Response Surface Optimization of Solar Drying Conditions and the Effect on the Quality Attributes and Drying Characteristics of Qula Casein

Abstract

:1. Introduction

2. Materials and Methods

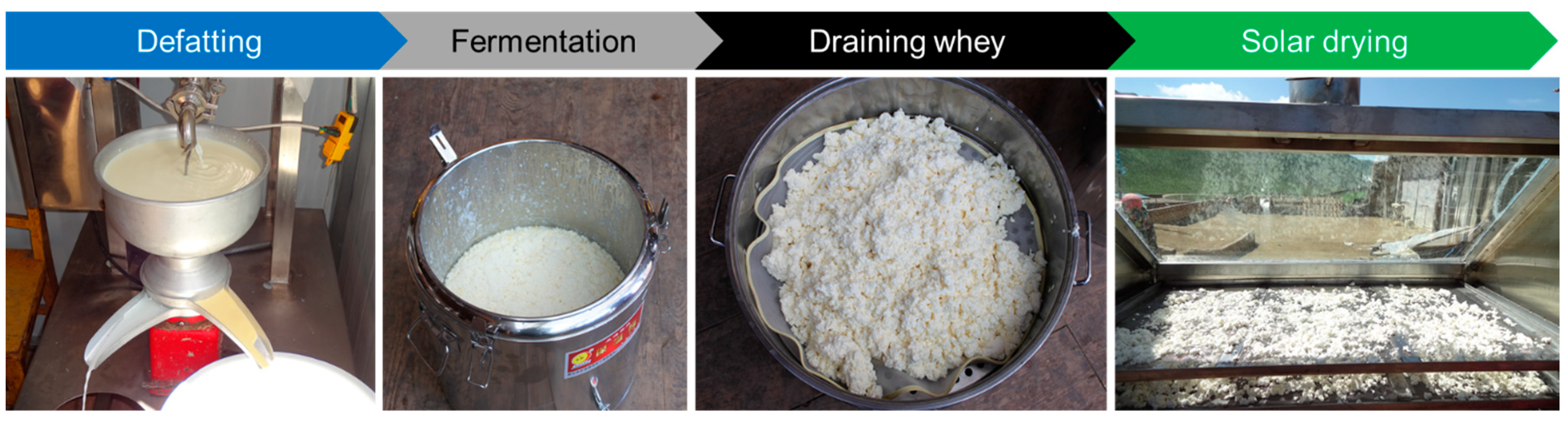

2.1. Material Preparation

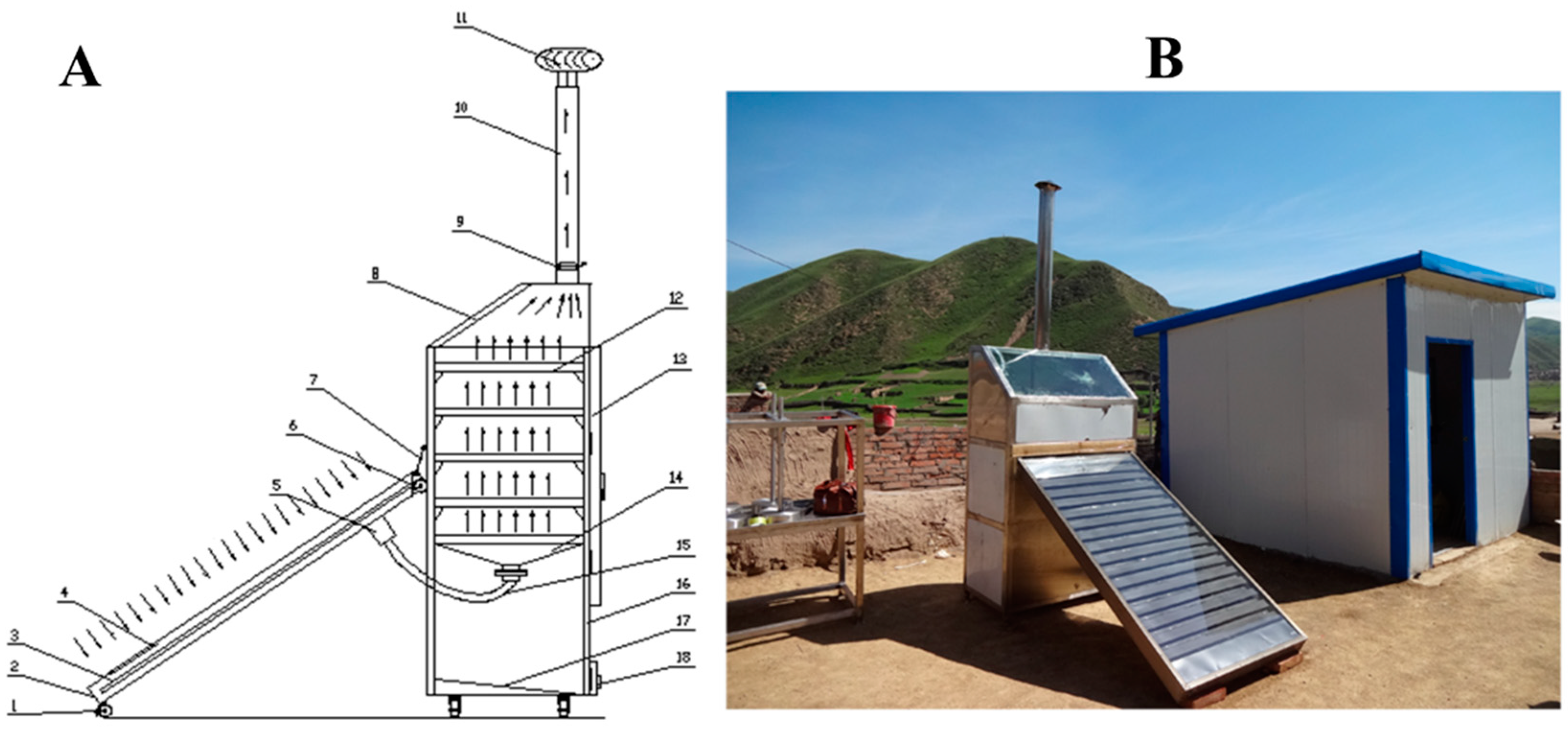

2.2. Mixed-Mode Solar Dryer

2.3. Experimental Design

2.4. Quality Attributes’ Determination

2.4.1. POV

2.4.2. TBARS

2.4.3. 5-HMF

2.4.4. Nutritional Components and Color Parameters

2.5. Drying Kinetics

2.5.1. Drying Curves

2.5.2. Mathematical Modeling

2.6. Statistical Analysis

3. Results and Discussion

3.1. Fitting Response Surface Models

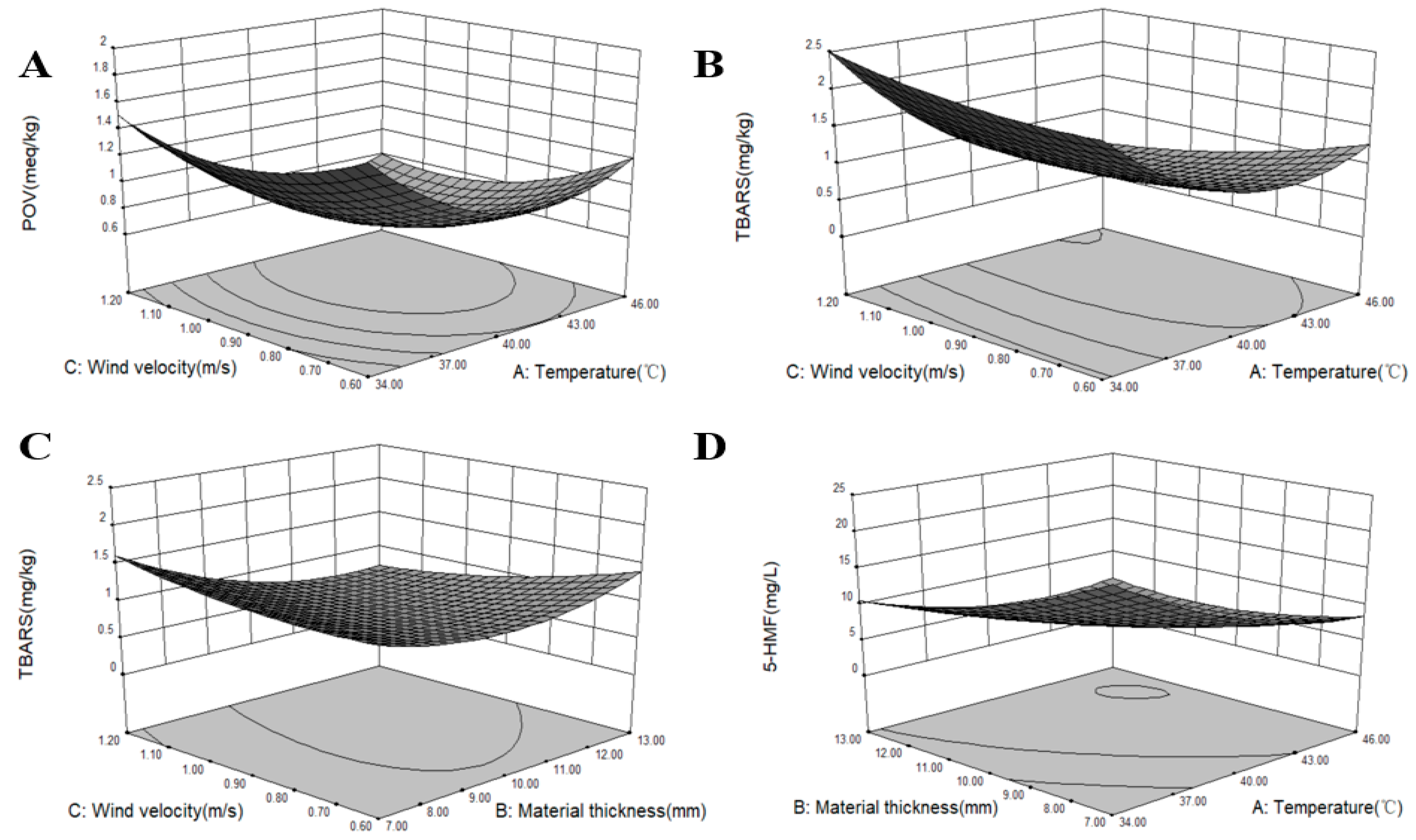

3.2. Effects of Solar Drying Conditions on the POV

3.3. Effects of Solar Drying Conditions on the TBARS

3.4. Effects of Solar Drying Conditions on 5-HMF

3.5. Optimization of Qula Solar Drying

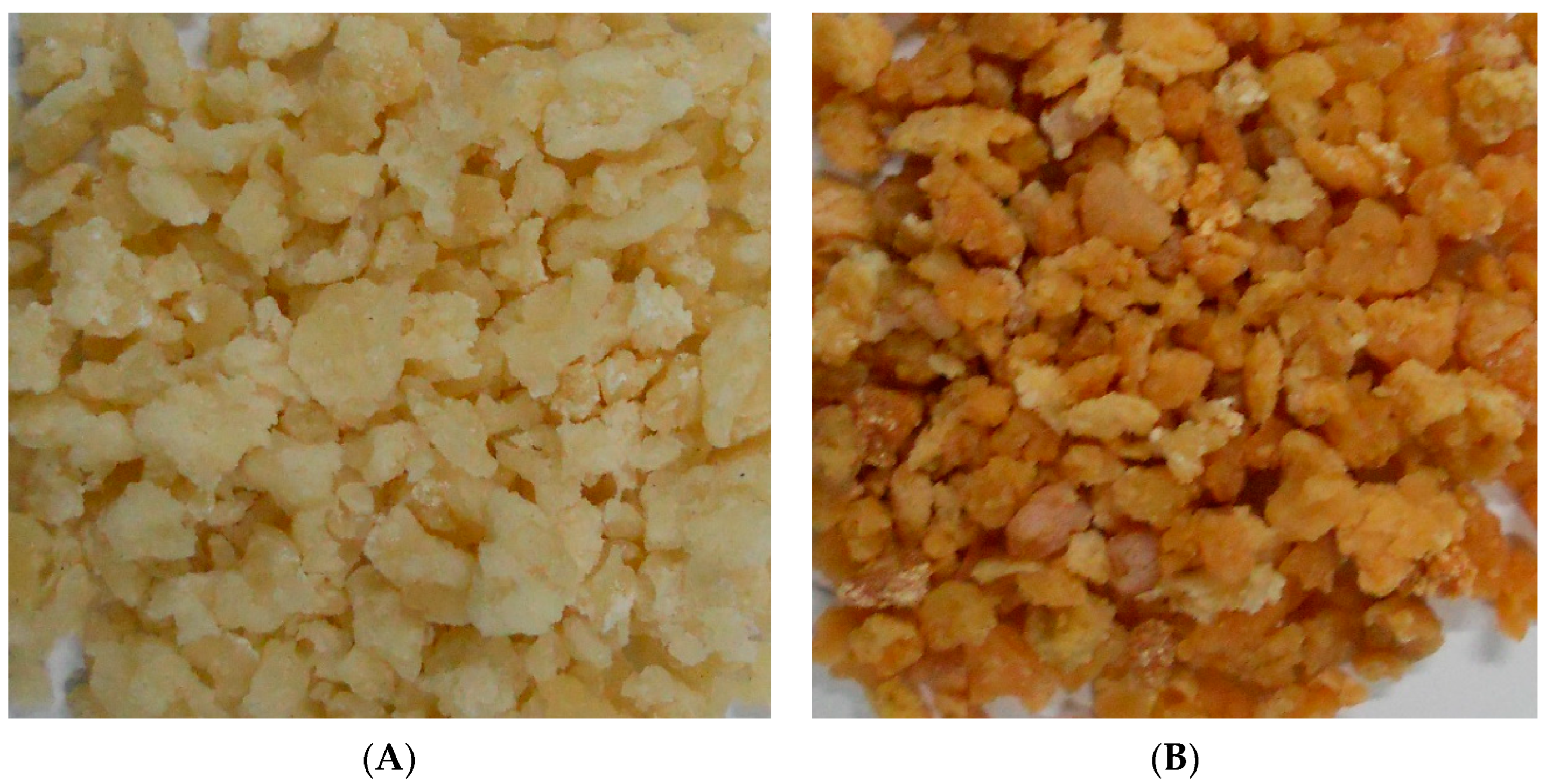

3.6. Model Verification and the Comparison between Solar Drying and Open Sun-Drying

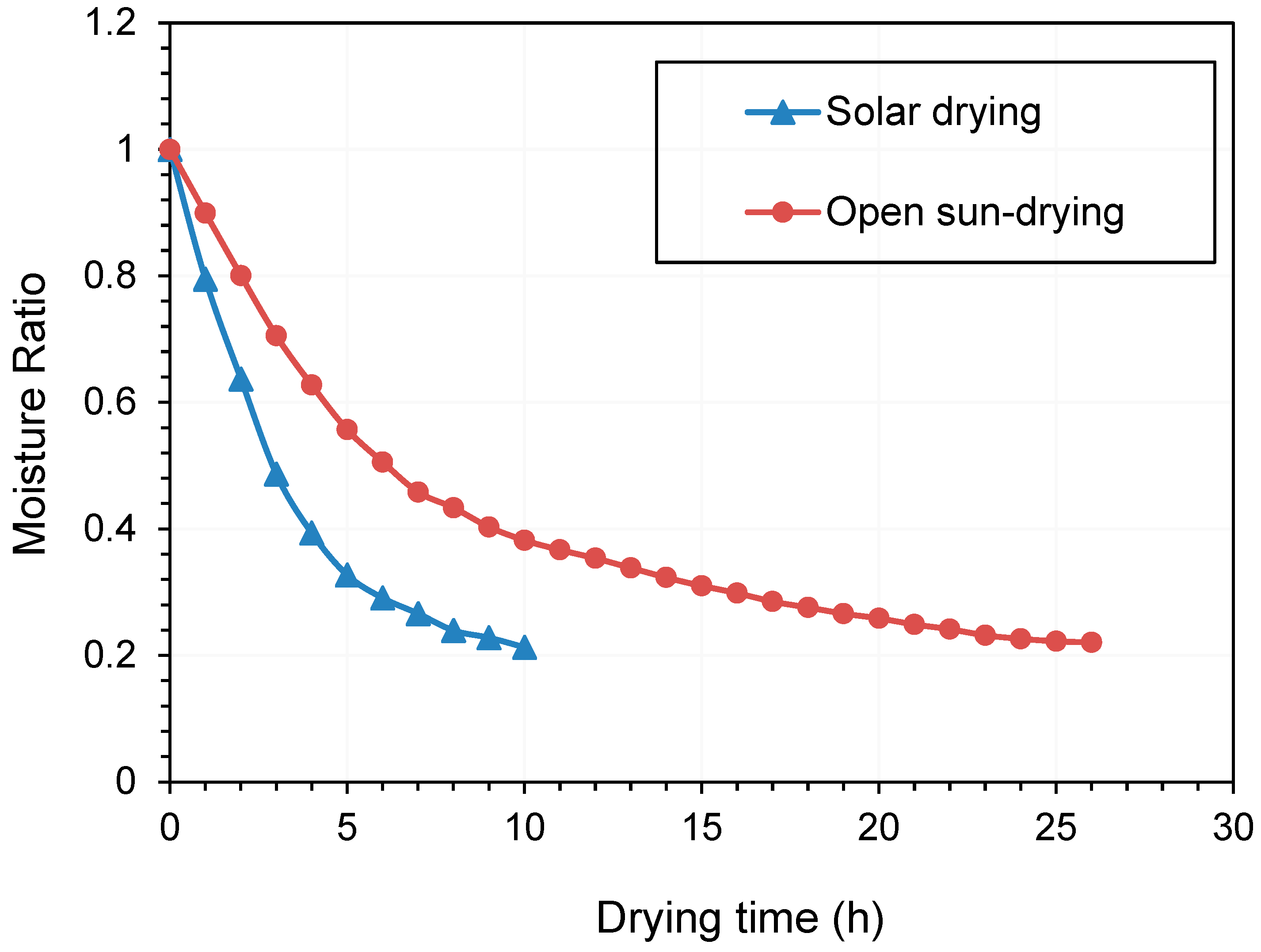

3.7. Drying Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| R2 | coefficient of determination |

| POV | peroxide |

| TBARS | thiobarbituric acid reactive substance |

| 5-HMF | 5-hydroxymethylfurfural |

| RSM | response surface methodology |

| CCD | central composite rotatable design |

| KI | potassium iodide |

| MDA | malondialdehyde |

| HPLC | high performance liquid chromatography |

| MR | moisture ratio |

| χ2 | reduced chi-squared parameter |

| RSS | residual sum of squares |

| R2-adj | adjusted coefficient of determination |

| R2-pred | predicted coefficient of determination |

| k, n, a, b, k0, k1, α, β, c | model parameters |

| t | drying time (h) |

| X1 | temperature (°C) |

| X2 | material thickness (mm) |

| X3 | wind velocity (m/s) |

| Y1 | peroxide value (meq/kg) |

| Y2 | thiobarbituric acid reactive substance value (mg/kg) |

| Y3 | 5-hydroxymethylfurfural content (mg/L) |

| L*, a*, b* | the color parameters |

| Mt | moisture content at t time of drying (kg water/kg dry matter) |

| M0 | initial moisture content (kg water/kg dry matter) |

| Me | equilibrium moisture content (kg water/kg dry matter) |

| MRexp,i | experimental dimensionless moisture ratio |

| MRpre,i | calculated dimensionless moisture ratio |

| N | number of experiments |

| z | number of constants |

| β0 | model intercept |

| β1, β2, β3, β11, β22, β33 | linear quadratic |

| β12, β13, β23 | interaction coefficients |

| ANOVA | analysis of variance |

| DF | degrees of freedom |

References

- Li, H.M.; Ma, Y.; Li, Q.M.; Wang, J.Q.; Cheng, J.J. The chemical composition and nitrogen distribution of Chinese yak (Maiwa) milk. Int. J. Mol. Sci. 2011, 12, 4885–4895. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, C.; Zhang, H.; Guo, H.; Wang, P.; Zhu, Y.; Ren, F. pH treatment as an effective tool to select the functional and structural properties of yak milk caseins. J. Dairy Sci. 2013, 96, 5494–5500. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, K.; Zhang, L.W.; Han, X.; Cheng, D.Y. Novel angiotensin I-converting enzyme inhibitory peptides from protease hydrolysates of Qula casein: Quantitative structure-activity relationship modeling and molecular docking study. J. Funct. Foods 2017, 32, 266–277. [Google Scholar] [CrossRef]

- Yamamoto, N.; Maeno, M.; Takano, T. Purification and characterization of an antihypertensive peptide from a yogurt-Like product fermented by lactobacillus helveticus CPN4. J. Dairy Sci. 1999, 82, 1388–1393. [Google Scholar] [CrossRef]

- Mao, X.Y.; Ni, J.R.; Sun, W.L.; Hao, P.P.; Fan, L. Value-added utilization of yak milk casein for the production of angiotensin-I-converting enzyme inhibitory peptides. Food Chem. 2007, 103, 1282–1287. [Google Scholar] [CrossRef]

- García-Valladares, O.; López-Vidaña, E.C.; Galindo-Luna, Y.R.; Luna-Solano, G.; Pilatowsky-Figueroa, I.; Domínguez-Niño, A. Effect of convective drying conditions on the physicochemical, microbiological, and thermophysical properties of cincho artisanal cheese. Rev. Mexi. Ing. Quími. 2022, 21, Alim2652. [Google Scholar] [CrossRef]

- Xiao, H.W.; Mujumdar, A.S. Importance of drying in support human welfare. Dry. Technol. 2020, 38, 1542–1543. [Google Scholar] [CrossRef] [Green Version]

- Nie, Z.; Bu, L.Z.; Zheng, M.P.; Huang, W.N. Experimental study of natural brine solar ponds in Tibet. Sol. Energy 2011, 85, 1537–1542. [Google Scholar] [CrossRef]

- Feng, L.; Lin, A.W.; Wang, L.C.; Qin, W.M.; Gong, W. Evaluation of sunshine-based models for predicting diffuse solar radiation in China. Renew. Sustain. Energy Rev. 2018, 94, 168–182. [Google Scholar] [CrossRef]

- Izadi, Z.; Mohebbi, M.; Shahidi, F.; Varidi, M.; Salahi, M.R. Cheese powder production and characterization: A foam-mat drying approach. Food Bioprod. Process. 2020, 123, 225–237. [Google Scholar] [CrossRef]

- Romeu-Nadal, M.; Chavez-Servin, J.L.; Castellote, A.I.; Rivero, M.; Lopez-Sabater, M.C. Oxidation stability of the lipid fraction in milk powder formulas. Food Chem. 2007, 100, 756–763. [Google Scholar] [CrossRef]

- Gutierrez, A.M.; Boylston, T.D.; Clark, S. Effects of pro-oxidants and antioxidants on the total antioxidant capacity and lipid oxidation products of milk during refrigerated storage. J. Food Sci. 2017, 83, 275–283. [Google Scholar] [CrossRef] [PubMed]

- Andoyo, R.; Guyomarc, F.; Cauty, C. Model mixtures evidence the respective roles of whey protein particles and casein micelles during acid gelation. Food Hydrocolloid. 2014, 37, 203–212. [Google Scholar] [CrossRef]

- Erbay, Z.; Koca, N.; Kaymak-Ertekin, F.; Ucuncu, M. Optimization of spray drying process in cheese powder production. Food Bioprod. Process. 2015, 93, 156–165. [Google Scholar] [CrossRef]

- Aguilera-Toro, M.; Poulsen, N.A.; Akkerman, M.; Rauh, V.; Larsen, L.B.; Nielsen, S.D.H. Development in maillard reaction and dehydroalanine pathway markers during storage of uht milk representing differences in casein micelle size and sedimentation. Foods 2022, 11, 1525. [Google Scholar] [CrossRef]

- Toker, O.S.; Dogan, M.; Ersöz, N.B.; Yilmaz, M.T. Optimization of the content of 5-hydroxymethylfurfural (HMF) formed in some molasses types: HPLC-DAD analysis to determine effect of different storage time and temperature levels. Ind Crop Prod. 2013, 50, 137–144. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Z.; Li, J.; Niu, Y.; Yu, L.L. Inhibition mechanism of l-cysteine on maillard reaction by trapping 5-hydroxymethylfurfural. Foods 2021, 10, 1391. [Google Scholar] [CrossRef]

- Capuano, E.; Ferrigno, A.; Acampa, I.; Serpen, A.; Acar, O.C.; Goekmen, V.; Fogliano, V. Effect of flour type on maillard reaction and acrylamide formation during toasting of bread crisp model systems and mitigation strategies. Food Res. Int. 2009, 42, 1295–1302. [Google Scholar] [CrossRef]

- Zhang, B.; Tan, Z.F.; Wang, Y.P.; Li, Z.W.; Huang, Q.C. Dynamic changes of the microbial communities during the preparation of traditional Tibetan Qula cheese. Dairy Sci. Technol. 2015, 2, 167–180. [Google Scholar] [CrossRef]

- Juhari, N.; Laseka, O.; Kharidah, M. Optimization of hot-air drying conditions on the physicochemical characteristics of torch ginger (Etlingera elatior). J. Food Agric. Environ. 2012, 10, 64–72. [Google Scholar]

- Sun, X.D.; Mujumdar, A.S.; Law, C.L.; Fang, X.M.; Peng, W.J.; Deng, L.Z.; Wang, J.; Xiao, H.W. Effect of drying air temperature on drying kinetics, color, carotenoid content, antioxidant capacity and oxidation of fat for lotus pollen. Dry. Technol. 2020, 38, 1151–1164. [Google Scholar]

- Gao, K.; Zhou, L.Y.; Bi, J.F.; Yi, J.Y.; Wu, X.Y.; Xiao, M. Research on the nonenzymatic browning reactions in model systems based on apple slices dried by instant controlled pressure drop drying. Dry. Technol. 2017, 35, 1302–1311. [Google Scholar] [CrossRef]

- Wang, J.; Law, C.L.; Nema, P.K.; Zhao, J.H.; Liu, Z.L.; Deng, L.Z.; Gao, Z.J.; Xiao, H.W. Pulsed vacuum drying enhances drying kinetics and quality of lemon slices. J. Food Eng. 2018, 224, 129–138. [Google Scholar] [CrossRef]

- Zhao, P.F.; Zhong, L.P.; Zhu, R.; Zhao, Y.M.; Luo, Z.F.; Yang, X.L. Drying characteristics and kinetics of Shengli lignite using different drying methods. Energy Convers. Manag. 2016, 120, 330–337. [Google Scholar] [CrossRef]

- Bruce, D.M. Exposed-layer barley drying, three models fitted to new data up to 150 °C. J. Agric. Eng. Res. 1985, 32, 337–347. [Google Scholar] [CrossRef]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 1949. [Google Scholar]

- Henderson, S.M.; Pabis, S. Grain drying theory, II. Temperature effects on drying coefficients. J. Agric. 1961, 44, 1111–1122. [Google Scholar]

- Celma, A.R.; Rojas, S.; Lo’pez, F.; Montero, I.; Miranda, T. Thin-layer drying behaviour of sludge of olive oil extraction. J. Food Eng. 2007, 80, 1261–1271. [Google Scholar] [CrossRef]

- Henderson, S.M. Progress in developing the thin layer drying equation. Trans. ASAE 1974, 17, 1167–1168. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H. Mathematical modelling of thin layer drying of pistachio by using solar energy. Energy Convers. Manag. 2003, 44, 1111–1122. [Google Scholar] [CrossRef]

- Wang, J.; Yang, X.-H.; Mujumdar, A.S.; Fang, X.-M.; Zhang, Q.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Effects of high-humidity hot air impingement blanching (HHAIB) pretreatment on the change of antioxidant capacity, the degradation kinetics of red pigment, ascorbic acid in dehydrated red peppers during storage. Food Chem. 2018, 259, 65–72. [Google Scholar] [CrossRef]

- Badwaik, L.; Prasad, K.; Deka, S. Optimization of extraction conditions by response surface methodology for preparing partially defatted peanut. Int. Food Res. J. 2012, 19, 341–346. [Google Scholar]

- Abnisa, F.; Wan, D.W.; Sahu, J. Optimization and characterization studies on bio-oil production from palm shell by pyrolysis using response surface methodology. Biomass. Bioenerg. 2011, 35, 3604–3616. [Google Scholar] [CrossRef]

- Abel, O.; Dominique, L.M.; Isabel, L. The effects of sous-vide cooking parameters on texture and cell wall modifications in two apple cultivars: A response surface methodology approach. Food Sci. Technol. Int. 2017, 23, 99–109. [Google Scholar]

- Yolmeh, M.; Najafi, M.B.H.; Farhoosh, R.; Hosseini, F. Optimization of ultrasound-assisted extraction of natural pigment from annatto seeds by response surface methodology (RSM). Food Chem. 2014, 55, 319–324. [Google Scholar] [CrossRef]

- Sahoo, C.; Gupta, A. Optimization of photocatalytic degradation of methyl blue using silver ion doped titanium dioxide by combination of experimental design and response surface approach. J. Hazard. Mater. 2012, 215, 302–310. [Google Scholar] [CrossRef]

- Erbay, Z.; Icier, F. Optimization of hot-air drying of olive leaves using response surface methodology. J. Food Eng. 2009, 91, 533–541. [Google Scholar] [CrossRef]

- Fu, J.; Zhao, Y.; Wu, Q. Optimising photoelectrocatalytic oxidation of fulvic acid using response surface methodology. J. Hazard. Mater. 2007, 144, 499–505. [Google Scholar] [CrossRef] [Green Version]

- Firatligil-Durmus, E.; Evranuz, O. Response surface methodology for protein extraction optimization of red pepper seed (Capsicum frutescens). LWT-Food Sci. Technol. 2010, 43, 226–231. [Google Scholar] [CrossRef]

- Stapelfeldt, H.; Nielsen, B.R.; Skibsted, L.L. Effect of heat treatment, water activity and storage temperature on the oxidative stability of whole milk powder. Int. Dairy J. 1997, 7, 331–339. [Google Scholar] [CrossRef]

- Jin, G.; Zhang, J.; Yu, X.; Zhang, Y.; Lei, Y.; Wang, J. Lipolysis and lipid oxidation in bacon during curing and drying–ripening. Food Chem. 2010, 123, 465–471. [Google Scholar] [CrossRef]

- Ajmal, M.; Nadeem, M.; Imran, M.; Junaid, M. Lipid compositional changes and oxidation status of ultra-high temperature treated milk. Lipids Health Dis. 2018, 17, 227. [Google Scholar] [CrossRef] [Green Version]

- Feng, C.-H.; Sun, D.-W. Optimisation of immersion vacuum cooling operation and quality of Irish cooked sausages by using response surface methodology. Int. J. Food Sci. Technol. 2014, 49, 1850–1858. [Google Scholar] [CrossRef]

- Dai, J.J.; Zhu, J.Y.; Chen, C.Z.; Weng, F. High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of titanium alloys and titanium aluminides. J. Alloy. Compd. 2016, 685, 784–798. [Google Scholar] [CrossRef]

- Swami, S.B.; Das, S.K.; Maiti, B. Convective hot air drying and quality characteristics of bori: A traditional indian nugget prepared from black gram pulse batter. J. Food Eng. 2007, 79, 225–233. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, J.; Yang, Y.; Bu, D.; Cui, H.; Sun, Y.; Xu, X.; Zhou, L. Effects of different fat mixtures on milk fatty acid composition and oxidative stability of milk fat. Anim. Feed Sci. Technol. 2013, 185, 35–42. [Google Scholar] [CrossRef]

- Lee, H.S.; Nagy, S. Relative reactivities of sugars in the formation of 5-hydroxymethylfurfural in sugarcatalyst model systems. J. Food Process. Preserv. 1990, 14, 171–178. [Google Scholar] [CrossRef]

- Gökmen, V.; Açar, Ö.Ç.; Serpen, A.; Morales, F.J. Effect of leavening agents and sugars on the formation of hydroxymethylfurfural in cookies during baking. Eur. Food Res. Technol. 2008, 226, 1031–1037. [Google Scholar] [CrossRef]

- Kroh, L.W. Caramelisation in food and beverages. Food Chem. 1994, 51, 373–379. [Google Scholar] [CrossRef]

- Oral, R.A.; Dogan, M.; Sarioglu, K. Monitoring of the hydroxymethylfurfural amount as an indicator of Maillard products in sweet whey and skim milk powder stored under different conditions. Milchwissenschaft-Milk Sci. Int. 2011, 66, 398–401. [Google Scholar]

- Matiacevich, S.B.; Santagapita, P.R.; Buera, M.P. Fluorescence from the Maillard reaction and its potential applications in food science. Critical Rev. Food Sci. Nutr. 2005, 45, 483–495. [Google Scholar] [CrossRef]

- Martins, S.I.; Jongen, W.M.; Van Boekel, M.A. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Lu, Y.; Riyanto, N.; Weavers, L.K. Sonolysis of synthetic sediment particles: Particle characteristics affecting particle dissolution and size reduction. Ultrason. Sonochem. 2002, 9, 181–188. [Google Scholar] [CrossRef]

- Thomsen, M.K.; Lauridsen, L.; Skibsted, L.H.; Risbo, J. Two types of radicals in whole milk powder. Effect of lactose crystallization, lipid oxidation, and browning reactions. J. Agric. Food Chem. 2005, 53, 1805–1811. [Google Scholar] [CrossRef] [PubMed]

- Xie, L.; Mujumdar, A.S.; Fang, X.M.; Wang, J.; Dai, J.W.; Du, Z.L.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Far-infrared radiation heating assisted pulsed vacuum drying (FIR-PVD) of wolfberry (Lycium barbarum L.): Effects on drying kinetics and quality attributes. Food Bioprod. Process. 2017, 102, 320–331. [Google Scholar] [CrossRef]

- Romauli, N.D.M.; Ambarita, H.; Qadry, A.; Sihombing, H.V. Effect of drying whole and half chili pods using a solar dryer with CaCl2 desiccant on quality of powder chili. Int. J. Food Sci. 2021, 2021, 9731727. [Google Scholar] [CrossRef]

| Independent Variables | Coded Levels | ||||

|---|---|---|---|---|---|

| −1.68 | −1 | 0 | +1 | +1.68 | |

| Temperature X1 (°C) | 30 | 34 | 40 | 46 | 50 |

| Material thickness X2 (mm) | 5 | 7 | 10 | 13 | 15 |

| Wind velocity X3 (m·s−1) | 0.4 | 0.6 | 0.9 | 1.2 | 1.4 |

| Run | Factor Level Coding | Response | ||||

|---|---|---|---|---|---|---|

| Temperature (°C) | Material Thickness (mm) | Wind Velocity (m/s) | POV (meq/kg) | TBARS (mg/kg) | 5-HMF (mg/L) | |

| X1 | X2 | X3 | ||||

| 1 | 34 (−1) | 7 (−1) | 0.6 (−1) | 2.15 | 2.367 | 23.67 |

| 2 | 46 (+1) | 7 (−1) | 0.6 (−1) | 1.55 | 1.538 | 11.99 |

| 3 | 34 (−1) | 13 (+1) | 0.6 (−1) | 1.88 | 2.546 | 13.15 |

| 4 | 46 (+1) | 13 (+1) | 0.6 (−1) | 1.55 | 1.635 | 10.22 |

| 5 | 34 (−1) | 7 (−1) | 1.2 (+1) | 2.06 | 3.360 | 18.81 |

| 6 | 46 (+1) | 7 (−1) | 1.2 (+1) | 1.24 | 1.080 | 6.27 |

| 7 | 34 (−1) | 13 (+1) | 1.2 (+1) | 1.77 | 2.258 | 11.28 |

| 8 | 46 (+1) | 13 (+1) | 1.2 (+1) | 1.02 | 0.519 | 5.38 |

| 9 | 30 (−1.68) | 10 (0) | 0.9 (0) | 2.08 | 3.759 | 22.47 |

| 10 | 50 (+1.68) | 10 (0) | 0.9 (0) | 1.34 | 1.453 | 7.56 |

| 11 | 40 (0) | 5 (−1.68) | 0.9 (0) | 1.78 | 2.077 | 20.02 |

| 12 | 40 (0) | 15 (+1.68) | 0.9 (0) | 1.36 | 1.265 | 6.68 |

| 13 | 40 (0) | 10 (0) | 0.4 (−1.68) | 1.45 | 1.293 | 16.56 |

| 14 | 40 (0) | 10 (0) | 1.4 (+1.68) | 1.03 | 1.021 | 9.89 |

| 15 | 40 (0) | 10 (0) | 0.9 (0) | 0.63 | 0.781 | 8.15 |

| 16 | 40 (0) | 10 (0) | 0.9 (0) | 0.77 | 0.978 | 7.25 |

| 17 | 40 (0) | 10 (0) | 0.9 (0) | 0.67 | 0.861 | 5.89 |

| 18 | 40 (0) | 10 (0) | 0.9 (0) | 0.75 | 0.772 | 6.98 |

| 19 | 40 (0) | 10 (0) | 0.9 (0) | 0.71 | 0.938 | 5.92 |

| 20 | 40 (0) | 10 (0) | 0.9 (0) | 0.61 | 0.771 | 8.44 |

| Models | Model Equations | References |

|---|---|---|

| Lewis | MR = exp(−kt) | Bruce (1985) [25] |

| Page | MR = exp(−ktn) | Page (1949) [26] |

| Henderson and Pabis | MR = aexp(−ktn) | Henderson and Pabis (1961) [27] |

| Logarithmic | MR = aexp(−kt) + c | Celma and Rojas (2007) [28] |

| Two term | MR = aexp(−k0t) + bexp(−k1t) | Henderson (1974) [29] |

| Midilli–Kucuk | MR = aexp(−k(tn)) + bt | Midilli and Kucuk (2003) [30] |

| Weibull | Wang and Yang (2018) [31] |

| Source | df | POV | df | TBARS | df | 5-HMF | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coefficient Estimate | Sum of Squares | p-Value | Coefficient Estimate | Sum of Squares | p-Value | Coefficient Estimate | Sum of Squares | p-Value | ||||

| Model | 7 | 0.69 | 5.14 | <0.0001 | 9 | 0.85 | 15.18 | <0.0001 | 9 | 7.16 | 629.97 | <0.0001 |

| X1 | 1 | −0.27 | 1.03 | <0.0001 | 1 | −0.71 | 6.80 | <0.0001 | 1 | −4.26 | 247.39 | <0.0001 |

| X2 | 1 | −0.11 | 0.16 | 0.0011 | 1 | −0.20 | 0.55 | <0.0001 | 1 | −3.16 | 136.31 | <0.0001 |

| X3 | 1 | −0.13 | 0.22 | 0.0003 | 1 | −0.097 | 0.13 | 0.0079 | 1 | −2.09 | 59.51 | 0.0004 |

| X1X2 | 1 | 0.057 | 0.026 | 0.1654 | 1 | 1.92 | 29.61 | 0.0043 | ||||

| X1X3 | 1 | −0.08 | 0.051 | 0.0344 | 1 | −0.28 | 0.65 | <0.0001 | 1 | −0.48 | 1.83 | 0.3830 |

| X2X3 | 1 | −0.24 | 0.47 | <0.0001 | 1 | 0.48 | 1.87 | 0.3782 | ||||

| X12 | 1 | 0.38 | 2.09 | <0.0001 | 1 | 0.63 | 5.72 | <0.0001 | 1 | 2.44 | 85.99 | <0.0001 |

| X22 | 1 | 0.33 | 1.58 | <0.0001 | 1 | 0.30 | 1.29 | <0.0001 | 1 | 1.85 | 49.54 | 0.0008 |

| X32 | 1 | 0.21 | 0.66 | <0.0001 | 1 | 0.12 | 0.20 | 0.0021 | 1 | 1.81 | 47.20 | 0.0009 |

| Residual | 12 | 0.11 | 10 | 0.12 | 10 | 22.02 | ||||||

| Lack of fit | 7 | 0.087 | 0.1227 | 5 | 0.076 | 0.2588 | 5 | 16.23 | 0.1413 | |||

| Pure error | 5 | 0.021 | 5 | 0.041 | 5 | 5.79 | ||||||

| Total | 19 | 5.25 | 19 | 15.30 | 19 | 651.99 | ||||||

| R2 | 0.9794 | 0.9923 | 0.9662 | |||||||||

| Adj-R2 | 0.9674 | 0.9854 | 0.9358 | |||||||||

| Pre-R2 | 0.9210 | 0.9533 | 0.7974 | |||||||||

| Adq-precision | 25.645 | 44.283 | 18.112 | |||||||||

| PRESS | 0.41 | 0.71 | 132.06 | |||||||||

| C.V. | 7.19 | 6.94 | 13.10 | |||||||||

| Models | Solar Drying | Open Sun-Drying | ||||||

|---|---|---|---|---|---|---|---|---|

| Estimated Parameters | χ2 (×10−3) | RSS | R2 | Estimated Parameters | χ2 (×10−3) | RSS | R2 | |

| Lewis | k = 0.2030 | 2.2000 | 0.0220 | 0.9678 | k = 0.0825 | 4.8100 | 0.1253 | 0.8971 |

| Page | k = 0.2827 n = 0.7929 | 0.9070 | 0.0082 | 0.9867 | k = 0.1880 n = 0.6716 | 0.8115 | 0.0203 | 0.9827 |

| Henderson and Pabis | a = 1.0140 k = 0.2934 n = 0.7793 | 0.9934 | 0.0080 | 0.9855 | a = 1.0393 k = 0.2123 n = 0.6395 | 0.7642 | 0.0183 | 0.9837 |

| Logarithmic | a = 0.8378 k = 0.3215 c = 0.1743 | 0.1694 | 0.0014 | 0.9975 | a = 0.6274 k = 0.1603 c = 0.2242 | 0.1554 | 0.0037 | 0.9967 |

| Two term | a = 0.9544 k0 = 0.2712 b = 0.0529 k1 = 0.1086 | 0.1265 | 8.8522 × 10−4 | 0.9982 | a = 0.6274 k0 = 0.2128 b = 0.3898 k1 = 0.0225 | 0.0733 | 0.0017 | 0.9984 |

| Midilli–Kucuk | a = 1.0012 k = 0.2521 n = 1.0620 b = 0.0168 | 0.8575 | 6.0024 × 10−4 | 0.9988 | a = 1.0186 k = 0.1595 n = 0.8497 b = 0.0059 | 0.2245 | 0.0052 | 0.9952 |

| Weibull | β = 4.9208 α = 0.7925 | 0.9070 | 0.0082 | 0.9867 | β = 12.0424 α = 0.6712 | 0.8115 | 0.0203 | 0.9827 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, L.; Wang, L.; Han, L.; Chen, L.; Tang, S.; Wen, P. Response Surface Optimization of Solar Drying Conditions and the Effect on the Quality Attributes and Drying Characteristics of Qula Casein. Foods 2022, 11, 2406. https://doi.org/10.3390/foods11162406

Wang J, Wang L, Wang L, Han L, Chen L, Tang S, Wen P. Response Surface Optimization of Solar Drying Conditions and the Effect on the Quality Attributes and Drying Characteristics of Qula Casein. Foods. 2022; 11(16):2406. https://doi.org/10.3390/foods11162406

Chicago/Turabian StyleWang, Jun, Lina Wang, Linlin Wang, Ling Han, Lianhong Chen, Shanhu Tang, and Pengcheng Wen. 2022. "Response Surface Optimization of Solar Drying Conditions and the Effect on the Quality Attributes and Drying Characteristics of Qula Casein" Foods 11, no. 16: 2406. https://doi.org/10.3390/foods11162406

APA StyleWang, J., Wang, L., Wang, L., Han, L., Chen, L., Tang, S., & Wen, P. (2022). Response Surface Optimization of Solar Drying Conditions and the Effect on the Quality Attributes and Drying Characteristics of Qula Casein. Foods, 11(16), 2406. https://doi.org/10.3390/foods11162406