Effects of Citrus Peel Hydrolysates on Retrogradation of Wheat Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of CPH

2.3. Characterization of CPH

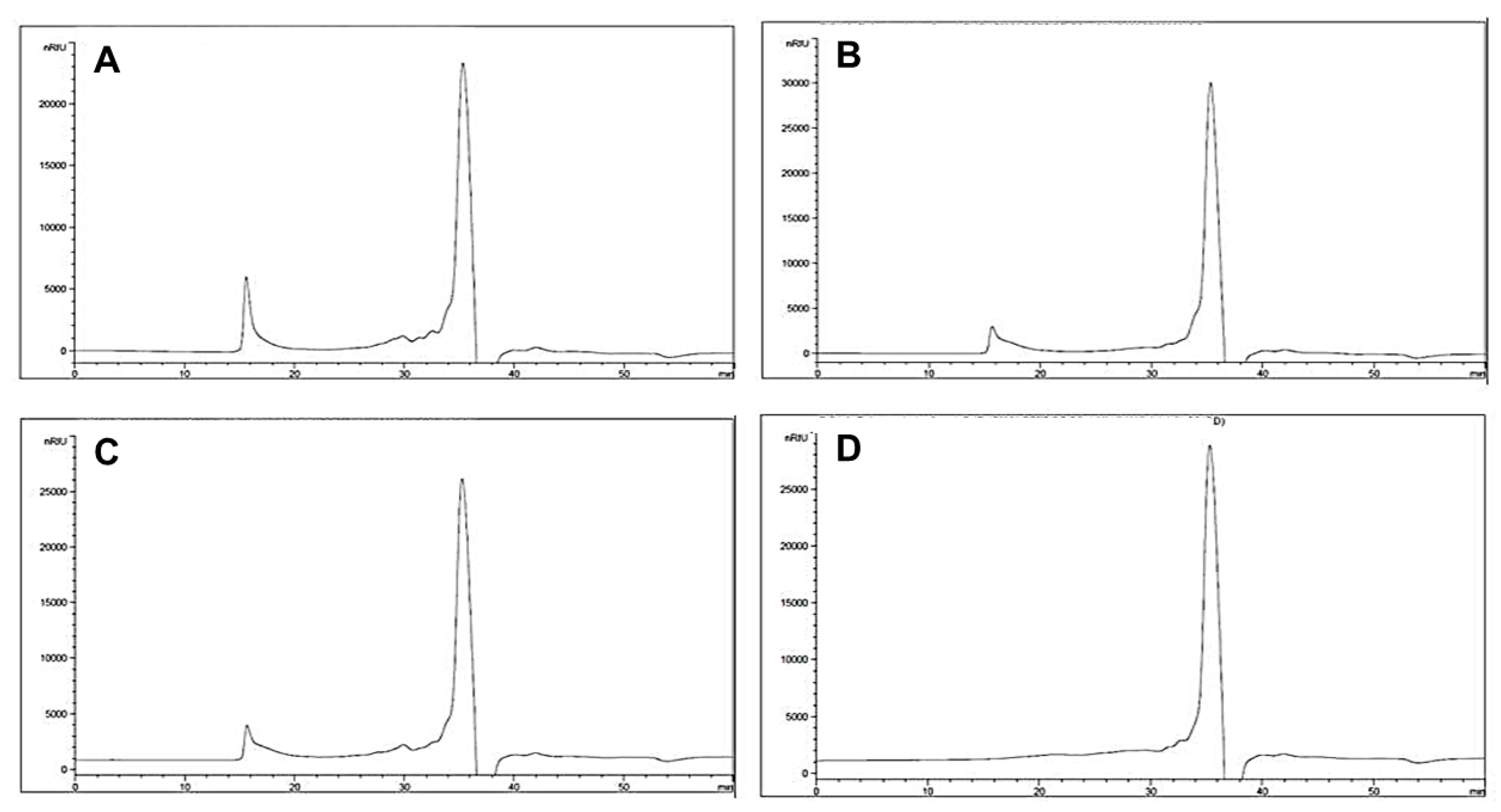

2.3.1. Molecular Distribution of CPH

2.3.2. The Chemical Composition of CPH

2.4. Analysis of Starch Retrogradation Adding CPH

2.4.1. Determination of Pasting Properties of CPH with Added Starch

2.4.2. Determination of Textural Properties of CPH with Added Starch Gel

2.4.3. Determination of Thermal Properties of CPH with Added Starch Gel

2.5. Statistical Analysis

3. Results and Discussion

3.1. Comparison of CPH Extraction Yield

3.2. Characterization of CPH Composition

3.3. The Effect of CPH on Starch Retrogradation

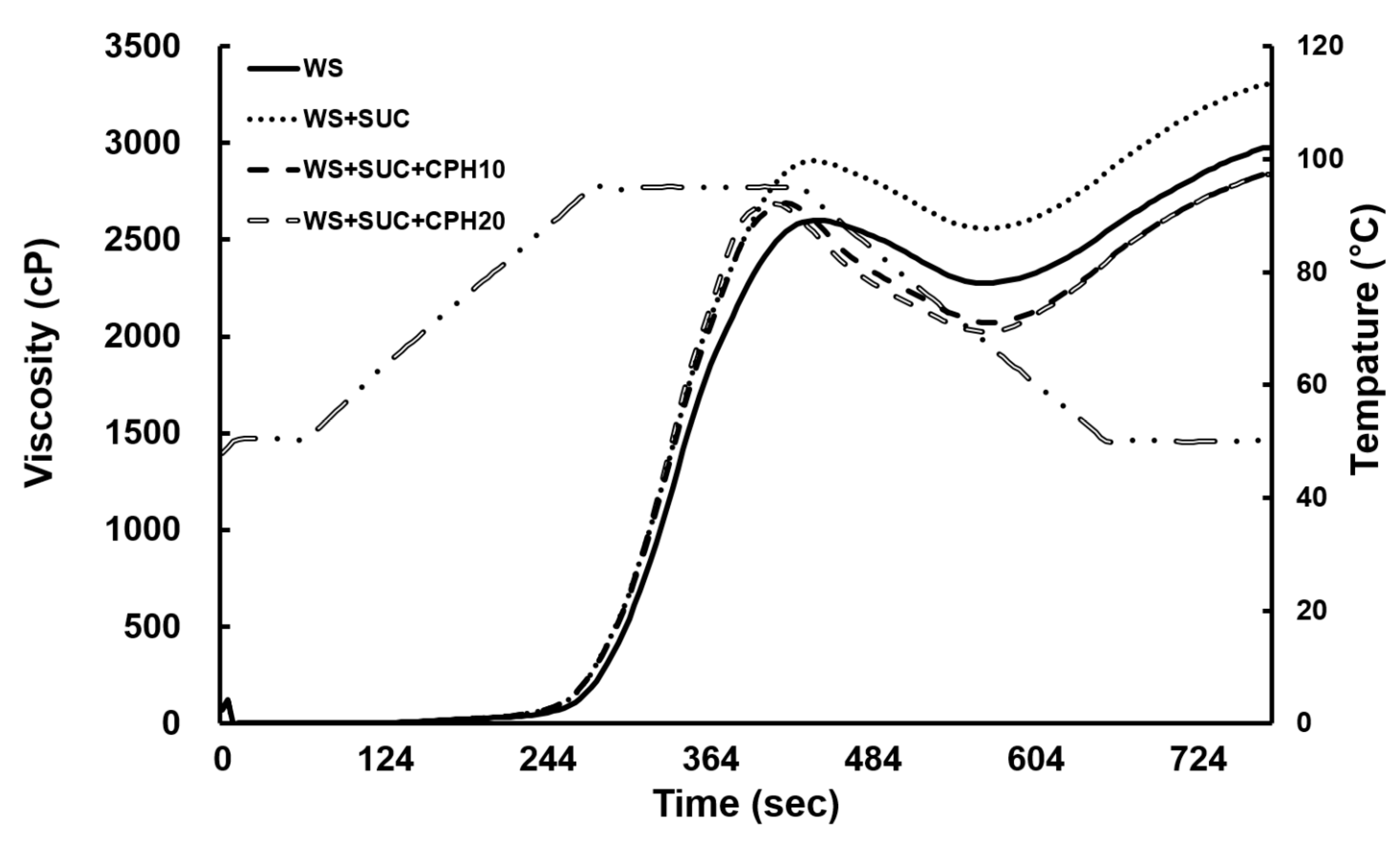

3.3.1. The Effect of CPH on the Pasting Properties of Starch

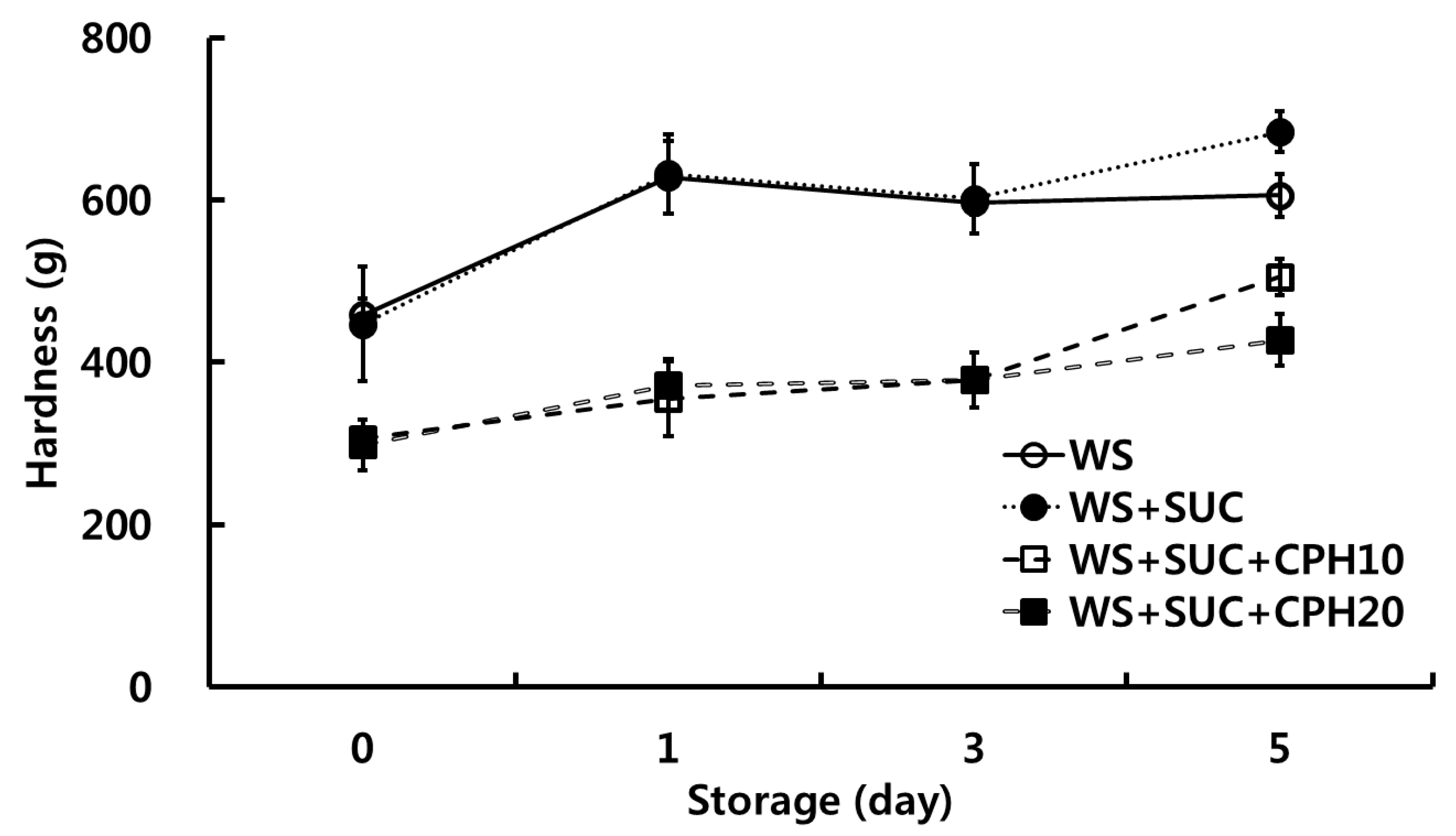

3.3.2. The Effect of CPH on Textural Properties of Starch Gel

3.3.3. The Effect of CPH on the Thermal Properties of Starch Gel

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, Z.-q.; Che, L.-m.; Li, D.; Wang, L.-j.; Adhikari, B. Effect of partially gelatinized corn starch on the rheological properties of wheat dough. LWT-Food Sci. Technol. 2016, 66, 324–331. [Google Scholar] [CrossRef]

- Niu, H.; Zhang, M.; Xia, X.; Liu, Q.; Kong, B. Effect of porcine plasma protein hydrolysates on long-term retrogradation of corn starch. Food Chem. 2018, 239, 172–179. [Google Scholar] [CrossRef] [PubMed]

- Matignon, A.; Tecante, A. Starch retrogradation: From starch components to cereal products. Food Hydrocoll. 2017, 68, 43–53. [Google Scholar] [CrossRef]

- Chen, X.; Guo, L.; Du, X.; Chen, P.; Ji, Y.; Hao, H.; Xu, X. Investigation of glycerol concentration on corn starch morphologies and gelatinization behaviours during heat treatment. Carbohydr. Polym. 2017, 176, 56–64. [Google Scholar] [CrossRef]

- Alishahi, A.; Farahnaky, A.; Majzoobi, M.; Blanchard, C.L. Physicochemical and textural properties of corn starch gels: Effect of mixing speed and time. Food Hydrocoll. 2015, 45, 55–62. [Google Scholar] [CrossRef]

- Ji, Z.; Yu, L.; Liu, H.; Bao, X.; Wang, Y.; Chen, L. Effect of pressure with shear stress on gelatinization of starches with different amylose/amylopectin ratios. Food Hydrocoll. 2017, 72, 331–337. [Google Scholar] [CrossRef]

- Sopade, P.A.; Halley, P.J.; Junming, L.L. Gelatinisation of starch in mixtures of sugars. II. Application of differential scanning calorimetry. Carbohydr. Polym. 2004, 58, 311–321. [Google Scholar] [CrossRef]

- Shujun, W.; Caili, L.; Les, C.; Qing, N.; Shuo, W. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar]

- Wang, L.; Xu, J.; Fan, X.; Wang, Q.; Wang, P.; Zhang, Y.; Cui, L.; Yuan, J.; Yu, Y. Effect of disaccharides of different composition and linkage on corn and waxy corn starch retrogradation. Food Hydrocoll. 2016, 61, 531–536. [Google Scholar] [CrossRef]

- Chen, L.; Tian, Y.; Tong, Q.; Zhang, Z.; Jin, Z. Effect of pullulan on the water distribution, microstructure and textural properties of rice starch gels during cold storage. Food Chem. 2017, 214, 702–709. [Google Scholar] [CrossRef]

- Zhang, X.; Tong, Q.; Zhu, W.; Ren, F. Pasting, rheological properties and gelatinization kinetics of tapioca starch with sucrose or glucose. J. Food Eng. 2013, 114, 255–261. [Google Scholar] [CrossRef]

- Babić, J.; Šubarić, D.; Milicevic, B.; Ačkar, D.; Kopjar, M.; Tiban, N.N. Influence of trehalose, glucose, fructose, and sucrose on gelatinisation and retrogradation of corn and tapioca starches. Czech J. Food Sci. 2009, 27, 151–157. [Google Scholar] [CrossRef] [Green Version]

- Gunaratne, A.; Ranaweera, S.; Corke, H. Thermal, pasting, and gelling properties of wheat and potato starches in the presence of sucrose, glucose, glycerol, and hydroxypropyl beta-cyclodextrin. Carbohydr. Polym. 2007, 70, 112–122. [Google Scholar] [CrossRef]

- Wang, L.; Xu, H.; Yuan, F.; Pan, Q.; Fan, R.; Gao, Y. Physicochemical characterization of five types of citrus dietary fibers. Biocatal. Agric. Biotechnol. 2015, 4, 250–258. [Google Scholar] [CrossRef]

- Burana-osot, J.; Soonthornchareonnon, N.; Chaidedgumjorn, A.; Hosoyama, S.; Toida, T. Determination of galacturonic acid from pomelo pectin in term of galactose by HPAEC with fluorescence detection. Carbohydr. Polym. 2010, 81, 461–465. [Google Scholar] [CrossRef]

- Garna, H.; Mabon, N.; Nott, K.; Wathelet, B.; Paquot, M. Kinetic of the hydrolysis of pectin galacturonic acid chains and quantification by ionic chromatography. Food Chem. 2006, 96, 477–484. [Google Scholar] [CrossRef]

- Deffenbaugh, L.B.; Walker, C.E. Use of the Rapid-Visco-Analyzer to measure starch pasting properties. Part I: Effect of sugars. Starch-Stärke 1989, 41, 461–467. [Google Scholar] [CrossRef]

- Zhou, D.-N.; Zhang, B.; Chen, B.; Chen, H.-Q. Effects of oligosaccharides on pasting, thermal and rheological properties of sweet potato starch. Food Chem. 2017, 230, 516–523. [Google Scholar] [CrossRef]

- JI, Y.; Zhu, K.; Qian, H.; Zhou, H. Staling of cake prepared from rice flour and sticky rice flour. Food Chem. 2007, 104, 53–58. [Google Scholar] [CrossRef]

- Hedayati, S.; Shahidi, F.; Koocheki, A.; Farahnaky, A. Comparing the effects of sucrose and glucose on functional properties of pregelatinized maize starch. Int. J. Biol. Macromol. 2016, 88, 499–504. [Google Scholar] [CrossRef]

- Biliaderis, C.G.; Maurice, T.J.; Vose, J.R. Starch gelatinization phenomena studied by differential scanning calorimetry. J. Food Sci. 1980, 45, 1669–1674. [Google Scholar] [CrossRef]

| Pectinex Ultra SP-L | Pectinex Ultra Pulp | |||

|---|---|---|---|---|

| Treatment Time (h) | Treatment Time (h) | |||

| 3 | 12 | 3 | 12 | |

| Extraction yield (%) | 16.7 | 21.8 | 18.6 | 22.8 |

| Monosaccharides content (mg/g) | ||||

| Fucose | 4.0 ± 0.1 | 3.8 ± 0.1 | 3.4 ± 0.1 | 4.0 ± 0.0 |

| Rhamnose | 14.6 ± 0.1 | 12.3 ± 0.1 | 13.3 ± 0.1 | 10.6 ± 0.2 |

| Arabinose | 137.4 ± 0.6 | 129.9 ± 0.6 | 133.3 ± 1.7 | 132.0 ± 1.3 |

| Galactose | 67.0 ± 0.8 | 60.3 ± 0.1 | 62.0 ± 0.5 | 58.8 ± 0.8 |

| Glucose | 122.4 ± 1.1 | 112.8 ± 0.4 | 108.9 ± 1.2 | 114.5 ± 1.3 |

| Mannose | 7.4 ± 0.0 | 9.2 ± 0.0 | 3.7 ± 0.1 | 8.5 ± 0.3 |

| Xylose | 5.7 ± 0.5 | 7.0 ± 0.1 | 4.9 ± 0.3 | 7.3 ± 0.2 |

| Galacturonic acid | 97.7 ± 5.0 | 110.1 ± 4.7 | 109.5 ± 4.1 | 105.5 ± 1.8 |

| Peak Viscosity (cP) | Trough Viscosity (cP) | Breakdown (cP) | Final Viscosity (cP) | Setback (cP) | Pasting Temp. (°C) | |

|---|---|---|---|---|---|---|

| WS | 2518.3 ± 26.6 c | 1774.3 ± 56.6 b | 744.0 ± 31.5 a | 2974.0 ± 58.6 a | 1199.7 ± 5.1 b | 93.9 ± 0.6 a |

| WS + SUC | 2824.3 ± 42.0 a | 2068.0 ± 25.5 a | 805.3 ± 51.5 a | 3303.7 ± 71.8 a | 1284.7 ± 18.6 a | 90.0 ± 0.4 b |

| WS + SUC + CPH10 | 2684.3 ± 7.5 b | 1965.0 ± 90.7 a | 719.3 ± 87.4 ab | 2837.7 ± 22.9 a | 872.7 ± 71.8 c | 90.3 ± 0.9 b |

| WS + SUC + CPH20 | 2630.0 ± 46.7 b | 2013.0 ± 64.2 a | 676.0 ± 49.5 b | 2836.7 ± 128.1 a | 823.7 ± 76.1 c | 90.6 ± 1.4 b |

| Onset Temp. (°C) | Peak Temp. (°C) | End Temp. (°C) | Retrogradation Enthalpy (ΔH, J/g) | |

|---|---|---|---|---|

| WS | 54.71 ± 0.23 ab | 57.37 ± 0.20 a | 58.29 ± 0.19 b | 0.354 ± 0.009 a |

| WS + SUC | 54.90 ± 0.18 a | 56.87 ± 0.49 b | 59.54 ± 0.33 a | 0.367 ± 0.010 a |

| WS + SUC + CPH10 | 54.70 ± 0.11 ab | 55.87 ± 0.25 b | 57.58 ± 0.21 c | 0.178 ± 0.023 b |

| WS + SUC + CPH20 | 54.19 ± 0.31 b | 56.86 ± 0.57 b | 59.05 ± 0.21 a | 0.212 ± 0.014 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.-Y.; Ryu, A.-R.; Kim, H.R.; Shin, K.-S.; Hong, J.S.; Choi, H.-D. Effects of Citrus Peel Hydrolysates on Retrogradation of Wheat Starch. Foods 2021, 10, 2422. https://doi.org/10.3390/foods10102422

Park H-Y, Ryu A-R, Kim HR, Shin K-S, Hong JS, Choi H-D. Effects of Citrus Peel Hydrolysates on Retrogradation of Wheat Starch. Foods. 2021; 10(10):2422. https://doi.org/10.3390/foods10102422

Chicago/Turabian StylePark, Ho-Young, A-Reum Ryu, Ha Ram Kim, Kwang-Soon Shin, Jung Sun Hong, and Hee-Don Choi. 2021. "Effects of Citrus Peel Hydrolysates on Retrogradation of Wheat Starch" Foods 10, no. 10: 2422. https://doi.org/10.3390/foods10102422

APA StylePark, H.-Y., Ryu, A.-R., Kim, H. R., Shin, K.-S., Hong, J. S., & Choi, H.-D. (2021). Effects of Citrus Peel Hydrolysates on Retrogradation of Wheat Starch. Foods, 10(10), 2422. https://doi.org/10.3390/foods10102422