Drying Treatments Change the Composition of Aromatic Compounds from Fresh to Dried Centennial Seedless Grapes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Chemicals

2.3. Sample Pre-Treatment

2.4. Preparation of Free- and Glycosidically Bound-Form Volatiles

2.5. Solid-Phase Microextraction Condition (SPME)

2.6. GC/MS Analysis

2.7. Quantification of VOCs

2.8. OAVs Calculation

2.9. Statistical Procedures

3. Results and Discussion

3.1. Free-Form Compounds

3.1.1. Aldehydes

3.1.2. Alcohols

3.1.3. Ester

3.1.4. Acids

3.1.5. Terpenoids

3.1.6. Furans and Pyrazines

3.1.7. Ketones, Benzenes and Phenol

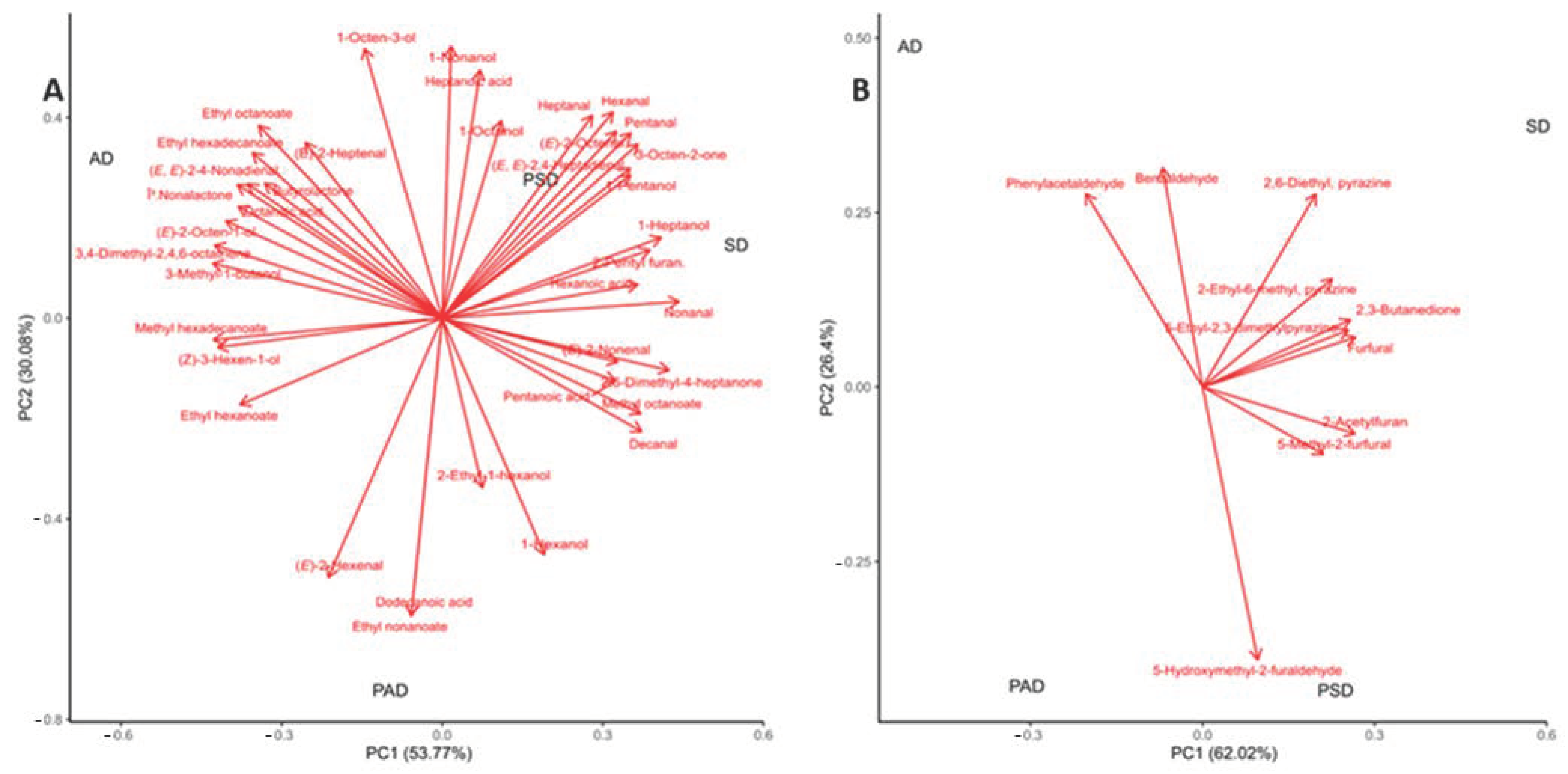

3.2. Effect of Drying Method on UFAO- and MR-VOCs

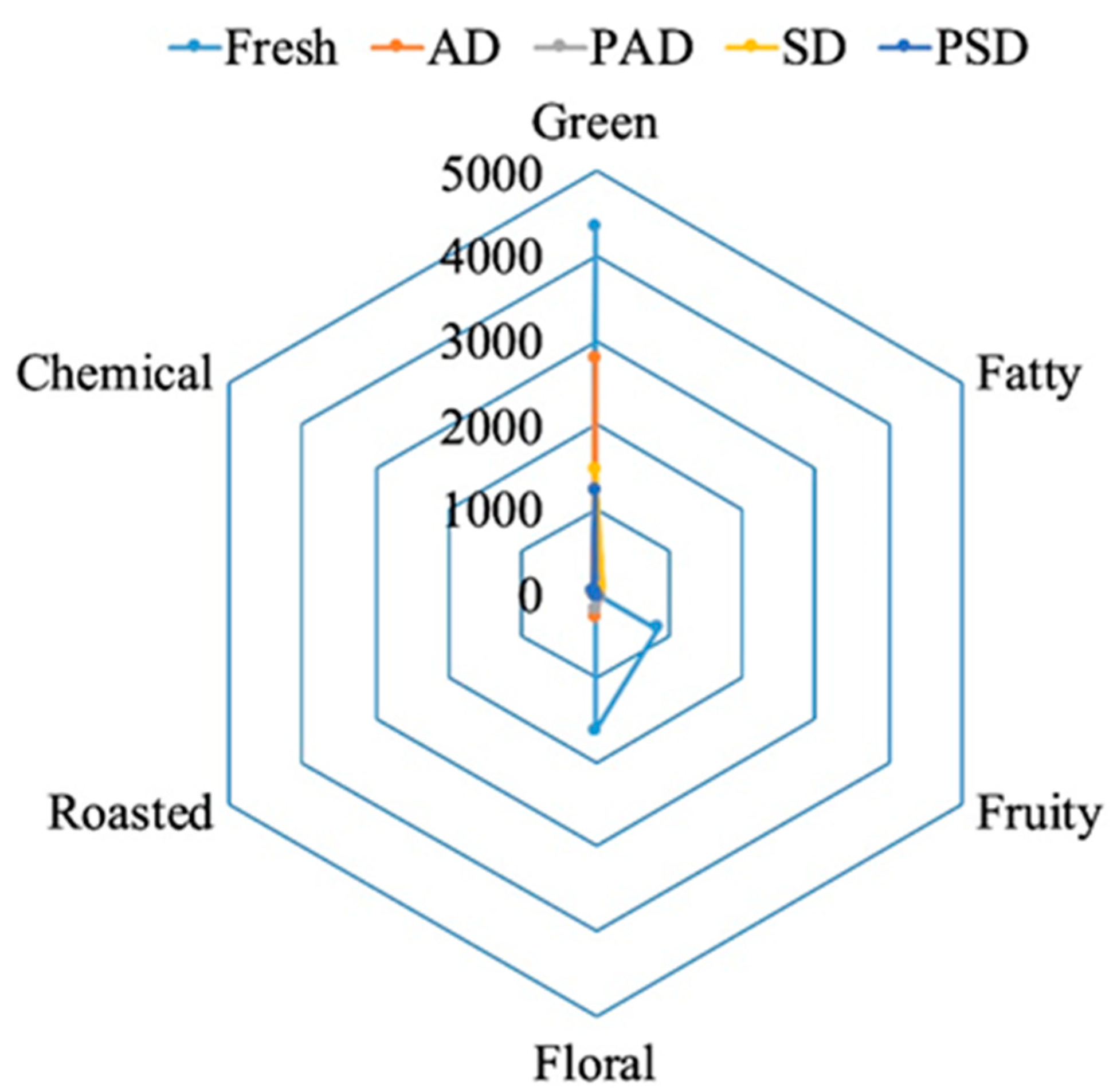

3.3. Aroma Profile

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Inouye, A. China—Peoples Republic of Raisin Annual; USDA Foreign Agricultural Services: Turpan, China, 2017.

- Wang, D.; Cai, J.; Zhu, B.Q.; Wu, G.F.; Duan, C.Q.; Chen, G.; Shi, Y. Study of free and glycosidically bound volatile compounds in air-dried raisins from three seedless grape varieties using HS-SPME with GC-MS. Food Chem. 2015, 177, 346–353. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Duan, C.-Q.; Shi, Y.; Zhu, B.-Q.; Javed, H.U.; Wang, J. Free and glycosidically bound volatile compounds in sun-dried raisins made from different fragrance intensities grape varieties using a validated HS-SPME with GC–MS method. Food Chem. 2017, 228, 125–135. [Google Scholar] [CrossRef] [PubMed]

- Araya-Farias, M.; Ratti, C. Dehydration of Foods. In Advances in Food Dehydration; Ratti, C., Ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: New York, NY, USA, 2008; pp. 1–36. ISBN 9781420052527. [Google Scholar]

- Javed, H.U.; Wang, D.; Wu, G.; Muhammad, Q.; Duana, C.-Q.; Shi, Y. Post-storage changes of volatile compounds in air- and sun-dried raisins with different packaging materials using HS-SPME with GC/MS. Food Res. Int. 2019, 119, 23–33. [Google Scholar] [CrossRef]

- Bingol, G.; Roberts, J.S.; Balaban, M.O.; Devres, Y.O.; Bingol, G.; Roberts, J.S.; Balaban, M.O.; Devres, Y.O. Effect of dipping temperature and dipping time on drying rate and color change of grapes. Dry. Technol. 2012, 30, 597–606. [Google Scholar] [CrossRef]

- Deng, L.; Mujumdar, A.S.; Zhang, Q.; Yang, X.; Wang, J.; Gao, Z.; Xiao, H. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes—A comprehensive review. Crit. Rev. Food Sci. Nutr. 2017, 59, 1408–1432. [Google Scholar] [CrossRef] [PubMed]

- Esmaiilia, M.; Sotudeh-Gharebaghb, R.; Mousavi, M.A.; Ghader, R. Influence of dipping on thin-layer drying characteristics of seedless grapes. Biosyst. Eng. 2007, 98, 411–421. [Google Scholar] [CrossRef]

- Doymaz, I.; Pala, M. The effects of dipping pretreatments on air-drying rates of the seedless grapes. J. Food Eng. 2002, 52, 413–417. [Google Scholar] [CrossRef]

- Mahmutoglu, T. Sun/solar drying of differently treated grapes and storage stability of dried grapes. J. Food Eng. 1996, 29, 289–300. [Google Scholar] [CrossRef]

- Di Matteo, M.; Cinquanta, L.; Galiero, G.; Crescitelli, S. Effect of a novel physical pretreatment process on the drying kinetics of seedless grapes. J. Food Eng. 2000, 46, 83–89. [Google Scholar] [CrossRef]

- Adiletta, G.; Senadeera, W.; Liguori, L.; Crescitelli, A. The influence of abrasive pretreatment on hot air drying of grape. Food Nutr. Sci. 2015, 6, 355–364. [Google Scholar] [CrossRef] [Green Version]

- Javed, H.U.; Wang, D.; Shi, Y.; Wu, G.F.; Xie, H.; Pan, Y.Q.; Duan, C.Q. Changes of free-form volatile compounds in pre-treated raisins with different packaging materials during storage. Food Res. Int. 2018, 107, 649–659. [Google Scholar] [CrossRef]

- Schwab, W.; Davidovich-Rikanati, R.; Lewinsohn, E. Biosynthesis of plant-derived flavor compounds. Plant J. 2008, 54, 712–732. [Google Scholar] [CrossRef] [PubMed]

- Kaack, K.; Christensen, L.P. Phenolic acids and flavonoids in tea processed from flowers of black elder (Sambucus nigra L.) stored in different packing materials. Eur. J. Hortic. Sci. 2010, 75, 214–220. [Google Scholar] [CrossRef]

- Ho, C.-T.; Zheng, X.; Li, S. Tea aroma formation. Food Sci. Hum. Wellness 2015, 4, 9–27. [Google Scholar] [CrossRef] [Green Version]

- Vilanova, M.; Genisheva, Z.; Bescansa, L.; Masa, A.; Oliveira, J.M. Changes in free and bound fractions of aroma compounds of four Vitis vinifera cultivars at the last ripening stages. Phytochemistry 2012, 74, 196–205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghaste, M.; Narduzzi, L.; Carlin, S.; Vrhovsek, U.; Shulaev, V.; Mattivi, F. Chemical composition of volatile aroma metabolites and their glycosylated precursors that can uniquely differentiate individual grape cultivars. Food Chem. 2015, 188, 309–319. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Duan, S.; Zhao, L.; Gao, Z.; Luo, M.; Song, S.; Xu, W.; Zhang, C.; Ma, C.; Wang, S. Aroma characterization based on aromatic series analysis in table grapes. Sci. Rep. 2016, 6, 1–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramshaw, E.H.; Hardy, P.J. Volatile compounds in dried grapes. J. Sci. Food Agric. 1969, 20, 619–621. [Google Scholar] [CrossRef]

- Joulain, D.; Fourniol, J.-P. “Craisins” versus raisins-The flavor standpoint. Flavour Sci. Technol. 1990, 45–48. [Google Scholar]

- Buttery, R.G.; Seifert, R.M.; Ling, L.C.; Soderstrom, E.J.; Yerington, A.P. Raisin and dried fig volatile components: Possible insect attractants. In Proceedings of the Quality of Selected Fruits and Vegetables of North America; Teranishi, R., Barrera-Benitez, H., Eds.; American Chemical Society: Washington, DC, USA, 1981; Volume 170, pp. 29–41. [Google Scholar]

- Guine, R.P.F.; Almeida, I.C.; Correia, A.C.; Goncalves, F.J. Evaluation of the physical, chemical and sensory properties of raisins produced from grapes of the cultivar Crimson. Food Meas. 2015, 9, 337–346. [Google Scholar] [CrossRef]

- Möller, T.E.; Nyberg, M. Ochratoxin A in raisins and currants: Basic extraction procedure used in two small marketing surveys of the occurrence and control of the heterogeneity of the toxins in samples. Food Addit. Contam. 2003, 20, 1072–1076. [Google Scholar] [CrossRef] [PubMed]

- Wen, Y.Q.; He, F.; Zhu, B.Q.; Lan, Y.; Pan, Q.H.; Li, C.Y.; Reeves, M.J.; Wang, J. Free and glycosidically bound aroma compounds in cherry (Prunus avium L.). Food Chem. 2014, 152, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Ubeda, C.; San-Juan, F.; Concejero, B.; Callejón, R.M.; Troncoso, A.M.; Morales, M.L.; Ferreira, V.; Hernández, P. Glycosidically Bound Aroma Compounds and Impact Odorants of. J. Agric. Food Chem. 2012, 60, 6095–6102. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Pan, Q.; Qu, W.; Duan, C. Comparison of volatile profiles of nine litchi (Litchi chinensis Sonn.) cultivars from Southern China. J. Agric. Food Chem. 2009, 57, 9676–9681. [Google Scholar] [CrossRef] [PubMed]

- Leffingwell & Associates Odour Thresholds Tables. Available online: http://www.leffingwell.com/odorthre.htm (accessed on 1 September 2016).

- Noguerol-Pato, R.; Gonzlez-Barreiro, C.; Cancho-Grande, B.; Santiago, J.L.; Martnez, M.C.; Simal-Gndara, J. Aroma potential of Brancellao grapes from different cluster positions. Food Chem. 2012, 132, 112–124. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meeting, A.C.S.; Ho, C.-T.; Hartman, T.G. Lipids in Food Flavors; American Chemical Society: Washington, DC, USA, 1994. [Google Scholar]

- Whitfield, F.B.; Mottram, D.S. Volatiles from interactions of Maillard reactions and lipids. Crit. Rev. Food Sci. Nutr. 1992, 31, 1–58. [Google Scholar] [CrossRef] [PubMed]

- Horvat, R.I.; Mcfadden, W.H.; Ng, H.; Lane, W.G.; Lee, A.; Lundin, R.E.; Scherer, R. Identification of Some Acids From Autoxidation of Methyl Linoleate. J. Am. Oil Chem. Soc. 1968, 46, 94–96. [Google Scholar] [CrossRef]

- Macleod, A.J.; de Troconis, G. Volatile flavour components of guava. Phytochemistry 1982, 21, 1339–1342. [Google Scholar] [CrossRef]

- Nishimura, O. Identification of the Characteristic Odorants in Fresh Rhizomes of Ginger ( Zingiber oficinale Roscoe) Using Aroma Extract Dilution Analysis and Modified Multidimensional Gas Chromatography-Mass Spectroscopy. J. Agric. Food Chem. 1995, 43, 2941–2945. [Google Scholar] [CrossRef]

- Cho, I.H.; Lee, S.; Jun, H.R.; Roh, H.J.; Kim, Y.S. Comparison of volatile Maillard reaction products from tagatose and other reducing sugars with amino acids. Food Sci. Biotechnol. 2010, 19, 431–438. [Google Scholar] [CrossRef]

- Tan, Z.; Yu, A. Volatiles from the Maillard reaction of L-ascorbic acid with L-glutamic acid/L-aspartic acid at different reaction times. Asia-Pac. J. Chem. Eng. 2012, 7, 563–571. [Google Scholar] [CrossRef]

- Fiddler, W.; Parker, W.E.; Wasserman, A.E.; Doerr, R.C. Thermal Decomposition of Ferulic Acid. J. Agric. Food Chem. 1967, 15, 757–761. [Google Scholar] [CrossRef]

- Baek, H.H.; Cadwallader, K.R. Contribution of Free and Glycosidically Bound Volatile Compounds to the Aroma of Muscadine Grape Juice. J. Food Sci. 1999, 64, 441–444. [Google Scholar] [CrossRef]

- Qian, M.C.; Wang, Y. Seasonal variation of volatile composition and odor activity value of ‘Marion’(Rubus spp. hyb) and ‘Thornless Evergreen’(R. laciniatus L.) blackberries. J. Food Sci. 2005, 70, 13–20. [Google Scholar] [CrossRef]

- Noguerol-Pato, R.; González-Álvarez, M.; González-Barreiro, C.; Cancho-Grande, B.; Simal-Gándara, J. Evolution of the aromatic profile in Garnacha Tintorera grapes during raisining and comparison with that of the naturally sweet wine obtained. Food Chem. 2013, 139, 1052–1061. [Google Scholar] [CrossRef]

- Chevance, F.; Guyot-Declerck, C.; Dupont, J.; Sonia, C. Investigation of the -damascenone level in fresh and aged commercial beers. J. Agric. Food Chem. 2002, 50, 3818–3821. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Finn, C.; Qian, M.C. Impact of growing environment on Chickasaw blackberry (Rubus l) aroma evaluated by gas chromatography olfactometry dilution analysis. J. Agric. Food Chem. 2005, 53, 3563–3571. [Google Scholar] [CrossRef] [PubMed]

- Toci, A.T.; Farah, A. Volatile fingerprint of Brazilian defective coffee seeds: Corroboration of potential marker compounds and identification of new low quality indicators. Food Chem. 2014, 153, 298–314. [Google Scholar] [CrossRef] [PubMed]

| S.N | RI | Compound Name | Ion m/z | ID | Source | Fresh | AD-Raisin | PAD-Raisin | SD-Raisin | PSD-Raisin |

|---|---|---|---|---|---|---|---|---|---|---|

| Aldehydes | ||||||||||

| 1 | 975 | Pentanal W,J | 44 | 2 | UFAO | 167.92 ± 13.06a | 69.36 ± 2.34cd | 64.23 ± 2.51d | 86.8 ± 6.14bc | 81.01 ± 7.64b |

| 2 | 1066 | Hexanal B,W,J | 44 | 1 | UFAO | 6972.72 ± 365.7a | 365.44 ± 24.86b | 285.95 ± 2.96b | 547.62 ± 13.12b | 551.07 ± 5.42b |

| 3 | 1178 | Heptanal B,W,J | 44 | 2 | UFAO | 86.1 ± 7.32a | 34.22 ± 0.87bc | 24.76 ± 1.43c | 48.17 ± 3.71b | 36.66 ± 0.74bc |

| 4 | 1292 | Octanal B,W | 43 | 2 | UFAO | 386.85 ± 45.07a | NF | NF | NF | NF |

| 5 | 1393 | Nonanal B,W,J | 57 | 1 | UFAO | 6.38 ± 0.08a | 1.18 ± 0.23c | 1.38 ± 0.07bc | 1.74 ± 0.35b | 1.49 ± 0.27bc |

| 6 | 1501 | Decanal B,W,J | 43 | 1 | UFAO | NF | NF | 1.88 ± 0.03a | 1.84 ± 0.07a | 2.08 ± 0.44a |

| 7 | 1217 | (E)-2-Hexenal B,W,J | 41 | 1 | UFAO | 3304.21 ± 85.45a | 63.7 ± 3.77c | 134.68 ± 9.12b | 17.77 ± 0.32c | 44.97 ± 2.29c |

| 8 | 1325 | (E)-2-Heptenal B,W,J | 41 | 2 | UFAO | 27.41 ± 2.29c | 111.29 ± 6.05a | 18.41 ± 0.37c | 57.83 ± 9.67b | 24.88 ± 3.41c |

| 9 | 1434 | (E)-2-Octenal B,W,J | 41 | 2 | UFAO | 22.7 ± 0.75a | 6.69 ± 1.41d | 4.68 ± 0.16e | 11.39 ± 1.92b | 8.38 ± 0.92c |

| 10 | 1539 | (E)-2-Nonenal B,W | 43 | 2 | UFAO | NF | NF | 2.5 ± 0.1b | 7.44 ± 0.38a | NF |

| 11 | 1497 | (E,E)-2,4-Heptadienal B,W,J | 81 | 2 | UFAO | NF | NF | NF | 86.71 ± 4.17b | 111.18 ± 7.03a |

| 12 | 1705 | (E,E)-2,4-Nonadienal B,W,J | 81 | 2 | UFAO | 179.65 ± 3.2b | 241.35 ± 13.59a | 95.46 ± 8c | 106.78 ± 12.96c | 94.33 ± 4.12c |

| 13 | 1530 | Benzaldehyde B,W,J | 77 | 1 | MR | 13.43 ± 0.13b | 25.6 ± 1.57a | 15.2 ± 0.64b | 14 ± 1.75b | 14.05 ± 1.46b |

| 14 | 1650 | Phenylacetaldehyde B,W,J | 91 | 1 | MR | 386.96 ± 11.48a | 326.67 ± 21.3b | 163.4 ± 23.81c | 141.21 ± 11.87d | 101.89 ± 9.17e |

| Alcohols | ||||||||||

| 15 | 1205 | 1-Pentanol W,J | 52 | 2 | UFAO | 14.81 ± 0.74a | 8.54 ± 0.77c | 8.69 ± 0.28c | 11.92 ± 0.66b | 12.99 ± 0.43b |

| 16 | 1349 | 1-Hexanol W,J | 56 | 2 | UFAO | 901.25 ± 76.68a | 74.36 ± 4.56c | 156.45 ± 7.01b | 110.57 ± 11.26bc | 128.71 ± 2.79bc |

| 17 | 1453 | 1-Heptanol W,J | 70 | 2 | UFAO | 9.65 ± 0.22a | NF | 2.21 ± 0.01c | 7.13 ± 0.95b | 7.58 ± 0.83b |

| 18 | 1555 | 1-Octanol B,W,J | 56 | 1 | UFAO | 6.71 ± 0.22a | 2.64 ± 0.19c | 1.37 ± 0.05d | 2.63 ± 0.46c | 5.55 ± 0.26b |

| 19 | 1657 | 1-Nonanol W,J | 56 | 1 | UFAO | 1.93 ± 0.06a | 0.58 ± 0.01bc | 0.32 ± 0.01d | 0.51 ± 0.06c | 0.7 ± 0.12b |

| 20 | 1411 | 2-Octanol B,W,J | 45 | 2 | UFAO | 0.83 ± 0.06a | NF | NF | NF | NF |

| 21 | 1488 | 2-Nonanol J | 45 | 2 | UFAO | 1.86 ± 0.07a | NF | NF | NF | NF |

| 22 | 1449 | 1-Octen-3-ol B,W,J | 57 | 1 | UFAO | 14.93 ± 0.62d | 23.18 ± 3.3c | 24.99 ± 0.8c | 36.48 ± 5.83b | 52.42 ± 2.3a |

| 23 | 1614 | (E)-2-Octen-1-ol W,J | 57 | 2 | UFAO | 3.15 ± 0.07d | 10.86 ± 0.09a | 5.65 ± 0.34c | 2.5 ± 0.57e | 7.42 ± 0.34b |

| 24 | 1487 | 2-Ethyl-1-hexanol W,J | 57 | 1 | UFAO | 15.26 ± 0.41a | 0.78 ± 0.08c | 3.31 ± 0.01b | 1.03 ± 0.51c | 3.24 ± 0.15b |

| 25 | 1395 | (Z)-3-Hexen-1-ol J | 67 | 2 | UFAO | 387.23 ± 28.45a | 52.3 ± 0.71b | 38.83 ± 0.74b | NF | 32.11 ± 0.19b |

| 26 | 1203 | 3-Methyl-1-butanol W,J | 55 | 1 | UFAO | NF | 1814.98 ± 32.3a | 1455.15 ± 26.93b | 1130.05 ± 32.01c | 1487.78 ± 24.13b |

| 27 | 1458 | Sulcatol J | 95 | 2 | CR (carotenoid) | 9.84 ± 0.14a | 2.73 ± 0.04b | 1.68 ± 0.03c | 0.74 ± 0.23d | 1.44 ± 0.16c |

| 28 | 942 | Ethyl alcohol J | 31 | 2 | 13,143.64 ± 1679ab | 13,526.01 ± 531a | 7751.14 ± 85.13c | 8197.47 ± 165c | 11,920.23 ± 732d | |

| 29 | 1317 | 3-Methyl-2-buten-1-ol W,J | 71 | 2 | NF | NF | NF | NF | NF | |

| 30 | 1879 | Benzyl alcohol W,J | 79 | 1 | 279.02 ± 18.52a | 283.38 ± 16.54a | 109.02 ± 3.61b | 23.96 ± 0.05c | 120.75 ± 5.05b | |

| 31 | 1914 | Phenylethyl alcohol W,J | 91 | 2 | 363.21 ± 32.76a | 358.05 ± 37.8a | 92.78 ± 2.82c | 43.41 ± 6.67d | 155.29 ± 13.89b | |

| 32 | 1148 | 1-Butanol J | 56 | 2 | 248.09 ± 35.63a | 47.43 ± 1.51b | 44.66 ± 0.93b | 37.55 ± 4.11b | 32.58 ± 2.4b | |

| Esters | ||||||||||

| 34 | 1227 | Ethyl hexanoate W,J | 88 | 1 | UFAO | 10.63 ± 2.55b | 14.38 ± 4.31a | 11.67 ± 0.21b | 6.32 ± 2.87 | 3.82 ± 1.48d |

| 35 | 1570 | Ethyl octanoate W,J | 88 | 1 | UFAO | 5.56 ± 0.45a | 2.43 ± 0.21b | 1.13 ± 0.03d | 1.17 ± 0.07d | 1.72 ± 0.13c |

| 36 | 1378 | Methyl octanoate J | 74 | 2 | UFAO | NF | NF | 0.14 ± 0b | 0.14 ± 0.01b | 0.17 ± 0.02a |

| 37 | 1570 | Ethyl nonanoate J | 88 | 1 | UFAO | NF | NF | 0.16 ± 0a | NF | NF |

| 38 | 1227 | Ethyl hexadecanoate W,J | 88 | 1 | UFAO | 47.55 ± 5.31a | 11.39 ± 0.54b | 7.71 ± 0.28b | 8.13 ± 0.09b | 8.29 ± 0.09b |

| 39 | 2163 | Methyl hexadecanoate J | 74 | 2 | UFAO | 0.44 ± 0.06a | 0.14 ± 0.01b | 0.07 ± 0c | NF | NF |

| 40 | 1636 | Butyrolactone W,J | 42 | 2 | UFAO | 3.75 ± 0.5d | 8.68 ± 0.12a | 6.58 ± 0.52b | 5.57 ± 0.4c | 8.19 ± 0.74a |

| 41 | 2035 | γ-Nonalactone W,J | 85 | 2 | UFAO | 3.34 ± 0.29b | 8.99 ± 0.68a | 1.49 ± 0.04c | 1.43 ± 0.12c | 1.81 ± 0.57c |

| 42 | 885 | Ethyl acetate W,J | 43 | 1 | 322.94 ± 20.33d | 1509.48 ± 34.63a | 1400.73 ± 63.66b | 368.82 ± 16.62d | 801.43 ± 22.32c | |

| 43 | 1677 | Diethyl succinate W,J | 101 | 1 | NF | NF | 1.57 ± 0.04a | NF | 1.46 ± 0.06b | |

| 44 | 1782 | Methyl salicylate J | 120 | 1 | NF | NF | 2.98 ± 0.09a | NF | NF | |

| 45 | 1253 | Ethyl salicylate J | 2 | NF | NF | 0.54 ± 0.01a | 0.36 ± 0.01b | NF | ||

| 46 | 942 | Ethyl alcohol J | 31 | 2 | 13,143.64 ± 1679.4ab | 13,526.01 ± 531.25a | 7751.14 ± 85.13c | 8197.47 ± 165.51c | 11,920.23 ± 732.92b | |

| 47 | 1470 | β-Ionone J | 177 | 2 | CR | 5.41 ± 0.21a | 1.07 ± 0.05b | 0.75 ± 0.02c | NF | NF |

| Acids | ||||||||||

| 48 | 1740 | Pentanoic acid W,J | 60 | 2 | UFAO | NF | NF | 74.41 ± 2.76b | 187.82 ± 8.88a | NF |

| 49 | 1847 | Hexanoic acid B,W,J | 60 | 1 | UFAO | 375.48 ± 19.8a | 153.07 ± 13.89b | 161.91 ± 26.48b | 214.5 ± 11.34b | 161.37 ± 56.99b |

| 50 | 1953 | Heptanoic acid B,W,J | 60 | 1 | UFAO | 3.19 ± 0.57a | 2.58 ± 0.17ab | 2.17 ± 0.11b | 2.52 ± 0.35ab | 2.96 ± 0.66a |

| 51 | 2060 | Octanoic acid B,W,J | 60 | 1 | UFAO | 2.41 ± 0.16b | 4.63 ± 0.19a | 2.33 ± 0.22b | 2.29 ± 0.12b | 2.11 ± 0.72b |

| 52 | 2166 | Nonanoic acid B,W,J | 60 | 2 | 20.16 ± 1.9a | 4.45 ± 0.17c | 8.69 ± 1.26b | 3.53 ± 0.03c | 4.76 ± 0.24c | |

| 53 | 2484 | Dodecanoic acid W,J | 73 | 2 | UFAO | NF | NF | 10.9 ± 2.72a | NF | NF |

| 54 | 1950 | 2-Ethylhexanoic acid W,J | 88 | 1 | NF | NF | 28.97 ± 0.51a | NF | NF | |

| 55 | 1433 | Acetic acid J | 2 | 135,518.4 ± 11152.8d | 265,800.8 ± 12361.5a | 180,758.57 ± 7545.9c | 209,013.96 ± 17456.5b | 114,244.24 ± 6693.1e | ||

| Terpenes | ||||||||||

| 56 | 1011 | α-Terpinene N | 121 | 2 | 377.96 ± 11.76a | 36.38 ± 3.67b | 18.52 ± 0.64c | NF | 19.33 ± 2.3c | |

| 57 | 1286 | Terpinolene J | 93 | 1 | 185.51 ± 8.78a | 17.59 ± 0.51b | 14.86 ± 0.16bc | 9.47 ± 0.09c | NF | |

| 58 | 1473 | Nerol oxide W,J | 68 | 2 | 141.28 ± 6.83b | 226.12 ± 6.18a | 65.67 ± 0.56d | 22.77 ± 4.76e | 99.44 ± 6.57c | |

| 59 | 1548 | Linalool W,J | 71 | 1 | 247.23 ± 32.98a | 15.44 ± 0.71b | 13.63 ± 0.49b | 4.81 ± 0.39b | 4.9 ± 0.69b | |

| 60 | 1610 | Hotrienol W,J | 71 | 1 | 99.66 ± 2.9a | 31.05 ± 0.44b | 25 ± 0.43c | 14.51 ± 0.82d | 10.67 ± 0.16e | |

| 61 | 1620 | p-Menth-1-en-9-al W,J | 94 | 2 | 40.38 ± 0.5a | 11.18 ± 0.09b | 6.55 ± 0.12c | 6.36 ± 0.32cd | 5.77 ± 0.43c | |

| 62 | 1698 | α-terpineol B,W,J | 59 | 1 | 77.53 ± 2.74a | 12.66 ± 0.6b | 9.63 ± 0.13c | 6.36 ± 0.15d | 7.29 ± 0.45d | |

| 63 | 1739 | cis-Pyran linalool oxide W,J | 2 | 8.69 ± 0.31a | 6.28 ± 0.08b | 2.86 ± 0.08c | 2.69 ± 0.07c | 2.45 ± 0.23c | ||

| 64 | 1764 | β-Citronellol J | 69 | 1 | 7.62 ± 0.28a | 2.84 ± 0.15b | 1.79 ± 0.45c | NF | NF | |

| 65 | 1799 | Nerol W,J | 69 | 2 | 276.43 ± 3.01a | 74.14 ± 3.33b | 26.37 ± 0.15d | 3.22 ± 0.18e | 30.93 ± 2.77c | |

| 66 | 1825 | β-damascenone W,J | 69 | 1 | 62.93 ± 7.23a | 3.26 ± 0.13b | 3.21 ± 0.1b | 2.21 ± 0.07b | 2.26 ± 0.4b | |

| 67 | 1847 | Geraniol W,J | 69 | 1 | 235.23 ± 2.38a | 71.45 ± 6.14b | 21.77 ± 0.09c | 1.54 ± 0.15d | 25.63 ± 2.38c | |

| 68 | 2049 | Nerolidol 2 J | 41 | 2 | NF | NF | 0.58 ± 0a | NF | NF | |

| 69 | 2340 | Geranic acid W,J | 69 | 1 | 489.07 ± 56.92a | 149.32 ± 5.42b | 86.18 ± 6.87c | 16.74 ± 0.4d | 25.57 ± 1.4d | |

| 70 | 1857 | Geranylacetone B,W,J | 43 | 1 | CR | 6.1 ± 0.74a | 1.4 ± 0.52b | 0.8 ± 0.07b | 0.77 ± 0.07b | 1.18 ± 0.1b |

| 71 | 1132 | 3,4-Dimethyl-2,4,6-octatriene J | 121 | 2 | UFAO | 187.64 ± 6.2a | 16.67 ± 0.14b | 11.21 ± 0.12c | 7.29 ± 0.05c | 12.04 ± 1.27bc |

| 72 | 1037 | α-Ocimene J | 93 | 2 | 679.06 ± 22.5a | 60.04 ± 7.26b | 26.77 ± 2.07c | NF | 27.13 ± 0.64c | |

| 73 | 1191 | Limonene W,J | 68 | 1 | 353.41 ± 27.2a | 28.49 ± 1.04b | 20.09 ± 0.85b | 10.04 ± 0.66b | 16.8 ± 3.05b | |

| 74 | 1353 | Rose oxide W,J | 139 | 2 | 26.9 ± 1.25a | 9.4 ± 0.32b | 4.88 ± 0.08cd | 4.01 ± 0.03d | 5.31 ± 0.3c | |

| 75 | 1724 | Lilac alcohol W | 2 | NF | 5.54 ± 0.15a | 3.87 ± 0.2c | 4.01 ± 0.01bc | 4.13 ± 0.03b | ||

| 76 | 1473 | Cosmene J | 2 | NF | NF | 9.01 ± 0.19a | NF | NF | ||

| 77 | Geranial N | 2 | 83.01 ± 2.27a | 16.54 ± 1.38b | 10.58 ± 0.24c | NF | 8.47 ± 0.51c | |||

| Ketones | ||||||||||

| 78 | 1167 | 2,6-Dimethyl-4-heptanone W,J | 57 | 2 | UFAO | 52.15 ± 2.42a | 8.06 ± 0.58d | 15.45 ± 1.56c | 22.78 ± 1.73b | 14.43 ± 0.29c |

| 79 | 1416 | 3-Octen-2-one J | 55 | 2 | UFAO | NF | 7.95 ± 0.5c | 3.16 ± 0.13cd | 31.07 ± 1.09a | 24.49 ± 7.54b |

| 80 | 955 | 2,3-Butanedione W,J | 43 | 1 | MR | NF | 32.56 ± 2.15c | 22.02 ± 0.36d | 77.8 ± 6.88a | 61.51 ± 10.39b |

| 81 | 1337 | Sulcatone W,J | 43 | 1 | CR | 24.55 ± 0.4b | 46.22 ± 1.46a | 22.15 ± 0.2c | 14.09 ± 1.86d | 21.21 ± 0.7c |

| 82 | 1596 | 6-Methyl-3,5-heptadiene-2-one B,W,J | 43 | 2 | CR | 5.47 ± 0.44c | 47.45 ± 1.77a | 11.86 ± 0.61c | 12.58 ± 2.38c | 30.45 ± 14.16b |

| 83 | 1289 | Acetoin W,J | 45 | 1 | NF | 265.02 ± 10.57c | 76.37 ± 8.53d | 581.23 ± 4.88a | 361.45 ± 9.94b | |

| 84 | 1656 | Acetophenone B,W,J | 105 | 2 | 26.27 ± 0.49a | 5.66 ± 0.17c | 3.65 ± 0.02d | 5.15 ± 0.46c | 8.45 ± 0.17b | |

| Furans | ||||||||||

| 85 | 1224 | 2-Pentyl furan W,J | 81 | 2 | UFAO | NF | NF | 6.89 ± 0.45c | 77.63 ± 1.2a | 20.7 ± 2.06b |

| 86 | 1469 | Furfural B,W,J | 96 | 1 | MR | NF | 58.72 ± 4.07c | 39.49 ± 7.05c | 339.24 ± 17.64a | 234.73 ± 14.13b |

| 87 | 1509 | 2-Acetylfuran B,W,J | 95 | 2 | MR | NF | NF | 4.23 ± 0.14c | 19.52 ± 0.56a | 18.06 ± 1.6b |

| 88 | 1578 | 5-Methyl-2-furfural B,W,J | 110 | 1 | MR | NF | 3.65 ± 0.29c | 2.69 ± 0.23c | 9 ± 0.85b | 13.06 ± 1.44a |

| 89 | 1270 | 5-Hydroxymethyl-2-furaldehyde J | 97 | 2 | MR | NF | NF | 14.13 ± 5.97b | 7.34 ± 0.93b | 18.8 ± 6.68a |

| Benzenes | ||||||||||

| 90 | 1259 | Styrene J | 104 | 2 | 130.9 ± 5.37a | 22.31 ± 2.14b | 19.53 ± 0.4b | 19.56 ± 0.17b | 19.75 ± 0.21b | |

| 91 | 1281 | o-Cymene J | 119 | 2 | 94.21 ± 3.59a | 7.68 ± 0.12b | 7.53 ± 0.32b | 4.44 ± 0.34bc | 5.73 ± 0.2b | |

| 92 | 1022 | Toluene J | 91 | 2 | 38.46 ± 1.4a | 4.29 ± 0.86b | 4.4 ± 0.25b | 4.78 ± 0.32b | 4.72 ± 0.18b | |

| 93 | 1757 | Naphthalene W,J | 128 | 1 | 16.47 ± 0.65a | 3.25 ± 0.12b | 2.28 ± 0.1c | 2.47 ± 0.03c | 2.52 ± 0.03c | |

| 94 | 1895 | 2-Methyl naphthalene W,J | 142 | 2 | 15.68 ± 0.54a | 3.24 ± 0.11b | 2.47 ± 0.07c | NF | NF | |

| Pyrazines | ||||||||||

| 95 | 1385 | 2-Ethyl-6-methyl, pyrazine W,J | 121 | 1 | MR | 29.19 ± 0.97a | 1.09 ± 0.09c | 1.65 ± 0.04c | 4.87 ± 0.43b | 1.58 ± 0.4c |

| 96 | 1435 | 2,6-Diethyl, pyrazine W,J | 135 | 1 | MR | NF | 3.56 ± 0.47b | 1.35 ± 0.09c | 9.76 ± 1.14a | 2.52 ± 0.39c |

| 97 | 1462 | 5-Ethyl-2,3-dimethylpyrazine W,J | 135 | 1 | MR | NF | NF | 1.57 ± 0.05bc | 7.18 ± 3.13a | 2.56 ± 0.31b |

| Phenols | ||||||||||

| 98 | 2010 | Phenol W,J | 95 | 1 | 5.16 ± 0.17a | NF | 1.06 ± 0.01c | 1.29 ± 0.1b | 0.85 ± 0.04d | |

| 99 | 2146 | 4-ethenyl-2-methoxyphenol J | 135 | 2 | 1.81 ± 0.38a | NF | NF | NF | NF | |

| S/N (Serial Number) | Compound Name | OTV | Aroma Descriptor | Aromatic Series | OAV | ||||

|---|---|---|---|---|---|---|---|---|---|

| Fresh | AD | PAD | SD | PSD | |||||

| 1 | Pentanal | 12 | Fat, Green e | Green | 13.99 | 5.78 | 5.35 | 0 | 6.75 |

| 2 | Hexanal | 4.5 | Green e | Green | 1549.49 | 81.21 | 63.54 | 121.69 | 122.46 |

| 3 | (E)-2-Hexenal | 17 | Green e | Green | 194.37 | 3.75 | 7.92 | 1.05 | 2.65 |

| 4 | (E,E)-2,4-Nonadienal | 0.09 | Green b | Green | 1996 | 2681 | 1060 | 1186 | 1048 |

| 5 | Geranic acid | 40 | Green e | Green | 12.23 | 3.73 | 2.15 | 0.17 | 0.64 |

| 6 | Octanal | 0.7 | Honey, Green e | Green | 552.64 | 0 | 0 | 0 | 0 |

| 7 | Nonanal | 1 | Green, Fruity e | Green; Fruity | 6.38 | 1.18 | 1.38 | 1.74 | 1.49 |

| 8 | Decanal | 0.1 | Sweet, citrus, green d | Green; Fruity | 0 | 0 | 18.76 | 18.4 | 20.78 |

| 9 | (Z)-3-Hexen-1-ol | 100 | Fruity, green b | Green; Fruity | 3.87 | 0.52 | 0.39 | 0 | 0.32 |

| 10 | 2-Pentyl furan | 6 | Fruity, green, sweet e | Green; Fruity | 0 | 0 | 1.15 | 12.94 | 3.45 |

| 11 | (E)-2-Octenal | 3 | Green, fatty, nut e | Green; Fatty | 7.57 | 8.9 | 1.56 | 3.8 | 2.79 |

| 12 | (E)-2-Nonenal | 0.08 | Green, fat a | Green; Fatty | 0 | 0 | 31.29 | 92.99 | 0 |

| 13 | (E)-2-Heptenal | 13 | Fatty, soapy, tallow e | Fatty | 2.11 | 8.56 | 1.42 | 4.45 | 1.91 |

| 14 | (E,E)-2,4-Heptadienal | 49 | Fatty, hay b | Fatty | 0 | 0 | 9.48 | 1.77 | 2.27 |

| 15 | Ethyl hexanoate | 1 | Fruity, apple-like a, e | Fruity | 10.63 | 14.38 | 11.67 | 0 | 3.16 |

| 16 | Ethyl hexadecanoate | 1 | Fruity, apple-like a, e | Fruity | 47.55 | 11.39 | 7.71 | 8.13 | 8.29 |

| 17 | Linalool | 6 | Fruity, sweet, grape b, e | Fruity | 41.2 | 2.57 | 2.27 | 0.8 | 0.82 |

| 18 | Limonene | 10 | Citrus-like | Fruity | 35.34 | 2.85 | 2.01 | 1 | 1.68 |

| 19 | Geranial/ α-Citral | 32 | lemon, mint flvt | Fruity | 2.59 | 0.52 | 0.33 | 0 | 0.26 |

| 20 | β-damascenone | 0.09 | Sweet, floral, fruity e | Fruity; Floral | 699.21 | 36.17 | 35.64 | 24.54 | 25.15 |

| 21 | Geraniol | 40 | Floral, rose, citrus e | Fruity; Floral | 5.88 | 1.79 | 0.54 | 0.04 | 0.64 |

| 22 | Phenylacetaldehyde | 4 | Flowery, Rose e | Floral | 96.74 | 81.67 | 40.85 | 25.47 | 0 |

| 23 | α-Terpineol | 350 | Floral, sweet e | Floral | 1.08 | 0.1 | 0.05 | 0 | 0.06 |

| 24 | β-Ionone | 0.007 | Balsamic, rose e | Floral | 772.31 | 152.95 | 107.55 | 0 | 0 |

| 25 | Rose oxide | 0.5 | Rose, floral a, e | Floral | 53.79 | 18.8 | 9.76 | 8.02 | 10.62 |

| 26 | 2,6-Diethyl, pyrazine | 6 | Roasted, nutty b | Roasted | 0 | 0.59 | 0.22 | 1.63 | 0.42 |

| 27 | 5-Ethyl-2,3-dimethylpyrazine | 3 | Nutty roasted, woody e | Roasted | 0 | 0 | 0.52 | 2.39 | 0.85 |

| 28 | Heptanal | 3 | Dry fish, solvent, smoky e | Chemical | 28.37 | 11.41 | 8.25 | 16.06 | 12.22 |

| 29 | 3-Methyl-1-butanol | 300 | Malt, whiskey a | Chemical | 0 | 9.38 | 4.85 | 3.77 | 4.96 |

| 30 | Acetic acid | 60,000 | Vinegar c | Chemical | 2.25 | 4.43 | 3.01 | 3.48 | 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Javed, H.U.; Wang, D.; Andaleeb, R.; Zahid, M.S.; Shi, Y.; Akhtar, S.; Shiping, W.; Duan, C.-Q. Drying Treatments Change the Composition of Aromatic Compounds from Fresh to Dried Centennial Seedless Grapes. Foods 2021, 10, 559. https://doi.org/10.3390/foods10030559

Javed HU, Wang D, Andaleeb R, Zahid MS, Shi Y, Akhtar S, Shiping W, Duan C-Q. Drying Treatments Change the Composition of Aromatic Compounds from Fresh to Dried Centennial Seedless Grapes. Foods. 2021; 10(3):559. https://doi.org/10.3390/foods10030559

Chicago/Turabian StyleJaved, Hafiz Umer, Dong Wang, Rani Andaleeb, Muhammad Salman Zahid, Ying Shi, Saeed Akhtar, Wang Shiping, and Chang-Qing Duan. 2021. "Drying Treatments Change the Composition of Aromatic Compounds from Fresh to Dried Centennial Seedless Grapes" Foods 10, no. 3: 559. https://doi.org/10.3390/foods10030559

APA StyleJaved, H. U., Wang, D., Andaleeb, R., Zahid, M. S., Shi, Y., Akhtar, S., Shiping, W., & Duan, C.-Q. (2021). Drying Treatments Change the Composition of Aromatic Compounds from Fresh to Dried Centennial Seedless Grapes. Foods, 10(3), 559. https://doi.org/10.3390/foods10030559