The Microhardness and Chemical Composition of Different Ceramic Self-Ligating Brackets: An In Vitro Study

Abstract

1. Introduction

2. Materials and Methods

- −

- 10 Damon ® Clear 2 brackets (ORMCO, Glendale, CA, USA), lot 062036755;

- −

- 10 Genius® Crystal brackets (Orthopartner, Tainan City, Taiwan, China), lot 5102017112020;

- −

- 10 Empower ® 2 Clear brackets (AO, Sheboygan, WI, USA), lot L68774;

- −

- 10 Clarity ® Ultra brackets (3M, Monrovia, CA, USA), lot LA8HK;

- −

- 10 Alpine SL® Clear brackets (RMO, Denver, CO, USA), lot 20096-43;

- −

- 10 Experience Ceramic® brackets (GC, Breckerfeld, Germany), lot A145931.

Statistical Analysis

- −

- The average microhardness of each sample to that of enamel;

- −

- The average microhardness of each sample to that of stainless steel;

- −

- The average microhardness of each sample to that of cobalt–chromium;

- −

- The average microhardness of each sample to that of gold.

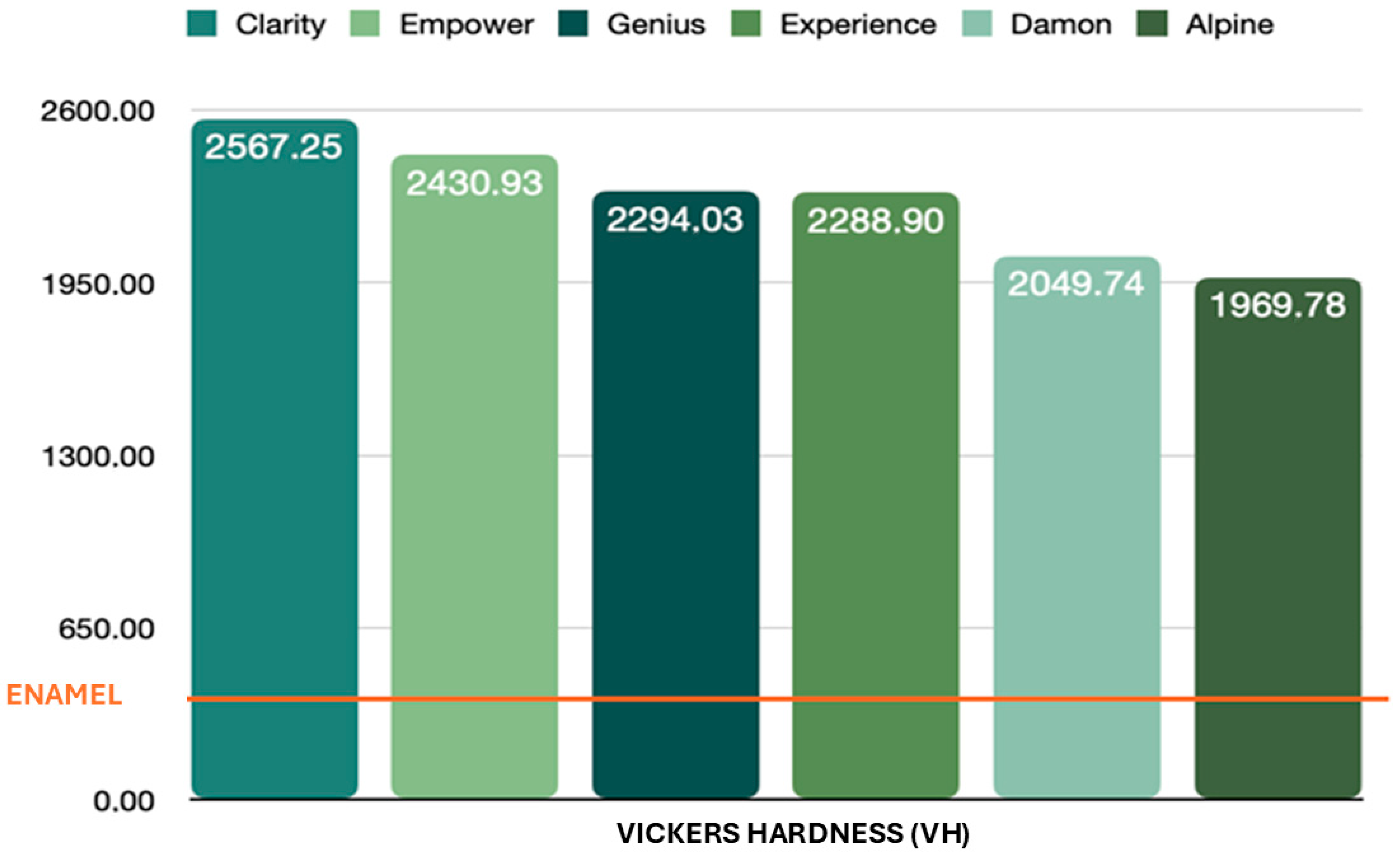

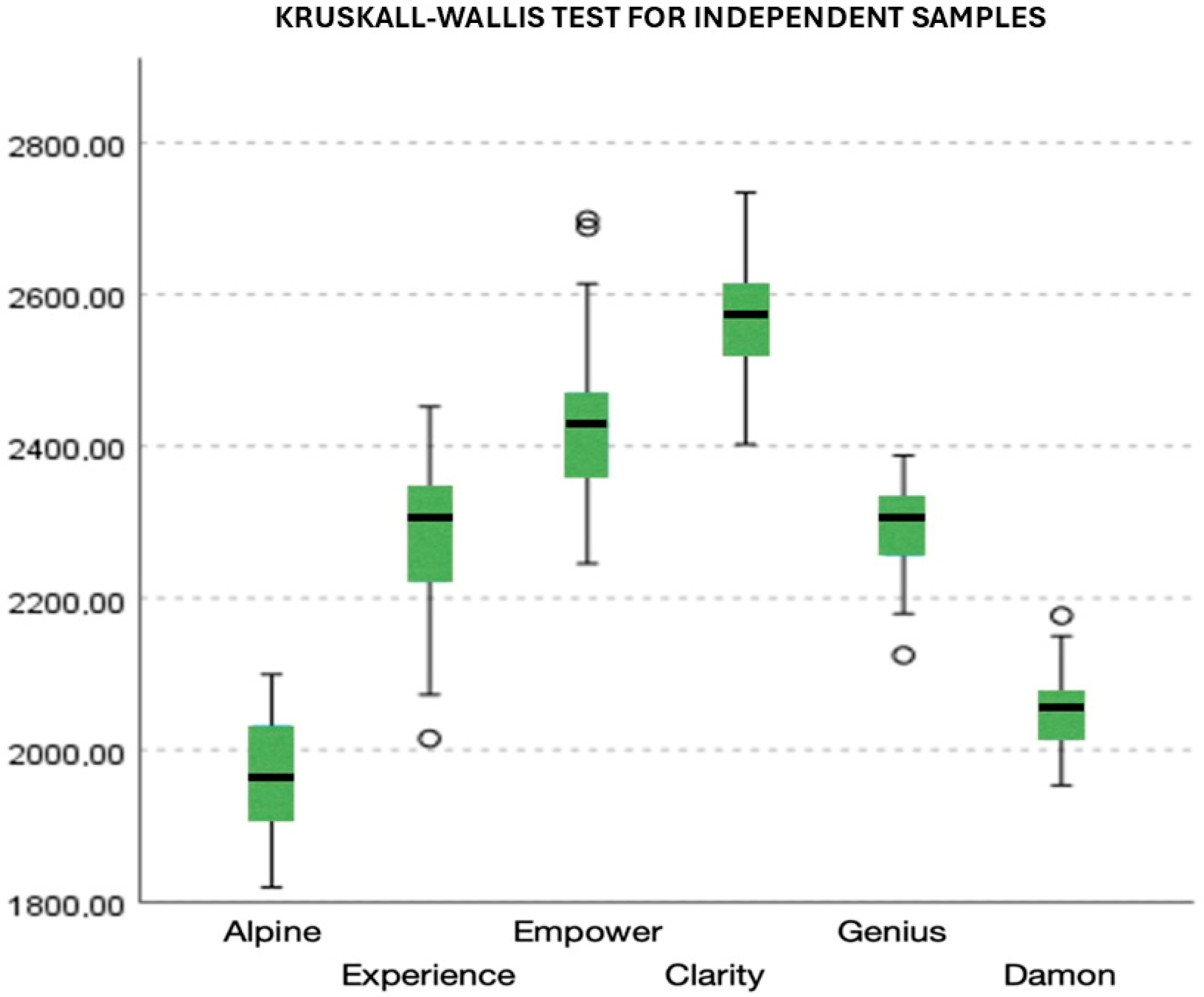

3. Results

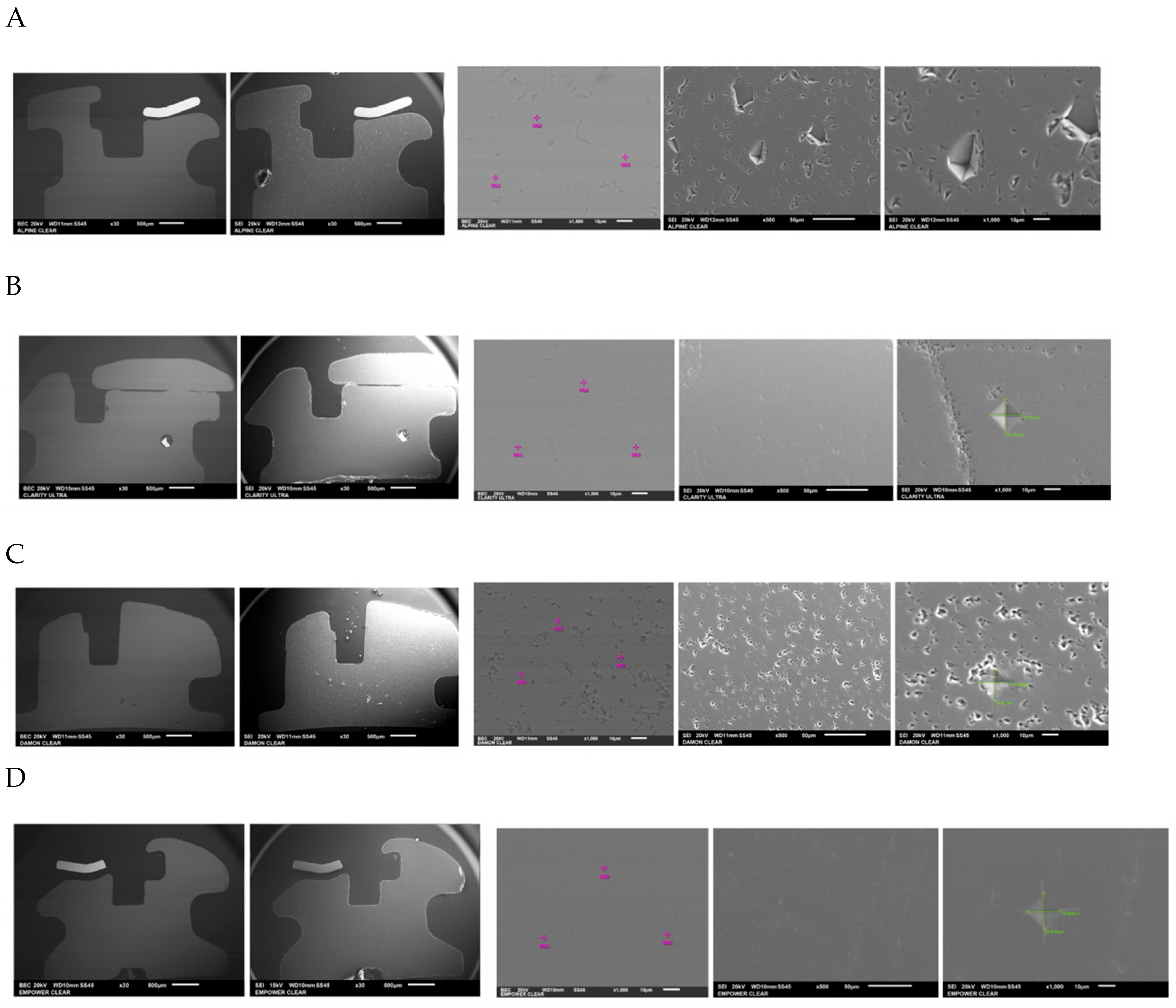

3.1. Damon® Clear 2 (ORMCO, Glendora, CA, USA)

3.2. Genius® Crystal (Orthopartner, Tainan, Taiwan)

3.3. Empower® 2 Clear (American Orthodontics, Sheboygan, WI, USA)

3.4. Clarity® Ultra (3M, Monrovia, LR, USA)

3.5. Alpine SL® Clear (RMO, Denver, CO, USA)

3.6. Experience Ceramic® (GC, Breckerfeld, Germany)

4. Discussion

Limitations

5. Conclusions

- o

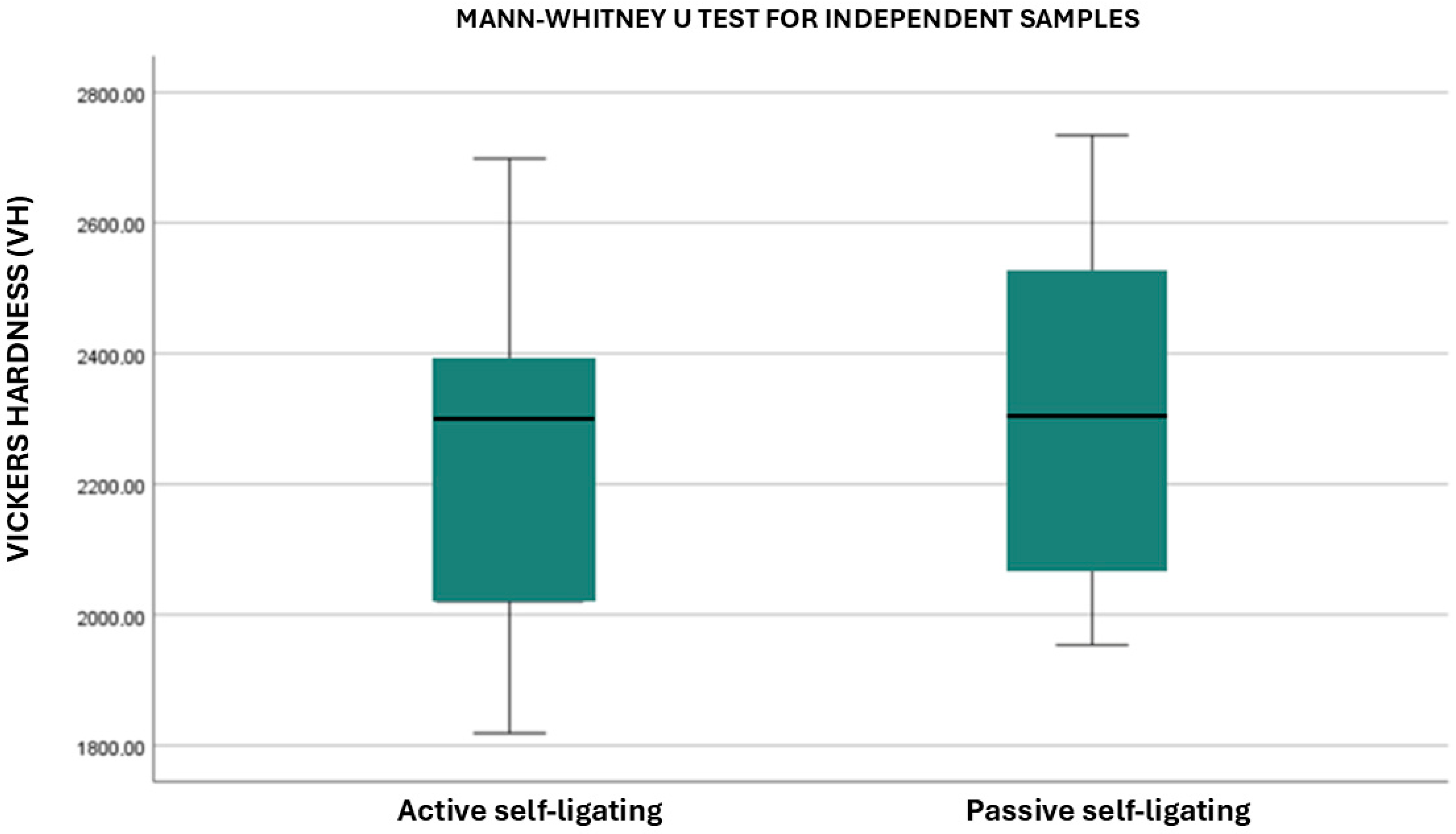

- Self-ligating ceramic orthodontic brackets are at least six times harder than enamel and are therefore traumatic to the enamel of the antagonistic teeth. It is advisable to refrain from bonding ceramic attachments to the mandible, or to ensure that the occlusion is elevated with turbo-bites to avoid traumatic contact.

- o

- As the data from the literature on this subject is weak, the present study obtained microhardness values for self-ligating ceramic orthodontic brackets with a satisfactory sample size.

- o

- Studying the brackets’ composition helped explain some of the difference in the microhardness found between the different types of brackets, thanks to their greater or lesser oxygen content.

- o

- Alpine® brackets have the lowest microhardness values and therefore appear to be the brackets of choice among self-ligating ceramic orthodontic brackets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Papageorgiou, S.N.; Polychronis, G.; Panayi, N.; Zinelis, S.; Eliades, T. New aesthetic in-house 3D-printed brackets: Proof of concept and fundamental mechanical properties. Prog. Orthod. 2022, 23, 6. [Google Scholar] [CrossRef] [PubMed]

- Ziuchkovski, J.P.; Fields, H.W.; Johnston, W.M.; Lindsey, D.T. Assessment of perceived orthodontic appliance attractiveness. Am. J. Orthod. Dentofacial. Orthop. 2008, 133 (Suppl. 4), S68–S78. [Google Scholar] [CrossRef] [PubMed]

- Maizeray, R.; Wagner, D.; Lefebvre, F.; Lévy-Bénichou, H.; Bolender, Y. Is there any difference between conventional, passive and active self-ligating brackets? A systematic review and network meta-analysis. Int Orthod. 2021, 19, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Khan, H. Orthodontic Brackets Selection, Placement and Debonding. J. Orthod. Res. 2015, 3, 208. [Google Scholar]

- Darvell, B.W. Materials Science for Dentistry; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- Ghafari, J. Problems associated with ceramic brackets suggest limiting use to selected teeth. Angle Orthod. 1992, 62, 145–152. [Google Scholar]

- Kitahara-Céia, F.M.F.; Mucha, J.N.; Marques dos Santos, P.A. Assessment of enamel damage after removal of ceramic brackets. Am. J. Orthod. Dentofacial Orthop. 2008, 134, 548–555. [Google Scholar] [CrossRef]

- Warkentin, M.; Freyse, C.; Specht, O.; Behrend, D.; Maletz, R.; Janda, R.; Ottl, P. Correlation of ultrasound microscopy and Vickers hardness measurements of human dentin and enamel—A pilot study. Dent. Mater. 2018, 34, 1036–1040. [Google Scholar] [CrossRef]

- Gutiérrez-Salazar, M.D.P.; Reyes-Gasga, J. Microhardness and chemical composition of human tooth. Mater. Res. 2003, 6, 367–373. [Google Scholar] [CrossRef]

- Sa, Y.; Liang, S.; Ma, X.; Lu, S.; Wang, Z.; Jiang, T.; Wang, Y. Compositional, structural and mechanical comparisons of normal enamel and hypomaturation enamel. Acta Biomater. 2014, 10, 5169–5177. [Google Scholar] [CrossRef]

- Aydın, B.; Pamir, T.; Baltaci, A.; Orman, M.N.; Turk, T. Effect of storage solutions on microhardness of crown enamel and dentin. Eur. J. Dent. 2015, 9, 262–266. [Google Scholar] [CrossRef]

- Elhennawy, K.; Manton, D.J.; Crombie, F.; Zaslansky, P.; Radlanski, R.J.; Jost-Brinkmann, P.G.; Schwendicke, F. Structural, mechanical and chemical evaluation of molar-incisor hypomineralization-affected enamel: A systematic review. Arch. Oral. Biol. 2017, 83, 272–281. [Google Scholar] [CrossRef] [PubMed]

- Swartz, M.L. Ceramic brackets. J. Clin. Orthod. 1988, 22, 82–88. [Google Scholar] [PubMed]

- Douglass, J.B. Enamel wear caused by ceramic brackets. Am. J. Orthod. Dentofac. Orthop. 1989, 95, 96–98. [Google Scholar] [CrossRef] [PubMed]

- Viazis, A.D.; DeLong, R.; Bevis, R.R.; Rudney, J.D.; Pintado, M.R. Enamel abrasion from ceramic orthodontic brackets under an artificial oral environment. Am. J. Orthod. Dentofac. Orthop. 1990, 98, 103–109. [Google Scholar] [CrossRef]

- Zinelis, S.; Annousaki, O.; Makou, M.; Eliades, T. Metallurgical characterization of orthodontic brackets produced by Metal Injection Molding (MIM). Angle Orthod. 2005, 75, 1024–1031. [Google Scholar]

- Kim, K.B. Orthodontics: Current principles and techniques. Am. J. Orthod. Dentofac. Orthop. 2018, 153, 162. [Google Scholar] [CrossRef]

- Eliades, T.; Zinelis, S.; Eliades, G.; Athanasiou, A.E. Characterization of as-received, retrieved, and recycled stainless steel brackets. J. Orofac. Orthop. 2003, 64, 80–87. [Google Scholar] [CrossRef]

- Colmant, M.; Fawaz, P.; Stanton, K.; MacMichael, O.; Vande Vannet, B. Microhardness and Chemical Composition of Different Metallic Brackets: An In Vitro Study. Dent. J. 2023, 11, 202. [Google Scholar] [CrossRef]

- NF EN ISO 6507-1; Metallic materials—Vickers Hardness Test. ISO: Geneva, Switserland, 2023.

- Fenjiro, I. Les Attaches Orthodontiques Linguales Ont-Elles Toutes la Même Dureté: Incidences Clliniques. 2025 HAL-05121921v1 (accepted) Mémoire DES ODF 2017. Université de Lorraine: Nancy, France, 2017. [Google Scholar]

- Zinelis, S.; Sifakakis, I.; Katsaros, C.; Eliades, T. Microstructural and mechanical characterization of contemporary lingual orthodontic brackets. Eur. J. Orthod. 2014, 36, 389–393. [Google Scholar] [CrossRef]

- Viazis, A.D.; DeLong, R.; Bevis, R.R.; Douglas, W.H.; Speidel, T.M. Enamel surface abrasion from ceramic orthodontic brackets: A special case report. Am. J. Orthod. Dentofac. Orthop. 1989, 96, 514–518. [Google Scholar] [CrossRef]

- Polychronis, G.; Papageorgiou, S.N.; Riollo, C.S.; Panayi, N.; Zinelis, S.; Eliades, T. Fracture toughness and hardness of in-office, 3D-printed ceramic brackets. Orthod. Craniofacial. Res. 2023, 26, 476–480. [Google Scholar] [CrossRef] [PubMed]

- Alexopoulou, E.; Polychronis, G.; Konstantonis, D.; Sifakakis, I.; Zinelis, S.; Eliades, T. A study of the mechanical properties of as-received and intraorally exposed single-crystal and polycrystalline orthodontic ceramic brackets. Eur. J. Orthod. 2020, 42, 72–77. [Google Scholar] [CrossRef] [PubMed]

- Iwasaki, T.; Nagata, S.; Ishikawa, T.; Tanimoto, Y. Mechanical characterization of aesthetic orthodontic brackets by the dynamic indentation method. Dent. Mater. J. 2022, 41, 860–867. [Google Scholar] [CrossRef] [PubMed]

- Noorollahian, S.; Zarei, Z.; Sadeghalbanaei, L.; Pakzamir, K. The Effect of Bonding Surface Design on Shear Bond Strength of 3D-Printed Orthodontic Attachments. Int. J. Dent. 2023, 2023, 6697178. [Google Scholar] [CrossRef]

- Sfondrini, M.F.; Cacciafesta, V.; Scribante, A.; De Angelis, M.; Klersy, C. Effect of blood contamination on shear bond strength of brackets bonded with conventional and self-etching primers. Am. J. Orthod. Dentofac. Orthop. 2004, 125, 357–360. [Google Scholar] [CrossRef]

| Active Self Ligating Brackets | Passive Self Ligating Brackets | ||||

|---|---|---|---|---|---|

Experience Ceramic® (GC, Breckerfeld, Germany) | Alpine SL® Clear (RMO, Denver, CO, USA) | Empower 2® Clear (AO, Sheboygan, WI, USA)  | Clarity Ultra® (3M, Monrovia, CA, USA) | Genius Crystal® (Orthopartner, Tainan city, Taiwan, China) | Damon® Clear2 (ORMCO, Glendale, CA, USA) |

| Alumina oxide with PTFE (polytetrafluoroethylene) coating. Clip in cobalt nickel alloy (Co, Ni, Cr, Mo, Fe, Nb, Ti, Mn) with rhodium coating (rhodium, gold). | Polycrystalline ceramic. Clip in nickel titanium with rhodium coating. | Polycrystalline ceramics. Clip: alloy (Co, Ni, Cr, Mo) with rhodium coating. | Polycrystalline ceramics based on very fine microcrystalline silica. | Alumina oxide formula. | Polycrystalline aluminium oxide (PAO) formula |

| Steps | Protocol | Images |

|---|---|---|

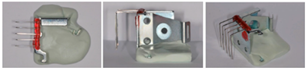

| Brackets positioning | The brackets are inserted into a positioning device equipped with 0.19 × 25 stainless steel archwire (identical angulation, perpendicular to the arch segments and presenting the same side to be tested) |  |

| Brackets fixation | Brackets are held in place by sculpting wax (Dentify, Engen, Germany) |  |

| Molding and connecting brackets | Brackets are molded into a flat silicone base using Helio Seal© photopolymerizable compomer resin, to create a flat resin bar that groups brackets from the same series |  |

| Obtaining sample bars | 12 strips are produced, each containing 5 brackets from the same series |  |

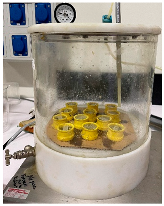

| Positioning strips in molds | Bars containing 5 brackets each are fitted with 2 rider clips (Buehler sample support clips) and then placed in molds previously lubricated with an aerosol release agent (Bluesil silicones). 12 molds are made, each containing 1 bar of each bracket |  |

| Embedding samples in molds | Samples are coated with ESCIL DBF self-curing araldite epoxy resin, to which ESCIL HY 956 hardener is added. The mixing ratio is 82% monomer to 18% hardener. The components are weighed using a precision balance (KERN PCB, Sigma-Aldrich, St Louis, MO, USA). The resin is reheated to 40 °C to fluidize it and make the monomer/hardener mix more homogeneous. |  |

| Vacuum packing of samples | The resin is placed for a few minutes under vacuum to remove the bubbles incorporated during preparation |  |

| Sample demolding | Once the resin has set completely, the preparations are demolded by hand |  |

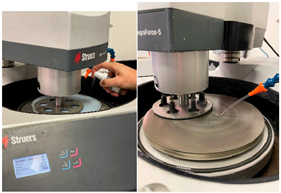

| Manual polishing | A first polishing phase is carried out with 2 diamond disks of decreasing granulometry under water. The discs are mounted in a STRUERS ROTOPOL-2 (Struers, Copenhagen, Denmark)manual polisher at a speed of 150 to 300 rpm. |  |

| Automatic polishing | A second polishing phase is carried out using cloths loaded with a liquid diamond suspension of equivalent and decreasing particle size (9,6,3,1). The cloths are mounted in a STRUERS TEGRAPOL-31 (Struers, Copenhagen, Denmark) automatic polisher at a speed of 150–300 rpm under a pressure of 20 N/turn for 10/5/5 min |  |

| Ready to test samples | The 12 samples are removed from the automatic polisher, rinsed with running water, dried with alcohol and then dried in a hair dryer. |  |

| Enamel | Stainless Steel | Cobalt Chrome | Gold |

|---|---|---|---|

| 330.52 VH | 362.58 VH | 335.35 VH | 280 VH |

| Colmant et al. (2023) [19] | Colmant et al. (2023) [19] | Colmant et al. (2023) [19] | Fenjiro et al. (2017) [21] |

| Chemical Composition | Vickers Hardness | |||

|---|---|---|---|---|

| O | Al | (VH) | ||

| Alpine® | Mean | 49.11 | 50.89 | 1969.8 |

| SD | 0.6 | 0.4 | 62.9 | |

| Empower® | Mean | 48.69 | 51.31 | 2430.9 |

| SD | 0.58 | 0.39 | 62.7 | |

| Genius® | Mean | 47.97 | 52.03 | 2294 |

| SD | 0.6 | 0.4 | 40.5 | |

| Clarity® | Mean | 48.87 | 51.53 | 2567.3 |

| SD | 0.6 | 0.4 | 71.5 | |

| Experience® | Mean | 48.5 | 51.50 | 2288.9 |

| SD | 0.59 | 0.39 | 72.1 | |

| Damon® | Mean | 50.06 | 49.94 | 2049.7 |

| SD | 0.55 | 0.38 | 50.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez, M.; Fawaz, P.; El Sayegh, P.; Rapin, C.; Vande Vannet, B. The Microhardness and Chemical Composition of Different Ceramic Self-Ligating Brackets: An In Vitro Study. Dent. J. 2025, 13, 285. https://doi.org/10.3390/dj13070285

Martinez M, Fawaz P, El Sayegh P, Rapin C, Vande Vannet B. The Microhardness and Chemical Composition of Different Ceramic Self-Ligating Brackets: An In Vitro Study. Dentistry Journal. 2025; 13(7):285. https://doi.org/10.3390/dj13070285

Chicago/Turabian StyleMartinez, Mallaury, Paul Fawaz, Patrick El Sayegh, Christophe Rapin, and Bart Vande Vannet. 2025. "The Microhardness and Chemical Composition of Different Ceramic Self-Ligating Brackets: An In Vitro Study" Dentistry Journal 13, no. 7: 285. https://doi.org/10.3390/dj13070285

APA StyleMartinez, M., Fawaz, P., El Sayegh, P., Rapin, C., & Vande Vannet, B. (2025). The Microhardness and Chemical Composition of Different Ceramic Self-Ligating Brackets: An In Vitro Study. Dentistry Journal, 13(7), 285. https://doi.org/10.3390/dj13070285