Effect of Electric Field Distribution on the Heating Uniformity of a Model Ready-to-Eat Meal in Microwave-Assisted Thermal Sterilization Using the FDTD Method

Abstract

1. Introduction

2. Materials and Methods

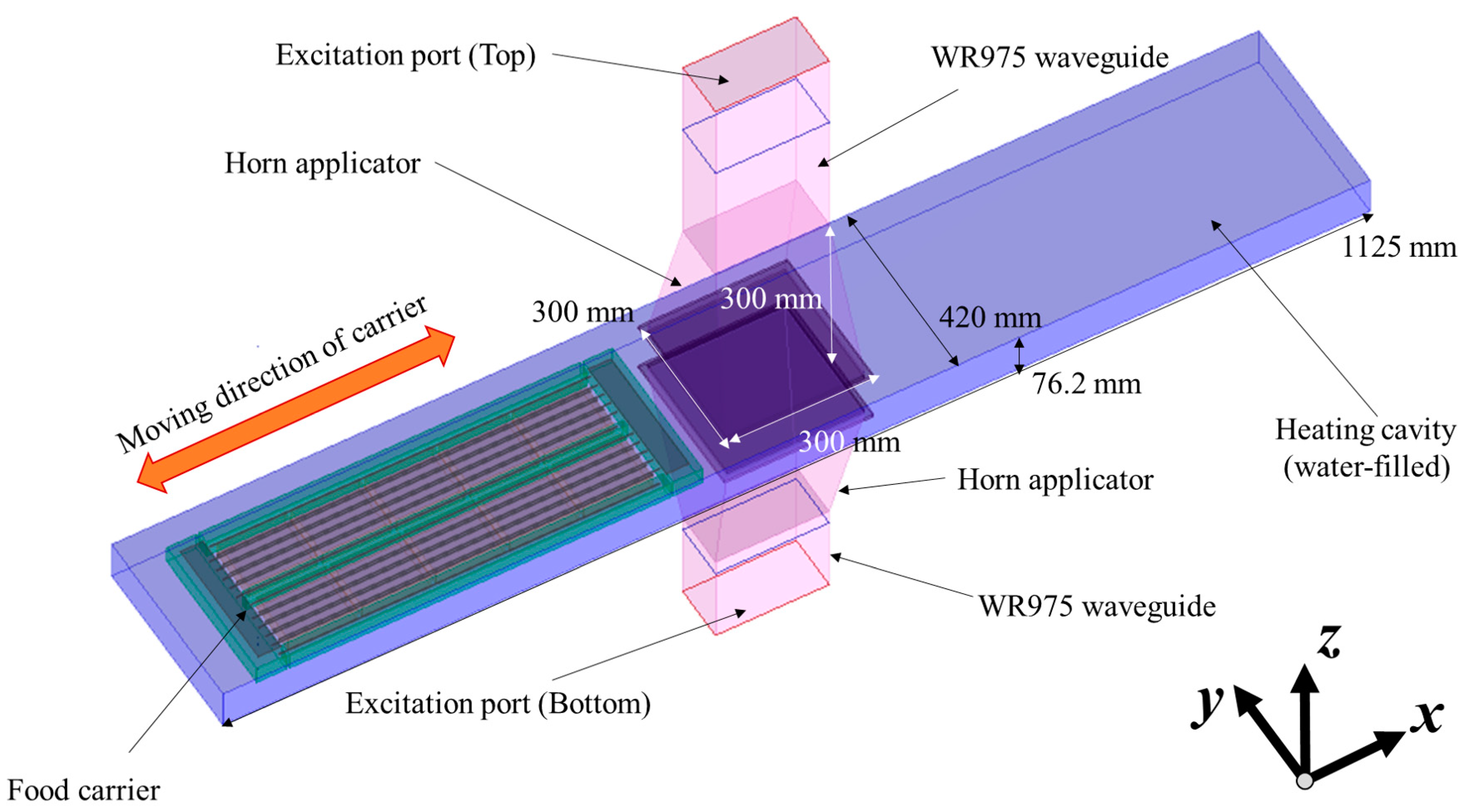

2.1. 3D Numerical Simulation

2.2. Experimental Validation

2.2.1. Model Food Preparation

2.2.2. MATS Processing Conditions

2.2.3. Heating Pattern Analysis Using a Computer Vision Technique

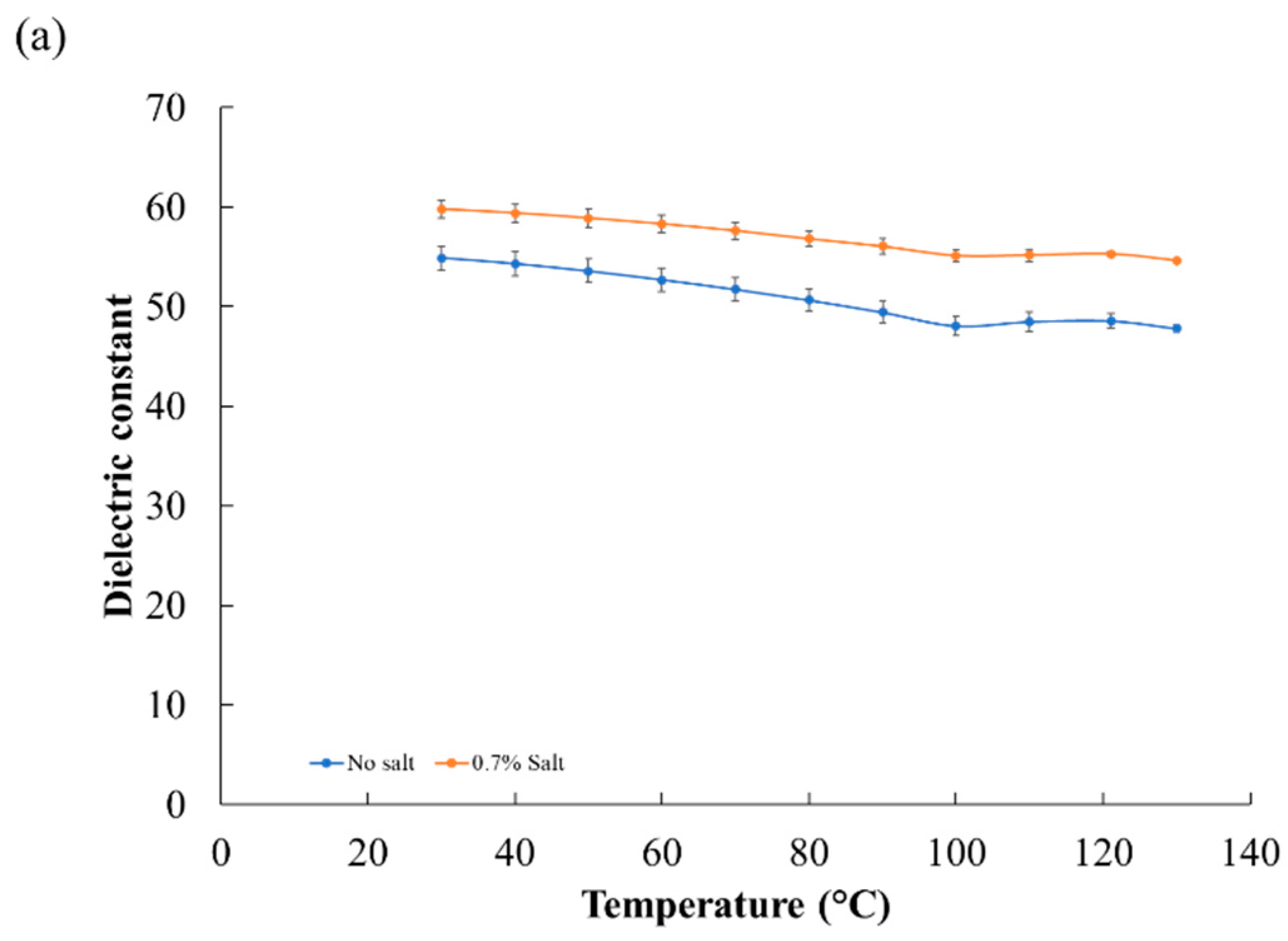

2.2.4. Dielectric and Thermal Property Measurement

3. Results and Discussion

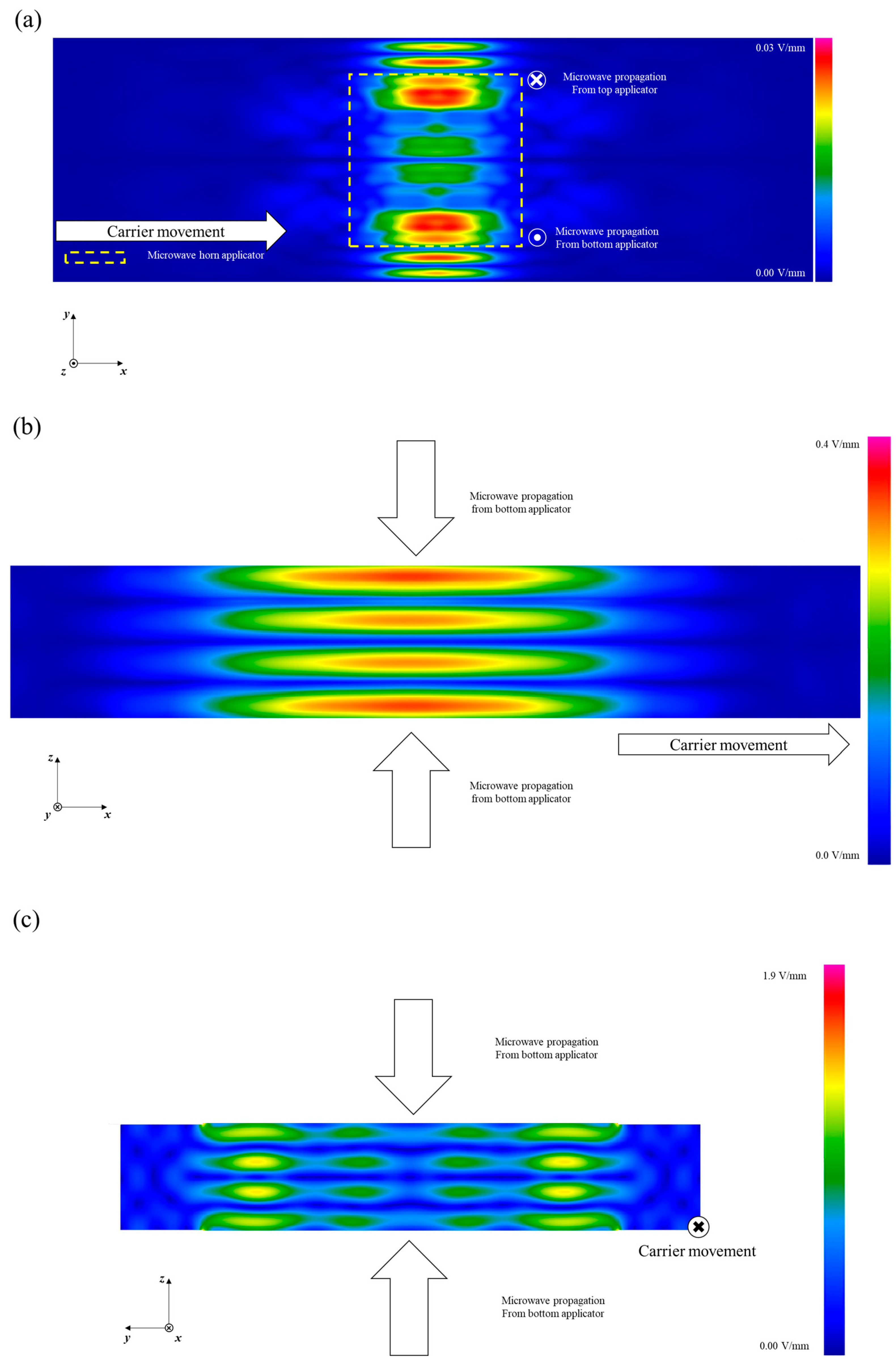

3.1. Electric Field Distribution of the Empty Microwave Cavity

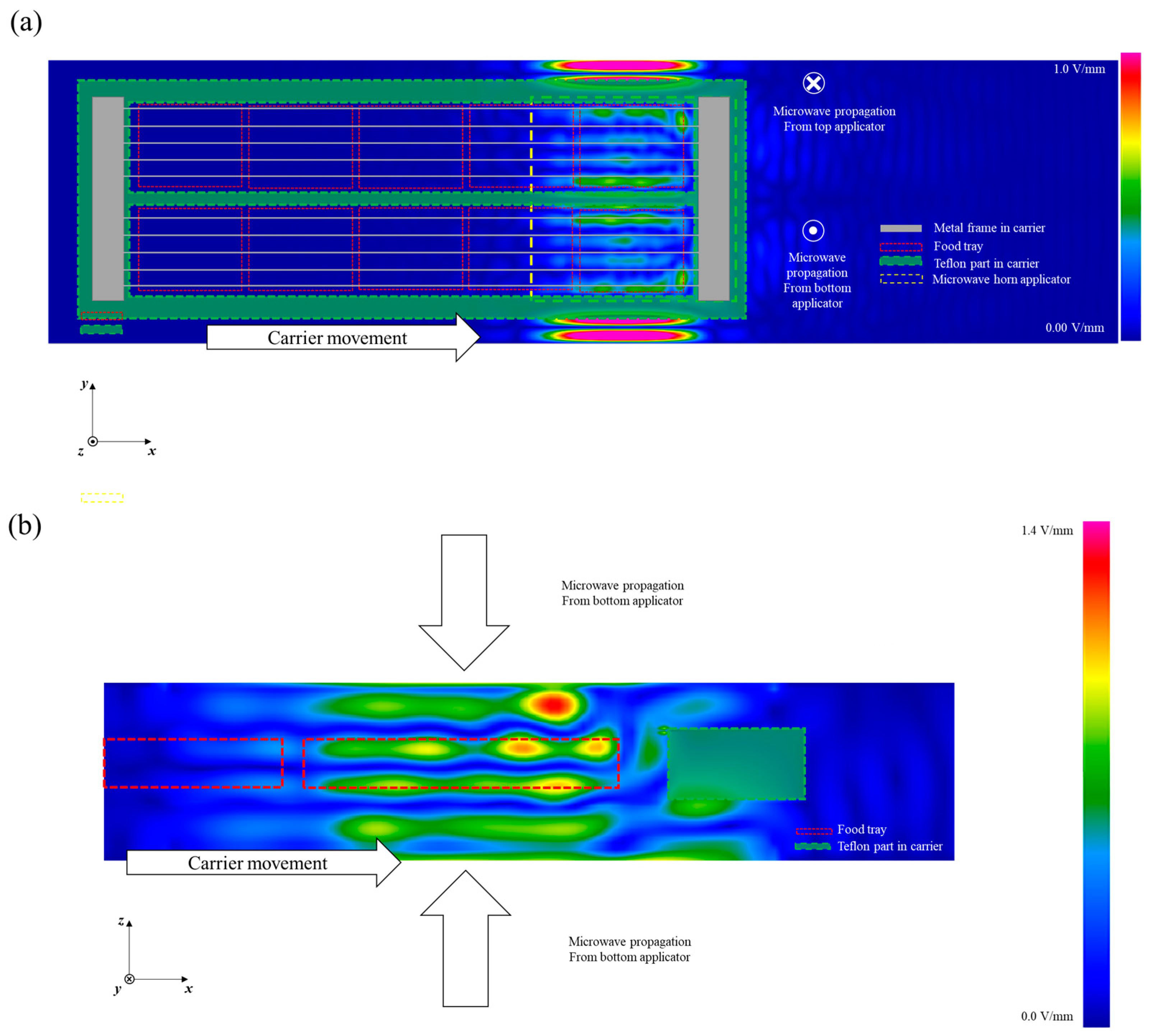

3.2. Electric Field Distribution of the Loaded Microwave Cavity

3.3. Actual Heating Pattern Analysis with Model Food

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, J. Unlocking Potentials of Microwaves for Food Safety and Quality. J. Food Sci. 2015, 80, E1776–E1793. [Google Scholar] [CrossRef] [PubMed]

- Chizoba Ekezie, F.-G.; Sun, D.-W.; Han, Z.; Cheng, J.-H. Microwave-assisted food processing technologies for enhancing product quality and process efficiency: A review of recent developments. Trends Food Sci. Tech. 2017, 67, 58–69. [Google Scholar] [CrossRef]

- Tang, J.; Hong, Y.-K.; Inanoglu, S.; Liu, F. Microwave Pasteurization for Ready-to-Eat Meals. Curr. Opin. Food Sci. 2018, 23. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave material processing—A review. AIChE J. 2012, 58, 330–363. [Google Scholar] [CrossRef]

- Raaholt, B.W.; Isaksson, S. Improving the heating uniformity in microwave processing. In The Microwave Processing of Foods; Elsevier: Amsterdam, The Netherlands, 2017; pp. 381–406. [Google Scholar]

- Zhu, H.; He, J.; Hong, T.; Yang, Q.; Wu, Y.; Yang, Y.; Huang, K. A rotary radiation structure for microwave heating uniformity improvement. Appl. Therm. Eng. 2018, 141, 648–658. [Google Scholar] [CrossRef]

- Luan, D.; Tang, J.; Pedrow, P.D.; Liu, F.; Tang, Z. Analysis of electric field distribution within a microwave assisted thermal sterilization (MATS) system by computer simulation. J. Food Eng. 2016, 188, 87–97. [Google Scholar] [CrossRef]

- Jain, D.; Tang, J.; Liu, F.; Tang, Z.; Pedrow, P.D. Computational evaluation of food carrier designs to improve heating uniformity in microwave assisted thermal pasteurization. Innov. Food Sci. Emerg. 2018, 48, 274–286. [Google Scholar] [CrossRef]

- Luan, D.; Tang, J.; Pedrow, P.D.; Liu, F.; Tang, Z. Using mobile metallic temperature sensors in continuous microwave assisted sterilization (MATS) systems. J. Food Eng. 2013, 119, 552–560. [Google Scholar] [CrossRef]

- Resurreccion, F.P.; Luan, D.; Tang, J.; Liu, F.; Tang, Z.; Pedrow, P.D.; Cavalieri, R. Effect of changes in microwave frequency on heating patterns of foods in a microwave assisted thermal sterilization system. J. Food Eng. 2015, 150, 99–105. [Google Scholar] [CrossRef]

- Chen, H.; Tang, J.; Liu, F. Simulation model for moving food packages in microwave heating processes using conformal FDTD method. J. Food Eng. 2008, 88, 294–305. [Google Scholar] [CrossRef]

- WSU Insider. India Partnership Deploys New WSU Microwave Technologies for Safer Meals. Available online: https://news.wsu.edu/2020/03/31/india-partnership-deploys-new-wsu-microwave-technologies-safer-meals/ (accessed on 15 January 2021).

- Pathak, S.; Liu, F.; Tang, J. Finite difference time domain (FDTD) characterization of a single mode applicator. J. Microwave Power Electromagn. Energy 2003, 38, 37–48. [Google Scholar] [CrossRef]

- Resurreccion, F.P.; Tang, J.; Pedrow, P.; Cavalieri, R.; Liu, F.; Tang, Z. Development of a computer simulation model for processing food in a microwave assisted thermal sterilization (MATS) system. J. Food Eng. 2013, 118, 406–416. [Google Scholar] [CrossRef]

- Zhao, X.; Yan, L.; Huang, K. Review of Numerical simulation of Microwave Heating Process. In Advances in Induction and Microwave Heating of Mineral and Organic Materials; Grundas, S., Ed.; IntechOpen: London, UK, 2011; pp. 27–48. [Google Scholar] [CrossRef]

- Jain, D.; Tang, J.; Pedrow, P.D.; Tang, Z.; Sablani, S.; Hong, Y.-K. Effect of changes in salt content and food thickness on electromagnetic heating of rice, mashed potatoes and peas in 915 MHz single mode microwave cavity. Food Res. Int. 2019, 119, 584–595. [Google Scholar] [CrossRef]

- Balanis, C.A. Advanced Engineering Electromagnetics; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Datta, A.K. Fundamentals of Heat and Moisture Transport for Microwaveable Food Product and Process Development. In Handbook of Microwave Technology for Food Application; Datta, A.K., Ed.; CRC Press: Boca Raton, FL, USA, 2001; pp. 115–172. [Google Scholar]

- Geankoplis, C.J. Transport Processes and Separation Process Principles:(Includes Unit Operations); Prentice Hall Professional Technical Reference: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Ehrlich, P. Dielectric properties of teflon from room temperature to 314 °C and from frequencies of 102 to 105 c/s. J. Res. Nat. Bur. Stand. 1953, 51, 185. [Google Scholar] [CrossRef]

- Ghodgaonkar, D.K.; Varadan, V.V.; Varadan, V.K. A free-space method for measurement of dielectric constants and loss tangents at microwave frequencies. IEEE Trans. Instrum. Meas. 1989, 38, 789–793. [Google Scholar] [CrossRef]

- Rattanadecho, P. The simulation of microwave heating of wood using a rectangular wave guide: Influence of frequency and sample size. Chem. Eng. Sci. 2006, 61, 4798–4811. [Google Scholar] [CrossRef]

- Luan, D.; Tang, J.; Pedrow, P.D.; Liu, F.; Tang, Z. Performance of mobile metallic temperature sensors in high power microwave heating systems. J. Food Eng. 2015, 149, 114–122. [Google Scholar] [CrossRef]

- Gupta, R.; Mikhaylenko, G.; Balasubramaniam, V.M.; Tang, J. Combined pressure–temperature effects on the chemical marker (4-hydroxy-5-methyl- 3(2H)-furanone) formation in whey protein gels. LWT Food Sci. Technol. 2011, 44, 2141–2146. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, J.; Rasco, B.; Wang, S.; Alshami, A.A.; Kong, F. Using whey protein gel as a model food to study dielectric heating properties of salmon (Oncorhynchus gorbuscha) fillets. LWT Food Sci. Technol. 2009, 42, 1174–1178. [Google Scholar] [CrossRef]

- Wang, Y.; Lau, M.H.; Tang, J.; Mao, R. Kinetics of chemical marker M-1 formation in whey protein gels for developing sterilization processes based on dielectric heating. J. Food Eng. 2004, 64, 111–118. [Google Scholar] [CrossRef]

- Auksornsri, T.; Tang, J.; Tang, Z.; Lin, H.; Songsermpong, S. Dielectric properties of rice model food systems relevant to microwave sterilization process. Innov. Food Sci. Emerg. 2018, 45, 98–105. [Google Scholar] [CrossRef]

- Pandit, R.B.; Tang, J.; Liu, F.; Mikhaylenko, G. A computer vision method to locate cold spots in foods in microwave sterilization processes. Pattern Recogn. 2007, 40, 3667–3676. [Google Scholar] [CrossRef]

- Soto-Reyes, N.; Temis-Pérez, A.L.; López-Malo, A.; Rojas-Laguna, R.; Sosa-Morales, M.E. Effects of Shape and Size of Agar Gels on Heating Uniformity During Pulsed Microwave Treatment. J. Food Sci. 2015, 80, E1021–E1025. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Hong, T.; Liao, Y.; Chen, F.; Ye, J.; Zhu, H.; Huang, K. Frequency-selected method to improve microwave heating performance. Appl. Therm. Eng. 2018, 131, 642–648. [Google Scholar] [CrossRef]

- Plaza-Gonzalez, P.; Monzo-Cabrera, J.; Catala-Civera, J.M.; Sanchez-Hernandez, D. Effect of mode-stirrer configurations on dielectric heating performance in multi-mode microwave applicators. IEEE Trans. Microw. Theory Tech. 2005, 53, 1699–1706. [Google Scholar] [CrossRef]

- Bornhorst, E.R.; Tang, J.; Sablani, S.S.; Barbosa-Cánovas, G.V. Development of model food systems for thermal pasteurization applications based on Maillard reaction products. LWT Food Sci. Technol. 2017, 75, 417–424. [Google Scholar] [CrossRef]

- Bornhorst, E.R.; Tang, J.; Sablani, S.S.; Barbosa-Cánovas, G.V.; Liu, F. Green pea and garlic puree model food development for thermal pasteurization process quality evaluation. J. Food Sci. 2017, 82, 1631–1639. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Tang, J.; Liu, F.; Bohnet, S.; Tang, Z. Chemical marker M2 (4-hydroxy-5-methyl-3(2H)-furanone) formation in egg white gel model for heating pattern determination of microwave-assisted pasteurization processing. J. Food Eng. 2014, 125, 69–76. [Google Scholar] [CrossRef]

- Auksornsri, T.; Bornhorst, E.R.; Tang, J.; Tang, Z.; Songsermpong, S. Developing model food systems with rice based products for microwave assisted thermal sterilization. LWT Food Sci. Technol. 2018, 96, 551–559. [Google Scholar] [CrossRef]

- Pandit, R.B.; Tang, J.; Mikhaylenko, G.; Liu, F. Kinetics of chemical marker M-2 formation in mashed potato—a tool to locate cold spots under microwave sterilization. J. Food Eng. 2006, 76, 353–361. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, M.; Mujumdar, A.S.; Jiang, H. Effect of salt and sucrose content on dielectric properties and microwave freeze drying behavior of re-structured potato slices. J. Food Eng. 2011, 106, 290–297. [Google Scholar] [CrossRef]

- Wang, J.; Tang, J.; Park, J.W.; Rasco, B.; Tang, Z.; Qu, Z. Thermal gelation of Pacific whiting surimi in microwave assisted pasteurization. J. Food Eng. 2019, 258, 18–26. [Google Scholar] [CrossRef]

- Hong, Y.-K.; Liu, F.; Tang, Z.; Pedrow, P.D.; Sablani, S.S.; Yang, R.; Tang, J. A simplified approach to assist process development for microwave assisted pasteurization of packaged food products. Innov. Food Sci. Emerg. 2021, 102628. [Google Scholar] [CrossRef]

| Parameter | Set Value | ||

|---|---|---|---|

| Process conditions | Time step (s) | 12 | |

| Exciting mode of port | TE 10 | ||

| Excitation amplitude per port (V/m) | 46.54 | ||

| Initial temperature of food (°C) | 85 | ||

| Initial temperature of carrier (°C) | 85 | ||

| Temperature of water in heating cavity (°C) | 121 | ||

| Moving speed (cm/min) | 168 | ||

| Properties of materials 1 | PTFE plastic | Dielectric constant | 2.02 |

| Loss factor | 7.86 × 10−4 | ||

| Density (kg/m3) | 1400 | ||

| Specific heat (J/(kg·°C)) | 1300 | ||

| Thermal conductivity (W/(m·°C)) | 0.447 | ||

| Model food | Volumetric specific heat (MJ/(m3·°C)) | 3.11/3.89 | |

| (0.0/0.7% salt) | Thermal conductivity (W/(m·°C)) | 0.852/0.773 | |

| Water | Dielectric constant | 50.0 | |

| Loss factor | 0.76 | ||

| Density (kg/m3) | 950 | ||

| Specific heat (J/(kg·°C)) | 4200 | ||

| Thermal conductivity (W/(m·°C)) | 0.677 | ||

| Section | Process Condition | Set Value | |

|---|---|---|---|

| Pre-heating | Temperature [°C] | 85 | |

| Time [min] | 25 | ||

| Microwave heating | First pass | Temperature [°C] | 110 |

| Generator power [kW] | 9 | ||

| Dwell time [min] 1 | 0.1 | ||

| Second pass | Temperature [°C] | 115 | |

| Generator power [kW] | 9 | ||

| Dwell time [min] | 0.36 | ||

| Third pass | Temperature [°C] | 121 | |

| Generator power [kW] | 8 | ||

| Dwell time 1 [min] | 0.1 | ||

| Fourth pass | Temperature [°C] | 125 | |

| Generator power [kW] | 8 | ||

| Dwell time [min] | 0.1 | ||

| Holding | Temperature [°C] | 125 | |

| Time [min] | 5 | ||

| Cooling | Temperature [°C] | 30/15 | |

| Time [min] | 5/5 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Y.-K.; Stanley, R.; Tang, J.; Bui, L.; Ghandi, A. Effect of Electric Field Distribution on the Heating Uniformity of a Model Ready-to-Eat Meal in Microwave-Assisted Thermal Sterilization Using the FDTD Method. Foods 2021, 10, 311. https://doi.org/10.3390/foods10020311

Hong Y-K, Stanley R, Tang J, Bui L, Ghandi A. Effect of Electric Field Distribution on the Heating Uniformity of a Model Ready-to-Eat Meal in Microwave-Assisted Thermal Sterilization Using the FDTD Method. Foods. 2021; 10(2):311. https://doi.org/10.3390/foods10020311

Chicago/Turabian StyleHong, Yoon-Ki, Roger Stanley, Juming Tang, Lan Bui, and Amir Ghandi. 2021. "Effect of Electric Field Distribution on the Heating Uniformity of a Model Ready-to-Eat Meal in Microwave-Assisted Thermal Sterilization Using the FDTD Method" Foods 10, no. 2: 311. https://doi.org/10.3390/foods10020311

APA StyleHong, Y.-K., Stanley, R., Tang, J., Bui, L., & Ghandi, A. (2021). Effect of Electric Field Distribution on the Heating Uniformity of a Model Ready-to-Eat Meal in Microwave-Assisted Thermal Sterilization Using the FDTD Method. Foods, 10(2), 311. https://doi.org/10.3390/foods10020311