Assessment of Textural Properties of Puffed Corn Cakes during Storage at Different Relative Humidity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Sample

2.2. Instrumental Texture Analysis

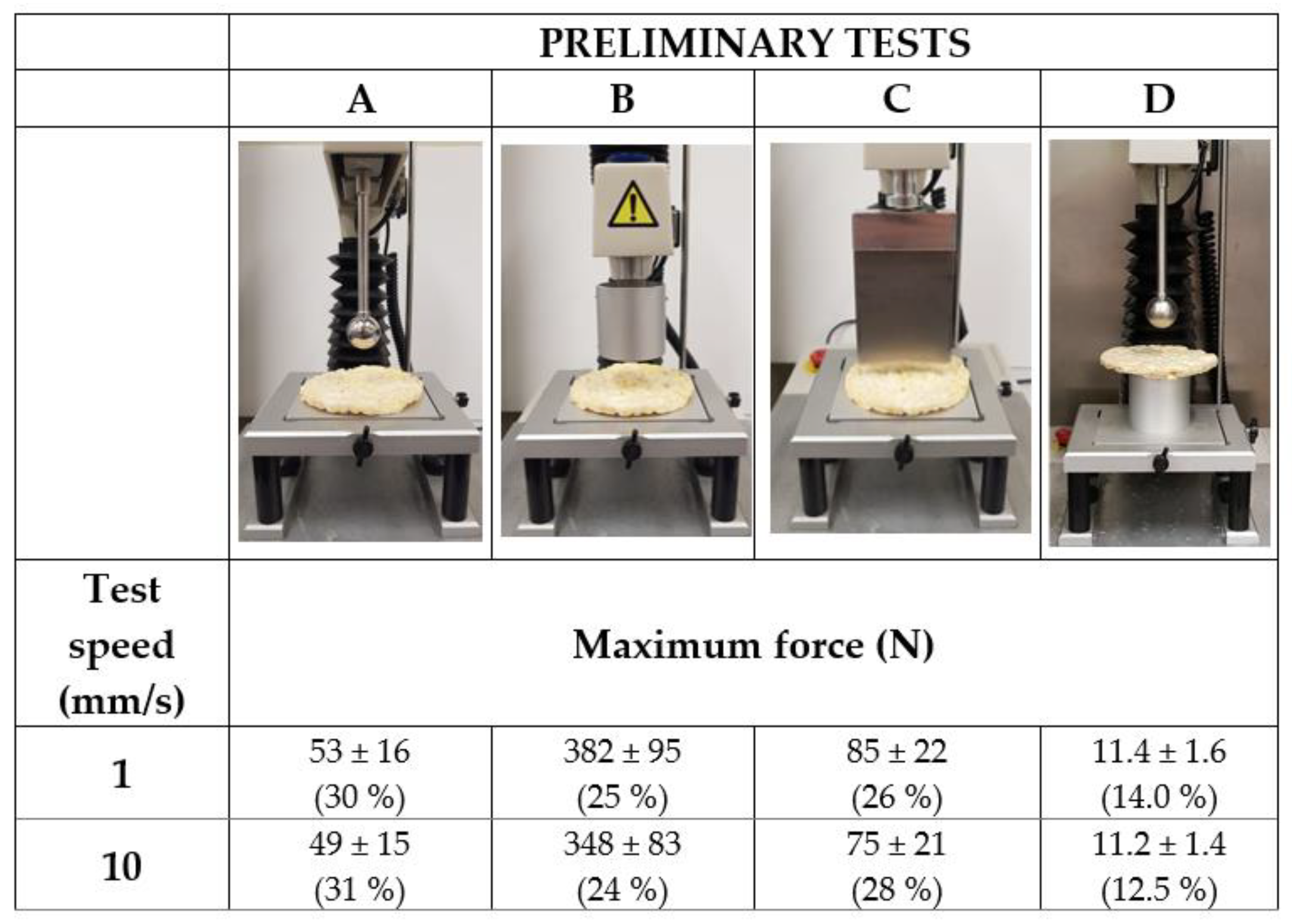

2.2.1. Selection of the Texture Probe Set-Up and the Test Speed

2.2.2. Selection of the Batch Size

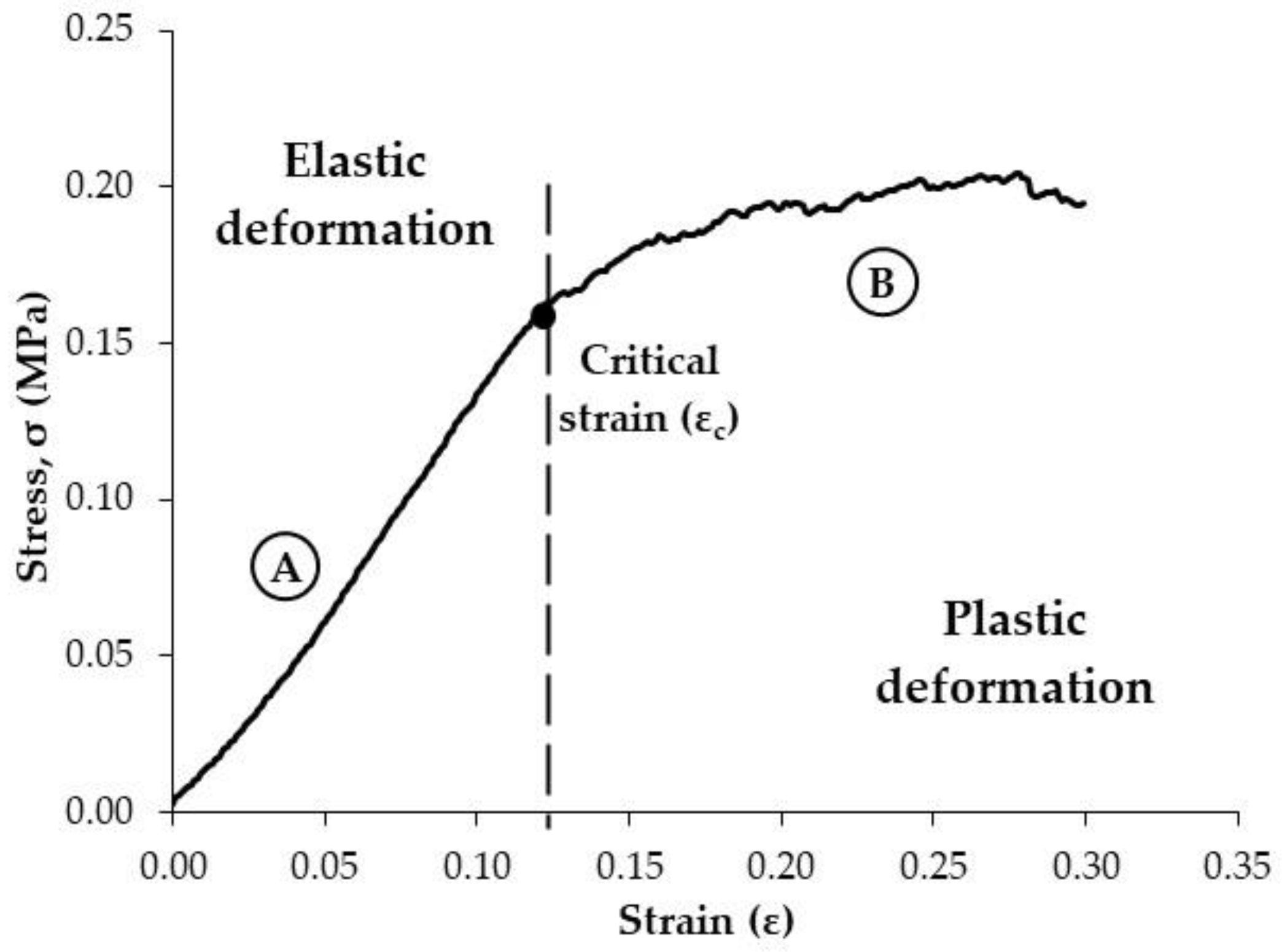

2.3. Modelling of Stress–Strain Curves of PCC after Water Adsorption

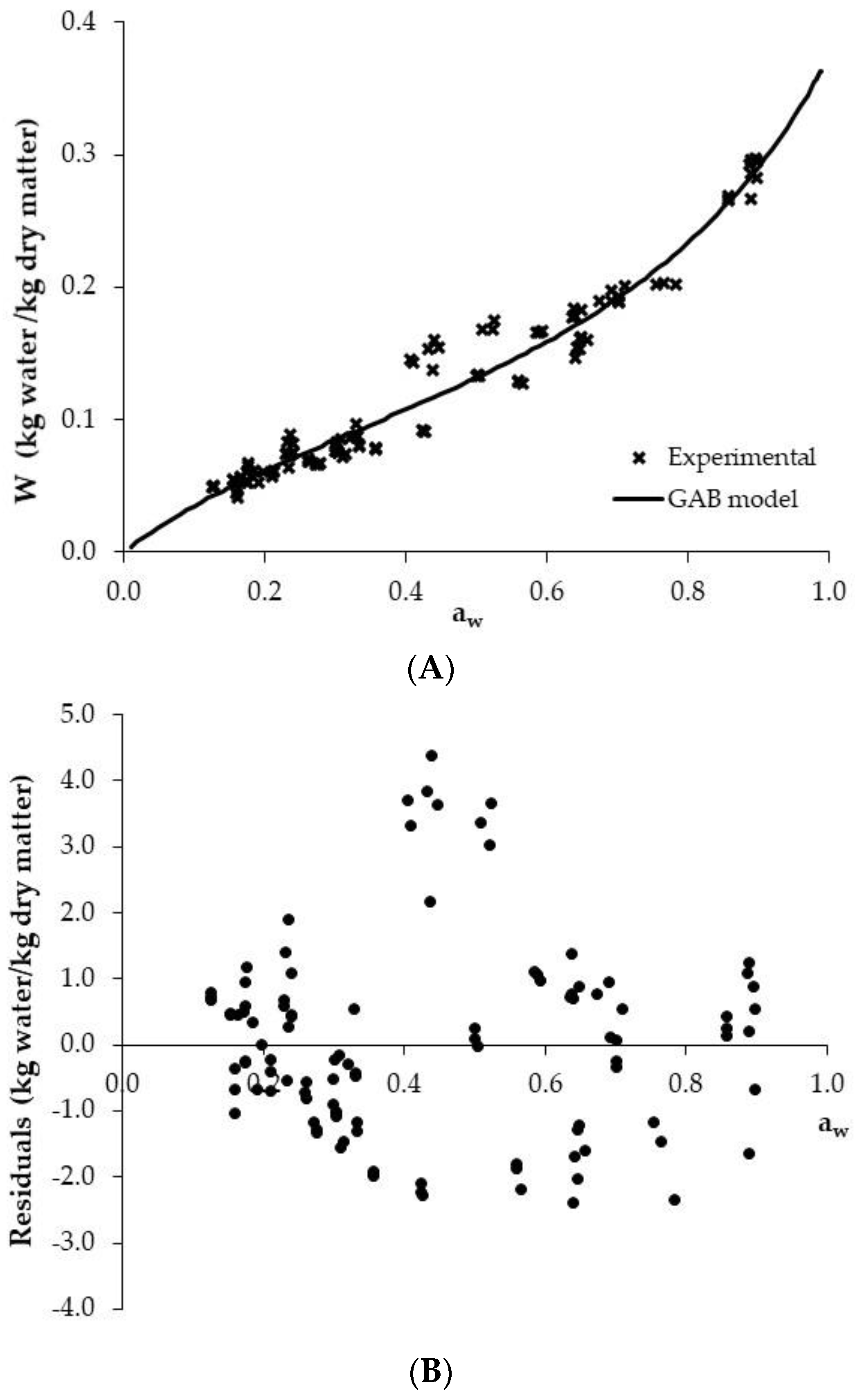

2.4. Moisture Adsorption

2.4.1. Adsorption Experiments

2.4.2. Moisture Content and Water Activity Measurement

2.4.3. Modelling the Moisture Adsorption Isotherm

2.5. Statistical Analysis

3. Results and Discussion

3.1. Selection of the Texture Method

3.1.1. Effect of the Texture Probe Configuration and Test Speed

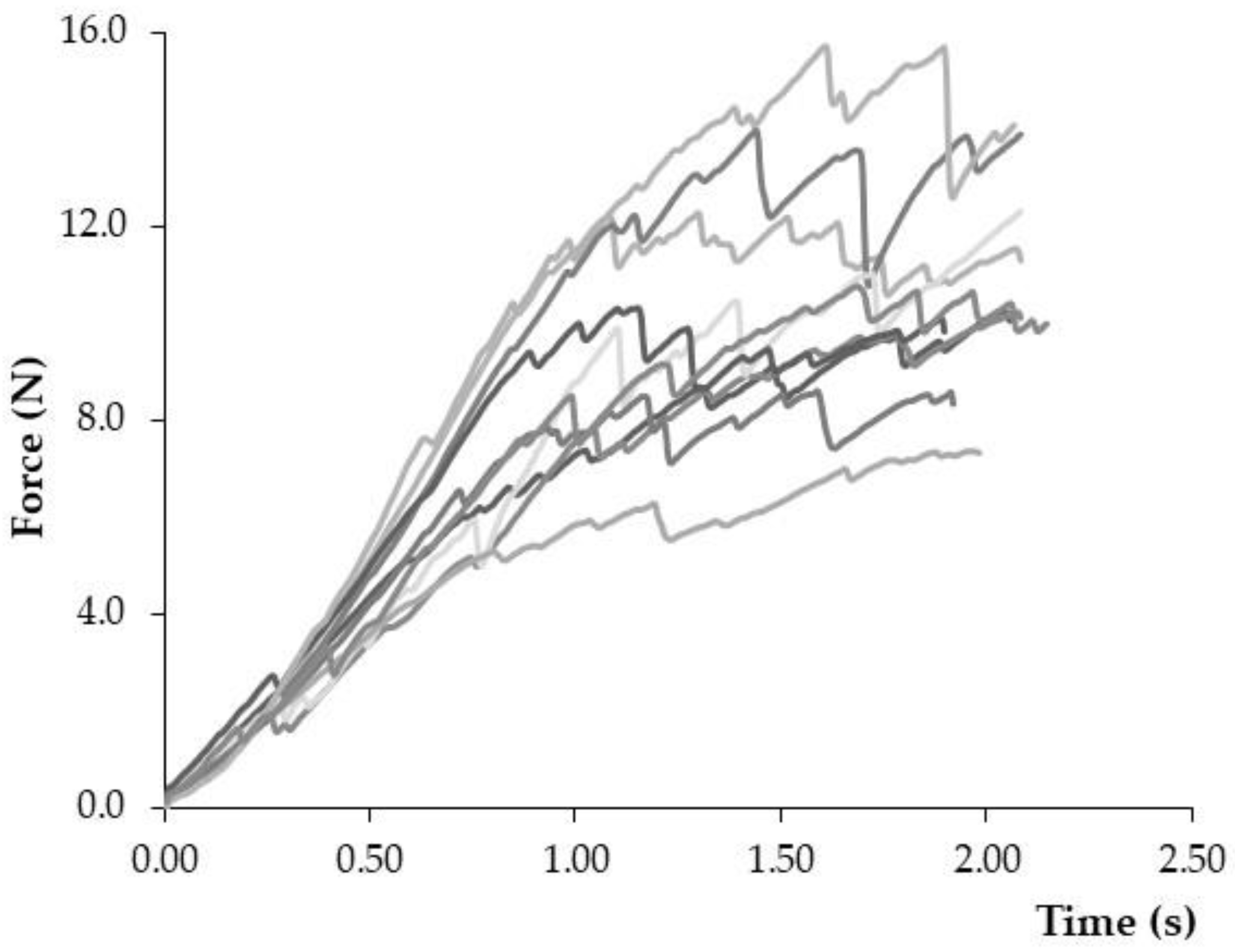

3.1.2. Influence of the Number of Samples on Texture Analysis

3.2. Adsorption Isotherm

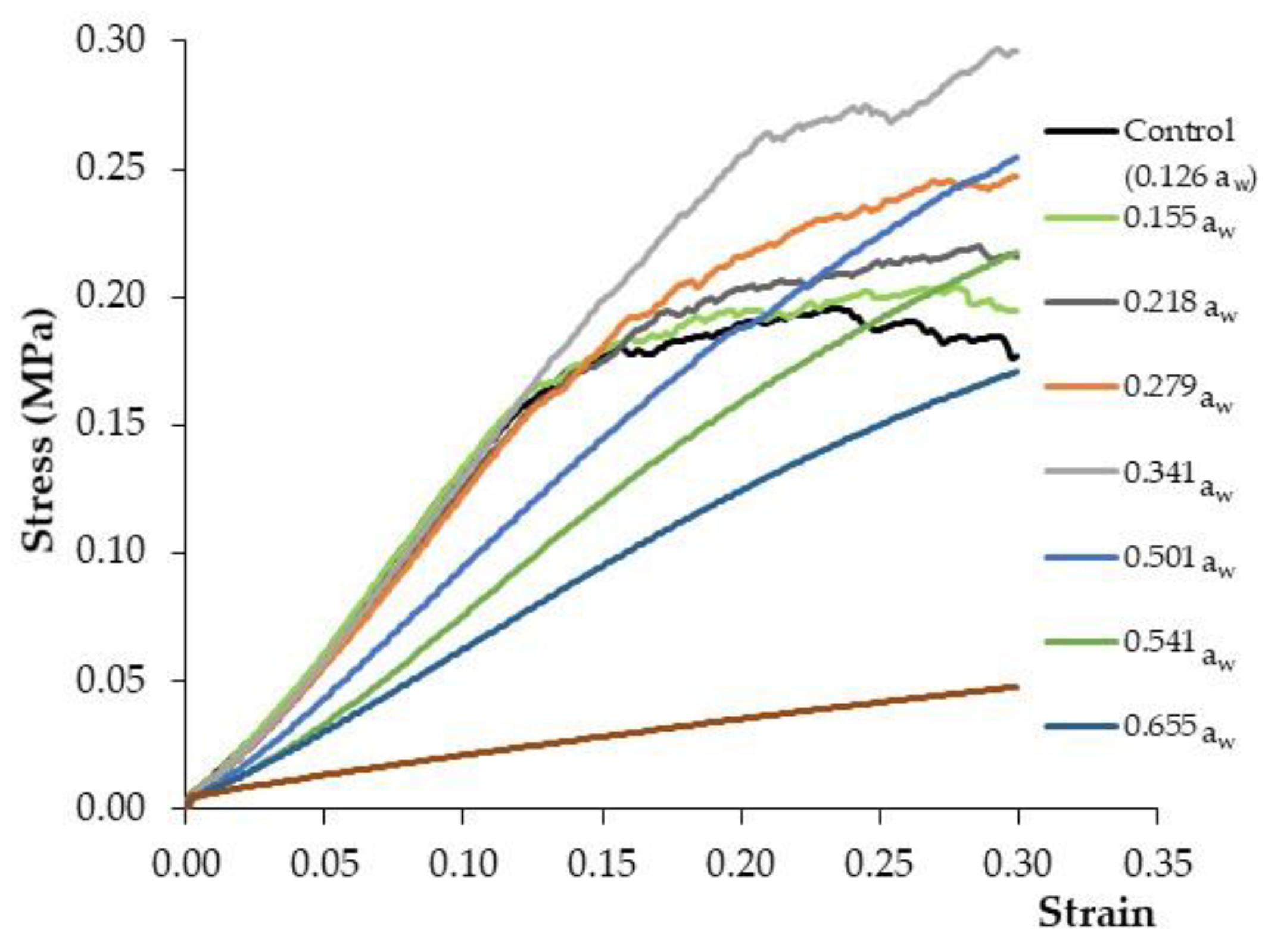

3.3. Influence of the Moisture Adsorption Process on the Experimental Stress–Strain Curves

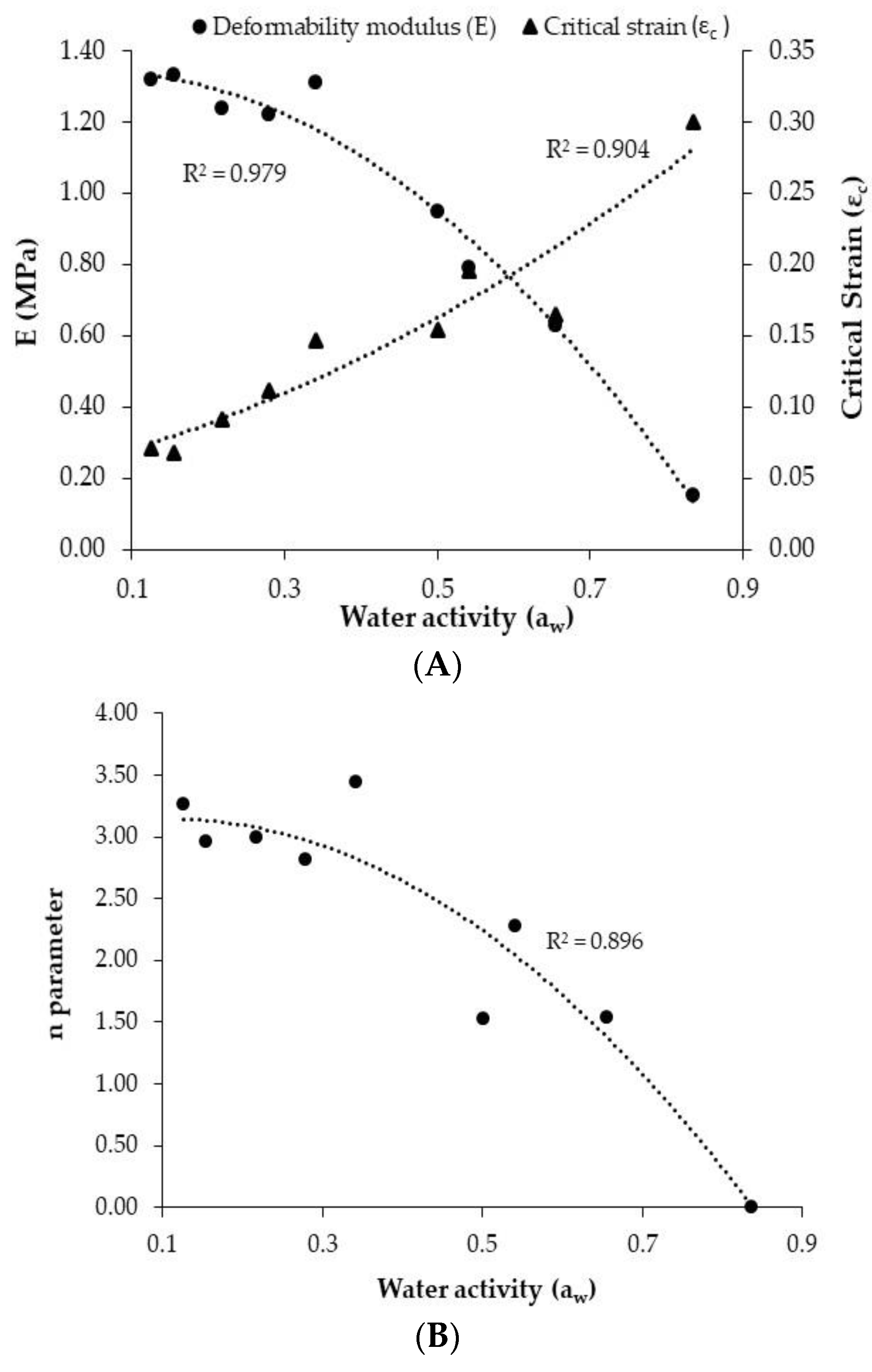

3.4. Modelling of Stress–Strain Curves and Modification of Textural Properties by Moisture Adsorption

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wani, S.A.; Kumar, P. Moisture Sorption Isotherms and Evaluation of Quality Changes in Extruded Snacks during Storage. LWT Food Sci. Technol. 2016, 74, 448–455. [Google Scholar] [CrossRef]

- Nikmaram, N.; Leong, S.Y.; Koubaa, M.; Zhu, Z.; Barba, F.J.; Greiner, R.; Oey, I.; Roohinejad, S. Effect of Extrusion on the Anti-Nutritional Factors of Food Products: An Overview. Food Control 2017, 79, 62–73. [Google Scholar] [CrossRef]

- Lee, J.C.; Kim, J.D.; Hsieh, F.H.; Eun, J.B. Production of Black Rice Cake Using Ground Black Rice and Medium-Grain Brown Rice. Int. J. Food Sci. Technol. 2008, 43, 1078–1082. [Google Scholar] [CrossRef]

- Hsieh, F.; Hu, L.; Peng, I.C.; Huff, H.E. Pretreating Dent Corn Grits for Puffing in a Rice Cake Machine. J. Food Sci. 1990, 55, 1345–1348. [Google Scholar] [CrossRef]

- Li, Y.; Kloeppel, K.M.; Hsieh, F. Texture of Glassy Corn Cakes as a Function of Moisture Content. J. Food Sci. 1998, 63, 869–872. [Google Scholar] [CrossRef]

- Orts, W.J.; Glenn, G.M.; Nobes, G.A.R.; Wood, D.F. Wheat Starch Effects on the Textural Characteristics of Puffed Brown Rice Cakes. Cereal Chem. 2000, 77, 18–23. [Google Scholar] [CrossRef]

- Sharma, J.K. The Structure and Properties of Puffed Rice Cakes; B.Sc Science Punjab Agricultural University: Ludhiana, PB, India, 2012. [Google Scholar]

- Laurindo, J.B.; Peleg, M. Mechanical Measurements in Puffed Rice Cakes. J. Texture Stud. 2007, 38, 619–634. [Google Scholar] [CrossRef]

- Luyten, H.; Plijter, J.J.; Vliet, T. Crispy/Crunchy Crusts of Cellular Solid Foods. J. Texture Stud. 2004, 35, 445–492. [Google Scholar] [CrossRef]

- Hsieh, F.; Huff, H.E.; Peng, I.C.; Marek, S.W. Puffing of Rice Cakes as Influenced by Tempering and Heating Conditions. J. Food Sci. 1989, 54, 1310–1312. [Google Scholar] [CrossRef]

- Xie, M.; Huff, H.; Hsieh, F.; Mustapha, A. Puffing of Okara/Rice Blends Using a Rice Cake Machine. J. Food Sci. 2008, 73, E341–E348. [Google Scholar] [CrossRef]

- Duizer, L.M. Measurement of the Texture of Dry Crisp Products; Woodhead Publishing Limited: Cambridge, UK, 2013; ISBN 9780857098856. [Google Scholar]

- Jiang, Z.; Wang, K.; Zhao, X.; Li, J.; Yu, R.; Fu, R.; He, Y.; Zhao, P.; Oh, K.C.; Hou, J. High-Protein Nutrition Bars: Hardening Mechanisms and Anti-Hardening Methods during Storage. Food Control 2021, 127, 108127. [Google Scholar] [CrossRef]

- Lewicki, P.; Jakubczyk, E. Effect of Water Activity on Mechanical Properties of Dry Cereal Products. Acta Agrophysica 2004, 4, 381–391. [Google Scholar]

- Miele, N.A.; Volpe, S.; Cavella, S.; Masi, P.; di Monaco, R.; Torrieri, E. Implication of Different Sensory Methodologies and Failure Criteria on the Shelf-Life of a Pumpkin-Orange Cake. Food Packag. Shelf Life 2022, 31, 100777. [Google Scholar] [CrossRef]

- Deng, L.Z.; Xiong, C.H.; Pei, Y.P.; Zhu, Z.Q.; Zheng, X.; Zhang, Y.; Yang, X.H.; Liu, Z.L.; Xiao, H.W. Effects of Various Storage Conditions on Total Phenolic, Carotenoids, Antioxidant Capacity, and Color of Dried Apricots. Food Control 2022, 136, 108846. [Google Scholar] [CrossRef]

- Roos, Y.H.; Roininen, K.; Jouppila, K.; Tuorila, H. Glass Transition and Water Plasticization Effects on Crispness of a Snack Food Extrudate. Int. J. Food Prop. 1998, 1, 163–180. [Google Scholar] [CrossRef]

- Katz, E.E.; Labuza, T.P. Effect of Water Activity on the Sensory Crispness and Mechanical Deformation of Snack Food Products. J. Food Sci. 1981, 46, 403–409. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers. In European Journal of Engineering Education; John Wiley and Sons: Hoboken, NJ, USA, 2002; Volume 19, p. 383. ISBN 0471204544. [Google Scholar]

- Gallego, C.F. Cálculo Del Tamaño de La Muestra. Matronas Prof. 2004, 5, 5–13. [Google Scholar]

- Peleg, M. A Model of Mechanical Changes in Biomaterials at and around Their Glass Transition. Biotechnol. Prog. 1994, 10, 385–388. [Google Scholar] [CrossRef]

- Ulbricht, D.; Normand, M.D.; Peleg, M. Creating Typical Jagged Force-deformation Relationships from the Irregular and Irreproducible Compression Data of Crunchy Foods. J. Sci. Food Agric. 1995, 67, 453–459. [Google Scholar] [CrossRef]

- Berthaume, M.A. Food Mechanical Properties and Dietary Ecology. Am. J. Phys. Anthropol. 2016, 159, S79–S104. [Google Scholar] [CrossRef] [PubMed]

- Bourne, M.C. Food Texture and Viscosity. In Concept and Measurement; Elsevier Science Imprint: Amsterdam, The Netherlands, 2002; Volume 53, ISBN 0-12-119062-5. [Google Scholar]

- García-Pérez, J.V.; Cárcel, J.A.; Clemente, G.; Mulet, A. Water Sorption Isotherms for Lemon Peel at Different Temperatures and Isosteric Heats. LWT Food Sci. Technol. 2008, 41, 18–25. [Google Scholar] [CrossRef]

- Santacatalina, J.V.; Rodríguez, O.; Simal, S.; Cárcel, J.A.; Mulet, A.; García-Pérez, J.V. Ultrasonically Enhanced Low-Temperature Drying of Apple: Influence on Drying Kinetics and Antioxidant Potential. J. Food Eng. 2014, 138, 35–44. [Google Scholar] [CrossRef]

- Barretto, T.L.; Polachini, T.C.; da Barretto, A.C.S.; Telis-Romero, J. Water Sorption Isotherms of Cooked Hams as Affected by Temperature and Chemical Composition. Food Sci. Technol. 2019, 39, 677–683. [Google Scholar] [CrossRef]

- Wolf, W.; Spiess, W.E.L.; Jung, G. Properties of Water in Foods in Relation to Quality and Stability. In Properties of Water in Foods; Simatos, D., Multon, J.L., Eds.; Springer: Dordrecht, The Netherlands, 1985; pp. 661–679. ISBN 9789401087568. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis. Method 945.46. In Official Methods of Analysis, 16th ed.; AOAC International: Rockville, MD, USA, 1997. [Google Scholar]

- Guiné, R.P.F.; Barroca, M.J.; Pereira, D.; Correia, P.M.R. Adsorption Isotherms of Maria Biscuits from Different Brands. J. Food Process Eng. 2014, 37, 329–337. [Google Scholar] [CrossRef]

- Forde, C.G.; Leong, C.; Chia-Ming, E.; McCrickerd, K. Fast or Slow-Foods? Describing Natural Variations in Oral Processing Characteristics across a Wide Range of Asian Foods. Food Funct. 2017, 8, 595–606. [Google Scholar] [CrossRef]

- Ulbricht, D.; Normanda, M.D.; Peleg, M.; Horowitz, J. Assessment of the Crumbliness of Individual Fragile Particulates from That of Their Assemblies. Powder Technol. 1994, 81, 83–91. [Google Scholar] [CrossRef]

- Heidenreich, S.; Jaros, D.; Rohm, H.; Ziems, A. Relationship between Water Activity and Crispness of Extruded Rice Crisps. J. Texture Stud. 2004, 35, 621–633. [Google Scholar] [CrossRef]

- Peleg, M. Models of Sigmoid Equilibrium Moisture Sorption Isotherms With and Without the Monolayer Hypothesis. Food Eng. Rev. 2020, 12, 1–13. [Google Scholar] [CrossRef]

- Jensen, P.N.; Risbo, J. Oxidative Stability of Snack and Cereal Products in Relation to Moisture Sorption. Food Chem. 2007, 103, 717–724. [Google Scholar] [CrossRef]

- Barrett, A.H.; Kaletunc, G. Quantitative Description of Fracturability Changes in Puffed Corn Extrudates Affected by Sorption of Low Levels of Moisture. Cereal Chem. 1998, 75, 695–698. [Google Scholar] [CrossRef]

- Chang, Y.P.; Cheah, P.B.; Seow, C.C. Variations in Flexural and Compressive Fracture Behavior of a Brittle Cellular Food (Dried Bread) in Response to Moisture Sorption. J. Texture Stud. 2000, 31, 525–540. [Google Scholar] [CrossRef]

- Mazumder, P.; Roopa, B.S.; Bhattacharya, S. Textural Attributes of a Model Snack Food at Different Moisture Contents. J. Food Eng. 2007, 79, 511–516. [Google Scholar] [CrossRef]

- Saleem, Q.; Wildman, R.D.; Huntley, J.M.; Whitworth, M.B. Material Properties of Semi-Sweet Biscuits for Finite Element Modelling of Biscuit Cracking. J. Food Eng. 2005, 68, 19–32. [Google Scholar] [CrossRef]

- Roudaut, G.; Dacremont, C.; Le Meste, M. Influence of Water on the Crispness of Cereal-Based Foods: Acoustic, Mechanical, and Sensory Studies. J. Texture Stud. 1998, 29, 199–213. [Google Scholar] [CrossRef]

- Jakubczyk, E.; Marzec, A.; Lewicki, P.P. Relationship Between Water Activity of Crisp Bread and Its Mechanical Properties and Structure. Pol. J. Food Nutr. Sci. 2008, 58, 45–51. [Google Scholar]

| Salts | R.H. (%) | aw | Moisture (kg Water/kg Dry Matter) | E (MPa) | εc | n | VAR (%) | MRE (%) | L (mm) |

|---|---|---|---|---|---|---|---|---|---|

| Control | - | 0.126 ± 0.009 a | 0.037 ± 0.006 a | 1.32 | 0.071 | 3.26 | 99.2 | 3.58 | 7.02 ± 0.76 b |

| LiCl | 10 | 0.155 ± 0.018 a | 0.051 ± 0.005 a | 1.33 | 0.068 | 2.96 | 99.1 | 3.87 | 7.44 ± 0.65 c,d,e |

| CH3COOK | 20 | 0.218 ± 0.036 b | 0.065 ± 0.008 b | 1.24 | 0.091 | 3.00 | 99.5 | 3.68 | 7.54 ± 0.69 d,e |

| MgCl2 | 30 | 0.279 ± 0.047 c | 0.076 ± 0.006 b,c | 1.22 | 0.111 | 2.82 | 99.8 | 2.78 | 7.56 ± 0.48 e |

| K2CO3 | 40 | 0.341 ± 0.045 d | 0.083 ± 0.008 c | 1.31 | 0.147 | 3.44 | 99.6 | 3.90 | 7.18 ± 0.70 b,c |

| NaNO2 | 60 | 0.501 ± 0.067 e | 0.142 ± 0.016 d | 0.95 | 0.154 | 1.53 | 99.9 | 2.71 | 7.52 ± 0.56 d,e |

| NaCl | 70 | 0.541 ± 0.092 e | 0.151 ± 0.013 d | 0.79 | 0.196 | 2.28 | 99.8 | 4.82 | 7.47 ± 0.46 c,d,e |

| KCl | 80 | 0.655 ± 0.086 f | 0.185 ± 0.012 e | 0.63 | 0.165 | 1.54 | 99.9 | 0.93 | 7.20 ± 0.73 b,c,d |

| KNO3 | 90 | 0.836 ± 0.082 g | 0.262 ± 0.039 f | 0.15 | 0.300 | - | 99.4 | 3.20 | 4.76 ± 0.86 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchez-Jimenez, V.; Gomez Alvarez-Arenas, T.E.; Rincón, M.; Benedito, J.; Garcia-Perez, J.V. Assessment of Textural Properties of Puffed Corn Cakes during Storage at Different Relative Humidity. Foods 2022, 11, 2882. https://doi.org/10.3390/foods11182882

Sanchez-Jimenez V, Gomez Alvarez-Arenas TE, Rincón M, Benedito J, Garcia-Perez JV. Assessment of Textural Properties of Puffed Corn Cakes during Storage at Different Relative Humidity. Foods. 2022; 11(18):2882. https://doi.org/10.3390/foods11182882

Chicago/Turabian StyleSanchez-Jimenez, Virginia, Tomas E. Gomez Alvarez-Arenas, Marta Rincón, Jose Benedito, and Jose V. Garcia-Perez. 2022. "Assessment of Textural Properties of Puffed Corn Cakes during Storage at Different Relative Humidity" Foods 11, no. 18: 2882. https://doi.org/10.3390/foods11182882

APA StyleSanchez-Jimenez, V., Gomez Alvarez-Arenas, T. E., Rincón, M., Benedito, J., & Garcia-Perez, J. V. (2022). Assessment of Textural Properties of Puffed Corn Cakes during Storage at Different Relative Humidity. Foods, 11(18), 2882. https://doi.org/10.3390/foods11182882