The Comparison of Microwave Thawing and Ultra-High-Pressure Thawing on the Quality Characteristics of Frozen Mango

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Frozen Mango Preparation

2.2.2. Thawing Process

2.2.3. Color Measurement

2.2.4. Firmness Measurement

2.2.5. Drip Loss Measurement

2.2.6. Vitamin C Content Measurement

2.2.7. Sensory Analysis

2.2.8. Statistical Analysis

3. Results

3.1. Thawing Time

3.2. Color Changes

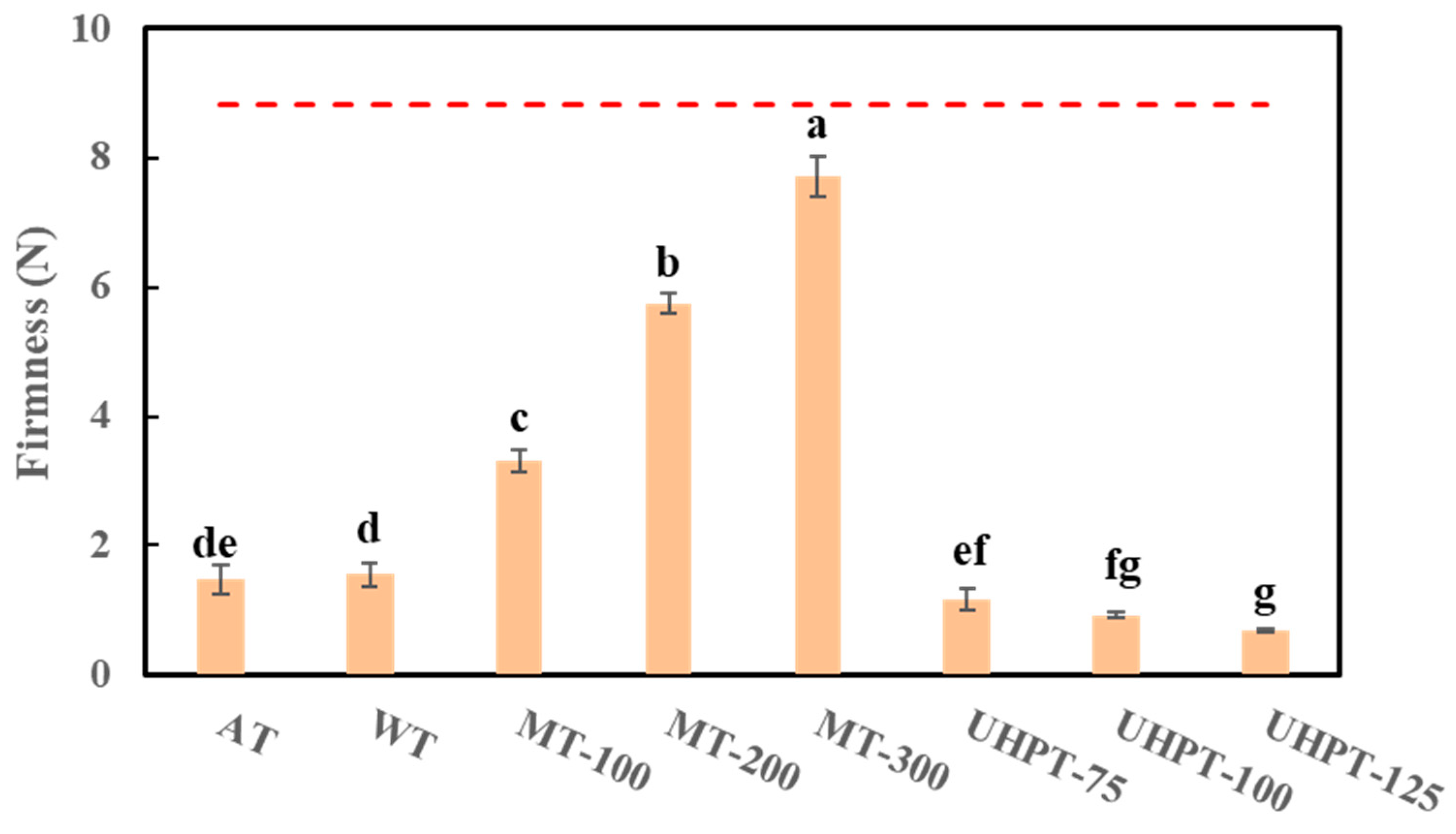

3.3. Firmness

3.4. Drip Loss

3.5. Vitamin C Content

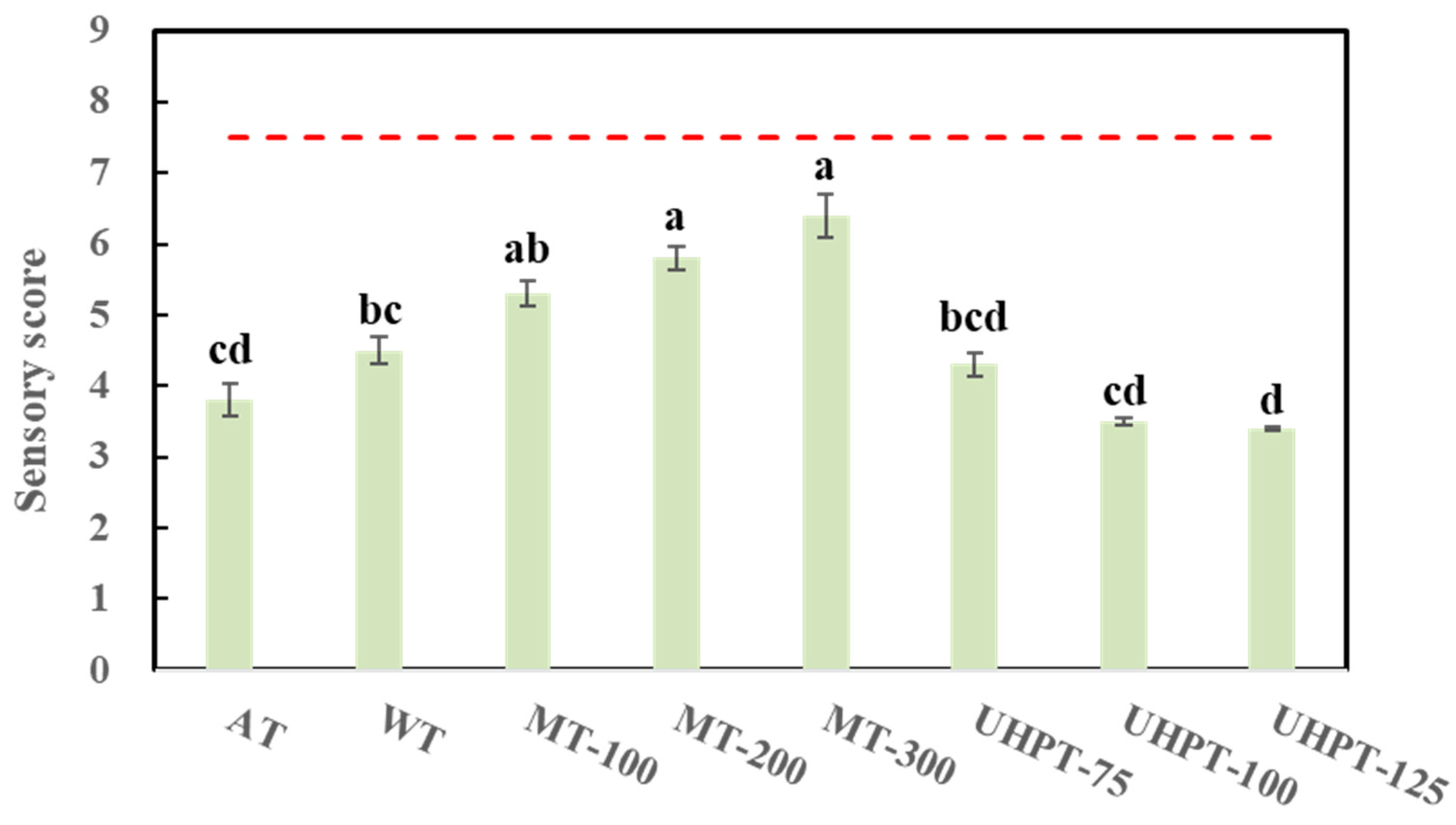

3.6. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lucifero, N. Food Loss and Waste in the EU Law between Sustainability of Well-being and the Implications on Food System and on Environment. Agric. Agric. Sci. Procedia 2016, 8, 282–289. [Google Scholar] [CrossRef][Green Version]

- Warshawsky, D.N. Food waste, sustainability, and the corporate sector: Case study of a US food company. Geogr. J. 2015, 182, 384–394. [Google Scholar] [CrossRef]

- Zhao, J.-H.; Liu, F.; Wen, X.; Xiao, H.-W.; Ni, Y.-Y. State diagram for freeze-dried mango: Freezing curve, glass transition line and maximal-freeze-concentration condition. J. Food Eng. 2015, 157, 49–56. [Google Scholar] [CrossRef]

- Berardini, N.; Fezer, R.; Conrad, J.; Beifuss, U.; Carle, R.; Schieber, A. Screening of Mango (Mangifera indica L.) Cultivars for Their Contents of Flavonol O- and Xanthone C-Glycosides, Anthocyanins, and Pectin. J. Agric. Food Chem. 2005, 53, 1563–1570. [Google Scholar] [CrossRef]

- Pott, I.; Marx, M.; Neidhart, S.; Mühlbauer, W.; Carle, R. Quantitative Determination of β-Carotene Stereoisomers in Fresh, Dried, and Solar-Dried Mangoes (Mangifera indica L.). J. Agric. Food Chem. 2003, 51, 4527–4531. [Google Scholar] [CrossRef]

- Firuzi, O.; Miri, R.; Tavakkoli, M.; Saso, L. Antioxidant Therapy: Current Status and Future Prospects. Curr. Med. Chem. 2011, 18, 3871–3888. [Google Scholar] [CrossRef]

- Gulcin, İ. Antioxidants and antioxidant methods: An updated overview. Arch. Toxicol. 2020, 94, 651–715. [Google Scholar] [CrossRef]

- Anusuya, P.; Nagaraj, R.; Janavi, G.J.; Subramanian, K.S.; Paliyath, G.; Subramanian, J. Pre-harvest sprays of hexanal formulation for extending retention and shelf-life of mango (Mangifera indica L.) fruits. Sci. Hortic. 2016, 211, 231–240. [Google Scholar] [CrossRef]

- George, R. Freezing proceseses used in the food industry. Trends Food Sci. Technol. 1993, 4, 134–138. [Google Scholar] [CrossRef]

- Celli, G.B.; Ghanem, A.; Brooks, M.S.-L. Influence of freezing process and frozen storage on the quality of fruits and fruit products. Food Rev. Int. 2015, 32, 280–304. [Google Scholar] [CrossRef]

- Leygonie, C.; Britz, T.J.; Hoffman, L. Impact of freezing and thawing on the quality of meat: Review. Meat Sci. 2012, 91, 93–98. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Cao, M.; Regenstein, J.; Cao, A. Recent Advances in Food Thawing Technologies. Compr. Rev. Food Sci. Food Saf. 2019, 18, 953–970. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Orikasa, T.; Tokuyasu, K.; Shiina, T.; Tagawa, A. Applicability of vacuum-dehydrofreezing technique for the long-term preservation of fresh-cut eggplant: Effects of process conditions on the quality attributes of the samples. J. Food Eng. 2009, 91, 560–565. [Google Scholar] [CrossRef]

- Wu, X.-F.; Zhang, M.; Adhikari, B.; Sun, J. Recent developments in novel freezing and thawing technologies applied to foods. Crit. Rev. Food Sci. Nutr. 2017, 57, 3620–3631. [Google Scholar] [CrossRef] [PubMed]

- Ganjeh, A.M.; Hamdami, N.; Soltanizadeh, N. Impact of high voltage electric field thawing on the quality of frozen tuna fish (Thunnus albacares). J. Food Eng. 2015, 156, 39–44. [Google Scholar] [CrossRef]

- Arocas, A.; Sanz, T.; Hernando, M.I.; Fiszman, S.M. Comparing microwave- and water bath-thawed starch-based sauces: Infrared thermography, rheology and microstructure. Food Hydrocoll. 2011, 25, 1554–1562. [Google Scholar] [CrossRef]

- James, S.; James, C.; Purnell, G. Microwave-assisted thawing and tempering. In The Microwave Processing of Foods, 2nd ed.; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 252–272. [Google Scholar]

- Venkatesh, M.; Raghavan, G. An Overview of Microwave Processing and Dielectric Properties of Agri-food Materials. Biosyst. Eng. 2004, 88, 1–18. [Google Scholar] [CrossRef]

- Kim, T.-H.; Choi, J.-H.; Choi, Y.-S.; Kim, H.-Y.; Kim, S.-Y.; Kim, H.-W.; Kim, C.-J. Physicochemical properties of thawed chicken breast as affected by microwave power levels. Food Sci. Biotechnol. 2011, 20, 971–977. [Google Scholar] [CrossRef]

- Holzwarth, M.; Korhummel, S.; Carle, R.; Kammerer, D.R. Evaluation of the effects of different freezing and thawing methods on color, polyphenol and ascorbic acid retention in strawberries (Fragaria × ananassa Duch.). Food Res. Int. 2012, 48, 241–248. [Google Scholar] [CrossRef]

- Yaldagard, M.; Mortazavi, S.A.; Tabatabaie, F. The principles of ultra high pressure technology and its application in food processing/preservation: A review of microbiological and quality aspects. Afr. J. Biotechnol. 2008, 7, 2739–2767. [Google Scholar]

- Li, B.; Sun, D.-W. Novel methods for rapid freezing and thawing of foods—A review. J. Food Eng. 2002, 54, 175–182. [Google Scholar] [CrossRef]

- Kalichevsky, M.T.; Knorr, D.; Lillford, P.J. Potential food applications of high-pressure effects on ice-water transitions. Trends Food Sci. Technol. 1995, 6, 253–259. [Google Scholar] [CrossRef]

- Dervisi, P.; Lamb, J.; Zabetakis, I. High pressure processing in jam manufacture: Effects on textural and colour properties. Food Chem. 2001, 73, 85–91. [Google Scholar] [CrossRef]

- Van Buggenhout, S.; Messagie, I.; Maes, V.; Duvetter, T.; Van Loey, A.; Hendrickx, M. Minimizing texture loss of frozen strawberries: Effect of infusion with pectinmethylesterase and calcium combined with different freezing conditions and effect of subsequent storage/thawing conditions. Eur. Food Res. Technol. 2006, 223, 395–404. [Google Scholar] [CrossRef]

- Wen, X.; Hu, R.; Zhao, J.-H.; Peng, Y.; Ni, Y.-Y. Evaluation of the effects of different thawing methods on texture, colour and ascorbic acid retention of frozen hami melon (Cucumis melo var. saccharinus). Int. J. Food Sci. Technol. 2015, 50, 1116–1122. [Google Scholar] [CrossRef]

- AOAC International. Appendix F: Guidelines for Standard Method Performance Requirements; AOAC International: Rockville, MD, USA, 2016. [Google Scholar]

- Zhao, J.-H.; Hu, R.; Xiao, H.-W.; Yang, Y.; Liu, F.; Gan, Z.-L.; Ni, Y.-Y. Osmotic dehydration pretreatment for improving the quality attributes of frozen mango: Effects of different osmotic solutes and concentrations on the samples. Int. J. Food Sci. Technol. 2013, 49, 960–968. [Google Scholar] [CrossRef]

- Barrett, D.M.; Beaulieu, J.; Shewfelt, R. Color, Flavor, Texture, and Nutritional Quality of Fresh-Cut Fruits and Vegetables: Desirable Levels, Instrumental and Sensory Measurement, and the Effects of Processing. Crit. Rev. Food Sci. Nutr. 2010, 50, 369–389. [Google Scholar] [CrossRef]

- Xu, B.; Chen, J.; Yuan, J.; Azam, S.M.R.; Zhang, M. Effect of different thawing methods on the efficiency and quality attributes of frozen red radish. J. Sci. Food Agric. 2021, 101, 3237–3245. [Google Scholar] [CrossRef]

- He, X.; Liu, R.; Tatsumi, E.; Nirasawa, S.; Liu, H. Factors affecting the thawing characteristics and energy consumption of frozen pork tenderloin meat using high-voltage electrostatic field. Innov. Food Sci. Emerg. Technol. 2014, 22, 110–115. [Google Scholar] [CrossRef]

- Knorr, D.; Schlueter, O.; Heinz, V. Impact of high hydrostatic pressure on phase transitions of foods. Food Technol. 1998, 52, 42–45. [Google Scholar]

- Harold, E. Pattee Evaluation of Quality of Fruits and Vegetables; Springer US: Berlin/Heidelberg, Germany, 1985. [Google Scholar]

- Zhang, M.; Chen, D. Effects of low temperature soaking on color and texture of green eggplants. J. Food Eng. 2006, 74, 54–59. [Google Scholar] [CrossRef]

- Hendrickx, M.; Ludikhuyze, L.; Broeck, I.V.D.; Weemaes, C. Effects of high pressure on enzymes related to food quality. Trends Food Sci. Technol. 1998, 9, 197–203. [Google Scholar] [CrossRef]

- Terefe, N.S.; Yang, Y.H.; Knoerzer, K.; Buckow, R.; Versteeg, C. High pressure and thermal inactivation kinetics of polyphenol oxidase and peroxidase in strawberry puree. Innov. Food Sci. Emerg. Technol. 2010, 11, 52–60. [Google Scholar] [CrossRef]

- Chisari, M.; Barbagallo, R.N.; Spagna, G.; Artés, F. Improving the quality of fresh-cut melon through inactivation of degradative oxidase and pectinase enzymatic activities by UV-C treatment. Int. J. Food Sci. Technol. 2011, 46, 463–468. [Google Scholar] [CrossRef]

- Sirijariyawat, A.; Charoenrein, S.; Barrett, D.M. Texture improvement of fresh and frozen mangoes with pectin methylesterase and calcium infusion. J. Sci. Food Agric. 2012, 92, 2581–2586. [Google Scholar] [CrossRef]

- Boonsumrej, S.; Chaiwanichsiri, S.; Tantratian, S.; Suzuki, T.; Takai, R. Effects of freezing and thawing on the quality changes of tiger shrimp (Penaeus monodon) frozen by air-blast and cryogenic freezing. J. Food Eng. 2007, 80, 292–299. [Google Scholar] [CrossRef]

- Javadian, S.R.; Rezaei, M.; Soltani, M.; Kazemian, M.; Pourgholam, R. Effects of Thawing Methods on Chemical, Biochemical, and Microbial Quality of Frozen Whole Rainbow Trout (Oncorhynchus mykiss). J. Aquat. Food Prod. Technol. 2013, 22, 168–177. [Google Scholar] [CrossRef]

- Phothiset, S.; Charoenrein, S. Effects of freezing and thawing on texture, microstructure and cell wall composition changes in papaya tissues. J. Sci. Food Agric. 2014, 94, 189–196. [Google Scholar] [CrossRef]

- Duun, A.; Rustad, T. Quality of superchilled vacuum packed Atlantic salmon (Salmo salar) fillets stored at −1.4 and −3.6 °C. Food Chem. 2008, 106, 122–131. [Google Scholar] [CrossRef]

- Ngapo, T.; Babare, I.; Reynolds, J.; Mawson, R. Freezing and thawing rate effects on drip loss from samples of pork. Meat Sci. 1999, 53, 149–158. [Google Scholar] [CrossRef]

- Chassagne-Berces, S.; Poirier, C.; Devaux, M.-F.; Fonseca, F.; Lahaye, M.; Pigorini, G.; Girault, C.; Marin, M.; Guillon, F. Changes in texture, cellular structure and cell wall composition in apple tissue as a result of freezing. Food Res. Int. 2009, 42, 788–797. [Google Scholar] [CrossRef]

- Shrestha, S.; Schaffner, D.; Nummer, B.A. Sensory quality and food safety of boneless chicken breast portions thawed rapidly by submersion in hot water. Food Control 2009, 20, 706–708. [Google Scholar] [CrossRef]

- Davey, M.W.; Van Montagu, M.; Inzé, D.; Sanmartin, M.; Kanellis, A.; Smirnoff, N.; Benzie, I.F.F.; Strain, J.J.; Favell, D.; Fletcher, J. Plant L-ascorbic acid: Chemistry, function, metabolism, bioavailability and effects of processing. J. Sci. Food Agric. 2000, 80, 825–860. [Google Scholar] [CrossRef]

| Properties | Mean ± SD |

|---|---|

| Water content (g/100 g) | 86.52 ± 0.24 |

| Total soluble solids (%) | 15.80 ± 0.25 |

| Vitamin C content (mg/100 g) | 17.04 ± 0.48 |

| Firmness (N) | 8.82 ± 0.31 |

| Color parameters | |

| Lightness (L*) | 59.95 ± 0.67 |

| Redness (a*) | 17.12 ± 0.29 |

| Yellowness (b*) | 82.07± 0.92 |

| Thawing Methods | L* | a* | b* | ΔE |

|---|---|---|---|---|

| AT | 54.45 ± 1.90 d | 18.08 ± 0.51 a | 91.19 ± 2.82 ab | 11.10 ± 1.23 ab |

| WT | 56.44 ± 0.05 c | 16.48 ± 2.01 a | 93.65 ± 1.69 a | 12.32 ± 1.41 a |

| MT-100 | 61.32 ± 0.92 b | 14.65 ± 1.06 b | 88.52 ± 1.37 bc | 7.20 ± 0.90 c |

| MT-200 | 65.38 ± 0.56 a | 12.90 ± 0.60 c | 89.50 ± 1.33 bc | 10.12 ± 1.30 b |

| MT-300 | 65.91 ± 0.48 a | 13.10 ± 0.54 bc | 80.24 ± 0.95 d | 7.36 ± 0.24 c |

| UHPT-75 | 61.09 ± 0.75 b | 11.07 ± 0.78 d | 77.47 ± 2.00 d | 7.63 ± 1.76 c |

| UHPT-100 | 55.43 ± 1.00 cd | 17.12 ± 0.38 a | 87.92 ± 0.60 c | 9.64 ± 0.32 b |

| UHPT-125 | 52.42 ± 0.37 e | 11.91 ± 0.48 cd | 92.59 ± 1.52 a | 12.67 ± 1.15 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Y.; Zhao, J.; Wen, X.; Ni, Y. The Comparison of Microwave Thawing and Ultra-High-Pressure Thawing on the Quality Characteristics of Frozen Mango. Foods 2022, 11, 1048. https://doi.org/10.3390/foods11071048

Peng Y, Zhao J, Wen X, Ni Y. The Comparison of Microwave Thawing and Ultra-High-Pressure Thawing on the Quality Characteristics of Frozen Mango. Foods. 2022; 11(7):1048. https://doi.org/10.3390/foods11071048

Chicago/Turabian StylePeng, Yu, Jinhong Zhao, Xin Wen, and Yuanying Ni. 2022. "The Comparison of Microwave Thawing and Ultra-High-Pressure Thawing on the Quality Characteristics of Frozen Mango" Foods 11, no. 7: 1048. https://doi.org/10.3390/foods11071048

APA StylePeng, Y., Zhao, J., Wen, X., & Ni, Y. (2022). The Comparison of Microwave Thawing and Ultra-High-Pressure Thawing on the Quality Characteristics of Frozen Mango. Foods, 11(7), 1048. https://doi.org/10.3390/foods11071048