Role of Hydrocolloids in the Structure, Cooking, and Nutritional Properties of Fiber-Enriched, Fresh Egg Pasta Based on Tiger Nut Flour and Durum Wheat Semolina

Abstract

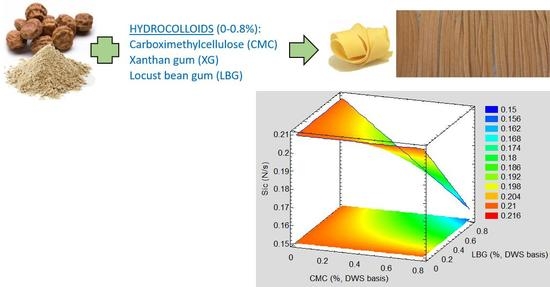

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Experimental Design

2.3. Pasta Preparation

2.4. Pasta Cooking

2.5. Proximate Chemical Composition of Both Cooked and Uncooked Pasta Samples

2.6. Pasta Technological Properties

2.7. Statistical Analysis

3. Results and Discussion

3.1. Mechanical Properties of the Uncooked and the Cooked Fresh Egg Pasta

3.2. Cooking Quality and Color Attributes of Uncooked and Cooked Fresh Egg Pasta

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Gasparre, N.; Rosell, C.M. Role of hydrocolloids in gluten free noodles made with tiger nut flour as non-conventional powder. Food Hydrocoll. 2019, 97, 105194. [Google Scholar] [CrossRef]

- Ukwuru, M.U.; Ibeneme, C.L.; Agbo, C.I. New Product Development from Tigernut (Cyperus esculentus) and Their Sensory, Proximate and Microbiological Evaluation. Pak. J. Nutr. 2011, 10, 101–105. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Zapata, E.; Fernández-López, J.; Pérez-Alvarez, J.A. Tiger Nut (Cyperus esculentus) Commercialization: Health Aspects, Composition, Properties, and Food Applications. Compr. Rev. Food Sci. F 2012, 11, 366–377. [Google Scholar] [CrossRef]

- Alegría-Torán, A.; Farré-Rovira, R. Horchata y Salud: Aspectos Nutricionales y Dietéticos. In Jornada Chufa y Horchata: Tradición y Salud, 1st ed.; Fundación Valenciana de Estudios Avanzados, Ed.; Consellería de Agricultura, Pesca y Alimentación: Valencia, Spain, 2003; pp. 55–70. [Google Scholar]

- Martín-Esparza, M.E.; Raigón, M.D.; Raga, A.; Albors, A. Functional, thermal and rheological properties of high fibre fresh pasta: Effect of tiger nut flour and xanthan gum addition. Food Bioprocess Tech. 2018, 11, 2131–2141. [Google Scholar] [CrossRef]

- Chinma, C.E.; Abu, J.O.; Abubakar, Y.A. Effect of tigernut (Cyperus esculentus) flour addition on the quality of wheat-based cake. Int. J. Food Sci. Tech. 2010, 45, 1746–1752. [Google Scholar] [CrossRef]

- Albors, A.; Raigon, M.D.; Garcia-Martinez, M.D.; Martin-Esparza, M.E. Assessment of techno-functional and sensory attributes of tiger nut fresh egg tagliatelle. Lebensm-Wiss. Technol. 2016, 74, 183–190. [Google Scholar] [CrossRef]

- Martín-Esparza, M.E.; Raigón, M.D.; Raga, A.; Albors, A. High fibre tiger nut pasta and xanthan gum: Cooking quality, microstructure, physico-chemical properties and consumer acceptance. Food Sci. Biotechnol. 2018, 27, 1075–1084. [Google Scholar] [CrossRef] [PubMed]

- Aguilar, N.; Albanell, E.; Miñarro, B.; Guamis, B.; Capellas, M. Effect of tiger nut-derived products in gluten-free batter and bread. Food Sci. Technol. Int. 2014, 21, 323–331. [Google Scholar] [CrossRef]

- Demirkesen, I.; Sumnu, G.; Sahin, S. Quality of Gluten-Free Bread Formulations Baked in Different Ovens. Food Bioprocess Tech. 2013, 6, 746–753. [Google Scholar] [CrossRef]

- Foschia, M.; Peressini, D.; Sensidoni, A.; Brennan, C.S. The effects of dietary fibre addition on the quality of common cereal products. J. Cereal Sci. 2013, 58, 216–227. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Chillo, S.; Civica, V.; Iannetti, M.; Suriano, N.; Del Nobile, M.A. A multistep optimization approach for the production of healthful pasta based on nonconventional flours. J. Food Process Eng. 2012, 35, 601–621. [Google Scholar] [CrossRef]

- RI. Fresh Pasta Market to 2025—Global Analysis, Industry Growth, Regional Share, Trends, Competitor Analysis, January 2020. Available online: https://www.reportsinsights.com/industry-forecast/fresh-pasta-market-analysis-1605 (accessed on 12 October 2020).

- Arribas, C.; Cabellos, B.; Guillamón, E.; Pedrosa, M.M. Cooking and sensorial quality, nutritional composition and functional properties of cold-extruded rice/white bean gluten-free fettuccine fortified with whole carob fruit flour. Food Funct. 2020, 11, 7913. [Google Scholar] [CrossRef] [PubMed]

- Borneo, R.; Aguirre, A. Chemical Composition, Cooking Quality, and Consumer Acceptance of Pasta made with Dried Amaranth Leaves Flour. Lebensm-Wiss. Technol. 2008, 41, 1748–1751. [Google Scholar] [CrossRef]

- Chillo, S.; Laverse, J.; Falcone, P.M.; Protopapa, A.; Del Nobile, M.A. Influence of the addition of buckwheat flour and durum wheat bran on spaghetti quality. J. Cereal Sci. 2008, 47, 144–152. [Google Scholar] [CrossRef]

- Nilusha, R.A.T.; Jayasinghe, J.M.J.K.; Perera, O.D.A.N.; Perera, P.I.P. Development of pasta products with nonconventional ingredients and their effect on selected quality characteristics: A brief overview. Int. J. Food Sci. 2019, 2019, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Optimization of rheological properties of gluten-free pasta dough using mixture design. J. Cereal Sci. 2013, 57, 520–526. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Chillo, S.; Iannetti, M.; Civica, V.; del Nobile, M.A. Formulation optimisation of gluten-free functional spaghetti based on quinoa, maize and soy flours. Int. J. Food Sci. Tech. 2011, 46, 1201–1208. [Google Scholar] [CrossRef]

- Mercier, S.; Moresoli, C.; Mondor, M.; Villeneuve, S.; Marcos, B. A Meta-Analysis of Enriched Pasta: What Are the Effects of Enrichment and Process Specifications on the Quality Attributes of Pasta? Compr. Rev. Food Sci. Food Saf. 2016, 15, 685–704. [Google Scholar] [CrossRef] [Green Version]

- Wahanik, A.L.; Neri-Numa, I.A.; Pastore, G.M.; Chang, Y.K.; Pedrosa, M.T. Turmeric (Curcuma longa L.): New application as source of fiber and antioxidants in pasta with whole wheat flour. Rev. Fac. Nac. Agron. Medellín 2018, 71, 8423–8435. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Fellows, C.M. Effect of soluble fibre (guar gum and carboxymethylcellulose) addition on technological, sensory and structural properties of durum wheat spaghetti. Food Chem. 2012, 131, 893–900. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- Llavata, B.; Albors, A.; Martin-Esparza, M.E. High Fibre Gluten-Free Fresh Pasta with Tiger Nut, Chickpea and Fenugreek: Technofunctional, Sensory and Nutritional Properties. Foods 2020, 9, 11. [Google Scholar] [CrossRef] [Green Version]

- Trevisan, S.; Pasini, G.; Simonato, B. An overview of expected glycaemic response of one ingredient commercial gluten free pasta. Lebensm-Wiss Technol. 2019, 109, 13–16. [Google Scholar] [CrossRef]

- Mariotti, M.; Iametti, S.; Cappa, C.; Rasmussen, P.; Lucisano, M. Characterisation of gluten-free pasta through conventional and innovative methods: Evaluation of the uncooked products. J. Cereal Sci. 2011, 53, 319–327. [Google Scholar] [CrossRef]

- Bustos, M.C.; Perez, G.T.; Leon, A.E. Combination of resistant starches types II and IV with minimal amounts of oat bran yields good quality, low glycaemic index pasta. Int. J. Food Sci. Tech. 2013, 48, 309–315. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgion, M.; Belc, N.; Biliaderis, C.G. Effect of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Alamprese, C.; Casiraghi, E.; Rossi, M. Modeling of fresh egg pasta characteristics for egg content and albumen to yolk ratio. J. Food Eng. 2009, 93, 302–307. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, D.; Foster, T.J.; Liu, Y.; Wang, Y.; Nirasawa, S.; Tatsumi, E.; Cheng, Y. Konjac glucomannan-induced changes in thiol/disulphide exchange and gluten conformation upon dough mixing. Food Chem. 2014, 143, 163–169. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yadav, M.P.; Li, J. Effect of different hydrocolloids on gluten proteins, starch and dough microstructure. J. Cereal Sci. 2019, 87, 85–90. [Google Scholar] [CrossRef]

- Jia, F.; Ma, Z.; Hu, X. Controlling dough rheology and structural characteristics of chickpea-wheat composite flour-based noodles with different levels of Artemisia sphaerocephala Krasch. gum addition. Int. J. Biol. Macromol. 2020, 150, 605–616. [Google Scholar] [CrossRef]

- Brennan, C.S.; Blake, D.E.; Ellis, P.R.; Schofield, J.D. Effects of guar galactomannan on wheat bread microstructure and on in vitro and vivo digestibility of starch from pasta. J. Cereal Sci. 1996, 24, 151–160. [Google Scholar] [CrossRef]

- Giovanni, M. Response Surface Methodology and product optimization. Food Technol. 1983, 37, 41–45. [Google Scholar]

- Abd Rahman, N.A.; Abdul Razak, S.Z.; Lokmanalhakim, L.A.; Taip, F.S.; Mustapa Kamal, S.M. Response surface optimization for hot air-frying technique and its effects on the quality of sweet potato snack. J. Food Process Eng. 2017, 40, 12507. [Google Scholar] [CrossRef]

- Aliaa, A.N.; Mazlina, M.S.; Taip, F.S.; Abdullah, A.L. Response surface optimization for clarification of white pitaya juice using a commercial enzyme. J. Food Process. Eng. 2010, 33, 333–347. [Google Scholar] [CrossRef]

- Shyu, S.; Hwang, L.S. Effects of processing conditions on the quality of vacuum fried apple chips. Food Res. Int. 2001, 34, 133–142. [Google Scholar] [CrossRef]

- Shyu, S.; Hau, L.; Hwang, L.S. Effects of processing conditions on the quality of vacuum fried carrot chips. J. Sci. Food Agric. 2005, 85, 1903–1908. [Google Scholar] [CrossRef]

- Sobukola, O.P.; Awonorin, S.O.; Sanni, L.O.; Bamiro, F.O. Optimization of blanching conditions prior to deep fat frying of yam slices. Int. J. Food Prop. 2008, 11, 379–391. [Google Scholar] [CrossRef]

- Sobukola, O.P.; Awonorin, S.O.; Sanni, L.O.; Bamiro, F.O. Optimization of pre-fry drying of yam slices using response surface methodology. J. Food Process Eng. 2010, 33, 626–648. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2005. [Google Scholar]

- European Council. Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, 404, 9–25. [Google Scholar]

- Yaakob, H.; Ahmed, N.R.; Daud, S.K.; Malek, R.A.; Rahma, R.A. Optimization of ingredient and processing levels for the production of coconut yogurt using response surface methodology. Food Sci. Biotechol. 2012, 21, 933–940. [Google Scholar] [CrossRef]

- Cruz, A.G.; Faria, J.A.F.; Walter, E.H.M.; Andrade, R.R.; Cavalcanti, R.N.; Oliveira, C.A.F.; Granato, D. Processing optimization of probiotic yogurt containing glucose oxidasa using response surface methodology. J. Dairy Sci. 2010, 93, 5059–5068. [Google Scholar] [CrossRef] [Green Version]

- Kaur, G.; Sharma, S.; Nagi, H.P.S.; Dar, B.N. Functional properties of pasta enriched with variable cereal brans. J. Food Sci. Tech. 2012, 49, 467–474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manthey, F.A.; Sandhu, G.K. Effect of additives on the processing and cooking properties of pasta containing flax seed flour. In Proceedings of the 62nd Flax Institute of the USA, Fargo, ND, USA, 23–25 March 2000; Carter, J.F., Ed.; Flax Institute of the USA: Fargo, ND, USA, 2008; pp. 143–149. [Google Scholar]

- Widelska, G.; Wójtowicz, A.; Kasprzak, K.; Dib, A.; Oniszczuk, T.; Olech, M.; Wojtunik-Kulesza, K.; Nowak, R.; Sujak, A.; Dobrzański, B.; et al. Impact of xanthan gum addition on phenolic acids composition and selected properties of new gluten free maize-field bean pasta. Open Chem. 2019, 17, 587–598. [Google Scholar] [CrossRef]

- Resmini, P.; Pagani, M.A. Ultrastructure Studies of Pasta. A Review. Food Microst. 1983, 2, 1–12. [Google Scholar]

| DWS | TNF | LE | CMC * | XG * | LBG * | |

|---|---|---|---|---|---|---|

| Water | 13.67 (0.03) | 8.83 (0.05) | 79 (2) | 10 | 15 | 12 |

| Protein | 13.2 (0.7) | 4.95 (0.07) | 11.4 (0.6) | - | - | - |

| Fat | 0.90 (0.05) | 25.07 (0.02) | 7.83 (0.98) | - | - | - |

| Ash | 1.71 (0.07) | 2.05 (0.04) | 0.60 (0.04) | - | 13 | 1 |

| Dietary Fiber | 10.00 (0.02) | 15.85 (0.03) | - | 90 | 72 | 87 |

| DC ** | 60.54 (0.02) | 43.25 (0.03) | 0.91 (0.02) | - | - | - |

| Factors * | Response Variable ** | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Run Order | CMC | XG | LBG | YFo | YSio | YAo | YFc | YSic | YAc | YWI | Y%CL | Y%SI | YL*o | Ya*o | Yb*o | YC*ab,o | Yh*ab,o | YL*c | Ya*c | Yb*c | YC*ab,c | Yh*ab,c | %P | %L | %A | %FL |

| 1 | +1 | +1 | 0 | 6.15 | 0.48 | 18.38 | 1.72 | 0.21 | 5.89 | 1.39 | 2.424 | 1.69 | 55.89 | 4.82 | 19.37 | 19.96 | 1.33 | 62.00 | 2.06 | 13.67 | 13.83 | 1.42 | −0.13 | −0.16 | −0.15 | −0.54 |

| 2 | −1 | +1 | 0 | 19.59 | 1.41 | 30.64 | 1.98 | 0.24 | 6.75 | 1.10 | 6.64 | 1.28 | 55.69 | 5.09 | 18.58 | 19.26 | 1.30 | 62.92 | 2.03 | 14.07 | 14.22 | 1.43 | −0.13 | −0.06 | −0.22 | −0.50 |

| 3 | 0 | −1 | +1 | 14.01 | 1.13 | 21.69 | 1.23 | 0.18 | 4.44 | 1.18 | 8.11 | 1.36 | 56.09 | 5.32 | 20.56 | 21.24 | 1.32 | 61.42 | 2.55 | 14.94 | 15.16 | 1.40 | −0.09 | −0.002 | −0.15 | −0.51 |

| 4 | +1 | −1 | 0 | 14.89 | 1.34 | 22.34 | 1.27 | 0.19 | 4.99 | 1.17 | − | 1.68 | 56.25 | 4.93 | 20.17 | 20.76 | 1.33 | 56.72 | 1.95 | 12.08 | 12.24 | 1.41 | −0.10 | 0.03 | −0.08 | −0.49 |

| 5 | 0 | 0 | 0 | 5.29 | 0.36 | 10.68 | 1.47 | 0.24 | 5.03 | 1.26 | 6.84 | 1.49 | 55.36 | 4.79 | 20.21 | 20.77 | 1.34 | 61.18 | 2.23 | 13.71 | 13.89 | 1.41 | −0.11 | −0.04 | −0.14 | −0.46 |

| 6 | 0 | +1 | +1 | 7.62 | 0.57 | 22.68 | 1.87 | 0.21 | 6.26 | 1.34 | 5.61 | 1.69 | 56.23 | 4.67 | 19.40 | 19.96 | 1.33 | 62.86 | 1.50 | 12.75 | 12.84 | 1.45 | −0.10 | −0.08 | −0.17 | −0.54 |

| 7 | 0 | 0 | 0 | 5.30 | 0.09 | 10.76 | 1.47 | 0.22 | 4.75 | 1.23 | 7.08 | 1.52 | 56.43 | 4.94 | 20.86 | 21.43 | 1.34 | 60.71 | 2.39 | 14.52 | 14.72 | 1.41 | −0.06 | −0.19 | −0.18 | −0.50 |

| 8 | −1 | 0 | −1 | 12.87 | 0.63 | 15.59 | 1.62 | 0.27 | 5.77 | 1.20 | 7.67 | 1.37 | 56.61 | 5.26 | 19.73 | 20.42 | 1.31 | 61.55 | 2.16 | 13.22 | 13.39 | 1.41 | −0.16 | −0.12 | −0.18 | −0.39 |

| 9 | −1 | −1 | 0 | 9.07 | 0.34 | 11.40 | 1.50 | 0.20 | 5.71 | 1.15 | 6.95 | 0.94 | 54.63 | 4.87 | 20.25 | 20.83 | 1.34 | 61.17 | 2.47 | 14.44 | 14.65 | 1.40 | −0.11 | −0.06 | −0.18 | −0.40 |

| 10 | 0 | +1 | −1 | 9.89 | 1.35 | 21.26 | 1.92 | 0.25 | 7.32 | 1.16 | 6.25 | 1.39 | 58.24 | 4.37 | 18.39 | 18.90 | 1.34 | 62.98 | 2.12 | 13.86 | 14.03 | 1.42 | −0.10 | −0.14 | −0.13 | −0.51 |

| 11 | +1 | 0 | −1 | 7.78 | 0.87 | 18.05 | 1.57 | 0.22 | 6.20 | 1.31 | 7.12 | 1.59 | 59.15 | 3.91 | 17.81 | 18.23 | 1.36 | 61.69 | 2.35 | 14.28 | 14.48 | 1.41 | −0.13 | 0.07 | −0.04 | −0.53 |

| 12 | 0 | −1 | −1 | 11.60 | 0.67 | 11.84 | 1.28 | 0.21 | 4.77 | 1.15 | − | 1.30 | 56.65 | 5.13 | 20.29 | 20.93 | 1.32 | 64.55 | 1.97 | 14.24 | 14.38 | 1.43 | −0.09 | −0.13 | −0.24 | −0.43 |

| 13 | 0 | 0 | +1 | 6.75 | 0.59 | 17.71 | 1.54 | 0.22 | 5.25 | 1.14 | 6.60 | 1.48 | 53.94 | 5.69 | 20.97 | 21.73 | 1.31 | 60.38 | 2.05 | 13.37 | 13.53 | 1.42 | −0.10 | −0.15 | −0.06 | −0.57 |

| 14 | +1 | 0 | +1 | 6.34 | 0.45 | 12.68 | 1.39 | 0.19 | 4.27 | 1.22 | 5.60 | 1.52 | 56.06 | 4.91 | 20.39 | 20.97 | 1.33 | 60.73 | 1.96 | 13.53 | 13.68 | 1.43 | −0.12 | −0.17 | 0.0005 | −0.53 |

| 15 | 0 | 0 | 0 | 5.67 | 0.40 | 11.82 | 1.49 | 0.24 | 4.71 | 1.18 | 7.23 | 1.57 | 53.84 | 5.55 | 21.26 | 21.97 | 1.32 | 60.96 | 2.08 | 13.77 | 13.92 | 1.42 | −0.11 | −0.09 | −0.13 | −0.52 |

| Variables | Sources Of Variations | SS | DF | MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Model | 211.398 | 3 | 70.466 | 18.85 | 0.0001 | |

| Fo (N) | Residual | 41.131 | 11 | 3.739 | ||

| Corrected total | 252.529 | 14 | ||||

| Model | 0.687 | 2 | 0.344 | 61.58 | <0.0001 | |

| Fc (N) | Residual | 0.067 | 12 | 0.006 | ||

| Corrected total | 0.754 | 14 | ||||

| Model | 0.006 | 3 | 0.002 | 14.63 | 0.0004 | |

| Sic (N/s) | Residual | 0.002 | 11 | 0.0001 | ||

| Corrected total | 0.008 | 14 | ||||

| Model | 9.012 | 2 | 4.506 | 26.12 | <0.0000 | |

| Ac (N·s) | Residual | 2.071 | 12 | 0.173 | ||

| Corrected total | 11.083 | 14 | ||||

| Model | 0.057 | 1 | 0.057 | 20.82 | 0.0005 | |

| WAI (g/g) | Residual | 0.036 | 13 | 0.003 | ||

| Corrected total | 0.092 | 14 | ||||

| Model | 22.383 | 4 | 5.596 | 31.57 | 0.0001 | |

| %CL | Residual | 1.418 | 8 | 0.177 | ||

| Corrected total | 23.802 | 12 | ||||

| %SI | Model | 0.361 | 2 | 0.180 | 12.79 | 0.0011 |

| Residual | 0.169 | 12 | 0.014 | |||

| Corrected total | 0.530 | 14 | ||||

| %FL | Model | 0.031 | 4 | 0.008 | 15.14 | 0.0003 |

| Residual | 0.005 | 10 | 0.001 | |||

| Corrected total | 0.037 | 14 |

| Variables | Coefficient Estimate | Standard Error | 95% Confidence Interval Low | 95% Confidence Interval High | t−Value | p−Value | |

|---|---|---|---|---|---|---|---|

| Fo (N) | βo | 8.561 | 0.93 | 6.52 | 10.60 | 9.25 | <0.0001 |

| CMC*CMC | 12.015 | 3.04 | 5.33 | 18.70 | 3.95 | 0.0023 | |

| XG*XG | 16.790 | 3.01 | 10.17 | 23.41 | 5.58 | 0.0002 | |

| CMC*XG | −36.539 | 5.03 | −47.622 | −25.46 | −7.26 | <0.0001 | |

| Fc (N) | βo | 1.449 | 0.04 | 1.36 | 1.54 | 35.19 | <0.0001 |

| CMC | −0.226 | 0.07 | −0.38 | −0.07 | −3.19 | 0.0078 | |

| XG*XG | 0.822 | 0.08 | 0.65 | 0.99 | 10.51 | <0.0001 | |

| Sic (N/s) | βo | 0.209 | 0.01 | 0.19 | 0.22 | 32.13 | <0.0001 |

| XG | 0.132 | 0.03 | 0.06 | 0.20 | 4.04 | 0.0019 | |

| XG*XG | −0.118 | 0.04 | −0.20 | −0.03 | −3.06 | 0.0109 | |

| CMC*LBG | −0.084 | 0.02 | −0.12 | −0.05 | −5.01 | 0.0004 | |

| Ac (N·s) | βo | 5.275 | 0.187 | 4.868 | 5.683 | 28.19 | <0.0001 |

| XG*XG | 2.544 | 0.435 | 1.597 | 3.491 | 5.85 | 0.0001 | |

| CMC*LBG | −2.340 | 0.585 | −3.614 | −1.065 | −4.00 | 0.0018 | |

| WAI (g/g) | βo | 1.154 | 0.019 | 1.113 | 1.194 | 61.97 | <0.0001 |

| CMC*XG | 0.343 | 0.075 | 0.180 | 0.505 | 4.56 | 0.0005 | |

| %CL | βo | 7.084 | 0.243 | 6.523 | 7.645 | 29.142 | <0.0001 |

| CMC | 6.614 | 1.435 | 3.306 | 9.923 | 4.611 | 0.0017 | |

| CMC*CMC | −3.505 | 1.492 | −6.945 | −0.065 | −2.350 | 0.0467 | |

| CMC*XG | −10.003 | 1.135 | −12.620 | −7.387 | −8.817 | 0.0000 | |

| CMC*LBG | −2.542 | 0.789 | −4.361 | −0.723 | −3.222 | 0.0122 | |

| %SI | βo | 1.144 | 0.071 | 0.990 | 1.299 | 16.162 | <0.0001 |

| CMC | 0.501 | 0.113 | 0.264 | 0.756 | 4.524 | 0.0007 | |

| XG | 0.238 | 0.105 | 0.009 | 0.466 | 2.263 | 0.0429 | |

| %FL | βo | −0.358 | 0.020 | −0.402 | −0.314 | −18.089 | <0.0001 |

| CMC | −0.171 | 0.036 | −0.252 | −0.090 | −4.694 | 0.0008 | |

| XG | −0.076 | 0.020 | −0.121 | −0.031 | −3.760 | 0.0037 | |

| LBG | −0.179 | 0.045 | −0.280 | −0.078 | −3.956 | 0.0027 | |

| CMC*LBG | 0.221 | 0.088 | 0.024 | 0.418 | 2.504 | 0.0312 |

| Fo (N) | Fc (N) | Sic (N/s) | Ac (N·s) | ||

|---|---|---|---|---|---|

| Constant (βo) | 8.561 | 1.449 | 0.209 | 5.275 | |

| β | CMC | ns | −0.226 | ns | ns |

| XG | ns | ns | 0.132 | ns | |

| LBG | ns | ns | ns | ns | |

| CMC*CMC | 12.015 | ns | ns | ns | |

| XG*XG | 16.790 | 0.822 | −0.118 | 2.544 | |

| LBG*LBG | ns | ns | ns | ns | |

| CMC*XG | −36.539 | ns | ns | ns | |

| CMC*LBG | ns | ns | −0.084 | −2.340 | |

| XG*LBG | ns | ns | ns | ns | |

| Lack of fit | 41.037 | 0.06682 | 0.001716 | 2.0096 | |

| Pure error | 0.094 | 0.00018 | 0.000284 | 0.0614 | |

| Lack of fit p-value | 0.999 | 0.999 | 0.823 | 0.997 | |

| R2 | 83.71 | 91.121 | 79.97 | 81.317 | |

| R2adj | 79.27 | 89.641 | 74.50 | 78.204 | |

| Standard error of est. | 1.93 | 0.075 | 0.012 | 0.415 | |

| Mean absolute error | 1.40 | 0.048 | 0.007 | 0.324 | |

| Durbin–Watson statistic (p-value) | 1.417 (0.126) | 2.214 (0.637) | 2.727 (0.919) | 2.047 (0.485) |

| WAI (g/g) | %CL | %SI | %FL | ||

|---|---|---|---|---|---|

| Constant (βo) | 1.154 | 7.084 | 1.144 | −0.358 | |

| β | CMC | ns | 6.614 | 0.510 | −0.171 |

| XG | ns | ns | 0.238 | −0.076 | |

| LBG | ns | ns | ns | −0.179 | |

| CMC*CMC | ns | −3.505 | ns | ns | |

| XG*XG | ns | ns | ns | ns | |

| LBG*LBG | ns | ns | ns | ns | |

| CMC*XG | 0.343 | −10.003 | ns | ns | |

| CMC*LBG | ns | ns | ns | 0.221 | |

| XG*LBG | ns | −2.542 | ns | ns | |

| Lack of fit | 0.032733 | 1.3395 | 0.165749 | 0.003120 | |

| Pure error | 0.003267 | 0.0785 | 0.003369 | 0.002074 | |

| Lack of fit p-value | 0.244 | 0.135 | 0.096 | 0.870 | |

| R2 | 61.56 | 94.04 | 68.07 | 85.83 | |

| R2adj | 58.61 | 91.06 | 62.75 | 80.16 | |

| Standard error of est. | 0.052 | 0.421 | 0.119 | 0.023 | |

| Mean absolute error | 0.040 | 0.289 | 0.09 | 0.014 | |

| Durbin−Watson statistic (p-value) | 1.676 (0.250) | 1.737 (0.285) | 1.552 (0.185) | 1.553 (0.186) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Esparza, M.E.; Raigón, M.D.; García-Martínez, M.D.; Albors, A. Role of Hydrocolloids in the Structure, Cooking, and Nutritional Properties of Fiber-Enriched, Fresh Egg Pasta Based on Tiger Nut Flour and Durum Wheat Semolina. Foods 2021, 10, 2510. https://doi.org/10.3390/foods10102510

Martín-Esparza ME, Raigón MD, García-Martínez MD, Albors A. Role of Hydrocolloids in the Structure, Cooking, and Nutritional Properties of Fiber-Enriched, Fresh Egg Pasta Based on Tiger Nut Flour and Durum Wheat Semolina. Foods. 2021; 10(10):2510. https://doi.org/10.3390/foods10102510

Chicago/Turabian StyleMartín-Esparza, Maria Eugenia, Maria Dolores Raigón, Maria Dolores García-Martínez, and Ana Albors. 2021. "Role of Hydrocolloids in the Structure, Cooking, and Nutritional Properties of Fiber-Enriched, Fresh Egg Pasta Based on Tiger Nut Flour and Durum Wheat Semolina" Foods 10, no. 10: 2510. https://doi.org/10.3390/foods10102510

APA StyleMartín-Esparza, M. E., Raigón, M. D., García-Martínez, M. D., & Albors, A. (2021). Role of Hydrocolloids in the Structure, Cooking, and Nutritional Properties of Fiber-Enriched, Fresh Egg Pasta Based on Tiger Nut Flour and Durum Wheat Semolina. Foods, 10(10), 2510. https://doi.org/10.3390/foods10102510