The Effect of Pre-Treatment (Blanching, Ultrasound and Freezing) on Quality of Freeze-Dried Red Beets

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Technological Methods

2.2.1. Blanching

2.2.2. Ultrasonic Pre-Treatment

2.2.3. Freezing

- −

- fast freezing—in the ProfiMaster Personal Freezers PMU series 0380 (National Lab GmbH, Schleswig-Holstein, Germany) shock freezer, using a low freezing temperature of −80 °C for 2 h,

- −

- slow freezing—in a chamber freezer (Whirlpool, Siena, Italy) at −18 °C, with storage for 2 weeks,

- −

- combined freezing—using a low freezing temperature in a shock freezer −80 °C for 2 h and storage of samples for 2 weeks in a chamber freezer at −18 °C.

2.2.4. Freeze-Drying

2.3. Analytical Methods

2.3.1. Water Activity Determination

2.3.2. The Shrinkage Determination

- Vd—the volume of dried sample

- Vo—the volume of raw sample

2.3.3. The Porosity Determination

Porosity

- Pc—whole porosity [%]

- d—apparent density of the material measured by pycnometer [g/cm3]

- dp—real density [g/cm3]

2.3.4. Structure

2.4. Statistical Methods

3. Results

3.1. The Effect of Type and Parameters of Pre-Treatment on the Quality of Freeze-Dried Red Beet

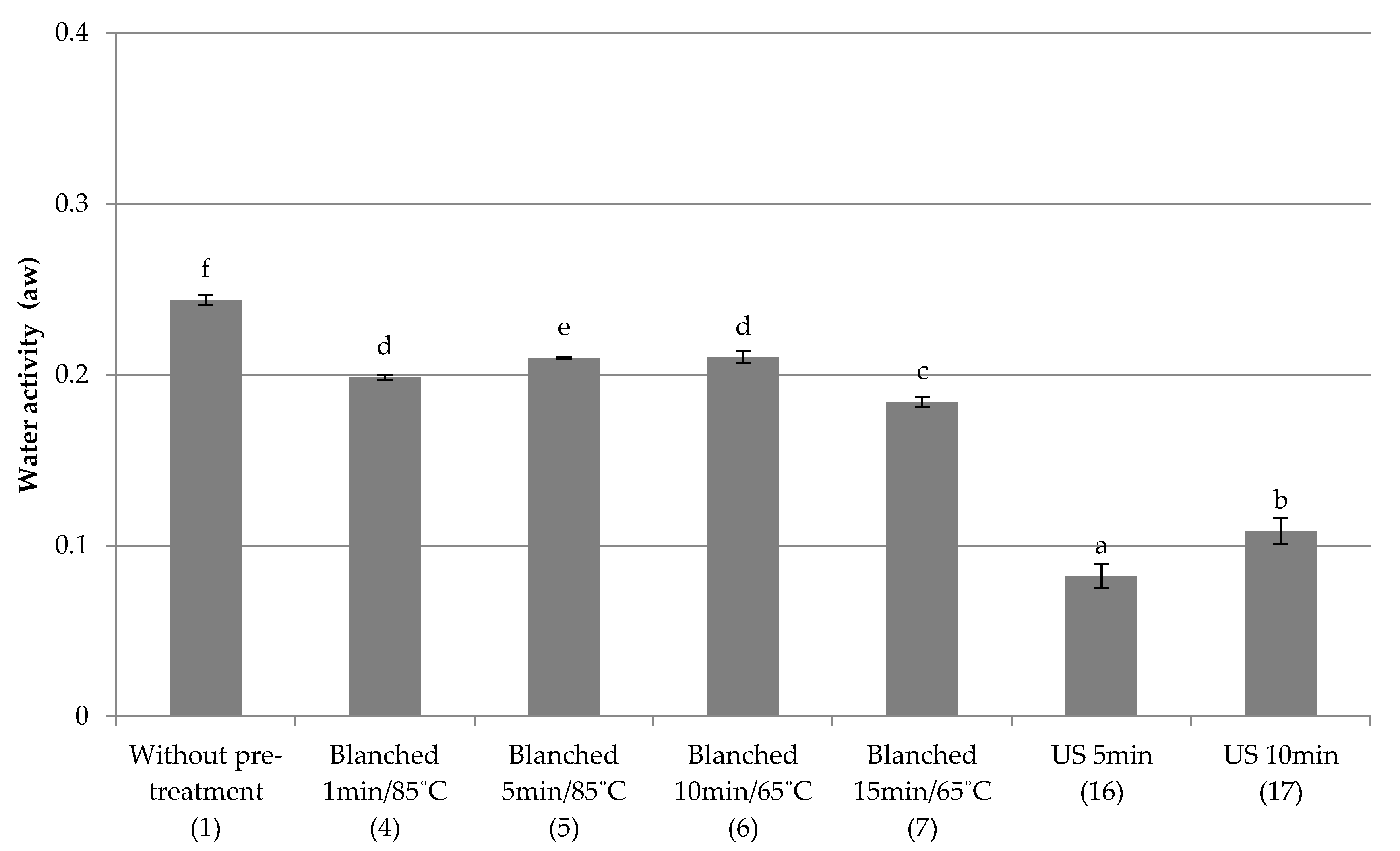

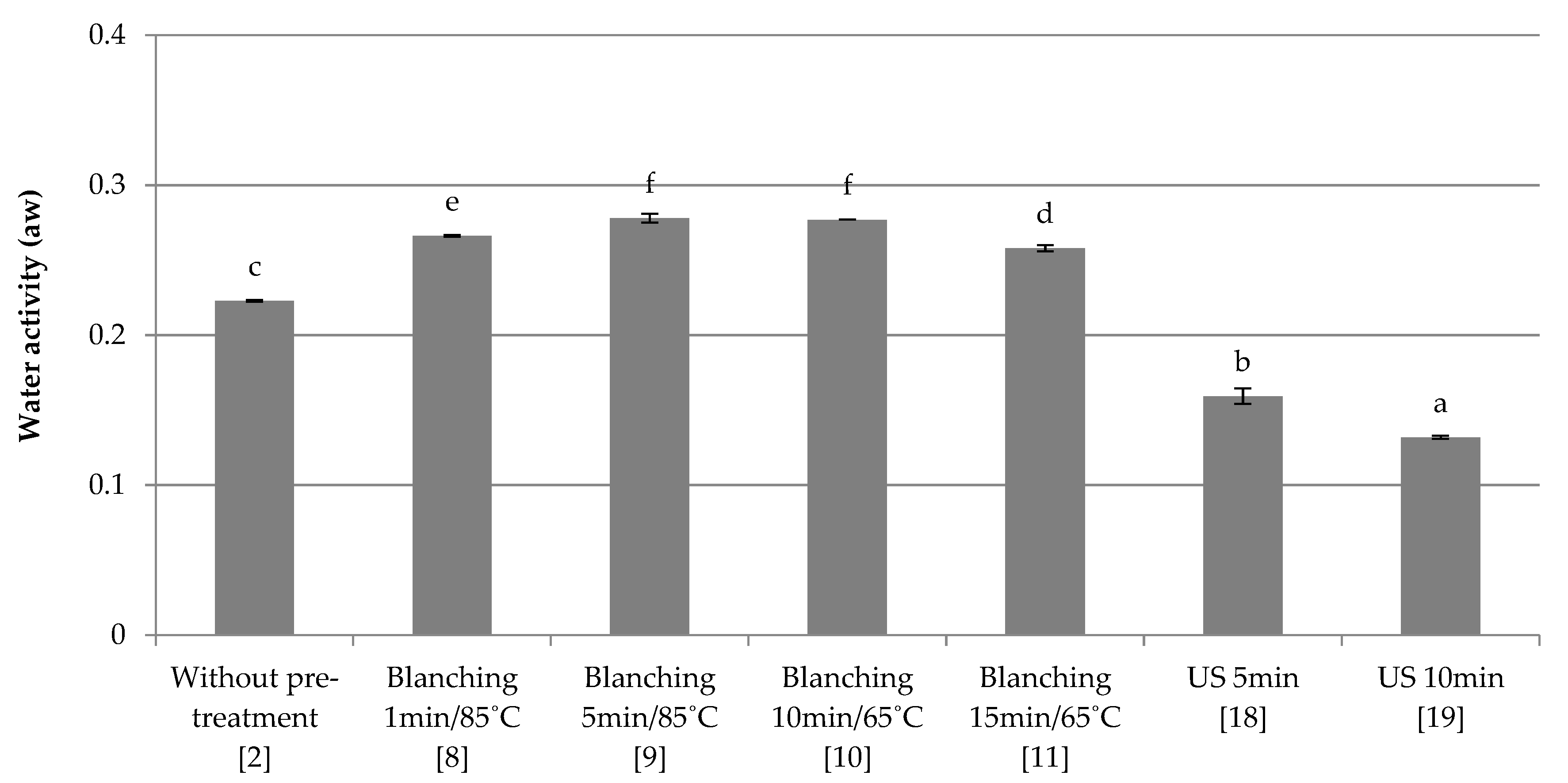

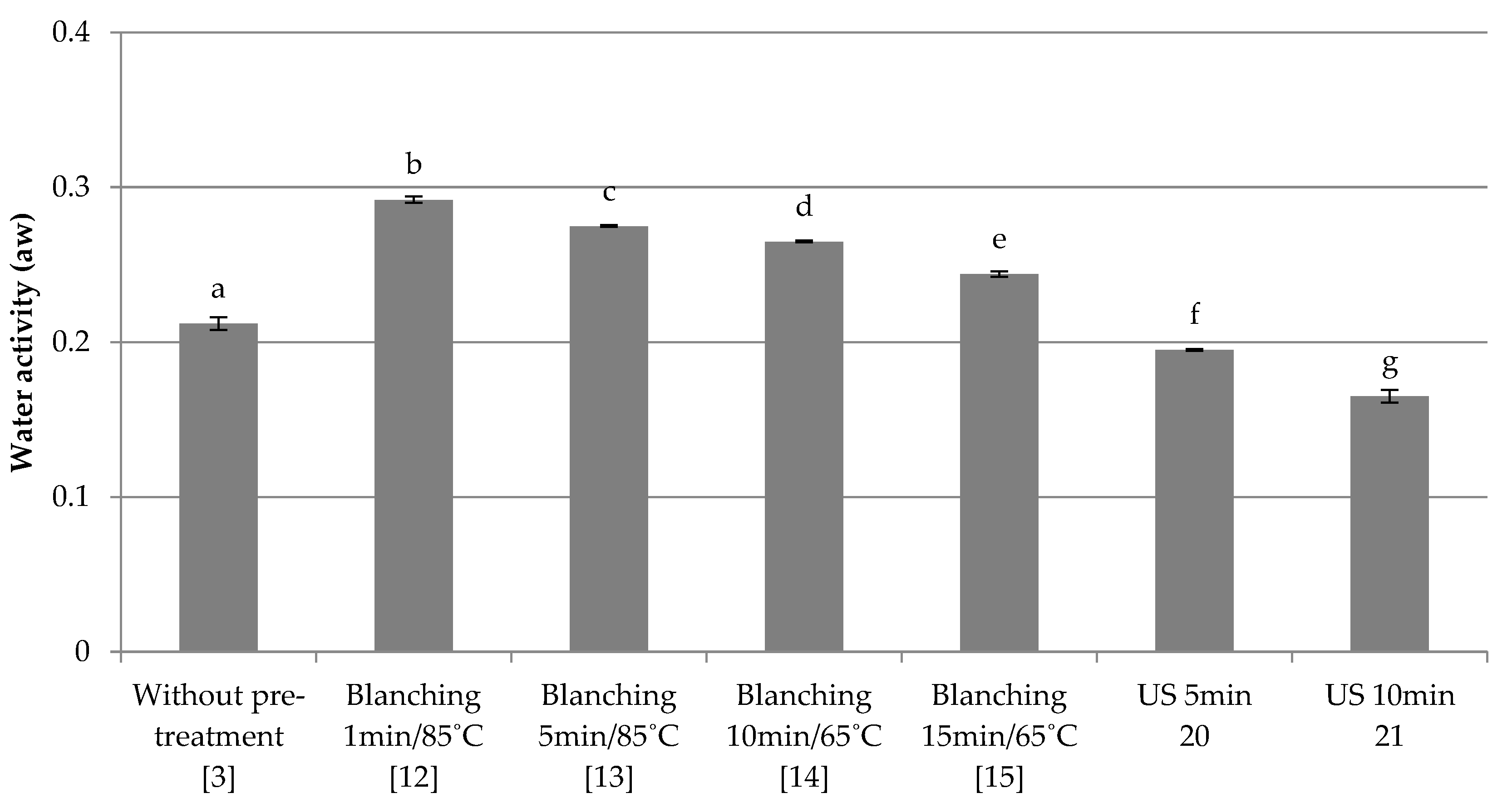

3.1.1. Water Activity

- Quick freezing

- Combined freezing

- Slow freezing

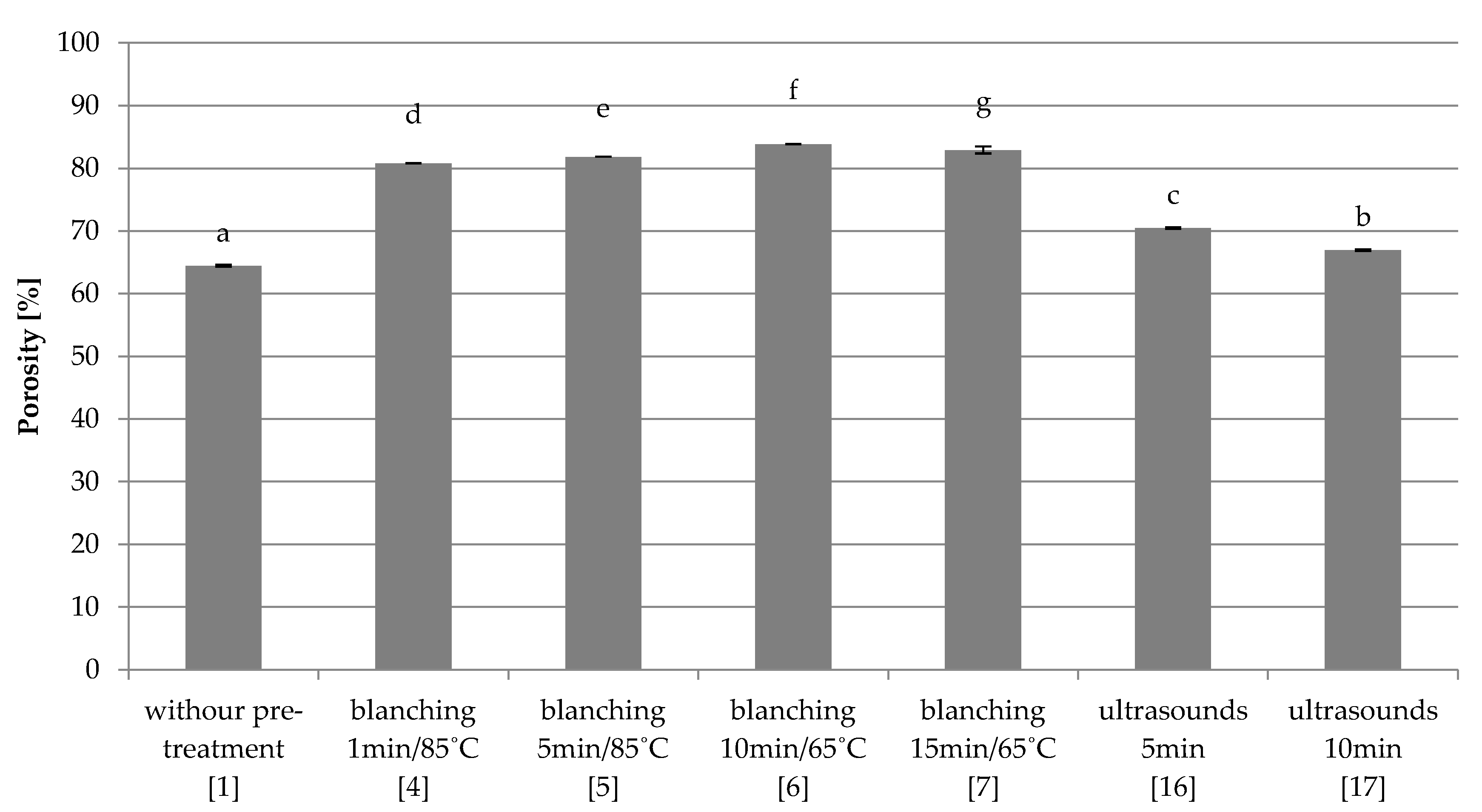

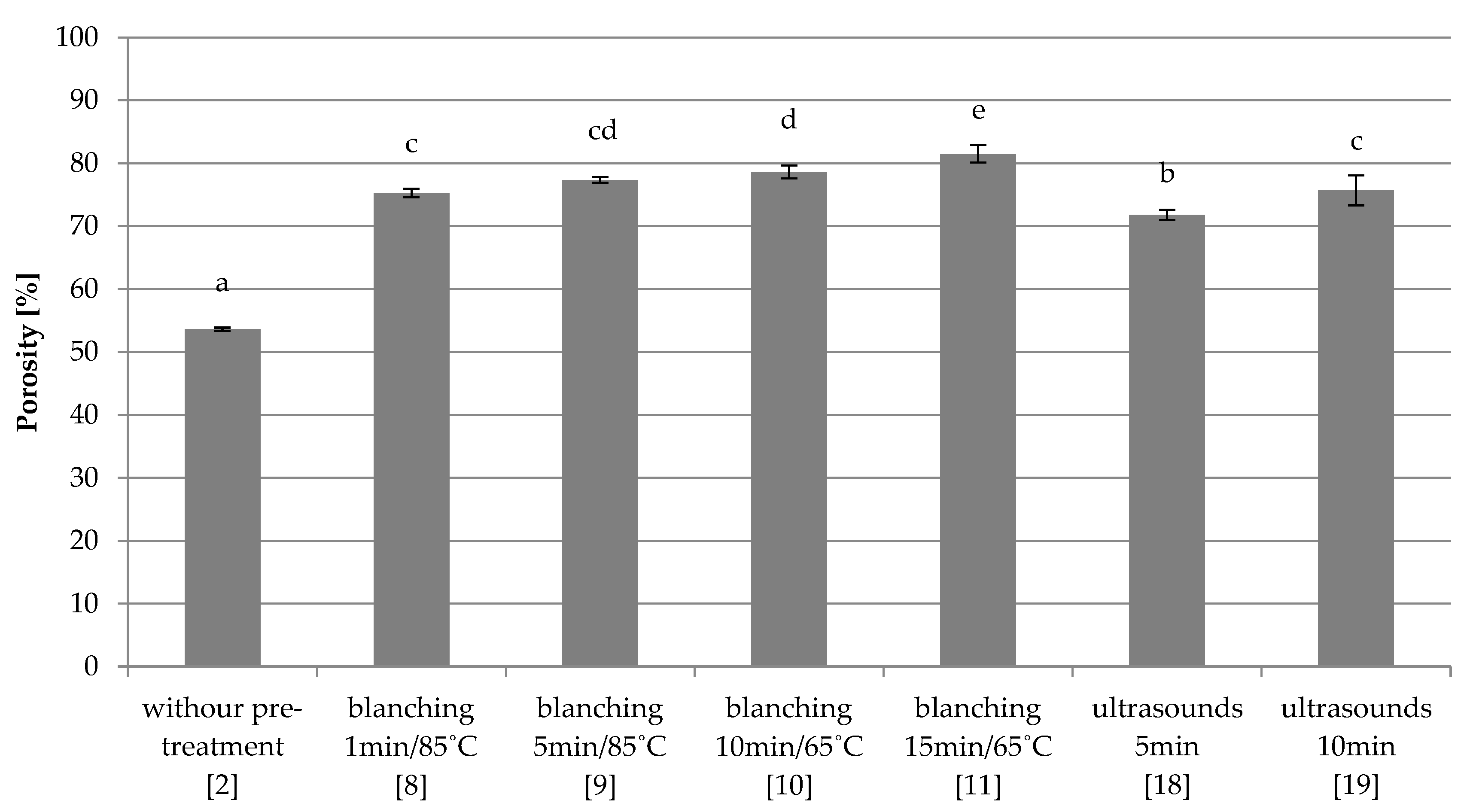

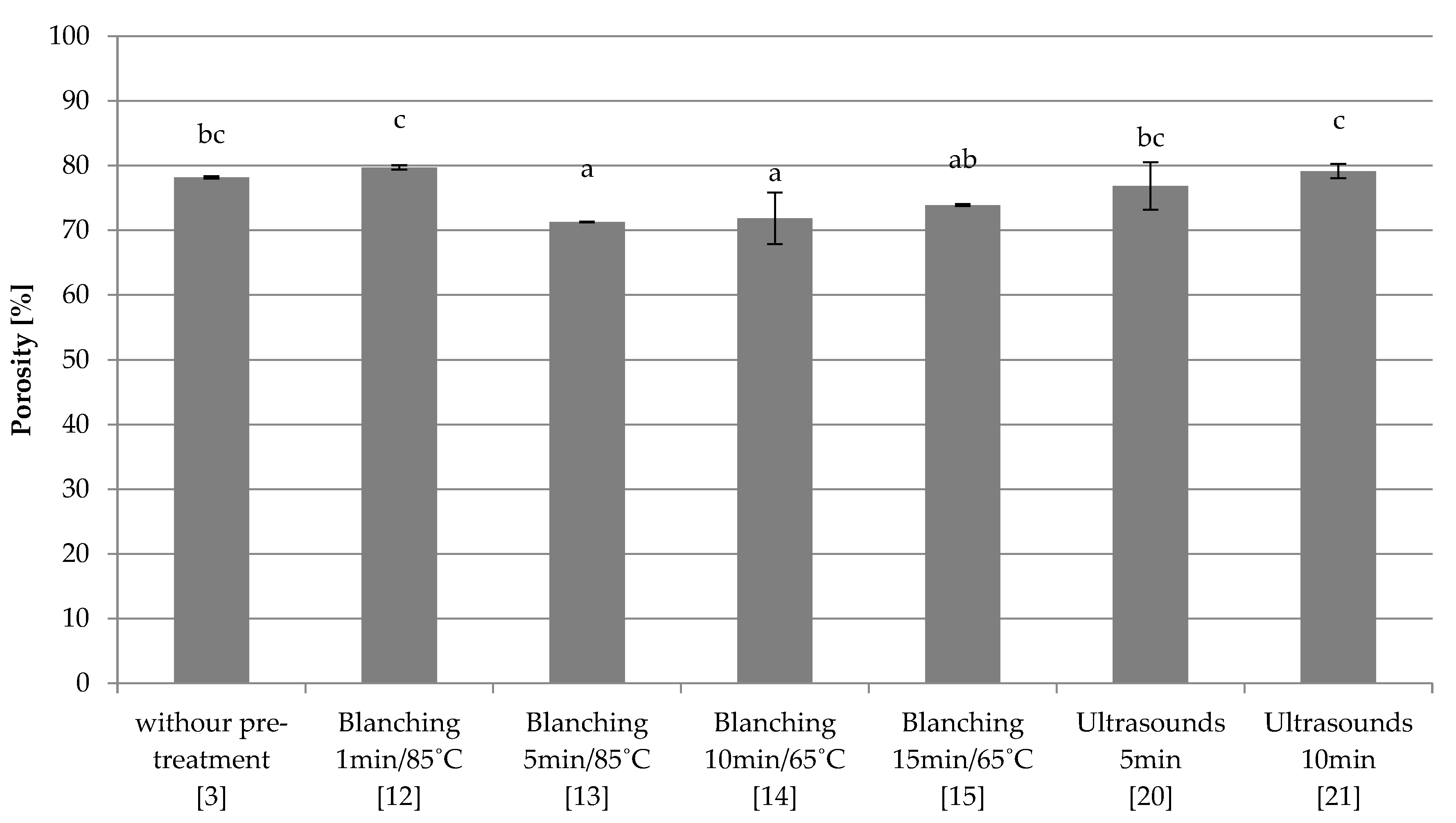

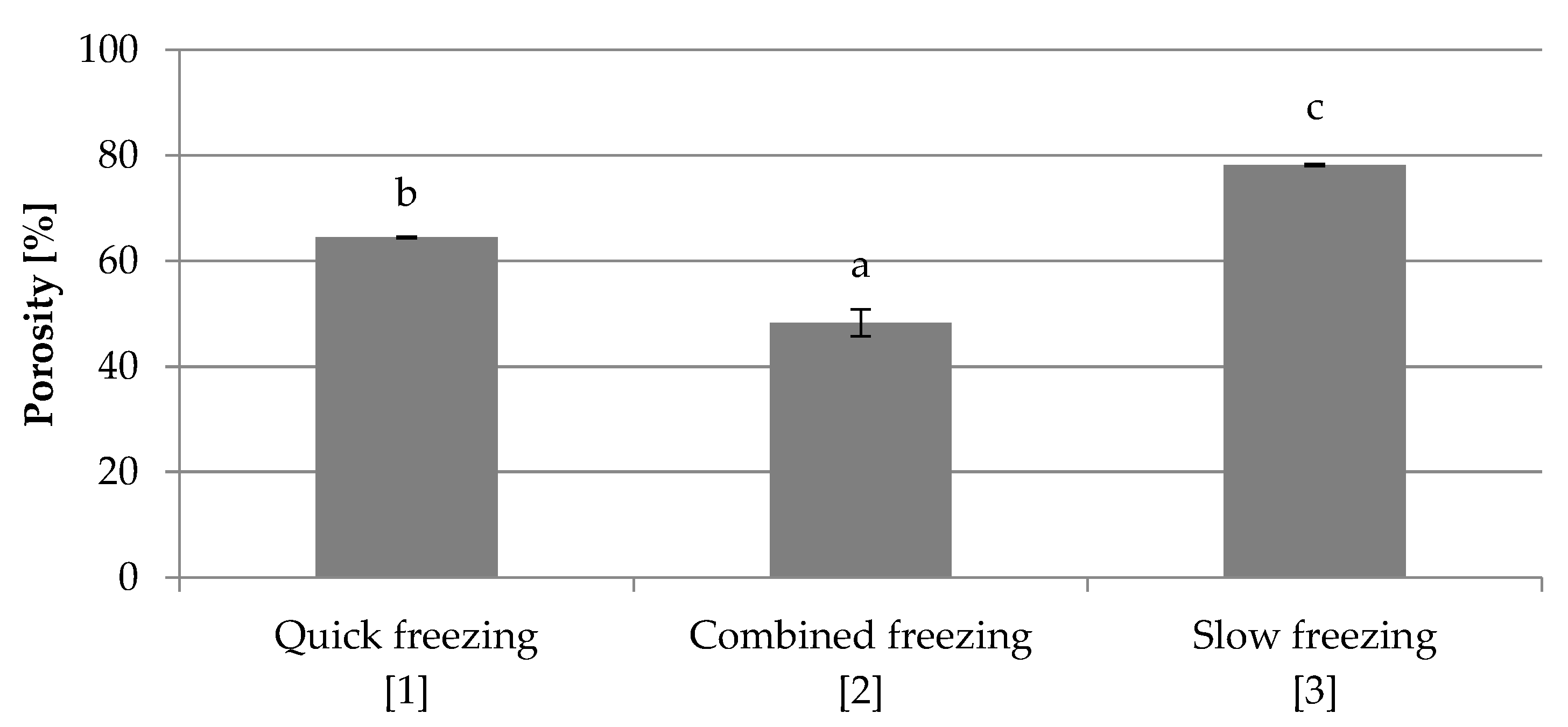

3.1.2. Porosity

- Quick freezing

- Combined freezing

- Slow freezing

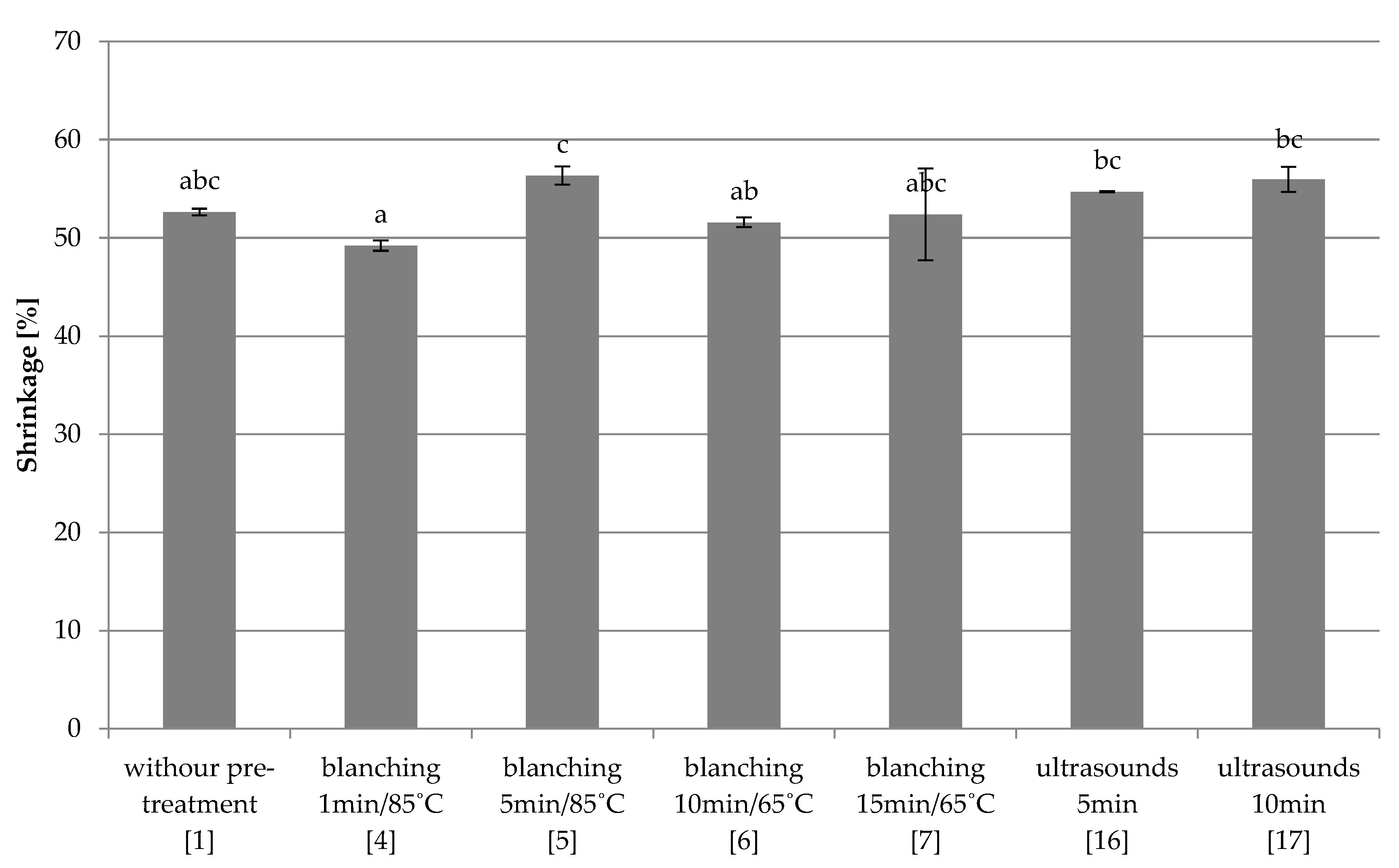

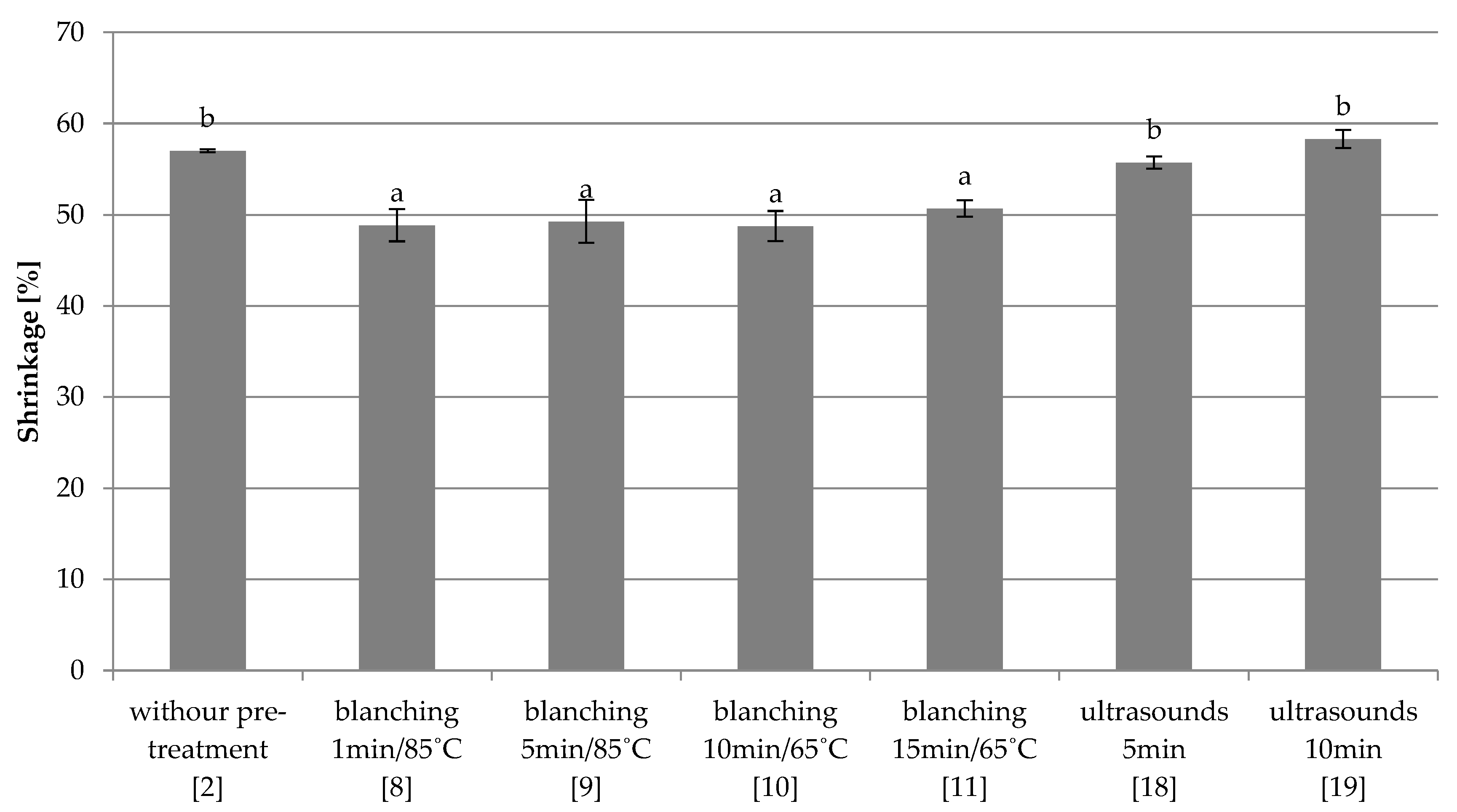

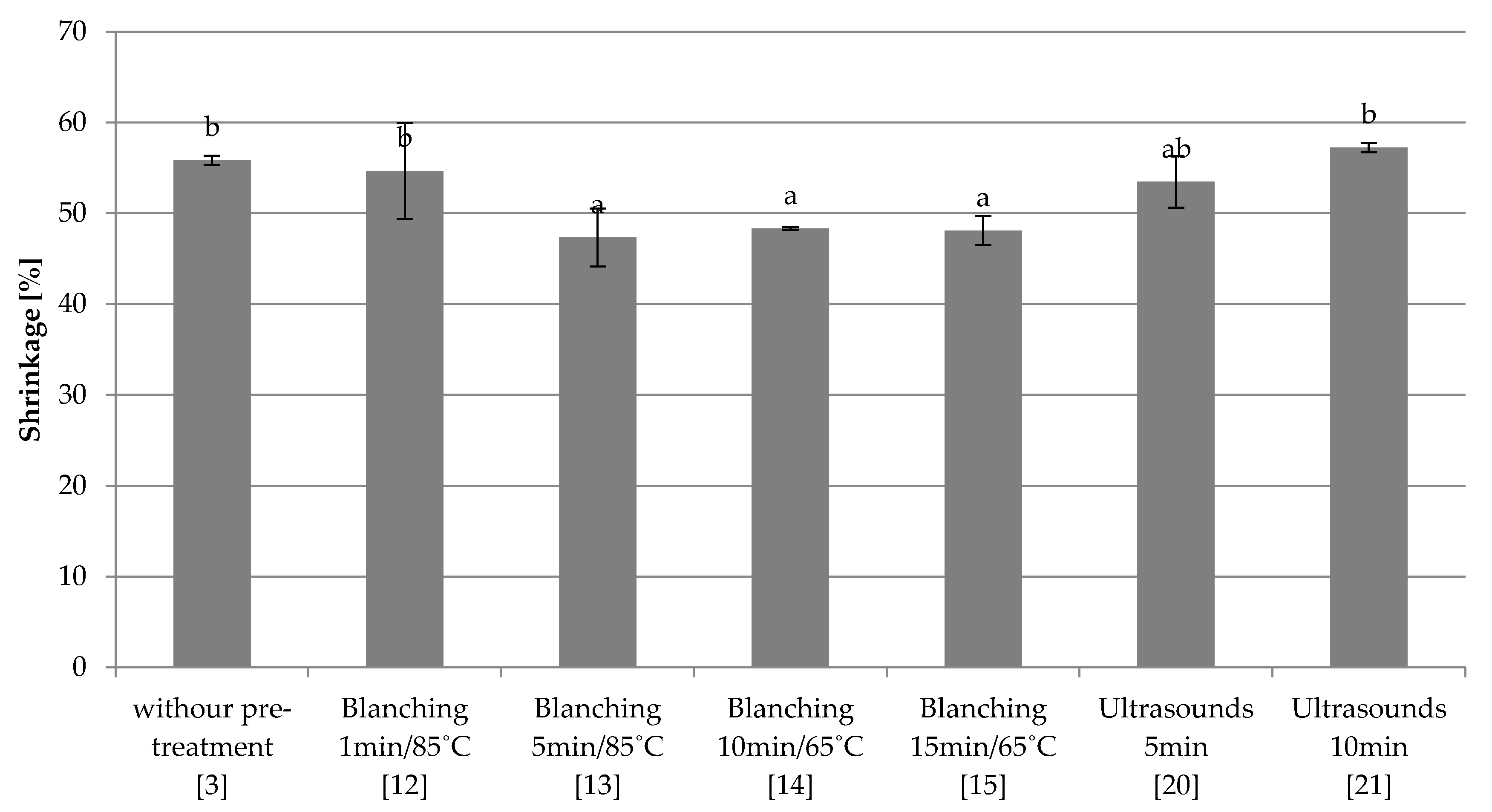

3.1.3. Shrinkage

- Quick freezing

- Combined freezing

- Slow freezing

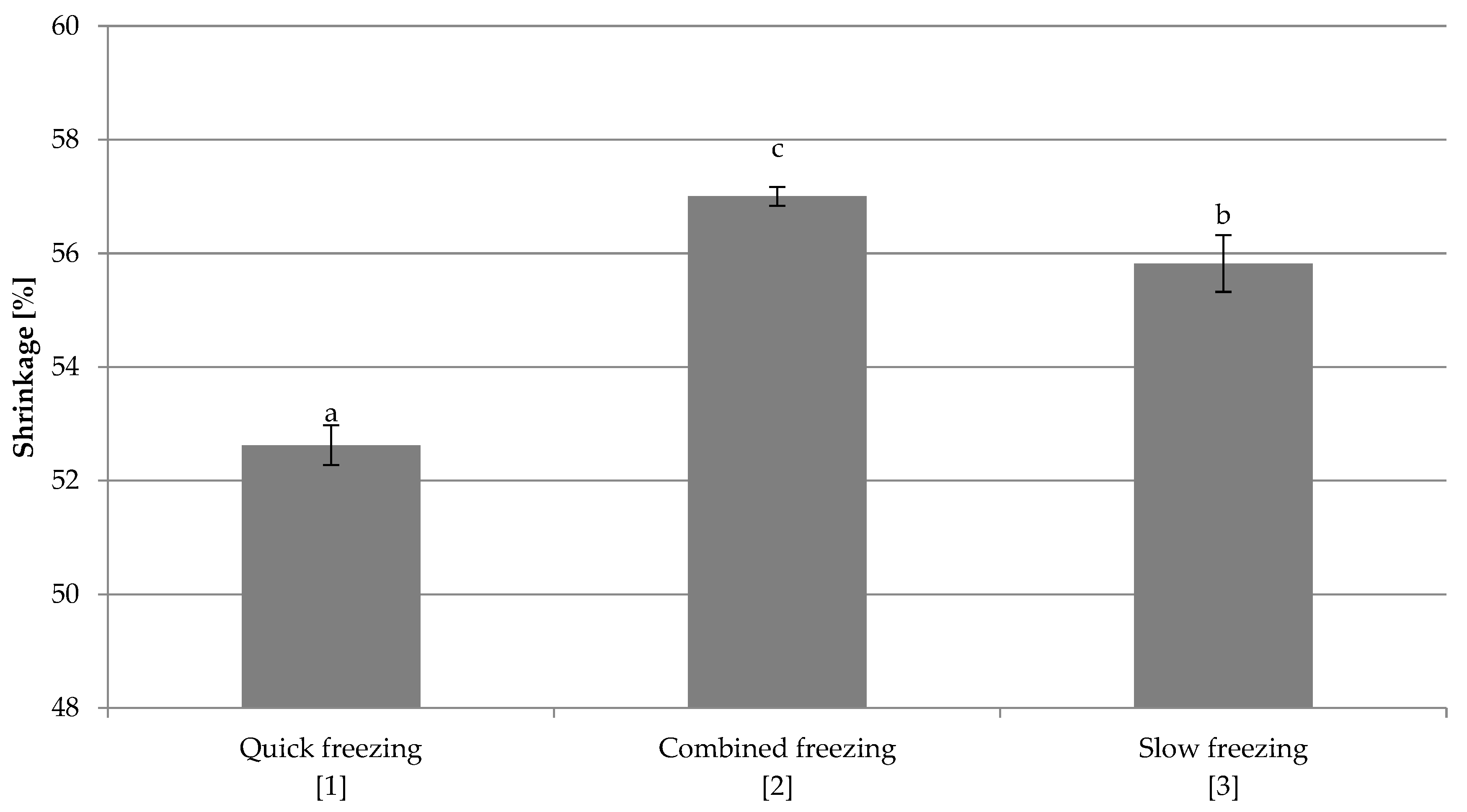

3.2. The Effect of Freezing Conditions on the Quality of Freeze-Dried Red Beet

3.2.1. Water Activity

3.2.2. Porosity

3.2.3. Shrinkage

4. Discussion

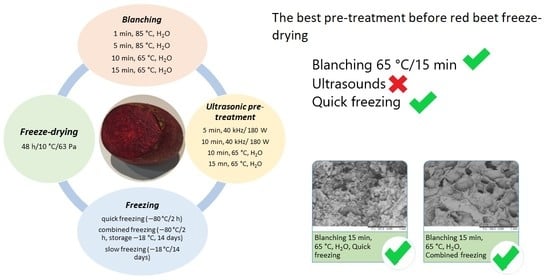

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chhikara, N.; Kushwaha, K.; Sharma, P.; Gat, Y.; Panghal, A. Bioactive compounds of red beet and utilization in food processing industry: A critical review. Food Chem. 2019, 272, 192–200. [Google Scholar] [PubMed]

- Fidelis, M.; Santos, S.J.; Coelho, A.L.K.; Rodionova, O.E.; Pomeranstev, A.; Granato, D. Authentication of juices from antioxidant and chemical perspectives: A feasibility quality control study using chemometrics. Food Control 2017, 73, 796–805. [Google Scholar] [CrossRef]

- Piwowar, A.; Teleszko, M.; Rychlik, M. Dried vegetables snacks—Review of the process technologies and consumption preferences among students. J. Agribus. Rural Dev. 2017, 1, 191–199. [Google Scholar] [CrossRef]

- Galoburda, R.; Kuka, M.; Cakste, I.; Klava, D. The effect of blanching temperature on the quality of microwave-vacuum dried mushroom Cantharellus cibarius. Agron. Res. 2015, 13, 929–938. [Google Scholar]

- Xiao, H.W.; Pan, Z.; Deng, L.Z.; El-Mashad, H.M.; Yang, X.H.; Mujumdar, A.S.; Gao, Z.J.; Zhang, Q. Recent developments and trends in thermal blanching—A comprehensive review. Inf. Process. Agric. 2017, 4, 101–127. [Google Scholar] [CrossRef]

- Orikasa, T.; Ono, N.; Watanabe, T.; Ando, Y.; Shiina, T.; Koide, S. Impact of blanching pretreatment on the drying rate and energy consumption during far-infrared drying of Paprika (Capsicum annuum L.). Food Qual. Saf. 2018, 2, 97–103. [Google Scholar] [CrossRef]

- Ismail, A.; Marjan, Z.M.; Foong, C.W. Total antioxidant activity and phenolic content in selected vegetables. Food Chem. 2004, 87, 581–586. [Google Scholar] [CrossRef]

- Cheeke, N.; David, J. Fundamentals and Applications of Ultrasonic Waves, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Nowacka, M.; Wedzik, M. Effect of ultrasound treatment on microstructure, colour and carotenoid content in fresh and dried carrot tissue. Appl. Acoust. 2016, 103, 163–171. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Rodrigues, S. Ultrasound as pre-treatment for drying of fruits: Dehydration of banana. J. Food Eng. 2007, 82, 261–267. [Google Scholar] [CrossRef]

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Food drying enhancement by ultrasound—A review. Trends Food Sci. Technol. 2016, 56, 126–141. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, M.J.; Miano, A.C.; Siche, R.; Pedro, A. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Śledź, M.; Wiktor, A.; Rybak, K.; Nowacka, M.; Witrowa-Rajchert, D. The impact of ultrasound and steam blanching pre-treatments on the drying kinetics, energy consumption and selected properties of parsley leaves. Appl. Acoust. 2016, 103, 148–156. [Google Scholar] [CrossRef]

- Azoubel, P.M.; Baima, M.A.M.; Amorim, M.R.; Oliveira, S.S.B. Effect of ultrasound on banana cv Pacovan drying kinetics. J. Food Eng. 2010, 97, 194–198. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Mason, T.J.; Paniwnyk, L.; Lelas, V. Accelerated drying of button mushrooms, brussels sprouts and cauliflower by applying power ultrasound and its rehydration properties. J. Food Eng. 2007, 81, 88–97. [Google Scholar] [CrossRef]

- Chen, Z.G.; Guo, X.Y.; Wu, T. A novel dehydration technique for carrot slices implementing ultrasound and vacuum drying methods. Ultrason. Sonochemistry 2016, 30, 28–34. [Google Scholar] [CrossRef]

- Gallo, M.; Ferrara, L.; Naviglio, D. Application of ultrasound in food science and technology: A perspective. Foods 2018, 7, 164. [Google Scholar] [CrossRef]

- Ceballos, A.M.; Giraldo, G.I.; Orrego, C.E. Effect of freezing rate on quality parameters of freeze dried soursop fruit pulp. J. Food Eng. 2012, 111, 360–365. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A. Effect of the aerated structure on selected properties of freeze-dried hydrocolloid gels. Int. Agrophysics 2016, 30, 9–17. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Mieszkowska, A.; Olsiński, I.; Lenart, A. The effect of composition and aeration on selected physical and sensory properties of freeze-dried hydrocolloid gels. Food Hydrocoll. 2017, 67, 94–103. [Google Scholar] [CrossRef]

- He, Z.; Yang, F.; Yi, S.; Gao, J. Effect of ultrasound pretreatment on vacuum drying of chinese catalpa wood. Dry. Technol. 2012, 30, 1750–1755. [Google Scholar] [CrossRef]

- Fenandes, F.A.N.; Gallao, M.I.; Rodrigues, S. Effect of osmotic dehydration and ultrasound pre-treatment on cell structure: Melon dehydration. LWT-Food Sci. Technol. 2008, 41, 604–610. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, Y. Effect of pulsed vacuum and ultrasound osmopre-treatments on glass transition temperature, texture, microstructure and calcium penetration of dried apples (Fuji). LWT-Food Sci. Technol. 2008, 41, 1575–1585. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Cichowska, J.; Kowalska, H.; Czajkowska, K.; Lenart, A. Osmotic dehydration of Braeburn variety apples in the productionof sustainable food products. Int. Agrophysics 2018, 32, 141–146. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, M.; Mujumdar, A.S.; Zhong, Q.; Wang, Z. Effects of ultrasonic pretreatments on quality, energy consumption and sterilization of barley grass in freeze drying. Ultrason. Sonochemistry 2018, 40, 333–340. [Google Scholar] [CrossRef]

- Gallego-Juárez, J.A.; Rodriguez-Corral, G.; Gálvez-Moraleda, J.C.; Yang, T.S. A new high intensity ultrasonic technology for food dehydration. Dry. Technol. 1999, 17, 597–608. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A.; Kawka, P. Wpływ blanszowania i sposobu mrożenia na wybrane właściwości liofilizowanej dyni. Żywność. Nauka. Technologia. Jakość 2013, 2, 150–161. [Google Scholar]

- Halder, A.; Datta, A.K.; Spanswick, R.M. Water transport in cellular tissues during thermal processing. Am. Inst. Chem. Eng. J. 2011, 57, 2574–2588. [Google Scholar] [CrossRef]

- Canet, W.; Alvarez, M.D.; Luna, P.; Fernndez, C.; Tortosa, M.E. Blanching effects on chemistry, quality and structure of green beans (cv. Moncayo). Eur. Food Res. Technol. 2005, 220, 421–430. [Google Scholar] [CrossRef]

- Nowacka, M.; Laghi, L.; Rybak, K.; Dalla Rosa, M.; Witrowa-Rajchert, D.; Tylewicz, U. Water state and sugars in cranberry fruits subjected to combined treatments: Cutting, blanching and sonication. Food Chem. 2019, 299, 125122. [Google Scholar] [CrossRef]

- Liu, E.Z.; Scanlon, M.G. Modeling the effect of blanching conditions on the texture of potato strips. J. Food Eng. 2007, 81, 292–297. [Google Scholar] [CrossRef]

- Wang, H.; Fu, Q.; Chen, S.; Hu, Z.; Xie, H. Effect of hot-water blanching pretreatment on drying characteristics and product qualities for the novel integrated freeze-drying of apple slices. J. Food Qual. 2018, 2018, 1347513. [Google Scholar] [CrossRef]

- Fijalkowska, A.; Nowacka, M.; Witrowa-Rajchert, D. The physical, optical and reconstitution properties of apples subjected to ultrasound before drying. Ital. J. Food Sci. 2017, 29, 343–356. [Google Scholar]

- Koc, B.; Eren, I.; Ertekin, F.K. Modelling bulk density, porosity and shrinkage of quince during drying: The effect of drying method. J. Food Eng. 2008, 85, 340–349. [Google Scholar] [CrossRef]

- Akonor, P.T.; Tortoe, C. Effect of blanching and osmotic pre-treatment on drying kinetics, shrinkage and rehydration of chayote (sechium edule) during convective drying. Br. J. Appl. Sci. Technol. 2014, 4, 1215–1229. [Google Scholar] [CrossRef]

- Kapadiya, D.C.; Makavana, J.M.; Kathiria, M.K. Effect of hot water blanching treatment on quality of dried potato slices. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 2754–2764. [Google Scholar] [CrossRef]

- Nowacka, M.; Fijałkowska, A.; Wiktor, A.; Dadan, M.; Tylewicz, U.; Dalla Rosa, M.; Witrowa-Rajchert, D. Influence of power ultrasound on the main quality properties and cell viability of osmotic dehydrated cranberries. Ultrasonics 2018, 83, 33–41. [Google Scholar] [CrossRef] [PubMed]

- Witrowa-Rajchert, D.; Fabisiak, A.; Stawczyk, J.; Sheng, L. Wpływ metody suszenia i temperatury procesu na właściwości higroskopijne suszu jabłkowego. Inżynieria Rol. 2006, 7, 457–463. [Google Scholar]

| Sample Code | Pre-Treatment | Freezing [Temp/Time] | |

|---|---|---|---|

| (1) | - | −80 °C/2 h | quick freezing |

| (2) | - | −80 °C/2 h, storage—18 °C, 14 days | combined freezing |

| (3) | - | −18 °C/14 days | slow freezing |

| (4) | 1 min, 85 °C, H2O | −80 °C/2 h | quick freezing |

| (5) | 5 min, 85 °C, H2O | −80 °C/2 h | |

| (6) | 10 min, 65 °C, H2O | −80 °C/2 h | |

| (7) | 15 min, 65 °C, H2O | −80 °C/2 h | |

| (8) | 1 min, 85 °C, H2O | −80 °C/2 h, storage—18 °C/14 days | combined freezing |

| (9) | 5 min, 85 °C, H2O | −80 °C/2 h, storage—18 °C/14 days | |

| (10) | 10 min, 65 °C, H2O | −80 °C/2 h, storage—18 °C/14 days | |

| (11) | 15 min, 65 °C, H2O | −80 °C/2 h, storage—18 °C/14 days | |

| (12) | 1 min, 85 °C, H2O | −18 °C/14 days | slow freezing |

| (13) | 5 min, 85 °C, H2O | −18 °C/14 days | |

| (14) | 10 min, 65 °C, H2O | −18 °C/14 days | |

| (15) | 15 min, 65 °C, H2O | −18 °C/14 days | |

| (16) | 5 min, 40 kHz/180 W | −80 °C/2 h | quick freezing |

| (17) | 10 min, 40 kHz/180 W | −80 °C/2 h | |

| (18) | 5 min, 40 kHz/180 W | −80 °C/2 h, storage—18 °C/14 days | combined freezing |

| (19) | 10 min, 40 kHz/180 W | −80 °C/2 h, storage—18 °C/14 days | |

| (20) | 5 min, 40 kHz/180 W | −18 °C/14 days | slow freezing |

| (21) | 10 min, 40 kHz/180 W | −18 °C/14 days | |

| Sample Name | Water Activity ± Standard Deviation |

|---|---|

| (1) | a 0.243 ± 0.003055 |

| (3) | b 0.223 ± 0.000577 |

| (2) | c 0.211 ± 0.004041 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciurzyńska, A.; Falacińska, J.; Kowalska, H.; Kowalska, J.; Galus, S.; Marzec, A.; Domian, E. The Effect of Pre-Treatment (Blanching, Ultrasound and Freezing) on Quality of Freeze-Dried Red Beets. Foods 2021, 10, 132. https://doi.org/10.3390/foods10010132

Ciurzyńska A, Falacińska J, Kowalska H, Kowalska J, Galus S, Marzec A, Domian E. The Effect of Pre-Treatment (Blanching, Ultrasound and Freezing) on Quality of Freeze-Dried Red Beets. Foods. 2021; 10(1):132. https://doi.org/10.3390/foods10010132

Chicago/Turabian StyleCiurzyńska, Agnieszka, Julita Falacińska, Hanna Kowalska, Jolanta Kowalska, Sabina Galus, Agata Marzec, and Ewa Domian. 2021. "The Effect of Pre-Treatment (Blanching, Ultrasound and Freezing) on Quality of Freeze-Dried Red Beets" Foods 10, no. 1: 132. https://doi.org/10.3390/foods10010132

APA StyleCiurzyńska, A., Falacińska, J., Kowalska, H., Kowalska, J., Galus, S., Marzec, A., & Domian, E. (2021). The Effect of Pre-Treatment (Blanching, Ultrasound and Freezing) on Quality of Freeze-Dried Red Beets. Foods, 10(1), 132. https://doi.org/10.3390/foods10010132