Functionalization of a Vegan Mayonnaise with High Value Ingredient Derived from the Agro-Industrial Sector

Abstract

:1. Introduction

2. Materials and Methods

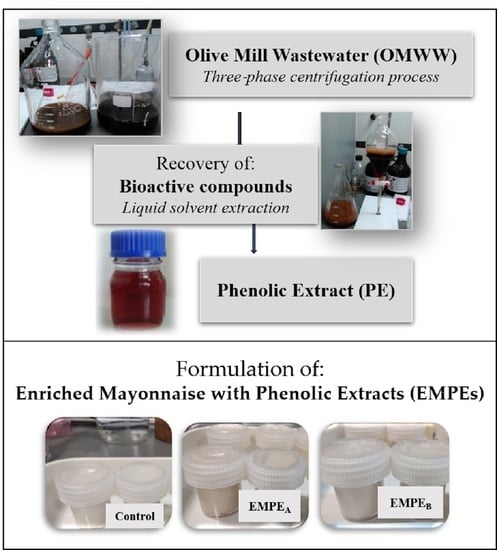

2.1. Phenolic Extract Preparation

2.2. Mayonnaise Preparation

2.3. Antioxidant Characterization of Phenolic Extracts

2.4. Physicochemical, Microbiological and Antioxidant Evaluation of Enriched Mayonnaise Samples (EM)

2.4.1. Physicochemical Analysis

2.4.2. Microbiological Analysis

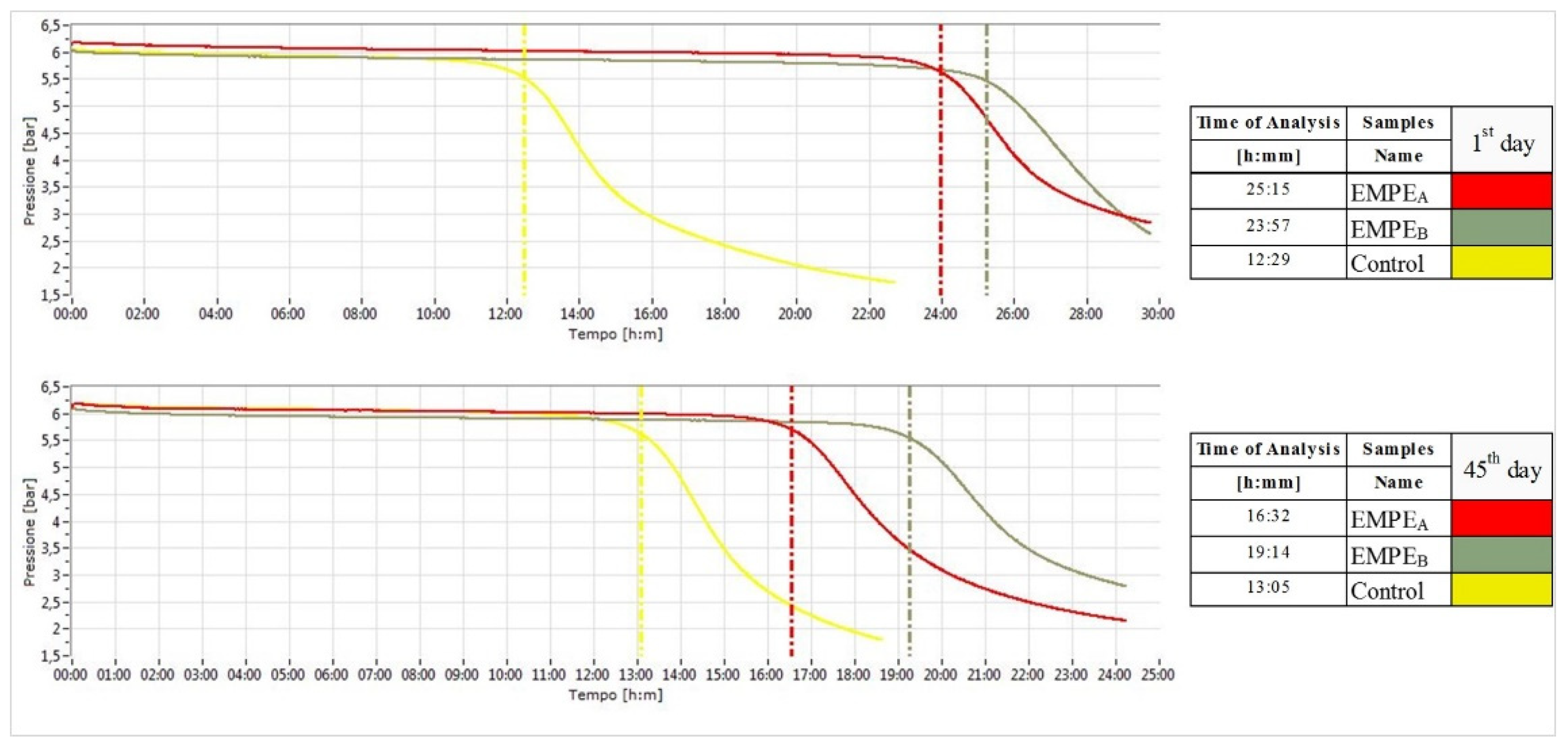

2.4.3. Oxidative Stability in Accelerated Storage Test

2.4.4. Analysis of Antioxidant Compounds

2.4.5. Sensory Evaluation

2.5. Statistical Analysis

3. Results

3.1. Characterization of Phenolic Extracts

3.2. Qualitative and Quantitative Characterization of Enriched Vegan Mayonnaise (EM)

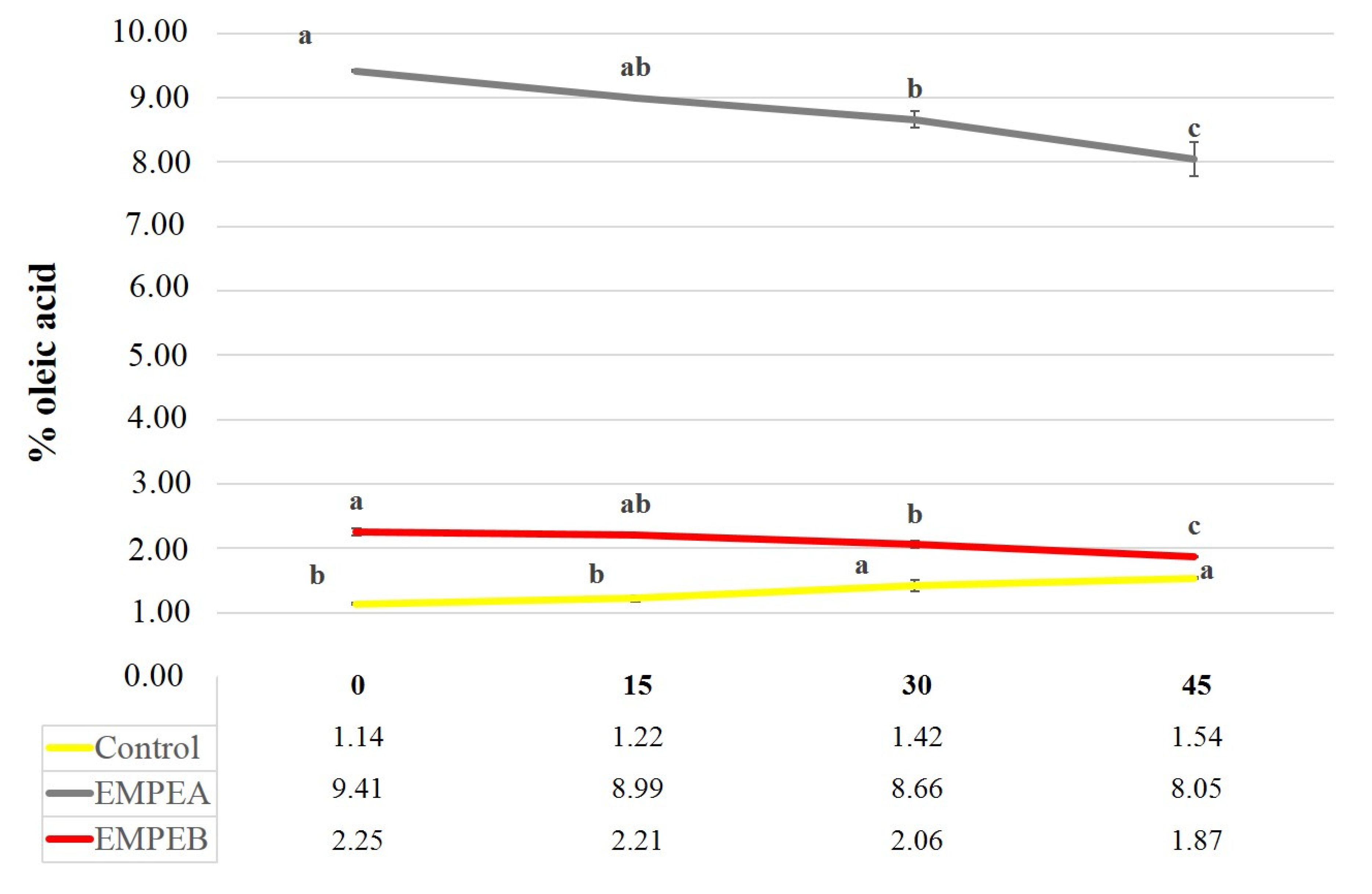

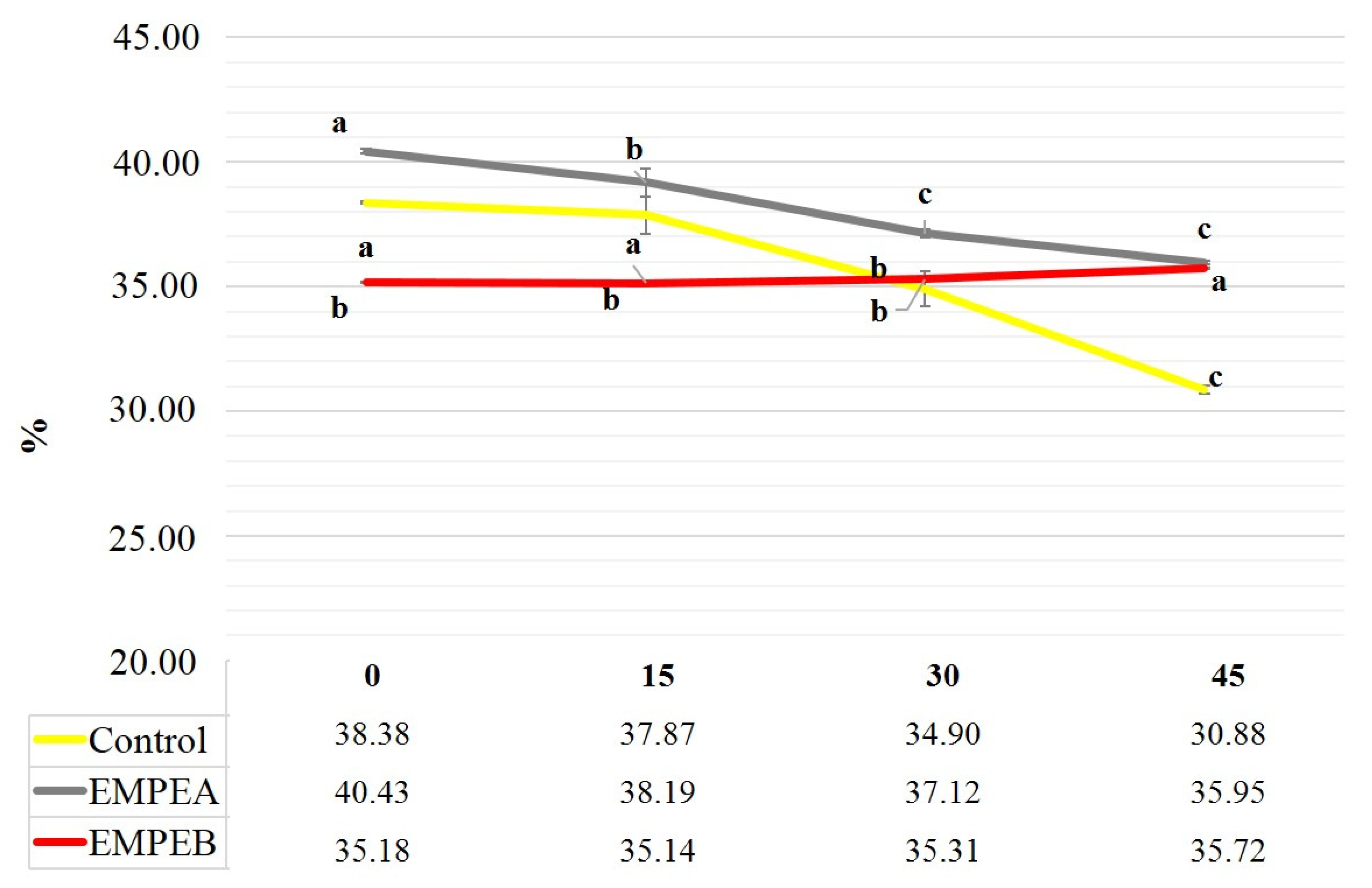

3.2.1. Physicochemical Aspects

3.2.2. Microbiological Parameters

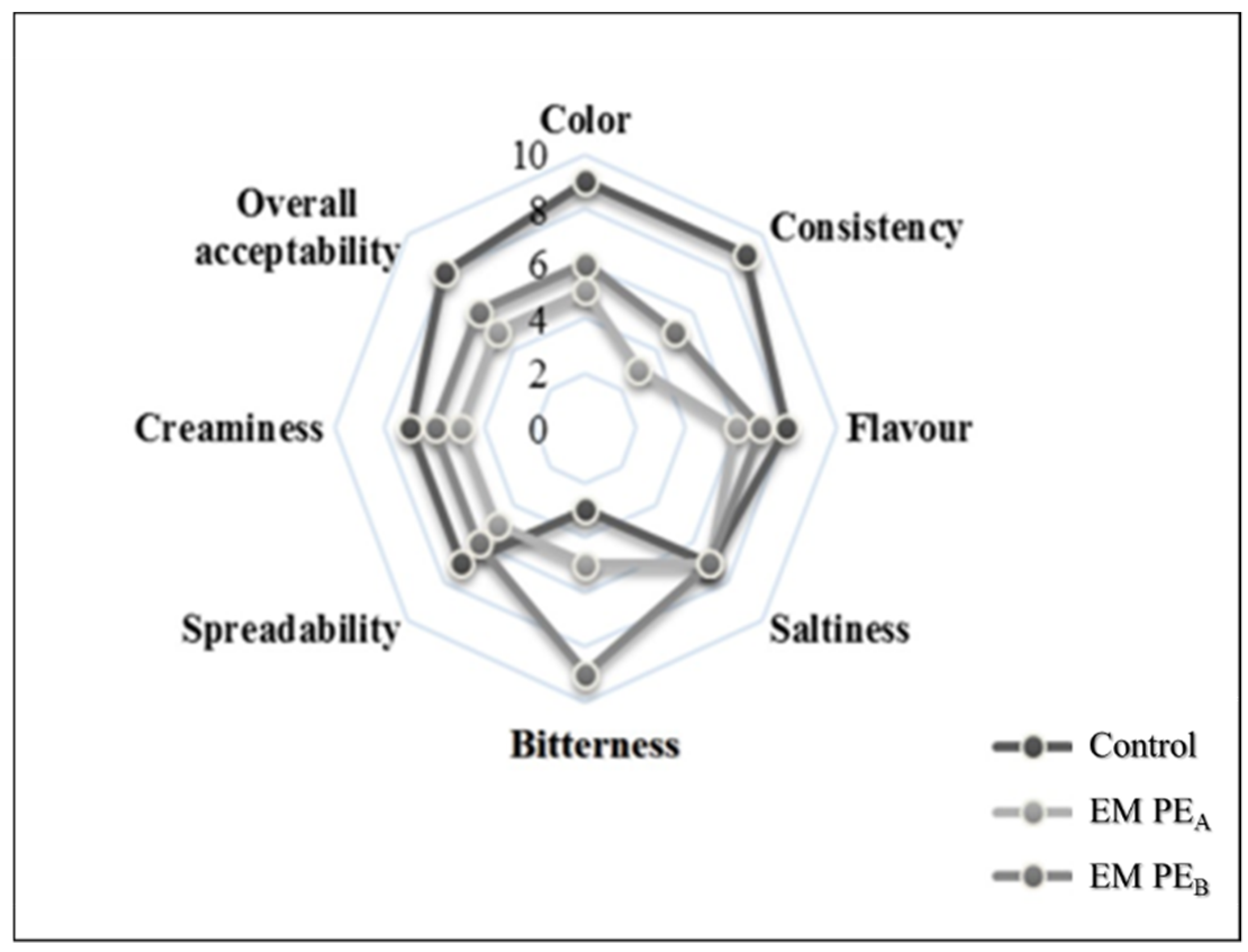

3.2.3. Sensory Parameters

3.2.4. Oxidative Stability and Antioxidant Activity of EM

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caporaso, N.; Formisano, D.; Genovese, A. Use of phenolic compounds from olive mill wastewater as valuable ingredients for functional foods. Crit. Rev. Food Sci. Nutr. 2017, 58, 2829–2841. [Google Scholar] [CrossRef]

- Giuffrè, A.M.; Piscopo, A.; Sicari, V.; Poiana, M. The effects of harvesting on phenolic compounds and fatty acids content in virgin olive oil (cv Roggianella). Riv. Ital. Sostanze Grasse 2012, 87, 14–23. [Google Scholar]

- Afkhami, R.; Goli, M.; Keramat, J. Functional orange juice enriched with encapsulated polyphenolic extract of lime waste and hesperidin. Int. J. Food Sci. Technol. 2018, 53, 634–643. [Google Scholar] [CrossRef]

- Romeo, R.; De Bruno, A.; Imeneo, V.; Piscopo, A.; Poiana, M. Evaluation of enrichment with antioxidants from olive oil mill wastes in hydrophilic model system. J. Food Process. Preserv. 2019, 43, e14211. [Google Scholar] [CrossRef]

- Romeo, R.; De Bruno, A.; Imeneo, V.; Piscopo, A.; Poiana, M. Impact of Stability of Enriched Oil with Phenolic Extract from Olive Mill Wastewaters. Foods 2020, 9, 856. [Google Scholar] [CrossRef] [PubMed]

- Romeo, R.; De Bruno, A.; Piscopo, A.; Brenes, M.; Poiana, M. Effects of Phenolic Enrichment on Antioxidant Activity of Mayonnaise. Chem. Eng. Trans. 2021, 87, 127–132. [Google Scholar]

- Anton, M.; Martinet, V.; Dalgararrondo, M.; Beaumal, V.; David-Briand, E.; Rabesona, H. Chemical and structural characterisation of low-density lipoproteins purified from hen egg yolk. Food Chem. 2003, 83, 175–183. [Google Scholar] [CrossRef]

- Karshenas, M.; Goli, M.; Zamindar, N. The effect of replacing egg yolk with sesame–peanut defatted meal milk on the physicochemical, colorimetry, and rheological properties of low-cholesterol mayonnaise. Food Sci. Nutr. 2018, 6, 824–833. [Google Scholar] [CrossRef] [PubMed]

- Raikos, V.; Hayes, H.; Ni, H. Aquafaba from commercially canned chickpeas as potential egg replacer for the development of vegan mayonnaise: Recipe optimisation and storage stability. Int. J. Food Sci. Tech. 2020, 55, 1935–1942. [Google Scholar] [CrossRef]

- Ghorbani Gorji, S.; Smyth, H.E.; Sharma, M.; Fitzgerald, M. Lipid oxidation in mayonnaise and the role of natural antioxidants: A review. Trends Food Sci. Technol. 2016, 56, 88–102. [Google Scholar] [CrossRef] [Green Version]

- Azhagu Saravana Babu, P.; Vajiha Aafrin, B.; Archana, G.; Sabina, K.; Sudharsan, K.; Radha Krishnan, K.; Babuskin, S.; Sivarajan, M.; Sukumar, M. Polyphenolic and phytochemical content of Cucumis sativus seeds and study on mechanism of preservation of nutritional and quality outcomes in enriched mayonnaise. Int. J. Food Sci. Tech. 2016, 51, 1417–1424. [Google Scholar] [CrossRef]

- Ahmad, M.; Kaloo, Z.A.; Ganai, B.A.; Ganaie, H.A.; Singh, S. Phytochemical screening of Meconopsis aculeata royle an important medicinal plant of Kashmir Himalaya: A perspective. Res. J. Phytochem 2016, 10, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Song, X.; Xiaonan, S.; Qi, B.; Wang, Z.; Li, Y.; Jiang, L. Rosemary extract can be used as a synthetic antioxidant to improve vegetable oil oxidative stability. Ind. Crop Prod. 2016, 80, 141–147. [Google Scholar] [CrossRef]

- Farhadi, K.; Esmaeilzadeh, F.; Hatam, M.; Forough, M.; Molaie, R. Determination of phenolic compounds content and antioxidant active in skin, pulp, seed, cane and leaf of five native grape cultivars in We Azerbaijan province, Iran. Food Chem. 2016, 199, 847–855. [Google Scholar] [CrossRef]

- Samec, D.; Maretic, M.; Lugaric, I.; Mesic, A.; Sondi, B.A.; Duralija, B. Assessment of the differences in the physical, chemical and phytochemical properties of four strawberry cultivars using principal component analysis. Food Chem. 2016, 194, 828–834. [Google Scholar] [CrossRef]

- De Bruno, A.; Romeo, R.; Piscopo, A.; Poiana, M. Antioxidant quantification in different portions obtained during olive oil extraction process in an olive oil press mill. J. Sci. Food Agric. 2020, 101, 1119–1126. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemistry. Official Methods of Analysis of AOAC International, 17th ed.; Author: Gaithersburg, MD, USA, 2005. [Google Scholar]

- AOCS. Method Ca 5a 40. In Official Methods and Recommended Practices of the American Oil Chemists’ Society, 6th ed.; AOCS Press: Champaign, IL, USA, 2017. [Google Scholar]

- AOCS. Method Cd 8–53. In Official Methods and Recommended Practices of the American Oil Chemists’ Society, 6th ed.; AOCS Press: Champaign, IL, USA, 2017. [Google Scholar]

- AOCS. Method Ch 5-91. In Official Methods and Recommended Practices of the American Oil Chemists’ Society; AOCS Press: Champaign, IL, USA, 1989. [Google Scholar]

- AOCS. Method Cd 12c-16. In Official Methods and Recommended Practices of the American Oil Chemists’ Society, 6th ed.; AOCS Press: Champaign, IL, USA, 2017. [Google Scholar]

- Soberón, L.F.; Carelli, A.A.; González, M.T.; Ceci, L.N. Method for phenol recovery from “alperujo”: Numerical optimization and predictive model. Eur. Food Res. Technol. 2019, 245, 1641–1650. [Google Scholar] [CrossRef]

- Brahmi, F.; Mechri, B.; Dabbou, S.; Dhibi, M.; Hammami, M. The efficacy of phenolics compounds with different polarities as antioxidants from olive leaves depending on seasonal variations. Ind Crop Prod. 2012, 38, 146–152. [Google Scholar] [CrossRef]

- Bibi Sadeer, N.; Montesano, D.; Albrizio, S.; Zengin, G.; Mahomoodally, M.F. The Versatility of Antioxidant Assays in Food Science and Safety-Chemistry- Applications, Strengths, and Limitations. Antioxidants 2020, 9, 709. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, C.; Yuan, J.; Zhang, C. Adsorption characteristics of adsorbent resins and antioxidant capacity for enrichment of phenolics from two-phase olive waste. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2016, 1040, 38–46. [Google Scholar] [CrossRef]

- Di Mattia, C.; Paradiso, V.M.; Andrich, L.; Giarnetti, L.; Caponio, F.; Pittia, P. Effect of Olive Oil Phenolic Compounds and Maltodextrins on the Physical Properties and Oxidative Stability of Olive Oil O/W Emulsions. Food Biophys. 2014, 9, 396–405. [Google Scholar] [CrossRef]

- Flamminii, F.; Di Mattia, C.D.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and Sensory Properties of Mayonnaise Enriched with Encapsulated Olive Leaf Phenolic Extracts. Foods 2020, 9, 997. [Google Scholar] [CrossRef] [PubMed]

- Altunkaya, A.; Hedegaard, R.V.; Harholt, J.; Brimer, L.; Gokmene, V.; Skibsted, L.H. Oxidative stability and chemical safety of mayonnaise enriched with grape seed extract. Food Funct. 2013, 4, 1647–1653. [Google Scholar] [CrossRef]

- Martillanes, S.; Rocha-Pimienta, J.; Gil, M.V.; Ayuso-Yuste, M.C.; Delgado-Adámez, J. Antioxidant and antimicrobial evaluation of rice bran (Oryza sativa L.) extracts in a mayonnaise-type emulsion. Food Chem. 2020, 308, 125633. [Google Scholar] [CrossRef] [PubMed]

- Park, J.J.; Olawuyi, I.F.; Lee, W. Characteristics of low-fat mayonnaise using different modified arrowroot starches as fat replacer. Int. J. Biol. Macromol. 2020, 153, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Rasmy, N.M.; Hassan, A.A.; Foda, M.I.; El-Moghazy, M.M. Assessment of the antioxidant activity of sage (Salvia officinalis L.) extracts on the shelf life of mayonnaise. World J. Dairy Food Sci. 2012, 7, 28–40. [Google Scholar]

- Giacintucci, V.; Di Mattia, C.; Sacchetti, G.; Neri, L.; Pittia, P. Role of olive oil phenolics in physical properties and stability of mayonnaise-like emulsions. Food Chem. 2016, 213, 369–377. [Google Scholar] [CrossRef]

- Kiokias, S.; Varzakas, T.H.; Arvanitoyannis, I.S.; Labropoulos, A.E. Lipid Oxidation and Control of Oxidation. Adv. J. Food Biochem. 2009, 383–408. [Google Scholar]

- Raikos, V.; McDonagh, A.; Ranawana, V.; Duthie, G. Processed beetroot (Beta vulgaris L.) as a natural antioxidant in mayonnaise: Effects on physical stability, texture and sensory attributes. Food Sci. Hum. Well. 2016, 5, 191–198. [Google Scholar]

- Paradiso, V.M.; Flamminii, F.; Pittia, P.; Caponio, F.; Di Mattia, C. Radical Scavenging Activity of Olive Oil Phenolic Antioxidants in Oil or Water Phase during the Oxidation of O/W Emulsions: An Oxidomics Approach. Antioxidants 2020, 9, 996. [Google Scholar] [CrossRef]

- Sorensen, A.; Nielsen, N.; Decker, E.; Let, M.; Xu, X.; Jacobsen, C. The efficacy of compounds with different polarities as antioxidants in emulsions with omega-3 lipids. J. Am. Oil Chem. Soc. 2011, 88, 489–502. [Google Scholar] [CrossRef]

| Antioxidant Properties | PEA | PEB | Sign |

|---|---|---|---|

| DPPH | 1156 ± 18 | 1071 ± 9 | * |

| ABTS | 25,716 ± 35 | 28,604 ± 18 | ** |

| TPC | 7895 ± 8 | 7258 ± 14 | ** |

| Hydroxytyrosol | 759 ± 1 | 837 ± 4 | ** |

| Tyrosol | 152 ± 2 | 148 ± 0.3 | ns |

| Chlorogenic Acid | 17 ± 0.1 | 16 ± 0.3 | ns |

| Vanillic Acid | 39 ± 0.0 | 40 ± 0.5 | ns |

| Caffeic Acid | 26 ± 0.2 | 21 ± 0.3 | ** |

| p-coumaric Acid | 64 ± 0.3 | 61 ± 0.0 | ** |

| Oleuropein | 28 ± 0.8 | 75 ± 0.3 | ** |

| Parameters | Time | Control | EMPEA | EMPEB | Sign. |

|---|---|---|---|---|---|

| L* | 0 | 89.03 ± 0.39 aA | 82.10 ± 0.47 bB | 76.26 ± 0.20 cB | ** |

| 15 | 88.93 ± 0.54 aAB | 82.33 ± 0.33 bB | 76.29 ± 0.16 cB | ** | |

| 30 | 88.37 ± 0.37 aB | 82.47 ± 0.29 bB | 76.45 ± 0.36 cB | ** | |

| 45 | 87.59 ± 0.67 aC | 83.12 ± 0.21 bA | 76.82 ± 0.29 cA | ** | |

| Sign. | ** | ** | ** | ||

| a* | 0 | −0.29 ± 0.07 c | 3.41 ± 0.03 bA | 3.83 ± 0.03 aA | ** |

| 15 | −0.28 ± 0.09 c | 3.44 ± 0.05 bA | 3.79 ± 0.08 aA | ** | |

| 30 | −0.27 ± 0.05 c | 3.17 ± 0.10 bB | 3.48 ± 0.17 aB | ** | |

| 45 | −0.25 ± 0.09 c | 2.59 ± 0.05 bC | 3.30 ± 0.05 aC | ** | |

| Sign. | ns | ** | ** | ||

| b* | 0 | 10.78 ± 0.12 cB | 12.86 ± 0.11 bC | 14.71 ± 0.07 aC | ** |

| 15 | 10.68 ± 0.26 cB | 12.89 ± 0.12 bBC | 14.77 ± 0.12 aC | ** | |

| 30 | 10.89 ± 0.04 cB | 12.98 ± 0.08 bB | 15.13 ± 0.17 aB | ** | |

| 45 | 11.16 ± 0.28 cA | 14.11 ± 0.06 bA | 16.57 ± 0.19 aA | ** | |

| Sign. | ** | ** | ** |

| Time (Day) | EMPEA | EMPEB | Sign. | |

|---|---|---|---|---|

| DPPH | 1st | 78 ± 14 | 134 ± 11 | ** |

| 45th | 74 ± 11 | 100 ± 1 | * | |

| Sign. | n.s. | ** | ||

| ABTS | 1st | 463 ± 50 | 613 ± 74 | ** |

| 45th | 590 ± 38 | 752 ± 146 | ns | |

| Sign. | ** | ns | ||

| TPC | 1st | 323 ± 8 | 413 ± 18 | ** |

| 45th | 353 ± 18 | 404 ± 28 | * | |

| Sign. | * | ns | ||

| Hydroxytyrosol | 1st | 82.75 ± 1.06 | 66.63 ± 0.18 | ** |

| 45th | 44.00 ± 0.17 | 39.21 ± 0.08 | ** | |

| Sign. | ** | ** | ||

| Tyrosol | 1st | 19.28 ± 0.39 | 18.12 ± 0.16 | ns |

| 45th | 12.61 ± 0.07 | 10.32 ± 0.04 | ** | |

| Sign. | ** | ** | ||

| Clorogenic Acid | 1st | 4.61 ± 0.02 | 1.93 ± 0.06 | ** |

| 45th | 3.18 ± 0.04 | 1.26 ± 0.01 | ** | |

| Sign. | ** | ** | ||

| Vanillic Acid | 1st | 0.43 ± 0.02 | 1.66 ± 0.08 | ** |

| 45th | 0.37 ± 0.02 | 0.34 ± 0.02 | ns | |

| Sign. | ns | ** | ||

| Caffeic Acid | 1st | 2.95 ± 0.08 | 2.25 ± 0.06 | * |

| 45th | 2.18 ± 0.18 | 1.90 ± 0.08 | ns | |

| Sign. | * | * | ||

| p−cumaric Acid | 1st | 6.50 ± 0.11 | 7.06 ± 0.08 | * |

| 45th | 2.55 ± 0.06 | 4.36 ± 0.07 | ** | |

| Sign. | ** | ** | ||

| Oleuropein | 1st | 32.45 ± 0.20 | 32.55 ± 0.64 | ns |

| 45th | 28.74 ± 0.13 | 25.16 ± 0.04 | ** | |

| Sign. | ** | ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Bruno, A.; Romeo, R.; Gattuso, A.; Piscopo, A.; Poiana, M. Functionalization of a Vegan Mayonnaise with High Value Ingredient Derived from the Agro-Industrial Sector. Foods 2021, 10, 2684. https://doi.org/10.3390/foods10112684

De Bruno A, Romeo R, Gattuso A, Piscopo A, Poiana M. Functionalization of a Vegan Mayonnaise with High Value Ingredient Derived from the Agro-Industrial Sector. Foods. 2021; 10(11):2684. https://doi.org/10.3390/foods10112684

Chicago/Turabian StyleDe Bruno, Alessandra, Rosa Romeo, Antonio Gattuso, Amalia Piscopo, and Marco Poiana. 2021. "Functionalization of a Vegan Mayonnaise with High Value Ingredient Derived from the Agro-Industrial Sector" Foods 10, no. 11: 2684. https://doi.org/10.3390/foods10112684

APA StyleDe Bruno, A., Romeo, R., Gattuso, A., Piscopo, A., & Poiana, M. (2021). Functionalization of a Vegan Mayonnaise with High Value Ingredient Derived from the Agro-Industrial Sector. Foods, 10(11), 2684. https://doi.org/10.3390/foods10112684