Food Texture Design by 3D Printing: A Review

Abstract

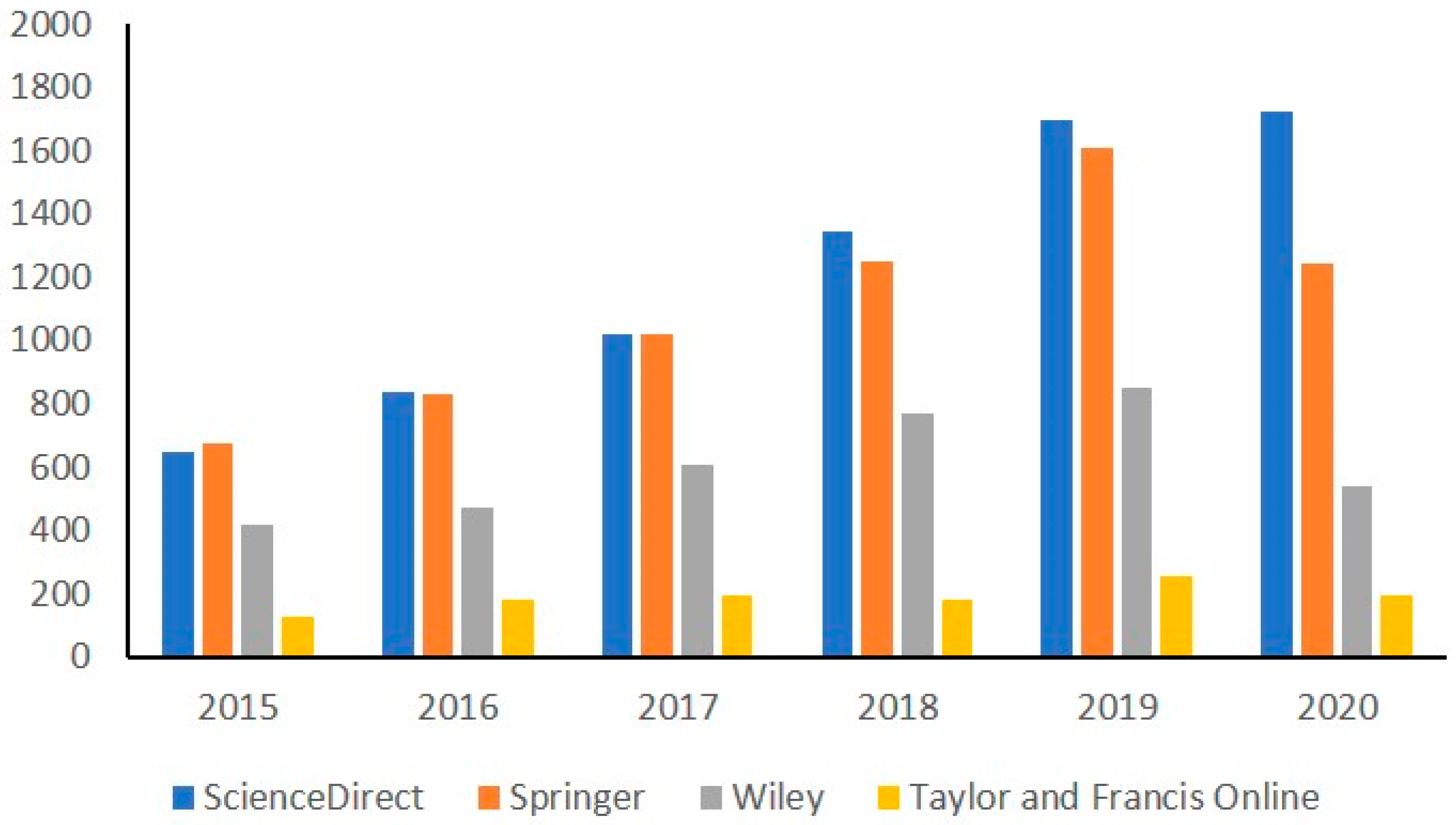

1. Introduction

2. Food Texture

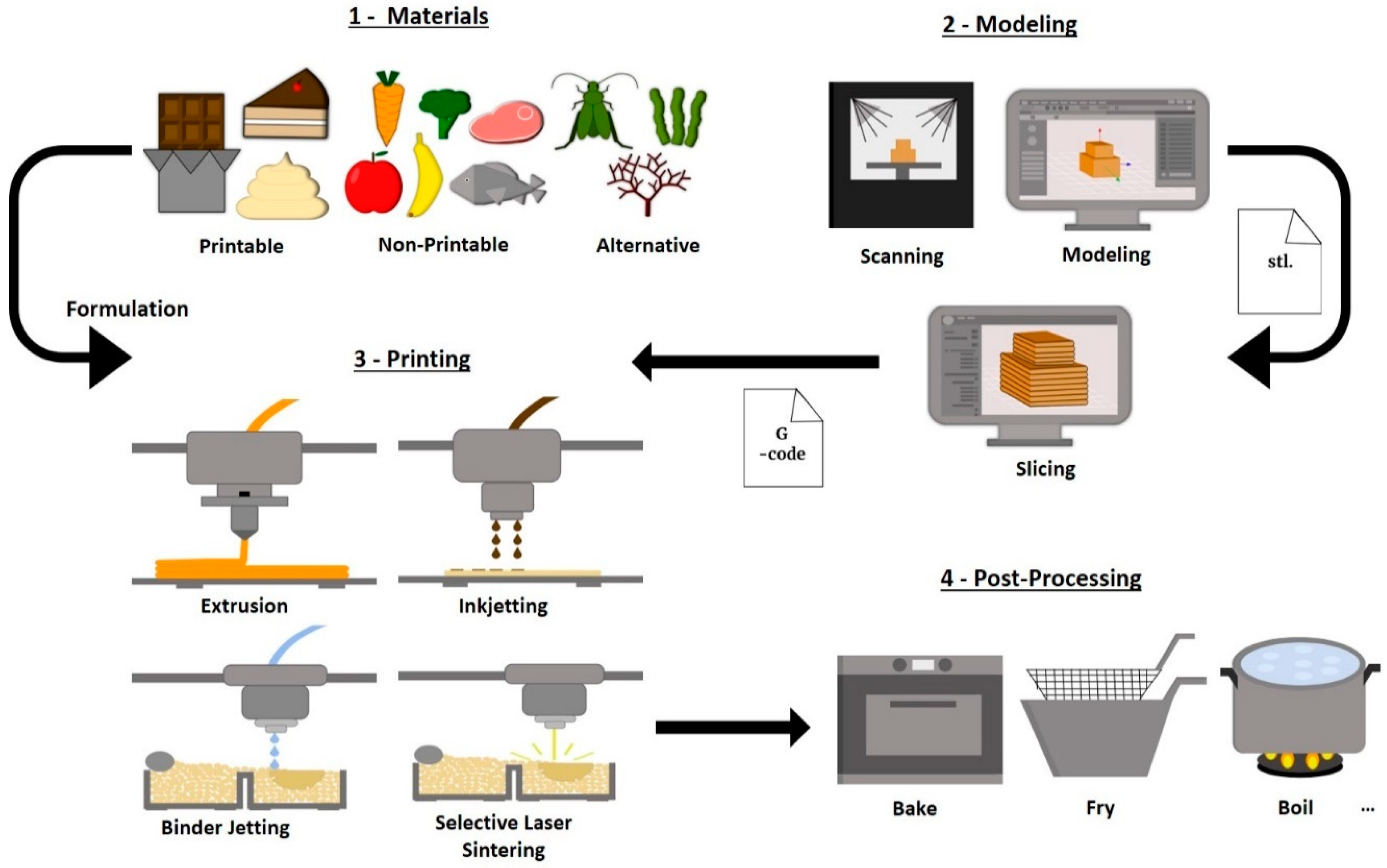

3. 3D Food Printing

4. Designing Food Texture with 3D Printing

4.1. Material-Based Texture

4.1.1. Source Material Effect on the Printed Product

4.1.2. Post-Processing Effect on the Printed Product

4.2. Model-Based Texture

5. Consumers’ Perception and Acceptability of 3D Printed Food Products

6. Future Trends and Key Limitations

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Periard, D.; Schaal, N.; Schaal, M.; Malone, E.; Lipson, H. Printing food. In Proceedings of the 18th Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2007; pp. 564–574. [Google Scholar]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3D printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Yan, L.; Huang, D.; Lin, L. Extrusion-based food printing for digitalized food design and nutrition control. J. Food Eng. 2018, 220, 1–11. [Google Scholar] [CrossRef]

- Krishnaraj, P.; Anukiruthika, T.; Choudhary, P.; Moses, J.A.; Anandharamakrishnan, C. 3D extrusion printing and post-processing of fibre-rich snack from indigenous composite flour. Food Bioprocess Technol. 2019, 12, 1776–1786. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Azzollini, D.; Severini, C. Application of 3D printing for customized food. A case on the development of a fruit-based snack for children. J. Food Eng. 2018, 220, 65–75. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Prakash, S.; Liu, Y. Physical properties of 3D printed baking dough as affected by different compositions. Innov. Food Sci. Emerg. Technol. 2018, 49, 202–210. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Ricci, I.; Severini, C. Critical variables in 3D food printing. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 41–91. ISBN 9780128145647. [Google Scholar]

- Keerthana, K.; Anukiruthika, T.; Moses, J.A.; Anandharamakrishnan, C. Development of fiber-enriched 3D printed snacks from alternative foods: A study on button mushroom. J. Food Eng. 2020, 287, 110116. [Google Scholar] [CrossRef]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Pérez, B.; Nykvist, H.; Brøgger, A.F.; Larsen, M.B.; Falkeborg, M.F. Impact of macronutrients printability and 3D-printer parameters on 3D-food printing: A review. Food Chem. 2019, 287, 249–257. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Huang, D.; Yan, L. 3D food printing: Perspectives. In Polymers for Food Applications; Gutiérrez, T.J., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 725–755. ISBN 9783319946252. [Google Scholar]

- Kakuk, C. The Ultimate Guide to 3D Food Printing. Available online: http://ww16.3dfoodprinting.us/wp-content/uploads/2019/04/The-Ultimate-Guide-to-3D-FoodPrinting041419.pdf?sub1=20210202-2030-1540-a773-f044d95581d1 (accessed on 12 March 2020).

- Aleph Farms. Aleph Farm Meat Growers. Available online: https://aleph-farms.com/ (accessed on 1 June 2020).

- Meatech Meatech. 3D Printed Clean and Real Meat. Available online: https://meatech3d.com/#intro (accessed on 1 June 2020).

- Redefine Meat for the Love of Meat. Redefine Meat. Why Redefine Meat? Available online: https://www.redefinemeat.com/ (accessed on 1 June 2020).

- Novameat Barcelona. Novameat Plant-Based Meat. Available online: https://www.novameat.com/ (accessed on 1 June 2020).

- Stokes, J.R.; Boehm, M.W.; Baier, S.K. Oral processing, texture and mouthfeel: From rheology to tribology and beyond. Curr. Opin. Colloid Interface Sci. 2013, 18, 349–359. [Google Scholar] [CrossRef]

- Sethupathy, P.; Moses, J.A.; Anandharamakrishnan, C. Food oral processing and tribology: Instrumental approaches and emerging applications. Food Rev. Int. 2020, 9129, 1–34. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, M.; Bhandari, B. Assessing the 3D printing precision and texture properties of brown rice induced by infill levels and printing variables. Food Bioprocess Technol. 2019, 12, 1185–1196. [Google Scholar] [CrossRef]

- Chen, J.; Rosenthal, A. Food texture and structure. In Modifying Food Texture: Novel Ingredients and Processing Techniques; Chen, J., Rosenthal, A., Eds.; Woodhead Publishing: Cambridge, UK, 2015; Volume 1, pp. 3–24. ISBN 9781782423331. [Google Scholar]

- Zargaraan, A.; Rastmanesh, R.; Fadavi, G.; Zayeri, F.; Mohammadifar, M.A. Rheological aspects of dysphagia-oriented food products: A mini review. Food Sci. Hum. Wellness 2013, 2, 173–178. [Google Scholar] [CrossRef]

- Aguilera, J.M.; Park, D.J. Texture-modified foods for the elderly: Status, technology and opportunities. Trends Food Sci. Technol. 2016, 57, 156–164. [Google Scholar] [CrossRef]

- Hemsley, B.; Palmer, S.; Kouzani, A.; Adams, S.; Balandin, S. Review informing the design of 3D food printing for people with swallowing disorders: Constructive, conceptual, and empirical problems. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Grand Wailea, HI, USA, 8–11 January 2019; pp. 5735–5744. [Google Scholar]

- Jeltema, M.; Beckley, J.; Vahalik, J. Food texture measurement and consumer choice. Ref. Modul. Food Sci. 2017, 1–9. [Google Scholar] [CrossRef]

- Stieger, M.; van de Velde, F. Microstructure, texture and oral processing: New ways to reduce sugar and salt in foods. Curr. Opin. Colloid Interface Sci. 2013, 18, 334–348. [Google Scholar] [CrossRef]

- Di Monaco, R.; Miele, N.A.; Cabisidan, E.K.; Cavella, S. Strategies to reduce sugars in food. Curr. Opin. Food Sci. 2018, 19, 92–97. [Google Scholar] [CrossRef]

- Mosca, A.C.; Rocha, J.A.; Sala, G.; van de Velde, F.; Stieger, M. Inhomogeneous distribution of fat enhances the perception of fat-related sensory attributes in gelled foods. Food Hydrocoll. 2012, 27, 448–455. [Google Scholar] [CrossRef]

- Chung, C.; McClements, D.J. Structure and texture development of food-emulsion products. In Modifying Food Texture: Novel Ingredients and Processing Techniques; Chen, J., Rosenthal, A., Eds.; Woodhead Publishing: Cambridge, UK, 2015; Volume 1, pp. 133–155. ISBN 9781782423331. [Google Scholar]

- Raghunathan, R.; Naylor, R.W.; Hoyer, W.D. The unhealthy = Tasty intuition and its effects on taste inferences, enjoyment, and choice of food products. J. Mark. 2006, 70, 170–184. [Google Scholar] [CrossRef]

- Prakash, S.; Bhandari, B.R.; Godoi, F.C.; Zhang, M. Future outlook of 3D food printing. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 373–381. ISBN 9780128145647. [Google Scholar]

- Ross, M.M.; Kelly, A.L.; Crowley, S.V. Potential applications of dairy products, ingredients and formulations in 3D printing. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 175–206. ISBN 9780128145647. [Google Scholar]

- Schutyser, M.A.I.; Houlder, S.; de Wit, M.; Buijsse, C.A.P.; Alting, A.C. Fused deposition modelling of sodium caseinate dispersions. J. Food Eng. 2018, 220, 49–55. [Google Scholar] [CrossRef]

- Sungsinchai, S.; Niamnuy, C.; Wattanapan, P.; Charoenchaitrakool, M.; Devahastin, S. Texture modification technologies and their opportunities for the production of dysphagia foods: A review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1898–1912. [Google Scholar] [CrossRef] [PubMed]

- Gholamipour-Shirazi, A.; Kamlow, M.-A.T.; Norton, I.; Mills, T. How to formulate for structure and texture via medium of additive manufacturing—A review. Foods 2020, 9, 497. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization (ISO). Sensory Analysis—Methodology—Texture Profile (IS0 11036); ISO: Geneva, Switzerland, 2020. [Google Scholar]

- Mouritsen, O.G.; Styrbæk, K. Mouthfeel. How Texture Makes Taste; Mouritsen, O.G., Styrbæk, K., Eds.; Columbia University Press: New York, NY, USA, 2017; ISBN 9780231543248. [Google Scholar]

- IDDSI International Dysphagia Diet Standardization Initiative. Available online: https://www.iddsi.org/ (accessed on 14 January 2021).

- McCrickerd, K.; Forde, C.G. Sensory influences on food intake control: Moving beyond palatability. Obes. Rev. 2016, 17, 18–29. [Google Scholar] [CrossRef] [PubMed]

- Biswas, D.; Szocs, C.; Krishna, A.; Lehmann, D.R. Something to chew on: The effects of oral haptics on mastication, orosensory perception, and calorie estimation. J. Consum. Res. 2014, 41, 261–273. [Google Scholar] [CrossRef]

- Pramudya, R.C.; Seo, H.-S. Hand-feel touch cues and their influences on consumer perception and behavior with respect to food products: A review. Foods 2019, 8, 259. [Google Scholar] [CrossRef]

- Jansson-Boyd, C.V.; Kobescak, M. To see is to hold: Using food surface textures to communicate product healthiness. Food Qual. Prefer. 2020, 81, 103866. [Google Scholar] [CrossRef]

- Van Rompay, T.J.L.; Groothedde, S. The taste of touch: Enhancing saltiness impressions through surface texture design. Food Qual. Prefer. 2019, 73, 248–254. [Google Scholar] [CrossRef]

- Van Rompay, T.J.L.; Kramer, L.-M.; Saakes, D. The sweetest punch: Effects of 3D-printed surface textures and graphic design on ice-cream evaluation. Food Qual. Prefer. 2018, 68, 198–204. [Google Scholar] [CrossRef]

- Van Rompay, T.J.L.; Finger, F.; Saakes, D.; Fenko, A. “See me, feel me”: Effects of 3D-printed surface patterns on beverage evaluation. Food Qual. Prefer. 2017, 62, 332–339. [Google Scholar] [CrossRef]

- Rapisarda, M.; Valenti, G.; Carbone, D.C.; Rizzarelli, P.; Recca, G.; La Carta, S.; Paradisi, R.; Fincchiaro, S. Strength, fracture and compression properties of gelatins by a new 3D printed tool. J. Food Eng. 2018, 220, 38–48. [Google Scholar] [CrossRef]

- Norton, I.T.; Spyropoulos, F.; Cox, P. Practical Food Rheology: An Interpretive Approach; Norton, I.T., Spyropoulos, F., Cox, P., Eds.; Wiley-Blackwell: Oxford, UK, 2011; ISBN 9781444391060. [Google Scholar]

- O’Sullivan, M.G. Instrumental assessment of the sensory quality of food and beverage products. In A Handbook for Sensory and Consumer-Driven New Product Development; O’Sullivan, M.G., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 151–175. ISBN 9780081003527. [Google Scholar]

- Lu, R. Principles of solid food texture analysis. In Instrumental Assessment of Food Sensory Quality; Kilcast, D., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 103–128. ISBN 9780857098856. [Google Scholar]

- Le Tohic, C.; O’Sullivan, J.J.; Drapala, K.P.; Chartrin, V.; Chan, T.; Morrison, A.P.; Kerry, J.P.; Kelly, A.L. Effect of 3D printing on the structure and textural properties of processed cheese. J. Food Eng. 2018, 220, 56–64. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Stability of 3D printing using a mixture of pea protein and alginate: Precision and application of additive layer manufacturing simulation approach for stress distribution. J. Food Eng. 2021, 288, 110127. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Bhandari, B.; Liu, Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT 2018, 87, 67–76. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Le-Bail, A.; Maniglia, B.C.; Le-Bail, P. Recent advances and future perspective in additive manufacturing of foods based on 3D printing. Curr. Opin. Food Sci. 2020, 35, 54–64. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Huang, D.; Fuh, J.Y.H.; Hong, G.S. An overview of 3D printing technologies for food fabrication. Food Bioprocess Technol. 2015, 8, 1605–1615. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M. 3D food printing technologies and factors affecting printing precision. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 19–40. ISBN 9780128145647. [Google Scholar]

- Nachal, N.; Moses, J.A.; Karthik, P.; Anandharamakrishnan, C. Applications of 3D printing in food processing. Food Eng. Rev. 2019, 11, 123–141. [Google Scholar] [CrossRef]

- Caporizzi, R.; Derossi, A.; Severini, C. Cereal-based and insect-enriched printable food. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 93–116. ISBN 9780128145647. [Google Scholar]

- Liu, Z.; Zhang, M.; Bhandari, B.; Wang, Y. 3D printing: Printing precision and application in food sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef]

- Tamay, D.G.; Dursun Usal, T.; Alagoz, A.S.; Yucel, D.; Hasirci, N.; Hasirci, V. 3D and 4D printing of polymers for tissue engineering applications. Front. Bioeng. Biotechnol. 2019, 7, 22. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. 3D printing of meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Paolillo, M.; Severini, C. Programmable texture properties of cereal-based snack mediated by 3D printing technology. J. Food Eng. 2021, 289, 110160. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innov. Food Sci. Emerg. Technol. 2017, 44, 21–29. [Google Scholar] [CrossRef]

- Lanaro, M.; Desselle, M.R.; Woodruff, M.A. 3D Printing Chocolate: Properties of Formulations for Extrusion, Sintering, Binding and Ink Jetting. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 151–173. ISBN 9780128145647. [Google Scholar]

- Liu, Z.; Bhandari, B.; Prakash, S.; Zhang, M. Creation of internal structure of mashed potato construct by 3D printing and its textural properties. Food Res. Int. 2018, 111, 534–543. [Google Scholar] [CrossRef] [PubMed]

- Severini, C.; Derossi, A.; Ricci, I.; Caporizzi, R.; Fiore, A. Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. J. Food Eng. 2018, 220, 89–100. [Google Scholar] [CrossRef]

- Lupton, D.; Turner, B. “I can’t get past the fact that it is printed”: Consumer attitudes to 3D printed food. Food Cult. Soc. 2018, 21, 402–418. [Google Scholar] [CrossRef]

- Theagarajan, R.; Moses, J.A.; Anandharamakrishnan, C. 3D extrusion printability of rice starch and optimization of process variables. Food Bioprocess Technol. 2020, 13, 1048–1062. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, T.; Duan, S.; Qin, Z.; Zhao, H.; Wang, M.; Li, C.; Zhang, Z.; Liu, A.; Han, G.; et al. Applicability of rice doughs as promising food materials in extrusion-based 3D printing. Food Bioprocess Technol. 2020, 13, 548–563. [Google Scholar] [CrossRef]

- Liu, L.; Yang, X.; Bhandari, B.; Meng, Y.; Prakash, S. Optimization of the formulation and properties of 3D-printed complex egg white protein objects. Foods 2020, 9, 164. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Bhandari, B. Texture-modified 3D printed dark chocolate: Sensory evaluation and consumer perception study. J. Texture Stud. 2019, 50, 386–399. [Google Scholar] [CrossRef]

- Mosca, A.C.; Bult, J.H.F.; Stieger, M. Effect of spatial distribution of tastants on taste intensity, fluctuation of taste intensity and consumer preference of (semi-)solid food products. Food Qual. Prefer. 2013, 28, 182–187. [Google Scholar] [CrossRef]

- Vancauwenberghe, V.; Baiye Mfortaw Mbong, V.; Vanstreels, E.; Verboven, P.; Lammertyn, J.; Nicolai, B. 3D printing of plant tissue for innovative food manufacturing: Encapsulation of alive plant cells into pectin based bio-ink. J. Food Eng. 2019, 263, 454–464. [Google Scholar] [CrossRef]

- Zhu, S.; Stieger, M.A.; van der Goot, A.J.; Schutyser, M.A.I. Extrusion-based 3D printing of food pastes: Correlating rheological properties with printing behaviour. Innov. Food Sci. Emerg. Technol. 2019, 58, 102214. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Yang, C. Dual extrusion 3D printing of mashed potatoes/strawberry juice gel. LWT 2018, 96, 589–596. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Saeed, A.; Lan, W.; Qin, W. Properties of 3D printed dough and optimization of printing parameters. Innov. Food Sci. Emerg. Technol. 2019, 54, 9–18. [Google Scholar] [CrossRef]

- Kim, H.W.; Bae, H.; Park, H.J. Reprint of: Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2018, 220, 28–37. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Dong, X.; Prakash, S. Feasibility study of hydrocolloid incorporated 3D printed pork as dysphagia food. Food Hydrocoll. 2020, 107, 105940. [Google Scholar] [CrossRef]

- Tan, C.; Toh, W.Y.; Wong, G.; Lin, L. Extrusion-based 3D food printing—Materials and machines. Int. J. Bioprinting 2018, 4, 1–13. [Google Scholar] [CrossRef]

- Azam, R.S.M.; Zhang, M.; Bhandari, B.; Yang, C. Effect of different gums on features of 3D printed object based on vitamin-D enriched orange concentrate. Food Biophys. 2018, 13, 250–262. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B. Effect of gums on the rheological, microstructural and extrusion printing characteristics of mashed potatoes. Int. J. Biol. Macromol. 2018, 117, 1179–1187. [Google Scholar] [CrossRef]

- Kim, H.W.; Lee, I.J.; Park, S.M.; Lee, J.H.; Nguyen, M.-H.; Park, H.J. Effect of hydrocolloid addition on dimensional stability in post-processing of 3D printable cookie dough. LWT 2019, 101, 69–75. [Google Scholar] [CrossRef]

- Cohen, D.; Lipton, J.; Cutler, M.; Coulter, D.; Vesco, A.; Lipson, H. Hydrocolloid printing: A novel platform for customized food production. In Proceedings of the 20th Annual International Solid Freeform Fabrication Symposium SFF, Austin, TX, USA, 3–5 August 2009; pp. 807–818. [Google Scholar]

- Hao, L.; Li, Y.; Gong, P.; Xiong, W. Material, process and business development for 3D chocolate printing. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 207–255. ISBN 9780128145647. [Google Scholar]

- Mantihal, S.; Prakash, S.; Bhandari, B. Textural modification of 3D printed dark chocolate by varying internal infill structure. Food Res. Int. 2019, 121, 648–657. [Google Scholar] [CrossRef] [PubMed]

- Feng, C.; Zhang, M.; Bhandari, B. Controlling the three-dimensional printing mechanical properties of Nostoc sphaeroides system. Food Biophys. 2020, 15, 240–248. [Google Scholar] [CrossRef]

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On printability, quality and nutritional properties of 3D printed cereal based snacks enriched with edible insects. Food Res. Int. 2018, 106, 666–676. [Google Scholar] [CrossRef] [PubMed]

- Vieira, M.V.; Oliveira, S.M.; Amado, I.R.; Fasolin, L.H.; Vicente, A.A.; Pastrana, L.M.; Fuciños, P. 3D printed functional cookies fortified with Arthrospira platensis: Evaluation of its antioxidant potential and physical-chemical characterization. Food Hydrocoll. 2020, 107, 105893. [Google Scholar] [CrossRef]

- Lee, J.H.; Won, D.J.; Kim, H.W.; Park, H.J. Effect of particle size on 3D printing performance of the food-ink system with cellular food materials. J. Food Eng. 2019, 256, 1–8. [Google Scholar] [CrossRef]

- Lipton, J.; Arnold, D.; Nigl, F.; Lopez, N.; Cohen, D.; Norén, N.; Lipson, H. Mutli-material food printing with complex internal structure suitable for conventional post-processing. In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference SFF, Austin, TX, USA, 9–11 August 2010; pp. 809–815. [Google Scholar]

- Dong, X.; Pan, Y.; Zhao, W.; Huang, Y.; Qu, W.; Pan, J.; Qi, H.; Prakash, S. Impact of microbial transglutaminase on 3D printing quality of Scomberomorus niphonius surimi. LWT 2020, 124, 109123. [Google Scholar] [CrossRef]

- Holland, S.; Foster, T.; Tuck, C. Creation of food structures through binder jetting. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; Volume 1867, pp. 257–288. ISBN 9780128145647. [Google Scholar]

- Holland, S.; Tuck, C.; Foster, T. Selective recrystallization of cellulose composite powders and microstructure creation through 3D binder jetting. Carbohydr. Polym. 2018, 200, 229–238. [Google Scholar] [CrossRef]

- Noort, M.; Van Bommel, K.; Renzetti, S. 3D-printed cereal foods. Cereal Foods World 2017, 62, 272–277. [Google Scholar] [CrossRef]

- Kim, H.W.; Lee, J.H.; Park, S.M.; Lee, M.H.; Lee, I.W.; Doh, H.S.; Park, H.J. Effect of hydrocolloids on rheological properties and printability of vegetable inks for 3D food printing. J. Food Sci. 2018, 83, 2923–2932. [Google Scholar] [CrossRef]

- Kouzani, A.Z.; Adams, S.J.; Whyte, D.; Oliver, R.; Hemsley, B.; Palmer, S.; Balandin, S. 3D printing of food for people with swallowing difficulties. KnE Eng. 2017, 2, 23. [Google Scholar] [CrossRef]

- Park, S.M.; Kim, H.W.; Park, H.J. Callus-based 3D printing for food exemplified with carrot tissues and its potential for innovative food production. J. Food Eng. 2020, 271, 109781. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. Post-processing feasibility of composite-layer 3D printed beef. Meat Sci. 2019, 153, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Ghazal, A.F.; Zhang, M.; Liu, Z. Spontaneous color change of 3D printed healthy food product over time after printing as a novel application for 4D food printing. Food Bioprocess Technol. 2019, 12, 1627–1645. [Google Scholar] [CrossRef]

- He, C.; Zhang, M.; Guo, C. 4D printing of mashed potato/purple sweet potato puree with spontaneous color change. Innov. Food Sci. Emerg. Technol. 2020, 59, 102250. [Google Scholar] [CrossRef]

- Hertafeld, E.; Zhang, C.; Jin, Z.; Jakub, A.; Russell, K.; Lakehal, Y.; Andreyeva, K.; Bangalore, S.N.; Mezquita, J.; Blutinger, J.; et al. Multi-material three-dimensional food printing with simultaneous infrared cooking. 3D Print. Addit. Manuf. 2019, 6, 13–19. [Google Scholar] [CrossRef]

- Vancauwenberghe, V.; Delele, M.A.; Vanbiervliet, J.; Aregawi, W.; Verboven, P.; Lammertyn, J.; Nicolaï, B. Model-based design and validation of food texture of 3D printed pectin-based food simulants. J. Food Eng. 2018, 231, 72–82. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, M.; Bhandari, B.; Ye, Y. Use of potato processing by-product: Effects on the 3D printing characteristics of the yam and the texture of air-fried yam snacks. LWT 2020, 125, 109265. [Google Scholar] [CrossRef]

- Liu, Z.; Dick, A.; Prakash, S.; Bhandari, B.; Zhang, M. Texture modification of 3D printed air-fried potato snack by varying its internal structure with the potential to reduce oil content. Food Bioprocess Technol. 2020, 13, 564–576. [Google Scholar] [CrossRef]

- Severini, C.; Derossi, A.; Azzollini, D. Variables affecting the printability of foods: Preliminary tests on cereal-based products. Innov. Food Sci. Emerg. Technol. 2016, 38, 281–291. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Bhandari, B. Model building and slicing in food 3D printing processes: A review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1052–1069. [Google Scholar] [CrossRef]

- Yang, F.; Guo, C.; Zhang, M.; Bhandari, B.; Liu, Y. Improving 3D printing process of lemon juice gel based on fluid flow numerical simulation. LWT 2019, 102, 89–99. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Liu, Y. Effect of post-treatment microwave vacuum drying on the quality of 3D-printed mango juice gel. Dry. Technol. 2019, 37, 1757–1765. [Google Scholar] [CrossRef]

- Zhang, L.; Lou, Y.; Schutyser, M.A.I. 3D printing of cereal-based food structures containing probiotics. Food Struct. 2018, 18, 14–22. [Google Scholar] [CrossRef]

- Abbot, D.W.; Kallon, D.V.V.; Anghel, C.; Dube, P. Finite element analysis of 3D printed model via compression tests. Procedia Manuf. 2019, 35, 164–173. [Google Scholar] [CrossRef]

- Srirekha, A.; Bashetty, K. Infinite to finite: An overview of finite element analysis. Indian J. Dent. Res. 2010, 21, 425. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.-F.; Zhang, M.; Bhandari, B. A comparative study between syringe-based and screw-based 3D food printers by computational simulation. Comput. Electron. Agric. 2019, 162, 397–404. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, N.; Wei, W.; Hu, X.; Tan, Y.; Yu, Y.; Deng, Y.; Bi, C.; Zhang, L.; Zhang, H. Assessing the dynamic extrusion-based 3D printing process for power-law fluid using numerical simulation. J. Food Eng. 2020, 275, 109861. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Devahastin, S. 3D extrusion-based printability evaluation of selected cereal grains by computational fluid dynamic simulation. J. Food Eng. 2020, 286, 110113. [Google Scholar] [CrossRef]

- Lupton, D.; Turner, B. Food of the future? Consumer responses to the idea of 3D-printed meat and insect-based foods. Food Foodways 2018, 26, 269–289. [Google Scholar] [CrossRef]

- Brunner, T.A.; Delley, M.; Denkel, C. Consumers’ attitudes and change of attitude toward 3D-printed food. Food Qual. Prefer. 2018, 68, 389–396. [Google Scholar] [CrossRef]

- Manstan, T.; McSweeney, M.B. Consumers’ attitudes towards and acceptance of 3D printed foods in comparison with conventional food products. Int. J. Food Sci. Technol. 2020, 55, 323–331. [Google Scholar] [CrossRef]

- Caulier, S.; Doets, E.; Noort, M. An exploratory consumer study of 3D printed food perception in a real-life military setting. Food Qual. Prefer. 2020, 86, 104001. [Google Scholar] [CrossRef]

- Strother, H.; Moss, R.; McSweeney, M.B. Comparison of 3D printed and molded carrots produced with gelatin, guar gum and xanthan gum. J. Texture Stud. 2020, 1–9. [Google Scholar] [CrossRef]

- Fiorentini, M.; Kinchla, A.J.; Nolden, A.A. Role of sensory evaluation in consumer acceptance of plant-based meat analogs and meat extenders: A scoping review. Foods 2020, 9, 1334. [Google Scholar] [CrossRef] [PubMed]

- Team Open Meals Restaurant Sushi Singularity|Open Meals. Available online: http://www.open-meals.com/sushisingularity/index_e.html (accessed on 25 September 2020).

- Wang, W.; Yao, L.; Zhang, T.; Cheng, C.-Y.; Levine, D.; Ishii, H. Transformative appetite. In Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems; ACM: New York, NY, USA, 2017; pp. 6123–6132. [Google Scholar]

| Advantages | Limitations | References |

|---|---|---|

| - Personalized nutrition content and development of healthier foods | - Still presents high costs associated | [2,31,35,52,61,65,66,67] |

| - Freedom to design novel and more complex visual structures and textures | - Low number of compatible materials | |

| - Food waste reduction | - Still very slow to print | |

| - Potential to use alternative sources of materials | - Food safety and printer sanitation concerns | |

| - Can solve problems related to allergies and cross-contamination | - Consumers’ perception | |

| - Potential to simplify and speed up the manufacturing process | - Limited printing accuracy and surface finishes | |

| - Decentralized production | ||

| - Reductions in energy and transportation needs |

| Material | Printer | Structure Pattern | Parameters Studied | Effects on the Printed Products | Reference |

|---|---|---|---|---|---|

| Cereal | 3D printer Delta 2039 | Parallelepiped with internal cubes | - Void number (4, 5, 6, 7, 8, 10, and 12); - Void position | - Pore size and position influence the printed products; - Porosity presents a negative influence on weight, moisture, and water activity; - Porosity influences hardness which decreases with the decrease in the relative density of the printed products; - Increase in dough porosity during baking (exterior to the model) accounts for the decrease in hardness. | [62] |

| Dough | 3D printer | Cube, Cone, and Sphere | - Compressive pressure (300, 400, 500, 600, and 700 kPa); - Needle velocity (3, 6, 9, 12, and 15 mm/s); - Needle diameter (0.25, 0.41, 0.58, 0.84, and 1.19 mm); - Infill levels (10, 30, 50, 70, and 100%) | - Best printing results at 600 kPa, 6 mm/s printing speed, 0.58 mm nozzle diameter, and 50% infill level; - Addition of olive oil and mango powder causes a decrease in hardness but an increase in elasticity and resilience of the printed product; - The printing process leads to further reduction in the hardness, adhesiveness, elasticity, and resilience. | [76] |

| Dark chocolate | Printer with rotary extrusion (Porimy 1.0) | Cylinder with Star, Hilbert curve, and Honeycomb internal patterns | - Infill levels (5, 30, 60, and 100%); - Infill patterns | - Infill level influences the weight of the printed product, which in turn influences the void on the structures; - Increasing infill percentage causes an increase in the weight of the prints and decrease the void fraction on the structures; - Increasing the infill level also increases the hardness of the products but even a 100% infill presents lower hardness than cast chocolate; - Star and honeycomb patterns provide the most stability and hardness at 60% infill to the printed results. | [35,85] |

| Brown rice with xanthan gum and guar gum | 3D Printer | Cylinder with crossing lines | - Nozzle diameter (0.84, 1.2, and 1.56 mm); - Perimeters (3, 5, and 7); - Infill level (15, 45, and 75%) | - Nozzle diameter and perimeter affect the printed structures’ height and diameter; - All parameters positively impact the weight of the products; - Faster printing speeds can be achieved using wider nozzles at lower infill densities and perimeters, but can cause dimensional deviations; - All tested parameters affect the samples’ texture (hardness and gumminess), with the infill level exerting the biggest effect. | [20] |

| Yam and Potato | Dual nozzle extrusion printer (Shinnove -D1) | Cylinder with Rectilinear, Wiggle, Triangular, and Honeycomb internal patterns | - Infill Level (20, 50, and 80%); - Infill patterns | - Printed products present a slightly larger dimensional structure than the model; - Infill level influences the porosity, weight, texture, moisture content, hardness, and air-frying processing time; - Higher infill levels decrease the porosity and moisture and increase the weight, hardness, and air-frying processing time (12 min at 20% infill level, 16 min at 50%, and 24 min at 80%); - Infill patterns also influence the hardness of the products, with triangular structures presenting higher hardness at 50 and 80% infill. | [103] |

| Mashed potatoes | Dual nozzle extrusion printer | Cylinder with Rectilinear, Hilbert curve, and Honeycomb internal patterns | - Infill levels (10, 40, and 70%); - Number of shell perimeters (3, 5, and 7); - Infill patterns | - Infill level, more than the other infill parameters (no effect with the pattern, and limited effect with perimeter), presents a strong influence on weight, void fraction, hardness, gumminess, firmness, and Young’s modulus; - Higher infill levels increase all characteristics except for the void fraction which decreases; - Even at 100% infill level, the printed samples present lower hardness compared to the cast samples. | [65] |

| Potato | 3D Printer | Cylinder with Rectilinear, Cubic, and Honeycomb internal patterns | - Infill patterns; - Infill levels (20, 50, and 70%) | - Infill level and pattern both influence the printing time, extrusion rate, weight, hardness, and fracturability; - Higher infill levels increase all properties tested; - An increase in the infill level and complexity pattern increases the printing time. Longer times are needed to produce honeycomb structures and shorter for rectilinear. | [104] |

| Dark chocolate | 3D Printer (Shinnove -D1) | Rectangular with Rectilinear and Honeycomb internal patterns | - Infill levels (25, 50, and 100%); - Infill patterns | - Infill levels influence the hardness of the samples. Increasing the infill also increases the force necessary to break the samples. | [71] |

| Wheat dough | 3D printer Delta 2040 | Cylinder with crossing lines | - Infill levels (10, 15, and 20%); - Layer height (0.3, 0.4, and 0.5 mm) | - Layer height positively influences structures’ diameter and negatively influences the solid matrix fraction and height of the printed snacks. Higher layer height results in a rougher visual aspect of the printed product; - Infill level positively influences the diameter, solid matrix fraction, and hardness of samples; - Cooking of the printed snacks leads to an increase in porosity and weight loss; - Samples printed with a 20% infill level and 0.3 mm of layer height show the highest moisture, hardness, and solid fraction. | [105] |

| Mashed potatoes and strawberry juice gel | 3D Printer | Cylinder with varied internal patterns (triangular, circle, hexagon, and square), a cube with varied layer disposition, and a cube with rectilinear lines | - Mashed potatoes volume ratio (7.44, 20.67, and 41.35%); - Infill levels (40, 60, 80, and 100%); - Infill patterns | - Volume ratio of mashed potatoes influences the hardness and gumminess of the printed products independently of the internal pattern; - Infill levels influence the printing time and rate, hardness, fracturability, and weight of the printed products; - At higher infill levels there is an increase in the weight, printing time and rate, young’s modulus, hardness, firmness, and gumminess, and a decrease in adhesiveness of the printed structures. | [75] |

| Drawbacks | Comments |

|---|---|

| Several studies have attempted to establish a correlation between the materials’ rheological properties and the printing parameters on the printing performance (i.e., [6,68,74]). However, by using distinct formulations, the printing conditions present different effects on the printing performance. A definitive correlation between these conditions and the printing results, capable of being applied in most materials used, has yet to be reached, slowing the development of 3D printed products. |

| A few studies have attempted to test the effects of the materials’ properties (viscosity), products structure (infill level), printing parameters, hydrocolloid addition, and post-processing on the sensory response (see [10,68,71,108,119]). Nonetheless, thus far, the knowledge is still limited and scattered. Further research on the influence of the mentioned parameters on the sensory response would benefit the development of printed food products with good consumer acceptability. |

| Computer-aided software (CAD) software is used during the modeling and slicing stages of the printing process, however, most of the software was developed for the printing of thermoplastic materials and does not take into account the properties of food materials [8,106]. The same happens with finite element method (FEM)-based software that is being used to predict the mechanical and flow properties of the materials [102,107]. The fact that the existing software does not consider the food’s properties will create dimensional discrepancies between the virtual model and predicted structures and the real printed products [8]. |

| People have different nutritional needs according to their specific age, occupation, activity level, etc., and thus, each person will present an individual nutritional profile. The development of personalized software that considers these factors would enable the production of tailored food products for specific groups of people [106]. |

| At least one study has shown microbial growth on the printed products, which suggests the possibility of contamination during the printing process [66]. Other possible hazard risks include the fragmentation of printer parts or the production of health-hazardous compounds [24]. Thus, as key factors in the food industry, sanitation protocols and further studies on the safety of 3D printed food should be performed. |

| Some alternative food material sources have been successfully printed (algae, mushrooms, insects) but their use is still limited [9,58,88]. In the specific case of the printing of meat, it could be served as an alternative for people that follow a vegetarian diet. As the meat is printed with alternative sources or cell cultures, there is no need to sacrifice live animals, and thus it can be consumed without the conflicted views associated with animal consumption [57]. |

| Microencapsulation and electrospinning can potentiate the introduction of functional ingredients to the food formulations [12,57]. Incorporating cooking technologies to the printer would accelerate the printing process [101]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, T.; Barroso, S.; Gil, M.M. Food Texture Design by 3D Printing: A Review. Foods 2021, 10, 320. https://doi.org/10.3390/foods10020320

Pereira T, Barroso S, Gil MM. Food Texture Design by 3D Printing: A Review. Foods. 2021; 10(2):320. https://doi.org/10.3390/foods10020320

Chicago/Turabian StylePereira, Tatiana, Sónia Barroso, and Maria M. Gil. 2021. "Food Texture Design by 3D Printing: A Review" Foods 10, no. 2: 320. https://doi.org/10.3390/foods10020320

APA StylePereira, T., Barroso, S., & Gil, M. M. (2021). Food Texture Design by 3D Printing: A Review. Foods, 10(2), 320. https://doi.org/10.3390/foods10020320