b | 37.43 3b | 2.21 | ||||||

| Lipid oxidation | |||||||||||||

| TBARS (mg MAL/kg) | 0.04 1a | 0.03 1a | 0.04 1a | 0.00 | 0.04 1ac | 0.05 1ab | 0.06 1ab | 0.00 | 0.05 1abc | 0.06 1ab | 0.07 1ab | 0.00 | |

| Acid value (mg KOH/g) | 0.93 1a | 1.55 2a | 1.99 3a | 0.15 | 1.00 1a | 1.65 2a | 1.66 2b | 0.11 | 2.32 1b | 3.47 2b | 4.33 3c | 0.29 | |

| Peroxide value (meq/kg) | 4.24 1a | 4.68 2a | 4.14 1a | 0.08 | 4.30 1a | 4.74 2a | 3.21 3b | 0.23 | 3.54 1b | 1.52 2b | 0.90 3c | 0.40 | |

| TPA test | |||||||||||||

| Hardness (n) | 5.00 1a | 7.12 2a | 8.97 3a | 0.34 | 13.01 1b | 23.38 2b | 36.44 3b | 1.91 | 24.12 1c | 38.70 2c | 50.57 3c | 2.28 | |

| Springiness | 0.62 1a | 0.63 1a | 0.71 2a | 0.01 | 0.64 1a | 0.73 2b | 0.81 3b | 0.02 | 0.60 1a | 0.70 12bc | 0.69 2a | 0.01 | |

| Cohesiveness | 0.42 1a | 0.47 2ab | 0.43 12a | 0.01 | 0.39 1a | 0.45 1a | 0.53 2b | 0.01 | 0.46 1ab | 0.49 2ab | 0.52 2bc | 0.01 | |

| Gumminess (n) | 2.06 1a | 3.13 2a | 3.77 3a | 0.15 | 6.99 1b | 10.41 2b | 15.87 3b | 0.74 | 12.48 1c | 20.87 2c | 30.19 3c | 1.46 | |

| Chewiness (n) | 1.31 1a | 2.03 2a | 2.61 3a | 0.11 | 4.72 1b | 7.12 2b | 12.87 3b | 0.70 | 7.22 1b | 12.68 2c | 20.15 3c | 1.08 | |

| Resilience | 0.06 1a | 0.09 2a | 0.08 2a | 0.00 | 0.08 1ab | 0.10 2abc | 0.17 3b | 0.01 | 0.10 1bc | 0.12 2b | 0.13 2c | 0.00 | |

| Colour | |||||||||||||

| Meat | L* | 51.43 1a | 51.57 1a | 51.29 1a | 0.66 | 49.86 1ab | 51.71 1a | 51.29 1a | 1.47 | 43.71 1b | 43.43 1b | 40.57 1a | 0.87 |

| a* | 39.14 1a | 38.57 1a | 39.43 1ac | 0.63 | 35.86 1ab | 35.43 1ab | 35.71 1abc | 0.54 | 33.86 1ab | 32.71 1b | 33.43 1bc | 0.61 | |

| b* | 15.71 1a | 16.14 1a | 16.86 1a | 0.57 | 13.57 1a | 12.14 1ab | 14.14 1ab | 0.60 | 13.71 1a | 12.57 1ab | 13.85 1ab | 0.63 | |

| Fat | L* | 81.57 1a | 79.71 1ab | 81.71 1a | 0.51 | 78.57 1a | 82.14 1b | 81.71 1a | 0.60 | 70.57 1b | 68.86 1c | 71.29 1b | 0.94 |

| a* | 8.57 1ab | 9.86 1a | 7.86 1abc | 0.41 | 9.57 1ab | 7.86 1ab | 8.14 1abc | 0.38 | 12.86 1a | 11.29 1a | 9.71 1a | 0.68 | |

| b* | 1.14 1a | 0.86 1a | 0.57 1a | 0.34 | −0.29 1a | −1.14 1ab | −0.29 1ab | 0.38 | −1.29 1a | −1.14 1ab | −2.14 1ab | 0.35 | |

| Casings | L* | 45.57 1a | 44.57 1a | 45.71 1a | 0.84 | 25.57 1b | 23.43 1b | 23.86 1b | 0.59 | 16.43 1c | 16.29 1b | 18.43 1bc | 0.97 |

| a* | 45.29 1a | 43.57 1a | 43.57 1a | 0.45 | 38.86 1b | 36.14 12b | 34.19 2b | 0.57 | 26.57 1c | 24.29 1c | 23.43 1c | 0.74 | |

| b* | 19.57 1a | 17.00 12ab | 14.71 1a | 0.61 | 26.71 1b | 22.71 12a | 18.71 2a | 0.95 | 16.57 1a | 13.43 1b | 13.86 1a | 0.76 | |

| Processing Time (Days) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 21 | SEM | 28 | SEM | 35 | SEM | ||||||||

| HF | MF | LF | HF | MF | LF | HF | MF | LF | |||||

| Shrinkage (%) | 24.45 1c | 32.27 2b | 40.37 3c | 2.31 | 28.00 1d | 37.18 2c | 42.45 3cd | 2.12 | 29.87 1d | 39.41 2c | 44.41 3d | 2.14 | |

| Chemical parameters | |||||||||||||

| pH | 5.01 1c | 5.11 2d | 5.27 3d | 0.04 | 4.95 1b | 5.05 2b | 5.19 3e | 0.03 | 5.08 1d | 5.15 2e | 5.21 3f | 0.02 | |

| aw | 0.908 1d | 0.890 2d | 0.866 3d | 0.01 | 0.890 1e | 0.872 2e | 0.846 3e | 0.01 | 0.875 1f | 0.824 2f | 0.807 3f | 0.01 | |

| Protein (% DM) | 34.21 1a | 39.12 2a | 44.73 3a | 1.52 | 32.90 1a | 40.05 2a | 46.05 3a | 1.90 | 34.18 1a | 40.33 2a | 45.22 3a | 1.60 | |

| Fat (% DM) | 55.52 1bc | 50.92 2bc | 44.34 3ab | 1.62 | 59.15 1a | 49.58 2cd | 44.31 3ab | 2.18 | 57.22 1b | 48.38 2d | 44.72 3a | 1.86 | |

| Moisture | 40.58 1d | 37.67 2d | 35.18 3d | 0.78 | 36.28 1e | 34.43 2e | 32.70 3e | 0.52 | 33.60 1f | 30.76 2f | 29.72 3f | 0.58 | |

| Ash | 4.12 1c | 4.72 2d | 5.28 3d | 0.17 | 4.06 1c | 4.86 2d | 5.67 3e | 0.23 | 4.54 1d | 5.34 2f | 5.84 3e | 0.19 | |

| Weight loss (%) | 25.42 1c | 35.92 2c | 41.30 3c | 2.34 | 28.23 1d | 38.58 2d | 44.43 3d | 2.37 | 30.56 1e | 40.98 2e | 46.98 3e | 2.40 | |

| Lipid oxidation | |||||||||||||

| TBARS (mg MAL/kg) | 0.05 1ac | 0.07 12b | 0.08 2b | 0.00 | 0.08 1bc | 0.06 1b | 0.08 1b | 0.02 | 0.07 1bc | 0.08 1b | 0.07 1ab | 0.00 | |

| Acid value (mg KOH/g) | 3.71 1c | 3.63 1c | 4.76 2d | 0.18 | 5.84 1d | 5.58 2d | 7.65 3e | 0.32 | 6.23 1e | 6.72 2f | 7.62 e | 0.20 | |

| Peroxide value (meq/kg) | 2.35 1c | 1.65 2c | 0.95 3cd | 0.20 | 2.63 1d | 1.63 2c | 1.05 3de | 0.23 | 2.34 1c | 1.93 2d | 1.08 3e | 0.19 | |

| TPA test | |||||||||||||

| Hardness (n) | 34.30 1d | 48.12 2d | 63.67 3d | 2.48 | 45.69 1e | 58.59 2e | 74.26 3d | 2.55 | 57.12 1f | 70.15 2f | 90.64 3e | 3.09 | |

| Springiness | 0.67 1ab | 0.65 1ac | 0.56 2c | 0.01 | 0.58 1ac | 0.60 1a | 0.55 1c | 0.01 | 0.61 12a | 0.63 1a | 0.55 2c | 0.01 | |

| Cohesiveness | 0.46 1ac | 0.44 1a | 0.48 1ac | 0.01 | 0.40 1a | 0.41 1ac | 0.46 2a | 0.01 | 0.37 1ad | 0.37 1c | 0.44 2a | 0.01 | |

| Gumminess (n) | 17.21 1d | 26.55 2d | 39.64 3d | 1.85 | 25.42 1e | 32.33 2e | 50.00 3e | 2.08 | 30.75 1f | 40.52 2f | 61.14 3f | 2.59 | |

| Chewiness (n) | 12.91 1c | 20.56 2d | 31.71 3d | 1.57 | 18.65 1d | 28.78 2e | 37.27 3e | 1.54 | 25.59 1e | 33.79 2f | 44.33 3f | 1.72 | |

| Resilience | 0.11 1c | 0.12 1b | 0.12 1c | 0.00 | 0.08 1abd | 0.09 1acd | 0.13 2c | 0.00 | 0.07 1ad | 0.07 1d | 0.12 2c | 0.00 | |

| Colour | |||||||||||||

| Meat | L* | 44.14 1b | 42.86 1b | 40.71 1a | 0.89 | 45.57 1ab | 44.29 1b | 44.86 1a | 0.71 | 44.57 1ab | 45.71 1ab | 45.86 1a | 0.64 |

| a* | 32.86 1b | 33.14 1b | 32.14 1b | 0.46 | 36.86 1ab | 36.57 1ab | 34.14 1bc | 0.45 | 39.43 1a | 36.57 1ab | 37.43 1c | 0.57 | |

| b* | 12.86 1a | 12.14 1ab | 14.14 1ab | 0.51 | 15.43 1a | 15.71 1ab | 13.57 1ab | 0.41 | 12.29 1a | 11.71 1b | 11.57 1b | 0.25 | |

| Fat | L* | 75.14 1ab | 75.29 1a | 72.57 1b | 0.97 | 78.29 1ab | 78.14 1ab | 76.29 1ab | 0.67 | 77.29 1ab | 78.86 1ab | 76.71 1ab | 0.74 |

| a* | 11.14 1ab | 9.14 1a | 10.57 1a | 0.61 | 9.29 1ab | 8.14 1ab | 9.86 1a | 0.36 | 6.86 1b | 4.71 1b | 5.14 1c | 0.38 | |

| b* | −1.29 1a | −2.00 1b | −2.71 1ab | 0.46 | −1.86 1a | −2.43 1b | −3.57 1b | 0.31 | −1.14 1a | −1.29 1ab | −1.86 1ab | 0.39 | |

| Casing | L* | 16.00 1c | 17.71 1b | 15.57 1c | 0.79 | 16.57 1c | 17.57 1b | 16.14 1c | 0.54 | 15.86 1c | 16.00 1b | 17.71 1bc | 0.74 |

| a* | 28.86 1cd | 25.57 1c | 23.86 1c | 0.89 | 32.57 1d | 29.57 1bc | 28.57 1bc | 1.38 | 30.71 1cd | 27.43 1c | 25.00 1bc | 0.88 | |

| b* | 18.29 1a | 18.14 1ab | 14.57 1a | 0.77 | 17.14 1a | 17.43 1ab | 14.43 1a | 0.76 | 17.43 1a | 18.86 1ab | 15.57 1a | 0.72 | |

| 35 Day | 28 Day | |||||

|---|---|---|---|---|---|---|

| Attributes | HF (Control) | MF | LF | HF | MF | LF |

| Colour | 4.50 ± 0.67 a | 3.75 ± 0.79 ab | 3.33 ± 0.49 b | 3.83 ± 0.58 ab | 4.42 ± 0.79 a | 3.58 ± 0.51 ab |

| Aroma | 4.58 ± 0.45 a | 4.33 ± 0.89 ab | 3.33 ± 0.52 b | 4.08 ± 0.90 ab | 4.50 ± 0.67 ac | 3.67 ± 0.49 bc |

| Taste | 4.67 ± 0.49 a | 3.92 ± 0.90 ab | 3.42 ± 0.67 b | 4.00 ± 0.43 ab | 4.25 ± 0.96 ab | 3.75 ± 0.45 ab |

| Consistency | 3.96 ± 0.67 a | 4.08 ± 0.79 a | 3.83 ± 0.83 a | 3.67 ± 0.49 a | 4.17 ± 0.71 a | 3.92 ± 0.79 a |

| Overall acceptability | 4.67 ± 0.49 a | 3.83 ± 0.71 b | 3.08 ± 0.29 b | 3.75 ± 0.62 b | 4.75 ± 0.45 a | 3.42 ± 0.51 b |

| Number of Chews | Consumption Time of One Bite (s) | Chewing Rate (chew/s) | Average Bite Size (g) | Eating Rate (g/s) | Fat Intake Rate (fat/s) | |

|---|---|---|---|---|---|---|

| HF-35 | 28.88 ± 3.5 a | 17.21 ± 1.8 a | 1.68 ± 0.06 a | 7.12 ± 0.55 a | 0.42 ± 0.04 a | 0.15 ± 0.01 a |

| MF-28 | 29.67 ± 5.1 a | 17.46 ± 2.7 a | 1.69 ± 0.06 a | 7.04 ± 0.74 a | 0.41 ± 0.02 ab | 0.14 ± 0.01 b |

| LF-28 | 32.75 ± 7.0 a | 20.96 ± 4.5 b | 1.56 ± 0.08 b | 7.46 ± 0.69 a | 0.37 ± 0.07 b | 0.12 ± 0.02 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simunovic, S.; Đorđević, V.Ž.; Rašeta, M.; Lukić, M.; Lorenzo, J.M.; Djekic, I.; Tomašević, I. Reformulation of Traditional Fermented Tea Sausage Utilizing Novel (Digital) Methods of Analysis. Foods 2022, 11, 1090. https://doi.org/10.3390/foods11081090

Simunovic S, Đorđević VŽ, Rašeta M, Lukić M, Lorenzo JM, Djekic I, Tomašević I. Reformulation of Traditional Fermented Tea Sausage Utilizing Novel (Digital) Methods of Analysis. Foods. 2022; 11(8):1090. https://doi.org/10.3390/foods11081090

Chicago/Turabian StyleSimunovic, Stefan, Vesna Ž. Đorđević, Mladen Rašeta, Mirjana Lukić, José M. Lorenzo, Ilija Djekic, and Igor Tomašević. 2022. "Reformulation of Traditional Fermented Tea Sausage Utilizing Novel (Digital) Methods of Analysis" Foods 11, no. 8: 1090. https://doi.org/10.3390/foods11081090

APA StyleSimunovic, S., Đorđević, V. Ž., Rašeta, M., Lukić, M., Lorenzo, J. M., Djekic, I., & Tomašević, I. (2022). Reformulation of Traditional Fermented Tea Sausage Utilizing Novel (Digital) Methods of Analysis. Foods, 11(8), 1090. https://doi.org/10.3390/foods11081090