Effect of Modified Manufacturing Conditions on the Composition of Greek Strained Yogurt and the Quantity and Composition of Generated Acid Whey

Abstract

1. Introduction

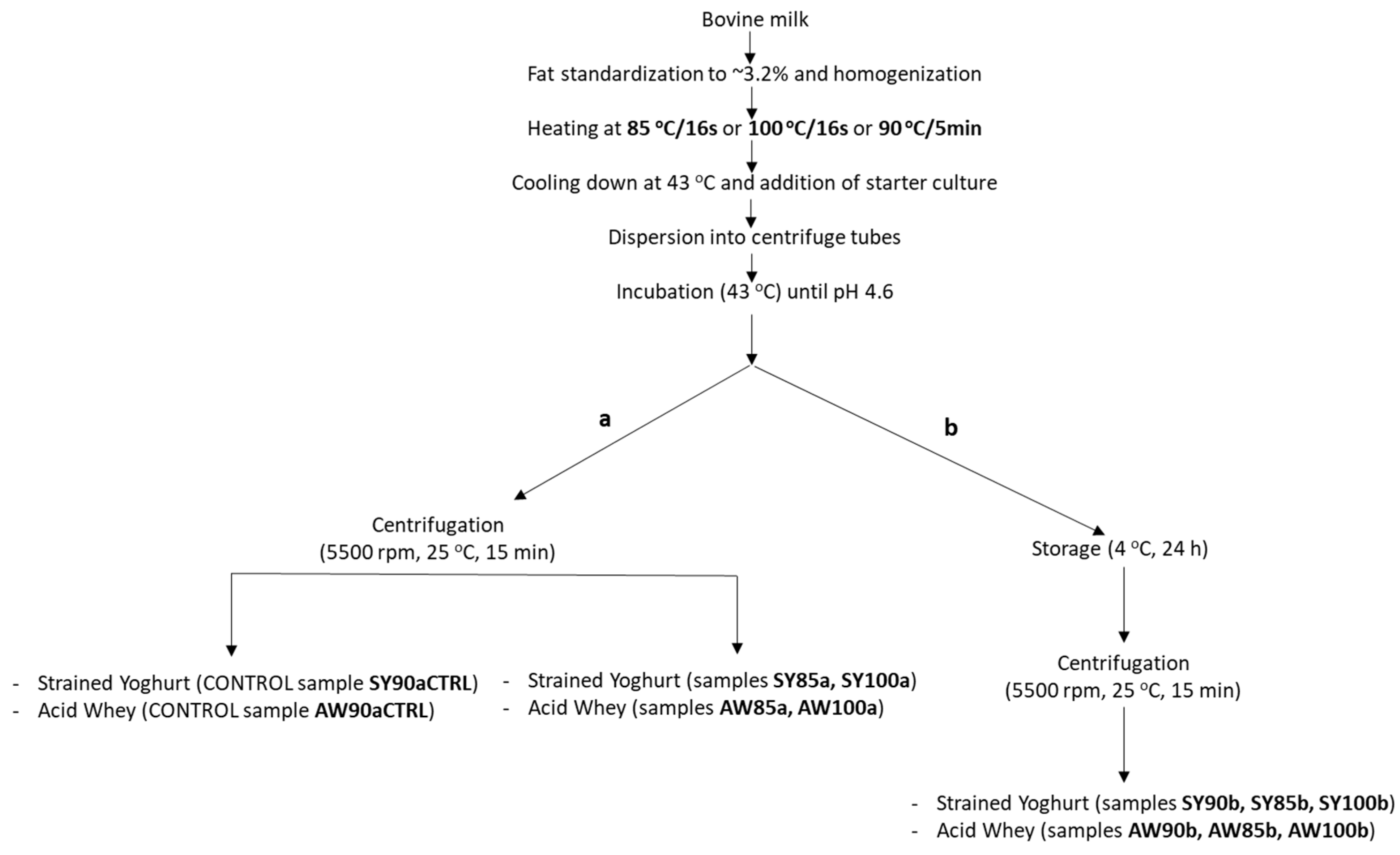

2. Materials and Methods

2.1. Yogurt Manufacture

2.2. Physicochemical Analyses of Strained Yogurt and Acid Whey

2.3. Sensory Evaluation of Strained Yogurt

2.4. Statistical Analysis

3. Results and Discussion

3.1. Quantity and Composition of Acid Whey

3.2. Composition of Strained Yogurt

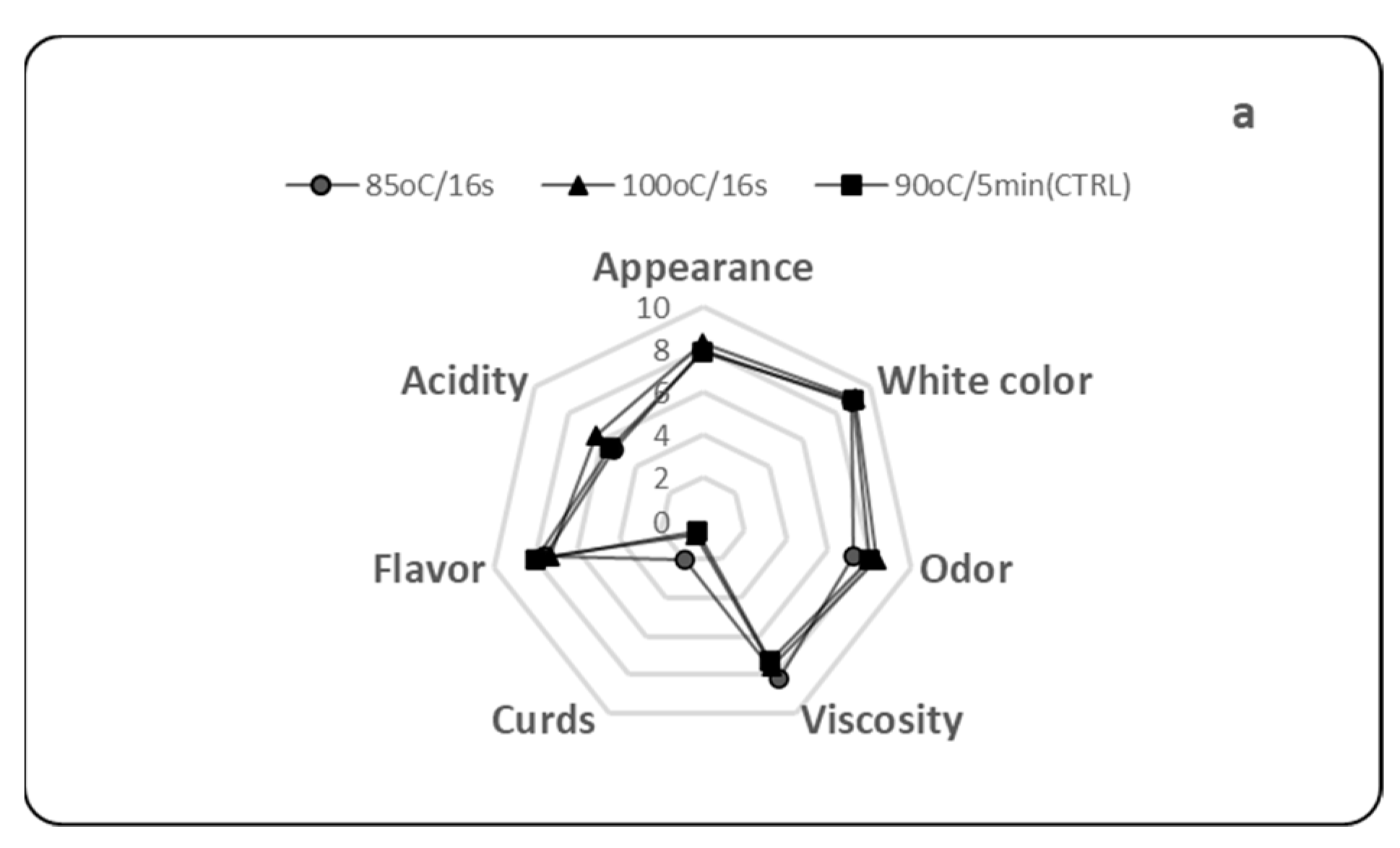

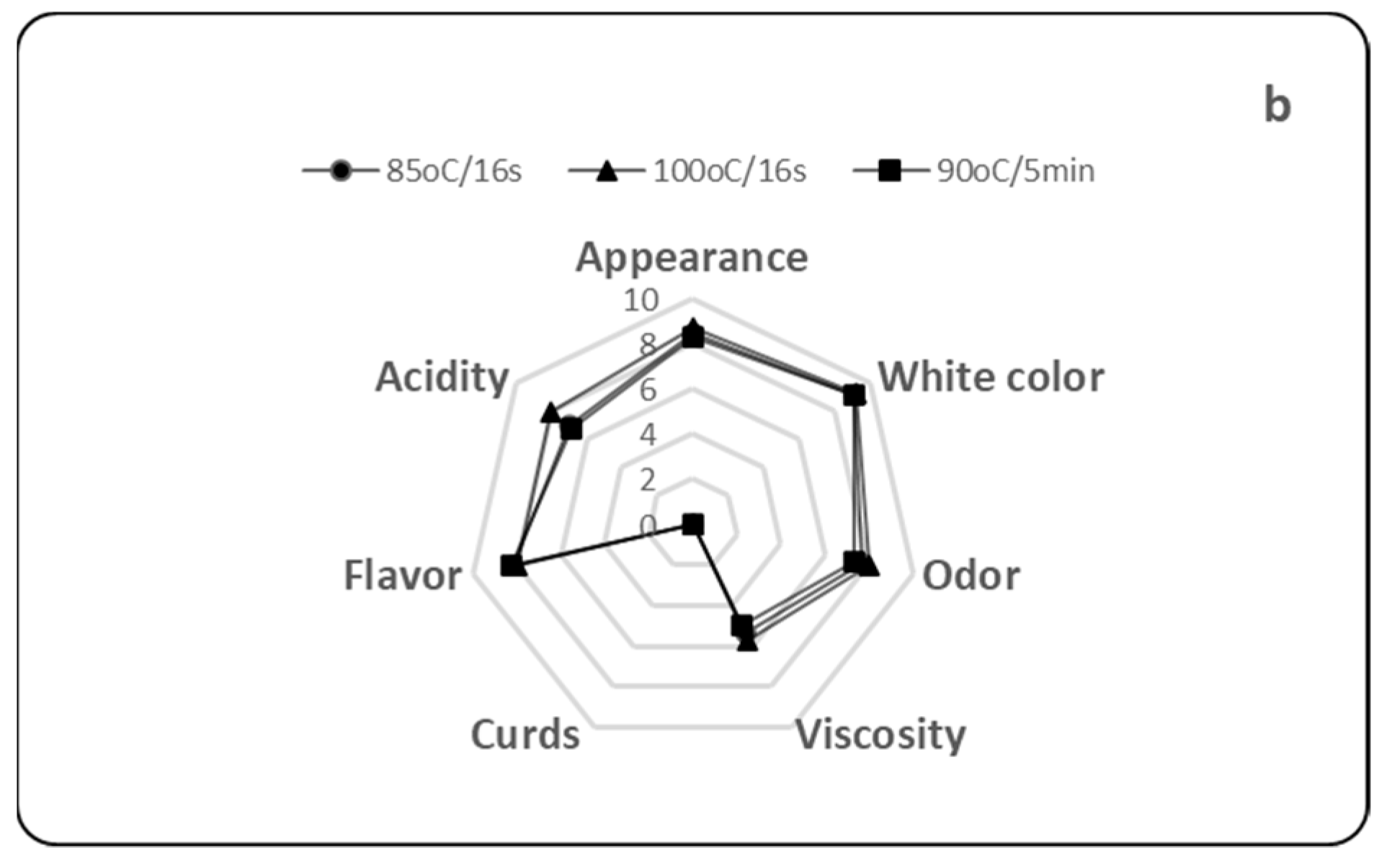

3.3. Organoleptic Characteristics of Strained Yogurt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moschopoulou, E.; Moatsou, G. Greek Dairy Products. In Mediterranean Food: Composition and Processing; Cruz, R., Vieira, M., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 267–320. [Google Scholar]

- Tamime, A.Y.; Hickey, M.; Muir, D.D. Strained fermented milks—A review of existing legislative provisions, survey of nutritional labelling of commercial products in selected markets and terminology of products in some selected countries. Int. J. Dairy Technol. 2014, 67, 305–333. [Google Scholar] [CrossRef]

- Lange, I.; Mleko, S.; Tomczyńska-Mleko, M.; Polischuk, G.; Janas, P.; Ozimek, L. Technology and factors influencing Greek-style yogurt—A review. Ukrainian Food J. 2020, 9, 7–35. [Google Scholar] [CrossRef]

- Uduwerella, G.; Chandrapala, J.; Vasiljevic, T. Minimising generation of acid whey during Greek yoghurt manufacturing. J. Dairy Res. 2017, 84, 346–354. [Google Scholar] [CrossRef] [PubMed]

- Blaschek, K.; Wendorff, W.L.; Rankin, S.A. Survey of salty and sweet whey composition from various cheese plants in Wisconsin. J. Dairy Sci. 2007, 90, 2029–2034. [Google Scholar] [CrossRef] [PubMed]

- Menchik, P.; Zuber, T.; Zuber, A.; Moraru, I. Composition of coproduct streams from dairy processing: Acid whey and milk permeate. J. Dairy Sci. 2019, 102, 3978–3984. [Google Scholar] [CrossRef] [PubMed]

- Chandrapala, J.; Chen, G.Q.; Kezia, K.; Bowman, E.G.; Vasiljevic, T.; Kentish, S.E. Removal of lactate from acid whey using nanofiltration. J. Food Eng. 2016, 177, 59–64. [Google Scholar] [CrossRef]

- Erickson, E.B. Acid whey: Is the waste product an untapped goldmine? Chem. Eng. News. 2017, 95, 26–30. [Google Scholar]

- Sodini, I.; Remeuf, F.; Haddad, S.; Corrieu, G. The Relative Effect of Milk Base, Starter, and Process on Yogurt Texture: A Review. Crit. Rev. Food Sci. Nutr. 2004, 44, 113–137. [Google Scholar] [CrossRef]

- Robinson, R.K.; Lucey, J.A.; Tamime, A.Y. Manufacture of Yoghurt. In Fermented, Milks; Tamime, A.Y., Ed.; Blackwell Science Ltd.: Oxford, UK, 2006; pp. 53–75. [Google Scholar]

- Savello, P.A.; Dargan, R.A. Reduced yoghurt syneresis using ultrafiltration and very high temperature heating. Milchwissenschaft 1997, 52, 573–577. [Google Scholar]

- Ichimura, T.; Osada, T.; Yonekura, K.; Horiuchi, H. A new method for producing superior set yogurt, focusing on heat treatment and homogenization. J. Dairy Sci. 2022, 105, 2978–2987. [Google Scholar] [CrossRef]

- Domagala, J. Instrumental texture, syneresis and microstructure of yoghurts prepared from goat, cow and sheep milk. Int. J. Food Prop. 2009, 12, 605–615. [Google Scholar] [CrossRef]

- Gyawali, R.; Ibrahim, S.A. Effects of hydrocolloids and processing conditions on acid whey production with reference to Greek yogurt. Trends Food Sci. Technol. 2016, 56, 61–76. [Google Scholar] [CrossRef]

- Gyawali, R.; Ibrahim, S.A. Addition of pectin and whey protein concentrate minimises the generation of acid whey in Greek-style yogurt. J. Dairy Res. 2018, 85, 238–242. [Google Scholar] [CrossRef]

- Uduwerella, G.; Chandrapala, J.; Vasiljevic, T. Preconcentration of yoghurt base by ultrafiltration for reduction in acid whey generation during Greek yoghurt manufacturing. Intern. J. Dairy Technol. 2018, 71, 71–80. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 12th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1975; p. 254. [Google Scholar]

- Kaminarides, S.; Stamou, P.; Massouras, T. Changes of organic acids, volatile aroma compounds and sensory characteristics of Halloumi cheese kept in brine. Food Chem. 2007, 100, 219–225. [Google Scholar] [CrossRef]

- International Standard ISO 22662/IDF 198; Milk and Milk Products-Determination of Lactose Content by High Performance Liquid Chromatography (Reference Method). International Dairy Federation: Brussels, Belgium, 2007.

- International Standard IDF 119/ISO 8070; Milk and Milk Products—Determination of Calcium, Sodium, Potassium and Magnesium Contents—Atomic Absorption Spectrometric Method. International Dairy Federation: Brussels, Belgium, 2007.

- International Standard IDF 42/ISO 9874; Milk—Determination of total phosphorus content—Method using molecular absorption spectrometry. International Dairy Federation: Brussels, Belgium, 2006.

- Moatsou, G.; Hatzinaki, A.; Samolada, M.; Anifantakis, E. Major whey proteins in ovine and caprine acid wheys from indigenous Greek breeds. Int. Dairy J. 2005, 15, 123–131. [Google Scholar] [CrossRef]

- Ozer, B. Production of Concentrated Products. In Fermented Milks; Tamime, A.Y., Ed.; Blackwell Science Ltd.: Oxford, UK, 2006; pp. 128–155. [Google Scholar]

- Kehagias, C.; Kalavritinos, L.; Triadopoulou, C. Effect of pH on the yield and solids recovery of strained yoghurt from goat and cow milk. Cultured Dairy Prod. J. 1992, 27, 10–14. [Google Scholar]

- Menchik, P.; Zuber, T.; Zuber, A.; Moraru, I. The acid whey conundrum. Dairy Foods 2018, 41–43. [Google Scholar]

- Sakkas, L.; Moutafi, A.; Moschopoulou, E.; Moatsou, G. Assessment of heat treatment of various types of milk. Food Chem. 2014, 159, 293–301. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Skriver, A.; Nilsson, L.-E. Starter Cultures. In Fermented Milks; Tamime, A.Y., Ed.; Blackwell Science Ltd.: Oxford, UK, 2006; pp. 11–52. [Google Scholar]

- Kirdar, S.S.; Toprak, G.; Güzel, E. Determination of the mineral content in yogurt whey. Eur. Int. J. Sci. Technol. 2017, 2304–9693. [Google Scholar]

- Smith, S.; Smith, T.J.; Drake, M.A. Flavor and flavor stability of cheese, rennet, and acid wheys. J. Dairy Sci. 2016, 99, 3434–3444. [Google Scholar] [CrossRef] [PubMed]

- Nishanthi, M.; Chandrapala, J.; Vasiljevic, T. Compositional and structural properties of whey proteins of sweet, acid and salty whey concentrates and their respective spray dried powders. Int. Dairy J. 2017, 74, 49–56. [Google Scholar] [CrossRef]

- Moschopoulou, E.; Sakkas, L.; Zoidou, E.; Theodorou, G.; Sgouridou, E.; Kalathaki, C.; Liarakou, A.; Chatzigeorgiou, A.; Politis, I.; Moatsou, G. Effect of milk kind and storage on the biochemical, textural and biofunctional characteristics of set-type yoghurt. Int. Dairy J. 2018, 77, 47–55. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Robinson, R.K. Yogurt Science and Technology, 3rd ed.; Woodhead Publishing, Limited: Sawston, UK; CRC Press: Cambridge, UK, 2007. [Google Scholar]

- Robinson, R.K.; Itsaranuwat, P. Properties of yoghurt and their appraisal. In Fermented Milks; Tamime, A.Y., Ed.; Blackwell Science Ltd.: Oxford, UK, 2006; pp. 76–94. [Google Scholar]

- Desai, N.T.; Shepard, L.; Drake, M.A. Sensory properties and drivers of liking for Greek yogurts. J. Dairy Sci. 2013, 96, 7454–7466. [Google Scholar] [CrossRef]

| Sample † | pH | Acidity | Fat | Protein | Total Sugars | Ash | Total solids | Quantity |

|---|---|---|---|---|---|---|---|---|

| AW85a | 4.55 ± 0.28 a,* | 0.45 ± 0.04 a | 0.05 ± 0.03 a,b | 0.63 ± 0.01 a | 4.29 ± 0.16 a | 0.69 ± 0.01 ab | 5.94 ± 0.10 ab | 2.75 ± 0.27 a,* |

| AW100a | 4.60 ± 0.19 a | 0.45 ± 0.02 a | 0.04 ± 0.01 a,b | 0.51 ± 0.01 b,c | 4.31 ± 0.01 a | 0.69 ± 0.00 a,b | 5.85 ± 0.08 a | 2.32 ± 0.04 b |

| AW90aCTRL | 4.47 ± 0.05 a | 0.48 ± 0.01 a,b | 0.04 ± 0.01 a | 0.41 ± 0.00 d | 4.43 ± 0.07 a | 0.73 ± 0.01 b | 6.10 ± 0.06 b | 1.9 ± 0.19 d |

| AW85b | 4.42 ± 0.08 a | 0.50 ± 0.03 b | 0.13 ± 0.04 c | 0.68 ± 0.05 a | 4.29 ± 0.13 a | 0.69 ± 0.03 a,b | 6.03 ± 0.12 a,b | 2.32 ± 0.16 b,c |

| AW100b | 4.37 ± 0.12 a | 0.49 ± 0.02 a,b | 0.10 ± 0.03 b,c | 0.55 ± 0.03 b | 4.22 ± 0.31 a | 0.67 ± 0.03 a | 5.93 ± 0.14 a | 2.04 ± 0.09 d,c |

| AW90b | 4.37 ± 0.07 a | 0.52 ± 0.02 b | 0.09 ± 0 a,b,c | 0.45 ± 0.02 c,d | 4.50 ± 0.08 a | 0.70 ± 0.02 a,b | 6.10 ± 0.07 b | 1.8 ± 0.09 d |

| Sample † | Total Whey Proteins | α-La | β-Lg |

|---|---|---|---|

| AW85a | 100 a,* | 100 a | 100 a |

| AW100a | 59.53 ± 2.35 b | 91.72 ±3.02 a | 37.97 ± 1.62 b |

| AW90aCTRL | 11.15 ± 4.46 c | 23.84 ± 9.22 b | 3.06 ± 0.89 d |

| AW85b | 100 a | 100 a | 100 a |

| AW100b | 60.46 ± 6.53 b | 94.43 ± 10.67 a | 21.64 ± 0.36 c |

| AW90b | 13.67 ± 3.53 c | 31.16 ± 4.52 b | 1.87 ± 0.02 d |

| Sample † | Lactose | Galactose | Lactic Acid |

|---|---|---|---|

| AW85a | 3.53 ± 0.21 a,b,* | 0.69 ± 0.06 a | 0.75 ± 0.08 a |

| AW100a | 3.57 ± 0.04 a,b | 0.69 ± 0.04 a | 0.76 ± 0.04 a |

| AW90aCTRL | 3.66 ± 0.06 a,b | 0.72 ± 0.02 a | 0.80 ± 0.02 a |

| AW85b | 3.47 ± 0.06 a,b | 0.74 ± 0.06 a | 0.81 ± 0.07 a |

| AW100b | 3.41 ± 0.23 a | 0.74 ± 0.06 a | 0.80 ± 0.04 a |

| AW90b | 3.67 ± 0.04 a,b | 0.78 ± 0.05 a | 0.86 ± 0.06 a |

| Sample † | Calcium | Phosphorus | Magnesium | Potassium | Sodium |

|---|---|---|---|---|---|

| AW85a | 119.32 ± 11.08 a,b,* | 56.94 ± 1.86 a,b | 15.86 ± 0.58 a | 218.43 ± 8.23 a | 76.82 ± 13 a |

| AW100a | 116.54 ± 8.70 a,b | 53.70 ± 1.71 a,b | 15.77 ± 0.58 a | 221.49 ± 16.96 a | 77.70 ± 0.50 a |

| AW90aCTRL | 124.55 ± 5.86 b | 59.85 ± 4.72 a | 16.77 ± 0.41 a | 258.34 ± 22.25 b | 82.63 ± 7.78 a |

| AW85b | 115.80 ± 7.70 b,a | 51.84 ± 0.40 b | 15.79 ± 0.78 a | 229.01 ± 6.21 a | 93.86 ± 3.24 a |

| AW100b | 110.25 ± 9.16 b,a | 51.89 ± 3.60 b | 13,96 ± 1,11 a | 222.57 ± 7.29 a | 85.05 ± 5.35 a |

| AW90b | 105.71 ± 0.93 b | 53.35 ± 2.73 b | 15.43 ± 0.83 a | 236.34 ± 6.54 b,a | 76.46 ± 7.07 a |

| Sample † | pH | Acidity | Fat | Protein | Total Sugars | Ash | Total Solids |

|---|---|---|---|---|---|---|---|

| SY85a | 4.37 ± 0.04 a,b,* | 1.17 ± 0.02 a | 12.44 ± 1.69 a | 9.63 ± 1.01 a | 2.91 ± 0.03 a | 0.65 ± 0.02 a,b | 28.31 ± 3.08 a |

| SY100a | 4.29 ± 0.07 a,b | 1.14 ± 0.02 a | 10.92 ± 0.98 b,a | 9.16 ± 0.63 a | 2.93 ± 0.16 a,b | 0.64 ± 0.00 a | 25.77 ± 1.94 b,a |

| SY90aCTRL | 4.25 ± 0.01 a | 1.15 ± 0.10 a | 10.13 ± 0.2 b | 8.58 ± 0.01 a | 3.21 ± 0.07 b,c | 0.68 ± 0.04 b | 24.66 ± 0.05 b |

| SY85b | 4.37 ± 0.06 b | 1.13 ± 0.02 a | 10.93 ± 0.27 a,b | 9.16 ± 0.84 a | 3.05 ± 0.09 a,b | 0.66 ± 0.01 a,b | 25.89 ± 0.77 a,b |

| SY100b | 4.43 ± 0.03 b | 1.09 ± 0.04 a | 10.20 ± 0.42 b | 8.74 ± 0.79 a | 3.03 ± 0.21 a,b | 0.64 ± 0.02 a | 24.46 ± 0.77 b |

| SY90b | 4.31 ± 0.08 b,a | 1.12 ± 0.03 a | 9.81 ± 0.52 b | 8.73 ± 0.72 a | 3.30 ± 0,10 c | 0.68 ± 0,03 b | 24.34 ± 0.6 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karastamatis, S.; Zoidou, E.; Moatsou, G.; Moschopoulou, E. Effect of Modified Manufacturing Conditions on the Composition of Greek Strained Yogurt and the Quantity and Composition of Generated Acid Whey. Foods 2022, 11, 3953. https://doi.org/10.3390/foods11243953

Karastamatis S, Zoidou E, Moatsou G, Moschopoulou E. Effect of Modified Manufacturing Conditions on the Composition of Greek Strained Yogurt and the Quantity and Composition of Generated Acid Whey. Foods. 2022; 11(24):3953. https://doi.org/10.3390/foods11243953

Chicago/Turabian StyleKarastamatis, Stavros, Evangelia Zoidou, Golfo Moatsou, and Ekaterini Moschopoulou. 2022. "Effect of Modified Manufacturing Conditions on the Composition of Greek Strained Yogurt and the Quantity and Composition of Generated Acid Whey" Foods 11, no. 24: 3953. https://doi.org/10.3390/foods11243953

APA StyleKarastamatis, S., Zoidou, E., Moatsou, G., & Moschopoulou, E. (2022). Effect of Modified Manufacturing Conditions on the Composition of Greek Strained Yogurt and the Quantity and Composition of Generated Acid Whey. Foods, 11(24), 3953. https://doi.org/10.3390/foods11243953