Reformulation of Muffins Using Inulin and Green Banana Flour: Physical, Sensory, Nutritional and Shelf-Life Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Recipe Development

2.2. Muffin Ingredients

2.3. Muffins Formulations

2.4. Muffin Preparation

2.5. Muffin Physical Properties

2.5.1. Muffin Texture

2.5.2. Colour

2.6. Baking Losses

2.7. Sensory Properties, Purchase Intent and Price

2.8. Nutritional Properties

2.8.1. Energy Reduction

2.8.2. Glycaemic Response

Study Design

Blood Collection and Analysis

2.8.3. Hunger

2.9. Muffins Shelf-Life

2.10. Statistical Analysis

3. Results and Discussion

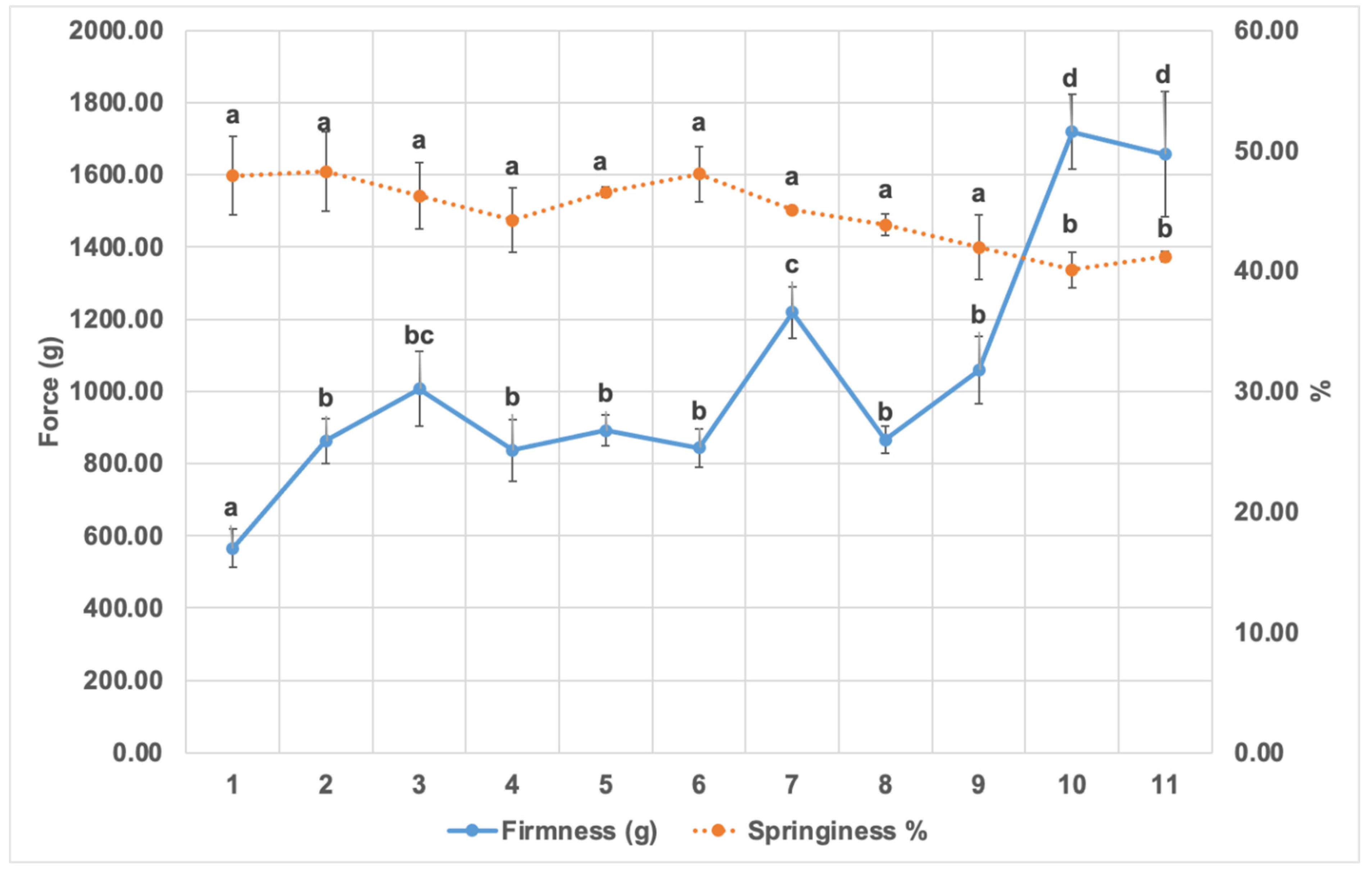

3.1. Muffin Texture Properties

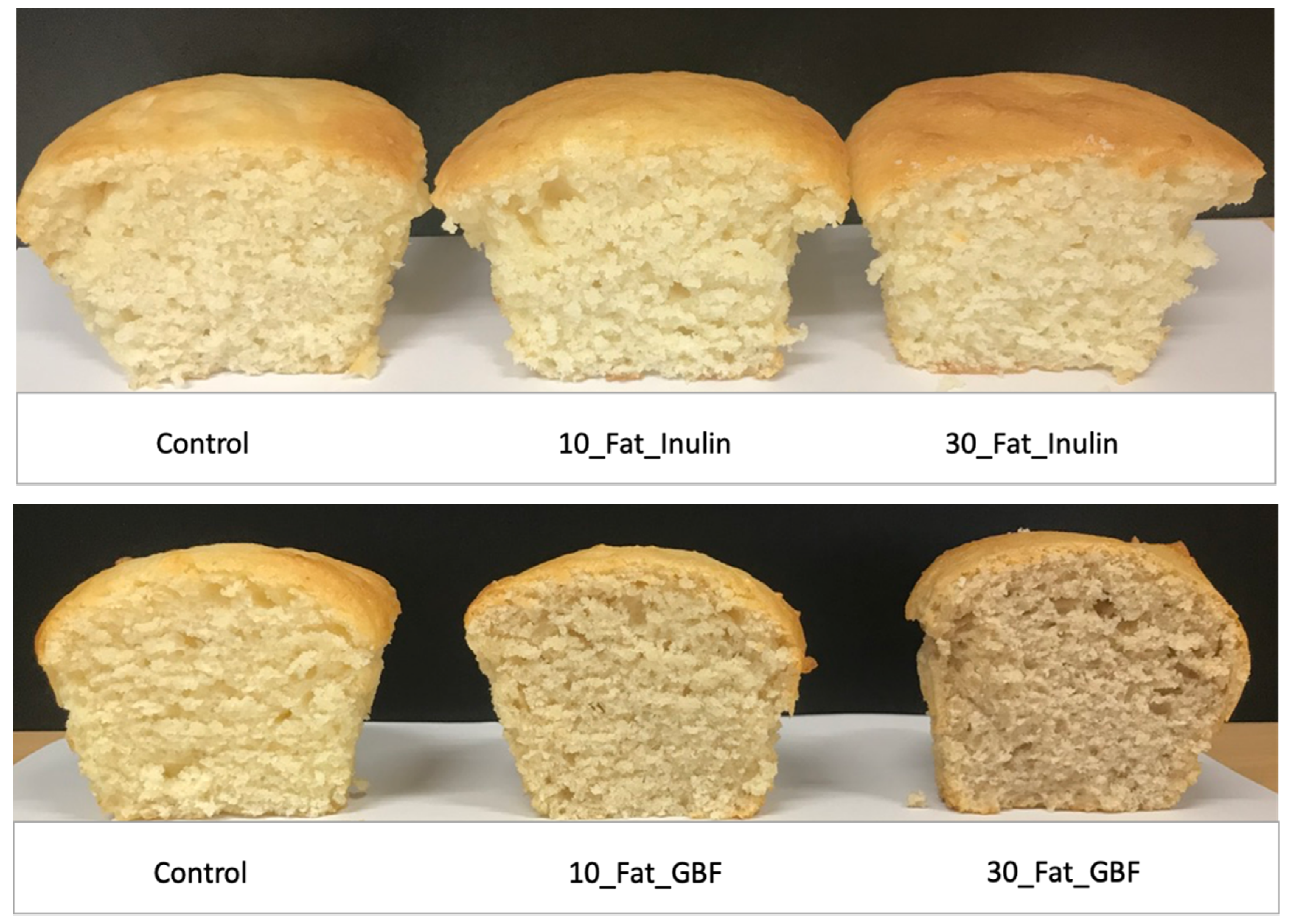

3.2. Colour

3.3. Baking Losses

3.4. Sensory Analysis and Purchase Intent

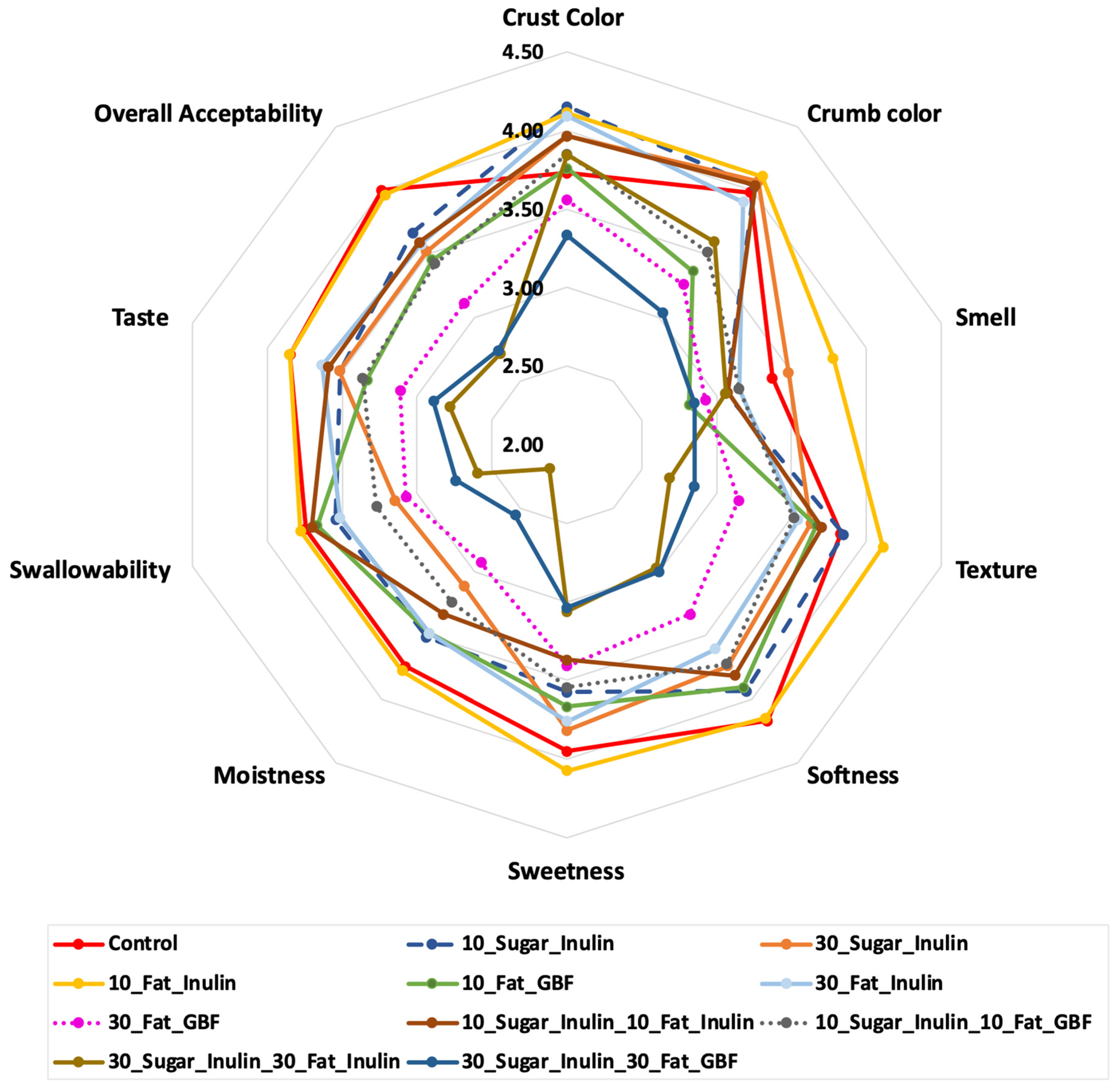

3.4.1. Sensory Properties

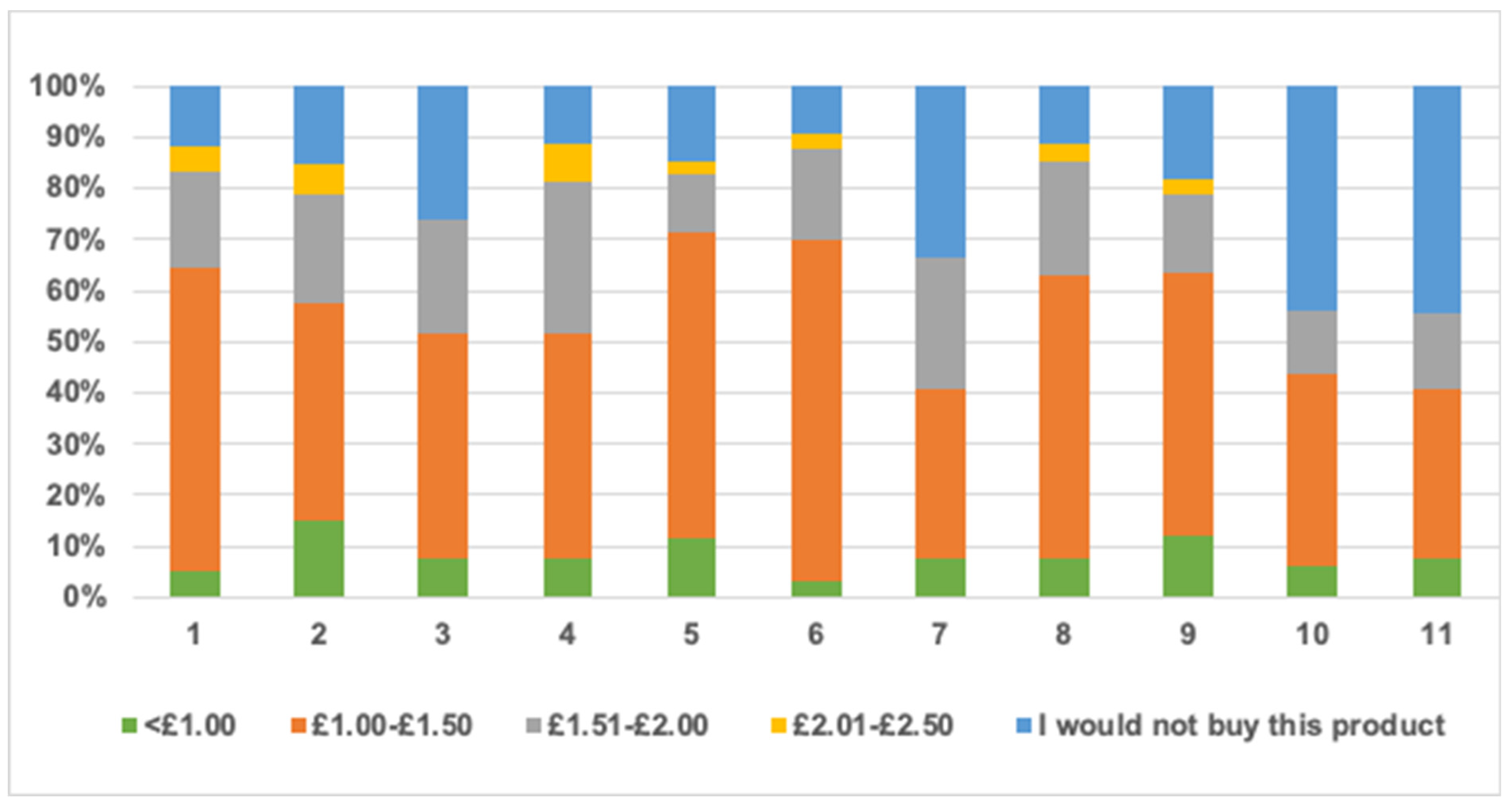

3.4.2. Purchase Intent and Price

3.5. Nutritional Properties

3.5.1. Calorie Reduction and Nutritional Claims

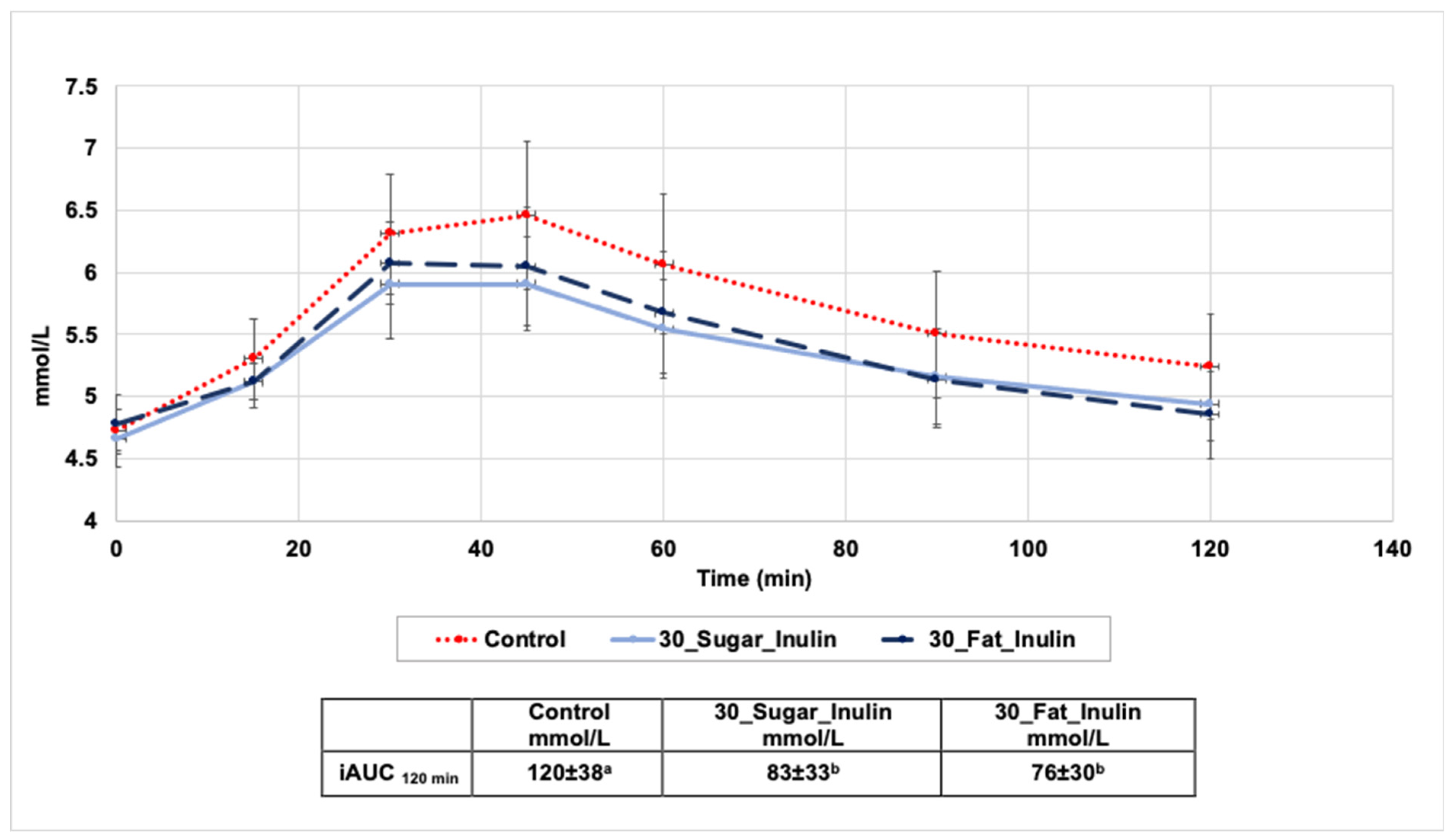

3.5.2. Glycaemic Response

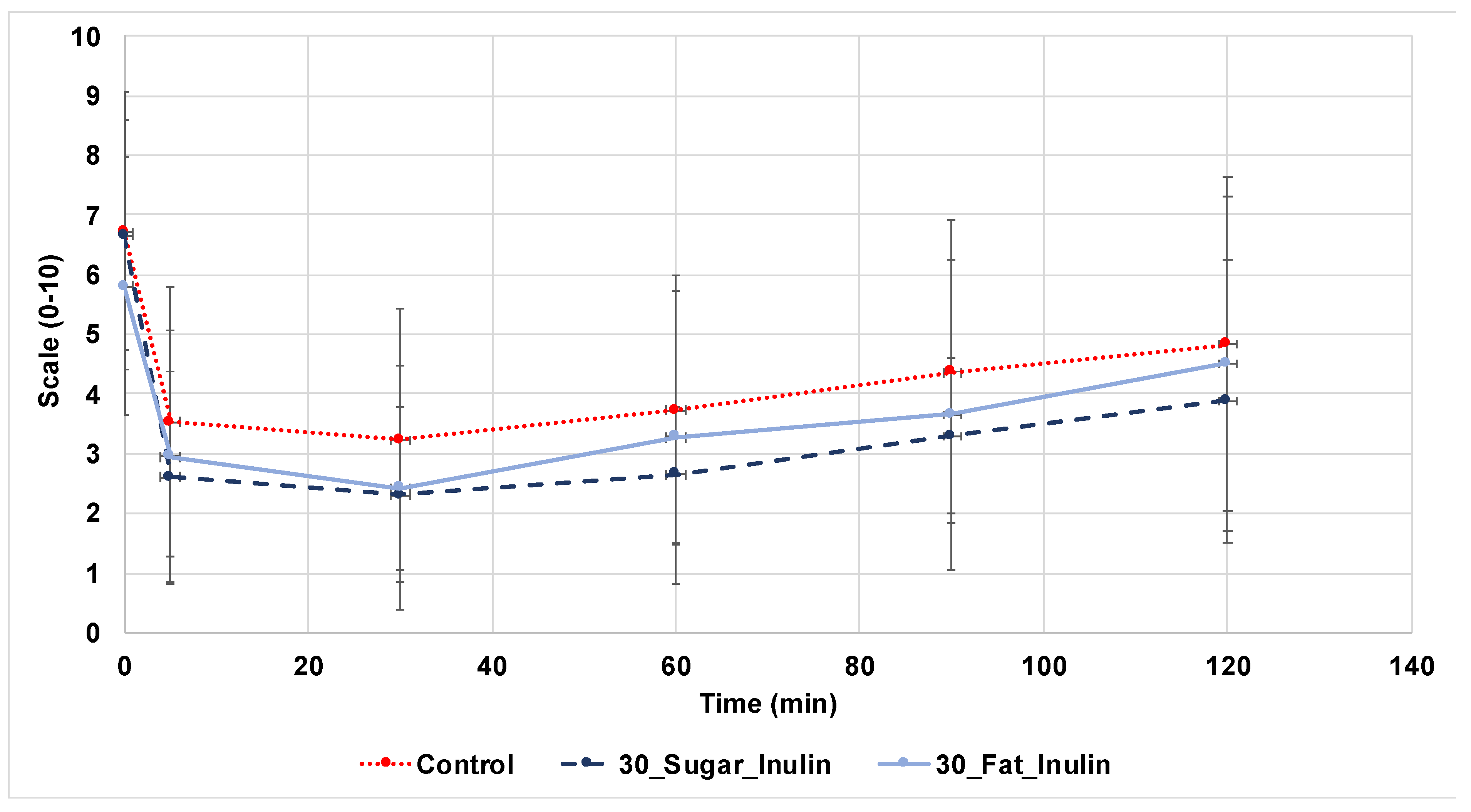

3.5.3. Hunger Perception

3.6. Shelf-Life

4. Additional Costs and Industrial Considerations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Eknoyan, G. A History of Obesity, or How What Was Good Became Ugly and Then Bad. Adv. Chronic Kidney Dis. 2006, 13, 421–427. [Google Scholar] [CrossRef] [PubMed]

- Poti, J.M.; Braga, B.; Qin, B. Ultra-processed Food Intake and Obesity: What Really Matters for Health—Processing or Nutrient Content? Curr. Obes. Rep. 2017, 6, 420–431. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, C.A.; Moubarac, J.-C.; Levy, R.B.; Canella, D.; Louzada, M.L.D.C.; Cannon, G. Household availability of ultra-processed foods and obesity in nineteen European countries. Public Heal. Nutr. 2017, 21, 18–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Buttriss, J.L. Food reformulation: The challenges to the food industry. Proc. Nutr. Soc. 2012, 72, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Norton, I.; Fryer, P.; Moore, S. Product/Process integration in food manufacture: Engineering sustained health. AIChE J. 2006, 52, 1632–1640. [Google Scholar] [CrossRef]

- Harastani, R.; James, L.J.; Walton, J.; Woolley, E. Tackling obesity: A knowledge-base to enable industrial food reformulation. Innov. Food Sci. Emerg. Technol. 2020, 64, 102433. [Google Scholar] [CrossRef]

- Absolute Reports. Global Muffins Market Research Report 2020. 2020. Available online: https://www.absolutereports.com/global-muffins-market-15040981 (accessed on 8 April 2021).

- Irish Food Board [IFB]. Healthy Snaking UK and Ireland. 2018. Available online: https://www.bordbia.ie/globalassets/bordbia.ie/industry/marketing-reports/consumer-reports/healthy-snacking-uk-and-ireland-january-2018.pdf (accessed on 5 December 2020).

- Hashem, K.M.; He, F.J.; Alderton, S.A.; MacGregor, G.A. Cross-sectional survey of the amount of sugar and energy in cakes and biscuits on sale in the UK for the evaluation of the sugar-reduction programme. BMJ Open 2018, 8, e019075. [Google Scholar] [CrossRef]

- Research and Markets. Global Muffins Market 2017–2021. 2017. Available online: https://www.researchandmarkets.com/reports/4376211/global-muffins-market-2017-2021 (accessed on 3 April 2021).

- World Health Organisation [WHO]. Obesity and Overweight. 2018. Available online: https://www.who.int/news-room/fact-sheets/detail/obesity-and-overweight (accessed on 8 October 2019).

- Public Health England [PHE]. Sugar Reduction: Achieving the 20%: A Technical Report Outlining Progress to Date, Guidelines for Industry, 2015 Baseline Levels in Key Foods and Next Steps. 2017. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/604336/Sugar_reduction_achieving_the_20_.pdf (accessed on 19 February 2021).

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Næs, T.; Varela, P. Making sense of the “clean label” trends: A review of consumer food choice behavior and discussion of industry implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef]

- European Commission. Regulation (EU) No 1131/2011: Amending Annex II to Regulation (EC) No 1333/2008 of the European Parliament and of the Council with Regard to Steviol Glycosides. Off. J. Eur. Union 2011, L 295, 205–211. [Google Scholar]

- European Commission. Regulation (EU) 2018/97: Amending Annex II to Regulation (EC) No 1333/2008 of the European Parliament and of the Council as Regards the Use of Sweeteners in Fine Bakery Wares. Off. J. Eur. Union 2018, L17, 11–13. [Google Scholar]

- Gao, J.; Brennan, M.; Mason, S.L.; Brennan, C. Effect of sugar replacement with stevianna and inulin on the texture and predictive glycaemic response of muffins. Int. J. Food Sci. Technol. 2016, 51, 1979–1987. [Google Scholar] [CrossRef] [Green Version]

- Miller, R.A.; Dann, O.E.; Oakley, A.R.; Angermayer, M.E.; Brackebusch, K.H. Sucrose replacement in high ratio white layer cakes. J. Sci. Food Agric. 2017, 97, 3228–3232. [Google Scholar] [CrossRef] [PubMed]

- Burgos, K.; Subramaniam, P.; Arthur, J. Reformulation Guide Spotlight on Sugars for Small to Medium Sized Companies. Leatherhead Food Research. 2016. Available online: https://www.fdf.org.uk/corporate_pubs/Reformulation-Guide-Sugars-Aug2016.pdf (accessed on 20 January 2021).

- Struck, S.; Jaros, D.; Brennan, C.; Rohm, H. Sugar replacement in sweetened bakery goods. Int. J. Food Sci. Technol. 2014, 49, 1963–1976. [Google Scholar] [CrossRef]

- Brooker, B.E. The Stabilisation of Air in Cake Batters—The Role of Fat. Food Struct. 1993, p. 12. Available online: https://digitalcommons.usu.edu/foodmicrostructure/vol12/iss3/2 (accessed on 20 June 2020).

- Zahn, S.; Pepke, F.; Rohm, H. Effect of inulin as a fat replacer on texture and sensory properties of muffins. Int. J. Food Sci. Technol. 2010, 45, 2531–2537. [Google Scholar] [CrossRef]

- Marchetti, L.; Califano, A.; Andrés, S. Partial replacement of wheat flour by pecan nut expeller meal on bakery products. Effect on muffins quality. LWT 2018, 95, 85–91. [Google Scholar] [CrossRef]

- Oh, I.K.; Lee, S. Utilization of foam structured hydroxypropyl methylcellulose for oleogels and their application as a solid fat replacer in muffins. Food Hydrocoll. 2018, 77, 796–802. [Google Scholar] [CrossRef]

- Acosta, K.; Cavender, G.; Kerr, W.L. Sensory and Physical properties of muffins made with waxy whole wheat flour. J. Food Qual. 2011, 34, 343–351. [Google Scholar] [CrossRef]

- Sanz, T.; Salvador, A.; Baixauli, R.; Fiszman, S.M. Evaluation of four types of resistant starch in muffins. II. Effects in texture, colour and consumer response. Eur. Food Res. Technol. 2009, 229, 197–204. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; De La Hera, E.; Sanz, T.; Gomez, M.; Salvador, A. Effect of using Erythritol as a Sucrose Replacer in Making Spanish Muffins Incorporating Xanthan Gum. Food Bioprocess Technol. 2011, 5, 3203–3216. [Google Scholar] [CrossRef]

- Zahn, S.; Forker, A.; Krügel, L.; Rohm, H. Combined use of rebaudioside A and fibres for partial sucrose replacement in muffins. LWT 2013, 50, 695–701. [Google Scholar] [CrossRef]

- Grigelmomiguel, N.; Carreras-Boladeras, E.; Martin-Belloso, O. Influence of the Addition of Peach Dietary Fiber in Composition, Physical Properties and Acceptability of Reduced-Fat Muffins. Food Sci. Technol. Int. 2001, 7, 425–431. [Google Scholar] [CrossRef]

- Duffrin, M.W.; Holben, D.H.; Bremner, M.J. Consumer Acceptance of Pawpaw (Asimina triloba) Fruit Puree as a Fat-Reducing Agent in Muffins, Compared to Muffins Made with Applesauce and Fat. Fam. Consum. Sci. Res. J. 2001, 29, 281–287. [Google Scholar] [CrossRef]

- Giacomozzi, A.S.; Carrín, M.E.; Palla, C.A. Muffins Elaborated with Optimized Monoglycerides Oleogels: From Solid Fat Replacer Obtention to Product Quality Evaluation. J. Food Sci. 2018, 83, 1505–1515. [Google Scholar] [CrossRef] [PubMed]

- Soong, Y.Y.; Quek, R.Y.C.; Henry, C.J. Glycemic potency of muffins made with wheat, rice, corn, oat and barley flours: A comparative study between in vivo and in vitro. Eur. J. Nutr. 2015, 54, 1281–1285. [Google Scholar] [CrossRef]

- Stewart, M.L.; Zimmer, J.P. Postprandial glucose and insulin response to a high-fiber muffin top containing resistant starch type 4 in healthy adults: A double-blind, randomized, controlled trial. Nutrition 2018, 53, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Rolls, B.J.; Drewnowski, A.; Ledikwe, J. Changing the Energy Density of the Diet as a Strategy for Weight Management. J. Am. Diet. Assoc. 2005, 105, 98–103. [Google Scholar] [CrossRef] [PubMed]

- Garcia, J.R.; Sahi, S.S.; Hernando, I. Functionality of lipase and emulsifiers in low-fat cakes with inulin. LWT 2014, 58, 173–182. [Google Scholar] [CrossRef]

- Chetachukwu, A.S.; Thongraung, C.; Yupanqui, C.T.; Adegoke, S.C. Effect of short-chain inulin on the rheological and sensory characteristics of reduced fat set coconut milk yoghurt. J. Texture Stud. 2018, 49, 434–447. [Google Scholar] [CrossRef] [PubMed]

- Sarawong, C.; Schoenlechner, R.; Sekiguchi, K.; Berghofer, E.; Ng, P.K. Effect of extrusion cooking on the physicochemical properties, resistant starch, phenolic content and antioxidant capacities of green banana flour. Food Chem. 2014, 143, 33–39. [Google Scholar] [CrossRef] [PubMed]

- Aurore, G.; Parfait, B.; Fahrasmane, L. Bananas, raw materials for making processed food products. Trends Food Sci. Technol. 2009, 20, 78–91. [Google Scholar] [CrossRef]

- Alves, L.A.A.D.S.; Lorenzo, J.M.; Gonçalves, C.A.A.; dos Santos, B.A.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of healthier bologna type sausages using pork skin and green banana flour as a fat replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Biswas, A.K.; Sahoo, J.; Chatli, M.K.; Sivakumar, S. Quality and storability of chicken nuggets formulated with green banana and soybean hulls flours. J. Food Sci. Technol. 2011, 50, 1058–1068. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhang, M.; Mujumdar, A.S. Influence of green banana flour substitution for cassava starch on the nutrition, color, texture and sensory quality in two types of snacks. LWT 2012, 47, 175–182. [Google Scholar] [CrossRef]

- Khoozani, A.A.; Kebede, B.; Bekhit, A.E.-D.A. Rheological, textural and structural changes in dough and bread partially substituted with whole green banana flour. LWT 2020, 126, 109252. [Google Scholar] [CrossRef]

- Karp, S.; Wyrwisz, J.; Kurek, M.; Wierzbicka, A. Physical properties of muffins sweetened with steviol glycosides as the sucrose replacement. Food Sci. Biotechnol. 2016, 25, 1591–1596. [Google Scholar] [CrossRef] [PubMed]

- Struck, S.; Gundel, L.; Zahn, S.; Rohm, H. Fiber enriched reduced sugar muffins made from iso-viscous batters. LWT 2016, 65, 32–38. [Google Scholar] [CrossRef]

- Arifin, N.; Siti Nur Izyan, M.A.; Faujan, N.H. Physical properties and consumer acceptability of basic muffin made from pumpkin puree as butter replacer. Food Res. 2019, 840–845. [Google Scholar] [CrossRef]

- Atwater, W.O.; Bryant, A.P. The Availability and Fuel Values of Food Materials. Connecticut (Storrs) Agricultural Experiment Station 12th Annual Report. 1899. Available online: http://www.fao.org/3/Y5022E/Y5022E00.htm (accessed on 13 August 2021).

- Food and Agriculture Organisation [FAO]. Food Energy—Methods of Analysis and Conversion Factors. Report of a Technical Workshop, Rome. 2003. Available online: http://www.fao.org/3/Y5022E/Y5022E00.htm (accessed on 10 April 2020).

- Public Health England [PHE]. Composition of Foods Integrated Dataset (CoFID). 2019. Available online: https://www.gov.uk/government/publications/composition-of-foods-integrated-dataset-cofid (accessed on 21 January 2021).

- USDA. U.S. Department of Agriculture. Food Data Central. Food Composition Table. Available online: https://fdc.nal.usda.gov/ (accessed on 3 March 2021).

- Brouns, F.; Bjorck, I.; Frayn, K.N.; Gibbs, A.L.; Lang, V.; Slama, G.; Wolever, T.M.S. Glycaemic index methodology. Nutr. Res. Rev. 2005, 18, 145–171. [Google Scholar] [CrossRef] [Green Version]

- Quílez, J.; Bulló, M.; Salas-Salvadó, J. Improved Postprandial Response and Feeling of Satiety after Consumption of Low-Calorie Muffins with Maltitol and High-Amylose Corn Starch. J. Food Sci. 2007, 72, S407–S411. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; Salvador, A.; Sanz, T. Cellulose ether emulsions as fat replacers in muffins: Rheological, thermal and textural properties. LWT 2015, 63, 1083–1090. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; Sanz, T.; Salvador, A.; Fiszman, S. Rheological, textural and sensorial properties of low-sucrose muffins reformulated with sucralose/polydextrose. LWT 2011, 45, 213–220. [Google Scholar] [CrossRef]

- Pateras, I.M.C.; Rosenthal, A. Effects of sucrose replacement by poly dextrose on the mechanism of structure formation in high ratio cakes. Int. J. Food Sci. Nutr. 1992, 43, 25–30. [Google Scholar] [CrossRef]

- Sikorski, Z.E.; Sikorska-Wisniewska, G.; Williams, C.; Buttriss, J. The role of lipids in food quality. In Improving the Fat Content of Foods; Woodhead Publishing: Swaston, UK, 2006; pp. 213–235. [Google Scholar] [CrossRef]

- Heo, Y.; Kim, M.-J.; Lee, J.-W.; Moon, B. Muffins enriched with dietary fiber from kimchi by-product: Baking properties, physical-chemical properties, and consumer acceptance. Food Sci. Nutr. 2019, 7, 1778–1785. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Cervera, S.; Salvador, A.; Muguerza, B.; Moulay, L.; Fiszman, S. Cocoa fibre and its application as a fat replacer in chocolate muffins. LWT 2010, 44, 729–736. [Google Scholar] [CrossRef]

- European Commission. Nutrition Claims, Annex of Regulation (EC) No 1924/2006 Amended by Regulation (EU) No 1047/2012. 2012. Available online: https://ec.europa.eu/food/safety/labelling_nutrition/claims/nutrition_claims_en (accessed on 10 December 2019).

- Food Standards Agency [FSA]. Guide to Creating a Front of Pack (FoP) Nutrition Label for Pre-Packed Products Sold through Retail Outlets. 2016. Available online: https://www.food.gov.uk/sites/default/files/media/document/fop-guidance_0.pdf (accessed on 10 March 2021).

- Singh, J.; Dartois, A.; Kaur, L. Starch digestibility in food matrix: A review. Trends Food Sci. Technol. 2010, 21, 168–180. [Google Scholar] [CrossRef]

- Guillon, F.; Champ, M. Structural and physical properties of dietary fibres, and consequences of processing on human physiology. Food Res. Int. 2000, 33, 233–245. [Google Scholar] [CrossRef]

- Brennan, C.S.; Kuri, V.; Tudorica, C.M. Inulin-enriched pasta: Effects on textural properties and starch degradation. Food Chem. 2004, 86, 189–193. [Google Scholar] [CrossRef]

- Borczak, B.; Sikora, E.; Sikora, M.; Rosell, C.M.; Collar, C. Glycaemic response to frozen stored wheat rolls enriched with inulin and oat fibre. J. Cereal Sci. 2012, 56, 576–580. [Google Scholar] [CrossRef]

- Lightowler, H.; Thondre, S.; Holz, A.; Theis, S. Replacement of glycaemic carbohydrates by inulin-type fructans from chicory (oligofructose, inulin) reduces the postprandial blood glucose and insulin response to foods: Report of two double-blind, randomized, controlled trials. Eur. J. Nutr. 2017, 57, 1259–1268. [Google Scholar] [CrossRef]

- Slavin, J.; Green, H. Dietary fibre and satiety. Nutr. Bull. 2007, 32, 32–42. [Google Scholar] [CrossRef]

- Archer, B.J.; Johnson, S.K.; Devereux, H.M.; Baxter, A.L. Effect of fat replacement by inulin or lupin-kernel fibre on sausage patty acceptability, post-meal perceptions of satiety and food intake in men. Br. J. Nutr. 2004, 91, 591–599. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hiel, S.; Bindels, L.B.; Pachikian, B.D.; Kalala, G.; Broers, V.; Zamariola, G.; Chang, B.P.I.; Kambashi, B.; Rodriguez, J.; Cani, P.D.; et al. Effects of a diet based on inulin-rich vegetables on gut health and nutritional behavior in healthy humans. Am. J. Clin. Nutr. 2019, 109, 1683–1695. [Google Scholar] [CrossRef]

- Salmean, Y.A. Acute fiber supplementation with inulin-type fructans curbs appetite sensations: A randomized, double-blind, placebo-controlled study. Food Nutr. Res. 2017, 61, 1341808. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.P.; Daifas, D.P.; El-Khoury, W.; Koukoutsis, J.; El-Khoury, A. Shelf Life and Safety Concerns of Bakery Products—A Review. Crit. Rev. Food Sci. Nutr. 2004, 44, 19–55. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, M.V.; Medina, L.M.; Jordano, R. Prolongation of shelf life of sponge cakes using modified atmosphere packaging. Acta Aliment. 2002, 31, 191–196. [Google Scholar] [CrossRef]

- Bryan, F.L.; Guzewich, J.J.; Todd, E.C.D. Surveillance of Foodborne Disease III. Summary and Presentation of Data on Vehicles and Contributory Factors; Their Value and Limitations. J. Food Prot. 1997, 60, 701–714. [Google Scholar] [CrossRef]

- Doulia, D.; Katsinis, G.; Rigas, F. Prediction of the Mould-Free Shelf Life of Muffins. Int. J. Food Prop. 2006, 9, 637–650. [Google Scholar] [CrossRef]

- Lund, B. Foodborne disease due to Bacillus and Clostridium species. Lancet 1990, 336, 982–986. [Google Scholar] [CrossRef]

- Grabitske, H.A.; Slavin, J.L. Gastrointestinal Effects of Low-Digestible Carbohydrates. Crit. Rev. Food Sci. Nutr. 2009, 49, 327–360. [Google Scholar] [CrossRef]

- Bruhwyler, J.; Carreer, F.; Demanet, E.; Jacobs, H. Digestive tolerance of inulin-type fructans: A double-blind, placebo-controlled, cross-over, dose-ranging, randomized study in healthy volunteers. Int. J. Food Sci. Nutr. 2009, 60, 165–175. [Google Scholar] [CrossRef]

- Bonnema, A.L.; Kolberg, L.W.; Thomas, W.; Slavin, J.L. Gastrointestinal Tolerance of Chicory Inulin Products. J. Am. Diet. Assoc. 2010, 110, 865–868. [Google Scholar] [CrossRef] [PubMed]

- Marotta, G.; Simeone, M.; Nazzaro, C. Product reformulation in the food system to improve food safety. Evaluation of policy interventions. Appetite 2014, 74, 107–115. [Google Scholar] [CrossRef] [PubMed]

| Ingredient | Mass (g) | g/100 g | Baker’s Mass *% |

|---|---|---|---|

| Flour | 125 | 25.95 | 100 |

| Sugar | 110 | 22.84 | 88.00 |

| Rapeseed oil | 80 | 16.61 | 64.00 |

| Tap water | 70 | 14.53 | 56.00 |

| Eggs | 60 | 12.46 | 48.00 |

| Starch | 15 | 3.11 | 12.00 |

| Skimmed milk powder | 8 | 1.66 | 6.40 |

| Baking powder | 2.5 | 0.52 | 2.00 |

| Glycerine | 2.5 | 0.52 | 2.00 |

| Soy lecithin | 2.5 | 0.52 | 2.00 |

| Whey protein powder | 2 | 0.42 | 1.60 |

| Lemon peel (Flavouring) | 2 | 0.42 | 1.60 |

| Citric acid | 1 | 0.21 | 0.80 |

| Xanthan gum | 1 | 0.21 | 0.80 |

| Potassium sorbate | 0.2 | 0.04 | 0.16 |

| Batter total weight | 481.7 | 100 | 385.36 |

| Formulation | Formulation Code | Sugar * | Rapeseed Oil * | Inulin * | GBF * | |

|---|---|---|---|---|---|---|

| Original muffins | (1) Control | Control | 110 | 80 | - | - |

| Sugar reduced muffins | (2) 10% reduced sugar using inulin | 10_Sugar_Inulin | 99 | 80 | 11 | - |

| (3) 30% reduced sugar using inulin | 30_Sugar_Inulin | 77 | 80 | 33 | - | |

| Fat reduced muffins | (4) 10% reduced fat using inulin | 10_Fat_Inulin | 110 | 72 | 8 | - |

| (5) 10% reduced fat using GBF | 10_Fat_GBF | 110 | 72 | - | 8 | |

| (6) 30% reduced fat using inulin | 30_Fat_Inulin | 110 | 56 | 24 | - | |

| (7) 30% reduced fat using GBF | 30_Fat_GBF | 110 | 56 | - | 24 | |

| Sugar and fat reduced muffins | (8) 10% reduced sugar and 10% reduced fat using inulin | 10_Sugar_Inulin_10_Fat_Inulin | 99 | 72 | 19 | - |

| (9) 10% reduced sugar using inulin and 10% reduced fat using GBF | 10_Sugar_Inulin_10_Fat_GBF | 99 | 72 | 11 | 8 | |

| (10) 30% reduced sugar and 30% reduced fat using inulin | 30_Sugar_Inulin_30_Fat_Inulin | 77 | 56 | 57 | - | |

| (11) 30% reduced sugar using inulin and 30% reduced fat using GBF | 30_Sugar_Inulin_30_Fat_GBF | 77 | 56 | 33 | 24 |

| Step | Method |

|---|---|

| (1) Preparing the emulsification gel and preservative mixture | (a) Lecithin was added to 50 mL water and mixed at speed 3 (high speed) for 2 min (VonShef model 07/067 hand mixer). (b) Xanthan gum and potassium sorbate were mixed with glycerine manually. (a) and (b) were added and mixed at speed 1 (low speed) for 1 min. |

| (2) Mixing | Sugar was mixed with eggs, oil and lemon peel at speed 2 (moderate speed) for 2 min until a creamy colour was formed. |

| (3) Preparing the acidity regulator | Citric acid was dissolved in 20 mL water. |

| (4) Mixing dry ingredients | Wheat flour, corn starch, whey, skimmed milk powder and baking powder were sifted and mixed manually with a whisk. Inulin and GBF were added in this step when they were used as sugar/fat substitutes. |

| (5) Combining | Components of step (2) and (3) were mixed at low speed for 30 s then mixed with components of step (1). |

| (6) Final muffin batter | Components of step (4) were mixed gradually with components in step (5) at low speed for 1 min. |

| (7) Filling and baking | The resulting batter was filled into muffin paper cups each weighing 82 ± 2 g. The muffin tray was then placed on the middle rack of an electric fan oven (John Lewis & Partners JLBIOS616 Single Oven, Stainless Steel) which was set to 180 °C (top and bottom) for 22 min. |

| (8) Cooling | Baked muffins were left to cool on a cooling rack for 60 min then packed in clean airtight bags for further analysis. |

| Formulation | Crust | Crumb | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| Control | 60.20 ± 3.15 | 11.50 ± 3.91 | 33.27 ± 2.14 | 72.87 ± 2.37 | 0.43 ± 0.40 | 18.57 ± 0.90 |

| 10_Sugar_Inulin | 60.06 ± 5.84 | 10.16 ± 5.41 | 33.54 ± 2.28 | 74.35 ± 0.70 | 0.33 ± 0.10 | 16.03 ± 0.65 |

| 30_Sugar_Inulin | 55.80 ± 1.21 | 16.87 ± 1.10 | 33.47 ± 1.23 | 75.63 ± 0.87 | 0.37 ± 0.31 | 17.63 ± 0.97 |

| 10_Fat_Inulin | 54.87 ± 4.50 | 16.49 ± 2.63 | 33.03 ± 2.50 | 74.20 ± 1.44 | 0.17 ± 0.15 | 15.63 ± 2.02 |

| 10_Fat_GBF | 57.28 ± 4.72 | 13.08 ± 2.85 | 29.88 ± 1.01 | 69.92 ± 2.58 | 2.06 ± 1.56 | 16.93 ± 1.46 |

| 30_Fat_Inulin | 61.88 ± 3.50 | 10.80 ± 4.43 | 33.45 ± 2.96 | 74.23 ± 1.46 | 0.98 ± 0.59 | 16.50 ± 1.06 |

| 30_Fat_GBF | 54.70 ± 2.16 | 15.47 ± 0.58 | 26.77 ± 2.38 a | 66.47 ± 2.11 a | 4.23 ± 0.55 a | 18.47 ± 0.38 |

| 10_Sugar_Inulin_10_Fat_Inulin | 59.20 ± 1.38 | 14.30 ± 0.73 | 35.40 ± 1.27 | 74.38 ± 1.51 | 0.50 ± 0.12 | 16.28 ± 0.78 |

| 10_Sugar_Inulin_10_Fat_GBF | 54.80 ± 2.26 | 15.48 ± 1.09 | 33.53 ± 1.73 | 72.23 ± 3.16 | 1.80 ± 0.72 | 16.47 ± 0.95 |

| 30_Sugar_Inulin_30_Fat_Inulin | 54.42 ± 4.92 | 17.48 ± 1.71 | 30.40 ± 2.06 | 76.30 ± 0.35 | 0.60 ± 0.20 | 16.40 ± 0.53 |

| 30_Sugar_Inulin_30_Fat_GBF | 57.28 ± 0.94 | 14.23 ± 1.98 | 28.48 ± 2.21 a | 65.73 ± 0.67 a | 4.20 ± 0.10 a | 18.00 ± 0.44 |

| Formulation | Mean Percentage of Baking Loss% |

|---|---|

| Control | 9.14 ± 0.35 a |

| 10_Sugar_Inulin | 8.72 ± 0.40 a |

| 30_Sugar_Inulin | 8.86 ± 0.49 a |

| 10_Fat_Inulin | 8.52 ± 0.30 a |

| 10_Fat_GBF | 8.60 ± 0.36 a |

| 30_Fat_Inulin | 8.63 ± 0.33 a |

| 30_Fat_GBF | 8.54 ± 0.49 a |

| 10_Sugar_Inulin_10_Fat_Inulin | 9.03 ± 0.42 a |

| 10_Sugar_Inulin_10_Fat_GBF | 7.78 ± 0.39 b |

| 30_Sugar_Inulin_30_Fat_Inulin | 7.90 ± 0.35 b |

| 30_Sugar_Inulin_30_Fat_GBF | 7.31 ± 0.30 b |

| Formulation | Theoretical Energy kcal/100 g | Theoretical Reduction of Calories % | Fibre Content Per Portion (baked ~75 g) | Sugar Content g/100 g and FoP Colour | Fat Content g/100 g and FoP Colour | Nutritional Claims European Commission [57] |

|---|---|---|---|---|---|---|

| Control | 370 | - | - | 22.84 | 16.61 | - |

| 10_Sugar_Inulin | 366 | 1.02% | 1.87 | 20.55 | 16.61 | N/A |

| 30_Sugar_Inulin | 358 | 3.06% | 5.62 | 15.99 | 16.61 | Reduced sugar/High in fibre ≥ 6 g/100 g |

| 10_Fat_Inulin | 359 | 3.03% | 1.36 | 22.84 | 14.95 | N/A |

| 10_Fat_GBF | 361 | 2.45% | 1.36 | 22.84 | 14.95 | N/A |

| 30_Fat_Inulin | 336 | 9.08% | 4.10 | 22.84 | 11.63 | Reduced fat/Source of fibre ≥ 3 g/100 g |

| 30_Fat_GBF | 342 | 7.36% | 4.10 | 22.84 | 11.63 | Reduced fat/Source of fibre ≥ 3 g/100 g |

| 10_Sugar_Inulin_10_Fat_Inulin | 355 | 4.05% | 3.23 | 20.55 | 14.95 | Source of fibre ≥ 3 g/100 g |

| 10_Sugar_Inulin_10_Fat_GBF | 357 | 3.47% | 3.23 | 20.55 | 14.95 | Source of fibre ≥ 3 g/100 g |

| 30_Sugar_Inulin_30_Fat_Inulin | 325 | 12.14% | 9.70 | 15.99 | 11.63 | Reduced sugar/Reduced fat/ High in fibre ≥ 6 g/100 g |

| 30_Sugar_Inulin_30_Fat_GBF | 331 | 10.42% | 9.70 | 15.99 | 11.63 | Reduced sugar/Reduced fat/ High in fibre ≥ 6 g/100 g |

| Parameter | All Participants (n = 13) |

|---|---|

| Sex (Male/Female) | 12/1 |

| Age (y) | 31.4 ± 7 |

| BMI (kg/m2) | 24.7 ± 3.8 |

| Height (m) | 1.77 ± 0.08 |

| Weight (kg) | 78.3 ± 17.3 |

| Fasting Blood Glucose (Mmol/L) | 4.7 ± 0.2 |

| Yeasts and Moulds | |||

| Storage Day | Control (log CFU/g) | 30_Sugar_Inulin (log CFU/g) | 30_Fat_Inulin (log CFU/g) |

| 1 | <1 | <1 | <1 |

| 3 | <1 | <1 | <1 |

| 7 | <1 | <1 | <1 |

| 10 | <1 | <1 | <1 |

| Total Viable Count | |||

| Storage day | Control (log CFU/g) | 30_Sugar_Inulin (log CFU/g) | 30_Fat_Inulin (log CFU/g) |

| 1 | <1 | <1 | <1 |

| 3 | 1.10 ± 0.17 a | 1.20 ± 0.35 a | 0.97 ± 0.85 a |

| 7 | 0.67 ± 0.58 a | 0.87 ± 0.81 a | 0.77 ± 0.68 a |

| 10 | <1 | <1 | <1 |

| Formulation | Fibre Content Per Portion (Baked ~75 g) | Additional Raw Material Cost Per Portion GBP £ | Cost Per Retail Pack (4 Muffins) £ |

|---|---|---|---|

| Control | - | - | 1.18 |

| 10_Sugar_Inulin | 1.87 | 0.041 | 1.34 |

| 30_Sugar_Inulin | 5.62 | 0.124 | 1.67 |

| 10_Fat_Inulin | 1.36 | 0.029 | 1.29 |

| 10_Fat_GBF | 1.36 | 0.027 | 1.29 |

| 30_Fat_Inulin | 4.10 | 0.086 | 1.52 |

| 30_Fat_GBF | 4.10 | 0.082 | 1.51 |

| 10_Sugar_Inulin_10_Fat_Inulin | 3.23 | 0.070 | 1.46 |

| 10_Sugar_Inulin_10_Fat_GBF | 3.23 | 0.068 | 1.45 |

| 30_Sugar_Inulin_30_Fat_Inulin | 9.70 | 0.210 | 2.02 |

| 30_Sugar_Inulin_30_Fat_GBF | 9.70 | 0.206 | 2.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harastani, R.; James, L.J.; Ghosh, S.; Rosenthal, A.J.; Woolley, E. Reformulation of Muffins Using Inulin and Green Banana Flour: Physical, Sensory, Nutritional and Shelf-Life Properties. Foods 2021, 10, 1883. https://doi.org/10.3390/foods10081883

Harastani R, James LJ, Ghosh S, Rosenthal AJ, Woolley E. Reformulation of Muffins Using Inulin and Green Banana Flour: Physical, Sensory, Nutritional and Shelf-Life Properties. Foods. 2021; 10(8):1883. https://doi.org/10.3390/foods10081883

Chicago/Turabian StyleHarastani, Rania, Lewis J. James, Sourav Ghosh, Andrew J. Rosenthal, and Elliot Woolley. 2021. "Reformulation of Muffins Using Inulin and Green Banana Flour: Physical, Sensory, Nutritional and Shelf-Life Properties" Foods 10, no. 8: 1883. https://doi.org/10.3390/foods10081883

APA StyleHarastani, R., James, L. J., Ghosh, S., Rosenthal, A. J., & Woolley, E. (2021). Reformulation of Muffins Using Inulin and Green Banana Flour: Physical, Sensory, Nutritional and Shelf-Life Properties. Foods, 10(8), 1883. https://doi.org/10.3390/foods10081883