Effects of Fermentation Temperature and Time on the Color Attributes and Tea Pigments of Yunnan Congou Black Tea

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Tea Processing

2.3. Analyses of the Objective Indicators

2.3.1. Detection of the Appearance and Color Attributes of the Tea Samples

2.3.2. Detection of the Liquor Color Attributes of the Tea Samples

2.4. Determination of the TFs, TRs, TBs, Liquor Brightness (BT), and Total Liquor Color (TLC)

2.5. Statistical Analysis

3. Results and Discussion

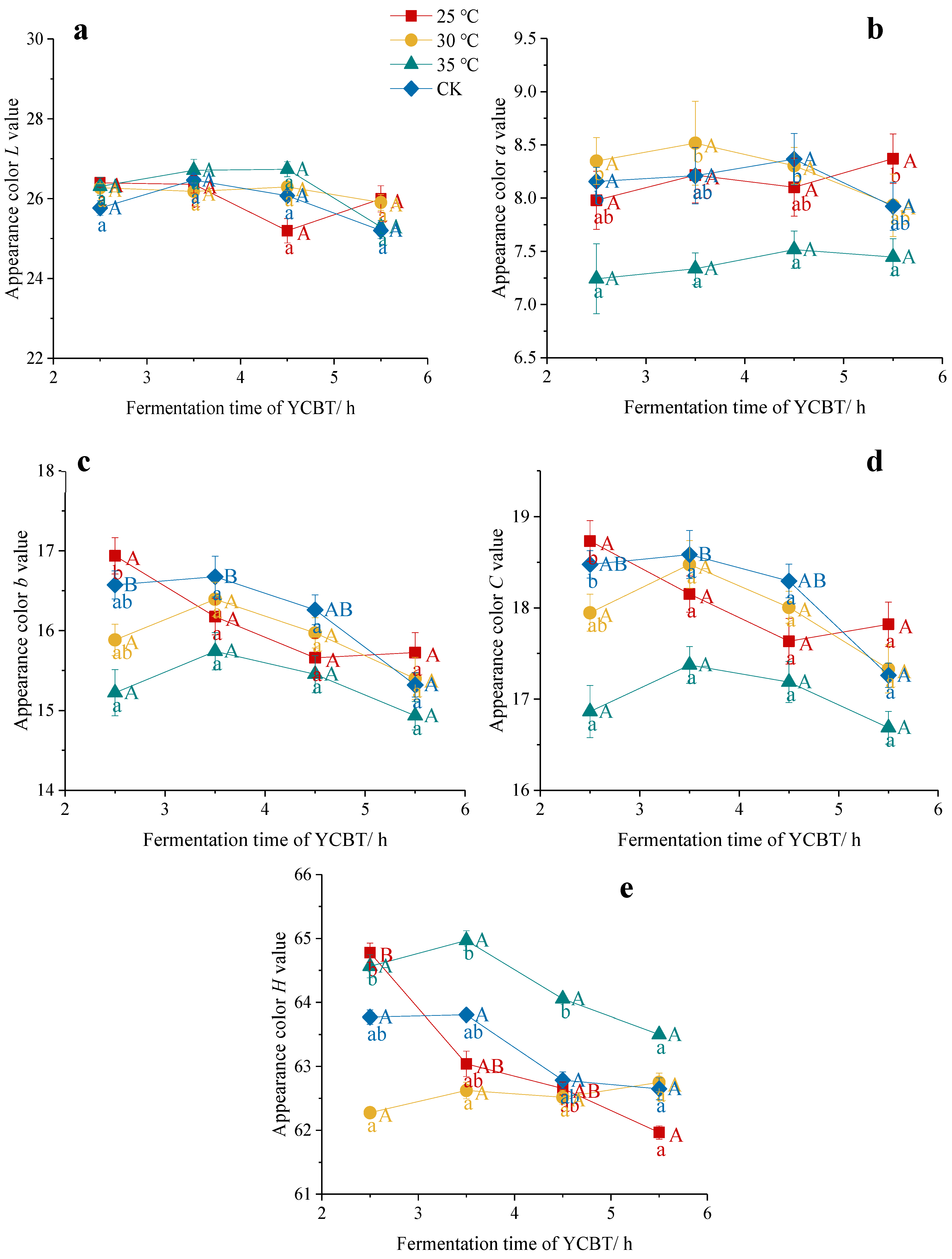

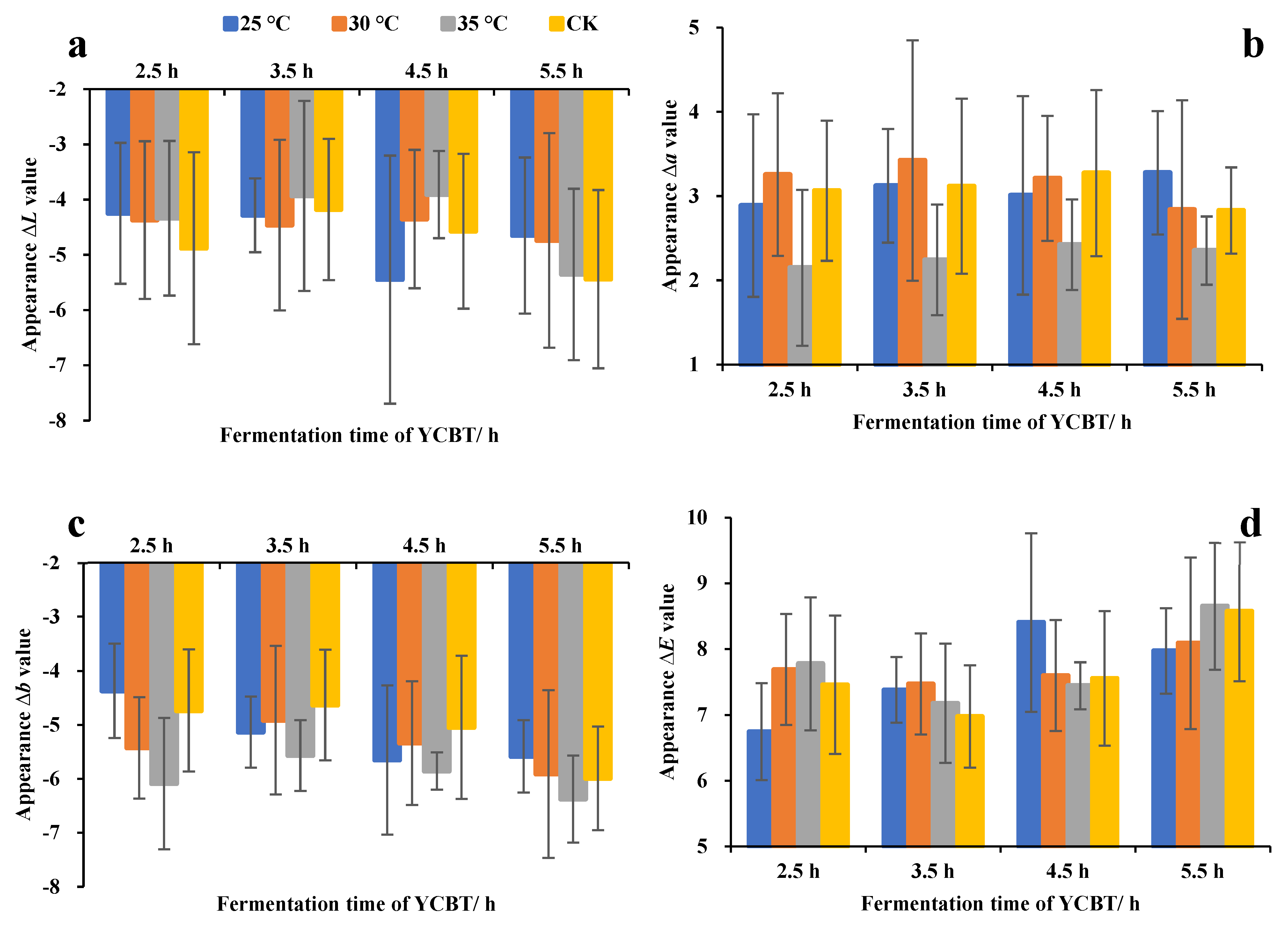

3.1. Effect of the Fermentation Temperature and Time on the Appearance Color Attributes

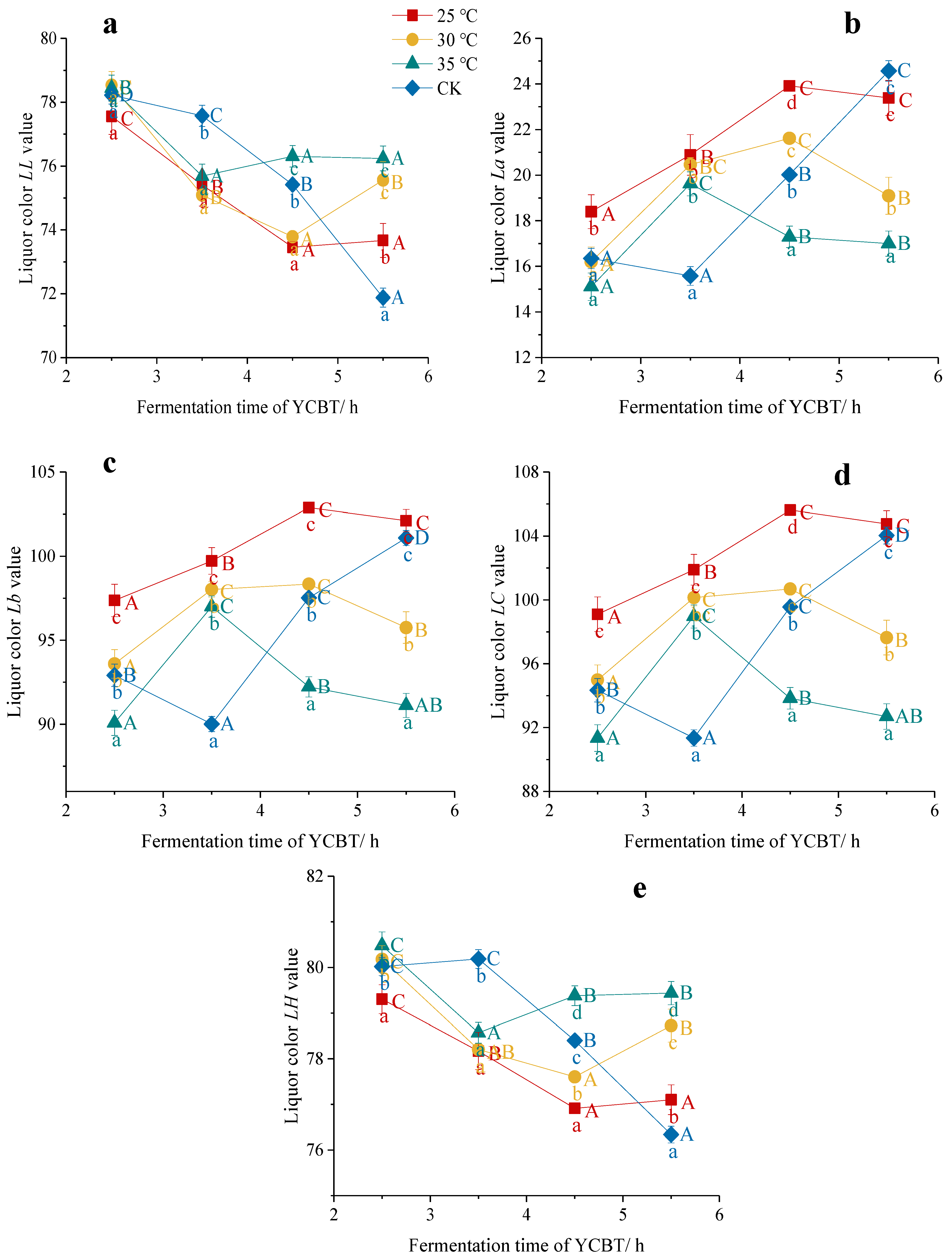

3.2. Effects of the Fermentation Temperature on the Liquor Color Attributes

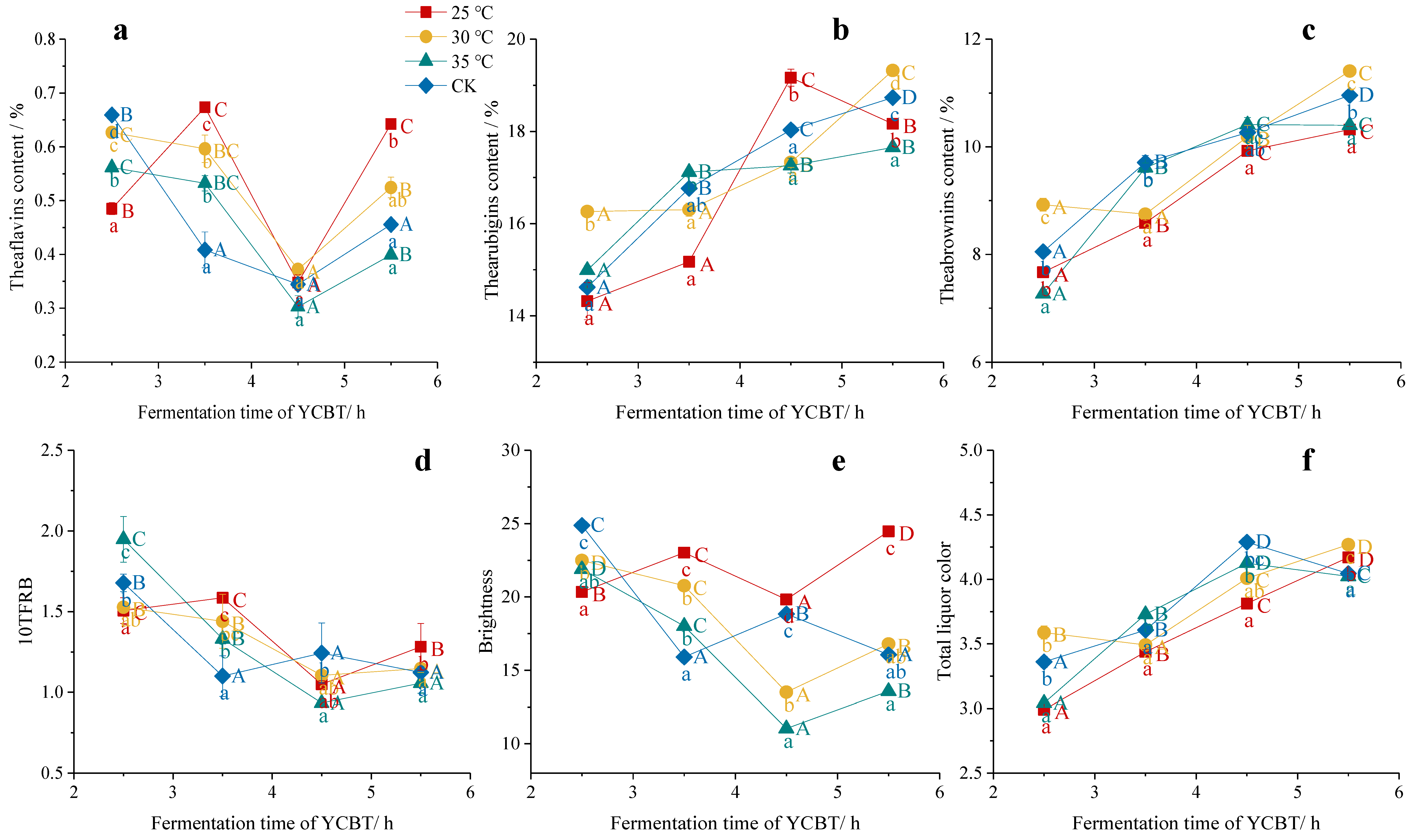

3.3. Effect of the Fermentation Temperature on the TFs, TRs, TBs, and Other Mass Fractions

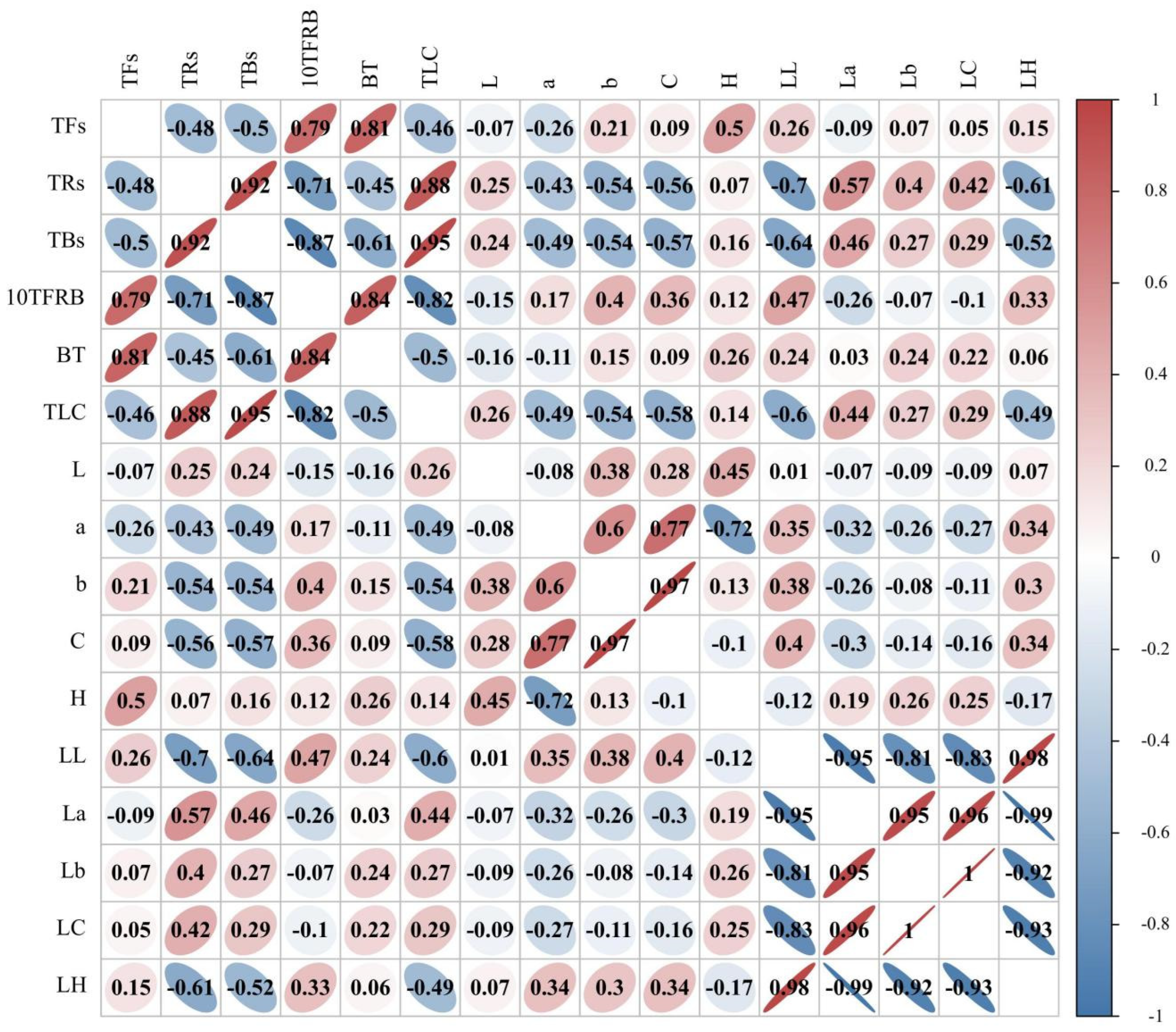

3.4. Correlation Analysis among the Appearance Color Attributes, Liquor Color Attributes, and Tea Pigments

3.5. Prediction Model for the TFs, TRs, and TBs Contents, and the 10TFRB Value

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McDowell, I.; Feakes, J.; Gay, C. Phenoliccomposition of black tea liquors as a means of predicting price and country of origin. J. Sci. Food Agric. 1991, 55, 627–641. [Google Scholar] [CrossRef]

- Biswas, A.K.; Biswas, A.K.; Sarkar, A.R. Biological and chemical factors affecting the valuation of North East Indian plains teas. III. Statistical evaluation of the biochemical constituents and their effects on colour, brightness and strength of black teas. J. Sci. Food Agric. 1973, 24, 1457–1477. [Google Scholar] [CrossRef]

- Liu, P.P.; Zheng, P.C.; Gong, Z.M.; Ye, F.; Feng, L.; Gao, S.W.; Wang, X.P.; Wang, S.P.; Teng, J.; Zheng, L.; et al. Quality Analysis and Comprehensive Evaluation of Chinese Congou Black Tea. Food Sci. 2021, 42, 11. [Google Scholar] [CrossRef]

- Fang, S.M.; Ning, J.M.; Huang, W.J.; Zhang, G.; Deng, W.W.; Zhang, Z.Z. Identification of geographical origin of Keemun Black Tea based on its volatile composition coupled with multivariate statistical analyses. J. Sci. Food Agric. 2019, 99, 4344–4352. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Li, Z.L.; Yuan, L.Y.; Zhong, Y.F.; Luo, H.Y.; Zhang, Y.; Wu, X.H.; Liu, S.Q. Comparison of the suitability of different tea varieties fresh leaves in summer for the production of Congou black tea. J. Food Saf. Qual. 2019, 10, 7. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.X.; Kong, Y.W.; Peng, X.P.; Li, C.W.; Liu, S.H.; Du, L.P.; Xiao, D.G.; Xu, Y.Q. A comparative study of volatile components in Dianhong teas from fresh leaves of four tea cultivars by using chromatography-mass spectrometry, multivariate data analysis, and descriptive sensory analysis. Food Res. Int. 2017, 100, 267–275. [Google Scholar] [CrossRef]

- Song, C.J.; Fan, F.Y.; Gong, S.Y.; Guo, H.W.; Li, C.L.; Zong, B.Z. Taste Characteristic and Main Contributing Compounds of Different Origin Black tea. Sci. Agric. Sin. 2020, 53, 383–394. [Google Scholar] [CrossRef]

- Gong, Z.M.; Liu, P.P.; Zheng, P.C.; Gao, S.W. Analysis of Quality Components in Black Tea from Middle and Lower Reaches of Yangtze River. Sci. Technol. Food Ind. 2018, 39, 253–260. [Google Scholar] [CrossRef]

- Meng, X.H.; Li, N.; Zhu, H.T.; Wang, D.; Yang, C.R.; Zhang, Y.J. Plant Resources, Chemical Constituents and Bioactivities of Tea Plants from the Genus Camellia Section Thea. J. Agric. Food Chem. 2018, 67, 5318–5349. [Google Scholar] [CrossRef]

- Wang, H.J.; Shen, S.; Wang, J.J.; Jiang, Y.W.; Li, J.; Yang, Y.Q.; Hua, J.J.; Yuan, H.B. Novel insight into the effect of fermentation time on quality of Yunnan Congou black tea—ScienceDirect. LWT 2021, 155, 112939. [Google Scholar] [CrossRef]

- Samanta, T.; Cheeni, V.; Das, S.; Roy, A.B.; Mitra, A. Assessing biochemical changes during standardization of fermentation time and temperature for manufacturing quality black tea. J. Food Sci. Technol. 2015, 52, 2387–2393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drynan, J.W.; Clifford, M.N.; Obuchowicz, J.; Kuhnert, N. The chemistry of low molecular weight black tea polyphenols. Nat. Prod. Rep. 2010, 27, 417–462. [Google Scholar] [CrossRef]

- Youngmok, K.; Kevin, L.G.; Dae, P.J.; Jeong, C.; Stephen, T.T. Changes in antioxidant phytochemicals and volatile composition of Camellia sinensis by oxidation during tea fermentation. Food Chem. 2011, 129, 1331–1342. [Google Scholar] [CrossRef]

- Tan, J.F.; Dai, W.D.; Lu, M.L.; Lv, H.P.; Guo, L.; Zhang, Y.; Zhu, Y.; Peng, Q.H.; Lin, Z. Study of the dynamic changes in the non-volatile chemical constituents of black tea during fermentation processing by a non-targeted metabolomics approach. Food Res. Int. 2016, 79, 106–113. [Google Scholar] [CrossRef]

- Tanaka, T.; Matsuo, Y. Production Mechanisms of Black Tea Polyphenols. Chem. Pharm. Bull. 2020, 68, 1131–1142. [Google Scholar] [CrossRef]

- Hua, J.J.; Yuan, H.B.; Yao, Y.F.; Jiang, Y.W.; Wang, J.J. The effcts of temperature on the color and pigment content of tea fermentation leaves. Trans. Chin. Soc. Agric. Eng. 2018, 34, 300–308. [Google Scholar] [CrossRef]

- Quan, Q. Processing equipment and application technology of strip black tea. J. China Tea 2011, 33, 16–18. [Google Scholar] [CrossRef]

- Martin, O.; Okinda, O.P.; Richard, M.o. Changes in the chemical and sensory quality parameters of black tea due to variations of fermentation time and temperature. Food Chem. 2002, 75, 395–404. [Google Scholar] [CrossRef]

- Hua, J.J.; Yuan, H.B.; Jiang, Y.W.; Liu, P.; Wang, W.W. Research progress on changes of physical and chemical characteristics of fresh leaves during withering and their control techniques. J. Tea Sci. 2013, 33, 465–472. [Google Scholar] [CrossRef]

- Qian, Y.F.; Ye, Y.; Zhou, X.F.; Wang, B. Analysis on the present research situation of black tea fermentation technology. Sci. Technol. Food Ind. 2012, 33, 388–392. [Google Scholar] [CrossRef]

- Pan, K.; Shen, Q.; Shen, D.; Du, X. Changes in Sensory and Physico-chemical Characteristics of Tea Leaves during Aerobic Fermentation for Black Tea. J. Food Sci. 2014, 35, 198–201. [Google Scholar] [CrossRef]

- Pan, K.; Feng, L.; Chen, J.; Du, X. Analysis of Aroma Compounds in Black Tea Ventilated with Oxygen for Different Durations during the Fermentation Process by Head Space-Solid Phase Micro-Extraction Coupled with Gas Chromatography-Mass Spectrometry. J. Food Sci. 2015, 36, 181–196. [Google Scholar] [CrossRef]

- Okinda, O.P.; Martin, O. Comparative responses in plain black tea quality parameters of different tea clones to fermentation temperature and duration. Food Chem. 2001, 72, 319–327. [Google Scholar] [CrossRef]

- Wang, Q.P.; Gong, J.S.; Zou, S.S. Relationship between color change and quality of Pu-erh Tea during fermentation. Trans. CSAE 2010, 26, 394–399. [Google Scholar] [CrossRef]

- Zhang, S.F.; Yang, Y.Q.; Cheng, X.F.; Thangaraj, K.; Arkorful, E.; Chen, X.; Li, X. Prediction of suitable brewing cuppages of Dahongpao tea based on chemical composition, liquor colour and sensory quality in different brewing. Sci. Rep. 2020, 10, 945. [Google Scholar] [CrossRef]

- Jiang, Y.W.; Hua, J.J.; Wang, B.; Yuan, H.B.; Ma, H.L. Effects of Variety, Season, and Region on Theaflavins Content of Fermented Chinese Congou Black Tea. J. Food Qual. 2018, 2018, 5427302. [Google Scholar] [CrossRef]

- Asil, M.H.; Rabiei, B.; Ansari, R.H. Optimal fermentation time and temperature to improve biochemical composition and sensory characteristics of black tea. Aust. J. Crop Sci. 2012, 6, 550–558. [Google Scholar]

- Yang, J.; Yuan, L.Y.; Zhong, Y.F.; Zhang, Y.; Luo, H.Y.; Li, Z.L. Study on Correlations between Color and Quality of Congou Made of Different Varieties of Tea. Southwest China J. Agric. Sci. 2014, 27, 2605–2610. [Google Scholar] [CrossRef]

- Cheng, Z.; Liao, Q.; Yao, Y. Correlation Between Tea Soup Color Difference and Quality Evaluation of the Congou Black Teas. Tianjin Agric. Sci. 2014, 20, 71–75. [Google Scholar] [CrossRef]

- Yu, S.P.; Yin, J.F.; Yuan, H.B.; Xu, Y.Q.; Deng, Y.L.; Wu, R.M.; Chen, G.S. Appearance chromatic aberration of fermented leaves of small leaf black tea and correlation analysis of the main quality components. J. Food Saf. Qual. 2015, 6, 2201–2208. [Google Scholar] [CrossRef]

- Wu, S.M.; Wang, J.Q.; Jiang, Y.W.; Yuan, H.B.; Li, J. Key Chemical Components Influencing the Brightness of Congou Black Tea Infusions. Food Sci. 2021, 42, 221–228. [Google Scholar] [CrossRef]

- Cloughley, J.B. The effect of fermentation temperature on the quality parameters and price evaluation of Central African black teas. J. Sci. Food Agric. 1980, 31, 911–919. [Google Scholar] [CrossRef]

- Wan, X.C.; Li, D.X.; Zhang, Z.Z.; Xia, T.; Lin, T.J.; Chen, Q. Research Advance on Tea Biochemistry. J. Tea Sci. 2015, 1, 002. [Google Scholar] [CrossRef]

- Thomas, M.; SenthilKumar, R.S. Influence of fermentation time on the development of compounds responsible for quality in black tea. Food Chem. 2007, 101, 98–102. [Google Scholar] [CrossRef]

- Hossain, M.A.; Ahmed, T.; Hossain, M.S.; Dey, P.; Ahmed, S.; Hossain, M.M. Optimization of the factors affecting BT-2 black tea fermentation by observing their combined effects on the quality parameters of made tea using Response Surface Methodology (RSM). Heliyon 2022, 8, e08948. [Google Scholar] [CrossRef]

- Hua, J.J.; Wang, H.J.; Wang, J.J.; Li, J.; Jiang, Y.W.; Wang, Y.L.; Yuan, H.B. Influences of first-drying methods on the quality of Congou black tea using partial least squares-discrimination analysis. Trans. Chin. Soc. Agric. Eng. 2020, 36, 260–270. [Google Scholar] [CrossRef]

- Somsong, P.; Santivarangkna, C.; Tiyayon, P.; Hsieh, C.-M.; Srichamnong, W. Assessing Polyphenol Components and Antioxidant Activity during Fermented Assam Tea Ball Processing. Sustainability 2020, 12, 5853. [Google Scholar] [CrossRef]

- Teshome, K. Effect of tea processing methods on biochemical composition and sensory quality of black tea (Camellia sinensis (L.) O. Kuntze): A review. J. Hortic. For. 2019, 11, 84–95. [Google Scholar] [CrossRef]

- Dutta, R.; Stein, A.; Bhagat, R.M. Integrating satellite images and spectroscopy to measuring green and black tea quality. Food Chem. 2011, 127, 866–874. [Google Scholar] [CrossRef]

- Tran, T.; Grandvalet, C.; Verdier, F.; Martin, A.; Alexandre, H.; Tourdot-Maréchal, R. Microbiological and technological parameters impacting the chemical composition and sensory quality of kombucha. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2050–2070. [Google Scholar] [CrossRef]

- Owuor, P.O.; Obanda, M.; Nyirenda, H.E.; Mphangwe, N.I.K.; Wright, L.P.; Apostolides, Z. The relationship between some chemical parameters and sensory evaluations for plain black tea (Camellia sinensis) produced in Kenya and comparison with similar teas from Malawi and South Africa. Food Chem. 2006, 97, 644–653. [Google Scholar] [CrossRef]

| Target Value | Source | DF | Sum of Squares | Mean Squares | F Value | p |

|---|---|---|---|---|---|---|

| TFs | Regression | 0.139 | 8 | 0.017 | 1.342 | 0.356 |

| Residual | 0.091 | 7 | 0.013 | |||

| Corresponding total amount | 0.230 | 15 | ||||

| TRs | Regression | 31.659 | 8 | 3.957 | 4.803 | 0.026 |

| Residual | 5.767 | 7 | 0.824 | |||

| Corresponding total amount | 37.426 | 15 | ||||

| TBs | Regression | 18.230 | 8 | 2.279 | 4.784 | 0.027 |

| Residual | 3.335 | 7 | 0.476 | |||

| Corresponding total amount | 21.564 | 15 | ||||

| 10TFRB | Regression | 0.657 | 8 | 0.082 | 1.919 | 0.203 |

| Residual | 0.300 | 7 | 0.043 | |||

| Corresponding total amount | 0.957 | 15 |

| Target Value | Variable | DF | Parameter Estimate | Standard Error | t Value | p |

|---|---|---|---|---|---|---|

| TRs | Constant variable | 1 | 60.014 | 11.640 | 5.156 | <0.0001 |

| LL | 1 | −0.568 | 0.154 | −3.701 | 0.002 | |

| TBs | Constant variable | 1 | −24.656 | 23.298 | −1.058 | 0.309 |

| LL | 1 | −1.695 | 0.457 | −3.712 | 0.003 | |

| LH | 1 | 2.067 | 0.709 | 2.917 | 0.012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Wang, J.; Yuan, H.; Ouyang, W.; Li, J.; Hua, J.; Jiang, Y. Effects of Fermentation Temperature and Time on the Color Attributes and Tea Pigments of Yunnan Congou Black Tea. Foods 2022, 11, 1845. https://doi.org/10.3390/foods11131845

Zhu J, Wang J, Yuan H, Ouyang W, Li J, Hua J, Jiang Y. Effects of Fermentation Temperature and Time on the Color Attributes and Tea Pigments of Yunnan Congou Black Tea. Foods. 2022; 11(13):1845. https://doi.org/10.3390/foods11131845

Chicago/Turabian StyleZhu, Jiayi, Jinjin Wang, Haibo Yuan, Wen Ouyang, Jia Li, Jinjie Hua, and Yongwen Jiang. 2022. "Effects of Fermentation Temperature and Time on the Color Attributes and Tea Pigments of Yunnan Congou Black Tea" Foods 11, no. 13: 1845. https://doi.org/10.3390/foods11131845

APA StyleZhu, J., Wang, J., Yuan, H., Ouyang, W., Li, J., Hua, J., & Jiang, Y. (2022). Effects of Fermentation Temperature and Time on the Color Attributes and Tea Pigments of Yunnan Congou Black Tea. Foods, 11(13), 1845. https://doi.org/10.3390/foods11131845