Microwave Modification as an Excellent Way to Produce Unique Lysozyme with Potential for Food and Human Health

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Modification of LLC

2.3. Electrophoretic Analysis

2.4. Hydrolytic Activity

2.5. Hydrophobicity

- (1)

- For test tube a: 50 µL of lysozyme and 50 µL of distilled water;

- (2)

- For test tube a’: 50 µL of lysozyme and 50 µL of 0.25% Tween 80 solution;

- (3)

- For test tube b: 100 µL of distilled water;

- (4)

- For test tube b’: 50 µL of distilled water and 50 µL of 0.25% Tween 80 solution.

2.6. Statistics Analysis

3. Results

3.1. Presenting Characteristics

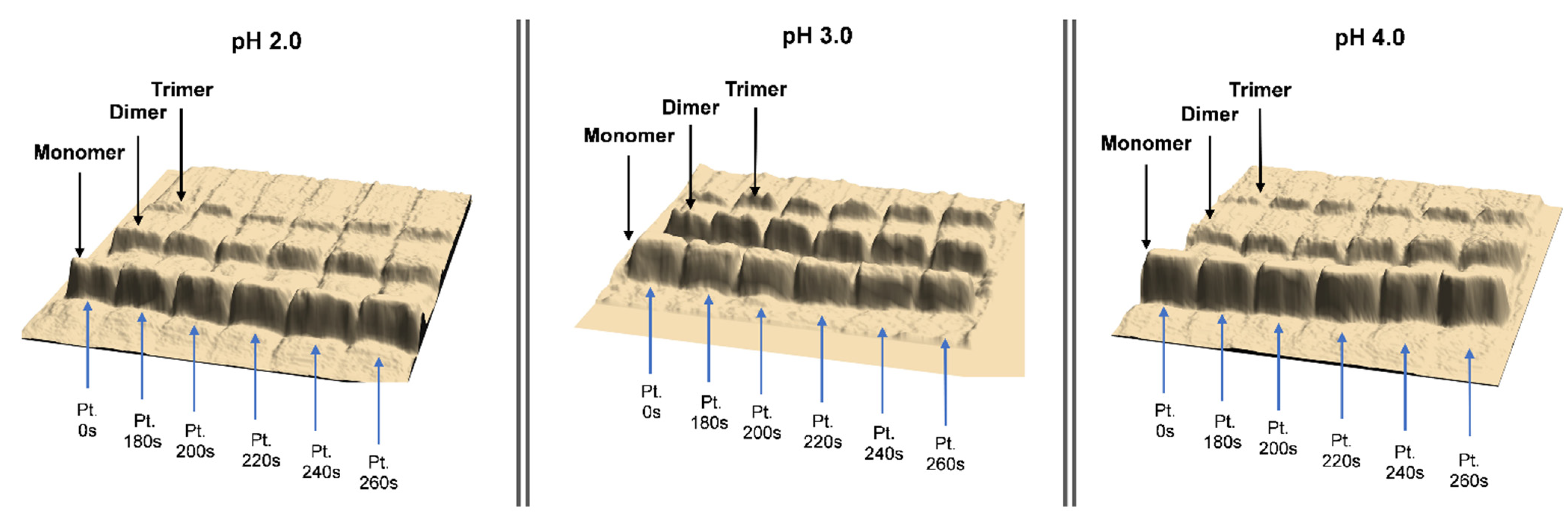

3.2. Analyzing Enzyme Oligomerization and Hydrolytic Activity

3.3. Analyzing Changes in Surface Hydrophobicity

4. Discussion

4.1. Characteristics of the New Method

4.2. Consideration of the Physicochemical Properties of the Modified Lysozyme

4.3. Final Assessment

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leśnierowski, G.; Kijowski, J. Lysozyme. In Bioactive Egg Compounds; Huopalathi, R., Lopez-Fandino, R., Anton, M., Schade, R., Eds.; Springer: Berlin/Heidelberg, German, 2007; pp. 33–42. [Google Scholar]

- Leśnierowski, G. Physicochemical Methods for the Modification and Measurement of Lysozyme Activity; Scientific Dissertations; University Publisher Poznan University of Life Sciences: Poznań, Poland, 2007; Volume 378, pp. 1–104. [Google Scholar]

- Ibrahim, H.R.; Higashiguchi, S.; Juneja, L.R.; Kim, M.; Yamamoto, T. A structural phase of heat-denatured lysozyme with novel antimicrobial action. J. Agric. Food Chem. 1996, 44, 1416–1423. [Google Scholar] [CrossRef]

- Ermakova, E. Lysozyme dimerization: Brownian dynamics simulation. J. Mol. Model. 2005, 12, 34–41. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, N.; Liu, Y.; Jin, Y.; Ma, M. The antimicrobial spectrum of lysozyme broadened by reductive modification. Poult. Sci. 2018, 97, 3992–3999. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Leśnierowski, G. Changes in selected physicochemical properties of lysozyme modified with a new method using microwave field and oxidation. PLoS ONE 2019, 14, e0213021. [Google Scholar] [CrossRef]

- Yang, T.; Leśnierowski, G. Thermal modification of hen egg white lysozyme using microwave treatment. Acta Sci. Pol. Technol. Aliment. 2020, 19, 149–157. [Google Scholar] [CrossRef] [PubMed]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 22, 680–687. [Google Scholar] [CrossRef] [PubMed]

- Lieske, B.; Konrad, G. A new approach to estimate surface hydrophobicity of proteins. Milchwissenschaft 1994, 49, 4. [Google Scholar]

- Cegielska-Radziejewska, R.; Szablewski, T. Inhibition of food-borne bacteria by thermo-chemically modified egg white lysozyme. Afr. J. Microbiol. Res. 2014, 8, 590–597. [Google Scholar] [CrossRef]

- Vilcacundo, R.; Méndez, P.; Reyes, W.; Romero, H.; Pinto, A.; Carrillo, W. Antibacterial activity of hen egg white lysozyme denatured by thermal and chemical treatments. Sci. Pharm. 2018, 86, 48. [Google Scholar] [CrossRef] [PubMed]

- Borowiak, R.; Leśnierowski, G. An attempt to increase the functionality of preparations obtained by high-temperature lysozyme modification (In Polish). Food Sci. Technol. Qual. 2012, 5, 124–134. [Google Scholar] [CrossRef]

- Ibrahim, H.R. On the novel catalytically-independent antimicrobial function of hen egg-white lysozyme: A conformation-dependent activity. Nahrung 1998, 42, 187–193. [Google Scholar] [CrossRef]

- Leśnierowski, G.; Cegielska-Radziejewska, R. Potential possibilities of production, modification and practical application of lysozyme. Acta Sci. Pol. Technol. Aliment. 2012, 11, 223–230. [Google Scholar] [PubMed]

- Cegielska-Radziejewska, R.; Leśnierowski, G.; Kijowski, J. Antibacterial activity of hen egg white lysozyme modified by thermochemical technique. Eur. Food Res. Technol. 2009, 228, 841–845. [Google Scholar] [CrossRef]

- Leśnierowski, G. Lysozyme and its modified forms: Properties, potential for its production and application. In Handbook of Eggs in Human Function; Watson, R., Meester, F., Eds.; Wageningen Academic Publisher: Wageningen, The Netherland, 2015; pp. 483–495. [Google Scholar]

- Ibrahim, H.R.; Thomas, U.; Pellegrini, A. A helix-loop-helix peptide at the upper lip of the active site cleft of lysozyme confers potent antimicrobial activity with membrane permeabilization action. J. Biol. Chem. 2001, 276, 43767–43774. [Google Scholar] [CrossRef]

- Leśnierowski, G.; Yang, T. Lysozyme and its modified forms: A critical appraisal of selected properties and potential. Trends Food Sci. Technol. 2021, 107, 333–342. [Google Scholar] [CrossRef]

- Ibrahim, H.R.; Matsuzaki, T.; Aoki, T. Genetic evidence that antibacterial activity of lysozyme is independent of its catalytic function. FEBS Lett. 2001, 506, 27–32. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Liu, Z.; Wang, P.; Mo, X.; Fu, W.; Liu, W.; Cheng, Y.; Han, W. LYG1 exerts antitumor function through promoting the activation, proliferation, and function of CD4+ T cells. Oncoimmunology 2017, 6, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Acharya, D.; Liu, G.Q.; Gack, M.U. Dysregulation of type I interferon responses in COVID-19. Nat. Rev. Immunol. 2020, 20, 297–398. [Google Scholar] [CrossRef]

- Shalhoub, S. Interferon beta-1b for COVID-19. Lancet (Comment) 2020, 395, 10238. [Google Scholar] [CrossRef]

| No. | pH | Duration Time (s) | Dimer (%) | Trimer (%) | Total Oligomers (%) | Residual Hydrolytic Activity (%) | Change in Surface Hydrophobicity ∆SH (%) |

|---|---|---|---|---|---|---|---|

| 1 | 2 | 0 | 13.47 ± 0.21 p | 5.20 ± 0.08 m | 18.67 ± 0.29 n | 68.61 ± 0.87 g | 13.82 ± 0.18 m |

| 2 | 2 | 180 | 20.00 ± 0.31 k | 7.35 ± 0.12 j | 27.35 ± 0.43 j | 54.60 ± 0.7 k | 32.25 ± 0.41 i |

| 3 | 2 | 200 | 21.12 ± 0.33 i | 7.96 ± 0.13 h | 29.08 ± 0.46 h | 45.25 ± 0.58 n | 35.33 ± 0.45 f |

| 4 | 2 | 220 | 24.69 ± 0.39 e | 10.00 ± 0.16 d | 34.69 ± 0.55 e | 38.76 ± 0.49 o | 39.42 ± 0.50 d |

| 5 | 2 | 240 | 26.22 ± 0.41 c | 11.53 ± 0.18 b | 37.75 ± 0.59 c | 33.88 ± 0.43 p | 45.65 ± 0.58 b |

| 6 | 2 | 260 | 28.26 ± 0.44 a | 12.65 ± 0.2 a | 40.91 ± 0.64 a | 31.88 ± 0.41 q | 49.88 ± 0.64 a |

| 7 | 3 | 0 | 10.41 ± 0.16 q | 4.18 ± 0.07 n | 14.59 ± 0.23 o | 83.38 ± 1.06 c | 12.12 ± 0.15 n |

| 8 | 3 | 180 | 16.53 ± 0.26 m | 7.14 ± 0.11 k | 23.67 ± 0.37 l | 75.62 ± 0.96 e | 29.86 ± 0.38 k |

| 9 | 3 | 200 | 17.45 ± 0.27 l | 7.55 ± 0.12 i | 25.00 ± 0.39 k | 66.48 ± 0.85 h | 32.83 ± 0.42 h |

| 10 | 3 | 220 | 21.53 ± 0.34 h | 9.08 ± 0.14 f | 30.61 ± 0.48 g | 57.30 ± 0.73 j | 35.33 ± 0.45 f |

| 11 | 3 | 240 | 24.08 ± 0.38 f | 10.30 ± 0.16 d | 34.38 ± 0.54 e | 51.82 ± 0.66 i | 38.63 ± 0.49 e |

| 12 | 3 | 260 | 27.04 ± 0.43 b | 11.63 ± 0.18 b | 38.67 ± 0.61 b | 49.58 ± 0.63 m | 41.26 ± 0.53 c |

| 13 | 4 | 0 | 10.00 ± 0.16 r | 3.06 ± 0.05 o | 13.06 ± 0.21 p | 91.66 ± 1.17 a | 10.75 ± 0.14 o |

| 14 | 4 | 180 | 15.10 ± 0.24 o | 6.63 ± 0.1 l | 21.73 ± 0.34 m | 88.31 ± 1.13 b | 27.33 ± 0.35 i |

| 15 | 4 | 200 | 16.53 ± 0.26 n | 7.14 ± 0.11 k | 23.67 ± 0.37 l | 80.08 ± 1.02 d | 29.35 ± 0.37 k |

| 16 | 4 | 220 | 20.30 ± 0.32 j | 8.06 ± 0.13 gh | 28.36 ± 0.45 i | 72.06 ± 0.92 f | 31.22 ± 0.40 j |

| 17 | 4 | 240 | 23.16 ± 0.36 g | 9.39 ± 0.15 e | 32.55 ± 0.51 f | 67.41 ± 0.86 h | 33.66 ± 0.43 g |

| 18 | 4 | 260 | 25.61 ± 0.4 d | 10.92 ± 0.17 c | 36.53 ± 0.57 d | 62.26 ± 0.79 i | 38.64 ± 0.49 e |

| Effect 1 | b* 2 | Standard Error of b* | b 3 | Standard Error of b | t | p-Value |

|---|---|---|---|---|---|---|

| Intercept | 21.18 | 1.40 | 15.12 | 0.000 | ||

| pH | −0.28 | 0.04 | −2.66 | 0.39 | −6.76 | 0.000 |

| Modification time (s) | 0.88 | 0.04 | 0.08 | 0.004 | 21.37 | 0.000 |

| Effect 1 | b* 2 | Standard Error of b* | b 3 | Standard Error of b | t | p-Value |

|---|---|---|---|---|---|---|

| Intercept | 22.58 | 1.01 | 22.35 | 0.000 | ||

| pH | −0.29 | 0.02 | −3.78 | 0.28 | −13.34 | 0.000 |

| Modification time (s) | 0.93 | 0.02 | 0.11 | 0.002 | 42.20 | 0.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.; Leśnierowski, G. Microwave Modification as an Excellent Way to Produce Unique Lysozyme with Potential for Food and Human Health. Foods 2021, 10, 1319. https://doi.org/10.3390/foods10061319

Yang T, Leśnierowski G. Microwave Modification as an Excellent Way to Produce Unique Lysozyme with Potential for Food and Human Health. Foods. 2021; 10(6):1319. https://doi.org/10.3390/foods10061319

Chicago/Turabian StyleYang, Tianyu, and Grzegorz Leśnierowski. 2021. "Microwave Modification as an Excellent Way to Produce Unique Lysozyme with Potential for Food and Human Health" Foods 10, no. 6: 1319. https://doi.org/10.3390/foods10061319

APA StyleYang, T., & Leśnierowski, G. (2021). Microwave Modification as an Excellent Way to Produce Unique Lysozyme with Potential for Food and Human Health. Foods, 10(6), 1319. https://doi.org/10.3390/foods10061319