Techno-Functional Performance of Emmer, Spelt and Khorasan in Spontaneously Fermented Sourdough Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sourdough Preparation

2.3. Sourdough Rheology

2.4. Scanning Electron Microscopy (SEM)

2.5. Breadmaking Procedure and Bread Evaluation

2.6. Bread Volume and Water Activity Estimation

2.7. Texture Measurements

2.8. Colour Measurements

2.9. Sensory Analysis

2.10. Consumer Test

2.11. Statistical Analysis

3. Results and Discussion

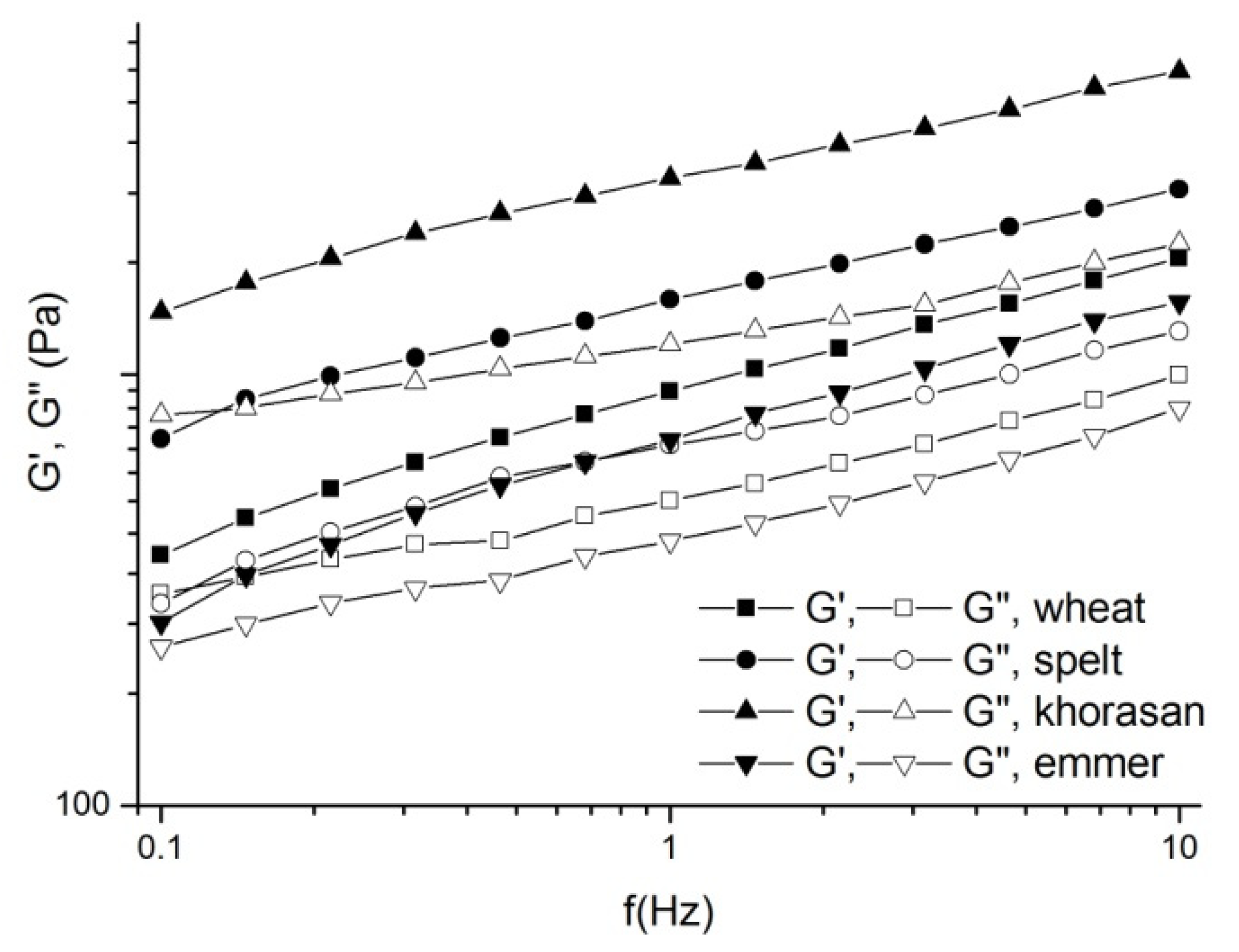

3.1. Rheological Behaviour of Sourdough Samples

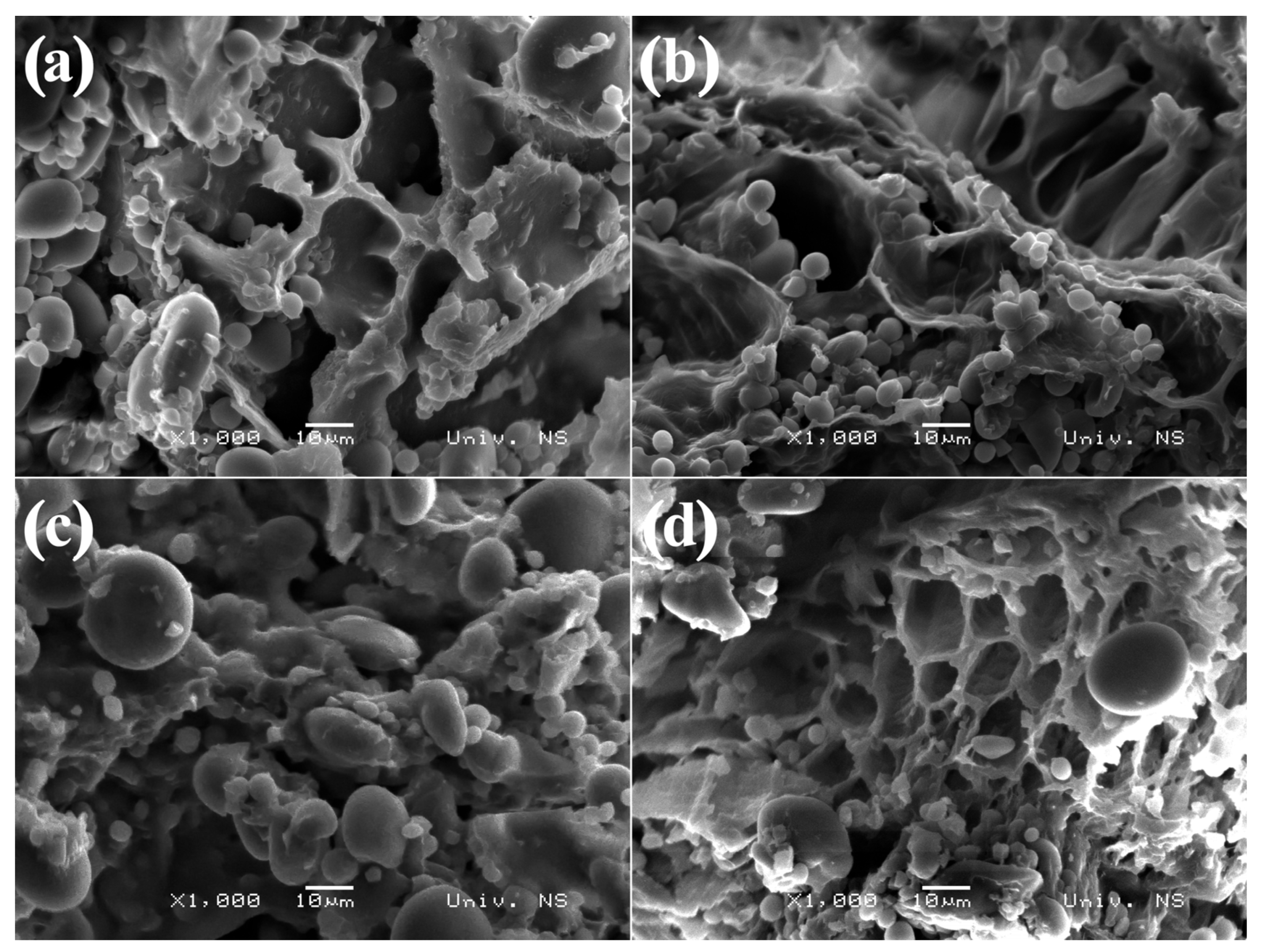

3.2. Scanning Electron Microscopy of Sourdough

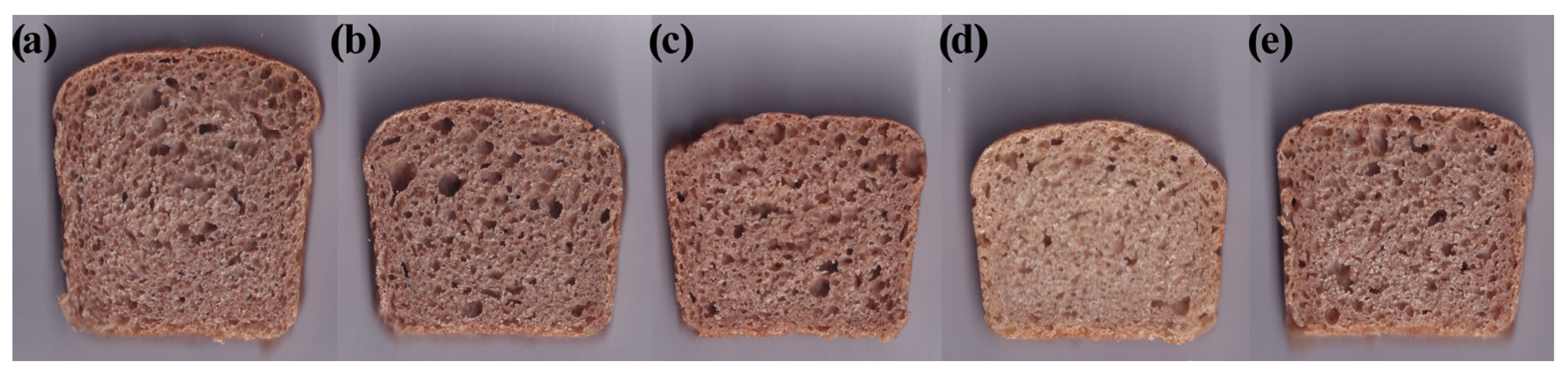

3.3. Bread Volume, Water Activity and Texture

3.4. Bread Colour and Appearance

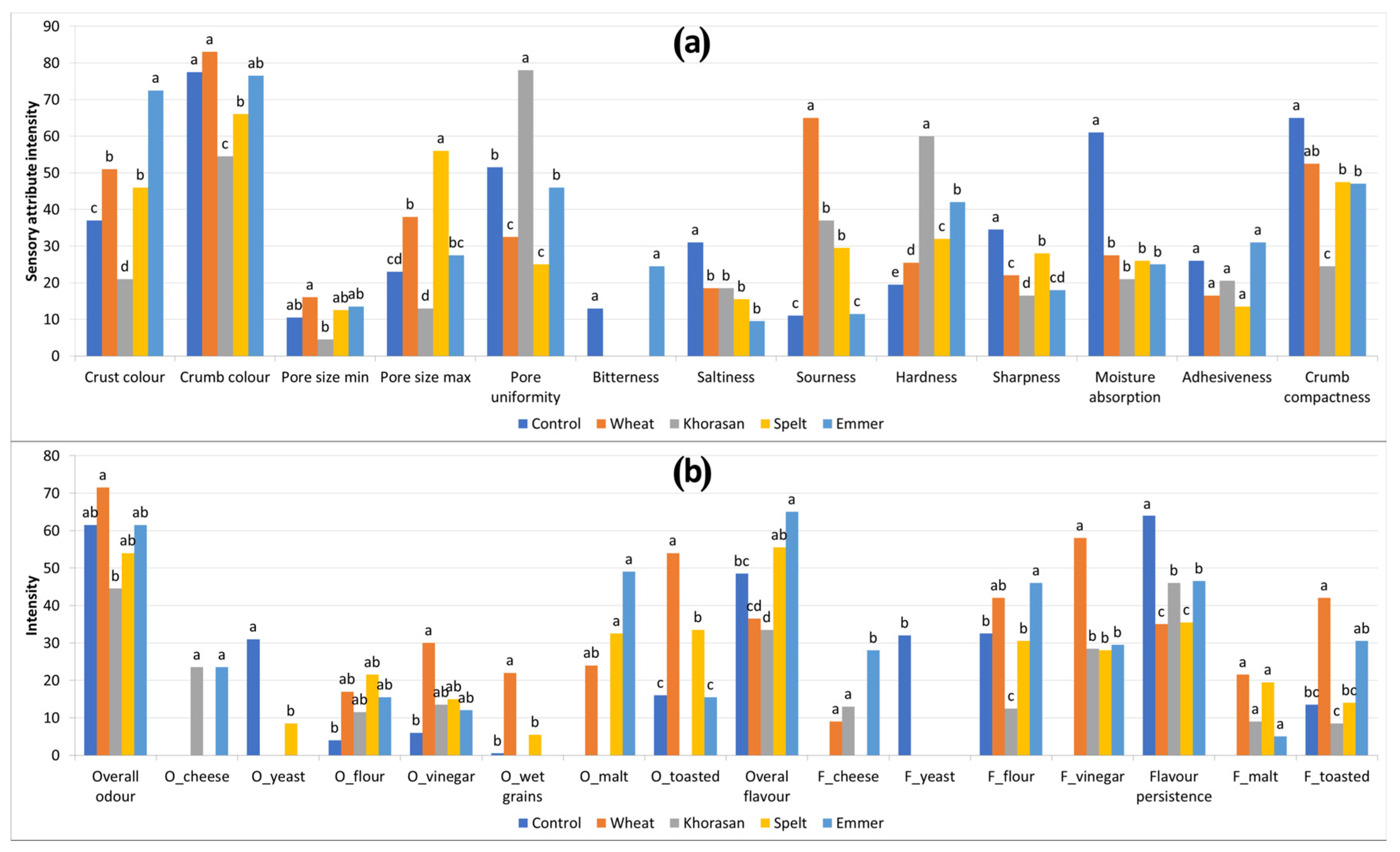

3.5. Sensory Analysis of Bread

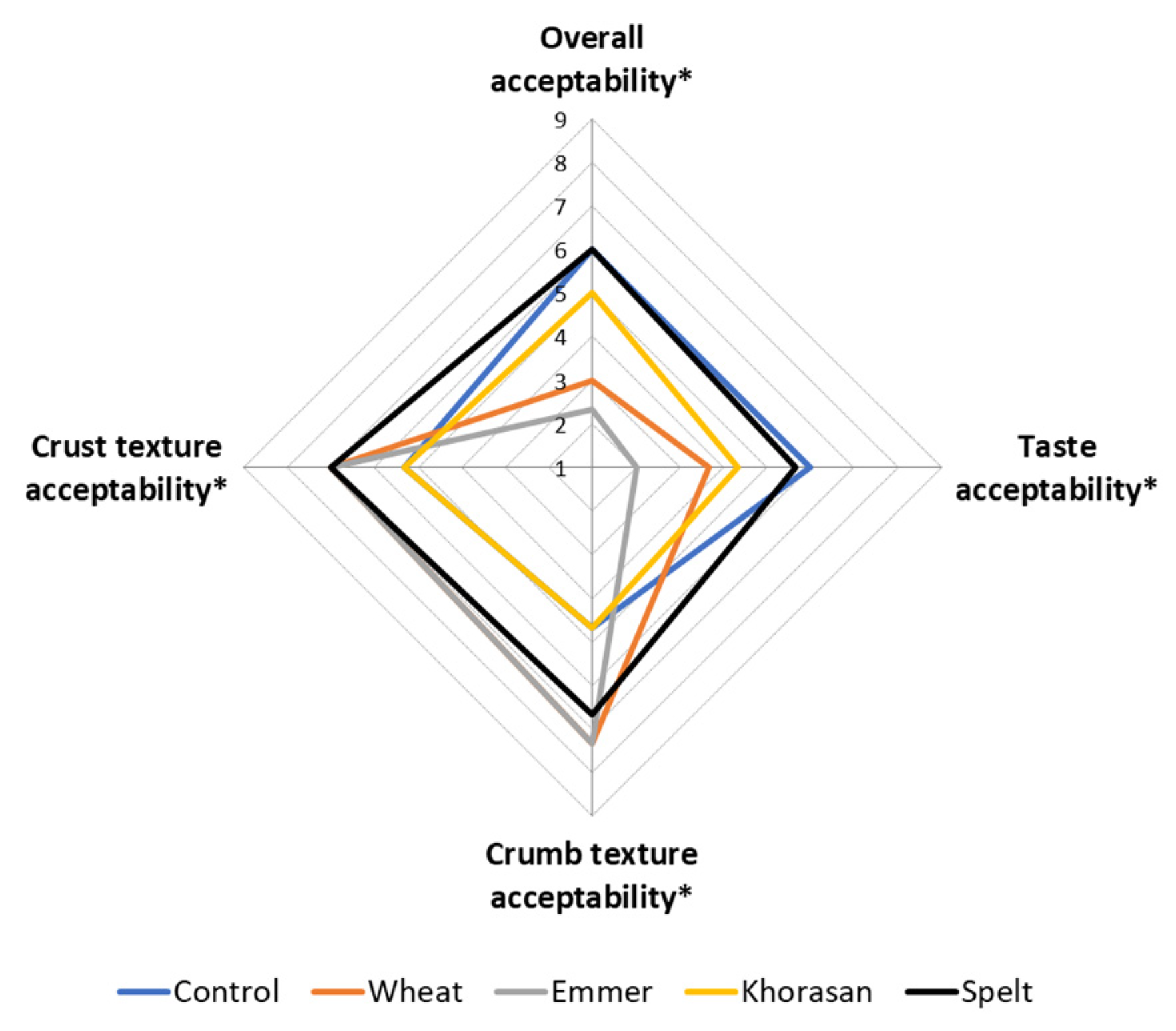

3.6. Consumer Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arzani, A.; Ashraf, M. Cultivated Ancient Wheats (Triticum Spp.): A Potential Source of Health-Beneficial Food Products. Compr. Rev. Food Sci. Food Saf. 2017, 16, 477–488. [Google Scholar] [CrossRef] [PubMed]

- Bencze, S.; Makádi, M.; Aranyos, T.J.; Földi, M.; Hertelendy, P.; Mikó, P.; Bosi, S.; Negri, L.; Drexler, D. Re-Introduction of Ancient Wheat Cultivars into Organic Agriculture—Emmer and Einkorn Cultivation Experiences under Marginal Conditions. Sustainability 2020, 12, 1584. [Google Scholar] [CrossRef]

- Piergiovanni, A.R.; Rizzi, R.; Pannacciulli, E.; Gatta, C. Della Mineral Composition in Hulled Wheat Grains: A Comparison between Emmer (Triticum Dicoccon Schrank) and Spelt (T. Spelta L.) Accessions. Int. J. Food Sci. Nutr. 1997, 48, 381–386. [Google Scholar] [CrossRef]

- Bordoni, A.; Danesi, F.; Di Nunzio, M.; Taccari, A.; Valli, V. Ancient Wheat and Health: A Legend or the Reality? A Review on KAMUT Khorasan Wheat. Int. J. Food Sci. Nutr. 2017, 68, 278–286. [Google Scholar] [CrossRef]

- Barański, M.; Lacko-Bartošová, M.; Rembiałkowska, E.; Lacko-Bartošová, L. The Effect of Species and Cultivation Year on Phenolic Acids Content in Ancient Wheat. Agronomy 2020, 10, 673. [Google Scholar] [CrossRef]

- Sobczyk, A.; Pycia, K.; Stankowski, S.; Jaworska, G.; Kuźniar, P. Evaluation of the Rheological Properties of Dough and Quality of Bread Made with the Flour Obtained from Old Cultivars and Modern Breeding Lines of Spelt (Triticum Aestivum Ssp. Spelta). J. Cereal Sci. 2017, 77, 35–41. [Google Scholar] [CrossRef]

- Geisslitz, S.; Longin, C.F.H.; Scherf, K.A.; Koehler, P. Comparative Study on Gluten Protein Composition of Ancient (Einkorn, Emmer and Spelt) and Modern Wheat Species (Durum and Common Wheat). Foods 2019, 8, 409. [Google Scholar] [CrossRef]

- Gobbetti, M.; De Angelis, M.; Di Cagno, R.; Calasso, M.; Archetti, G.; Rizzello, C.G. Novel Insights on the Functional/Nutritional Features of the Sourdough Fermentation. Int. J. Food Microbiol. 2019, 302, 103–113. [Google Scholar] [CrossRef]

- Arora, K.; Ameur, H.; Polo, A.; Di Cagno, R.; Rizzello, C.G.; Gobbetti, M. Thirty Years of Knowledge on Sourdough Fermentation: A Systematic Review. Trends Food Sci. Technol. 2021, 108, 71–83. [Google Scholar] [CrossRef]

- Coda, R.; Nionelli, L.; Rizzello, C.G.; De Angelis, M.; Tossut, P.; Gobbetti, M. Spelt and Emmer Flours: Characterization of the Lactic Acid Bacteria Microbiota and Selection of Mixed Starters for Bread Making. J. Appl. Microbiol. 2010, 108, 925–935. [Google Scholar] [CrossRef]

- Di Renzo, T.; Reale, A.; Boscaino, F.; Messia, M.C. Flavoring Production in Kamut®, Quinoa and Wheat Doughs Fermented by Lactobacillus Paracasei, Lactobacillus Plantarum, and Lactobacillus Brevis: A SPME-GC/MS Study. Front. Microbiol. 2018, 9, 429. [Google Scholar] [CrossRef] [PubMed]

- Callejo, M.J.; Vargas-Kostiuk, M.-E.; Rodríguez-Quijano, M. Selection, Training and Validation Process of a Sensory Panel for Bread Analysis: Influence of Cultivar on the Quality of Breads Made from Common Wheat and Spelt Wheat. J. Cereal Sci. 2015, 61, 55–62. [Google Scholar] [CrossRef]

- AACC. Measurement of Bread Firmness by Universal Testing Machine, Method: 74-09. In AACC Approved Methods of Analysis; AACC: Washington, DC, USA, 2000; pp. 7–10. [Google Scholar]

- Stone, H.; Sidel, J.L. Introduction to Sensory Evaluation. In Sensory Evaluation Practices; Elsevier: San Diego, CA, USA, 2004; pp. 1–19. ISBN 9780080474359. [Google Scholar]

- Angioloni, A.; Romani, S.; Pinnavaia, G.G.; Rosa, M.D. Characteristics of Bread Making Doughs: Influence of Sourdough Fermentation on the Fundamental Rheological Properties. Eur. Food Res. Technol. 2006, 222, 54–57. [Google Scholar] [CrossRef]

- Clarke, C.I.; Schober, T.J.; Dockery, P.; O’Sullivan, K.; Arendt, E.K. Wheat Sourdough Fermentation: Effects of Time and Acidification on Fundamental Rheological Properties. Cereal Chem. J. 2004, 81, 409–417. [Google Scholar] [CrossRef]

- Hadnađev, M.; Tomić, J.; Škrobot, D.; Dapčević-Hadnađev, T. Rheological Behavior of Emmer, Spelt and Khorasan Flours. J. Food Process. Preserv. 2022, 46, e15873. [Google Scholar] [CrossRef]

- Różyło, R.; Rudy, S.; Krzykowski, A.; Dziki, D. Novel Application of Freeze-Dried Amaranth Sourdough in Gluten-Free Bread Production. J. Food Process. Eng. 2015, 38, 135–143. [Google Scholar] [CrossRef]

- Mariotti, M.; Garofalo, C.; Aquilanti, L.; Osimani, A.; Fongaro, L.; Tavoletti, S.; Hager, A.-S.; Clementi, F. Barley Flour Exploitation in Sourdough Bread-Making: A Technological, Nutritional and Sensory Evaluation. LWT Food Sci. Technol. 2014, 59, 973–980. [Google Scholar] [CrossRef]

- Wolter, A.; Hager, A.-S.; Zannini, E.; Arendt, E.K. Influence of Sourdough on in Vitro Starch Digestibility and Predicted Glycemic Indices of Gluten-Free Breads. Food Funct. 2014, 5, 564–572. [Google Scholar] [CrossRef]

- Demirkesen-Bicak, H.; Arici, M.; Yaman, M.; Karasu, S.; Sagdic, O. Effect of Different Fermentation Condition on Estimated Glycemic Index, In Vitro Starch Digestibility, and Textural and Sensory Properties of Sourdough Bread. Foods 2021, 10, 514. [Google Scholar] [CrossRef]

- Abedfar, A.; Sadeghi, A. Response Surface Methodology for Investigating the Effects of Sourdough Fermentation Conditions on Iranian Cup Bread Properties. Heliyon 2019, 5, e02608. [Google Scholar] [CrossRef]

- Bojňanská, T.; Frančáková, H. The Use of Spelt Wheat (Triticum Spelta L.) for Baking Applications. Plant Soil Environ. 2011, 48, 141–147. [Google Scholar] [CrossRef]

- Boukid, F.; Folloni, S.; Sforza, S.; Vittadini, E.; Prandi, B. Current Trends in Ancient Grains-Based Foodstuffs: Insights into Nutritional Aspects and Technological Applications. Compr. Rev. Food Sci. Food Saf. 2018, 17, 123–136. [Google Scholar] [CrossRef] [PubMed]

- Sumczynski, D.; Bubelova, Z.; Sneyd, J.; Erb-Weber, S.; Mlcek, J. Total Phenolics, Flavonoids, Antioxidant Activity, Crude Fibre and Digestibility in Non-Traditional Wheat Flakes and Muesli. Food Chem. 2015, 174, 319–325. [Google Scholar] [CrossRef] [PubMed]

- Pruska-Kedzior, A.; Kedzior, Z.; Klockiewicz-Kaminska, E. Comparison of Viscoelastic Properties of Gluten from Spelt and Common Wheat. Eur. Food Res. Technol. 2008, 227, 199–207. [Google Scholar] [CrossRef]

- Buera, M.P.; Jouppila, K.; Roos, Y.H.; Chirife, J. Differential Scanning Calorimetry Glass Transition Temperatures of White Bread and Mold Growth in the Putative Glassy State. Cereal Chem. J. 1998, 75, 64–69. [Google Scholar] [CrossRef]

- Neylon, E.; Arendt, E.K.; Zannini, E.; Sahin, A.W. Fermentation as a Tool to Revitalise Brewers’ Spent Grain and Elevate Techno-Functional Properties and Nutritional Value in High Fibre Bread. Foods 2021, 10, 1639. [Google Scholar] [CrossRef]

- Goesaert, H.; Leman, P.; Delcour, J.A. Model Approach to Starch Functionality in Bread Making. J. Agric. Food Chem. 2008, 56, 6423–6431. [Google Scholar] [CrossRef]

- Skendi, A.; Biliaderis, C.G.; Papageorgiou, M.; Izydorczyk, M.S. Effects of Two Barley β-Glucan Isolates on Wheat Flour Dough and Bread Properties. Food Chem. 2010, 119, 1159–1167. [Google Scholar] [CrossRef]

- Seyhun, N.; Sumnu, G.; Sahin, S. Effects of Different Starch Types on Retardation of Staling of Microwave-Baked Cakes. Food Bioprod. Process. 2005, 83, 1–5. [Google Scholar] [CrossRef]

- Biliaderis, C.G.; Izydorczyk, M.S.; Rattan, O. Effect of Arabinoxylans on Bread-Making Quality of Wheat Flours. Food Chem. 1995, 53, 165–171. [Google Scholar] [CrossRef]

- Novotni, D.; Čukelj, N.; Smerdel, B.; Ćurić, D. Quality Attributes and Firming Kinetics of Partially Baked Frozen Wholewheat Bread with Sourdough. Int. J. Food Sci. Technol. 2013, 48, 2133–2142. [Google Scholar] [CrossRef]

- Pasqualone, A.; Piergiovanni, A.R.; Caponio, F.; Paradiso, V.M.; Summo, C.; Simeone, R. Evaluation of the Technological Characteristics and Bread-Making Quality of Alternative Wheat Cereals in Comparison with Common and Durum Wheat. Food Sci. Technol. Int. 2011, 17, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Gänzle, M.G. Enzymatic and Bacterial Conversions during Sourdough Fermentation. Food Microbiol. 2014, 37, 2–10. [Google Scholar] [CrossRef] [PubMed]

- Makhoul, S.; Romano, A.; Capozzi, V.; Spano, G.; Aprea, E.; Cappellin, L.; Benozzi, E.; Scampicchio, M.; Märk, T.D.; Gasperi, F.; et al. Volatile Compound Production During the Bread-Making Process: Effect of Flour, Yeast and Their Interaction. Food Bioprocess Technol. 2015, 8, 1925–1937. [Google Scholar] [CrossRef]

- Pétel, C.; Onno, B.; Prost, C. Sourdough Volatile Compounds and Their Contribution to Bread: A Review. Trends Food Sci. Technol. 2017, 59, 105–123. [Google Scholar] [CrossRef]

- Kam, W.Y.; Wan Aida, W.M.; Sahilah, A.M.; Maskat, M.Y. Volatile Compounds and Lactic Acid Bacteria in Spontaneous Fermented Sourdough. Sains Malays. 2011, 40, 135–138. [Google Scholar]

- Troadec, R.; Nestora, S.; Niquet-Léridon, C.; Marier, D.; Jacolot, P.; Sarron, E.; Regnault, S.; Anton, P.M.; Jouquand, C. Effect of Leavening Agent on Maillard Reaction and the Bifidogenic Effect of Traditional French Bread. Food Chem. 2022, 393, 133387. [Google Scholar] [CrossRef]

- Škrobot, D.; Pezo, L.; Tomić, J.; Pestorić, M.; Sakač, M.; Mandić, A. Insights into Sensory and Hedonic Perception of Wholegrain Buckwheat Enriched Pasta. LWT 2022, 153, 112528. [Google Scholar] [CrossRef]

- Lassoued, N.; Delarue, J.; Launay, B.; Michon, C. Baked Product Texture: Correlations between Instrumental and Sensory Characterization Using Flash Profile. J. Cereal Sci. 2008, 48, 133–143. [Google Scholar] [CrossRef]

| Bread Sample | Specific Volume (mL/g) | aw Value |

|---|---|---|

| Control | 2.30 ± 0.072 d | 0.949 ± 0.0007 a |

| Wheat | 1.83 ± 0.020 c | 0.946 ± 0.0021 a |

| Emmer | 1.69 ± 0.033 b | 0.942 ± 0.0035 a |

| Khorasan | 1.52 ± 0.019 a | 0.944 ± 0.0002 a |

| Spelt | 1.81 ± 0.025 c | 0.948 ± 0.0001 a |

| Bread Sample | Firmness (g) | ||

|---|---|---|---|

| 24 h | 48 h | 72 h | |

| Control | 283.2 ± 4.04 aA | 295.6 ± 33.93 abA | 312.2 ± 28.08 bA |

| Wheat | 473.3 ± 4.07 aB | 491.3 ± 33.67 abB | 512.5 ± 53.24 bB |

| Emmer | 679.7 ± 61.47 aD | 702.9 ± 70.18 aC | 783.3 ± 60.70 bC |

| Khorasan | 910.4 ± 81.76 aE | 972.5 ± 57.39 bD | 1084.9 ± 45.57 cD |

| Spelt | 577.7 ± 51.50 aC | 707.9 ± 60.61 bC | 804.4 ± 71.76 cC |

| Bread Sample | Crust | Crumb | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| Control | 49.50 ± 1.506 c | 11.05 ± 0.313 a | 23.38 ± 0.275 bc | 48.33 ± 1.595 ab | 6.58 ± 0.301 ab | 16.10 ± 0.516 a |

| Wheat | 43.81 ± 1.010 a | 13.63 ± 0.465 b | 22.10 ± 0.582 ab | 47.05 ± 0.969 a | 6.67 ± 0.157 ab | 16.09 ± 0.357 a |

| Emmer | 42.69 ± 0.575 a | 14.82 ± 0.177 b | 21.83 ± 1.049 a | 48.54 ± 0.311 ab | 7.15 ± 0.230 b | 17.16 ± 0.526 ab |

| Khorasan | 55.08 ± 1.093 d | 11.49 ± 1.676 a | 27.98 ± 1.355 d | 58.46 ± 0.994 c | 5.28 ± 0.256 a | 19.48 ± 0.528 c |

| Spelt | 47.09 ± 0.755 b | 13.57 ± 0.356 b | 23.83 ± 0.533 c | 49.66 ± 2.527 b | 7.30 ± 2.826 b | 17.85 ± 1.637 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Škrobot, D.; Dapčević-Hadnađev, T.; Tomić, J.; Maravić, N.; Popović, N.; Jovanov, P.; Hadnađev, M. Techno-Functional Performance of Emmer, Spelt and Khorasan in Spontaneously Fermented Sourdough Bread. Foods 2022, 11, 3927. https://doi.org/10.3390/foods11233927

Škrobot D, Dapčević-Hadnađev T, Tomić J, Maravić N, Popović N, Jovanov P, Hadnađev M. Techno-Functional Performance of Emmer, Spelt and Khorasan in Spontaneously Fermented Sourdough Bread. Foods. 2022; 11(23):3927. https://doi.org/10.3390/foods11233927

Chicago/Turabian StyleŠkrobot, Dubravka, Tamara Dapčević-Hadnađev, Jelena Tomić, Nikola Maravić, Nikola Popović, Pavle Jovanov, and Miroslav Hadnađev. 2022. "Techno-Functional Performance of Emmer, Spelt and Khorasan in Spontaneously Fermented Sourdough Bread" Foods 11, no. 23: 3927. https://doi.org/10.3390/foods11233927

APA StyleŠkrobot, D., Dapčević-Hadnađev, T., Tomić, J., Maravić, N., Popović, N., Jovanov, P., & Hadnađev, M. (2022). Techno-Functional Performance of Emmer, Spelt and Khorasan in Spontaneously Fermented Sourdough Bread. Foods, 11(23), 3927. https://doi.org/10.3390/foods11233927