Antihypertensive Peptides from Ultrafiltration and Fermentation of the Ricotta Cheese Exhausted Whey: Design and Characterization of a Functional Ricotta Cheese

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microrganisms

2.2. RCEW Fermentation

2.3. RCEW ACE-Inhibitory Activity

2.4. RCEW Fractionation and Characterization

2.5. R-UF Fermentation

2.6. Spray-Drying

2.7. Purification and Identification of the Bioactive Peptides

2.8. Ricotta Production

2.9. Ricotta Characterization

2.10. Sensory Analysis

2.11. Texture Profile Analysis of Ricotta

2.12. Statistical Analysis

3. Results

3.1. LAB Selection

3.2. RCEW Fractionation

3.3. Fermentation and Characterization of the Protein-Rich RCEW Fraction

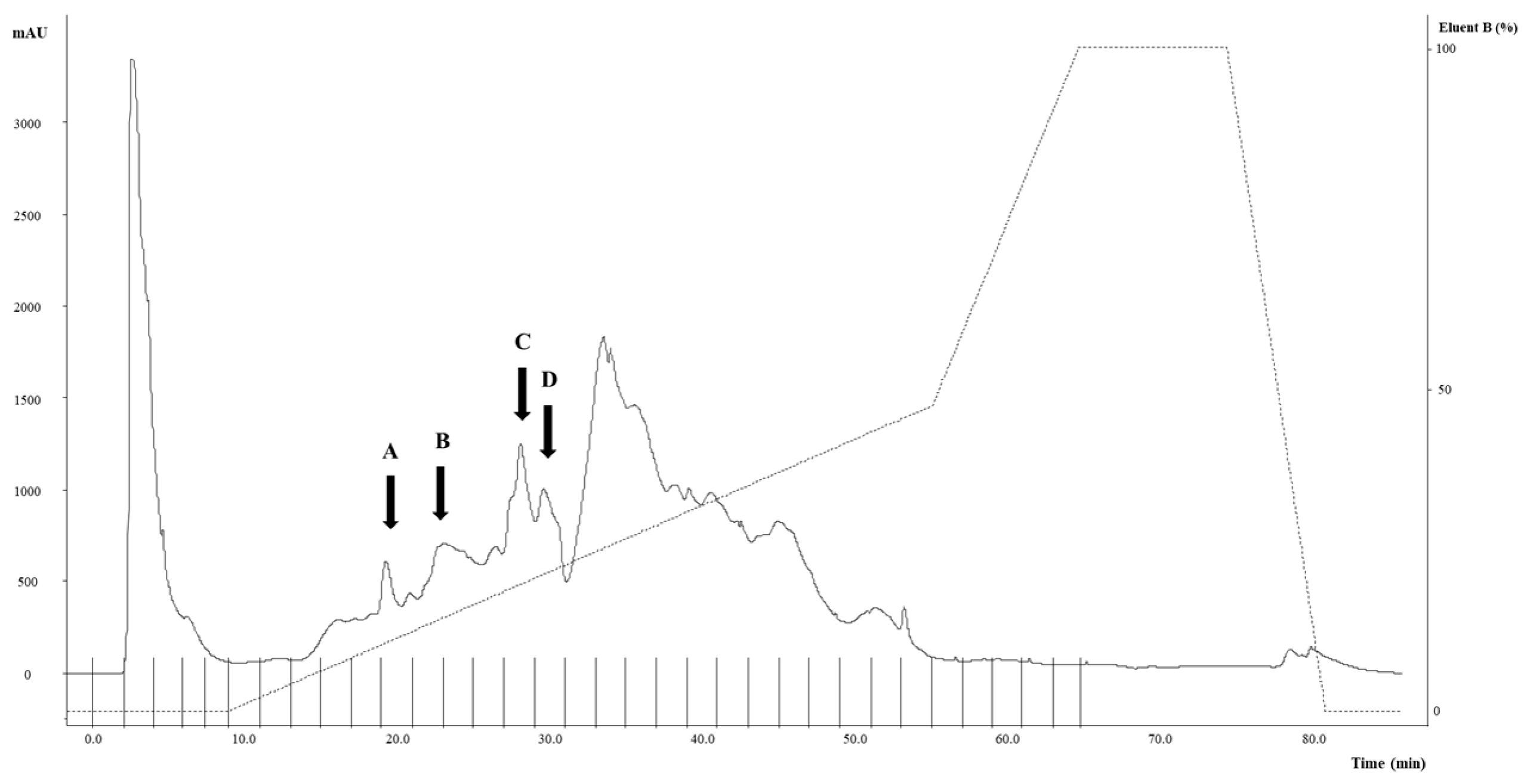

3.4. ACE-Inhibitory Peptides

3.5. Ricotta Cheeses Characterization

3.6. Sensory and Textural Characteristics of Ricotta Cheese

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pires, A.F.; Marnotes, N.G.; Rubio, O.D.; Garcia, A.C.; Pereira, C.D. Dairy by-products: A review on the valorization of whey and second cheese whey. Foods 2021, 10, 1067. [Google Scholar] [CrossRef] [PubMed]

- Castelli, H.; Du Vale, L. Handbook on Cheese: Production, Chemistry and Sensory Properties; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2013. [Google Scholar]

- Jelen, P. Whey processing. Utilization and products. In Encyclopedia of Dairy Sciences; Fuquay, J., Fox, P., McSweeney, P., Eds.; Academic Press: London, UK, 2003. [Google Scholar]

- Ryan, M.P.; Walsh, G. The biotechnological potential of whey. Rev. Environ. Sci. Bio/Technol. 2016, 15, 479–498. [Google Scholar] [CrossRef] [Green Version]

- Pires, A.F.; Marnotes, N.G.; Bella, A.; Viegas, J.; Gomes, D.M.; Henriques, M.H.; Pereira, C.J. Use of ultrafiltrated cow’s whey for the production of whey cheese with Kefir or probiotics. J. Sci. Food Agric. 2021, 101, 555–563. [Google Scholar] [CrossRef] [PubMed]

- Prazeres, A.R.; Carvalho, F.; Rivas, J. Cheese whey management: A review. J. Environ. Manag. 2012, 110, 48–68. [Google Scholar] [CrossRef]

- Madureira, A.; Pereira, C.; Truszkowska, K.; Gomes, A.; Pintado, M.; Malcata, F. Survival of probiotic bacteria in a whey cheese vector submitted to environmental conditions prevailing in the gastrointestinal tract. Int. Dairy J. 2005, 15, 921–927. [Google Scholar] [CrossRef]

- Sommella, E.; Pepe, G.; Ventre, G.; Pagano, F.; Conte, G.M.; Ostacolo, C.; Manfra, M.; Tenore, G.C.; Russo, M.; Novellino, E. Detailed peptide profiling of “Scotta”: From a dairy waste to a source of potential health-promoting compounds. Dairy Sci. Technol. 2016, 96, 763–771. [Google Scholar] [CrossRef] [Green Version]

- Maragkoudakis, P.; Vendramin, V.; Bovo, B.; Treu, L.; Corich, V.; Giacomini, A. Potential use of scotta, the by-product of the ricotta cheese manufacturing process, for the production of fermented drinks. J. Dairy Res. 2016, 83, 104. [Google Scholar] [CrossRef]

- Macedo, A.; Duarte, E.; Pinho, M. The role of concentration polarization in ultrafiltration of ovine cheese whey. J. Membr. Sci. 2011, 381, 34–40. [Google Scholar] [CrossRef]

- Yadav, J.S.S.; Yan, S.; Pilli, S.; Kumar, L.; Tyagi, R.D.; Surampalli, R.Y. Cheese whey: A potential resource to transform into bioprotein, functional/nutritional proteins and bioactive peptides. Biotechnol. Adv. 2015, 33, 756–774. [Google Scholar] [CrossRef]

- Argenta, A.B.; Scheer, A.D.P. Membrane separation processes applied to whey: A review. Food Rev. Int. 2019, 36, 499–528. [Google Scholar] [CrossRef]

- Secchi, N.; Giunta, D.; Pretti, L.; García, M.R.; Roggio, T.; Mannazzu, I.; Catzeddu, P. Bioconversion of ovine scotta into lactic acid with pure and mixed cultures of lactic acid bacteria. J. Ind. Microbiol. Biotechnol. 2012, 39, 175–181. [Google Scholar] [CrossRef]

- Sansonetti, S.; Curcio, S.; Calabro, V.; Iorio, G. Bio-ethanol production by fermentation of ricotta cheese whey as an effective alternative non-vegetable source. Biomass Bioenergy 2009, 33, 1687–1692. [Google Scholar] [CrossRef]

- Macedo, A.; Duarte, E.; Fragoso, R. Assessment of the performance of three ultrafiltration membranes for fractionation of ovine second cheese whey. Int. Dairy J. 2015, 48, 31–37. [Google Scholar] [CrossRef]

- Tavares, T.G.; Malcata, F.X. Whey proteins as source of bioactive peptides against hypertension. In Bioactive Food Peptides in Health and Disease; Hernández-Ledesma, B., Hsieh, C.C., Eds.; IntechOpen: London, UK, 2013; p. 75. [Google Scholar]

- Pihlanto, A. Whey proteins and peptides: Emerging properties to promote health. Nutrafoods 2011, 10, 29–42. [Google Scholar] [CrossRef]

- Raho, S.; Carofiglio, V.E.; Montemurro, M.; Miceli, V.; Centrone, D.; Stufano, P.; Schioppa, E.; Pontonio, E.; Rizzello, C.G. Production of the polyhydroxyalkanoate PHBV from ricotta cheese exhausted whey by Haloferax mediterranei fermentation. Foods 2020, 9, 1459. [Google Scholar] [CrossRef]

- Siragusa, S.; De Angelis, M.; Di Cagno, R.; Rizzello, C.G.; Coda, R.; Gobbetti, M. Synthesis of γ-aminobutyric acid by lactic acid bacteria isolated from a variety of Italian cheeses. Appl. Environ. Microbiol. 2007, 73, 7283–7290. [Google Scholar] [CrossRef] [Green Version]

- Gobbetti, M.; Morea, M.; Baruzzi, F.; Corbo, M.R.; Matarante, A.; Considine, T.; Di Cagno, R.; Giunee, T.; Fox, P.F. Microbiological, compositional, biochemical and textural characterisation of Caciocavallo Pugliese cheese during ripening. Int. Dairy J. 2002, 12, 511–523. [Google Scholar] [CrossRef]

- Gatti, M.; Lazzi, C.; Rossetti, L.; Mucchetti, G.; Neviani, E. Biodiversity in Lactobacillus helveticus strains present in natural whey starter used for Parmigiano Reggiano cheese. J. Appl. Microbiol. 2003, 95, 463–470. [Google Scholar] [CrossRef]

- Nejati, F.; Rizzello, C.G.; Di Cagno, R.; Sheikh-Zeinoddin, M.; Diviccaro, A.; Minervini, F.; Gobbetti, M. Manufacture of a functional fermented milk enriched of Angiotensin-I Converting Enzyme (ACE)-inhibitory peptides and γ-amino butyric acid (GABA). LWT-Food Sci. Technol. 2013, 51, 183–189. [Google Scholar] [CrossRef]

- Church, F.C.; Swaisgood, H.E.; Porter, D.H.; Catignazni, G.L. Spectrophotometric assay using o-phthaldialdehyde for determination of proteolysis in milk and isolated milk proteins. J. Dairy Sci. 1983, 66, 1219–1227. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Nionelli, L.; Coda, R.; De Angelis, M.; Gobbetti, M. Effect of sourdough fermentation on stabilisation, and chemical and nutritional characteristics of wheat germ. Food Chem. 2010, 119, 1079–1089. [Google Scholar] [CrossRef]

- Cushman, D.W.; Cheung, H.S. Spectrophotometric assay and properties of the angiotensin-converting enzyme of rabbit lung. Biochem. Pharmacol. 1971, 20, 1637–1648. [Google Scholar] [CrossRef]

- Wu, J.; Ding, X. Characterization of inhibition and stability of soy-protein-derived angiotensin I-converting enzyme inhibitory peptides. Food Res. Int. 2002, 35, 367–375. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Cassone, A.; Di Cagno, R.; Gobbetti, M. Synthesis of angiotensin I-converting enzyme (ACE)-inhibitory peptides and γ-aminobutyric acid (GABA) during sourdough fermentation by selected lactic acid bacteria. J. Agric. Food Chem. 2008, 56, 6936–6943. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Singh, T.K.; Hillier, A.J. An HPLC assay for the determination of ACE inhibitory activity of food protein derived peptides. Aust. J. Dairy Technol. 2006, 61, 228. [Google Scholar]

- Miceli, V.; Camassa, A.; Pizzichini, D.; Russo, C. Il Trattamento Sostenibile Dei Reflui Provenienti Dai Comparti Olivicolo, Viti-Vinicolo e Lattiero Caseario al Centro Del Progetto Del Progetto Bio-Energy Smart Source System, ENEA. 2016. Available online: https://iris.enea.it/retrieve/handle/20.500.12079/6766/515/RT-2016-39-ENEA.pdf (accessed on 30 September 2021).

- ISO/FIL. Milk and Milk Products: Determination of Nitrogen Content. Part 1: Kjeldahl Principle and Crude Protein Calculation; Joint Standard ISO 8968-1/IDF 20-1:2001; International Standardisation Organisation: Geneva, Switzerland, 2001. [Google Scholar]

- Verni, M.; De Mastro, G.; De Cillis, F.; Gobbetti, M.; Rizzello, C.G. Lactic acid bacteria fermentation to exploit the nutritional potential of Mediterranean faba bean local biotypes. Food Res. Int. 2019, 125, 108571. [Google Scholar] [CrossRef]

- ISO/IDF. Milk. Determination of Fat Content; Joint Standard ISO 2446/IDF 226:2008; International Standardisation Organisation: Geneva, Switzerland, 2008. [Google Scholar]

- AOAC. Ash of milk-Gravimetric method, method 945.46. In Official Methods of Analysis of AOAC International, 20th ed.; Latimer, G.W., Ed.; AOAC International: Gaithersburg, MD, USA, 2016; p. 10. [Google Scholar]

- Chen, Y.; Kwon, S.W.; Kim, S.C.; Zhao, Y. Integrated approach for manual evaluation of peptides identified by searching protein sequence databases with tandem mass spectra. J. Proteome Res. 2005, 4, 998–1005. [Google Scholar] [CrossRef]

- AOAC Official methods of analysis of AOAC international. In Official method 926.08. Moisture in Cheese, 16th ed.; AOAC International: Rockville, MD, USA, 1995; Volume 2, p. 58.

- Kuchroo, C.N.; Fox, P.F. Soluble nitrogen in Cheddar cheese: Comparison of extraction procedures. Milchwissenschaft 1982, 37, 331–335. [Google Scholar]

- Rehman, S.-U.; McSweeney, P.L.H.; Fox, P.F. Protocol for the manufacture of miniature cheeses. Lait 1998, 78, 703–720. [Google Scholar]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer: New York, NY, USA, 2010; Volume 2. [Google Scholar]

- Lacivita, V.; Conte, A.; Manzocco, L.; Plazzotta, S.; Zambrini, V.A.; Del Nobile, M.A.; Nicoli, M.C. Surface UV-C light treatments to prolong the shelf-life of Fiordilatte cheese. Innov. Food Sci. Emerg. Technol. 2016, 36, 150–155. [Google Scholar] [CrossRef]

- Chen, C.; Wolle, D.; Sommer, D. Mozzarella. In The Sensory Evaluation of Dairy Products, 2nd ed.; Clark, M., Costello, M., Drake, M., Bodyfelt, F., Eds.; Springer Science + Business Media: Dordrecht, the Netherlands, 2009; pp. 468–469. [Google Scholar]

- Wang, G.; Li, X.; Wang, Z. APD3: The antimicrobial peptide database as a tool for research and education. Nucleic Acids Res. 2016, 44, 1087–1093. [Google Scholar] [CrossRef] [Green Version]

- Minhalma, M.; Magueijo, V.; Queiroz, D.P.; de Pinho, M.N. Optimization of “Serpa” cheese whey nanofiltration for effluent minimization and by-products recovery. J. Environ. Manag. 2007, 82, 200–206. [Google Scholar] [CrossRef]

- Monti, L.; Donati, E.; Zambrini, A.V.; Contarini, G. Application of membrane technologies to bovine Ricotta cheese exhausted whey (scotta). Int. Dairy J. 2018, 85, 121–128. [Google Scholar] [CrossRef]

- Daliri, E.B.M.; Oh, D.H.; Lee, B.H. Bioactive peptides. Foods 2017, 6, 32. [Google Scholar] [CrossRef]

- Sánchez, A.; Vázquez, A. Bioactive peptides: A review. Food Qual. Saf. 2017, 1, 29–46. [Google Scholar] [CrossRef]

- Daliri, E.B.M.; Lee, B.H.; Park, B.J.; Kim, S.H.; Oh, D.H. Antihypertensive peptides from whey proteins fermented by lactic acid bacteria. Food Sci. Biotechnol. 2018, 27, 1781–1789. [Google Scholar] [CrossRef]

- Brown, L.; Pingitore, E.V.; Mozzi, F.; Saavedra, L.; Villegas, J.M.; Hebert, E.M. Lactic acid bacteria as cell factories for the generation of bioactive peptides. Protein Pept. Lett. 2017, 24, 146–155. [Google Scholar] [CrossRef]

- Daliri, E.B.M.; Lee, B.H.; Oh, D.H. Current trends and perspectives of bioactive peptides. Crit. Rev. Food 2018, 58, 2273–2284. [Google Scholar] [CrossRef]

- Nakamura, K.; Naramoto, K.; Koyama, M. Blood-pressure-lowering effect of fermented buckwheat sprouts in spontaneously hypertensive rats. J. Funct. Foods 2013, 5, 406–415. [Google Scholar] [CrossRef]

- Manzanares, P.; Salom, J.B.; Garcı´a-Tejedor, A.; Fernández-Musoles, R.; Ruiz-Giménez, P.; Gimeno-Alcañíz, J.V. Unraveling the mechanisms of action of lactoferrin-derived antihypertensive peptides: ACE inhibition and beyond. Food Funct. 2015, 6, 2440–2452. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, H.R.; Ahmed, A.S.; Miyata, T. Novel angiotensin-converting enzyme inhibitory peptides from caseins and whey proteins of goat milk. J. Adv. Res. 2017, 8, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Monari, S.; Ferri, M.; Russo, C.; Prandi, B.; Tedeschi, T.; Bellucci, P.; Zambrini, A.V.; Donati, E.; Tassoni, A. Enzymatic production of bioactive peptides from scotta, an exhausted by-product of ricotta cheese processing. PLoS ONE 2019, 14, e0226834. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Venegas-Ortega, M.G.; Flores-Gallegos, A.C.; Martínez-Hernández, J.L.; Aguilar, C.N.; Nevárez-Moorillón, G.V. Production of bioactive peptides from lactic acid bacteria: A sustainable approach for healthier foods. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1039–1051. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gobbetti, M.; Minervini, F.; Rizzello, C.G. Angiotensin I-converting-enzyme-inhibitory and antimicrobial bioactive peptides. Int. J. Dairy Technol. 2004, 57, 173–188. [Google Scholar] [CrossRef]

- Brzozowski, B.; Lewandowska, M. Prolyl endopeptidase—Optimization of medium and culture conditions for enhanced production by Lactobacillus acidophilus. Electron. J. Biotechnol. 2014, 17, 204–210. [Google Scholar] [CrossRef] [Green Version]

- Hayes, M.; Stanton, C.; Slattery, H.; O’Sullivan, O.; Hill, C.; Fitzgerald, G.; Ross, R. Casein fermentate of Lactobacillus animalis DPC6134 contains a range of novel propeptide angiotensin-converting enzyme inhibitors. Appl. Environ. Microbiol. 2007, 73, 4658–4667. [Google Scholar] [CrossRef] [Green Version]

- Minervini, F.; Algaron, F.; Rizzello, C.G.; Fox, P.F.; Monnet, V.; Gobbetti, M. Angiotensin I-converting-enzyme-inhibitory and antibacterial peptides from Lactobacillus helveticus PR4 proteinase-hydrolyzed caseins of milk from six species. Appl. Environ. Microbiol. 2003, 69, 5297–5305. [Google Scholar] [CrossRef] [Green Version]

- Skrzypczak, K.; Gustaw, W.; Szwajgier, D.; Fornal, E.; Waśko, A. κ-casein as a source of short-chain bioactive peptides generated by Lactobacillus helveticus. J. Food Sci. Technol. 2017, 54, 3679–3688. [Google Scholar] [CrossRef]

- Pihlanto, A. Lactic fermentation and bioactive peptides. In Lactic Acid Bacteria-R & D for Food, Health and Livestock Purposes; Kongo, M., Ed.; InTechOpen Limited: London, UK, 2013; pp. 309–333. [Google Scholar]

- Sadat-Mekmene, L.; Genay, M.; Atlan, D.; Lortal, S.; Gagnaire, V. Original features of cell-envelope proteinases of Lactobacillus helveticus: A review. Int. J. Food Microbiol. 2011, 146, 1–13. [Google Scholar] [CrossRef]

- Tavares, T.; del Mar Contreras, M.; Amorim, M.; Pintado, M.; Recio, I.; Malcata, F.X. Novel whey-derived peptides with inhibitory effect against angiotensin-converting enzyme: In vitro effect and stability to gastrointestinal enzymes. Peptides 2011, 32, 1013–1019. [Google Scholar] [CrossRef]

- Abubakar, A.; Saito, T.; Kitazawa, H.; Kawai, Y.; Itoh, T. Structural analysis of new antihypertensive peptides derived from cheese whey protein by proteinase K digestion. J. Dairy Sci. 1998, 81, 3131–3138. [Google Scholar] [CrossRef]

- Lafarga, T.; Aluko, R.E.; Rai, D.K.; O’Connor, P.; Hayes, M. Identification of bioactive peptides from a papain hydrolysate of bovine serum albumin and assessment of an antihypertensive effect in spontaneously hypertensive rats. Food Res. Int. 2016, 81, 91–99. [Google Scholar] [CrossRef] [Green Version]

- Valk-Weeber, R.L.; Nichols, K.; Dijkhuizen, L.; Bijl, E.; van Leeuwen, S.S. Variations in N-linked glycosylation of glycosylation-dependent cell adhesion molecule 1 (GlyCAM-1) whey protein: Intercow differences and dietary effects. J. Dairy Sci. 2021, 104, 5056–5068. [Google Scholar] [CrossRef]

- Ganzorig, K.; Urashima, T.; Fukuda, K. Exploring potential bioactive peptides in fermented bactrian camel’s milk and mare’s milk made by mongolian nomads. Foods 2020, 9, 1817. [Google Scholar] [CrossRef]

- Marques, C.; Manuela Amorim, M.; Odila Pereira, J.; Estevez Pintado, M.; Moura, D.; Calhau, C.; Pinheiro, H. Bioactive peptides —Are there more antihypertensive mechanisms beyond ACE inhibition? Curr. Pharm. Des. 2012, 18, 4706–4713. [Google Scholar] [CrossRef]

- Pei, J.; Hua, Y.; Zhou, T.; Gao, X.; Dang, Y.; Wang, Y. Transport, in vivo antihypertensive effect, and pharmacokinetics of an Angiotensin-Converting Enzyme (ACE) inhibitory peptide LVLPGE. J. Agric. Food Chem. 2021, 69, 2149–2156. [Google Scholar] [CrossRef]

- Temussi, P.A. The good taste of peptides. J. Pept. Sci. 2012, 18, 73–82. [Google Scholar] [CrossRef]

| RCEW | ||||||

|---|---|---|---|---|---|---|

| CT | FC13 | B15Z | CR12 | PR4 | DIBCA2 | |

| pH | 4.87 ± 0.05 a | 4.10 ± 0.04 c | 3.92 ± 0.04 d | 4.02 ± 0.05 d | 3.76 ± 0.05 e | 4.26 ± 0.05 b |

| LAB density (log10 cfu/mL) | 3.9 ± 0.1 d | 8.5 ± 0.2 a | 7.9 ± 0.2 b | 8.1 ± 0.1 b | 9.0 ± 0.2 a | 7.5 ± 0.1 c |

| Peptides (mg/L) | 364 ± 4 e | 703 ± 10 c | 775 ± 15 b | 819 ± 9 a | 795 ± 12 b | 525 ± 6 d |

| ACE-inhibitory activity (%) | 7.2 ± 0.2 d | 16.9 ± 0.2 c | 26.5 ± 0.2 b | 7.9 ± 0.4 d | 68.4 ± 0.6 a | 7.5 ± 0.3 d |

| RCEW | R-UF | P-UF | |

|---|---|---|---|

| pH | 5.2 ± 0.1 a | 5.2 ± 0.2 a | 5.2 ± 0.1 a |

| Total Nitrogen (mg/L) | 60.02 ± 0.54 b | 290.02 ± 4.05 a | 1.34 ± 0.02 c |

| Proteins * (% w/v) | 0.38 ± 0.06 b | 1.85 ± 0.05 a | 0.08 ± 0.01 c |

| Total Free Amino Acids (mg/L) | 417 ± 5 b | 52 ± 2 c | 516 ± 9 a |

| Lactose (% w/v) | 3.80 ± 0.10 b | 5.19 ± 0.22 a | 3.42 ± 0.11 c |

| Glucose (% w/v) | <0.01 | <0.01 | <0.01 |

| Galactose (% w/v) | <0.01 | <0.01 | <0.01 |

| Fat (% w/v) | 0.16 ± 0.10 b | 0.75 ± 0.04 a | <0.01 |

| Ash (% w/v) | 1.08 ± 0.12 b | 0.23 ± 0.08 c | 1.35 ± 0.11 a |

| R-UF | fR-UF | |

|---|---|---|

| pH | 5.2 ± 0.1 a | 3.82 ± 0.2 b |

| LAB density (log10 cfu/mL) | 7.21 ± 0.2 b | 8.82 ± 0.4 a |

| Peptides (mg/L) | 65 ± 5 b | 3230 ± 25 a |

| TFAA (mg/L) | 50 ± 2 b | 896 ± 12 a |

| Lactose (%) | 5.2 ± 0.2 a | 3.5 ± 0.1 b |

| ACE-inhibitory activity (%) | nd | 88.2 ± 1.1 |

| Fraction | Sequence | Mass (Da) | Length (aa) | Net Charge * | Hydrophobic Ratio (%) | NCBI Accession n° (Protein) |

|---|---|---|---|---|---|---|

| A | TIASGEPTSTPTTEA | 1462.532 | 15 | −2 | 38 | CAF03625.1 (kappa-casein) |

| DAFLGSFLYEYSR | 1567.721 | 13 | −1 | 44 | P02769.4 (serum albumin) | |

| RHPYFYAPELLYYANK | 2045.327 | 16 | 1.24 | 42 | ||

| DETHLEAQPTDASAQ | 1612.63 | 15 | −3.75 | 32 | ABY26541.1 (glycosylation-dependant cell adhesion molecule 1) | |

| B | ILNKPEDETHLEAQPT | 1835.001 | 16 | −2.75 | 36 | AAB27385.1 (PP3 homolog) |

| C | VIESPPEINTVQVTSTA | 1884.118 | 17 | −2 | 49 | CAF03625.1 (kappa casein) |

| D | NQDKTEIPTINTIASGEPTSTPTIE | 2657.869 | 25 | −3 | 36 | ACF15188.1 (kappa casein) |

| AQPTDASAQFIR | 1304.428 | 12 | 0 | 49 | AAB27385.1 (PP3 homolog) |

| Ricotta cheeses | |||||

|---|---|---|---|---|---|

| RC | RC1 | RC5 | RCf1 | RCf5 | |

| Biochemical and nutritional characteristics | |||||

| pH | 5.02 ± 0.03 a | 5.02 ± 0.02 a | 5.02 ± 0.03 a | 4.95 ± 0.03 b | 4.88 ± 0.04 b |

| TTA (mL NaOH 0.1 M) | 8.1 ± 0.2 b | 8.1 ± 0.2 b | 8.2 ± 0.3 b | 8.5 ± 0.1 b | 8.9 ± 0.3 a |

| Moisture (%) | 76.6 ± 0.5 a | 76.5 ± 0.7 a | 73.1 ± 0.5 b | 76.2 ± 0.8 a | 73.0 ± 0.5 b |

| Proteins 1 (% w/v) | 9.8 ± 0.5 b | 10.3 ± 0.6 ab | 10.9 ± 0.7 a | 10.3 ± 0.4 ab | 11.0 ± 0.6 a |

| Fat (% w/v) | 10.2 ± 0.3 a | 10.3 ± 0.4 a | 10.7 ± 0.4 a | 10.3 ± 0.3 a | 10.7 ± 0.5 a |

| Carbohydrates (% w/v) | 3.5 ± 0.3 b | 3.9 ± 0.4 b | 6.3 ± 0.2 a | 3.7 ± 0.3 b | 5.8 ± 0.3 a |

| Ash (% w/v) | 2.4 ± 0.2 a | 2.5 ± 0.3 a | 2.6 ± 0.2 a | 2.5 ± 0.1 a | 2.6 ± 0.3 a |

| ACE-inhibitory activity | 7.2 ±0.2 c | 7.5 ± 0.3 c | 7.5 ± 0.2 c | 25.1 ± 0.2 b | 64.3 ± 0.2 a |

| Textural Profile Analysis | |||||

| Hardness (g) | 244.9 ± 11.0 b | 244.1 ± 23.5 b | 357.3 ± 32.0 a | 242.5 ± 14.5 b | 253.2 ± 19.3 b |

| Cohesiveness | 0.519 ± 0.015 b | 0.468 ± 0.016 c | 0.566 ± 0.034 a | 0.584 ± 0.027 a | 0.601 ± 0.028 a |

| Springiness | 0.716 ± 0.016 a | 0.694 ± 0.011 b | 0.608 ± 0.036 c | 0.709 ± 0.010 ab | 0.627 ± 0.021 c |

| Chewiness (g) | 91.0 ± 3.5 a | 79.9 ± 5.2 bc | 100.4 ± 6.9 a | 63.6 ± 10.4 c | 85.0 ± 11.8 ab |

| Attributes | RC | RC1 | RC5 | RCf1 | RCf5 |

|---|---|---|---|---|---|

| Visual aspect | |||||

| Color intensity | 5.1 ± 0.2 b | 5.3 ± 0.4 b | 5.3 ± 0.3 b | 5.3 ± 0.4 b | 6.0 ± 0.4 a |

| Color homogeneity | 4.5 ± 0.2 a | 4.8 ± 0.3 a | 4.0 ± 0.3 b | 4.8 ± 0.3 a | 4.8 ± 0.3 a |

| Odor | |||||

| Milk | 5.0 ± 0.3 a | 4.8 ± 0.4 ab | 4.8 ± 0.5 ab | 4.5 ± 0.2 ab | 3.8 ± 0.4 c |

| Acidic | 1.1 ± 0.4 ab | 1.1 ± 0.4 ab | 1.1 ± 0.2 b | 1.5 ± 0.3 ab | 1.8 ± 0.4 a |

| Flavor | |||||

| Sapidity | 3.5 ± 0.3 b | 3.5 ± 0.4 b | 3.5 ± 0.4 b | 4.0 ± 0.3 ab | 4.3 ± 0.4 a |

| Bitterness | 0.5 ± 0.3 b | 0.5 ± 0.2 b | 0.5 ± 0.2 b | 0.5 ± 0.2 b | 1.1 ± 0.4 a |

| Acidity | 4.0 ± 0.3 c | 4.3 ± 0.3 c | 4.3 ± 0.3 c | 5.3 ± 0.4 b | 6.5 ± 0.4 a |

| Sweetness | 2.8 ± 0.5 a | 2.1 ± 0.2 b | 2.0 ± 0.4 b | 2.0 ± 0.3 b | 2.0 ± 0.3 b |

| Milk | 3.0 ± 0.4 a | 2.8 ± 0.4 a | 2.8 ± 0.5 a | 3.0 ± 0.2 a | 2.7 ± 0.3 a |

| Butter | 3.3 ± 0.6 a | 2.7 ± 0.4 a | 2.7 ± 0.4 a | 2.7 ± 0.4 a | 2.7 ± 0.5 a |

| Off-flavors | 0.7 ± 0.3 a | 0.7 ± 0.3 a | 0.8 ± 0.4 a | 0.8 ± 0.4 a | 0.8 ± 0.2 a |

| Persitency | 3.2 ± 0.5 b | 3.0 ± 0.3 b | 3.2 ± 0.4 b | 3.8 ± 0.5 b | 6.0 ± 0.7 a |

| Texture | |||||

| Adhesiveness | 2.7 ± 0.5 ab | 3.0 ± 0.2 a | 3.0 ± 0.4 a | 3.3 ± 0.3 a | 2.3 ± 0.0 b |

| Graininess | 2.5 ± 0.3 b | 2.8 ± 0.5 ab | 3.2 ± 0.4 a | 2.5 ± 0.4 b | 2.7 ± 0.4 ab |

| Friability | 3.2 ± 0.4 a | 3.3 ± 0.4 a | 3.3 ± 0.2 a | 3.3 ± 0.5 a | 3.3 ± 0.4 a |

| Wetness | 5.0 ± 0.2 a | 5.0 ± 0.4 ab | 4.7 ± 0.2 ab | 4.7 ± 0.3 ab | 4.5 ± 0.2 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pontonio, E.; Montemurro, M.; De Gennaro, G.V.; Miceli, V.; Rizzello, C.G. Antihypertensive Peptides from Ultrafiltration and Fermentation of the Ricotta Cheese Exhausted Whey: Design and Characterization of a Functional Ricotta Cheese. Foods 2021, 10, 2573. https://doi.org/10.3390/foods10112573

Pontonio E, Montemurro M, De Gennaro GV, Miceli V, Rizzello CG. Antihypertensive Peptides from Ultrafiltration and Fermentation of the Ricotta Cheese Exhausted Whey: Design and Characterization of a Functional Ricotta Cheese. Foods. 2021; 10(11):2573. https://doi.org/10.3390/foods10112573

Chicago/Turabian StylePontonio, Erica, Marco Montemurro, Gina Valeria De Gennaro, Valerio Miceli, and Carlo Giuseppe Rizzello. 2021. "Antihypertensive Peptides from Ultrafiltration and Fermentation of the Ricotta Cheese Exhausted Whey: Design and Characterization of a Functional Ricotta Cheese" Foods 10, no. 11: 2573. https://doi.org/10.3390/foods10112573

APA StylePontonio, E., Montemurro, M., De Gennaro, G. V., Miceli, V., & Rizzello, C. G. (2021). Antihypertensive Peptides from Ultrafiltration and Fermentation of the Ricotta Cheese Exhausted Whey: Design and Characterization of a Functional Ricotta Cheese. Foods, 10(11), 2573. https://doi.org/10.3390/foods10112573