Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review

Abstract

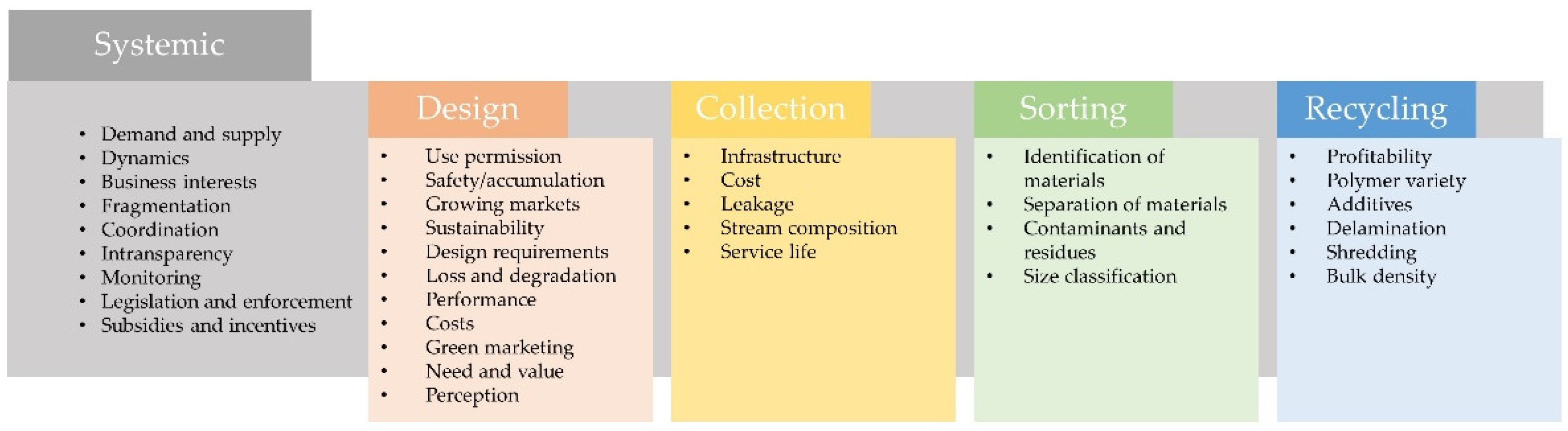

:1. Introduction

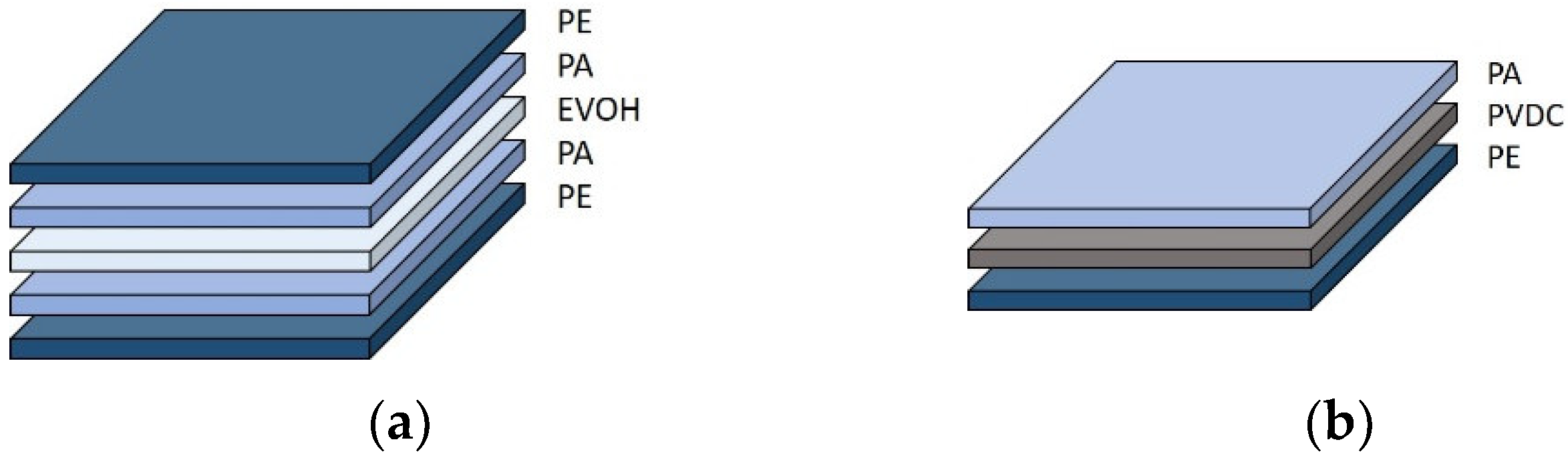

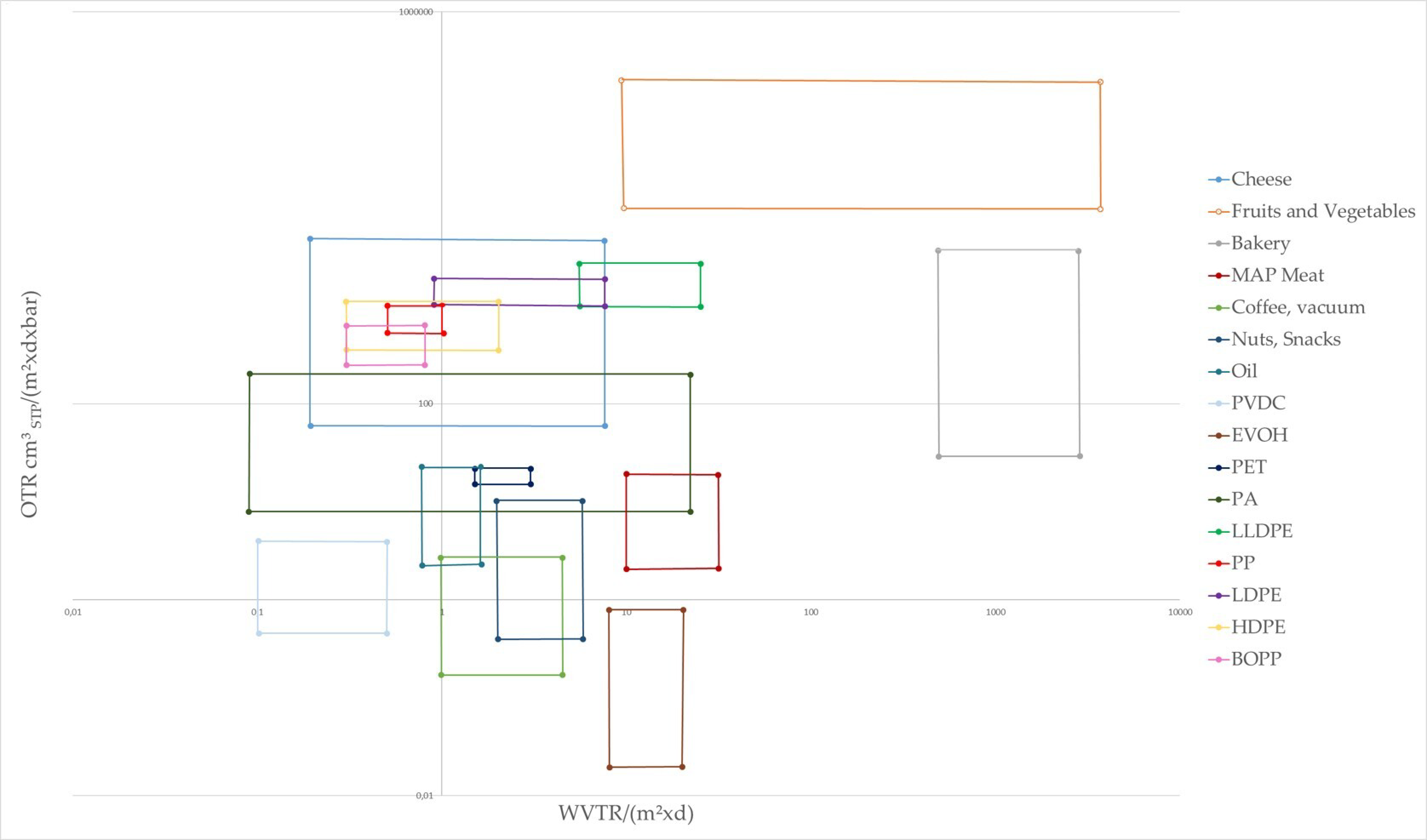

2. Multilayer Flexible Food Packaging

2.1. Production, Characteristics, and Application

2.2. Efficiency and Sustainability—Trade-Offs Regarding Recycling

| PE | PP | PVC | PS | PA | PET | |

|---|---|---|---|---|---|---|

| PE | + | ~ (+ *) | − | − | ~ (− *) | − |

| PP | ~ | + | − | − | ~ (− *) | − |

| PVC | − | − | + | ~ (- *) | − | − |

| PS | − | − | − | + | ~ (− *) | ~ (− *) |

| PA | − | − | − | ~ | + | ~ |

| PET | − | − | − | − (~ *) | ~ | + |

3. Discussion

3.1. Redesign and Trade-Offs to Fit the Actual Recycling Technology

- mono-polyolefins with EVOH,

- mono-polyolefins with SiOx or AlOx,

3.2. Harmonization of Recyclability Guidelines in Europe

3.3. Novel Recycling Technologies and Secondary Material for Food Contact

- chemically separating the layers of multi-material,

- recovering the aluminium content of multilayer food packaging by microwave-induced pyrolysis, and

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Robertson, G.L. Food packaging and shelf life. In Food Packaging and Shelf Life: A Practical Guide, 1st ed.; Robertson, G.L., Ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2009. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. The State of Food and Agriculture. 2019. Available online: http://www.fao.org/publications/sofa/2019/en/ (accessed on 16 February 2021).

- Robertson, G.L. Food Packaging: Principles and Practice, 3rd ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2012. [Google Scholar]

- PlasticsEurope. Plasctics—The Facts 2020. Brussels, Belgium. 2020. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 16 February 2021).

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1516265440535&uri=COM:2018:28:FIN (accessed on 16 February 2021).

- Smithers. Brand Owners and Converters Drive Packaging Recycling Growth. Available online: https://www.smithers.com/resources/2019/mar/brand-owners-drive-packaging-recycling-growth (accessed on 4 January 2021).

- European Commission. Towards a Circular Economy: A Zero Waste Programme for Europe; European Commission: Brussels, Belgium, 2014; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52014DC0398 (accessed on 16 February 2021).

- Bicket, M.; Guilcher, S.; Hestin, M.; Hudson, C.; Razzini, P.; Tan, A.; ten Brink, P.; van Dijl, E.; Vanner, R.; Watkins, E. Scoping Study to Identify Potential Circular Economy Actions, Priority Sectors, Material Flows and Value Chains; European Union: Luxembourg, 2014; Available online: https://op.europa.eu/de/publication-detail/-/publication/0619e465-581c-41dc-9807-2bb394f6bd07 (accessed on 16 February 2021). [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015DC0614 (accessed on 16 February 2021).

- Ceflex. Designing for a Circular Economy: Recyclability of Polylefin-Based Flexible Packaging. 2020. Available online: https://guidelines.ceflex.eu/ (accessed on 16 February 2021).

- RecyClass. PE Natural Flexible Film Guideline. 2020. Available online: https://recyclass.eu/wp-content/uploads/2020/07/PE-natural-films_guideline-1.pdf (accessed on 6 October 2020).

- FH Campus Wien. Circular Packaging Design Guideline: Empfehlungen für Recyclinggerechte Verpackungen; FH Campus Wien: Vienna, Austria, 2020; Available online: https://pub.fh-campuswien.ac.at/urn:nbn:at:at-fhcw:3-757 (accessed on 16 February 2021). [CrossRef]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef] [Green Version]

- Marrone, M.; Tamarindo, S. Paving the sustainability journey: Flexible packaging between circular economy and resource efficiency. J. Appl. Packag. Res. 2018, 10, 53–60. [Google Scholar]

- Morris, B. Appendix B: Examples of flexible packaging film structures. In The Science and Technology of Flexible Packaging; Elsevier: Oxford, UK; Cambridge, MA, USA, 2017; pp. 697–709. [Google Scholar] [CrossRef]

- Wellenreuther, F. Resource Efficient Packaging; IFEU (Institut für Energie- und Umweltforschung Heidelberg): Heidelberg, Germany, 2016; Available online: https://www.flexpack-europe.org/files/FPE/sustainability/IFEU_Resource%20Efficient%20Packaging_summary_2016.pdf (accessed on 16 February 2021).

- Wellenreuther, F. Potential Packaging Waste Prevention by the Usage of Flexible Packaging and Its Consequences for the Environment; IFEU (Institut für Energie- und Umweltforschung Heidelberg): Heidelberg, Germany, 2019; Available online: https://www.flexpack-europe.org/files/FPE/sustainability/2020/FPE-ifeu_Study_Update_2019_Executive_Summary.pdf (accessed on 16 February 2021).

- Gandenberger, C.; Orzanna, R.; Klingenfuß, S.; Sartorius, C. The Impact of Policy Interactions on the Recycling of Plastic Packaging Waste in Germany. Working Paper Sustainability and Innovation. 2014. Available online: https://www.econstor.eu/handle/10419/100033 (accessed on 16 February 2021).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nickel, W. Materialeinsatz. In Recycling-Handbuch: Strategien—Technologien—Produkte, 1st ed.; Nickel, W., Ed.; VDI Verlag: Düsseldorf, Germany, 1996; p. 83. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The New Plastics Economy: Catalysing Action. 2017. Available online: https://www.ellenmacarthurfoundation.org/publications/new-plastics-economy-catalysing-action (accessed on 16 February 2021).

- European Commission. A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe; European Commission: Brussels, Belgum, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 16 February 2021).

- Van Eygen, E.; Laner, D.; Fellner, J. Circular economy of plastic packaging: Current practice and perspectives in Austria. Waste Manag. 2018, 72, 55–64. [Google Scholar] [CrossRef] [PubMed]

- OÖ Landesabfallverband Umweltprofis. Der Gelbe Sack—Was Darf Hinein und Was Darf Nicht Hinein? 2018. Available online: https://www.umweltprofis.at/eferding/aktuelles/nachrichten_detail/n/detail/News/der_gelbe_sack_was_darf_hinein_und_was_darf_nicht_hinein.html (accessed on 16 February 2021).

- Institute Cyclos-HTP. Verification and Examination of Recyclability: Requirements and Assessment Catalogue of the Institute Cyclos-HTP for EU-Wide Certification (CHI-Standard); Institute Cyclos-HTP: Aachen, Germany, 2019; Available online: https://www.cyclos-htp.de/publications/r-a-catalogue/ (accessed on 16 February 2021).

- Nonclercq, A. Mapping Flexible Packaging in a Circular Economy [F.I.A.C.E.]; Delft University of Technology: Delft, Netherland, 2018; Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiq5tKBloD0AhVHsaQKHZIQDscQFnoECAMQAQ&url=https%3A%2F%2Fceflex.eu%2Fpublic_downloads%2FFIACE-Final-report-version-24-4-2017-non-confidential-version-Final.pdf&usg=AOvVaw1tmuElrEtQUh4PXQMnDH9s (accessed on 16 February 2021).

- RecyClass. PE Colored Flexible Films Guideline. 2020. Available online: https://recyclass.eu/wp-content/uploads/2020/07/PE-coloured-films_guideline.pdf (accessed on 6 October 2020).

- RecyClass. PP Colored Films Guideline. 2020. Available online: https://recyclass.eu/wp-content/uploads/2020/07/PP-colored-films_guideline-2.pdf (accessed on 6 October 2020).

- RecyClass. PP Natural Films Guideline. 2020. Available online: https://recyclass.eu/wp-content/uploads/2020/07/PP-natural-films_guideline-3.pdf (accessed on 6 October 2020).

- Barlow, C.; Morgan, D. Polymer film packaging for food: An environmental assessment. Resour. Conserv. Recycl. 2013, 78, 74–80. [Google Scholar] [CrossRef]

- van Sluisveld, M.; Worrell, E. The paradox of packaging optimization—A characterization of packaging source reduction in the Netherlands. Resour. Conserv. Recycl. 2013, 73, 133–142. [Google Scholar] [CrossRef]

- Flexible Packaging Europe. Fact Sheet: Flexible Packaging Supports Sustainable Consumption and Production; Flexible Packaging Europe: Düsseldorf, Germany, 2018; Available online: https://www.flexpack-europe.org/en/toolkit-downloads.html (accessed on 17 February 2021).

- Morris, B. End-use factors influencing the design of flexible packaging. In The Science and Technology of Flexible Packaging; Elsevier: Oxford, UK; Cambridge, MA, USA, 2017; pp. 617–654. [Google Scholar] [CrossRef]

- Selke, S.; Hernandez, R. Packaging: Polymers in flexible packaging. In Reference Module in Materials Science and Materials Engineering; Elsevier: Oxford, UK; Cambridge, MA, USA, 2016. [Google Scholar]

- Milios, L.; Holm Christensen, L.; McKinnon, D.; Christensen, C.; Rasch, M.K.; Hallstrøm Eriksen, M. Plastic recycling in the Nordics: A value chain market analysis. Waste Manag. 2018, 76, 180–189. [Google Scholar] [CrossRef]

- World Economic Forum. Towards the Circular Economy: Accelerating the Scale-Up Across Global Supply-Chains. 2014. Available online: http://www3.weforum.org/docs/WEF_ENV_TowardsCircularEconomy_Report_2014.pdf (accessed on 27 September 2021).

- Ellen MacArthur Foundation. Towards the Circular Economy Vol. 2: Opportunities for the Consumer Goods Sector; Ellen MacArthur Foundation: Isle of Wight, UK, 2013; Available online: https://www.ellenmacarthurfoundation.org/publications/towards-the-circular-economy-vol-2-opportunities-for-the-consumer-goods-sector (accessed on 17 February 2021).

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Fellner, J.; Lederer, J.; Scharff, C.; Laner, D. Present Potentials and Limitations of a Circular Economy with Respect to Primary Raw Material Demand. J. Ind. Ecol. 2017, 21, 494–496. [Google Scholar] [CrossRef]

- Singh, J.; Ordoñez, I. Resource recovery from post-consumer waste: Important lessons for the upcoming circular economy. J. Clean. Prod. 2016, 134A, 342–353. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Haig, S.; Morrish, L.; Mortin, R.; Wilkinson, S. Final Report: Film Reprocessing Technologies and Collection Schemes; The Waste and Resources Action Programme: Banbury, UK, 2012; Available online: https://www.wrap.org.uk/sites/files/wrap/Film%20reprocessing%20technologies%20and%20collection%20schemes.pdf (accessed on 4 October 2020).

- Kampmann Eriksen, M.; Damgaard, A.; Boldrin, A.; Astrup Fruergaard, T. Quality Assessment and Circularity Potential of Recovery Systems for Household Plastic Waste. J. Ind. Ecol. 2019, 23, 156–168. [Google Scholar] [CrossRef] [Green Version]

- Dainelli, D. 12-Recycling of food packaging materials: An overview. In Environmentally Compatible Food Packaging; Chiellini, E., Ed.; (Woodhead Publishing Series in Food Science, Technology and Nutrition); Elsevier: Amsterdam, The Netherlands, 2008; pp. 294–325. [Google Scholar] [CrossRef]

- Bartl, A. Moving from recycling to waste prevention: A review of barriers and enables. Waste Manag. Res. 2014, 32, 3–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carey, J. On the brink of a recycling revolution?: We’re awash in plastics, many of which are hard to recycle. Could innovations, girded by the right incentives, finally whittle down the piles of plastic waste? Proc. Natl. Acad. Sci. USA 2017, 114, 612–616. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horodytska, O.; Valdés, F.; Fullana, A. Plastic flexible films waste management–A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef]

- Iacovidou, E.; Gerassimidou, S. Sustainable packaging and the circular economy: An EU perspective. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- House of Commons Environmental Audit Committee. Growing a Circular Economy: Ending the Throwaway Society; House of Commons: London, UK, 2014; Available online: https://publications.parliament.uk/pa/cm201415/cmselect/cmenvaud/214/214.pdf (accessed on 27 September 2021).

- Dixon, J. Packaging Materials 9: Multilayer Packaging for Food and Beverages; ILSI Europe Report Series; ILSI Europe Packaging Materials: Washington, DC, USA, 2011; Available online: https://ilsi.eu/publication/packaging-materials-9-multilayer-packaging-for-food-and-beverages/ (accessed on 17 February 2011).

- Ellen MacArthur Foundation. Towards the Circular Economy Vol.1: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Isle of Wight, UK, 2013; Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 27 September 2021).

- Selke, S. Recycling: Polymers. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- PlasticsEurope. Plasctics—The Facts 2017; PlasticsEurope: Brussels, Belgium, 2020; Available online: https://www.plasticseurope.org/application/files/5715/1717/4180/Plastics_the_facts_2017_FINAL_for_website_one_page.pdf (accessed on 27 September 2021).

- European Commission. REGULATION (EC) No 282/2008 of 27 March 2008 on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods and Amending Regulation (EC). No 2023/2006; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Hultman, J.; Corvellec, H. The European Waste Hierarchy: From the sociomateriality of waste to a politics of consumption. Environ. Plan. A 2012, 44, 2413–2427. [Google Scholar] [CrossRef]

- European Commission. Green Paper: On a European Strategy on Plastic Waste in the Environment; European Commission: Brussels, Belgium, 2013; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52013DC0123 (accessed on 27 September 2021).

- Iacovidou, E.; Millward-Hopkins, J.; Busch, J.; Purnell, P.; Velis, C.; Hahladakis, J.; Zwirner, O.; Brown, A. A pathway to circular economy: Developing a conceptual framework for complex value assessment of resources recovered from waste. J. Clean. Prod. 2017, 168, 1279–1288. [Google Scholar] [CrossRef]

- Brems, A.; Baeyens, J.; Dewil, R. Recycling and recovery of post-consumer plastic solid waste in a European context. Therm. Sci. 2012, 16, 669–685. [Google Scholar] [CrossRef]

- Dahlbo, H.; Poliakova, V.; Mylläri, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61. [Google Scholar] [CrossRef]

- Allwood, J. Squaring the circular economy: The role of recycling within a hierarchy of material management strategies. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists; Worrell, E., Reuter, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 445–477. [Google Scholar] [CrossRef]

- Al-Salem, S.; Lettieri, P.; Baeyens, J.; Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Cooper, T. Developments in plastic materials and recycling systems for packaging food, beverages and other fast-moving consumer goods. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods (FMCG), 1st ed.; Farmer, N., Ed.; Woodhead Publishing Limited: Southston, UK, 2013; pp. 58–107. [Google Scholar]

- Luijsterburg, B.; Goossens, H. Assessment of plastic packaging waste: Material origin, methods, properties. Resour. Conserv. Recycl. 2014, 85, 88–97. [Google Scholar] [CrossRef]

- Tartakowski, Z. Recycling of packaging multilayer films: New materials for technical products. Resour. Conserv. Recycl. 2010, 55, 167–170. [Google Scholar] [CrossRef]

- Veelaert, L.; Du Els, B.; Hubo, S.; van Kets, K.; Ragaert, K. Design from recycling. In Proceedings of the International Conference on Experiential Knowledge and Emerging Materials, Delft, The Netherlands, 19–20 June 2017; Available online: https://www.eksig.org/PDF/EKSIG2017Proceedings.pdf (accessed on 27 September 2021).

- Favaro, S.L.; Pereira, A.G.B.; Fernandes Rodrigues, J.; Baron, O.; da Silva, C.T.P.; Moisés, M.P.; Radovanovic, E. Outstanding Impact Resistance of Post-Consumer HDPE/Multilayer Packaging Composites. Mater. Sci. Appl. 2017, 8, 15–25. [Google Scholar] [CrossRef] [Green Version]

- Drzyzga, O.; Prieto, A. Plastic waste management, a matter for the ‘community’. Microb. Biotechnol. 2019, 12, 66–68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grosso, M.; Niero, M.; Rigamonti, L. Circular economy, permanent materials and limitations to recycling: Where do we stand and what is the way forward? Waste Manag. Res. 2017, 35, 793–794. [Google Scholar] [CrossRef]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How Circular is the Global Economy?: An Assessment of Material Flows, Waste Production, and Recycling in the European Union and the World in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 2008/98/EC of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 27 September 2021).

- Briassoulis, D.; Tserotas, P.; Hiskakis, M. Mechanical and degradation behaviour of multilayer barrier films. Polym. Degrad. Stab. 2017, 143, 214–230. [Google Scholar] [CrossRef]

- Velis, C.; Brunner, P. Recycling and resource efficiency: It is time for a change from quantity to quality. Waste Manag. Res. 2013, 31, 539–540. [Google Scholar] [CrossRef]

- Garcia, J.; Robertson, M. The future of plastics recycling: Chemical advances are increasing the proportion of polymer waste that can be recycled. Science 2017, 358, 870–872. [Google Scholar] [CrossRef]

- Soto, J.M.; Blázquez, G.; Calero, M.; Quesada, L.; Godoy, V.; Martín-Lara, M.Á. A real case study of mechanical recycling as an alternative for managing of polyethylene plastic film presented in mixed municipal solid waste. J. Clean. Prod. 2018, 203, 777–787. [Google Scholar] [CrossRef]

- Morris, B. Barrier. In The Science and Technology of Flexible Packaging; Elsevier: Oxford, UK; Cambridge, MA, USA, 2017; pp. 259–308. [Google Scholar] [CrossRef]

- Morris, B. Commonly used resins and substrates in flexible packaging. In The Science and Technology of Flexible Packaging; Elsevier: Oxford, UK; Cambridge, MA, USA, 2017; pp. 69–119. [Google Scholar] [CrossRef]

- Häsänen, E. Composition Analysis and Compatibilization of Post-Consumer Recycled Multilayer Plastic Films. Master’s Thesis, Tampere University of Technology, Tampere, Finland, 2016. [Google Scholar]

- Farris, S. Main manufacturing processes for food packaging materials. In Reference Module in Food Science; Elsevier Inc.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Li, F.; Biagioni, P.; Finazzi, M.; Tavazzi, S.; Piergiovanni, L. Tunable green oxygen barrier through layer-by-layer self-assembly of chitosan and cellulose nanocrystals. Carbohydr. Polym. 2013, 92, 2128–2134. [Google Scholar] [CrossRef] [PubMed]

- Farris, S.; Uysal Unalan, I.; Introzzi, L.; Fuentes-Alventosa, J.M.; Cozzolino, C.A. Pullulan-based films and coatings for food packaging: Present applications, emerging opportunities, and future challenges. J. Appl. Polym. Sci. 2014, 131, 40539. [Google Scholar] [CrossRef] [Green Version]

- Siracusa, V.; Ingrao, C.; Lo Giudice, A.; Mbohwa, C.; Dalla Rosa, M. Environmental assessment of a multilayer polymer bag for food packaging and preservation: An LCA approach. Food Res. Int. 2014, 62, 151–161. [Google Scholar] [CrossRef]

- Reclay StewardEdge. Analysis of Flexible Film Plastics Packaging Diversion Systems. 2013. Available online: https://thecif.ca/projects/documents/714-Flexible_Film_Report.pdf (accessed on 16 February 2021).

- Morris, B. The Science and Technology of Flexible Packaging; Elsevier: Oxford, UK; Cambridge, MA, USA, 2017. [Google Scholar] [CrossRef]

- Ebnesajjad, S. Plastic Films in Food Packaging: Materials, Technology, and Applications; William Andrew: Oxford, UK; Waltham, MA, USA, 2013. [Google Scholar]

- Butler, T.I.; Morris, B. PE-based multilayer film structures. In Multilayer Flexible Packaging, 2nd ed.; Wagner, J., Ed.; William Andrew: Oxford, UK, 2016; pp. 281–310. [Google Scholar]

- Detzel, A.; Bodrogi, F.; Kauertz, B.; Bick, C.; Welle, F.; Schmid, M.; Schmitz, K.; Müller, K.; Käb, H. Biobasierte Kunststoffe als Verpackung von Lebensmitteln; Bundesministerium für Ernährung und Landwirtschaft: Endbericht, Heidelberg, Germany, 2018; Available online: https://www.ifeu.de/fileadmin/uploads/Endbericht-Bio-LVp_20180612.pdf (accessed on 27 September 2021).

- Flexible Packaging Association. A Holistic View of the Role of Flexible Packaging in a Sustainable World: A Flexible Packaging Association Report; Flexible Packaging Association: Annapolis, MD, USA, 2018; Available online: https://www.flexpack.org/resources/sustainability-resources#a-holistic-view-of-the-role-of-flexible-packaging-in-a-sustainable-world (accessed on 17 February 2021).

- Clark, D. Food packaging and sustainability: A manufacturer’s view. In Reference Module in Food Science; Elsevier Inc.: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Ecoplus, BOKU, Denkstatt, OFI. Lebensmittel-Verpackungen-Nachhaltigkeit: Ein Leitfaden für Verpackungshersteller, Handel, Politk & NGOs; Enstanden aus den Ergebnissen des Projektes “STOP waste–SAVE Food”: Wien, Austria, 2020; Available online: https://www.ecoplus.at/media/20682/leitfaden_stopwaste_de.pdf (accessed on 27 September 2021).

- Jönkkäri, I.; Poliakova, V.; Mylläri, V.; Anderson, R.; Andersson, M.; Vuorinen, J. Compounding and characterization of recycled multilayer plastic films. J. Appl. Polym. Sci. 2020, 137, 49101. [Google Scholar] [CrossRef]

- Scalice, R.K.; Becker, D.; Silveira, R.D. Developing a new compatibility table for design for recycling. Prod. Manag. Dev. 2009, 7, 141–148. [Google Scholar]

- Uehara, G.A.; França, M.P.; Canevarolo, S.V. Recycling assessment of multilayer flexible packaging films using design of experiments. Polímeros 2015, 25, 371–381. [Google Scholar] [CrossRef] [Green Version]

- Sustainable Packaging Coalition. Mechanical Recycling Options. Charlottesville, Virginia. Available online: https://sustainablepackaging.org/mechanical-recycling-options/ (accessed on 5 January 2021).

- Pinzón Moreno, D.D.; Saron, C. Low-density polyethylene/polyamide 6 blends from multilayer films waste. J. Appl. Polym. Sci. 2019, 136, 47456. [Google Scholar] [CrossRef]

- McKinlay, R.; Morrish, L. Reflex Project: A Summary Report on the Results and Findings from the REFLEX Project; Innovate UK: Swindon, UK, 2016; Available online: https://ceflex.eu/public_downloads/REFLEX-Summary-report-Final-report-November2016.pdf (accessed on 17 February 2021).

- Pahl, G.; Beitz, W.; Blessing, L.; Feldhusen, J.; Grote, K.-H.; Wallace, K. Engineering Design: A Systematic Approach, 3rd ed.; Springer: London, UK, 2007. [Google Scholar] [CrossRef]

- Chen, X.; Kroell, N.; Feil, A.; Pretz, T. Determination of the composition of multilayer plastic packaging with NIR spectroscopy. Detritus 2020, 13, 62–66. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Ellen MacArthur Foundation. The Initiative; Ellen MacArthur Foundation: Isle of Wight, UK, 2017. Available online: https://www.newplasticseconomy.org/about/the-initiative (accessed on 17 February 2021).

- RECOUP. Plastic Packaging. Recyclability by Design 2020 Update; RECOUP: Peterborough, UK, 2020; Available online: https://www.recyclingtoday.com/article/recoup-updates-recyclability-by-design-guidelines-film-plastics/ (accessed on 6 October 2020).

- Packaging SA. Design for Recycling: For Packaging and Paper in South Africa; Packaging SA: Bryanston, South Africa, 2017; Available online: https://www.packagingsa.co.za/wp-content/uploads/2019/11/PACSA-Recyclability-by-Design-WEB.pdf (accessed on 17 February 2021).

- RECOUP. Plastic Packaging. Recyclability by Design 2021; RECOUP: Peterborough, UK, 2021; Available online: https://www.recoup.org/p/130/recyclability-by-design (accessed on 27 September 2021).

- FH Campus Wien. Circular Packaging Design Guideline: Design Recommendations for Recyclable Packaging; FH Campus Wien: Vienna, Austria, 2019; Available online: https://www.fh-campuswien.ac.at/fileadmin/redakteure/Studium/01_Applied_Life_Sciences/b_Verpackungstechnologie/Dokumente/FH-Campus-Wien_Circular-Packaging-Design-Guideline_Version-01.pdf (accessed on 17 February 2021).

- RecyClass. RecyClass Tests Functional Barriers in PP Containers. Available online: https://recyclass.eu/de/recyclass-tests-functional-barriers-in-pp-containers/ (accessed on 5 September 2021).

- RecyClass. PP Colored Containers Guideline. 2020. Available online: https://recyclass.eu/wp-content/uploads/2020/07/PP-colored-containers_guideline.pdf (accessed on 6 October 2020).

- RecyClass. PP Natural Containers Guideline. 2020. Available online: https://recyclass.eu/wp-content/uploads/2020/07/PP-natural-containers_guideline-1.pdf (accessed on 6 October 2020).

- Wohner, B.; Gabriel, V.H.; Krenn, B.; Krauter, V.; Tacker, M. Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 2020, 738, 139846. [Google Scholar] [CrossRef] [PubMed]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the Environmental Sustainability of Food Packaging: An Extended Life Cycle Assessment including Packaging-Related Food Losses and Waste and Circularity Assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef] [Green Version]

- Australian Packaging Covenant Organisation. Available online: https://apco.org.au/ (accessed on 16 February 2021).

- Ludlow-Palafox, C.; Chase, H.A. Microwave-Induced Pyrolysis of Plastic Wastes. Ind. Eng. Chem. Res. 2001, 40, 4749–4756. [Google Scholar] [CrossRef]

- European Food Safety Authority. EFSA Journal; European Food Safety Authority: Parma, Italy, 2020; Available online: https://www.efsa.europa.eu/de/topics/topic/plastics-and-plastic-recycling (accessed on 7 January 2021).

- Cecon, V.S.; Da Silva, P.F.; Curtzwiler, G.W.; Vorst, K.L. The challenges in recycling post-consumer polyolefins for food contact applications: A review. Resour. Conserv. Recycl. 2021, 167, 105422. [Google Scholar] [CrossRef]

| Mechanical Stability | Oxygen Barrier | Moisture Barrier | Light Barrier | Tie Layer | Sealant |

|---|---|---|---|---|---|

| PO | EVOH | PO | Aluminium | PU | PO |

| PET | PVDC | EVA | Paper | PO | EVA |

| PS | PA | PVDC | PA | ||

| Paper | PET | Aluminium | PET | ||

| SiOx | |||||

| AlOx | |||||

| PVOH Aluminium |

| EVOH | Metallization | SiOx | AlOx | Acrylic Coatings | PVOH | PVDC | References | |

|---|---|---|---|---|---|---|---|---|

| PP-film | Conditional–limited | Conditional–limited | Fully compatible | Fully compatible | “any other barrier” no–low compatibility | No–low compatibility | [28,29] | |

| <5% | Compatible with PE or PP mechanical recycling | <5% | <5% | <5% | <5% | Further investigation | [10] | |

| PE-film | <5% | Conditional–limited | Fully compatible | Fully compatible | “any other barrier” no–low compatibility | No–low compatibility | [11,27] | |

| <5% | Compatible with PE or PP mechanical recycling | <5% | <5% | <5% | <5% | Further investigation | [10] | |

| Mechanical Stability | Oxygen Barrier | Moisture Barrier | Light Barrier | Tie Layer | Sealant |

|---|---|---|---|---|---|

| PO | EVOH | PO | Aluminium (metallised) | PO | |

| PO | |||||

| Aluminium (metallised) | |||||

| SiOx | |||||

| AlOx | |||||

Aluminium (metallised) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bauer, A.-S.; Tacker, M.; Uysal-Unalan, I.; Cruz, R.M.S.; Varzakas, T.; Krauter, V. Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review. Foods 2021, 10, 2702. https://doi.org/10.3390/foods10112702

Bauer A-S, Tacker M, Uysal-Unalan I, Cruz RMS, Varzakas T, Krauter V. Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review. Foods. 2021; 10(11):2702. https://doi.org/10.3390/foods10112702

Chicago/Turabian StyleBauer, Anna-Sophia, Manfred Tacker, Ilke Uysal-Unalan, Rui M. S. Cruz, Theo Varzakas, and Victoria Krauter. 2021. "Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review" Foods 10, no. 11: 2702. https://doi.org/10.3390/foods10112702

APA StyleBauer, A.-S., Tacker, M., Uysal-Unalan, I., Cruz, R. M. S., Varzakas, T., & Krauter, V. (2021). Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review. Foods, 10(11), 2702. https://doi.org/10.3390/foods10112702