Biochemical Properties Affecting the Nutritional Quality, Safety, and Aroma of Dry-Cured Products Manufactured from Meat of Rare Native Pig Breeds

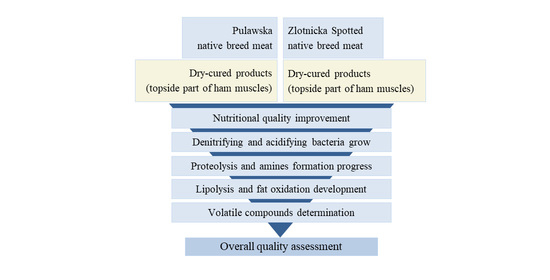

Abstract

1. Introduction

2. Materials and Methods

2.1. Dry-Cured Product Manufacturing

2.2. Sampling

2.3. Analysis

2.3.1. Basic Chemical Composition and Physicochemical and Microbiological Characteristics

2.3.2. Proteolytic Changes and Biogenic Amine Content

2.3.3. Fatty-Acid Profile and Oxidative Changes

2.3.4. Volatile Compound Content

2.3.5. Statistical Analysis

3. Results and Discussion

3.1. Basic Chemical Composition, and Physicochemical and Microbiological Characteristics

3.2. Proteolytic Changes and Biogenic Amines Content

3.3. Fatty-Acid Profile, Oxidative Changes, and Volatile Compound Content

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Babicz, M.; Blicharski, T.; Bajda, Z. (Eds.) Pigs of the Pulawy Breed, Heritage of the History of Polish Agriculture, 1st ed.; IGHZ PAN: Lublin, Poland, 2011. [Google Scholar]

- Babicz, M.; Kropiwiec, K.; Kasprzak, K.; Skrzypczak, E.; Hałabis, M. Analysis of the quality pork obtained from carcasses fatteners of Polish Landrace and Pulawska breed. Ann. UMCS Sect. EE 2013, 31, 1–7. [Google Scholar]

- Babicz, M.; Hałabis, M.; Skałecki, P.; Domaradzki, P.; Litwińczuk, A.; Kropiwiec-Domańska, K.; Łukasik, M. Breeding and performance potential of Pulawska pigs—A review. Ann. Anim. Sci. 2020, 20, 343–354. [Google Scholar] [CrossRef]

- Krupiński, J. Polish preserving breeds. In Atlas of Farm Animals Covered by the Protection Program in Poland, 1st ed.; IZ PIB: Kraków, Poland, 2012. [Google Scholar]

- Szyndler-Nędza, M.; Luciński, P.; Skrzypczak, E.; Szulc, K.; Bajda, Z. Pigs of native breeds—status of breeding and evaluation results. In Protection of Genetic Resources of Domestic Breeds of Pigs—Status of Breeding and Results of Evaluation for 2008, 1st ed.; Eckert, R., Ed.; IŻ PIB: Kraków, Poland, 2009. [Google Scholar]

- Szyndler-Nędza, M.; Luciński, P.; Szulc, K.; Bajda, Z. Pigs of native breeds—status of breeding and evaluation results. In Protection of Genetic Resources of Domestic Breeds of Pigs—Status of Breeding and Results of Evaluation for 2011, 1st ed.; Eckert, R., Ed.; IŻ PIB: Kraków, Poland, 2012. [Google Scholar]

- Kapelański, W.; Buczyński, T.J.; Bocian, M. Slaughter value and meat quality in the Polish native Zlotnicka Spotted pig. Anim. Sci. Pap. Rep. 2006, 24, 7–13. [Google Scholar]

- Grześkowiak, E.; Borys, A.; Borzuta, K.; Buczyński, J.; Lisiak, D. Slaughter value, meat quality and backfat fatty acid profile in Zlotnicka Spotted fatteners. Anim. Sci. Pap. Rep. 2009, 27, 115–125. [Google Scholar]

- Debrecéni, O.; Lípová, P.; Bučko, O.; Cebulska, A.; Kapelánski, W. Effect of pig genotypes from Slovak and Polish breeds on meat quality. Arch. Anim. Breed. 2018, 61, 99–107. [Google Scholar] [CrossRef]

- Szulc, K.; Skrzypczak, E.; Buczyński, J.T.; Stanisławski, D.; Jankowska-Małkosa, A.; Knecht, D. Evaluation of fattening and slaughter performance and determination of meat quality in Zlotnicka Spotted pigs and their crosses with the Duroc breed. Czech J. Anim. Sci. 2012, 57, 95–107. [Google Scholar] [CrossRef]

- Fabri, R.; Bergonzini, E. Performance of pure and crossbred spotted Poland pigs. Riv. Di Suinic. 1981, 22, 25–33. [Google Scholar]

- Jankowiak, H.; Kapelański, W.; Kwiatkowska, B.E.; Biegniewska, M.; Cebulska, A. Carcass and meat quality of Zlotnicka Spotted pigs in comparison to Polish Large White x Polish Landrace crossbred pigs. Res. Pig. Breed. 2009, 3, 4–6. [Google Scholar]

- Janiszewski, P.; Grześkowiak, E.; Lisiak, D.; Szulc, K.; Borzuta, K. Quality and technological suitability of meat from Złotnicka Spotted breed and its crossbreeds with the Duroc or Polish Large White. Sci. Ann. Pol. Soc. Anim. Prod. 2015, 11, 83–93. [Google Scholar]

- Cebulska, A. Quality and dietary value of pork meat of the Pulawska and Zlotnicka Spotted breeds, and commercial fattening pigs. Ann. Anim. Sci. 2018, 18, 281–291. [Google Scholar] [CrossRef]

- Migdał, W.; Kulig, R.; Walczycka, M.; Węsierska, E.; Zając, M.; Tkaczewska, J.; Kulawik, P.; Migdał, Ł.; Migdał, A.; Krępa-Stefanik, K. The quality of traditionally smoked tenderloins obtained from meat of native pig breeds. Biotechnol. Anim. Husb. 2020, 36, 49–61. [Google Scholar] [CrossRef][Green Version]

- Skałecki, P.; Babicz, M.; Domaradzki, P.; Litwińczuk, A.; Hałabis, M.; Ruda, B. Basic chemical composition, colour and content of PAHs and nitrates in smoked pork products made from Puławska breed. Vet. Med. 2019, 75, 422–425. [Google Scholar] [CrossRef]

- Pugliese, C.; Sirtori, F. Quality of meat and meat products produced from southern European pig breeds. Meat Sci. 2012, 90, 511–518. [Google Scholar] [CrossRef]

- ISO 1442:2000 Meat and Meat Products—Determination of Moisture Content (Reference Method); Polish Committee for Standardization: Warszawa, Poland, 2000.

- PN-75-A-04018:1975/Az3:2002 Agri-Food Products—Determination of Nitrogen Content by the Kjeldahl Method and the Conversion of Protein; Polish Committee for Standardization: Warszawa, Poland, 2002.

- ISO 1444:2000 Meat and Meat Products—Determination of Fat-Free; Polish Committee for Standardization: Warszawa, Poland, 2000.

- ISO 1841-1:2002 Meat and Meat Products—Determination of Chloride Content—Part 1: Volhard Method; Polish Committee for Standardization: Warszawa, Poland, 2002.

- ISO 4833:2004/Ap1:2005 Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Microorganisms; Colony-count technique at 30 °C; Polish Committee for Standardization: Warszawa, Poland, 2005.

- ISO 15214:2002 Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Mesophilic Lactic Acid bacteria; Colony-count technique at 30 °C; Polish Committee for Standardization: Warszawa, Poland, 2002.

- ISO 6888:2001/A1:2004 Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus Aureus and other Species); Part 1: Method using Baird-Parker agar; Polish Committee for Standardization: Warszawa, Poland, 2004.

- Kuchroo, C.V.; Ramilly, I.P.; Fox, P.F. Assessment of proteolysis in cheese by reaction with trinitrobenzensulphonic acid. J. Food Technol. 1983, 7, 129–133. [Google Scholar]

- Folch, J.; Lees, M.; Sloane, S.G.H. A simple method for the isolation and purification of total lipids from animal tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Rosmini, M.R.; Perlo, F.; Pérez-Alvarez, J.A.; Pagán-Moreno, M.J.; Gago-Gago, A.; López-Santovena, F.; Aranda-Catalá, V. TBA test by an extractive method applied to ‘pate’. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- Calik, J.; Krawczyk, J.; Świątkiewicz, S.; Gąsior, R.; Wojtycza, K.; Połtowicz, K.; Obrzut, J.; Puchała, M. Comparison of the physicochemical and sensory characteristics of Rhode Island Red (R-11) capons and cockerels. Ann. Anim. Sci. 2017, 17, 903–917. [Google Scholar] [CrossRef]

- Olivares, A.; Navarro, J.L.; Salvador, A.; Flores, M. Sensory acceptability of slow fermented sausages based on fat content and ripening time. Meat Sci. 2010, 86, 251–257. [Google Scholar] [CrossRef] [PubMed]

- Marušić, N.; Petrović, M.; Vidaček, S.; Petrak, T.; Medić, H. Characterization of traditional Istrian dry-cured ham by means of physical and chemical analyses and volatile compounds. Meat Sci. 2011, 88, 786–790. [Google Scholar] [CrossRef]

- Degnes, K.F.; Kvitvang, H.F.N.; Haslene-Hox, H.; Aasen, I.M. Changes in the profiles of metabolites originating from protein degradation during ripening of dry cured ham. Food Bioprocess Technol. 2017, 10, 1122–1130. [Google Scholar] [CrossRef]

- Spaziani, M.; Del Torre, M.; Stecchini, M.L. Changes of physicochemical, microbiological and textural properties during ripening of Italian low-acid sausages. Proteolysis, sensory and volatile profiles. Meat Sci. 2009, 81, 77–85. [Google Scholar] [CrossRef]

- Latorre-Moratalla, M.L.; Bosch-Fusté, J.; Bover-Cid, S.; Aymerich, T.; Vidal-Carou, M.C. Contribution of enterococci to the volatile profile of slightly-fermented sausages. LWT-Food Sci. Technol. 2011, 44, 145–152. [Google Scholar] [CrossRef]

- Ravyts, F.; De Vuyst, L.; Leroy, F. Bacterial diversity and functionalities in food fermentations. Eng. Life Sci. 2012, 12, 356–357. [Google Scholar] [CrossRef]

- Berardo, A.; Devreese, B.; De Maere, H.; Stavropoulou, D.A.; Van Royen, G.; Leroy, F.; De Smet, S. Actin proteolysis during ripening of dry fermented sausages at different pH values. Food Chem. 2017, 221, 1322–1332. [Google Scholar] [CrossRef]

- Węsierska, E.; Korzekwa, K.; Foks, S.; Mickowska, B. Influence of microflora composition on safety and colour parameters of „kumpia wieprzowa” during ripening. Pol. J. Vet. Sci. 2013, 16, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Węsierska, E.; Szołtysik, M.; Rak, L. Physico-chemical, biochemical and microbiological properties of traditional Polish pork fermented products during ripening. Food Bioprocess Technol. 2013, 6, 2986–2995. [Google Scholar] [CrossRef]

- Mati, M.; Staruch, L.; Šoral, M. Use of NMR spectroscopy in the analysis of carnosine and free amino acids in fermented sausages during ripening. Chem. Pap. 2015, 69, 1319–1324. [Google Scholar] [CrossRef]

- Mora, L.; Gallego, M.; Escudero, E.; Reig, M.; Aristoy, M.C.; Toldrá, F. Small peptides hydrolysis in dry-cured meats. Int. J. Food Microbiol. 2015, 212, 9–15. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Wang, Y.; Pan, D.D.; Cao, J.X.; Chen, Y.J.; Liu, Y.; Sun, Y.Y.; Ou, C.R. The changes in the proteolysis activity and the accumulation of free amino acids during Chinese traditional dry-cured loins processing. Food Sci. Biotechnol. 2017, 26, 679–687. [Google Scholar] [CrossRef]

- Innocente, N.; Biasutti, M.; Padovese, M.; Moret, S. Determination of biogenic amines in cheese using HPLC technique and direct derivation of acid extract. Food Chem. 2007, 101, 1285–1289. [Google Scholar] [CrossRef]

- Landeta, G.; de las Rivas, B.; Carrascosa, A.V.; Muñoz, R. Screening of biogenic amine production by coagulase-negative staphylococci isolated during industrial Spanish dry-cured ham processes. Meat Sci. 2007, 77, 556–561. [Google Scholar] [CrossRef][Green Version]

- Lorenzo, J.M.; Martínez, S.; Franco, I.; Carballo, J. Biogenic amine content during the manufacture of dry-cured lacón, a Spanish traditional meat product: Effect of some additives. Meat Sci. 2007, 77, 287–293. [Google Scholar] [CrossRef]

- Martuscelli, M.; Pittia, P.; Casamassima, L.M.; Manetta, A.C.; Lupieri, L.; Neri, L. Effect of intensity of smoking treatment on the free amino acids and biogenic amines occurrence in dry cured ham. Food Chem. 2009, 116, 955–962. [Google Scholar] [CrossRef]

- Stadnik, J.; Dolatowski, Z. Biogenic amines content during extended ageing of dry-cured pork loins inoculated with probiotics. Meat Sci. 2012, 91, 374–377. [Google Scholar] [CrossRef] [PubMed]

- Virgili, R.; Saccani, G.; Gabba, L.; Tanzi, E.; Soresi Bordini, C. Changes of free amino acids and biogenic amines during extended ageing of Italian dry-cured ham. LWT—Food Sci. Technol. 2007, 40, 871–878. [Google Scholar] [CrossRef]

- Martin, D.; Antequera, T.; Muriel, E.; Perez-Palacios, T.; Ruiz, J. Volatile compounds of fresh and dry-cured loin as affected by dietary conjugated linoleic acid and monounsaturated fatty acids. Meat Sci. 2009, 81, 549–556. [Google Scholar] [CrossRef]

- Resconi, V.C.; Campo, M.M.; Montossi, F.; Ferreira, V.; Sañudo, C.; Escudero, A. Relationship between odor-active compounds and flavor perception in meat from lambs fed different diets. Meat Sci. 2010, 85, 700–706. [Google Scholar] [CrossRef] [PubMed]

- Ventanas, S.; Ventanas, J.; Estevéz, M.; Ruiz, J. Analysis of volatile molecules in Iberian dry-cured loins as affected by genetic, feeding systems and ingredients. Eur. Food Res. Technol. 2010, 231, 225–235. [Google Scholar] [CrossRef]

- Soto, E.; Hoz, L.; Ordóñez, J.A.; Hierro, E.; Herranz, B.; López-Bote, C.; Cambero, M.I. Impact of feeding and rearing systems of Iberian pigs on volatile profile and sensory characteristics of dry-cured loin. Meat Sci. 2008, 79, 666–676. [Google Scholar] [CrossRef]

- Théron, L.; Tournayre, P.; Kondjoyan, N.; Abouelkaram, S.; Santé-Lhoutellier, V.; Berdagué, J.L. Analysis of the volatile profile and identification of odour-active compounds in Bayonne ham. Meat Sci. 2010, 85, 453–460. [Google Scholar] [CrossRef]

| Characteristics | Product (P) | Ripening Period (Week) (RP) | Interaction | |||||

|---|---|---|---|---|---|---|---|---|

| Pul | ZS | 0 | 2 | 4 | Source of Variance | |||

| M | M | M | M | M | P | RP | P × RP | |

| Water (%) | 72.15a | 71.02b | 74.29a | 72.19b | 69.12c | * | * | * |

| Protein (%) | 18.83a | 20.63b | 18.19a | 18.79a | 20.85b | * | * | ns |

| Fat (%) | 4.99a | 4.53b | 3.43a | 4.77b | 6.44c | * | * | * |

| Ash (%) | 3.02a | 4.04b | 1.31a | 3.96b | 4.55c | * | * | * |

| Salt (%) | 1.89a | 1.70b | 0.42a | 2.47b | 2.64c | * | * | * |

| pH | 5.52a | 5.69b | 5.69a | 5.68a | 5.33b | * | * | * |

| aw | 0.97a | 0.96b | 0.98a | 0.96b | 0.95c | * | * | * |

| Product | Pul | ZS | Product | Pul | ZS | ||||

|---|---|---|---|---|---|---|---|---|---|

| Amino Acid (mg/kg) | M | SD | M | SD | Amino Acid (mg/kg) | M | SD | M | SD |

| Asparagine | 11.47a | 0.95 | 4.02b | 0.16 | Valine | 28.14a | 0.69 | 22.69b | 0.89 |

| Serine | 34.70a | 1.13 | 32.68b | 1.28 | Methionine | 23.91a | 0.59 | 18.81b | 0.73 |

| Glutamine | 44.82a | 2.82 | 23.18b | 0.91 | Lysine | 26.76a | 1.67 | 22.92b | 0.90 |

| Glycine | 23.08a | 1.22 | 17.14b | 0.67 | Isoleucine | 25.63a | 0.75 | 19.89b | 0.78 |

| Histidine | 25.81a | 1.89 | 20.65b | 0.81 | Leucine | 40.87a | 1.15 | 32.83b | 1.28 |

| Arginine | 30.04a | 1.84 | 44.33b | 1.97 | Phenylalanine | 31.56a | 1.22 | 34.65b | 1.35 |

| Threonine | 43.66a | 1.55 | 31.78b | 1.24 | Free amine groups (g/100 g) | ||||

| Alanine | 47.45a | 1.17 | 30.45b | 1.19 | in H2O | 0.61a | 0.06 | 0.70b | 0.00 |

| Proline | 30.87a | 1.08 | 21.33b | 0.83 | in PTA | 0.06a | 0.00 | 0.06a | 0.01 |

| Tyrosine | 33.56a | 2.57 | 30.97b | 1.21 | |||||

| Product | Pul | ZS | ||

|---|---|---|---|---|

| Biogenic Amines (mg/kg) | M | SD | M | SD |

| Tryptamine | 4.73a | 1.28 | 9.08b | 0.56 |

| Phenylethylamine | 1.28a | 0.86 | 0.25a | 0.01 |

| Putrescine | 3.97a | 2.11 | 23.66b | 0.90 |

| Cadaverine | 28.53a | 2.94 | 54.31b | 3.03 |

| Histamine | 87.89a | 16.70 | 163.19b | 4.90 |

| Tyramine | 11.07a | 0.39 | 57.16b | 2.17 |

| Spermine | 2.75a | 0.19 | 1.94b | 0.07 |

| Spermidine | 21.69a | 1.04 | 10.47b | 0.43 |

| Product | Pul | ZS | Product | Pul | ZS | ||||

|---|---|---|---|---|---|---|---|---|---|

| Fatty Acids (%) | M | SD | M | SD | Fatty Acids (%) | M | SD | M | SD |

| 10;0 | 0.12a | 0.01 | 0.08b | 0.00 | 18; 2n-6 | 8.28a | 5.38 | 7.80a | 0.02 |

| 12;0 | 0.09a | 0.00 | 0.06b | 0.00 | 18; 3n-6 | 0.05a | 0.01 | 0.06a | 0.00 |

| 14;0 | 1.24a | 0.20 | 1.04a | 0.01 | 20; 3n-6 | 0.19a | 0.08 | 0.16a | 0.00 |

| 16;0 | 23.14a | 1.95 | 25.91a | 0.24 | 20; 4n-6 | 1.01a | 0.38 | 1.23a | 0.01 |

| 17;0 | 0.14a | 0.02 | 0.12a | 0.01 | 22; 4n-6 | 0.18a | 0.04 | 0.16a | 0.00 |

| 18;0 | 10.09a | 0.34 | 11.19b | 0.13 | 22; 5n-6 | 0.02a | 0.00 | 0.01a | 0.00 |

| 20;0 | 0.09a | 0.00 | 0.13b | 0.01 | |||||

| Σ SFA | 34.91 | 38.53 | Σ ω-6 | 9.73 | 9.42 | ||||

| 14;1 | 0.02a | 0.01 | 0.02a | 0.00 | 18; 3n-3 | 0.44a | 0.33 | 0.37a | 0.00 |

| 16;1n-7 | 4.04a | 0.92 | 3.33a | 0.02 | 20; 4n-3 | 0.07a | 0.05 | 0.06a | 0.00 |

| 16;1n-9 | 0.73a | 0.01 | 0.71a | 0.03 | 20; 5n-3 | 0.04a | 0.02 | 0.06a | 0.00 |

| 17;1 | 0.19a | 0.03 | 0.11b | 0.01 | 22; 5n-3 | 0.16a | 0.09 | 0.16a | 0.01 |

| 18;1n-7 | 4.46a | 0.85 | 3.93a | 0.08 | 22; 6n-3 | 0.08a | 0.03 | 0.07a | 0.00 |

| 18;1n-9 | 44.06a | 2.99 | 42.22a | 0.28 | CLA | 0.06a | 0.00 | 0.05b | 0.00 |

| 20;1 | 0.58a | 0.02 | 0.61a | 0.03 | Σ ω-3 | 0.85 | 0.77 | ||

| Σ MUFA | 54.08 | 50.93 | Σ PUFA | 10.58 | 10.19 | ||||

| TBA (mg/kg) | 0.32a | 0.04 | 0.52b | 0.13 | |||||

| Volatile Compound (ng/g) | Ret. Index ZB-5 | Ret. Index ZB-Wax | Ret. Time | Product Pul | Product ZS | Formation | Odor Impression | ||

|---|---|---|---|---|---|---|---|---|---|

| M | SD | M | SD | ||||||

| Ethanol (S) | <500 | 944 | 1.72 | 29.23a | 0.78 | 32.53b | 7.56 | Microb. act. (fermentation) | Alcoholic |

| Acetone (S) | <500 | 816 | 1.84 | 10.53a | 2.56 | 9.82b | 10.12 | Microb. act. (fermentation) | Solvent, ethereal, apple |

| Thiirane, methyl- | 596 | 885 | 2.39 | 11.37a | 1.28 | 27.21b | 1.98 | Spices (garlic) | |

| Acetic acid (S) | 641 | 1444 | 2.98 | 199.47a | 9.22 | 151.31b | 15.67 | Microb. act. (fermentation) | Pungent, vinegar |

| 3-Methylbutanal | 658 | 916 | 3.11 | 10.55a | 0.70 | 9.15b | 1.73 | Microb. act. (aa catabolism) | Rancid, raw ham-like |

| 1-Hydroxypropan-2-one | 679 | 1291 | 3.52 | 5.92a | 0.26 | 4.87b | 1.72 | Lipid oxidation | Caramellic, burnt |

| Allyl methyl sulfide | 697 | 953 | 3.86 | 9.56a | 0.54 | 9.38a | 0.28 | Spices (garlic) | Sulfuric, alliaceous |

| 3-Hydroxybutan-2-one | 719 | 1279 | 4.45 | 15.96a | 6.13 | 4.81b | 0.98 | Microb. act. (fermentation) | Buttery, milky, fatty |

| 3-Methylbutan-1-ol | 737 | 1214 | 4.98 | 41.77a | 0.19 | 41.55a | 1.46 | Microb. act. (aa catabolism) | Pungent, whisky-like |

| Pyridine (S) | 757 | 1181 | 5.54 | 16.43a | 2.97 | 10.09b | 0.69 | Pyrolysis | Fish-like |

| Toluen (S) | 767 | 1032 | 6.09 | 18.40a | 1.34 | 15.19b | 1.77 | Pyrolysis | Sweet |

| Hexanal (S) | 801 | 1075 | 7.82 | 11.28a | 7.24 | 42.54b | 1.63 | Lipid oxidation | Aldehydic, fatty, fruity |

| 2-Cyclopenten-1-one | 842 | 1343 | 10.12 | 7.21a | 2.68 | 5.89b | 0.02 | Lipid oxidation | Caramelized sugar |

| 2-Methylcyclopentanone | 848 | 1181 | 10.55 | 11.67a | 1.31 | 11.10a | 0.69 | Lipid oxidation | Meaty, roasted beef-like |

| Diallyl sulfide | 865 | 1150 | 11.86 | 9.83a | 0.90 | 5.60b | 1.58 | Spices (garlic) | Alliaceous, metallic |

| 2-Furanmethanol | 870 | 1660 | 12.20 | 112.18a | 2.89 | 53.21b | 5.40 | Spices | Burnt |

| p-Xylen | 874 | 1129 | 12.62 | 11.21a | 0.30 | 11.38a | 3.15 | Pyrolysis | Aromatic |

| Hexan-1-ol | 881 | 1358 | 13.12 | 5.57a | 1.00 | 6.72b | 1.13 | Spices | Freshly mown grass |

| o-Xylene (S) | 891 | 1173 | 14.16 | 10.53a | 0.36 | 5.99b | 0.73 | Pyrolysis | Geranium |

| 2-Cyclopenten-1-one, 2-methyl- | 905 | 1357 | 15.13 | 28.15a | 1.02 | 19.66b | 2.68 | Lipid oxidation | Caramelized sugar |

| Allyl methyl disulfide | 915 | 1269 | 15.63 | 5.93a | 2.56 | 7.25b | 5.99 | Spices (garlic) | Alliaceous |

| γ-Butyrolactone | 915 | 1599 | 15.65 | 21.77a | 1.80 | 21.30a | 3.00 | Lipid oxidation | Creamy, caramel |

| 2(5H)-Furanone | 917 | 1754 | 15.79 | 7.38a | 0.56 | 6.30b | 3.73 | Lipid oxidation | Buttery |

| α-Pinene (S) | 936 | 1013 | 16.75 | 17.92a | 0.28 | 17.26a | 1.17 | Spices (pepper) | Camphoraceous, pine |

| Camphene | 950 | 1053 | 17.56 | 8.39a | 0.53 | 6.11b | 0.26 | Spices | Pungent |

| 2-Furanmethanol, 5-methyl- | 963 | 1728 | 18.36 | 9.40a | 0.84 | 4.80b | 0.19 | Spices | Burnt |

| 2-Cyclopenten-1-one, 3-methyl- | 969 | 1504 | 18.63 | 15.48a | 1.75 | 8.70b | 0.27 | Lipid oxidation | Caramelized sugar |

| β-Pinene (S) | 976 | 1087 | 19.17 | 14.89a | 0.44 | 14.42a | 1.39 | Spices (pepper) | Piney, eucalyptus |

| Oct-1-en-3-ol (S) | 985 | 1453 | 19.65 | 6.10a | 0.62 | 7.76b | 0.08 | Spices | Mushroom |

| β-Myrcene | 993 | 1161 | 20.20 | 12.53a | 0.64 | 9.42b | 0.39 | Spices | Woody, rosy, celery |

| α-Phellandrene | 1001 | 1152 | 20.73 | 9.31a | 1.30 | 7.77b | 0.34 | Spices (pepper) | Citrus, terpenic |

| 3-Carene | 1008 | 1134 | 21.02 | 58.78a | 18.71 | 47.89b | 8.01 | Spices | Sweet, pungent |

| p-(o- or m-) Cymene | 1026 | 1261 | 21.79 | 13.22a | 0.15 | 10.29b | 1.32 | Spices | Terpenic, citrus |

| Limonene (S) | 1030 | 1183 | 21.98 | 80.92a | 0.74 | 65.34b | 6.47 | Spices (pepper) | Menthol, orange |

| 2-Ethylhexanol | 1034 | 1492 | 22.18 | 5.68a | 0.37 | 6.02b | 0.88 | Spices | Fresh floral, fatty |

| 2,3-Dimethyl-2-cyclopenten-1-one | 1040 | 1526 | 22.47 | 19.38a | 0.39 | 10.78b | 1.29 | Lipid oxidation | Caramelized sugar |

| Phenylacetalaldehyde | 1045 | 1618 | 22.72 | 20.47a | 3.33 | 8.80b | 1.05 | Lipid oxidation | Almond-like |

| γ-Terpinene | 1061 | 1234 | 23.48 | 14.59a | 1.08 | 11.55b | 2.58 | Spices (pepper) | Terpenic, tropical |

| Linalool oxide (S) | 1077 | 1439 | 24.23 | 8.53a | 0.65 | 4.90b | 0.22 | Spices | Orange, rose, terpenic |

| Diallyl disulfide | 1081 | 1487 | 24.38 | 107.78a | 10.27 | 67.41b | 1.11 | Spices (garlic) | Green onion meaty |

| Guaiacol | 1089 | 1866 | 24.89 | 99.79a | 5.04 | 66.44b | 3.93 | Pyrolysis | Whisky, roasted coffee |

| Linalool (S) | 1100 | 1542 | 25.44 | 222.12a | 1.98 | 144.86b | 1.83 | Spices | Orange, rose, terpenic |

| 2-Phenylethanol | 1114 | 1923 | 26.00 | 6.33a | 1.80 | 4.02b | 0.32 | Spices | Rose, floral |

| Camphor | 1146 | 1498 | 27.29 | 15.48a | 0.93 | 10.03b | 0.58 | Spices | Camphoraceous |

| Creosol | 1193 | 1948 | 29.32 | 46.14a | 5.35 | 27.56b | 1.76 | Pyrolysis | Coal tar |

| 4-Ethyl guaiacol | 1281 | 2034 | 32.69 | 15.27a | 1.68 | 8.51b | 0.55 | Pyrolysis | Whisky, roasted coffee |

| Eugenol | 1364 | 2176 | 35.41 | 73.98a | 8.34 | 43.39b | 1.27 | Spices | Clove-like, bacon-like |

| Caryophyllene | 1429 | 1572 | 37.23 | 11.83a | 0.71 | 11.09a | 3.22 | Spices | Pepper-like, citrus |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Węsierska, E.; Sobolewska-Zielińska, J.; Pasternak, M.; Niemczyńska-Wróbel, K.; Gąsior, R.; Wojtycza, K.; Pustkowiak, H.; Duda, I.; Migdał, W. Biochemical Properties Affecting the Nutritional Quality, Safety, and Aroma of Dry-Cured Products Manufactured from Meat of Rare Native Pig Breeds. Foods 2021, 10, 1597. https://doi.org/10.3390/foods10071597

Węsierska E, Sobolewska-Zielińska J, Pasternak M, Niemczyńska-Wróbel K, Gąsior R, Wojtycza K, Pustkowiak H, Duda I, Migdał W. Biochemical Properties Affecting the Nutritional Quality, Safety, and Aroma of Dry-Cured Products Manufactured from Meat of Rare Native Pig Breeds. Foods. 2021; 10(7):1597. https://doi.org/10.3390/foods10071597

Chicago/Turabian StyleWęsierska, Ewelina, Joanna Sobolewska-Zielińska, Małgorzata Pasternak, Katarzyna Niemczyńska-Wróbel, Robert Gąsior, Krzysztof Wojtycza, Henryk Pustkowiak, Iwona Duda, and Władysław Migdał. 2021. "Biochemical Properties Affecting the Nutritional Quality, Safety, and Aroma of Dry-Cured Products Manufactured from Meat of Rare Native Pig Breeds" Foods 10, no. 7: 1597. https://doi.org/10.3390/foods10071597

APA StyleWęsierska, E., Sobolewska-Zielińska, J., Pasternak, M., Niemczyńska-Wróbel, K., Gąsior, R., Wojtycza, K., Pustkowiak, H., Duda, I., & Migdał, W. (2021). Biochemical Properties Affecting the Nutritional Quality, Safety, and Aroma of Dry-Cured Products Manufactured from Meat of Rare Native Pig Breeds. Foods, 10(7), 1597. https://doi.org/10.3390/foods10071597