Research on Damage Properties of Apples Based on Static Compression Combined with the Finite Element Method

Abstract

:1. Introduction

2. Materials and Methods

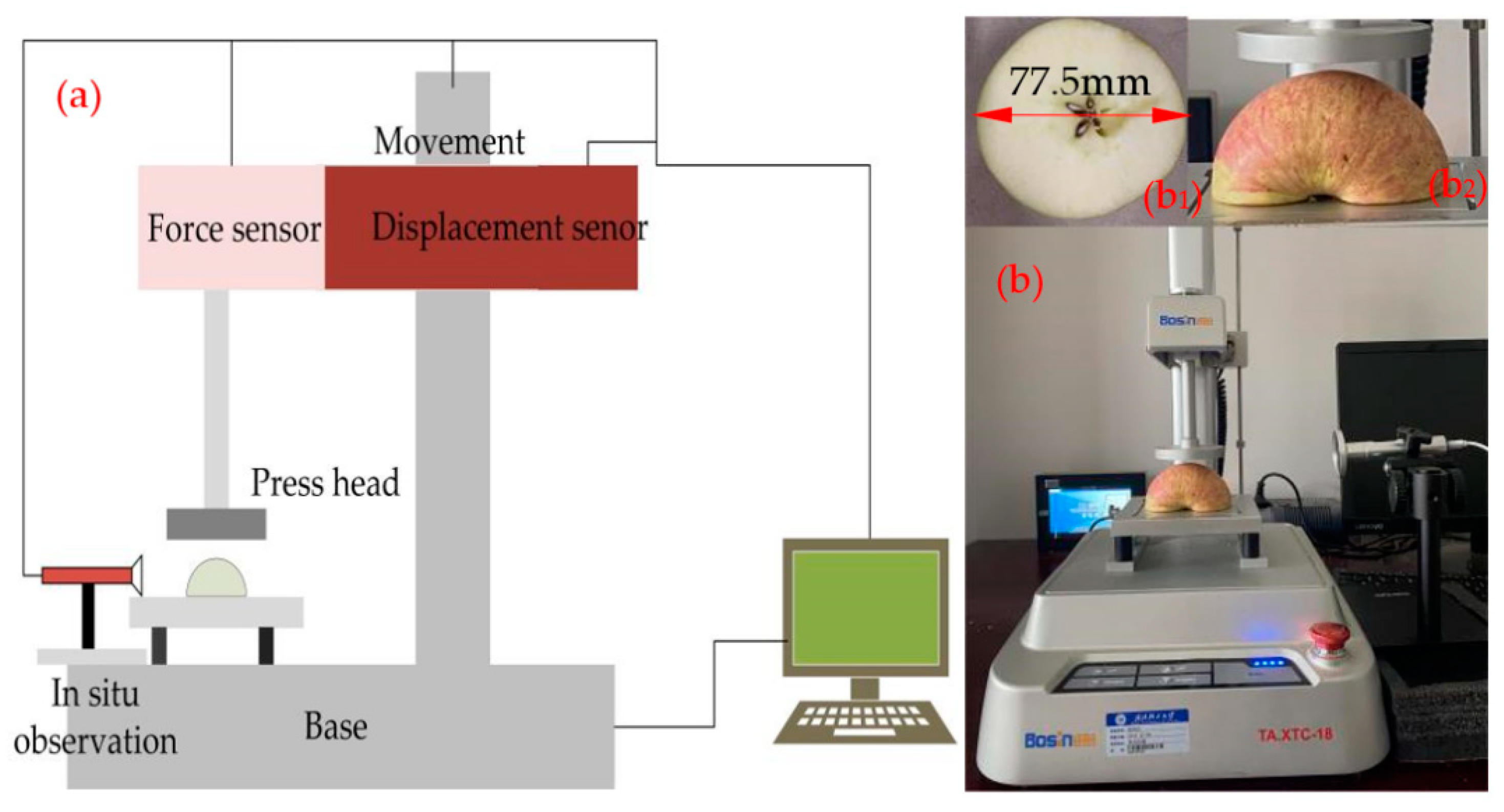

2.1. Experimental Material and Test Rig

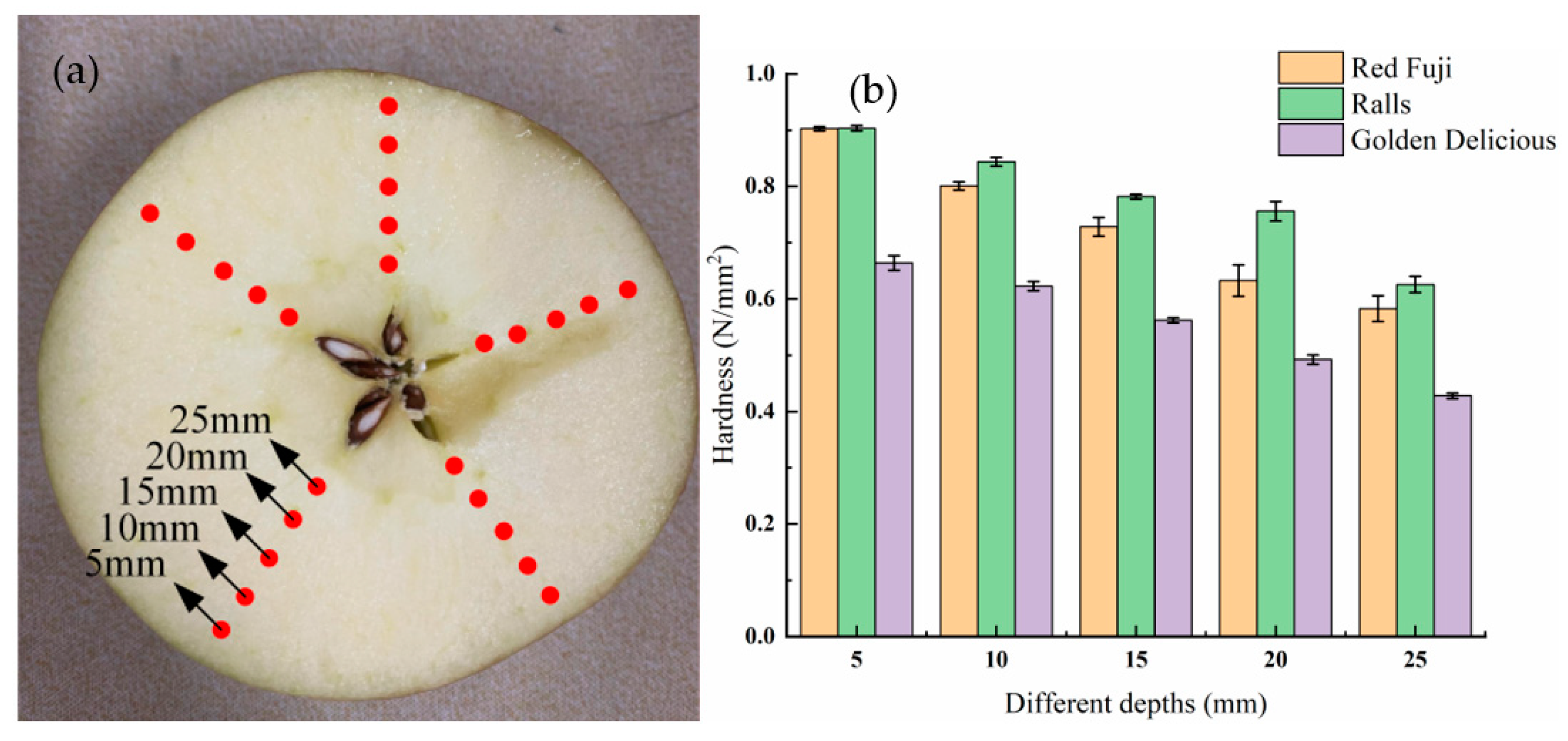

2.2. Test Sample Preparation and Test Method for TPA with Different Parts of Apples

2.3. Sample Preparation and Compression Testing

2.4. Apple Model Development and FE Simulation Parameter Settings

3. Results and Discussion

3.1. Structural and Distributive Mechanical Properties of Apples

3.2. Apple Compression Properties

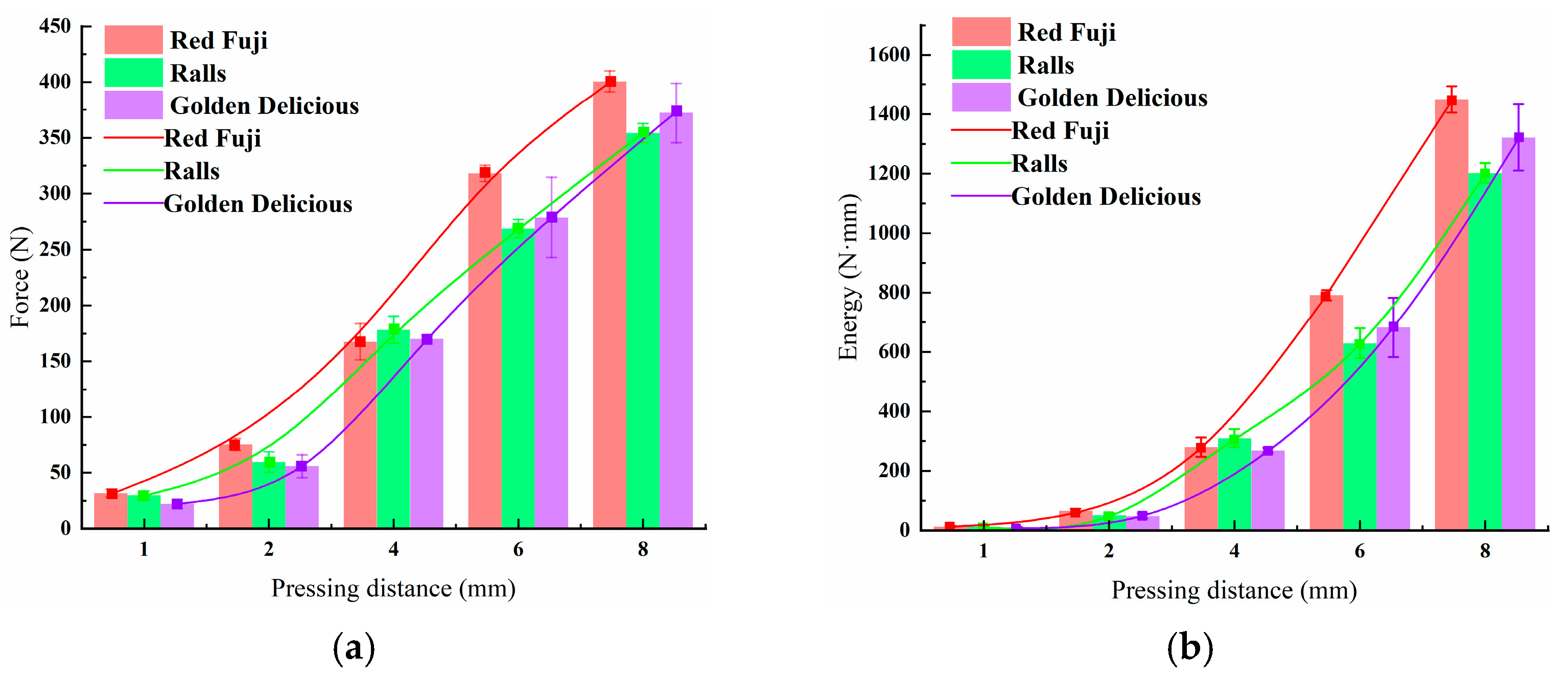

3.3. Effects of Pressing Distance on Apples’ Mechanical Properties

3.3.1. Compression Test at Different Pressing Distances

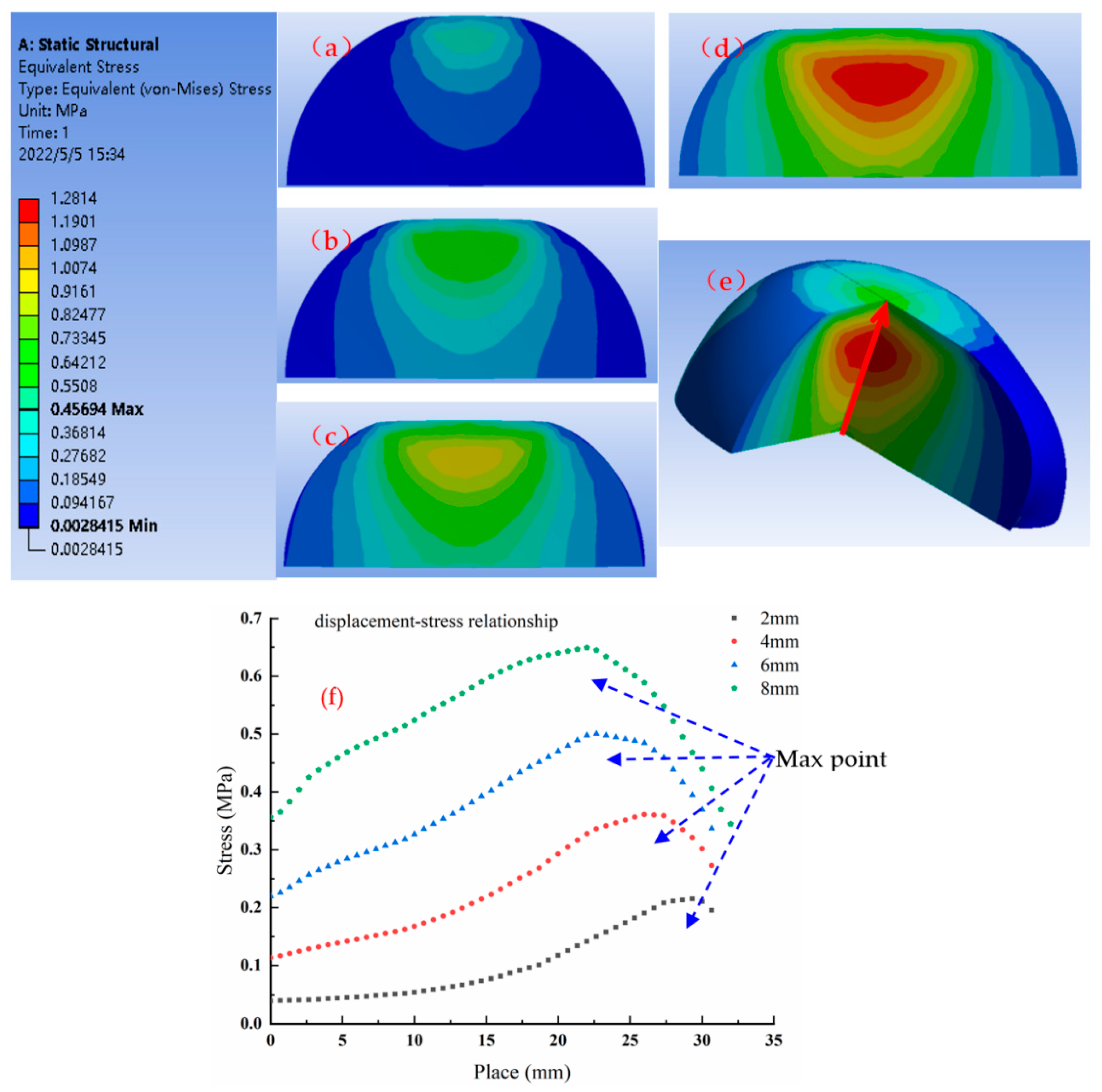

3.3.2. FE Results on Compression Tests

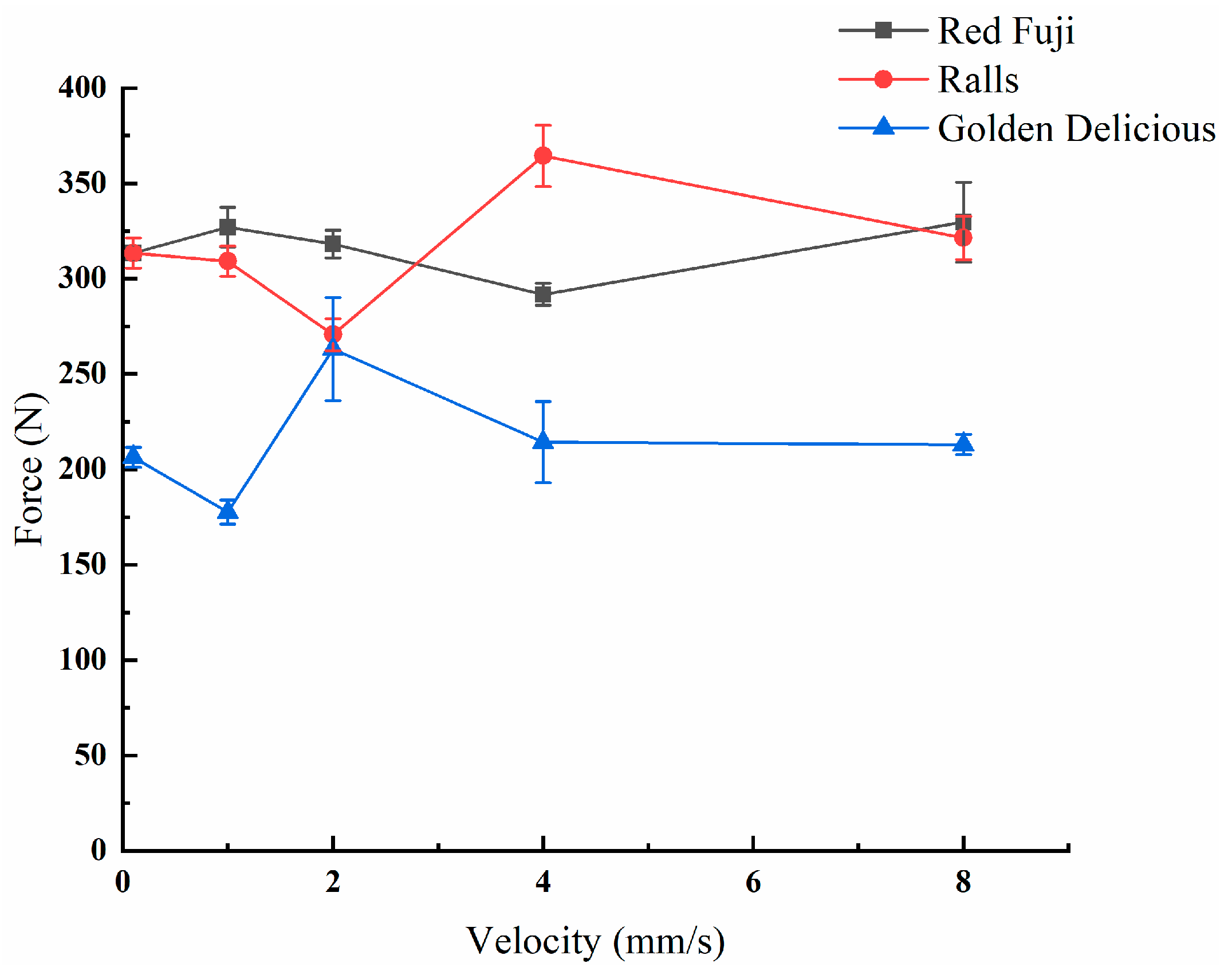

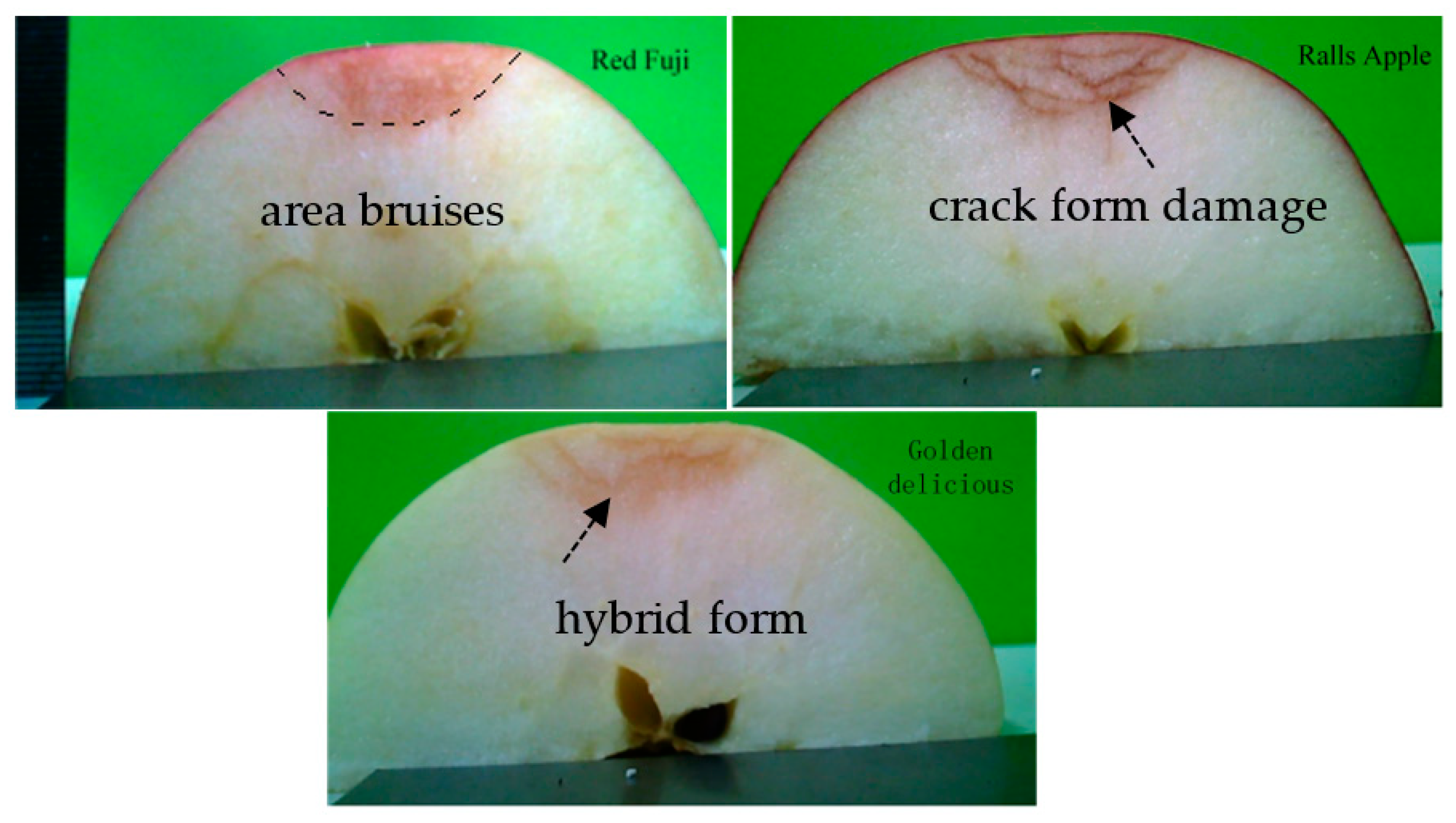

3.4. Effects of Speed on Apple Damage Properties

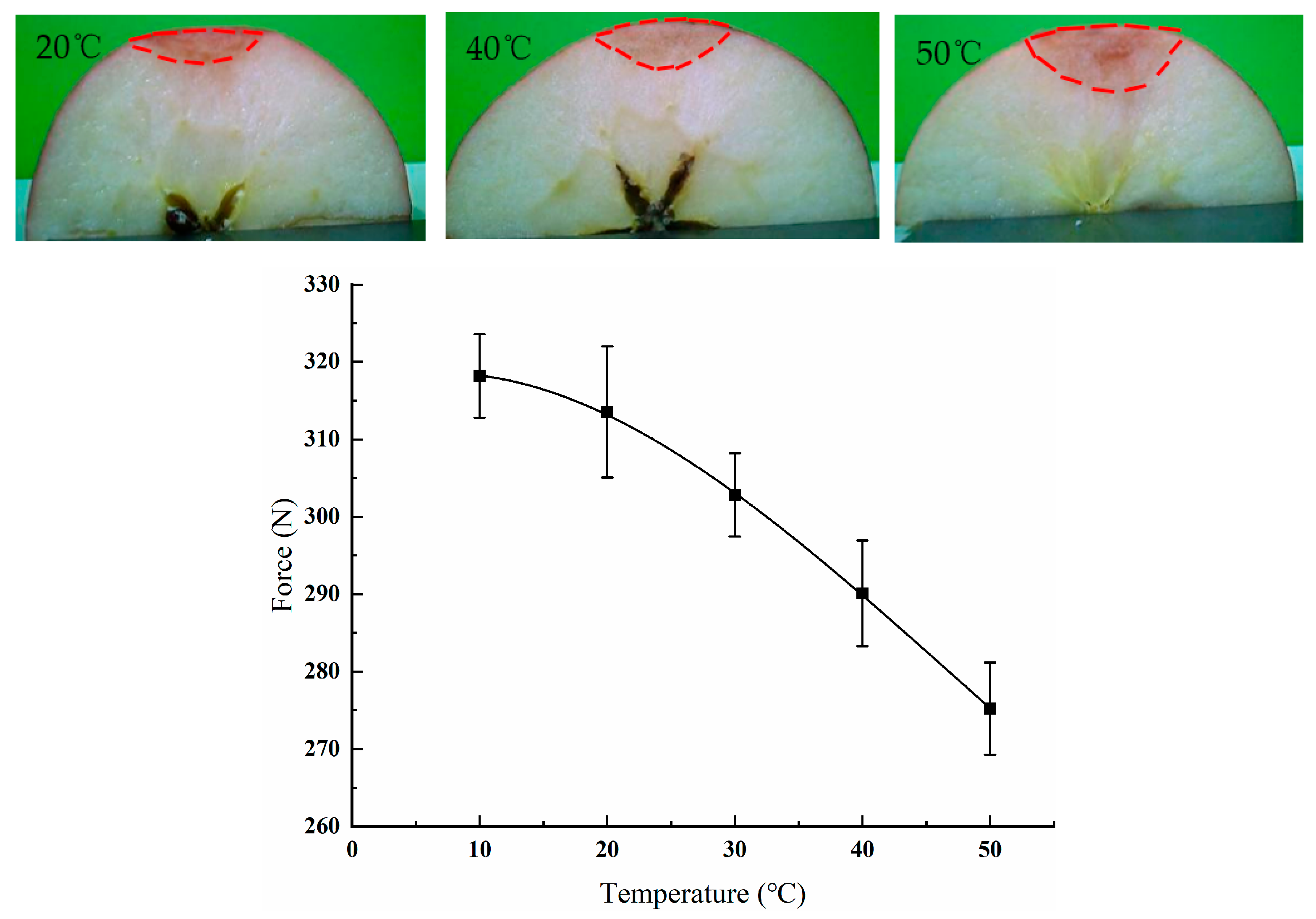

3.5. Effects of Temperature on the Damage Properties of Red Fuji Apples

4. Conclusions

- The pressure distance has an obvious impact on the structural damage. When the extrusion strength was less than 2.3 mm, the apple was in the elastic stage, with no structural damage. A mathematical model of peak force, energy, and pressure distance was developed, showing the “s” shape and upward parabolic shape.

- Apples with different forms of damage were affected differently by pressure velocity. The tests showed that the speed had a significant effect on the peak force of Ralls apples damaged in the form of cracks; there was no significant effect on the peak force of Red Fuji apples to produce area damage.

- The peak force–temperature curve has a downward parabolic shape as the preservation temperature increases. The decrease in temperature for texture softening leads to an increase in the area of damage to the apples. When the temperature is too high, the odor of the apples changes.

- The equivalent effect force verifies that the apple damage is mainly diffused vertically to the interior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mditshwa, A.; Vries, F.; Van Der Merwe, K.; Crouch, E.M.; Opara, U.L. Antioxidant content and phytochemical properties of apple’ Granny Smith’ at different harvest times. S. Afr. J. Plant Soil 2015, 32, 221–226. [Google Scholar] [CrossRef]

- Hussein, Z.; Caleb, O.J.; Opara, U.L. Perforation-mediated modified atmosphere packaging of fresh and minimally processed produce—A review. Food Packag. Shelf Life 2015, 6, 7–20. [Google Scholar] [CrossRef]

- Li, Z.; Thomas, C. Quantitative evaluation of mechanical damage to fresh fruits. Trends Food Sci. Technol. 2013, 35, 138–150. [Google Scholar] [CrossRef]

- Musacchi, S.; Serra, S. Apple fruit quality: Overview on pre-harvest factors. Sci. Hortic. 2018, 234, 409–430. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Preharvest factors influencing bruise damage of fresh fruits—A review. Sci. Hortic. 2018, 229, 45–58. [Google Scholar] [CrossRef]

- Boyer, J.; Liu, R.H. Apple phytochemicals and their health benefits. Nutr. J. 2004, 3, 5. [Google Scholar] [CrossRef] [Green Version]

- Dobson, R. Penetrating injuries cost NHS more than 3m a year. BMJ 2008, 337, a1070. [Google Scholar] [CrossRef]

- Zhou, R.; Wang, X.; Hu, Y.; Zhang, G.; Yang, P.; Huang, B. Reduction in Hami melon (Cucumis melo var. saccharinus) softening caused by transport vibration by using hot water and shellac coating. Postharvest Biol. Technol. 2015, 110, 214–223. [Google Scholar] [CrossRef]

- Celik, H.K.; Ustun, H.; Erkan, M.; Rennie, A.E.; Akinci, I. Effects of bruising of ‘Pink Lady’ apple under impact loading in drop test on firmness, colour and gas exchange of fruit during long term storage. Postharvest Biol. Technol. 2021, 179, 111561. [Google Scholar] [CrossRef]

- Li, Z.; Andrews, J.; Wang, Y. Mathematical modelling of mechanical damage to tomato fruits. Postharvest Biol. Technol. 2017, 126, 50–56. [Google Scholar] [CrossRef]

- Opara, L.U.; Al-Ghafri, A.; Agzoun, H.; Al-Issai, J.; Al-Jabri, F.; Opara, U.L. Design and development of a new device for measuring susceptibility to impact damage of fresh produce. N. Z. J. Crop Hortic. Sci. 2007, 35, 245–251. [Google Scholar] [CrossRef]

- Van Zeebroeck, M.; Ramon, H.; De Baerdemaeker, J.; Nicolaï, B.M.; Tijskens, E. Impact damage of apples during transport and handling. Postharvest Biol. Technol. 2007, 45, 157–167. [Google Scholar] [CrossRef]

- Ahmadi, E.; Barikloo, H.; Kashfi, M. Viscoelastic finite element analysis of the dynamic behavior of apple under impact loading with regard to its different layers. Comput. Electron. Agric. 2016, 121, 1–11. [Google Scholar] [CrossRef]

- Ahmadi, E.; Ghassemzadeh, H.R.; Sadeghi, M.; Moghaddam, M.; Neshat, S.Z.; Ettefagh, M.M. Dynamic modeling of peach fruit during normal impact. J. Food Process Eng. 2012, 35, 483–504. [Google Scholar] [CrossRef]

- Blahovec, J.; Paprštein, F. Susceptibility of pear varieties to bruising. Postharvest Biol. Technol. 2005, 38, 231–238. [Google Scholar] [CrossRef]

- Fu, H.; He, L.; Ma, S.; Karkee, M.; Chen, D.; Zhang, Q.; Wang, S. Bruise responses of apple-to-apple impact. IFAC-PapersOnLine 2016, 49, 347–352. [Google Scholar] [CrossRef]

- Stopa, R.; Szyjewicz, D.; Komarnicki, P.; Kuta, Ł. Determining the resistance to mechanical damage of apples under impact loads. Postharvest Biol. Technol. 2018, 146, 79–89. [Google Scholar] [CrossRef]

- Abedi, G.; Ahmadi, E. Design and evaluation a pendulum device to study postharvest mechanical damage in fruits: Bruise modeling of red delicious apple. Aust. J. Crop Sci. 2013, 7, 962. [Google Scholar]

- Eissa, A.H.A.; Alghannam, A.R.O.; Azam, M.M. Mathematical evaluation changes in rheological and mechanical properties of pears during storage under variable conditions. J. Food Sci. Eng. 2012, 2, 564–572. [Google Scholar]

- Komarnicki, P.; Stopa, R.; Szyjewicz, D.; Młotek, M. Evaluation of bruise resistance of pears to impact load. Postharvest Biol. Technol. 2016, 114, 36–44. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, R. Non-destructive defect detection of apples by spectroscopic and imaging technologies: A review. Trans. ASABE 2017, 60, 1765–1790. [Google Scholar] [CrossRef]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials, 2nd revised and updated ed.; Routledge: Abingdon-on-Thames, UK, 1986. [Google Scholar]

- Cardenas-Weber, M.; Stroshine, R.L.; Haghighi, K.; Edan, Y. Melon material properties and finite element analysis of melon compression with application to robot gripping. Trans. ASABE 1991, 34, 920–929. [Google Scholar] [CrossRef]

- Celik, H.K.; Rennie, A.E.W.; Akinci, I. Deformation behavior simulation of an apple under drop case by finite element method. J. Food Eng. 2011, 104, 293–298. [Google Scholar] [CrossRef]

- Kabas, O.; Celik, H.K.; Ozmerzi, A.; Akinci, I. Drop test simulation of a sample tomato with finite element method. J. Sci. Food Agric. 2008, 88, 1537–1541. [Google Scholar] [CrossRef]

- Ahmadi, E.; Ghassemzadeh, H.R.; Sadeghi, M.; Moghaddam, M.; Neshat, S.Z. The effect of impact and fruit properties on the bruising of peach. J. Food Eng. 2010, 97, 110–117. [Google Scholar] [CrossRef]

- Dintwa, E.; Van Zeebroeck, M.; Ramon, H.; Tijskens, E. Finite element analysis of the dynamic collision of apple fruit. Postharvest Biol. Technol. 2008, 49, 260–276. [Google Scholar] [CrossRef]

- Szyjewicz, D.; Kuta, Ł.; Działak, P.; Stopa, R. An attempt to model the surface pressures of apples using the finite element method. Appl. Sci. 2021, 11, 7579. [Google Scholar] [CrossRef]

- Yang, L.; Chen, H.; Yin, C.; Song, S.; Zhang, Y.; Liu, X.; Hu, Z. Research on mechanical-structure properties during sunflower seed extrusion-oil extraction. J. Food Process. Preserv. 2022, 46, e16158. [Google Scholar] [CrossRef]

- Kim, G.-W.; Kim, M.-S.; Sagara, Y.; Bae, Y.-H.; Lee, I.-B.; Do, G.-S.; Lee, S.-H.; Kang, S.-W. Determination of the viscoelastic properties of apple flesh under quasi-static compression based on finite element method optimization. Food Sci. Technol. Res. 2008, 14, 221–231. [Google Scholar] [CrossRef] [Green Version]

- Babu, D.R.; Rao, K.N.; Kumar, M.S.; Kumar, B.S. Handling of apples during sorting-grading operation and measuring the mechanical properties firmness after controlled atmosphere storage. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 617–634. [Google Scholar]

- Słupska, M.; Syguła, E.; Komarnicki, P.; Szulczewski, W.; Stopa, R. Simple method for apples’ bruise area prediction. Materials 2021, 15, 139. [Google Scholar] [CrossRef] [PubMed]

- Watkins, C.B.; Liu, F.W. Temperature and carbon dioxide interactions on quality of controlled atmosphere-stored ‘Empire’ apples. HortScience 2010, 45, 1708–1712. [Google Scholar] [CrossRef]

- Kweon, H.J.; Kang, I.K.; Kim, M.J.; Lee, J.; Moon, Y.S.; Choi, C.; Choi, D.G.; Watkins, C.B. Fruit maturity, controlled atmosphere delays and storage temperature affect fruit quality and incidence of storage disorders of ‘Fuji’ apples. Sci. Hortic. 2013, 157, 60–64. [Google Scholar] [CrossRef]

| Variables | Species | Pressing Distance (mm) | Velocity (mm/s) | Temperature (°C) |

|---|---|---|---|---|

| 1 | Golden Delicious | 1 | 0.1 | 10 |

| 2 | Rad Fuji | 2 | 1 | 20 |

| 3 | Ralls | 4 | 2 | 30 |

| 4 | - | 6 | 4 | 40 |

| 5 | - | 8 | 8 | 50 |

| a1 | a2 | a3 | a4 | R2 | |

|---|---|---|---|---|---|

| Red Fuji Peak Force | 11.72965 | 8.79338 | 12.90509 | −0.98859 | 0.99904 |

| Red Fuji Energy | 13.04673 | −25.1784 | 25.25889 | 0.06092 | 0.99941 |

| Ralls Peak Force | 5.73311 | 15.67235 | 8.74748 | −0.65923 | 0.99888 |

| Ralls Energy | 29.63372 | −46.32897 | 30.65879 | −0.82793 | 0.99882 |

| Golden Delicious Peak Force | 8.84371 | −0.34938 | 14.64444 | −1.11866 | 0.99982 |

| Golden Delicious Energy | 15.67289 | −28.20406 | 21.80668 | 0.26254 | 0.99998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Cao, Z.; Yang, L.; Chen, H.; Zhang, Y. Research on Damage Properties of Apples Based on Static Compression Combined with the Finite Element Method. Foods 2022, 11, 1851. https://doi.org/10.3390/foods11131851

Liu X, Cao Z, Yang L, Chen H, Zhang Y. Research on Damage Properties of Apples Based on Static Compression Combined with the Finite Element Method. Foods. 2022; 11(13):1851. https://doi.org/10.3390/foods11131851

Chicago/Turabian StyleLiu, Xiaopeng, Zhentao Cao, Liu Yang, Huan Chen, and Yonglin Zhang. 2022. "Research on Damage Properties of Apples Based on Static Compression Combined with the Finite Element Method" Foods 11, no. 13: 1851. https://doi.org/10.3390/foods11131851

APA StyleLiu, X., Cao, Z., Yang, L., Chen, H., & Zhang, Y. (2022). Research on Damage Properties of Apples Based on Static Compression Combined with the Finite Element Method. Foods, 11(13), 1851. https://doi.org/10.3390/foods11131851