Biotechnological Processes in Fruit Vinegar Production

Abstract

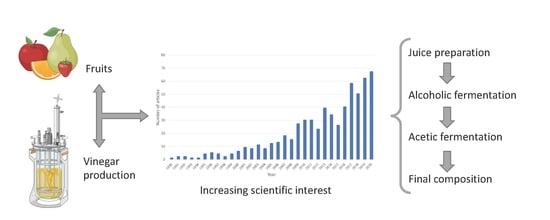

1. Introduction

2. Raw Material

3. Juice Extraction

4. Fermentation Processes

4.1. Alcoholic Fermentation

Microbiological Aspects of Alcoholic Fermentation on Fruit Vinegars

- Spontaneous Alcoholic Fermentation

- Alcoholic Fermentation using a Starter Culture

4.2. Acetic Fermentation

Acetification Systems

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Solieri, L.; Giudici, P. Vinegars of the World; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2009; pp. 1–16. [Google Scholar]

- Food and Agriculture Organization. The State of Food and Agriculture 2019: Moving Fordward on Food Loss and Waste Reduction; Food and Agriculture Organization: Rome, Italy, 2019. [Google Scholar]

- Bastante, M.J.C.; Guerrero, E.D.; Mejías, R.C.; Marín, R.N.; Dodero, M.C.R.; Barroso, C.G. Study of the Polyphenolic Composition and Antioxidant Activity of New Sherry Vinegar-Derived Products by Maceration with Fruits. J. Agric. Food Chem. 2010, 58, 11814–11820. [Google Scholar] [CrossRef]

- Cejudo-Bastante, M.J.; Durán, E.; Castro, R.; Rodríguez-Dodero, M.C.; Natera, R.; García-Barroso, C. Study of the volatile composition and sensory characteristics of new Sherry vinegar-derived products by maceration with fruits. LWT 2013, 50, 469–479. [Google Scholar] [CrossRef]

- Bruna-Maynou, F.J.; Castro, R.; Rodríguez-Dodero, M.C.; Barroso, C.G.; Durán-Guerrero, E. Flavored Sherry vinegar with citric notes: Characterization and effect of ultrasound in the maceration of orange peels. Food Res. Int. 2020, 133, 109165. [Google Scholar] [CrossRef] [PubMed]

- Perestrelo, R.; Silva, C.L.; Silva, P.; Câmara, J.S. Establishment of the Volatile Signature of Wine-Based Aromatic Vinegars Subjected to Maceration. Molecules 2018, 23, 499. [Google Scholar] [CrossRef]

- Vegas, C.; González, Á.; Mateo, E.; Mas, A.; Poblet, M.; Torija, M.J. Evaluation of representativity of the acetic acid bacteria species identified by culture-dependent method during a traditional wine vinegar production. Food Res. Int. 2013, 51, 404–411. [Google Scholar] [CrossRef]

- Larrauri, J.; Rupérez, P.; Bravo, L.; Saura-Calixto, F. High dietary fibre powders from orange and lime peels: Associated polyphenols and antioxidant capacity. Food Res. Int. 1996, 29, 757–762. [Google Scholar] [CrossRef]

- Ubandorivera, J. Mexican lime peel: Comparative study on contents of dietary fibre and associated antioxidant activity. Food Chem. 2005, 89, 57–61. [Google Scholar] [CrossRef]

- Figuerola, F.; Hurtado, M.L.; Estévez, A.M.; Chiffelle, I.; Asenjo, F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Marrufo-Curtido, A.; Cejudo-Bastante, M.J.; Rodríguez-Dodero, M.C.; Natera-Marín, R.; Castro-Mejías, R.; García-Barroso, C.; Durán-Guerrero, E. Novel vinegar-derived product enriched with dietary fiber: Effect on polyphenolic profile, volatile composition and sensory analysis. J. Food Sci. Technol. 2015, 52, 7608–7624. [Google Scholar] [CrossRef] [PubMed]

- Launholt, T.L.; Kristiansen, C.B.; Hjorth, P. Safety and side effects of apple vinegar intake and its effect on metabolic parameters and body weight: A systematic review. Eur. J. Nutr. 2020, 59, 2273–2289. [Google Scholar] [CrossRef]

- Cavdaroglu, C.; Ozen, B. Authentication of Vinegars with Targeted and Non-targeted Methods. Food Rev. Int. 2021, 1–18. [Google Scholar] [CrossRef]

- Laurent, D. Food Traceability and Authenticity Based on Volatile Compound Analysis. In Food Traceability and Authenticity; Apple Academic Press: Palm Bay, FL, USA, 2017; pp. 216–231. [Google Scholar]

- Luo, M.; Zheng, Y.; Xiong, C.; Li, B.; Chen, S.; Bai, W.; Zeng, Y.; Li, Y.; Zhang, X. A Geographical Discrimination of Shanxi Extra Aged Vinegars Using Polyalcohols as the Discriminators. J. AOAC Int. 2013, 96, 1048–1053. [Google Scholar] [CrossRef] [PubMed]

- Cagliani, L.R.; Scano, P.; Consonni, R. NMR-Based Metabolomics: Quality and Authenticity of Plant-Based Foods. In Modern Magnetic Resonance; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1709–1727. [Google Scholar]

- Jamin, E.; Thomas, F. SNIF-NMR Applications in an Economic Context: Fraud Detection in Food Products. In Modern Magnetic Resonance; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1405–1416. [Google Scholar]

- Śliwińska, M.; Wiśniewska, P.; Dymerski, T.; Wardencki, W.; Namieśnik, J. Advances in Electronic Noses and Tongues for Food Authenticity Testing. In Advances in Food Authenticity Testing; Woodhead Publishing: Kidlington, UK, 2016; pp. 201–225. [Google Scholar]

- Sengun, I.Y.; Kilic, G.; Ozturk, B. Screening physicochemical, microbiological and bioactive properties of fruit vinegars produced from various raw materials. Food Sci. Biotechnol. 2020, 29, 401–408. [Google Scholar] [CrossRef] [PubMed]

- Cunha, S.C.; Fernandes, J.O.; Ferreira, I.M. HPLC/UV determination of organic acids in fruit juices and nectars. Eur. Food Res. Technol. 2002, 214, 67–71. [Google Scholar] [CrossRef]

- Sun, J.; Chu, Y.-F.; Wu, X.; Liu, R.H. Antioxidant and Antiproliferative Activities of Common Fruits. J. Agric. Food Chem. 2002, 50, 7449–7454. [Google Scholar] [CrossRef] [PubMed]

- Mandrioli, R.; Mercolini, L.; Raggi, M.A. Recent trends in the analysis of amino acids in fruits and derived foodstuffs. Anal. Bioanal. Chem. 2013, 405, 7941–7956. [Google Scholar] [CrossRef] [PubMed]

- Chapman, G.W.; Horvat, R.J. Determination of nonvolatile acids and sugars from fruits and sweet potato extracts by capillary GLC and GLC/MS. J. Agric. Food Chem. 1989, 37, 947–950. [Google Scholar] [CrossRef]

- El Hadi, M.A.M.; Zhang, F.-J.; Wu, F.-F.; Zhou, C.-H.; Tao, J. Advances in Fruit Aroma Volatile Research. Molecules 2013, 18, 8200. [Google Scholar] [CrossRef]

- Rickman, J.C.; Barrett, D.M.; Bruhn, C.M. Nutritional comparison of fresh, frozen and canned fruits and vegetables. Part 1. Vitamins C and B and phenolic compounds. J. Sci. Food Agric. 2007, 87, 930–944. [Google Scholar] [CrossRef]

- Bakir, S.; Toydemir, G.; Boyacioglu, D.; Beekwilder, J.; Capanoglu, E. Fruit Antioxidants during Vinegar Processing: Changes in Content and in Vitro Bio-Accessibility. Int. J. Mol. Sci. 2016, 17, 1658. [Google Scholar] [CrossRef]

- Coelho, E.; Genisheva, Z.; Oliveira, J.M.; Teixeira, J.A.; Domingues, L. Vinegar production from fruit concentrates: Effect on volatile composition and antioxidant activity. J. Food Sci. Technol. 2017, 54, 4112–4122. [Google Scholar] [CrossRef] [PubMed]

- Cejudo-Bastante, C.; Durán-Guerrero, E.; García-Barroso, C.; Castro-Mejías, R. Comparative study of submerged and surface culture acetification process for orange vinegar. J. Sci. Food Agric. 2018, 98, 1052–1060. [Google Scholar] [CrossRef] [PubMed]

- Mas, A. Technological process for production of persimmon and strawberry vinegars. Int. J. Wine Res. 2010, 2, 55. [Google Scholar] [CrossRef]

- Ubeda, C.; Callejón, R.; Hidalgo, C.; Torija, M.; Troncoso, A.; Morales, M. Employment of different processes for the production of strawberry vinegars: Effects on antioxidant activity, total phenols and monomeric anthocyanins. LWT 2013, 52, 139–145. [Google Scholar] [CrossRef]

- Hidalgo, C.; García, D.; Romero, J.; Mas, A.; Torija, M.J.; Mateo, E. Acetobacter strains isolated during the acetification of blueberry (Vaccinium corymbosum L.) wine. Lett. Appl. Microbiol. 2013, 57, 227–232. [Google Scholar] [CrossRef]

- Fatima, B.; Mishra, A.A. Optimization of Process Parameter for the Production of vinegar from babana peel and coconut water. Int. J. Sci. Eng. Technol. 2015, 3, 817–823. [Google Scholar]

- Di Donna, L.; Bartella, L.; De Vero, L.; Gullo, M.; Giuffrè, A.M.; Zappia, C.; Capocasale, M.; Poiana, M.; D’Urso, S.; Caridi, A. Vinegar production from Citrus bergamia by-products and preservation of bioactive compounds. Eur. Food Res. Technol. 2020, 246, 1981–1990. [Google Scholar] [CrossRef]

- Giuffrè, A.M.; Zappia, C.; Capocasale, M.; Poiana, M.; Sidari, R.; Di Donna, L.; Bartella, L.; Sindona, G.; Corradini, G.; Giudici, P.; et al. Vinegar production to valorise Citrus bergamia by-products. Eur. Food Res. Technol. 2018, 245, 667–675. [Google Scholar] [CrossRef]

- Prisacaru, A.E.; Oroian, M.A. Quality evaluation of vinegar obtained from banana peel. In Proceedings of the International Multidisciplinary Scientific Geo Conference Surveying Geology and Mining Ecology Management (SGEM), Albena, Bulgaria, 30 June–9 July 2018; Volume 18, pp. 259–264. [Google Scholar]

- Karasawa, M.M.G.; Mohan, C. Fruits as Prospective Reserves of bioactive Compounds: A Review. Nat. Prod. Bioprospect. 2018, 8, 335–346. [Google Scholar] [CrossRef]

- Cejudo-Bastante, C.; Castro-Mejías, R.; Natera-Marín, R.; García-Barroso, C.; Durán-Guerrero, E. Chemical and sensory characteristics of orange based vinegar. J. Food Sci. Technol. 2016, 53, 3147–3156. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Y.; Bai, Y.; Fu, C.; Zhou, M.; Gao, B.; Wang, C.; Li, D.; Hu, Y.; Xu, N. Effects of mixed cultures of Saccharomyces cerevisiae and Lactobacillus plantarum in alcoholic fermentation on the physicochemical and sensory properties of citrus vinegar. LWT 2017, 84, 753–763. [Google Scholar] [CrossRef]

- Koh, J.-H.; Kim, Y.; Oh, J.-H. Chemical Characterization of Tomato Juice Fermented with Bifidobacteria. J. Food Sci. 2010, 75, C428–C432. [Google Scholar] [CrossRef] [PubMed]

- Roda, A.; Lucini, L.; Torchio, F.; Dordoni, R.; De Faveri, D.M.; Lambri, M. Metabolite profiling and volatiles of pineapple wine and vinegar obtained from pineapple waste. Food Chem. 2017, 229, 734–742. [Google Scholar] [CrossRef] [PubMed]

- Roda, A.; De Faveri, D.M.; Dordoni, R.; Lambri, M. Vinegar production from pineapple wastes-preliminary saccharification trials. Chem. Eng. Trans. 2014, 37, 607–612. [Google Scholar] [CrossRef]

- Tessaro, D.; Larsen, A.C.; Dallago, R.C.; Damasceno, S.G.; Sene, L.; Coelho, S.R.M. Avaliação das fermentações alcoólica e acética para produção de vinagre a partir de suco de laranja. Acta Sci. Technol. 2010, 32, 201–205. [Google Scholar] [CrossRef][Green Version]

- Dias, D.R.; Silva, M.S.; De Souza, A.C.; Magalhães-Guedes, K.T.; Ribeiro, F.S.D.R.; Schwan, R.F. Vinegar Production from Jabuticaba Fruits (Myrciaria jaboticaba) Using Immobilized Acetic Acid Bacteria. Food Technol. Biotechnol. 2016, 54, 351–359. [Google Scholar] [CrossRef]

- Özen, M.; Özdemir, N.; Filiz, B.E.; Budak, N.H.; Kök-Taş, T. Sour cherry (Prunus cerasus L.) vinegars produced from fresh fruit or juice concentrate: Bioactive compounds, volatile aroma compounds and antioxidant capacities. Food Chem. 2020, 309, 125664. [Google Scholar] [CrossRef]

- Kharchoufi, S.; Gomez, J.; Lasanta, C.; Castro, R.; Sainz, F.; Hamdi, M. Benchmarking laboratory-scale pomegranate vinegar against commercial wine vinegars: Antioxidant activity and chemical composition. J. Sci. Food Agric. 2018, 98, 4749–4758. [Google Scholar] [CrossRef]

- Zhao, H.; Zhou, X.; Huang, Y.; Wuyun, T.; Li, F.; Zhu, G.; Luo, Y. Two Types of New Natural Materials for Fruit Vinegar in Prunus Plants. MATEC Web Conf. 2017, 100, 4006. [Google Scholar] [CrossRef]

- Su, M.-S.; Chien, P.-J. Aroma impact components of rabbiteye blueberry (Vaccinium ashei) vinegars. Food Chem. 2010, 119, 923–928. [Google Scholar] [CrossRef]

- Zou, B.; Wu, J.; Yu, Y.; Xiao, G.; Xu, Y. Evolution of the antioxidant capacity and phenolic contents of persimmon during fermentation. Food Sci. Biotechnol. 2017, 26, 563–571. [Google Scholar] [CrossRef] [PubMed]

- Ubeda, C.; Callejon, R.M.; Troncoso, A.M.; Peña, F.; Morales, M.L.; Moreno-Rojas, J.M. Characterization of odour active compounds in strawberry vinegars. Flavour Fragr. J. 2012, 27, 313–321. [Google Scholar] [CrossRef]

- Lee, J.-H.; Cho, H.-D.; Jeong, J.-H.; Lee, M.-K.; Jeong, Y.-K.; Shim, K.-H.; Seo, K.-I. New vinegar produced by tomato suppresses adipocyte differentiation and fat accumulation in 3T3-L1 cells and obese rat model. Food Chem. 2013, 141, 3241–3249. [Google Scholar] [CrossRef] [PubMed]

- Zou, B.; Xiao, G.; Xu, Y.; Wu, J.; Yu, Y.; Fu, M. Persimmon vinegar polyphenols protect against hydrogen peroxide-induced cellular oxidative stress via Nrf2 signalling pathway. Food Chem. 2018, 255, 23–30. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo, C.; Torija, M.; Mas, A.; Mateo, E. Effect of inoculation on strawberry fermentation and acetification processes using native strains of yeast and acetic acid bacteria. Food Microbiol. 2013, 34, 88–94. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo, C.; Mateo, E.; Mas, A.; Torija, M. Identification of yeast and acetic acid bacteria isolated from the fermentation and acetification of persimmon (Diospyros kaki). Food Microbiol. 2012, 30, 98–104. [Google Scholar] [CrossRef]

- Ubeda, C.; Hidalgo, C.; Torija, M.; Mas, A.; Troncoso, A.; Morales, M. Evaluation of antioxidant activity and total phenols index in persimmon vinegars produced by different processes. LWT 2011, 44, 1591–1596. [Google Scholar] [CrossRef]

- Ubeda, C.; Callejón, R.; Troncoso, A.; Morales, M. Consumer acceptance of new strawberry vinegars by preference mapping. Int. J. Food Prop. 2017, 20, 2760–2771. [Google Scholar] [CrossRef]

- Ubeda, C.; Callejón, R.; Hidalgo, C.; Torija, M.; Mas, A.; Troncoso, A.; Morales, M. Determination of major volatile compounds during the production of fruit vinegars by static headspace gas chromatography—Mass spectrometry method. Food Res. Int. 2011, 44, 259–268. [Google Scholar] [CrossRef]

- Nie, Y.S.; Sun, G.R.; Zhang, X.L. Design of Green Processing Chain for Processing of Ginseng Fruit Vinegar. Adv. Mater. Res. 2014, 933, 988–993. [Google Scholar] [CrossRef]

- Boonsupa, W. Chemical Properties, Antioxidant Activities and Sensory Evaluation of Berry Vinegar. Walailak J. Sci. Technol. 2018, 16, 887–896. [Google Scholar] [CrossRef]

- Sossou, S.K.; Ameyapoh, Y.; Karou, S.D.; De Souza, C. Study of Pineapple Peelings Processing into Vinegar by Biotechnology. Pak. J. Biol. Sci. 2009, 12, 859–865. [Google Scholar] [CrossRef]

- Boonsupa, W.; Chumchuere, S.; Chaovarat, M. Physicochemical properties and antioxidant activity of banana vinegar produced using one-stage and two-stage fermentation. Agric. Nat. Resour. 2019, 53, 298–305. [Google Scholar] [CrossRef]

- Grewal, H.; Tewari, H.; Kalra, K. Vinegar production from substandard fruits. Biol. Wastes 1988, 26, 9–14. [Google Scholar] [CrossRef]

- Hornedo-Ortega, R.; Fernandez, M.A.; Cerezo, A.B.; Garcia-Garcia, I.; Troncoso, A.M.; Garcia-Parrilla, M.C. Influence of Fermentation Process on the Anthocyanin Composition of Wine and Vinegar Elaborated from Strawberry. J. Food Sci. 2017, 82, 364–372. [Google Scholar] [CrossRef] [PubMed]

- Koyama, M.; Ogasawara, Y.; Endou, K.; Akano, H.; Nakajima, T.; Aoyama, T.; Nakamura, K. Fermentation-induced changes in the concentrations of organic acids, amino acids, sugars, and minerals and superoxide dismutase-like activity in tomato vinegar. Int. J. Food Prop. 2016, 20, 888–898. [Google Scholar] [CrossRef]

- Ching, T.K.; Chin, W.H.; Ling, J.W.A.; Lazim, A.; Fazry, S.; Lim, S.J. Chemical Changes and Optimisation of Acetous Fermentation Time and Mother of Vinegar Concentration in the Production of Vinegar-like Fermented Papaya Beverage. Sains Malays. 2018, 47, 2017–2026. [Google Scholar] [CrossRef]

- Fonseca, M.D.S.; Santos, V.A.Q.; Calegari, G.C.; Dekker, R.F.H.; Barbosa-Dekker, A.D.M.; Da Cunha, M.A.A. Blueberry and honey vinegar: Successive batch production, antioxidant potential and antimicrobial ability. Braz. J. Food Technol. 2018, 21. [Google Scholar] [CrossRef]

- Ubeda, C.; Callejón, R.M.; Troncoso, A.M.; Moreno-Rojas, J.M.; Peña, F.; Morales, M.L. A comparative study on aromatic profiles of strawberry vinegars obtained using different conditions in the production process. Food Chem. 2016, 192, 1051–1059. [Google Scholar] [CrossRef] [PubMed]

- Su, M.-S.; Silva, J.L. Antioxidant activity, anthocyanins, and phenolics of rabbiteye blueberry (Vaccinium ashei) by-products as affected by fermentation. Food Chem. 2006, 97, 447–451. [Google Scholar] [CrossRef]

- Tsen, J.; Lin, Y.; Huang, H.; King, V. Studies on the fermentation of tomato juice by using k-carrageenan immobilized lactobacillus acidophilus. J. Food Process. Preserv. 2008, 32, 178–189. [Google Scholar] [CrossRef]

- Anthon, G.E.; Sekine, Y.; Watanabe, N.; Barrett, D.M. Thermal Inactivation of Pectin Methylesterase, Polygalacturonase, and Peroxidase in Tomato Juice. J. Agric. Food Chem. 2002, 50, 6153–6159. [Google Scholar] [CrossRef] [PubMed]

- Seybold, C.; Fröhlich, K.; Bitsch, R.; Otto, A.K.; Böhm, V. Changes in Contents of Carotenoids and Vitamin E during Tomato Processing. J. Agric. Food Chem. 2004, 52, 7005–7010. [Google Scholar] [CrossRef] [PubMed]

- Ordoudi, S.A.; Mantzouridou, F.; Daftsiou, E.; Malo, C.; Hatzidimitriou, E.; Nenadis, N.; Tsimidou, M.Z. Pomegranate juice functional constituents after alcoholic and acetic acid fermentation. J. Funct. Foods 2014, 8, 161–168. [Google Scholar] [CrossRef]

- Ameyapoh, Y.; Leveau, J.-Y.; Karou, S.D.; Bouix, M.; Sossou, S.K.; De Souza, C. Vinegar Production from Togolese Local Variety Mangovi of Mango Mangifera indica Linn. (Anacardiaceae). Pak. J. Biol. Sci. 2010, 13, 132–137. [Google Scholar] [CrossRef] [PubMed]

- Song, N.; Cho, S.; Baik, S. Microbial community, and biochemical and physiological properties of Korean traditional black raspberry (Robus coreanus Miquel) vinegar. J. Sci. Food Agric. 2016, 96, 3723–3730. [Google Scholar] [CrossRef]

- Song, N.-E.; Jeong, D.-Y.; Baik, S.-H. Application of indigenous Saccharomyces cerevisiae to improve the black raspberry (Rubus coreanus Miquel) vinegar fermentation process and its microbiological and physicochemical analysis. Food Sci. Biotechnol. 2019, 28, 481–489. [Google Scholar] [CrossRef]

- Kawa-Rygielska, J.; Adamenko, K.; Kucharska, A.Z.; Piórecki, N. Bioactive Compounds in Cornelian Cherry Vinegars. Molecules 2018, 23, 379. [Google Scholar] [CrossRef]

- Maal, B.K.; Shafiei, R.; Kabiri, N.; Maal, K.B.; Shafiei, R.; Kabiri, N. Production of apricot vinegar using an Isolated acetobacter strain from Iranian apricot. World Acad. Sci. Eng. Technol. 2010, 4, 810–813. [Google Scholar]

- Roda, A.; De Faveri, D.M.; Giacosa, S.; Dordoni, R.; Lambri, M. Effect of pre-treatments on the saccharification of pineapple waste as a potential source for vinegar production. J. Clean. Prod. 2016, 112, 4477–4484. [Google Scholar] [CrossRef]

- Mohamad, N.E.; Yeap, S.K.; Lim, K.L.; Yusof, H.M.; Beh, B.K.; Tan, S.W.; Ho, W.Y.; Sharifuddin, S.A.; Jamaluddin, A.; Long, K.; et al. Antioxidant effects of pineapple vinegar in reversing of paracetamol-induced liver damage in mice. Chin. Med. 2015, 10, 1–10. [Google Scholar] [CrossRef]

- Sharma, R.; Garg, P.; Kumar, P.; Bhatia, S.; Kulshrestha, S. Microbial Fermentation and Its Role in Quality Improvement of Fermented Foods. Fermentation 2020, 6, 106. [Google Scholar] [CrossRef]

- Leonés, A.; Durán-Guerrero, E.; Carbú, M.; Cantoral, J.M.; Barroso, C.G.; Castro, R. Development of vinegar obtained from lemon juice: Optimization and chemical characterization of the process. LWT 2019, 100, 314–321. [Google Scholar] [CrossRef]

- Yan, H.G.; Zhan, W.H.; Chen, J.H.; Ding, Z.E. Optimization of the alcoholic fermentation of blueberry juice by AS 2.316 Saccharomyces cerevisiae wine yeast. Afr. J. Biotechnol. 2012, 11, 3623–3630. [Google Scholar]

- López, N.E.L.; Leiva, V.U.; Carrasco, C.A. Development of a distilled-like alcoholic drink from blueberry (Vaccinium corymbosum) cv. Brigitta, and sensory analysis. Acta Agron. 2015, 65, 1–8. [Google Scholar] [CrossRef]

- Zohri, A.A.; Ramadan, A.M.; El-Tabakh, M.M.; Al-Tantawy, K. Key factors affecting the efficiency of ethanol fermentation using beet molasses. Egypt. Sugar J. 2015, 8, 27–52. [Google Scholar]

- Torija, M.J.; Beltran, G.; Novo, M.; Poblet, M.; Guillamón, J.M.; Mas, A.; Rozès, N. Effects of fermentation temperature and Saccharomyces species on the cell fatty acid composition and presence of volatile compounds in wine. Int. J. Food Microbiol. 2003, 85, 127–136. [Google Scholar] [CrossRef]

- Morimura, S.; Ling, Z.Y.; Kida, K. Ethanol production by repeated-batch fermentation at high temperature in a molasses medium containing a high concentration of total sugar by a thermotolerant flocculating yeast with improved salt-tolerance. J. Ferment. Bioeng. 1997, 83, 271–274. [Google Scholar] [CrossRef]

- Vamvakas, S.-S.; Kapolos, J. Factors affecting yeast ethanol tolerance and fermentation efficiency. World J. Microbiol. Biotechnol. 2020, 36, 1–8. [Google Scholar] [CrossRef]

- Silva, M.E.; Neto, A.B.T.; Silva, W.B.; Silva, F.L.H.; Swarnakar, R. Cashew wine vinegar production: Alcoholic and acetic fermentation. Braz. J. Chem. Eng. 2007, 24, 163–169. [Google Scholar] [CrossRef]

- Siqueira, P.F.; Karp, S.G.; Carvalho, J.C.; Sturm, W.; Rodríguez-León, J.A.; Tholozan, J.-L.; Singhania, R.R.; Pandey, A.; Soccol, C.R. Production of bio-ethanol from soybean molasses by Saccharomyces cerevisiae at laboratory, pilot and industrial scales. Bioresour. Technol. 2008, 99, 8156–8163. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Dubourdieu, D.; Donèche, B.; Lonvaud, A. The Microbiology of Wine and Vinifications. In Handbook of Enology; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Mamlouk, D.; Gullo, M. Acetic Acid Bacteria: Physiology and Carbon Sources Oxidation. Indian J. Microbiol. 2013, 53, 377–384. [Google Scholar] [CrossRef] [PubMed]

- Lea, A.G. Cider Vinegar. In Processed Apple Products; Van Nostrand Reinhold: New York, NY, USA, 1989. [Google Scholar]

- Tanaka, C.A.; Ruzon, F.I.; Caldeirão Rodrigues Miranda, L.; Galvan, D.; Spinosa, W.A.; Castro-Gómez Hernan, R.J. Modeling and Kinetics of Bioconversion and Chemical Properties (Wine and Vinegar) from Banana Pulp By-Products. Preprints 2016. [Google Scholar] [CrossRef][Green Version]

- Coelho, E.; Vilanova, M.; Genisheva, Z.; Oliveira, J.M.; Teixeira, J.A.; Domingues, L. Systematic approach for the development of fruit wines from industrially processed fruit concentrates, including optimization of fermentation parameters, chemical characterization and sensory evaluation. LWT 2015, 62, 1043–1052. [Google Scholar] [CrossRef]

- Chanprasartsuk, O.-O.; Prakitchaiwattana, C.; Sanguandeekul, R.; Fleet, G.H. Autochthonous yeasts associated with mature pineapple fruits, freshly crushed juice and their ferments; and the chemical changes during natural fermentation. Bioresour. Technol. 2010, 101, 7500–7509. [Google Scholar] [CrossRef] [PubMed]

- Duarte, W.F.; Dias, D.R.; Pereira, G.V.D.M.; Gervásio, I.M.; Schwan, R.F. Indigenous and inoculated yeast fermentation of gabiroba (Campomanesia pubescens) pulp for fruit wine production. J. Ind. Microbiol. Biotechnol. 2009, 36, 557–569. [Google Scholar] [CrossRef] [PubMed]

- Morrissey, W.; Davenport, B.; Querol, A.; Dobson, A. The role of indigenous yeasts in traditional Irish cider fermentations. J. Appl. Microbiol. 2004, 97, 647–655. [Google Scholar] [CrossRef]

- Cavaco, T.; Longuinho, C.; Quintas, C.; De Carvalho, I.S. Chemical and Microbial Changes during the Natural Fermentation of Strawberry Tree (Arbutus unedo L.) Fruits. J. Food Biochem. 2007, 31, 715–725. [Google Scholar] [CrossRef]

- Beltran, G.; Torija, M.J.; Novo, M.; Ferrer, N.; Poblet, M.; Guillamón, J.M.; Rozès, N.; Mas, A. Analysis of yeast populations during alcoholic fermentation: A six year follow-up study. Syst. Appl. Microbiol. 2002, 25, 287–293. [Google Scholar] [CrossRef]

- Ivit, N.N.; Longo, R.; Kemp, B. The Effect of Non-Saccharomyces and Saccharomyces Non-Cerevisiae Yeasts on Ethanol and Glycerol Levels in Wine. Fermentation 2020, 6, 77. [Google Scholar] [CrossRef]

- Benito, S.; Calderón, F. The Influence of Non-Saccharomyces Species on Wine Fermentation Quality Parameters. Fermentation 2019, 5, 54. [Google Scholar] [CrossRef]

- Giudici, P.; Gullo, M.; Solieri, L. Traditional Balsamic Vinegar. In Vinegars of the World; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2009; pp. 157–177. [Google Scholar]

- Štornik, A.; Skok, B.; Trček, J. Comparison of Cultivable Acetic Acid Bacterial Microbiota in Organic and Conventional Apple Cider Vinegar. Food Technol. Biotechnol. 2016, 54, 113–119. [Google Scholar] [CrossRef]

- Li, S.; Li, P.; Feng, F.; Luo, L.-X. Microbial diversity and their roles in the vinegar fermentation process. Appl. Microbiol. Biotechnol. 2015, 99, 4997–5024. [Google Scholar] [CrossRef] [PubMed]

- Degre, R. Selection and commercial cultivation of wine yeast and bacteria. In Wine Microbiology and Biotechnology; Fleet, G., Ed.; Taylor & Francis: London, UK, 1993; pp. 421–448. [Google Scholar]

- Mohamad, N.E.; Yeap, S.K.; Beh, B.K.; Romli, M.F.; Yusof, H.M.; Kristeen-Teo, Y.W.; Sharifuddin, S.A.; Long, K.; Alitheen, N.B. Comparison of in vivo toxicity, antioxidant and immunomodulatory activities of coconut, nipah and pineapple juice vinegars. J. Sci. Food Agric. 2018, 98, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Budak, N.H. Bioactive components of Prunus avium L. black gold (red cherry) and Prunus avium L. stark gold (white cherry) juices, wines and vinegars. J. Food Sci. Technol. 2016, 54, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Seo, K.-I.; Lee, J.; Choi, R.-Y.; Lee, H.-I.; Lee, J.-H.; Jeong, Y.-K.; Kim, M.-J.; Lee, M.-K. Anti-obesity and anti-insulin resistance effects of tomato vinegar beverage in diet-induced obese mice. Food Funct. 2014, 5, 1579. [Google Scholar] [CrossRef]

- Moon, Y.-J.; Choi, D.-S.; Oh, S.-H.; Song, Y.-S.; Cha, Y.-S. Effects of persimmon-vinegar on lipid and carnitine profiles in mice. Food Sci. Biotechnol. 2010, 19, 343–348. [Google Scholar] [CrossRef]

- Xiang, J.L.; Du, L.; Liu, Z.J.; Li, X.L.; Luo, L.; Zhu, W.X. Changes in biochemical parameters and organic acid content during liquid fermentation of peach vinegar. Mod. Food Sci. Technol. 2015, 31, 193–198. [Google Scholar] [CrossRef]

- Huh, W.-K.; Lee, B.-H.; Kim, S.-T.; Kim, Y.-R.; Rhie, G.-E.; Baek, Y.-W.; Hwang, C.-S.; Lee, J.-S.; Kang, S.-O. D-Erythroascorbic acid is an important antioxidant molecule in Saccharomyces cerevisiae. Mol. Microbiol. 1998, 30, 895–903. [Google Scholar] [CrossRef]

- Lorenzini, M.; Simonato, B.; Slaghenaufi, D.; Ugliano, M.; Zapparoli, G. Assessment of yeasts for apple juice fermentation and production of cider volatile compounds. LWT 2019, 99, 224–230. [Google Scholar] [CrossRef]

- Duarte, W.F.; Dias, D.R.; Oliveira, J.M.; Vilanova, M.; Teixeira, J.A.; E Silva, J.B.A.; Schwan, R.F. Raspberry (Rubus idaeus L.) wine: Yeast selection, sensory evaluation and instrumental analysis of volatile and other compounds. Food Res. Int. 2010, 43, 2303–2314. [Google Scholar] [CrossRef]

- De Backer, L.; Devleminck, S.; Willaert, R.; Baron, G. Reaction and diffusion in a gel membrane reactor containing immobilized cells. Biotechnol. Bioeng. 1992, 40, 322–328. [Google Scholar] [CrossRef] [PubMed]

- Nath, S.; Chand, S. Mass Transfer and Biochemical Reaction in Immobilized Cell Packed Bed Reactors: Correlation of Experiment with Theory. J. Chem. Technol. Biotechnol. 1996, 66, 286–292. [Google Scholar] [CrossRef]

- Nie, Z.; Zheng, Y.; Wang, M.; Han, Y.; Wang, Y.; Luo, J.; Niu, D. Exploring microbial succession and diversity during solid-state fermentation of Tianjin duliu mature vinegar. Bioresour. Technol. 2013, 148, 325–333. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.-W. Advances in Vinegar Production, 1st ed.; Bekatorou, A., Ed.; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9781351208475. [Google Scholar]

- Solieri, L.; Giudici, P. Acetic Acid Bacteria Taxonomy from Early Descriptions to Molecular Techniques. In Vinegars of the World; Springer: Berlin/Heidelberg, Germany, 2009; pp. 41–59. [Google Scholar]

- Garrido-Vidal, D.; Pizarro, C.; González-Sáiz, J.M. Study of Process Variables in Industrial Acetic Fermentation by a Continuous Pilot Fermentor and Response Surfaces. Biotechnol. Prog. 2003, 19, 1468–1479. [Google Scholar] [CrossRef] [PubMed]

- Davies, C.V.; Gerard, L.M.; Ferreyra, M.M.; Schvab, M.D.C.; Solda, C.A. Bioactive compounds and antioxidant activity analysis during orange vinegar production. Food Sci. Technol. 2017, 37, 449–455. [Google Scholar] [CrossRef]

- Maal, K.B.; Shafiei, R. A Thermotolerant Acetobacter Strain Isolated from Iranian Peach Suitable for Industrial Microbiology. Asian J. Biol. Sci. 2011, 4, 244–251. [Google Scholar] [CrossRef][Green Version]

- Ndoye, B.; Lebecque, S.; Dubois-Dauphin, R.; Tounkara, L.; Guiro, A.-T.; Kere, C.; Diawara, B.; Thonart, P. Thermoresistant properties of acetic acids bacteria isolated from tropical products of Sub-Saharan Africa and destined to industrial vinegar. Enzym. Microb. Technol. 2006, 39, 916–923. [Google Scholar] [CrossRef]

- García Garibay, M.; Quinteros Ramirez, R.; López Munguía, A. Biotecnología Alimentaria; Editorial LIMUSA | (Grupo Noriega Editores): México, MX, USA, 2007. [Google Scholar]

- Fregapane, G.; Rubio-Fernández, H.; Salvador, M. Influence of fermentation temperature on semi-continuous acetification for wine vinegar production. Eur. Food Res. Technol. 2001, 213, 62–66. [Google Scholar] [CrossRef]

- Kersters, K.; Lisdiyanti, P.; Komagata, K.; Swings, J. The Family Acetobacteraceae: The Genera Acetobacter, Acidomonas, Asaia, Gluconacetobacter, Gluconobacter, and Kozakia. Prokaryotes 2006, 5, 163–200. [Google Scholar]

- Trček, J.; Barja, F. Updates on quick identification of acetic acid bacteria with a focus on the 16S–23S rRNA gene internal transcribed spacer and the analysis of cell proteins by MALDI-TOF mass spectrometry. Int. J. Food Microbiol. 2015, 196, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Saeki, A. Application of gluconobacter oxydans subsp. sphaericus IFO 12467 to vinegar production. J. Ferment. Bioeng. 1993, 75, 232–234. [Google Scholar] [CrossRef]

- Pinto, L.; Malfeito-Ferreira, M.; Quintieri, L.; Silva, A.; Baruzzi, F. Growth and metabolite production of a grape sour rot yeast-bacterium consortium on different carbon sources. Int. J. Food Microbiol. 2019, 296, 65–74. [Google Scholar] [CrossRef]

- Prieto, C.; Saenz, C.; Silva, P.; Loyola, E. Balsamic Type Vinegar from Colored Ecotypes of Cactus Pear (Opuntia Ficus-Indica). Acta Hortic. 2009, 811, 123–126. [Google Scholar] [CrossRef]

- Molelekoa, T.J.; Regnier, T.; Da Silva, L.S.; Augustyn, W.A. Potential of marula (Sclerocarya birrea subsp. caffra) waste for the production of vinegar through surface and submerged fermentation. S. Afr. J. Sci. 2018, 114, 1–6. [Google Scholar] [CrossRef]

- Conner, H.A.; Allgeier, R.J. Vinegar: Its History and Development. Adv. Virus Res. 1976, 20, 81–133. [Google Scholar] [CrossRef]

- García-García, I.; Santos-Dueñas, C.; Jiménez-Ot, J.; Jiménez Hornero, J. Vinegar Engineering. In Vinegars of the World; Springer: Berlin/Heidelberg, Germany, 2009; pp. 97–120. [Google Scholar]

- Durán-Guerrero, E. Volatile Compounds, Polyphenols and Sensory Quality in the Production of Tomato Vinegar. J. Food Nutr. Res. 2017, 5, 391–398. [Google Scholar]

- Tesfaye, W.; Garcia-Parrilla, M.C.; Troncoso, A.M. Set Up and Optimization of a Laboratory Scale Fermentor for the Production of Wine Vinegar. J. Inst. Brew. 2000, 106, 215–220. [Google Scholar] [CrossRef]

- Cañete-Rodríguez, A.M.; Santos-Dueñas, I.M.; Jiménez-Hornero, J.E.; Ehrenreich, A.; Liebl, W.; García-García, I. Gluconic acid: Properties, production methods and applications—An excellent opportunity for agro-industrial by-products and waste bio-valorization. Process. Biochem. 2016, 51, 1891–1903. [Google Scholar] [CrossRef]

- Sainz, F.; Navarro, D.; Mateo, E.; Torija, M.; Mas, A. Comparison of d-gluconic acid production in selected strains of acetic acid bacteria. Int. J. Food Microbiol. 2016, 222, 40–47. [Google Scholar] [CrossRef] [PubMed]

- Raspor, P.; Goranovič, D. Biotechnological Applications of Acetic Acid Bacteria. Crit. Rev. Biotechnol. 2008, 28, 101–124. [Google Scholar] [CrossRef] [PubMed]

- De Ory, I.; Romero, L.E.; Cantero, D. Maximum yield acetic acid fermenter. Bioprocess Biosyst. Eng. 1999, 21, 187–190. [Google Scholar] [CrossRef]

- De Ory, I.; Romero, L.E.; Cantero, D. Operation in semi-continuous with a closed pilot plant scale acetifier for vinegar production. J. Food Eng. 2004, 63, 39–45. [Google Scholar] [CrossRef]

- Turhan, E.Ü.; Canbas, A. Chemical and Sensory Properties of Vinegar from Dimrit Grape by Submerged and Surface Method. GIDA J. Food 2016, 1–7. [Google Scholar] [CrossRef]

| Common Name | Botanic Name | °Brix |

|---|---|---|

| Apple | Malus domestica | 11.2 |

| Apricot | Prunus armeniaca | 11.2 |

| Banana | Musa x paradisiaca | 21.0 |

| Blackcurrant | Ribes nigrum | 11.0 |

| Grape | Vitis vinifera | 15.9 |

| Grapefruit | Citrus x paradisi | 10.0 |

| Guava | Psidium guajava | 8.5 |

| Lemon | Citrus limon | 8.0 |

| Mango | Mangifera indica | 13.5 |

| Orange | Citrus sinensis | 11.2 |

| Passion Fruit | Passiflora edulis | 12.0 |

| Peach | Prunus persica | 10.0 |

| Pear | Pyrus communis | 11.9 |

| Pineapple | Ananas comosus | 12.8 |

| Raspberry | Rubus idaeus | 7.0 |

| Cherry | Prunus cerasus | 13.5 |

| Strawberry | Fragaria x ananassa | 7.0 |

| Tomato | Lycopersicon esculentum | 5.0 |

| Tangerine | Citrus reticulata | 11.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luzón-Quintana, L.M.; Castro, R.; Durán-Guerrero, E. Biotechnological Processes in Fruit Vinegar Production. Foods 2021, 10, 945. https://doi.org/10.3390/foods10050945

Luzón-Quintana LM, Castro R, Durán-Guerrero E. Biotechnological Processes in Fruit Vinegar Production. Foods. 2021; 10(5):945. https://doi.org/10.3390/foods10050945

Chicago/Turabian StyleLuzón-Quintana, Luz María, Remedios Castro, and Enrique Durán-Guerrero. 2021. "Biotechnological Processes in Fruit Vinegar Production" Foods 10, no. 5: 945. https://doi.org/10.3390/foods10050945

APA StyleLuzón-Quintana, L. M., Castro, R., & Durán-Guerrero, E. (2021). Biotechnological Processes in Fruit Vinegar Production. Foods, 10(5), 945. https://doi.org/10.3390/foods10050945