Abstract

Zinc (Zn)-based alloys are considered promising bioresorbable materials for intracorporeal implants due to their good biocompatibility and suitable degradation rate in physiological environments. However, their broader application is hindered by insufficient mechanical properties, which are essential for fulfilling the therapeutic function of bioresorbable implants. This study investigates the effect of severe plastic deformation on the microstructure and mechanical properties of as-cast Zn–0.1Mg (wt.%) alloy. The as-cast alloy, characterised by a coarse-grained microstructure with intermetallic phases at grain boundaries and low strength and ductility, was subjected to two passes of Equal Channel Angular Pressing (ECAP). The intense plastic deformation transformed the coarse-grained structure into an ultrafine-grained solid solution matrix. This substantial microstructural refinement led to a significant enhancement in mechanical performance. The yield strength (YS) and ultimate tensile strength (UTS) more than doubled, reaching 198 MPa and 215 MPa, respectively. Remarkably, the elongation increased from 2.2% to 187% in tensile testing. These findings confirm the beneficial effect of grain refinement and dynamic recrystallisation on the mechanical behaviour of bioresorbable Zn–0.1Mg alloy and highlight the high potential of ECAP processing for optimising the mechanical properties of Zn-based biodegradable materials.

1. Introduction

Nowadays, research in the field of biomaterials has increasingly focused on biodegradable materials intended for intracorporeal implants [1]. Many studies have recently been published on biodegradable alloys based on magnesium (Mg), iron (Fe), and zinc (Zn). The main motivation of the biodegradable implants’ development is their ability to gradually degrade in physiological environments. The corrosion products of these materials are expected to elicit an appropriate host response, enabling their metabolism or assimilation by cells and tissues. Once the implant has fulfilled its therapeutic role in tissue regeneration, it is fully resorbed without leaving any residual material in the body [2,3].

In contrast to conventional corrosion-resistant alloys—such as stainless steels and Ni-, Ti-, Co-, and Cr-based alloys—which are commonly used in permanent implants for osteosynthesis, osteotomy, or the treatment of coronary artery stenosis [4,5,6], biodegradable alloys offer excellent biocompatibility without symptoms of local or systemic toxicity. Furthermore, they possess mechanical properties close to those of bone tissue and naturally resorb after fulfilling their therapeutic function, thus eliminating the need for secondary surgical explantation [1,3,7,8,9].

Zn-based alloys are increasingly being recognised as promising bioactive materials for the development of bioresorbable implants. Zinc, an essential trace element, plays a key role in various biological processes in the human body. Approximately 85% of total body Zn is found in bones and muscles, 11% in the skin and liver, and the remaining fraction in vital organs such as the brain, kidneys, and pancreas [10,11,12]. Its biodegradable character and excellent biocompatibility have been confirmed by several in vivo studies [9,13,14].

In addition to favourable biological properties, Zn-based alloys show potential to overcome several limitations associated with the more intensively studied Mg- and Fe-based biodegradable materials [15]. Although Mg alloys are attractive due to the fact that their Young’s modulus (41–45 GPa) is close to that of natural bone [3], the biocompatibility of Mg2+ ions [16], and their ability to stimulate bone regeneration [17], their primary drawback is an excessively high degradation rate. This leads to intense hydrogen evolution and local alkalisation, potentially triggering inflammatory responses, implant destabilisation, and premature failure [1,18]. On the other hand, Fe and its alloys are popular among biomaterials researchers due to their high mechanical strength and the absence of hydrogen evolution during degradation. However, their extremely slow degradation rate and the accumulation of corrosion products that are difficult to eliminate limit their clinical applicability [3,19,20]. Additionally, their magnetic properties may interfere with magnetic resonance imaging, thereby reducing diagnostic quality post-implantation [21].

In this context, Zn alloys represent a balanced alternative. Their corrosion potential (−0.76 V) lies between that of Fe (−0.44 V) and Mg (−2.37 V) [1], ensuring an optimal degradation rate. Hydrogen is not released during Zn degradation, and the Zn2+ ions are naturally integrated into metabolic pathways without toxic effects [22,23]. An in vivo experiment by Yang et al. [14] demonstrated that a zinc stent implanted into a rabbit aorta retained mechanical integrity for the first 6 months and degraded by approximately 40% of its volume after 12 months, without signs of inflammation or thrombosis, indicating excellent biological tolerance.

On the other hand, the mechanical properties of pure as-cast Zn (ultimate tensile strength (UTS) ≈ 30 MPa, yield strength (YS) ≈ 27 MPa, elongation (A) < 1%) [24] fall significantly short of the minimum requirements for orthopaedic implant materials, where mechanical thresholds are typically set at YS > 230 MPa, UTS > 300 MPa, and elongation (A) > 15% [25]. One effective strategy to enhance the mechanical performance of pure Zn is alloying with biocompatible and non-toxic elements such as Mg, Cu, Ca, Sr, Li, Ag, or Mn. Among these, Mg and Li provide the most pronounced strengthening effect [24,25,26]. Even microalloying Zn with just 0.1 wt.% Mg increases its strength to ~80 MPa; however, elongation remains limited to approximately 1% [24]. Zn–Mg alloys are among the most extensively investigated biodegradable systems, with their biological safety repeatedly confirmed by cytotoxicity and genotoxicity studies [27,28]. The presence of Mg in the alloy contributes to regulating Zn2+ ion release and maintaining its concentration within a physiologically safe range. Therefore, Zn–Mg alloys exhibit lower cytotoxicity and reduced inflammatory responses compared to pure Zn.

To significantly improve the mechanical properties of Zn–Mg alloys, thermomechanical processing techniques based on plastic deformation have proven effective. For example, cold rolling of Zn–0.6Mg (wt.%) alloy with a 75% thickness reduction increased its tensile strength to ~380 MPa while maintaining sufficient ductility (~26%) [29]. Particular research attention has been directed toward the application of Equal Channel Angular Pressing (ECAP), which enables intense grain refinement through severe plastic deformation without altering the macroscopic geometry of the sample [30]. Several studies have demonstrated the high efficiency of ECAP in enhancing the strength while retaining good ductility in microalloyed Zn–Mg alloys [31,32,33]. Despite these promising outcomes, the synergistic effect of ECAP processing on the microstructural and mechanical evolution of Zn alloys—in contrast to the extensively studied Mg systems—remains insufficiently explored. Therefore, comprehensive research into the deformation processing of Zn–Mg alloys is necessary to deepen our understanding of their deformation mechanisms and to optimise processing parameters for biomedical applications [32].

The objective of the present study is to analyse the effect of ECAP processing of cold-deformed, as-cast microalloyed Zn–0.1Mg alloy on its microstructure and mechanical properties, and to assess the potential of this technique for optimising material characteristics of bioresorbable metallic implants.

2. Results

2.1. Microstructural Analysis of Zn–0.1Mg Alloy in As-Cast and Equal Channel Angular Pressing (ECAP)-Processed States

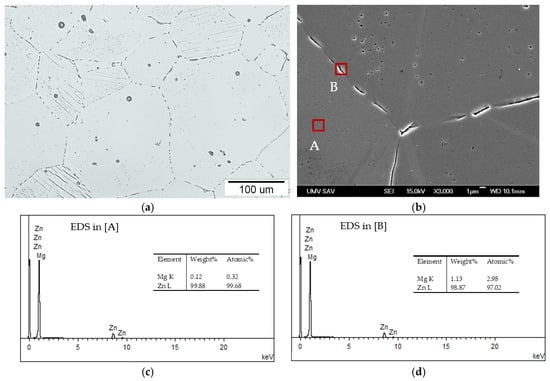

The microstructure of the as-cast Zn–0.1Mg alloy (Figure 1a) exhibits a polyhedric morphology consisting of coarse equiaxed grains of solid solution. Intermetallic secondary phase particles are located at the grain boundaries. Additionally, spherically shaped pores of varying sizes, uniformly distributed throughout the entire volume of the casting ingots, are present within this structure. Such pore morphology and distribution are characteristic of gravity-cast alloys. The average grain size of the solid solution, determined according to the STN EN ISO 643 standard [34], is 123 ± 18.8 µm.

Figure 1.

Microstructure of the as-cast Zn–0.1Mg alloy: (a) light microscopy (LM); (b) SEM microstructural analysis (region A representing the primary phase, and region B the secondary phase); (c) EDS analysis of the primary phase; (d) EDS analysis of the secondary phase.

Scanning Electron Microscope (SEM) analysis provided detailed insight into the morphology and distribution of the secondary phase (Figure 1b). This secondary phase predominantly precipitated at the grain boundaries in the form of elongated segmented structures. Semi-quantitative Energy-Dispersive X-ray Spectroscopy (EDS) analysis (Figure 1c) confirmed that solid solution grains near the grain boundaries contained slightly higher Mg content (0.12 wt.%) compared to the average Mg content of the alloy. The secondary particles at the grain boundaries contained significantly higher Mg content (1.13 wt.%) (Figure 1d). This observation aligns with the Zn–Mg binary phase diagram, indicating the low solubility of Mg in Zn at room temperature and the formation of the intermetallic Mg2Zn11 phase upon cooling at grain boundaries [13,35].

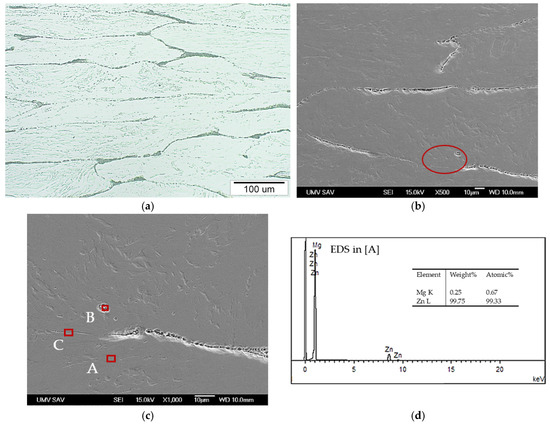

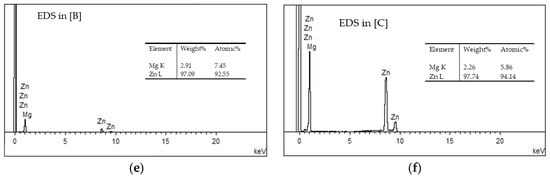

Severe deformation of the as-cast Zn–0.1Mg alloy through two passes of Equal Channel Angular Pressing (ECAP) altered the microstructural morphology significantly. The longitudinal cross-section of the deformed sample showed elongation of polyhedric grains along the longitudinal axis of the sample (Figure 2a,b). Parallel deformation bands, etched and oriented in the slip direction induced by ECAP processing, were observed within the grains. Intermetallic phase particles were primarily located at the original grain boundaries (Figure 2c—point C), though occasionally found inside the grains at interfaces between deformation bands (Figure 2c—point B). The chemical composition of these deformation bands, analysed by EDS, corresponded to a slightly supersaturated solid solution of Mg in Zn (0.25 wt.% Mg—Figure 2d). Globular particles with elevated Mg content (6.26 wt.% Mg—Figure 2e) were sporadically observed. According to EDS analysis, elongated narrow intermetallic phase structures at the former grain boundaries also had higher Mg content (0.62 wt.% Mg—Figure 2f).

Figure 2.

Microstructure of the Zn–0.1Mg alloy after ECAP processing: (a) LM micrograph; (b) SEM micrograph (the area marked with a red circle indicates the region selected for detailed SEM observation); (c) detailed SEM view; (d–f) EDS analysis in regions [A], [B], and [C], respectively.

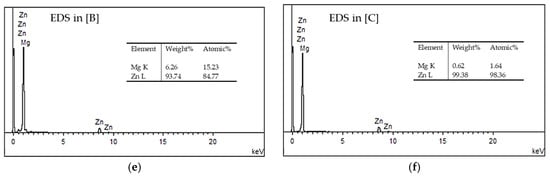

Detailed SEM analysis of the Zn–0.1Mg alloy microstructure after ECAP processing (Figure 3) revealed etched grain boundaries indicative of dynamically recrystallised ultrafine grains of the α-Zn solid solution within the deformation bands, exhibiting the highest degree of plastic deformation. These grains predominantly displayed equiaxed morphology, with slight elongation in the deformation direction and an average grain size around 1.5 µm.

Figure 3.

SEM micrograph of Zn–0.1Mg alloy after ECAP processing.

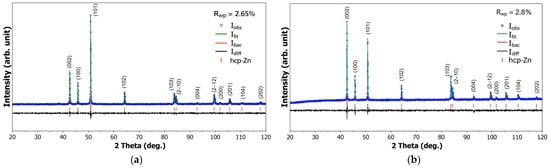

Additional phase and structural analysis of the Zn–0.1Mg alloy states was performed using X-ray diffraction (XRD). Diffraction patterns of both as-cast and ECAP-processed Zn–0.1Mg alloys (represented by blue symbols in Figure 4) revealed only Bragg peaks corresponding to the hexagonal hcp-Zn phase with the space group P63/mmc (194). No diffraction peaks corresponding to Mg-rich intermetallic phases were detected, reflecting their low volume fraction, likely below the detection limit of XRD analysis. Results of microstructural refinement of the Zn phase using Rietveld analysis are graphically presented in Figure 4a,b by the solid green line, and refined microstructural parameters are summarised in Table 1.

Figure 4.

The XRD patterns and Rietveld fit of: (a) the as-cast Zn–0.1Mg alloy sample; (b) the ECAPed Zn–0.1Mg alloy state.

Table 1.

Microstructural parameters of the hcp-Zn phase refined by Rietveld analysis of the diffraction profile fitting. Lattice parameters (a, c), isotropic displacement parameter (Uiso), microstrain (ε), and texture index.

The lattice parameters of the hcp-Zn phase are identical for both samples and closely match the reference values for pure Zn (PDF card no. 00-004-0831, a = 2.665 Å, c = 4.947 Å). The most significant difference was observed in the texture index calculated using the spherical harmonics model. The texture index numerically characterizes the degree of preferred crystallite orientation in the material based on the Orientation Distribution Function (ODF). For an ideally random (isotropic) texture, the texture index equals 1, while higher values indicate stronger preferred crystallite orientation.

2.2. Mechanical Properties of the Zn–0.1Mg Alloys

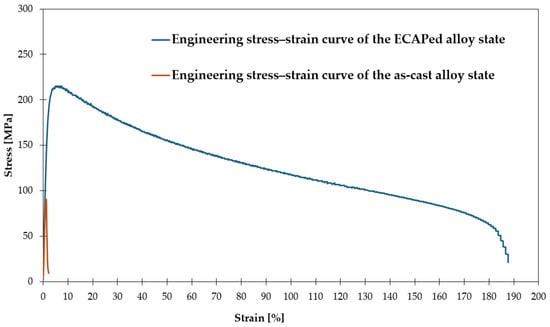

The mechanical properties of the Zn–0.1Mg alloy in both as-cast and ECAP-processed states were evaluated through tensile testing at room temperature, resulting in the stress–strain curve depicted in Figure 5. The basic mechanical characteristics, including strength and ductility, are summarised in Table 2. The as-cast alloy demonstrated relatively low strength, with yield strength (YS) of 83 MPa and ultimate tensile strength (UTS) of 91 MPa, accompanied by extremely low tensile ductility (elongation measured on a gauge length L0 = 2d, where d is the original specimen diameter) (A2 = 2.2%) and reduction in area (Z = 0.2%).

Figure 5.

Stress–strain curves of the analysed Zn–0.1Mg alloy state.

Table 2.

Mechanical properties of the analysed Zn–0.1Mg alloy state.

Severe plastic deformation of the as-cast Zn–0.1Mg alloy using ECAP significantly enhanced its mechanical properties. The most pronounced effect of intense plastic deformation via ECAP processing was reflected in an extreme increase in elongation (A2), reaching 187%, and a substantial improvement in reduction in area (Z) to 91%. Concurrently, the yield strength (YS) increased significantly to 198 MPa, and the ultimate tensile strength (UTS) reached 215 MPa. Furthermore, the conversion of tensile test results from the engineering stress–strain curve into the true stress–strain curve showed that the true ultimate tensile strength (true UTS) after ECAP processing reached up to 340 MPa.

2.3. Fractographic Analysis of the Zn–0.1Mg Alloys

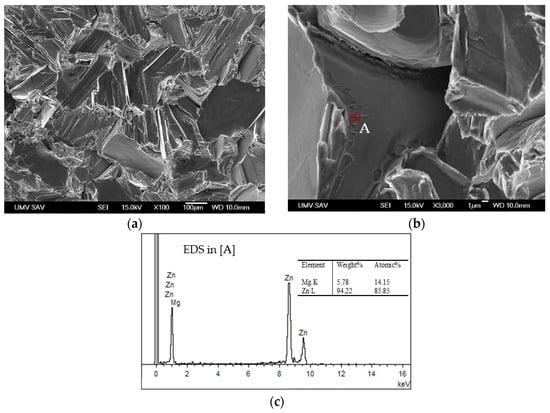

Fractographic analysis of the fracture surfaces of the as-cast Zn–0.1Mg alloy sample tested under tensile loading reflects the low ductility characteristics of this material state. The fracture surface, resulting from brittle fracture propagation across the grains of the solid solution, predominantly consists of transcrystalline cleavage facets oriented in various directions (Figure 6a). Intergranular areas formed by brittle separation along solid solution grain boundaries were also observed, exhibiting distinct intermetallic phase particles (Figure 6b). EDS analysis revealed elevated magnesium content (5.78 wt.% Mg—Figure 6c) in these particles, suggesting they are the same intermetallic phases identified at grain boundaries within the alloy microstructure (Figure 1).

Figure 6.

SEM micrographs of fracture surfaces of the as-cast Zn–0.1Mg alloy: (a) overview of the fracture surface; (b) detailed view of the selected area; (c) EDS analysis in area [A].

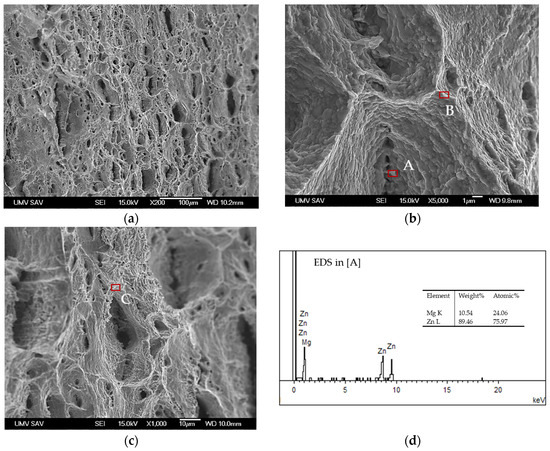

The fracture surface morphology of the ECAP-processed Zn–0.1Mg alloy sample post-tensile testing exhibits exclusively ductile fracture characteristics (Figure 7a). The fracture surface is notably irregular, featuring large, elongated dimples aligned with larger particles along the original grain boundaries and very fine dimples resulting from transcrystalline ductile fracture through highly deformed solid solution grains. This fracture morphology corresponds with the significantly enhanced ductility and reduction in area observed during tensile testing. Coarser intermetallic phase particles arranged in rows were noted within the larger elongated dimples (Figure 7b). EDS analysis confirmed a high Mg content in these particles (10.54 wt.% Mg—Figure 7d), validating that they correspond to particles observed in the ECAP-processed microstructure along elongated grain boundaries. Elevated Mg concentrations (2.91 wt.% Mg—Figure 7e) were also detected at the ridges of larger dimples. Fine intermetallic phase particles were identified within the smaller dimples resulting from transcrystalline fracture (Figure 7c). These fine particles, formed within originally cast grains, also showed elevated Mg content (2.91 wt.% Mg—Figure 7f), likely corresponding to Mg2Zn11 intermetallic phases.

Figure 7.

SEM micrographs of fracture surfaces of the Zn–0.1Mg alloy after ECAP processing: (a) overview of fracture surface; (b,c) detailed views of selected areas; (d–f) EDS analysis in areas [A], [B], and [C], respectively.

3. Discussion

The initial state of the analysed bioresorbable Zn–0.1Mg alloy consists of crystallised castings exhibiting a typical casting microstructure characterised by coarse-grained polyhedric morphology (Figure 1). The primary phase in the microstructure consists of polyhedric equiaxed α-Zn solid solution grains with an average size of approximately 123 µm, formed during alloy solidification and cooling. Upon cooling from the crystallisation temperature, a secondary intermetallic Mg-rich phase precipitated at the grain boundaries in segmented forms due to the decreasing solubility of Mg in Zn as temperature decreased, as described by the Zn–Mg phase diagram. These intermetallic particles represent a hard yet brittle component of the alloy’s microstructure [13]. The EDS analysis confirmed increased Mg content within these particles (Figure 1d). However, their precise stoichiometric composition was not conclusively determined. X-ray diffraction (XRD) analysis (Figure 4) identified only the α-Zn phase with an HCP lattice structure in the as-cast alloy. The volume fraction of the intermetallic phase is presumably below the detection limit of diffraction analysis. Nevertheless, based on the Zn–Mg phase diagram [13,35] and literature data [36,37,38,39], the observed secondary particles can be presumed to be the Mg2Zn11 intermetallic phase, frequently reported as dominant in Zn–Mg alloys with magnesium content at or above 0.1 wt.%. In alloys with higher Mg content (>0.1 wt.%), metastable MgZn2 phase particles can also form due to localised Mg enrichment during solidification, consistent with the Zn–Mg phase diagram [13,39]. Porosity resulting from gas entrapment during gravitational casting is also a characteristic feature of the as-cast microstructure.

Indications of deformation twinning were observed in some primary α-Zn solid solution grains (Figure 2a), resulting from internal stresses generated during alloy solidification and cooling. Twinning is a dominant plastic deformation mechanism in metals with hexagonal close-packed (HCP) lattices, such as Zn and Mg [40,41]. This phenomenon arises from the limited number of active slip systems (basal and prismatic), insufficient to satisfy von Mises’ criterion for plastic compatibility, requiring activation of at least five independent slip systems. Consequently, energetically more demanding pyramidal slip systems of type <c + a> must be activated [36,41]. For Zn and its alloys, the high lattice parameter ratio c/a (~1.856), exceeding the ideal value of 1.633, significantly increases the critical shear stress necessary for activating non-basal slip planes, thus favouring twinning, especially in coarse-grained microstructures and under cold deformation conditions [40,41].

The as-cast Zn–0.1Mg alloy structure was not macroscopically significantly altered by two ECAP passes (route A) at room temperature (Figure 2a,b). Polyhedric cast grains were elongated in the direction of extrusion axis during ECAP, with intermetallic phase particles remaining at grain boundaries. Intense plastic deformation resulted in the formation of deformation bands in the α-Zn grains oriented in the direction of shear within the ECAP die, and eliminated porosity (Figure 1a). Redistribution of Mg-rich intermetallic phase particles occurred, observed both at original grain boundaries and within the grain interiors (Figure 2c), attributed to intense shear deformation within the ECAP die. XRD analysis confirmed identical phase compositions of Zn–0.1Mg alloy in both as-cast and ECAP-processed states. No intermetallic phases were detected through diffraction analysis. However, significant textural development with a texture index of 1.939 was confirmed by XRD, indicating preferred crystallographic orientation of grains/subgrains after ECAP, consistent with literature findings [29,31,42].

Detailed SEM analysis revealed ultrafine dynamically recrystallised grains/subgrains of solid solution smaller than 1.5 µm in deformation bands (Figure 3). This microstructural refinement is attributed to dynamic recrystallisation induced by severe plastic deformation. Room temperature recrystallisation was facilitated by high deformation intensity and extremely low recrystallisation temperatures (~−12 °C) of Zn–Mg alloys [40]. Mg-rich intermetallic particles, such as Mg2Zn11, significantly aided grain nucleation during dynamic recrystallisation by acting as effective nucleation sites due to localised stress concentrations [24]. In contrast to the as-cast condition, ECAP processing eliminated signs of twinning (Figure 2a), due to grain refinement, shifting the dominant deformation mechanism to the dislocation slip [40].

Mg-rich intermetallic particles, presumably the Mg2Zn11 phase, play a significant role in the nucleation of new grains due to local stress concentration fields, acting as effective nucleation centres for dynamically recrystallised grains. Thus, they substantially enhance dynamic recrystallisation and accelerate microstructural refinement [24]. After ECAP processing, no signs of twinning were observed (Figure 2a), in contrast to the as-cast state, where twinning was present. This phenomenon is related to significant grain refinement, which suppresses twinning and transitions the deformation mechanism to the dominant dislocation slip [40]. The critical stress required for twinning activation increases significantly faster with decreasing grain size than the stress required for slip activation. According to the available literature [40,41,43,44,45], refining the microstructure of hexagonal close-packed (HCP) materials below a critical grain size (typically in the range of 1–10 μm) entirely suppresses twinning as a deformation mechanism. Consequently, dislocation slip mechanisms dominate, fundamentally affecting the plastic deformation behaviour. Li et al. [43], for example, demonstrated that reducing the grain size below 2.7 μm during ECAP processing of pure Mg not only suppresses twinning, but also results in reverse Hall–Petch behaviour characterised by reduced strength properties. Similar results were observed in Zn–Mn alloys, where grain size reduction from 4 μm to 2 μm led to a decrease in the volume fraction of twins from 14.2% to 2.3% [45]. Additionally, intermetallic particles present in the microstructure contribute to twinning suppression by acting as barriers to twin propagation [24]. When dislocation migration across grain boundaries and transcrystalline plastic deformation is significantly limited due to the absence of equivalent slip planes in adjacent grains, macroscopic deformation must proceed through alternative mechanisms. Under these conditions, grain boundary sliding (GBS) becomes the dominant mechanism ensuring continued plastic deformation [40].

The observed significant submicroscopic structural differences markedly influenced the mechanical behaviour of the Zn–0.1Mg alloy in the as-cast and ECAP-processed states. The coarse-grained microstructure of the as-cast state with twinning predisposed it to brittle fracture. In brittle HCP materials with only one active twinning mechanism, interaction between twins generates local stress concentrations, acting as initiators of microcracks and promoting further twinning, cyclically reducing material toughness [24,43]. This assumption was confirmed by tensile testing of the as-cast Zn–0.1Mg alloy, revealing relatively low yield strength (YS) of 83 MPa, low ultimate tensile strength (UTS) of 91 MPa, and extremely low elongation (A2) of 2.2% (Table 2, Figure 5). The reduction in area (Z) during tensile testing reached only 0.2%, indicating minimal plastic deformation before fracture. Fractographic analysis of fracture surfaces in the as-cast state (Figure 6) demonstrated dominant transcrystalline cleavage facets and intercrystalline separation, fundamental signs of brittle fracture. Sharp and uneven edges of cleavage facets indicate local slip and grain rotation before fracture, consistent with minimal elongation and confirming macroscopic brittleness. Similar low mechanical properties of as-cast Zn–Mg alloys were reported by other studies [13,16,24,46], where UTS typically did not exceed 150 MPa, YS was below 110 MPa, and elongation was less than 2% for alloys containing Mg ≤ 1 wt.%.

Microstructural refinement induced by intense cold plastic deformation of the as-cast alloy significantly improved mechanical properties. The ECAP-processed Zn–0.1Mg alloy achieved YS of 198 MPa, UTS of 215 MPa, elongation (A2) of 187%, and reduction in area (Z) of 91% (Table 2, Figure 5). Additionally, true ultimate tensile strength (true UTS) reached 340 MPa, significantly exceeding requirements for orthopaedic implant materials (YS > 230 MPa, UTS > 300 MPa, elongation (A) > 15%) [25]. Sufficient ductility of the ECAP-processed state allows for further improvement in mechanical properties through additional cold deformation methods, such as rolling. The obtained results notably surpass previously published data for Zn–Mg alloys processed through various technologies, including ECAP. Exceptional mechanical properties, particularly the remarkably high elongation (187%), significantly exceed literature-reported values for similarly processed Zn–Mg alloys (Table 3) [31,37,42,47,48].

Table 3.

Comparison of mechanical properties of the Zn–Mg alloys.

The fracture surface morphology of tensile-tested samples significantly changed following ECAP processing (Figure 7), correlating with improved mechanical properties of the analysed microalloyed Zn–Mg alloy. The presence of transcrystalline ductile fracture with dimples of various sizes and significant contraction clearly indicates considerable deformation energy absorption prior to fracture.

The significant enhancement in strength and ductility properties of the Zn–0.1Mg alloy following ECAP processing can be attributed to the synergistic effect of several microstructural factors. Key roles are played by grain refinement, elimination of porosity, and increased grain boundary sliding activity. The formation of a fine-grained microstructure primarily results in material strengthening, significantly influencing mechanical properties. According to the Hall–Petch relationship, yield strength increases with decreasing grain size due to the increased grain boundary area, effectively acting as barriers for dislocation movement. To verify the applicability of the Hall–Petch relationship in our case, we calculated the 0.2% strain offset yield strength (YS0.2) for both the as-cast and ECAP-processed alloy states. The calculation was based on the empirical relation stated for Zn material with an average grain size (dz) in the range from 0.6 to 400 μm [49]:

YS0.2 = 40.8 + 104.8 dz−0.5

The results demonstrated that the ECAP-processed alloy state exhibits a significantly higher calculated yield strength of 126.36 MPa, while the as-cast alloy state achieved a value of 50.25 MPa. The higher yield strength calculated for the ECAP-processed alloy, characterised by a grain-refined microstructure, supports the Hall–Petch relationship, suggesting that grain refinement enhances dislocation interactions with grain boundaries and thus improves resistance to plastic deformation. This strengthening mechanism markedly improves strength and is essential in increasing mechanical resilience of metals subjected to severe plastic deformation [38,40]. Additionally, the resultant fine-grained microstructure effectively suppresses twinning activation, often associated with microcracking during tensile loading. For instance, reduced twinning fraction from 14.2% to 2.3% in Zn–Mn alloys correlated with significant elongation improvement from 48% to 71% [45]. Moreover, grain boundaries enriched with finely dispersed secondary intermetallic phases significantly redistribute local stresses, reducing brittle fracture likelihood. These phases actively participate in coordinated deformation via grain boundary sliding, substantially increasing overall material ductility [29]. Increased activation of slip systems due to stress concentrations at grain boundaries leads to uniform plastic deformation, and grain boundary rotation facilitates continuous deformation without localised stress concentrations [31]. Additionally, dislocation movement along grain boundaries enhances toughness and, in some cases, enables superplastic behaviour, exemplified by extruded Zn–0.5Mn alloy achieving extraordinary tensile elongation of 236% with grain sizes around 0.35 μm [50].

4. Materials and Methods

The Zn–0.1Mg (wt.%) alloy was prepared by melting high-purity metals (Zn with a purity of 99.95% and Mg with a purity of 99.99%) in a Schmelzofen Goldbrunn 1000 electric resistance furnace (Goldbrunn Therm, Berlin, Germany) at a temperature of 730 °C. The molten alloy was mixed thoroughly for 10 min in a protective argon (Ar) atmosphere before being gravity-cast into graphite crucibles that had been preheated to 300 °C. After casting, the ingots were air-cooled naturally while still in the graphite crucibles. The resulting ingots had a cylindrical shape with a diameter of 20 mm and a length of 80 mm.

The chemical composition of the prepared as-cast alloy was analysed using spark optical emission spectrometry (OES) in accordance with the STN EN 12019 standard [51]. The analysis revealed that the Mg content in the alloy was 0.083 ± 0.017 wt.%. Additionally, trace concentrations of impurities were detected, with a total content not exceeding 0.013 wt.%, consisting of 0.006 wt.% Sn and 0.007 wt.% Cu.

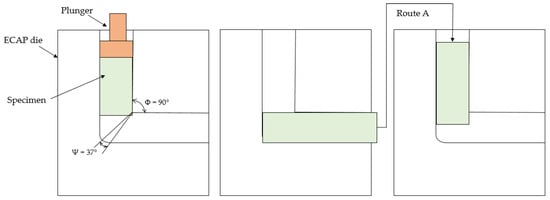

The as-cast Zn–0.1Mg alloy cylindrical samples were then machined to dimensions of ø 8 mm × 60 mm for processing by severe plastic deformation using the ECAP technique. These as-cast alloy samples were pressed twice through an ECAP die (die parameters: Φ = 90°, Ψ = 37°) at room temperature without rotation between passes, i.e., following route A (Figure 8), according to the standard classification outlined in the literature [52].

Figure 8.

Two-dimensional scheme of the alloy sample ECAP processing following route A.

The microstructure of the as-cast and ECAP-processed samples of the Zn–0.1Mg alloy was analysed in the longitudinal direction, i.e., along the axis of the ingots and the ECAP-processed cylindrical specimens (Figure 8) by an OLYMPUS Vanox-T light microscope (Olympus, Tokyo, Japan) and a JEOL JSM 7000F scanning electron microscope (SEM) (JEOL, Tokyo, Japan). Samples for microstructural analysis were prepared using standard cold-mounting techniques, followed by grinding with waterproof abrasive papers and polishing with diamond paste of 0.7 μm grit size. Final polishing was completed using a colloidal silica suspension. The microstructure was subsequently revealed by chemical etching in a 5% Nital solution. The microstructural analysis focused on the morphology and size of the solid solution features as well as the distribution of secondary phases. For a more detailed microstructural examination, energy-dispersive X-ray spectroscopy (EDS) was used to perform a semi-quantitative chemical composition analysis of the phases present. Phase analysis of the Zn–0.1Mg alloy in both the as-cast and ECAP-processed states was conducted using X-ray diffraction (XRD). X-ray diffraction measurements were performed using the Philips X’Pert Pro powder diffractometer (Malvern Panalytical, Almelo, The Netherlands) equipped with a Co X-ray tube within the 2θ range of 20° to 120°, with a step size of 0.03° and a dwell time of 10 s per step. Rietveld analysis of the measured diffractograms was performed using the software package GSAS-II (version 5.4.2) [53].

The mechanical properties of the studied alloy, in both the as-cast and ECAP-processed states, were evaluated by uniaxial tensile testing realised at room temperature using a Tinius Olsen H300K-V universal testing machine (Tinius Olsen, Horsham, PA, USA). The tensile tests were conducted according to Method A of the STN EN ISO 6892-1 standard [54], at a strain rate of 2.5 × 10−4 s−1. The tensile tests were performed on cylindrical samples with threaded heads, featuring a gauge diameter of 5 mm and a gauge length of 10 mm. The evaluated mechanical properties included yield strength (YS), ultimate tensile strength (UTS), and ductility parameters: elongation (A2) and reduction in area (Z). The tensile strength of ECAP-processed alloy state was assessed not only by the conventional engineering approach based on the initial cross-sectional area of the specimen, but also as true value reflecting the actual deformation state and the real cross-sectional reduction during tensile testing. This comprehensive method enables a more accurate evaluation of the material’s deformation behaviour under tensile loading. Following tensile testing, the morphology of the fracture surfaces was examined by fractography analysis using a JEOL JSM 7000F SEM scanning electron microscope, with EDS analysis performed to characterise the phases present on the fracture surfaces.

5. Conclusions

Zn–Mg alloys have high potential for use in biodegradable implants. Their chemical composition and processing methods significantly influence properties such as biocompatibility, degradation rate, and particularly mechanical characteristics. The desired strength characteristics and sufficient ductility of these alloys can be achieved through various forming techniques, including severe plastic deformation methods. This study investigated the effect of Equal Channel Angular Pressing (ECAP), a severe plastic deformation technique, on the microstructure and mechanical properties of the as-cast Zn–0.1Mg alloy. The main conclusions from this study are summarised as follows:

- The as-cast Zn alloy with 0.1 wt.% Mg exhibited a polyhedric casting microstructure consisting of coarse (average grain size dz = 123 µm) equiaxed grains of Mg solid solution in Zn with an H12 lattice and segmented secondary intermetallic phase formations, such as Mg2Zn11, precipitated at the grain boundaries of the solid solution.

- Severe cold plastic deformation of the as-cast alloy, achieved by two passes through the ECAP die using route A, led to significant changes in the microstructure of the solid solution grains. Deformation by shear in the ECAP die channel formed deformation bands in the original cast grains, within which ultrafine dynamically recrystallised substructures of solid solution with an average grain size not exceeding 1.5 µm were observed. ECAP processing also resulted in the formation of texture with preferred crystallographic orientation of grains/subgrains.

- Significant refinement of the alloy’s solid solution substructure induced by severe plastic deformation substantially improved its mechanical properties determined by tensile testing. The ECAP-processed Zn–0.1Mg alloy achieved a yield strength of 198 MPa and an ultimate tensile strength of 215 MPa, more than twice the values observed in the as-cast alloy. However, the most dramatic improvement was observed in ductility parameters. The ECAP-processed alloy reached elongation up to 187% and reduction in area up to 91%. Additionally, true ultimate tensile strength reached as high as 340 MPa. Sufficient ductility of the deformed alloy state allows for further strength enhancement through additional cold forming techniques, such as rolling, after ECAP processing.

- Significant improvement in ductility induced by ECAP also altered the fracture mechanism observed during tensile testing. Brittle fracture in the as-cast Zn–0.1Mg alloy, characterised by transcrystalline cleavage and intercrystalline separation, transformed into ductile transcrystalline fracture in the ECAP-processed alloy, evidenced by dimples of varying sizes on the fracture surface and high reduction in area. This indicates that the severely deformed alloy absorbed considerable deformation energy before fracture.

- Microstructural refinement in materials with a hexagonal close-packed (HCP) lattice below a critical grain size (typically in the range of 1–10 μm) completely suppresses twinning as a deformation mechanism. Consequently, alternative deformation mechanisms begin to dominate, fundamentally changing plastic deformation behaviour. Formation of an ultrafine-grained microstructure primarily strengthens the material, and significantly enhances ductility, as the refined microstructure provides an increased number of active slip systems and enables coordinated plastic deformation through grain boundary sliding of the solid solution grains.

Author Contributions

Conceptualization, I.C., M.F. and K.S.; methodology, I.C., M.F., Z.M., M.M., R.D., B.B., D.C., K.G. and K.S.; software, K.S., R.K. and P.P.; validation, I.C., K.S., R.K. and P.P.; formal analysis, I.C., M.F., R.K., P.P., Z.M., M.M., R.D., B.B., D.C., K.G. and K.S.; investigation, I.C., M.F., R.K., P.P., Z.M., M.M., R.D., B.B., D.C. and K.S.; resources, Z.M. and B.B.; data curation, I.C.; writing—original draft preparation, I.C.; writing—review and editing, I.C., M.F. and K.S.; visualization, I.C., M.F., K.G. and K.S.; supervision, M.F. and K.S.; project administration, K.G.; funding acquisition, K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under Contract No. APVV-23-0030, APVV-20-0205, VEGA project No. 1/0122/25, VEGA project No. 2/0039/23 and KEGA project No. 011TUKE-4/2025. This research was funded in part by the international project M-ERA.NET 3/2022/235/H2MobilHydride.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ECAP | Equal Channel Angular Pressing |

| YS | Yield Strength |

| UTS | Ultimate Tensile Strength |

| True UTS | True Ultimate Tensile Strength |

| A | Elongation |

| A2 | Elongation measured on a gauge length L0 = 2d (d—specimen diameter) |

| Z | Reduction in Area |

| SEM | Scanning Electron Microscopy |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| XRD | X-ray Diffraction |

| LM | Light Microscopy |

| ODF | Orientation Distribution Function |

| HCP | Hexagonal Close-Packed |

| GBS | Grain Boundary Sliding |

| OES | Optical Emission Spectrometry |

References

- Zheng, Y.F.; Gu, X.N.; Witte, F. Biodegradable metals. Mater. Sci. Eng. R Rep. 2014, 77, 1–34. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, Y.; Chen, X.H.; Yang, J.A.; Pan, H.; Chen, D.; Wang, L.; Zhang, J.; Zhu, D.; Wu, S.; et al. Fundamental theory of biodegradable metals—Definition, criteria, and design. Adv. Funct. Mater. 2019, 29, 1805402. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Z.; Smith, C.; Sankar, J. Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater. 2014, 10, 4561–4573. [Google Scholar] [CrossRef]

- Moravej, M.; Mantovani, D. Biodegradable metals for cardiovascular stent application: Interests and new opportunities. Int. J. Mol. Sci. 2011, 12, 4250–4270. [Google Scholar] [CrossRef]

- Xu, L.; Wei, C.; Deng, L.; Wang, P.; Zhong, W.; Huang, W. A review of non-biodegradable alloys implantation induced inflammatory and immune cell responses. J. Alloys Compd. 2024, 977, 173086. [Google Scholar] [CrossRef]

- Ormiston, J.A.; Serruys, P.W.S. Bioabsorbable coronary stents. Circ. Cardiovasc. Interv. 2009, 2, 255–260. [Google Scholar] [CrossRef]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Witte, F. The history of biodegradable magnesium implants: A review. Acta Biomater. 2010, 6, 1680–1692. [Google Scholar] [CrossRef]

- Bowen, P.K.; Drelich, J.; Goldman, J. Zinc exhibits ideal physiological corrosion behavior for bioabsorbable stents. Adv. Mater. 2013, 25, 2577–2582. [Google Scholar] [CrossRef]

- Li, H.; Yang, H.; Zheng, Y.; Zhou, F.; Qiu, K.; Wang, X. Design and characterizations of novel biodegradable ternary Zn-based alloys with IIA nutrient alloying elements Mg, Ca and Sr. Mater. Des. 2015, 83, 95–102. [Google Scholar] [CrossRef]

- Plum, L.M.; Rink, L.; Haase, H. The essential toxin: Impact of zinc on human health. Int. J. Environ. Res. Public Health 2010, 7, 1342–1365. [Google Scholar] [CrossRef]

- Kambe, T.; Tsuji, T.; Hashimoto, A.; Itsumura, N. The physiological, biochemical, and molecular roles of zinc transporters in zinc homeostasis and metabolism. Physiol. Rev. 2015, 95, 749–784. [Google Scholar] [CrossRef]

- Vojtech, D.; Kubásek, J.; Šerák, J.; Novák, P. Mechanical and corrosion properties of newly developed biodegradable Zn-based alloys for bone fixation. Acta Biomater. 2011, 7, 3515–3522. [Google Scholar] [CrossRef]

- Yang, H.T.; Wang, C.; Liu, C.Q.; Chen, H.W.; Wu, Y.F.; Han, J.T.; Jia, Z.C.; Lin, W.J.; Zhang, D.Y.; Li, W.T.; et al. Evolution of the degradation mechanism of pure zinc stent in the one-year study of rabbit abdominal aorta model. Biomaterials 2017, 145, 92–105. [Google Scholar] [CrossRef]

- Li, G.; Yang, H.; Zheng, Y.; Chen, X.H.; Yang, J.A.; Zhu, D.; Ruan, L.; Takashima, K. Challenges in the use of zinc and its alloys as biodegradable metals: Perspective from biomechanical compatibility. Acta Biomater. 2019, 97, 23–45. [Google Scholar] [CrossRef]

- Shen, C.; Liu, X.; Fan, B.; Lan, P.; Zhou, F.; Li, X.; Wang, H.; Xiao, X.; Li, L.; Zhao, S.; et al. Mechanical properties, in vitro degradation behavior, hemocompatibility and cytotoxicity evaluation of Zn–1.2Mg alloy for biodegradable implants. RSC Adv. 2016, 6, 86410–86419. [Google Scholar] [CrossRef]

- Seitz, J.-M.; Lucas, A.; Kirschner, M. Magnesium-based compression screws: A novelty in the clinical use of implants. JOM 2016, 68, 1177–1182. [Google Scholar] [CrossRef]

- Tong, X.; Dong, Y.; Han, Y.; Zhou, R.; Zhu, L.; Zhang, D.; Dai, Y.; Shen, X.; Li, Y.; Wen, C.; et al. A biodegradable Zn–5Gd alloy with biomechanical compatibility, cytocompatibility, antibacterial ability, and in vitro and in vivo osteogenesis for orthopedic applications. Acta Biomater. 2024, 177, 538–559. [Google Scholar] [CrossRef]

- Guo, H.; Cao, R.H.; Zheng, Y.F.; Bai, J.; Xue, F.; Chu, C.L. Diameter-dependent in vitro performance of biodegradable pure zinc wires for suture application. J. Mater. Sci. Technol. 2019, 35, 1662–1670. [Google Scholar] [CrossRef]

- Li, S.; Ren, J.; Wang, X.; Ding, Y.; Li, P.; Hu, Y.; Yang, Y. Dilemmas and countermeasures of Fe-based biomaterials for next-generation bone implants. J. Mater. Res. Technol. 2022, 20, 2034–2050. [Google Scholar] [CrossRef]

- Schinhammer, M.; Hänzi, A.C.; Löffler, J.F.; Uggowitzer, P.J. Design strategy for biodegradable Fe-based alloys for medical applications. Acta Biomater. 2010, 6, 1705–1713. [Google Scholar] [CrossRef]

- Bowen, P.K.; Shearier, E.R.; Zhao, S.; Guillory, R.J.; Zhao, F.; Goldman, J.; Drelich, J.W. Biodegradable metals for cardiovascular stents: From clinical concerns to recent Zn-Alloys. Adv. Healthc. Mater. 2016, 5, 1121–1140. [Google Scholar] [CrossRef]

- Liu, X.; Sun, J.; Qiu, K.; Yang, Y.; Pu, Z.; Li, L.; Zheng, Y. Effects of alloying elements (Ca and Sr) on microstructure, mechanical property and in vitro corrosion behavior of biodegradable Zn–1.5Mg alloy. J. Alloys Compd. 2016, 664, 444–452. [Google Scholar] [CrossRef]

- Liu, S.; Kent, D.; Doan, N.; Dargusch, M.; Wang, G. Effects of deformation twinning on the mechanical properties of biodegradable Zn-Mg alloys. Bioact. Mater. 2019, 4, 8–16. [Google Scholar] [CrossRef]

- Venezuela, J.; Dargusch, M.S. The influence of alloying and fabrication techniques on the mechanical properties, biodegradability and biocompatibility of zinc: A comprehensive review. Acta Biomater. 2019, 87, 1–40. [Google Scholar] [CrossRef]

- Li, Z.; Shi, Z.-Z.; Hao, Y.; Li, H.-F.; Zhang, H.-J.; Liu, X.-F.; Wang, L.-N. Insight into role and mechanism of Li on the key aspects of biodegradable ZnLi alloys: Microstructure evolution, mechanical properties, corrosion behavior and cytotoxicity. Mater. Sci. Eng. C 2020, 114, 111049. [Google Scholar] [CrossRef]

- Bao, G.; Fan, Q.; Ge, D.; Wang, K.; Sun, M.; Zhang, Z.; Guo, H.; Yang, H.; He, B.; Zheng, Y. In vitro and in vivo studies to evaluate the feasibility of Zn-0.1Li and Zn-0.8Mg application in the uterine cavity microenvironment compared to pure zinc. Acta Biomater. 2021, 123, 393–406. [Google Scholar] [CrossRef]

- Murni, N.S.; Dambatta, M.S.; Yeap, S.K.; Froemming, G.R.A.; Hermawan, H. Cytotoxicity evaluation of biodegradable Zn–3Mg alloy toward normal human osteoblast cells. Mater. Sci. Eng. C 2015, 49, 560–566. [Google Scholar] [CrossRef]

- Ji, C.; Ma, A.; Jiang, J.; Wu, H.; Liu, H.; Guo, S.; Yuan, Y. Regulating mechanical properties and degradation behavior of biodegradable Zn–0.6Mg alloy via ECAP plus cold rolling. J. Alloys Compd. 2023, 937, 168487. [Google Scholar] [CrossRef]

- Wang, C.; Ma, A.; Sun, J.; Liu, H.; Huang, H.; Yang, Z.; Jiang, J. Effect of ECAP process on as-cast and as-homogenized Mg–Al–Ca–Mn alloys with different Mg2Ca morphologies. J. Alloys Compd. 2019, 793, 259–270. [Google Scholar] [CrossRef]

- Ye, L.; Liu, H.; Sun, C.; Zhuo, X.; Ju, J.; Xue, F.; Bai, J.; Jiang, J.; Xin, Y. Achieving high strength, excellent ductility, and suitable biodegradability in a Zn–0.1Mg alloy using room temperature ECAP. J. Alloys Compd. 2022, 926, 166906. [Google Scholar] [CrossRef]

- Liu, H.; Huang, H.; Zhang, Y.; Xu, Y.; Wang, C.; Sun, J.; Jiang, J.; Ma, A.; Xue, F.; Bai, J. Evolution of Mg–Zn second phases during ECAP at different processing temperatures and its impact on mechanical properties of Zn–1.6Mg (wt.%) alloys. J. Alloys Compd. 2019, 811, 151987. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, H.; Ren, K.; Ye, L.; Zhuo, X.; Ju, J.; Xue, F.; Bai, J.; Jiang, J.; Xin, Y. A high strength and ductility Zn–Cu–Mg alloy achieved by bandlike distribution of ultra-fine CuZn5 and Mg2Zn11 particles. Mater. Sci. Eng. A 2022, 850, 143584. [Google Scholar] [CrossRef]

- STN EN ISO 643; Steels. Micrographic Determination of the Apparent Grain Size. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2024.

- Kubásek, J.; Vojtěch, D.; Pospíšilová, I.; Michalcová, A.; Maixner, J. Microstructure and mechanical properties of the micrograined hypoeutectic Zn–Mg alloy. Int. J. Miner. Metall. Mater. 2016, 23, 1167–1176. [Google Scholar] [CrossRef]

- Li, R.; Ding, Y.; Zhang, H. Toughness and strength coordination in a low-alloy Zn–0.5 Mg alloy via extrusion and post-deformation annealing. Met. Mater. Int. 2023, 29, 2807–2825. [Google Scholar] [CrossRef]

- Mostaed, E.; Sikora-Jasinska, M.; Mostaed, A.; Loffredo, S.; Demir, A.; Previtali, B.; Mantovani, D.; Beanland, R.; Vedani, M. Novel Zn-based alloys for biodegradable stent applications: Design, development and in vitro degradation. J. Mech. Behav. Biomed. Mater. 2016, 60, 581–602. [Google Scholar] [CrossRef]

- Jin, H.; Zhao, S.; Guillory, R.; Bowen, P.K.; Yin, Z.; Griebel, A.; Schaffer, J.; Earley, E.J.; Goldman, J.; Drelich, J.W. Novel high-strength, low-alloy Zn–Mg (<0.1 wt% Mg) and their arterial biodegradation. Mater. Sci. Eng. C 2018, 84, 67–79. [Google Scholar]

- Ye, L.; Huang, H.; Sun, C.; Zhuo, X.; Dong, Q.; Liu, H.; Ju, J.; Xue, F.; Bai, J.; Jiang, J. Effect of grain size and volume fraction of eutectic structure on mechanical properties and corrosion behavior of as-cast Zn–Mg binary alloys. J. Mater. Res. Technol. 2022, 16, 1673–1685. [Google Scholar] [CrossRef]

- Bednarczyk, W.; Wątroba, M.; Kawałko, J.; Bała, P. Can zinc alloys be strengthened by grain refinement? A critical evaluation of the processing of low-alloyed binary zinc alloys using ECAP. Mater. Sci. Eng. A 2019, 748, 357–366. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; Molina-Aldareguia, J.M.; Pérez-Prado, M.T. Origin of the twinning to slip transition with grain size refinement, with decreasing strain rate and with increasing temperature in magnesium. Acta Mater. 2015, 88, 232–244. [Google Scholar] [CrossRef]

- Wang, X.; Ma, Y.; Meng, B.; Wan, M. Effect of equal-channel angular pressing on microstructural evolution, mechanical property and biodegradability of an ultrafine-grained zinc alloy. Mater. Sci. Eng. A 2021, 824, 141857. [Google Scholar] [CrossRef]

- Li, J.; Xu, W.; Wu, X.; Ding, H.; Xia, K. Effects of grain size on compressive behaviour in ultrafine grained pure Mg processed by equal channel angular pressing at room temperature. Mater. Sci. Eng. A 2011, 528, 5993–5998. [Google Scholar] [CrossRef]

- Lapovok, R.; Thomson, P.F.; Cottam, R.; Estrin, Y. The effect of grain refinement by warm equal channel angular extrusion on room temperature twinning in magnesium alloy ZK60. J. Mater. Sci. 2005, 40, 1699–1708. [Google Scholar] [CrossRef]

- Sun, S.; Ren, Y.; Liqing, W.; Yang, B.; Li, H.; Qin, G. Abnormal effect of Mn addition on the mechanical properties of as-extruded Zn alloys. Mater. Sci. Eng. A 2017, 701, 129–133. [Google Scholar] [CrossRef]

- Li, H.F.; Xie, X.H.; Zheng, Y.F.; Cong, Y.; Zhou, F.Y.; Qiu, K.J.; Wang, X.; Chen, S.H.; Huang, L.; Tian, L.; et al. Development of biodegradable Zn–1X binary alloys with nutrient alloying elements Mg, Ca and Sr. Sci. Rep. 2015, 5, 10719. [Google Scholar]

- Wang, L.Q.; Ren, Y.P.; Sun, S.N.; Zhao, H.; Li, S.; Qin, G.-W. Microstructure, mechanical properties and fracture behavior of as-extruded Zn–Mg binary alloys. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 931–940. [Google Scholar] [CrossRef]

- Wang, L.Q.; He, Y.F.; Zhao, H.; Xie, H.B.; Li, S.; Ren, Y.P.; Qin, G.W. Effect of cumulative strain on the microstructural and mechanical properties of Zn-0.02 wt%Mg alloy wires during room-temperature drawing process. J. Alloys Compd. 2018, 740, 949–957. [Google Scholar] [CrossRef]

- Balog, M.; Krížik, P.; Školáková, A.; Švec, P.; Kubásek, J.; Pinc, J.; de Castro, M.M.; Figueiredo, R. Hall-Petch strengthening in ultrafine-grained Zn with stabilized boundaries. J. Mater. Res. Technol. 2024, 33, 7458–7468. [Google Scholar] [CrossRef]

- Guo, P.; Zhu, X.; Yang, L.; Deng, L.; Zhang, Q.; Li, B.Q.; Cho, K.; Sun, W.; Ren, T.; Song, Z. Ultrafine- and uniform-grained biodegradable Zn–0.5Mn alloy: Grain refinement mechanism, corrosion behavior, and biocompatibility in vivo. Mater. Sci. Eng. C 2021, 118, 111391. [Google Scholar] [CrossRef]

- STN EN 12019; Zinc and Zinc Alloys. Analysis by Optical Emission Spectrometry. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2000.

- Sun, Y.; Li, W.; Shi, X.; Tian, L. A uniformly fine-grained Mg–Y–Nd–Zr magnesium alloy with simultaneously optimized strength and ductility processed by forging and ECAP. Mater. Res. Express 2020, 7, 116520. [Google Scholar] [CrossRef]

- Toby, B.H.; Von Dreele, R.B. GSAS-II: The genesis of a modern open-source all-purpose crystallography software package. J. Appl. Crystallogr. 2013, 46, 544–549. [Google Scholar] [CrossRef]

- STN EN ISO 6892-1; Metallic Materials. Tensile Testing. Part 1: Method of Test at Room Temperature. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2022.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).