Application of Micro- and Nano-Bubbles as a Tool to Improve the Rheological and Microstructural Properties of Formulated Greek-Style Yogurts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Development of MNB Generation System

2.2. Preparation of Formulated Greek-Style Yogurt

2.3. Experimental Approach

2.4. Physicochemical Analysis

2.5. Confocal Laser Scanning Microscopy

2.6. Rheological Measurements

2.7. Graininess

2.8. Syneresis

2.9. Water-Holding Capacity

2.10. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Analysis

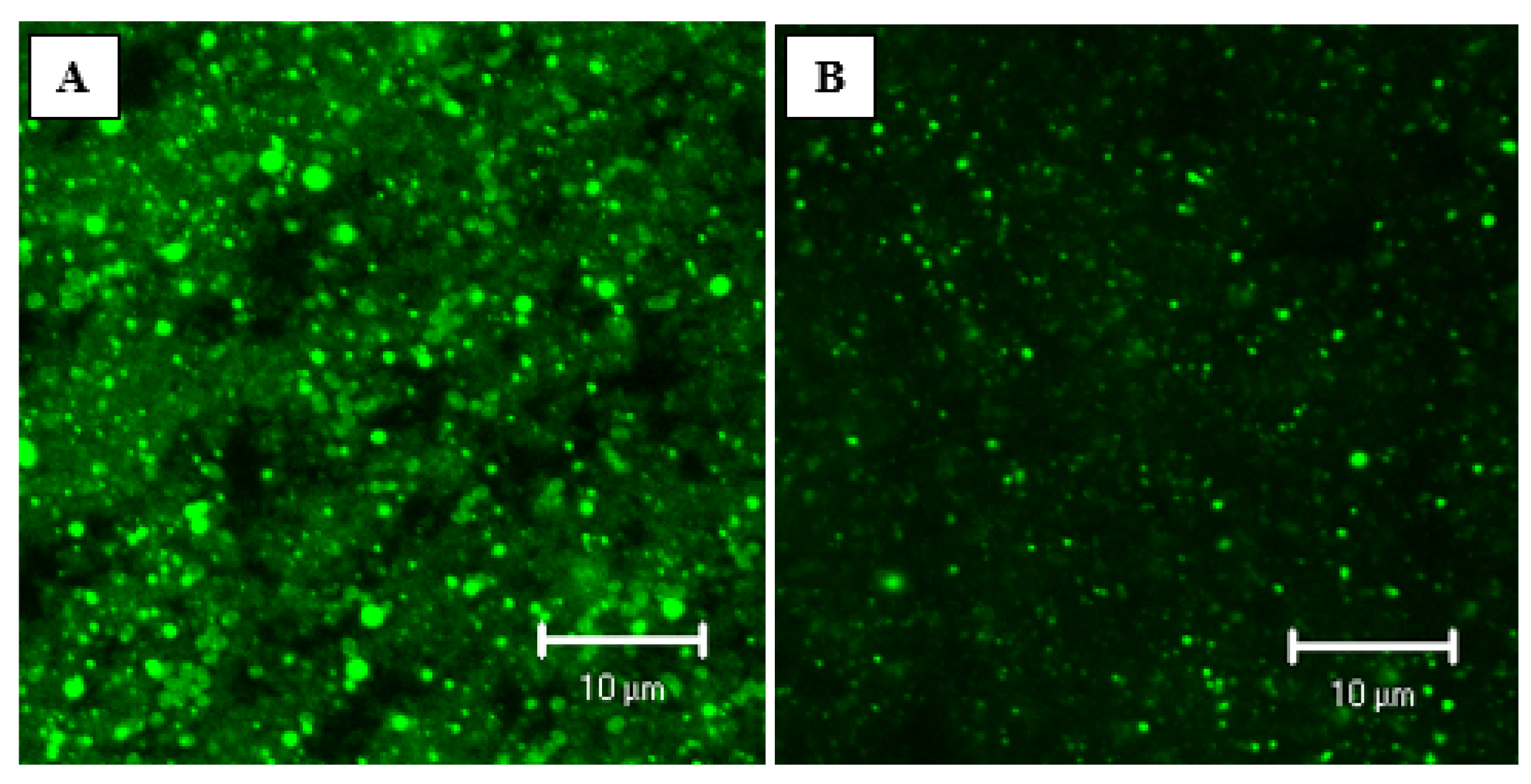

3.2. Microstructure

3.3. Rheological Characterization

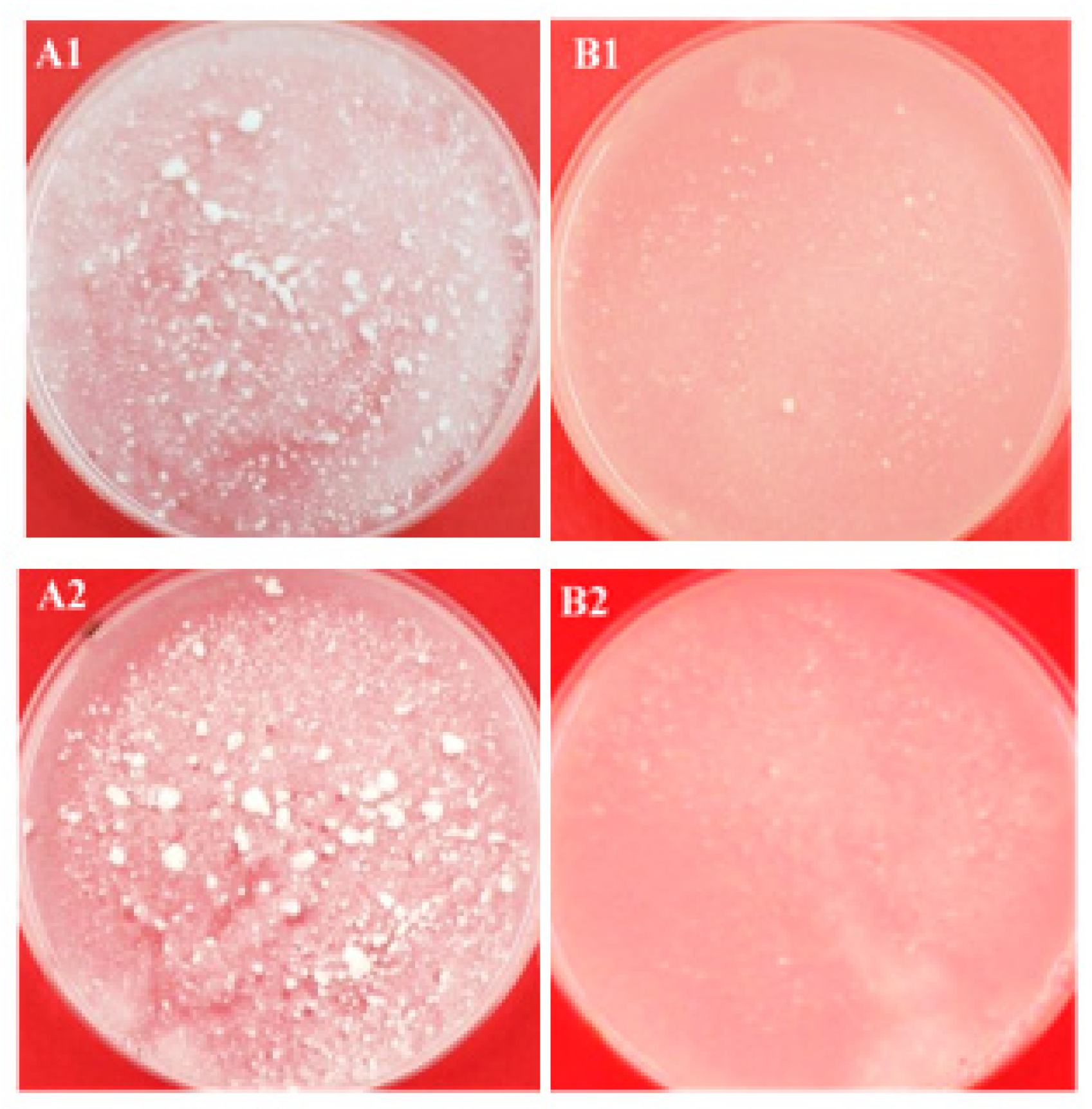

3.4. Graininess

3.5. Syneresis

3.6. Water-Holding Capacity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nsabimana, C.; Jiang, B.; Kossah, R. Manufacturing, Properties and Shelf Life of Labneh: A Review. Int. J. Dairy Technol. 2005, 58, 129–137. [Google Scholar] [CrossRef]

- Desai, N.T.; Shepard, L.; Drake, M.A. Sensory properties and drivers of liking for Greek yogurts. J. Dairy Sci. 2013, 96, 7454–7466. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dharmasena, S.; Okrent, A.; Capps, O., Jr. Consumer demand for Greek-style yogurt and its implications to the dairy industry in the United States. In Proceedings of the 2014 Annual Meeting, Minneapolis, MN, USA, 27–29 July 2014. No. 329–2016–13181. [Google Scholar]

- Bong, D.D.; Moraru, C.I. Use of micellar casein concentrate for greek-style yogurt manufacturing: Effects on processing and product properties. J. Dairy Sci. 2014, 97, 1259–1269. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S.; Beausire, R.L.; Patel, S.; Patel, H. Innovative uses of milk protein concentrates in product development. J. Food Sci. 2015, 80, A23–A29. [Google Scholar]

- Lee, W.J.; Lucey, J.A. Formation and physical properties of yogurt. Asian-Australas. J. Anim. Sci. 2010, 23, 1127–1136. [Google Scholar] [CrossRef]

- Peng, Y.; Serra, M.; Horne, D.S.; Lucey, J.A. Effect of fortification with various types of milk proteins on the rheological properties and permeability of nonfat set yogurt. J. Food Sci. 2009, 74, C666–C673. [Google Scholar] [CrossRef]

- Remeuf, F.; Mohammed, S.; Sodini, I.; Tissier, J.P. Preliminary observations on the effects of milk fortification and heating on microstructure and physical properties of stirred yogurt. Int. Dairy J. 2003, 13, 773–782. [Google Scholar] [CrossRef]

- Isleten, M.; Karagul-Yuceer, Y. Effects of dried dairy ingredients on physical and sensory properties of nonfat yogurt. J. Dairy Sci. 2006, 89, 2865–2872. [Google Scholar] [CrossRef]

- Marafon, A.P.; Sumi, A.; Granato, D.; Alcântara, M.R.; Tamime, A.Y.; de Oliveira, M.N. Effects of partially replacing skimmed milk powder with dairy ingredients on rheology, sensory profiling, and microstructure of probiotic stirred-type yogurt during cold storage. J. Dairy Sci. 2011, 94, 5330–5340. [Google Scholar] [CrossRef]

- Akalın, A.S.; Unal, G.; Dinkci, N.A.Y.İ.L.; Hayaloglu, A.A. Microstructural, textural, and sensory characteristics of probiotic yogurts fortified with sodium calcium caseinate or whey protein concentrate. J. Dairy Sci. 2012, 95, 3617–3628. [Google Scholar] [CrossRef]

- Meletharayil, G.H.; Metzger, L.E.; Patel, H.A. Influence of hydrodynamic cavitation on the rheological properties and microstructure of formulated Greek-style yogurts. J. Dairy Sci. 2016, 99, 8537–8548. [Google Scholar] [CrossRef]

- Körzendörfer, A.; Nöbel, S.; Hinrichs, J. Particle formation induced by sonication during yogurt fermentation–Impact of exopolysaccharide-producing starter cultures on physical properties. Food Res. Int. 2017, 97, 170–177. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Xie, S.; Yin, Y.; Feng, X.; Wang, S.; Guo, M.; Ni, C. Physiochemical, texture properties, and the microstructure of set yogurt using whey protein–sodium tripolyphosphate aggregates as thickening agents. J. Sci. Food Agric. 2017, 97, 2819–2825. [Google Scholar] [CrossRef] [PubMed]

- Körzendörfer, A.; Schäfer, J.; Hinrichs, J.; Nöbel, S. Power ultrasound as a tool to improve the processability of protein-enriched fermented milk gels for Greek yogurt manufacture. J. Dairy Sci. 2019, 102, 7826–7837. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, A.; Ng, W.J.; Liu, Y. Principle and applications of microbubble and nanobubble technology for water treatment. Chemosphere 2011, 84, 1175–1180. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.K.A.; Sun, C.; Hua, L.; Zhang, Z.; Zhang, Y.; Zhang, W.; Marhaba, T. Generation of nanobubbles by ceramic membrane filters: The dependence of bubble size and zeta potential on surface coating, pore size and injected gas pressure. Chemosphere 2018, 203, 327–335. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Kawagoe, Y.; Makino, Y.; Oshita, S. Effects of nanobubbles on the physicochemical properties of water: The basis for peculiar properties of water containing nanobubbles. Chem. Eng. Sci. 2013, 93, 250–256. [Google Scholar] [CrossRef]

- Takahashi, M.; Kawamura, T.; Yamamoto, Y.; Ohnari, H.; Himuro, S.; Shakutsui, H. Effect of shrinking microbubble on gas hydrate formation. J. Phys. Chem. B. 2003, 107, 2171–2173. [Google Scholar] [CrossRef]

- Chu, L.B.; Xing, X.H.; Yu, A.F.; Sun, X.L.; Jurcik, B. Enhanced treatment of practical textile wastewater by microbubble ozonation. Process Saf. Environ. Prot. 2008, 86, 389–393. [Google Scholar] [CrossRef]

- Zúñiga, R.N.; Aguilera, J.M. Aerated food gels: Fabrication and potential applications. Trends Food Sci. Technol. 2008, 19, 176–187. [Google Scholar] [CrossRef]

- Agarwal, A.; Xu, H.; Ng, W.J.; Liu, Y. Biofilm detachment by self-collapsing air microbubbles: A potential chemical-free cleaning technology for membrane biofouling. J. Mater. Chem. 2012, 22, 2203–2207. [Google Scholar] [CrossRef]

- Chen, H.; Mao, H.; Wu, L.; Zhang, J.; Dong, Y.; Wu, Z.; Hu, J. Defouling and cleaning using nanobubbles on stainless steel. Biofouling 2009, 25, 353–357. [Google Scholar] [CrossRef] [PubMed]

- Ago, K.I.; Nagasawa, K.; Takita, J.; Itano, R.; Morii, N.; Matsuda, K.; Takahashi, K. Development of an aerobic cultivation system by using a microbubble aeration technology. J. Chem. Eng. Jpn. 2005, 38, 757–762. [Google Scholar] [CrossRef]

- Bull, J.L. The application of microbubbles for targeted drug delivery. Expert Opin. Drug Deliv. 2007, 4, 475–493. [Google Scholar] [CrossRef] [PubMed]

- Lindner, J.R. Microbubbles in medical imaging: Current applications and future directions. Nat. Rev. Drug Discov. 2004, 3, 527–533. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; An, H.; Alheshibri, M.; Liu, L.; Terpstra, P.M.; Liu, G.; Craig, V.S. Cleaning with bulk nanobubbles. Langmuir 2016, 32, 11203–11211. [Google Scholar] [CrossRef]

- Singh, A.; Sekhon, A.S.; Unger, P.; Babb, M.; Yang, Y.; Michael, M. Impact of gas micro-nano-bubbles on the efficacy of commonly used antimicrobials in the food industry. J. Appl. Microbiol. 2020, 130, 1092–1105. [Google Scholar] [CrossRef]

- Amamcharla, J.; Li, B.; Liu, Z. Use of Micro- and Nano-Bubbles in Liquid Processing. U.S. Patent 16/071,385, 20 January 2017. [Google Scholar]

- Phan, K.; Truong, T.; Wang, Y.; Bhandari, B. Effect of CO2 nanobubbles incorporation on the viscosity reduction of fruit juice concentrate and vegetable oil. Int. J. Food Sci. Technol. 2021, 56, 4278–4286. [Google Scholar] [CrossRef]

- Phan, K.K.T.; Truong, T.; Wang, Y.; Bhandari, B. Nanobubbles: Fundamental characteristics and applications in food processing. Trends Food Sci. Technol. 2020, 95, 118–130. [Google Scholar] [CrossRef]

- Babu, K.S.; Amamcharla, J.K. Application of micro- and nano-bubbles in spray drying of milk protein concentrates. J. Dairy Sci. 2021. [Google Scholar]

- Ahmadi, R.; Khodadadi Darban, A. Modeling and optimization of nano-bubble generation process using response surface methodology. Int. J. Nanosci. Nanotechnol. 2013, 9, 151–162. [Google Scholar]

- Karam, M.C.; Gaiani, C.; Barbar, R.; Hosri, C.; Scher, J. Effect of dairy powder rehydration state on gel formation during yogurt process. J. Dairy Res. 2012, 79, 280–286. [Google Scholar] [CrossRef] [PubMed]

- Wehr, H.M.; Frank, J.F. Standard Methods for the Examination of Dairy Products; American Public Health Association: Washington, DC, USA, 2004. [Google Scholar]

- Gandhi, G.; Amamcharla, J.K.; Boyle, D. Effect of milk protein concentrate (MPC80) quality on susceptibility to fouling during thermal processing. Lebensm. Wiss. Technol. 2017, 81, 170–179. [Google Scholar] [CrossRef]

- Singh, G.; Muthukumarappan, K. Influence of calcium fortification on sensory, physical and rheological characteristics of fruit yogurt. LWT Food Sci. Technol. 2008, 41, 1145–1152. [Google Scholar] [CrossRef]

- Khaira, N.M.; Abd Rahmana, N.A.; Baharuddina, A.S.; Hafidb, H.S.; Wakisakab, M. Capturing the impact of nanobubble liquid in enhancing the physical quality of ice cream. J. Agric. Food Chem. 2020, 2, 0012. [Google Scholar]

- Adhikari, B.M.; Truong, T.; Prakash, S.; Bansal, N.; Bhandari, B. Impact of incorporation of CO2 on the melting, texture and sensory attributes of soft-serve ice cream. Int. Dairy J. 2020, 109, 104789. [Google Scholar] [CrossRef]

- Coutinho, N.M.; Silveira, M.R.; Pimentel, T.C.; Freitas, M.Q.; Moraes, J.; Fernandes, L.M.; Cruz, A.G. Chocolate milk drink processed by cold plasma technology: Physical characteristics, thermal behavior and microstructure. LWT Food Sci. Technol. 2019, 102, 324–329. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, H.; Qi, N.; Qin, Y.; Zhang, X.; Li, Y. Generation and stability of size-adjustable bulk nanobubbles based on periodic pressure change. Sci. Rep. 2019, 9, 1118. [Google Scholar] [CrossRef] [Green Version]

- Ramaswamy, H.S.; Basak, S. Rheology of stirred yogurts. J. Texture Stud. 1991, 22, 231–241. [Google Scholar] [CrossRef]

- Vélez-Ruiz, J.F.; Barbosa Cánovas, G.V.; Peleg, M. Rheological properties of selected dairy products. Crit. Rev. Food Sci. Nutr. 1997, 37, 311–359. [Google Scholar] [CrossRef]

- Oestergaard, B. Hydrodynamic Cavitation Helps Dairy Powder Processing; SPX Flow Technology: Charlotte, NC, USA, 2016. [Google Scholar]

- Li, K.; Woo, M.W.; Patel, H.; Metzger, L.; Selomulya, C. Improvement of rheological and functional properties of milk protein concentrate by hydrodynamic cavitation. J. Food Eng. 2018, 221, 106–113. [Google Scholar] [CrossRef]

- Besagni, G.; Inzoli, F.; De Guido, G.; Pellegrini, L.A. The dual effect of viscosity on bubble column hydrodynamics. Chem. Eng. Sci. 2017, 158, 509–538. [Google Scholar] [CrossRef] [Green Version]

- Gregersen, S.B.; Wiking, L.; Bertelsen, K.B.; Tangsanthatkun, J.; Pedersen, B.; Poulsen, K.R.; Hammershøj, M. Viscosity reduction in concentrated protein solutions by hydrodynamic cavitation. Int. Dairy J. 2019, 97, 1–4. [Google Scholar] [CrossRef]

- Calgaroto, S.; Azevedo, A.; Rubio, J. Flotation of quartz particles assisted by nanobubbles. Int. J. Miner. Process. 2015, 137, 64–70. [Google Scholar] [CrossRef]

- Zhang, M.; Seddon, J.R. Nanobubble–nanoparticle interactions in bulk solutions. Langmuir 2016, 32, 11280–11286. [Google Scholar] [CrossRef] [PubMed]

- Sodini, I.; Lucas, A.; Tissier, J.P.; Corrieu, G. Physical properties and microstructure of yoghurts supplemented with milk protein hydrolysates. Int. Dairy J. 2005, 15, 29–35. [Google Scholar] [CrossRef]

- Lucey, J.A.; Teo, C.T.; Munro, P.A.; Singh, H. Rheological properties at small (dynamic) and large (yield) deformations of acid gels made from heated milk. J. Dairy Res. 1997, 64, 591–600. [Google Scholar] [CrossRef]

- Dönmez, Ö.; Mogol, B.A.; Gökmen, V. Syneresis and rheological behaviors of set yogurt containing green tea and green coffee powders. J. Dairy Sci. 2017, 100, 901–907. [Google Scholar] [CrossRef]

- Ramirez-Santiago, C.; Ramos-Solis, L.; Lobato-Calleros, C.; Peña-Valdivia, C.; Vernon-Carter, E.J.; Alvarez-Ramírez, J. Enrichment of stirred yogurt with soluble dietary fiber from Pachyrhizus erosus L. urban: Effect on syneresis, microstructure and rheological properties. J. Food Eng. 2010, 101, 229–235. [Google Scholar] [CrossRef]

- Considine, T.; Noisuwan, A.; Hemar, Y.; Wilkinson, B.; Bronlund, J.; Kasapis, S. Rheological investigations of the interactions between starch and milk proteins in model dairy systems: A review. Food Hydrocoll. 2011, 25, 2008–2017. [Google Scholar] [CrossRef]

- Lucey, J.A. The relationship between rheological parameters and whey separation in milk gels. Food Hydrocoll. 2001, 15, 603–608. [Google Scholar] [CrossRef]

| Source of Variation | Apparent Viscosity | % Lost Structure | Grain Counts | % Syneresis | % Water Holding Capacity | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| df | MS | df | MS | df | MS | DF | MS | DF | MS | |

| Whole-plot | ||||||||||

| Treatment | 1 | 0.91 * (0.003) | 1 | 554.93 (0.06) | 1 | 122,931 * (0.004) | 1 | 50.81 (0.196) | 1 | 0.933 (0.67) |

| Error | 2 | 0.003 | 2 | 42.87 | 2 | 490 | 2 | 13.9 | 2 | 3.9 |

| Sub-plot | ||||||||||

| Time | 4 | 0.02 * (0.04) | 4 | 17.02 (0.67) | 4 | 1644 * (0.02) | 4 | 56.6 * (0.0001) | 4 | 5.9 (0.1007) |

| Time × Treatment | 4 | 0.01(0.16) | 4 | 126.24 * (0.03) | 4 | 1420 * (0.03) | 4 | 0.91 (0.618) | 4 | 2.1 (0.4650) |

| Error (time) | 8 | 0.006 | 8 | 28.57 | 8 | 303.1 | 8 | 1.31 | 8 | 2.12 |

| Sample Type | Storage Time | Apparent Viscosity (Pa·s) | % Lost Structure | Grain Counts | Syneresis (%) | Water Holding Capacity (%) |

|---|---|---|---|---|---|---|

| Control Greek-style yogurt | Week-0 | 1.09 ± 0.08 a | 34.14 ± 2.28 a | 143.5 ± 11.5 a | 8.66 ± 1.74 a | 33.18 ± 1.18 a |

| Week-1 | 0.88 ± 0.06 a | 38.55 ± 3.22 a | 243 ± 11 a | 7.36 ± 1.34 a | 29.95 ± 0.55 a | |

| Week-2 | 1.01 ± 0.11 a | 21.01 ± 5.45 a | 180 ± 19 a | 14.52 ± 0.09 a | 29.3 ± 1.01 a | |

| Week-3 | 0.98 ± 0.07 a | 36.74 ± 7.93 a | 182 ± 10 a | 16.41 ± 0.34 a | 30.95 ± 1.05 a | |

| Week-4 | 0.94 ± 0.07 a | 32.02 ± 0.14 a | 178.5 ± 26.5 a | 10.45 ± 1.05 a | 31.55 ± 1.85 a | |

| Micro- and nano-bubble-treated Greek-style yogurt | Week-0 | 0.71 ± 0.01 b | 26.11 ± 3.77 a | 37.5 ± 3.5 b | 5.42 ± 0.54 a | 30.77 ± 1.07 a |

| Week-1 | 0.61 ± 0.09 a | 17.24 ± 0.32 b | 36.5 ± 11.5 b | 3.88 ± 0.61 a | 28.81 ± 0.31 a | |

| Week-2 | 0.42 ± 0.08 b | 28.21 ± 5.12 a | 23 ± 4 b | 12.24 ± 1.09 a | 30.15 ± 0.25 a | |

| Week-3 | 0.56 ± 0.05 b | 18.05 ± 2.53 a | 21 ± 5 b | 11.81 ± 2.47 a | 30.31 ± 1.41 a | |

| Week-4 | 0.46 ± 0.01 b | 20.18 ± 1.36 b | 3.5 ± 0.5 b | 8.12 ± 2.28 b | 32.71 ± 2.11 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babu, K.S.; Liu, D.Z.; Amamcharla, J.K. Application of Micro- and Nano-Bubbles as a Tool to Improve the Rheological and Microstructural Properties of Formulated Greek-Style Yogurts. Foods 2022, 11, 619. https://doi.org/10.3390/foods11040619

Babu KS, Liu DZ, Amamcharla JK. Application of Micro- and Nano-Bubbles as a Tool to Improve the Rheological and Microstructural Properties of Formulated Greek-Style Yogurts. Foods. 2022; 11(4):619. https://doi.org/10.3390/foods11040619

Chicago/Turabian StyleBabu, Karthik Sajith, Dylan Zhe Liu, and Jayendra K. Amamcharla. 2022. "Application of Micro- and Nano-Bubbles as a Tool to Improve the Rheological and Microstructural Properties of Formulated Greek-Style Yogurts" Foods 11, no. 4: 619. https://doi.org/10.3390/foods11040619

APA StyleBabu, K. S., Liu, D. Z., & Amamcharla, J. K. (2022). Application of Micro- and Nano-Bubbles as a Tool to Improve the Rheological and Microstructural Properties of Formulated Greek-Style Yogurts. Foods, 11(4), 619. https://doi.org/10.3390/foods11040619